Flatten shaping and reversing equipment for soft bag packaging

A technology of reversing equipment and soft bags, applied in packaging, transportation and packaging, conveyors, etc., can solve the problems of waste of manpower and material resources, slow reversing speed, and high error rate of automatic reversing of soft bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

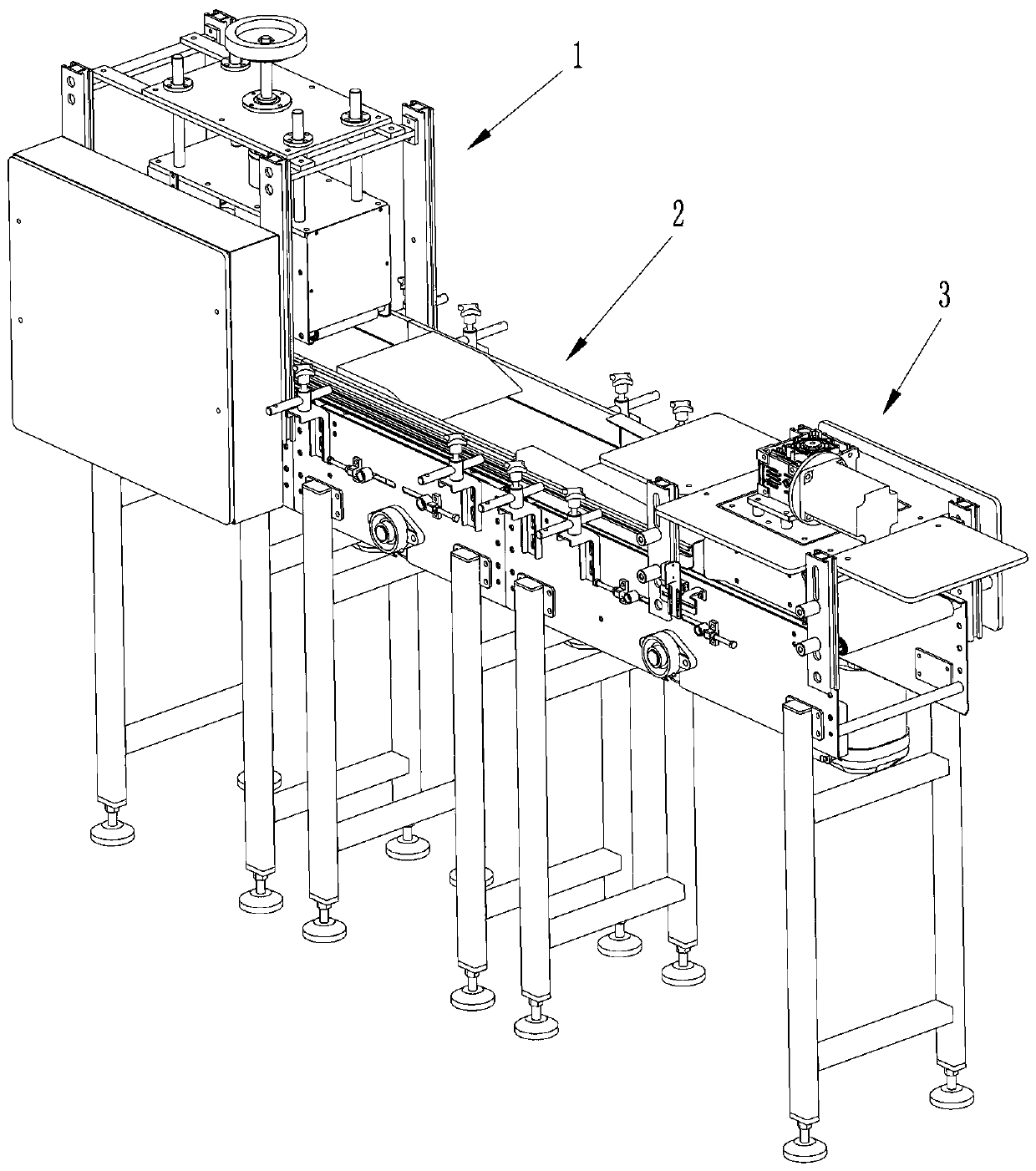

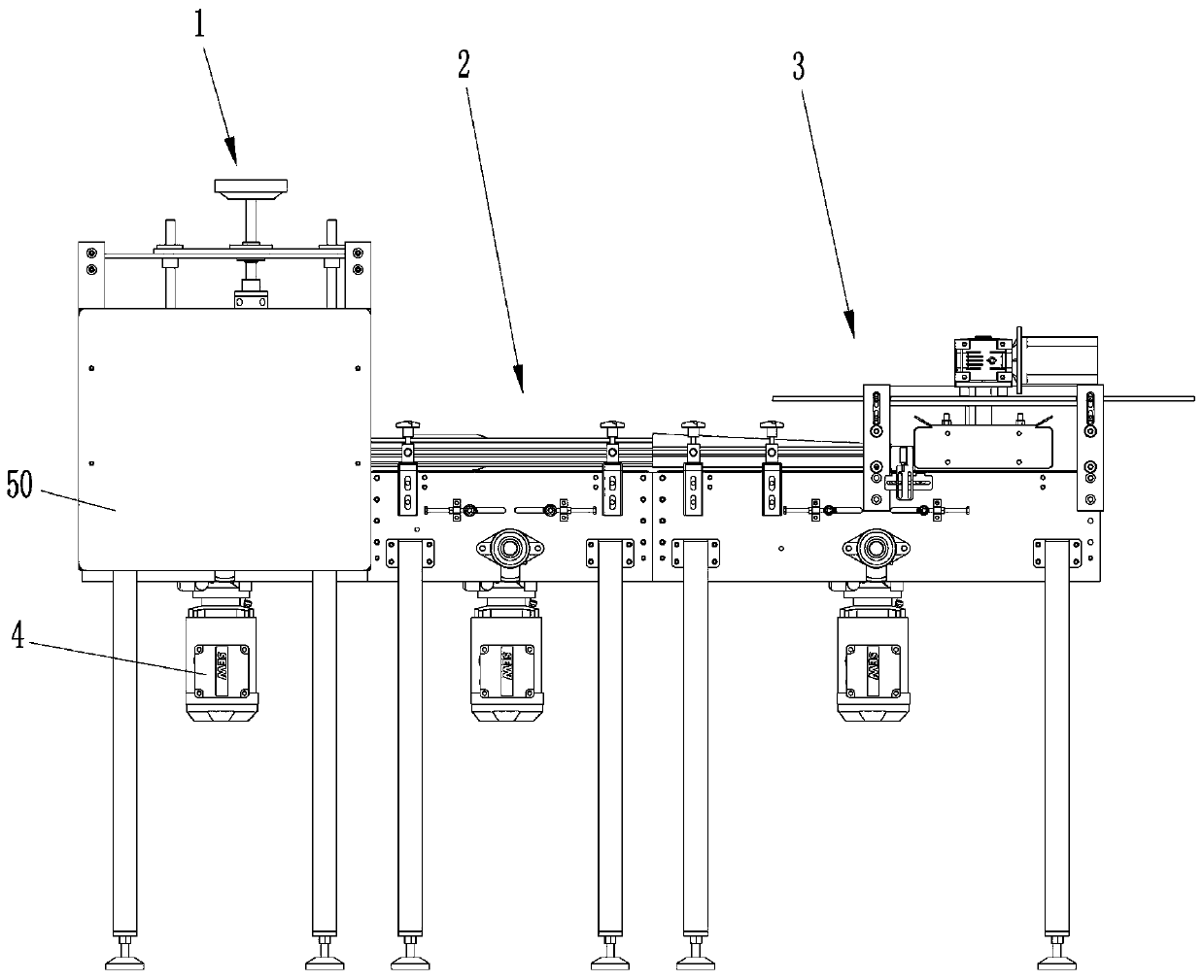

[0026] like figure 1 , 2 As shown, a pressing and reversing equipment for soft bag packaging includes a pressing and conveying device 1 for flattening and shaping the soft bag, an accelerating conveying device 2 and a reversing and conveying device 3 for rotating the soft bag by 180 degrees; The whole conveying device 1, the accelerating conveying device 2 and the reversing conveying device 3 are arranged in sequence along the conveying direction of the soft bag.

