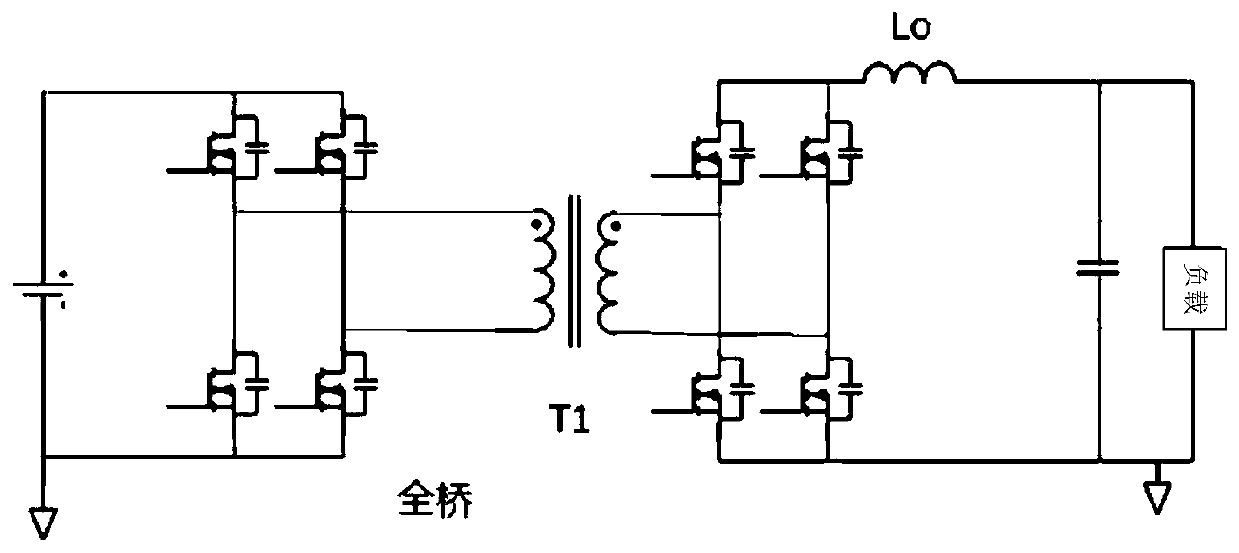

Full-bridge circuit and full-bridge converter

A technology of full-bridge circuit and bridge circuit, which is applied in the direction of adjusting electrical variables, high-efficiency power electronic conversion, instruments, etc., can solve problems such as poor overall efficiency of soft switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

