Patents

Literature

44results about How to "Limited adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

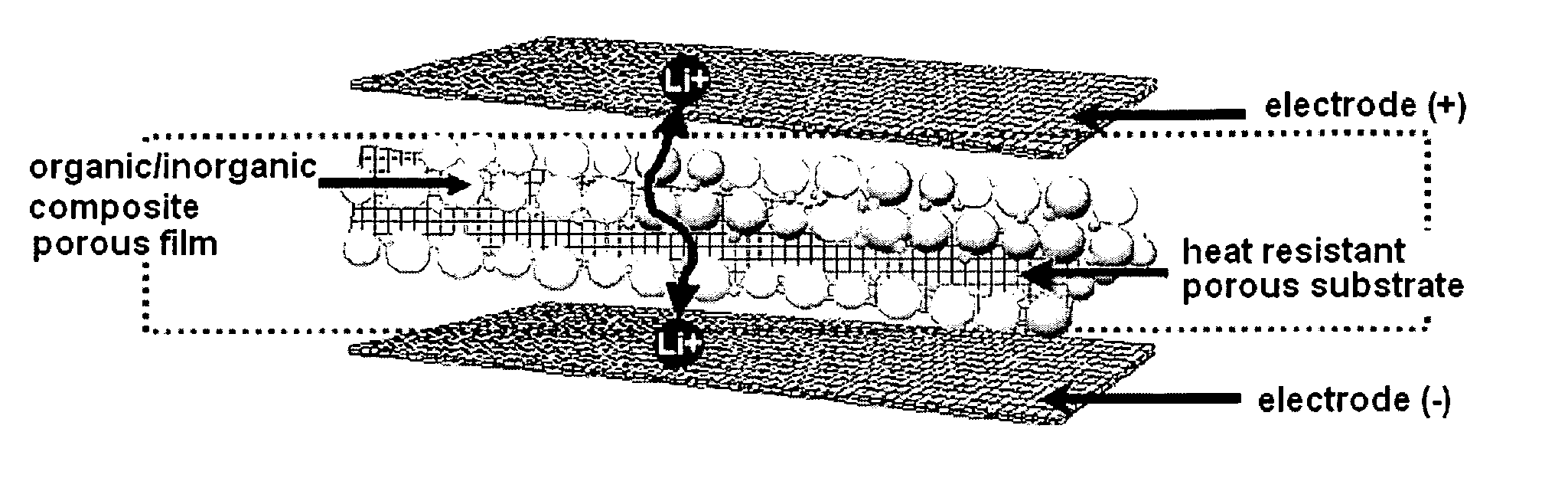

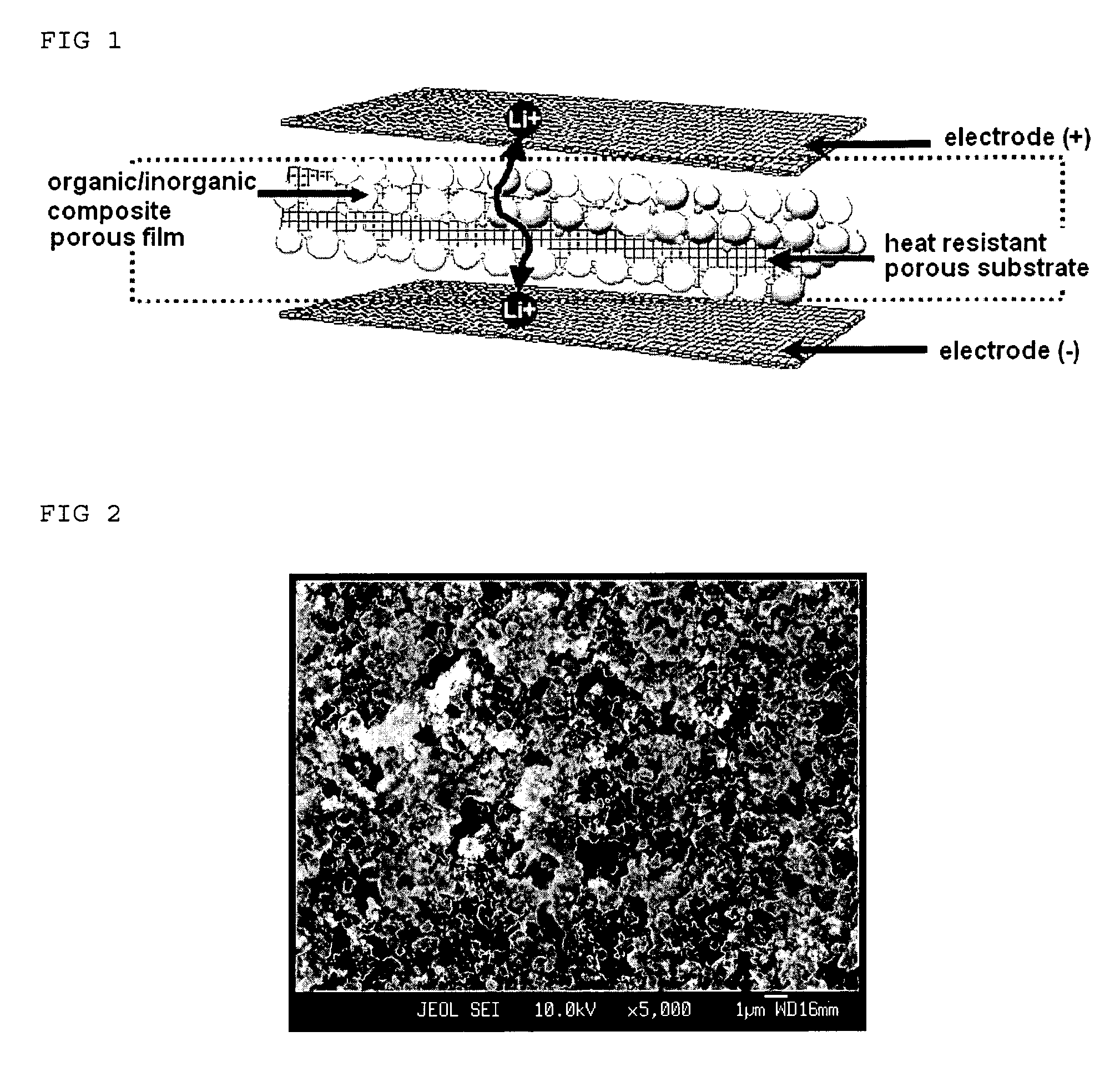

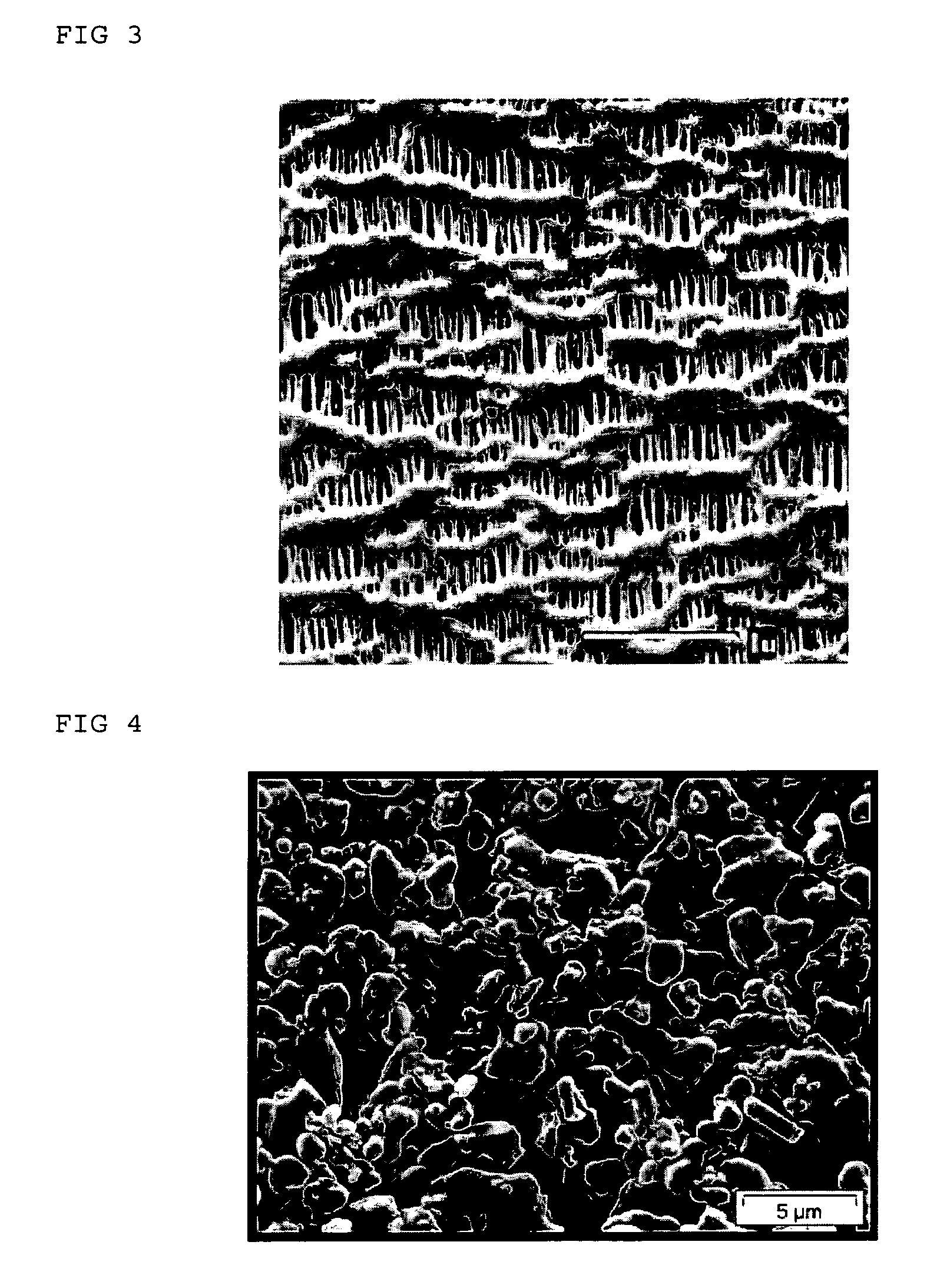

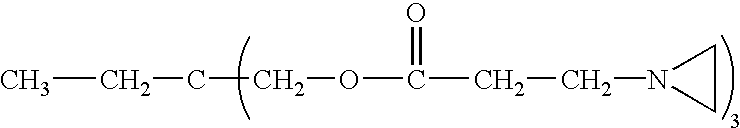

