Electrohydraulic servo oil cylinder and numerical control machine tool using same

An electro-hydraulic servo and servo motor technology, applied in the direction of servo motors, servo motor components, mechanical equipment, etc., can solve the problems of no servo follow-up, unsatisfactory, large moment of inertia, etc., and achieve fast commutation speed and stable working performance , the effect of high movement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

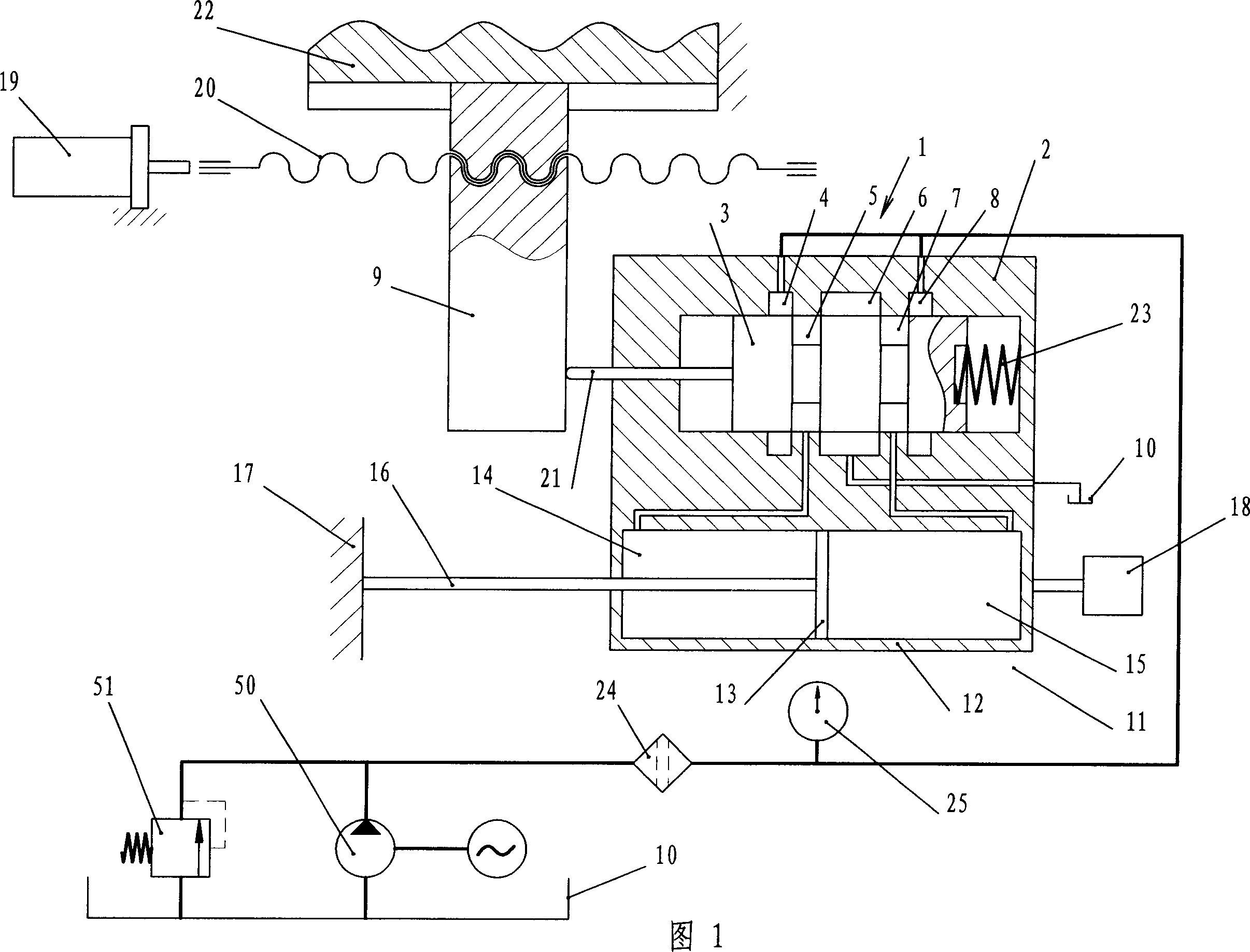

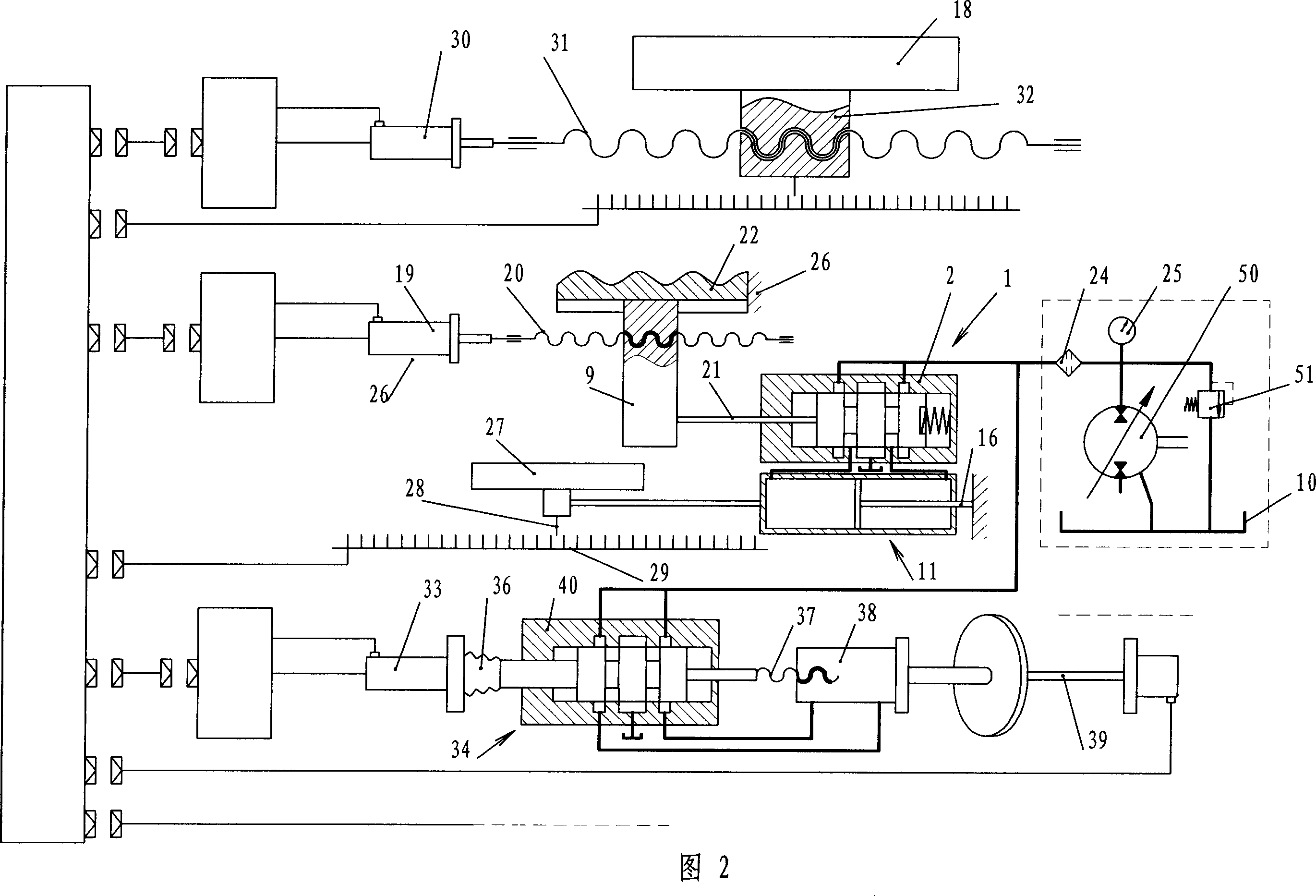