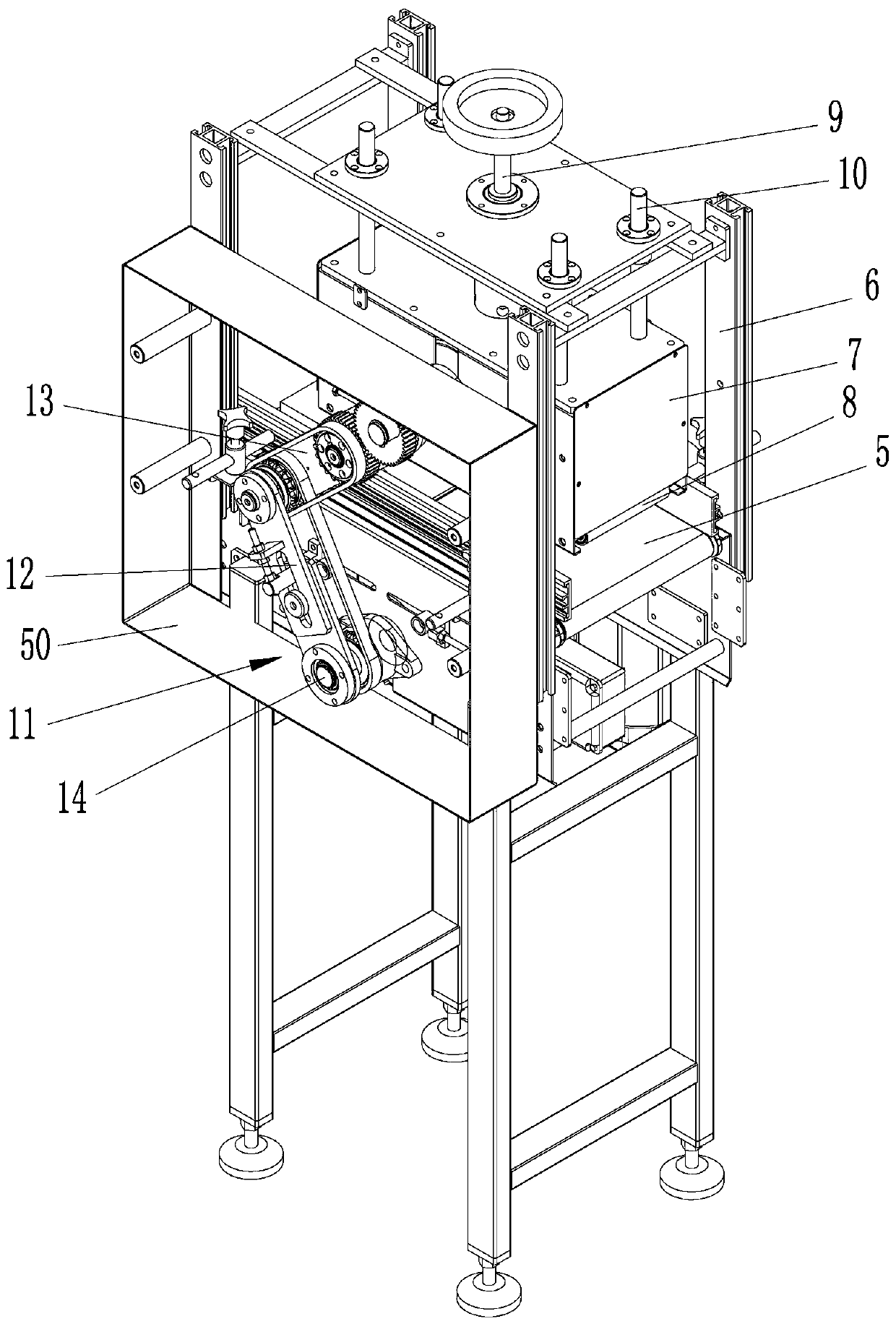

[0027] like figure 2 , 3 As shown, the pressing and conveying device 1 includes a second conveying mechanism, a reduction motor 4 for driving the second conveying mechanism, a third conveying mechanism arranged on the top of the second conveying mechanism, and a third conveying mechanism arranged on one side of the third conveying mechanism and driving the third conveying mechanism. The mechanism follows the transmission mechanism 11 that moves synchronously with the second conveying mechanism. The transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com