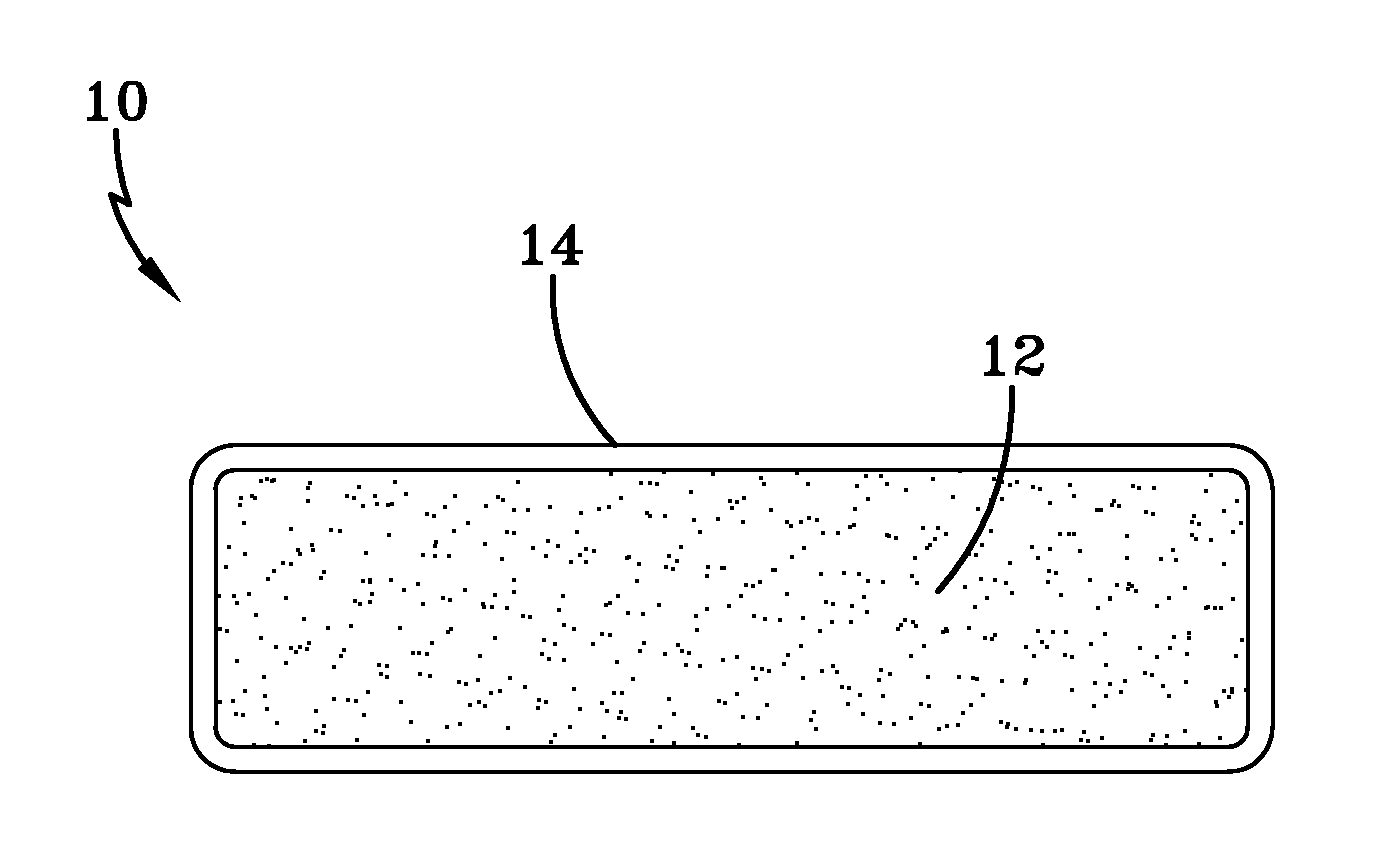

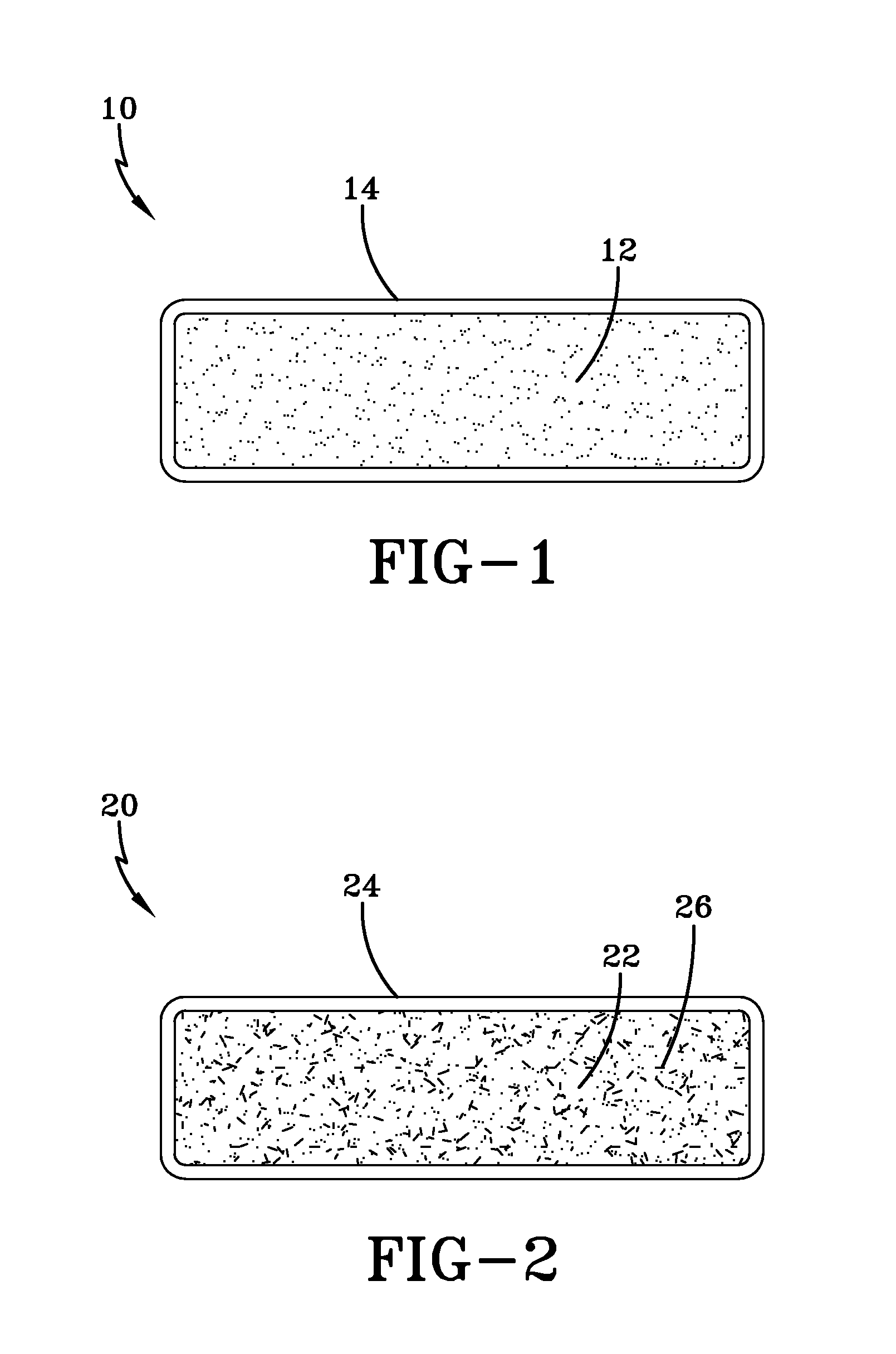

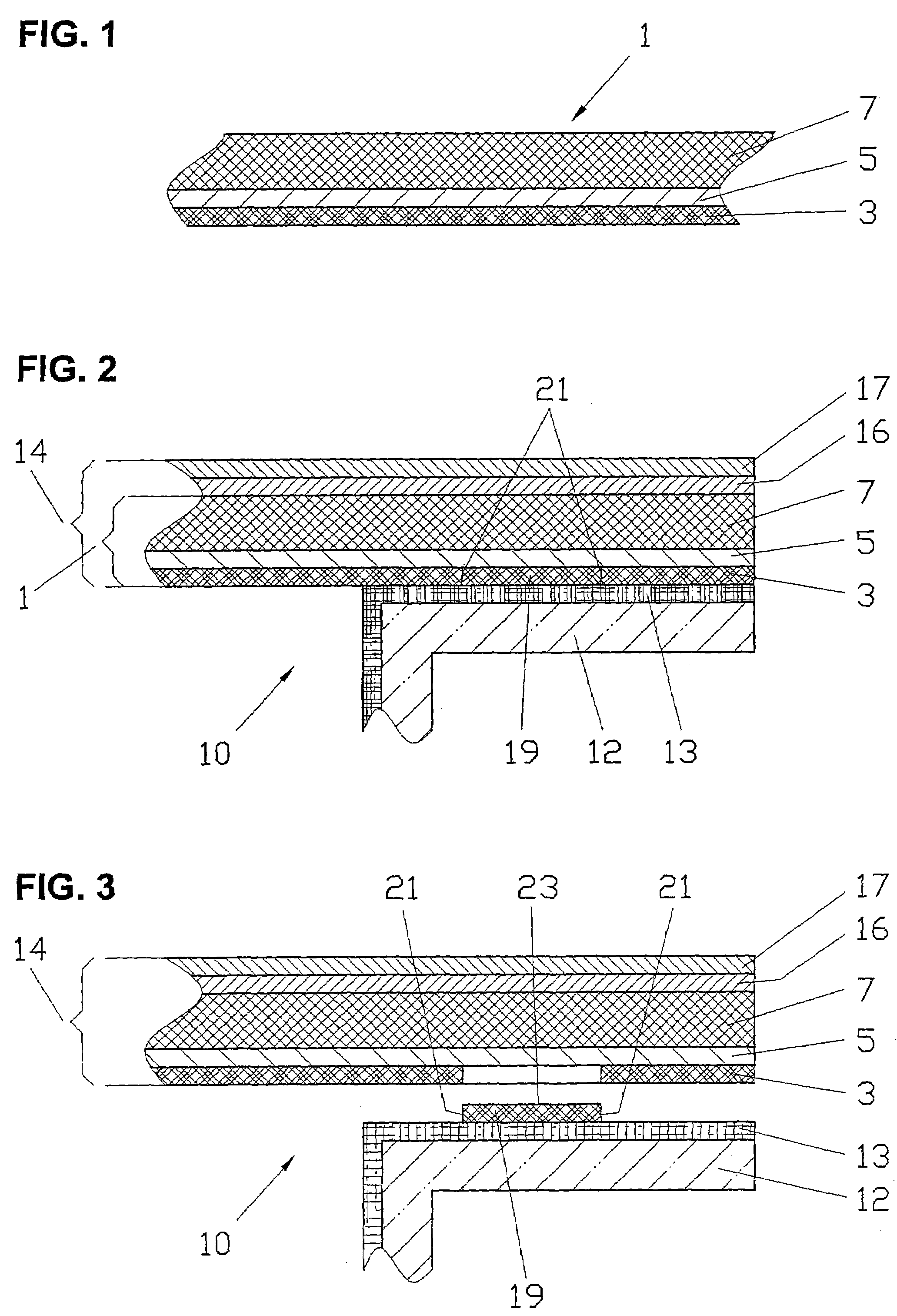

Organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveUS20060008700A1Improve thermal safetyImprove adhesionSolid electrolytesLi-accumulatorsPorous substrateInorganic particle

Disclosed is an organic / inorganic composite porous film comprising: (a) a porous substrate having pores; and (b) an active layer formed by coating a surface of the substrate or a part of the pores in the substrate with a mixture of inorganic particles and a binder polymer, wherein the inorganic particles in the active layer are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a pore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality, simultaneously.

Owner:LG ENERGY SOLUTION LTD +1

Antimicrobial adhesion surface

InactiveUS6468649B1Limit inhibit adhesionLimiting microbial adherenceSynthetic resin layered productsSurgeryHydrophilic coatingIn vivo

The present invention provides an implantable medical device having a substrate with a hydrophilic coating composition to limit in vivo colonization of bacteria and fungi. The hydrophilic coating composition includes a hydrophilic polymer with a molecular weight in the range from about 100,000 to about 15 million selected from copolymers acrylic acid, methacrylic acid, isocrotonic acid and combinations thereof.