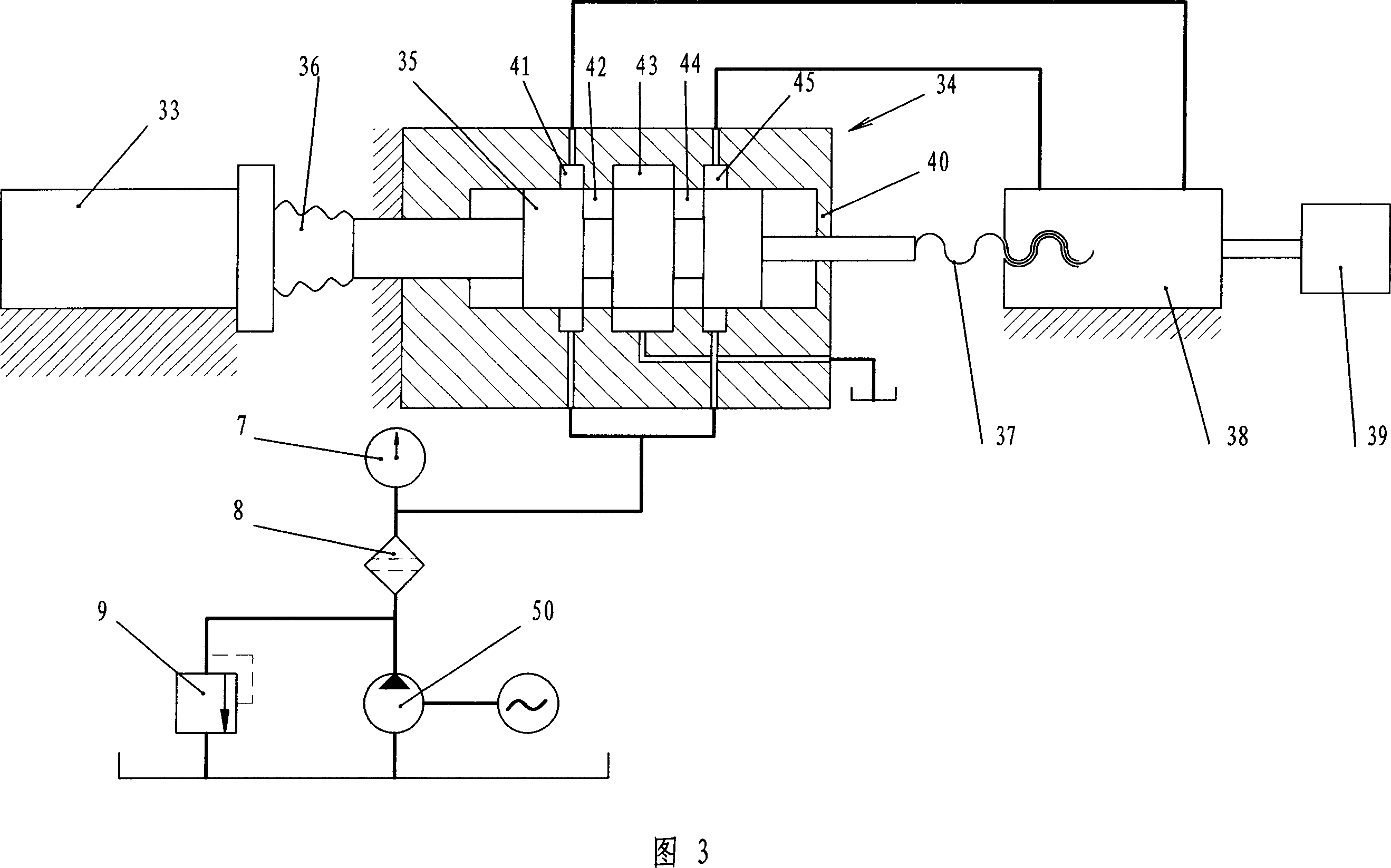

[0019]As shown in Figure 1, the electro-hydraulic servo cylinder of the present invention includes a cylinder 11 and a four-side slide valve 1, the piston 13 of the cylinder 11 divides the inner cavity of the cylinder body 12 of the cylinder 11 into a left working chamber 14 and a right working chamber 15, and the four-side slide valve A valve core 3 is dynamically installed in the valve seat 2 of the valve 1. A left high pressure oil chamber 4, a left drive chamber 5, and a return valve are arranged in sequence from left to right between the outer wall of the valve core 3 and the inner wall of the valve seat 2. The oil chamber 6, the right drive chamber 7 and the right high-pressure oil chamber 8, the left high-pressure oil chamber 4 and the right high-pressure oil chamber 8 communicate with the hydraulic source through pipelines respectively, the oil return chamber 6 communicates with the oil tank 10 through pipelines, and the valve seat 2 Fixed on the cylinder body 12 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com