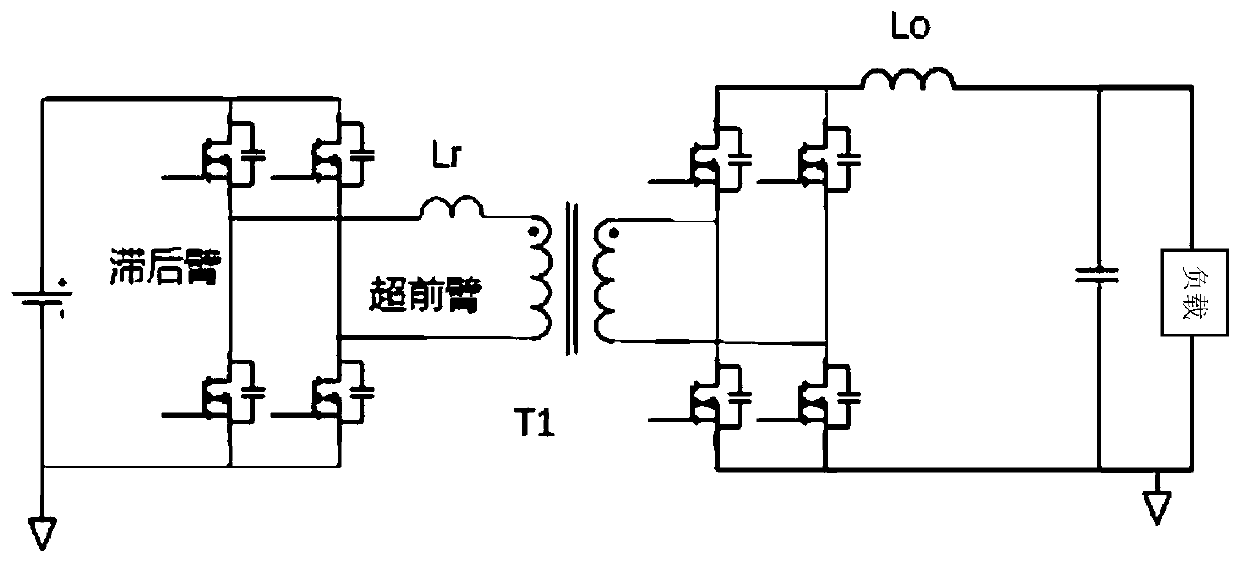

Method used

Image

Examples

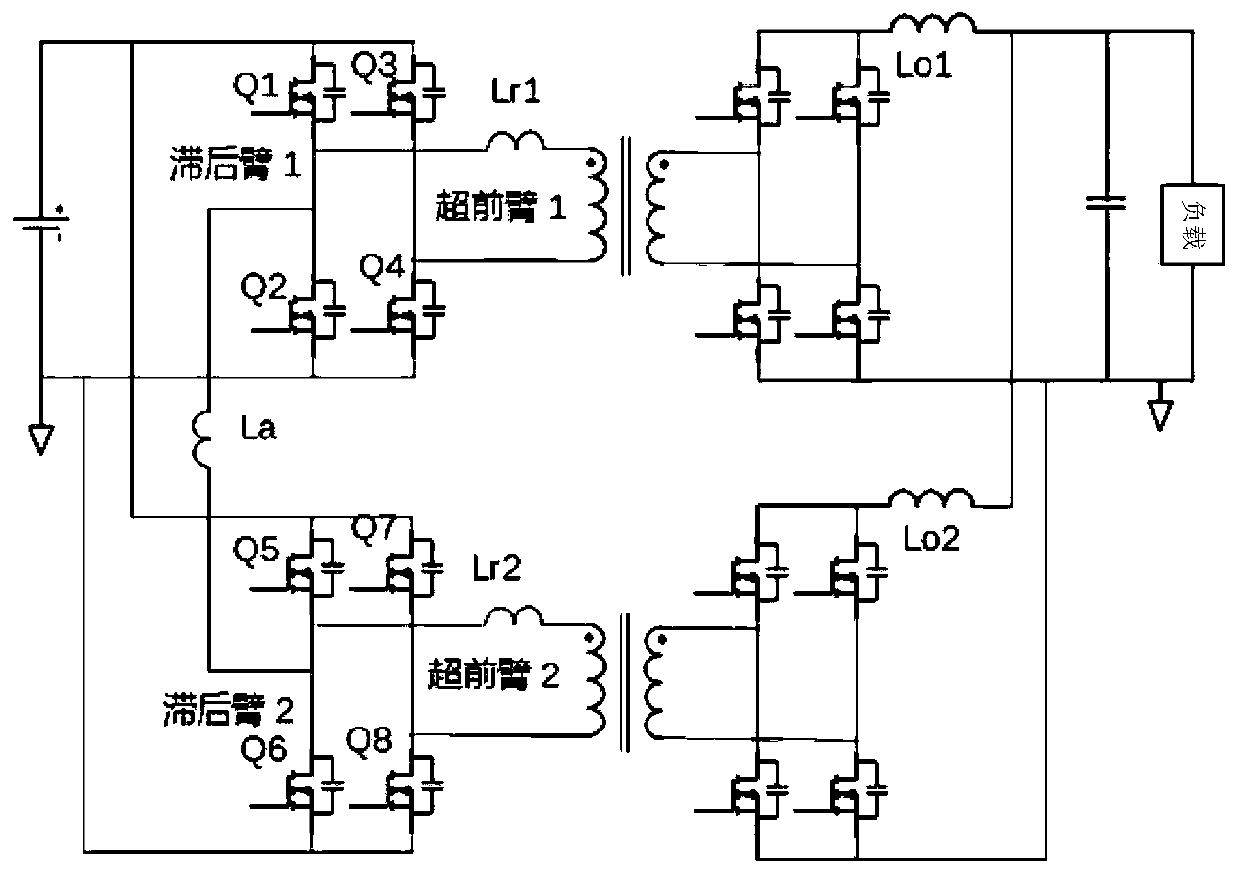

Embodiment 1

[0033] Such as image 3 As shown, the main circuit of the embodiment of the present invention is a parallel structure of dual-channel full-bridge circuits. Among them, Lr1 and Lr2 are the primary inductances used by the traditional phase-shifting full-bridge circuit to realize soft switching. In actual work, when Q1 and Q2 are turned on, the inductance Lr1 is charged, and the super forearm composed of Q3 and Q4 is turned off. (Q4 is turned off), the current of the inductor Lr1 discharges the output parasitic capacitance of Q3 and Q4, so that the Vds of Q3 is close to 0, and the zero-voltage conduction of Q3 is realized. Since the current of Lr1 is clamped by the output inductor Io during the dead time when the super forearm is turned off, and the output inductance is usually relatively large, the super forearm usually has enough energy to achieve ZVS zero voltage conduction. When the lagging arm composed of Q1 and Q2 is turned off (Q1 is turned off), the current of Lr1 commut...

Embodiment 2

[0038] Such as Figure 6 As shown, the dual-channel full-bridge circuit of Embodiment 2 is in image 3 Based on the improved use of a transformer to achieve, because in the embodiment of the present invention, the phase shift of the two full bridges is controlled by 180 degrees, and the output voltages of the two full bridges are just reversed, so they can be respectively connected to a The two reverse primary side windings of the transformer can be realized by using the same transformer and magnetic core. Meanwhile, in this embodiment, as Figure 6 As shown, the rectification circuit and output inductor on the secondary side can also be simplified into a set of circuits. Therefore, this embodiment is a preferred embodiment of a power supply with high efficiency and high power density. It should be noted that, in this embodiment, other control methods and processes are the same as those in Embodiment 1 above, and will not be repeated here.

Embodiment 3

[0040] Such as Figure 7 As shown, the difference from the above-mentioned embodiments is that in this embodiment 3, the secondary side of the transformer adopts a double-winding synchronous rectification circuit, compared with Figure 6 In the shown embodiment 2, the synchronous rectification of the secondary side of this embodiment can be realized by two switching tubes, therefore, the number of components can be further simplified and the cost can be reduced in certain application occasions. It should be noted that, in this embodiment, other control methods and processes are the same as those in the above embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com