Oil distributing valve of hydraulic impactor

A technology of hydraulic impactor and oil distribution valve, which is applied in the direction of fluid pressure actuator, servo motor assembly, mechanical equipment, etc., and can solve the problem of large volume and mass of the valve core, large fuel consumption and leakage, and slow reversing speed and other problems, to achieve the effect of small volume and mass of the spool, fast reversing speed, and reduced mass of the spool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and specific embodiments.

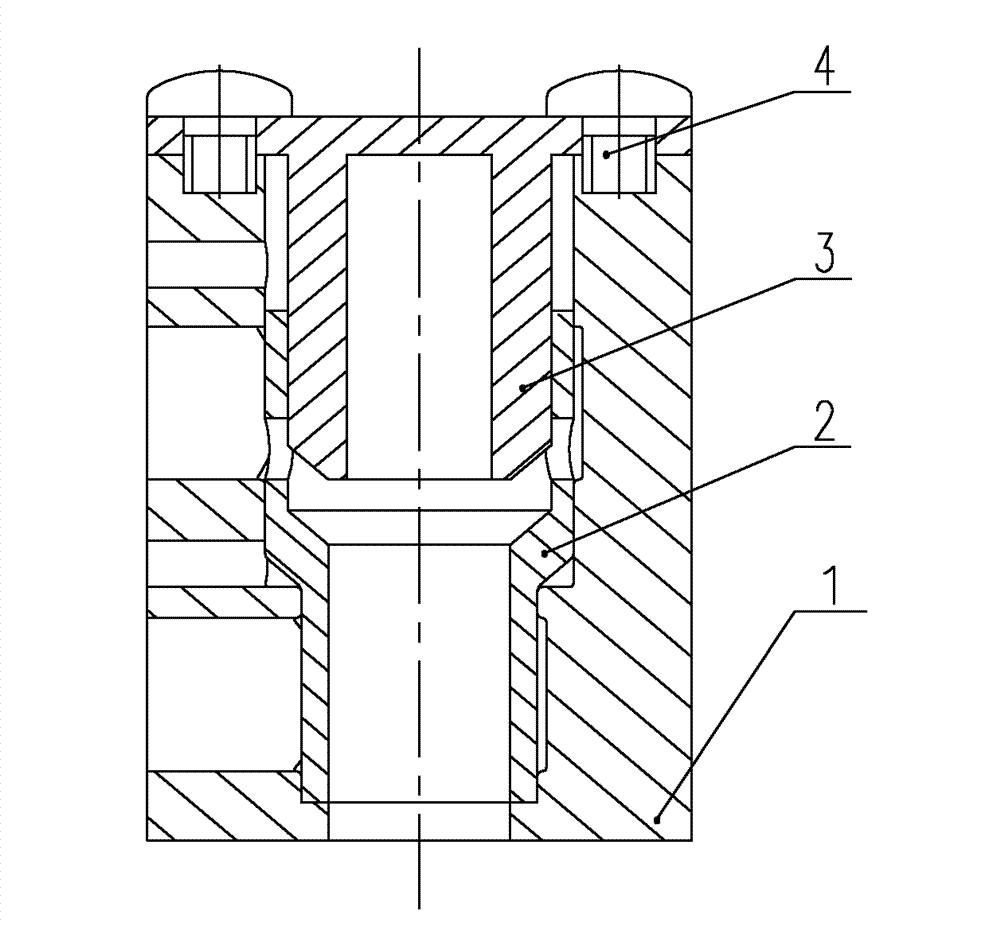

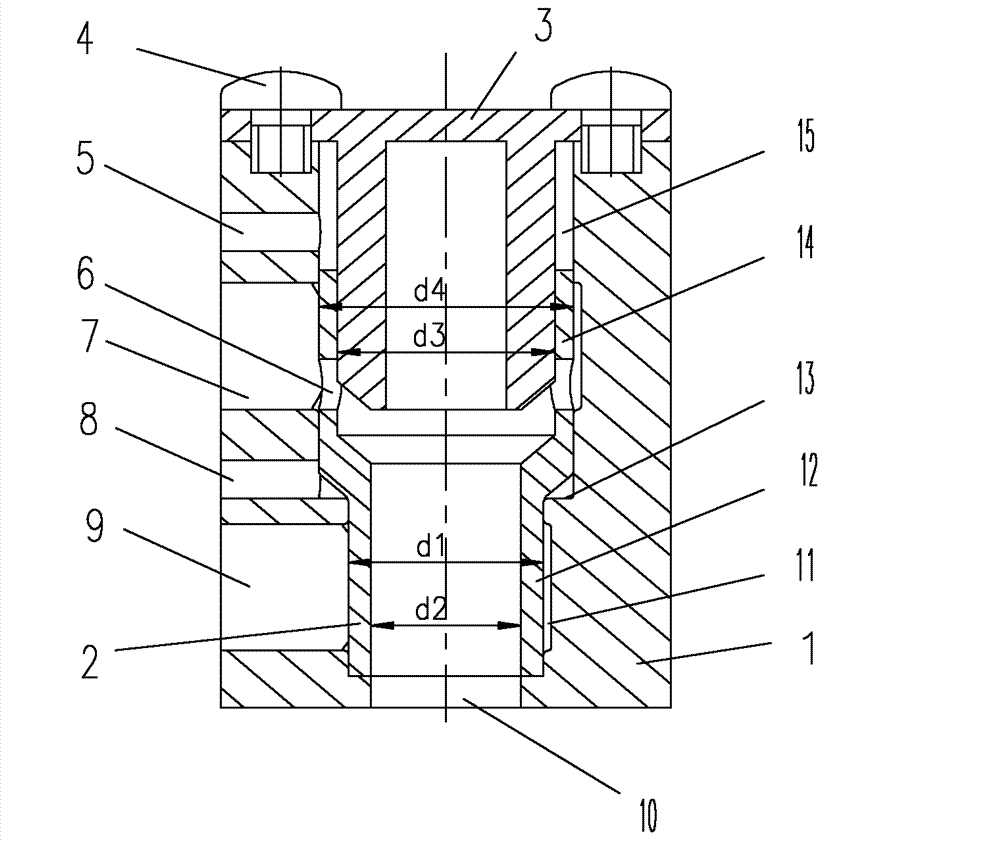

[0017] See figure 1 with figure 2 The valve cavity of the valve body 1 is composed of a rear cavity 15 with a larger diameter and a front cavity 11 with a smaller diameter. The front cavity 11 and the rear cavity 5 form a stepped surface 13, and the valve cavity of the valve body 1 is provided with energy Axial sliding spool 2. The spool 2 is hollow and consists of a rear end 14 adapted to the size of the rear cavity 15 and a front end 12 adapted to the size of the front cavity 11. One end of the valve cover 3 is slidably fitted on the rear end of the spool 2 In 14, the other end is fixed on the valve body 1 by the connecting screw 4. The valve body 1 is provided with a first high pressure oil port 5 communicating with the rodless cavity of the rear cavity 15, and an oil return communicating with the rod cavity of the rear cavity 15. Port 7, the feedback oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com