Owner:BOSTON SCI SCIMED INC

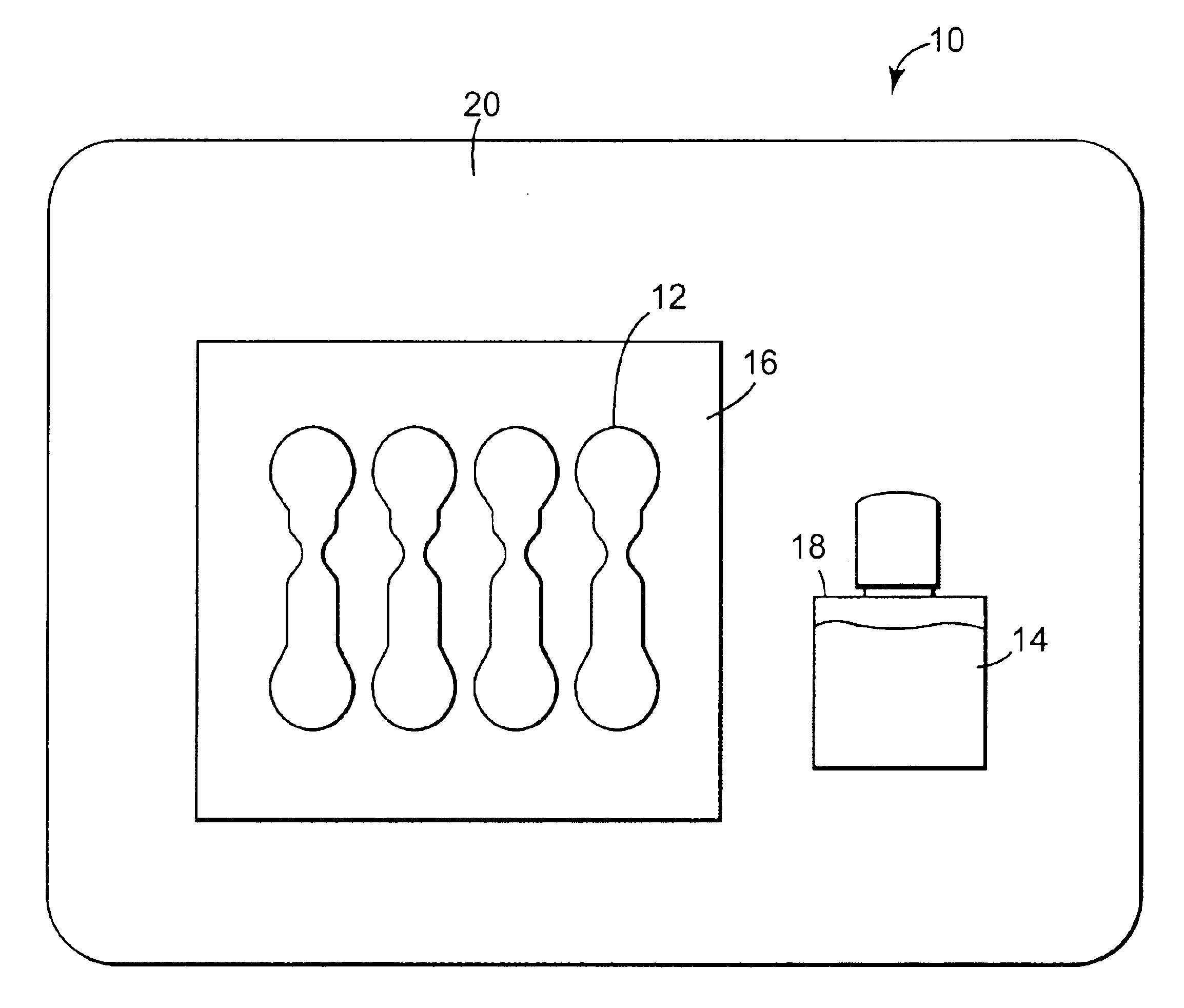

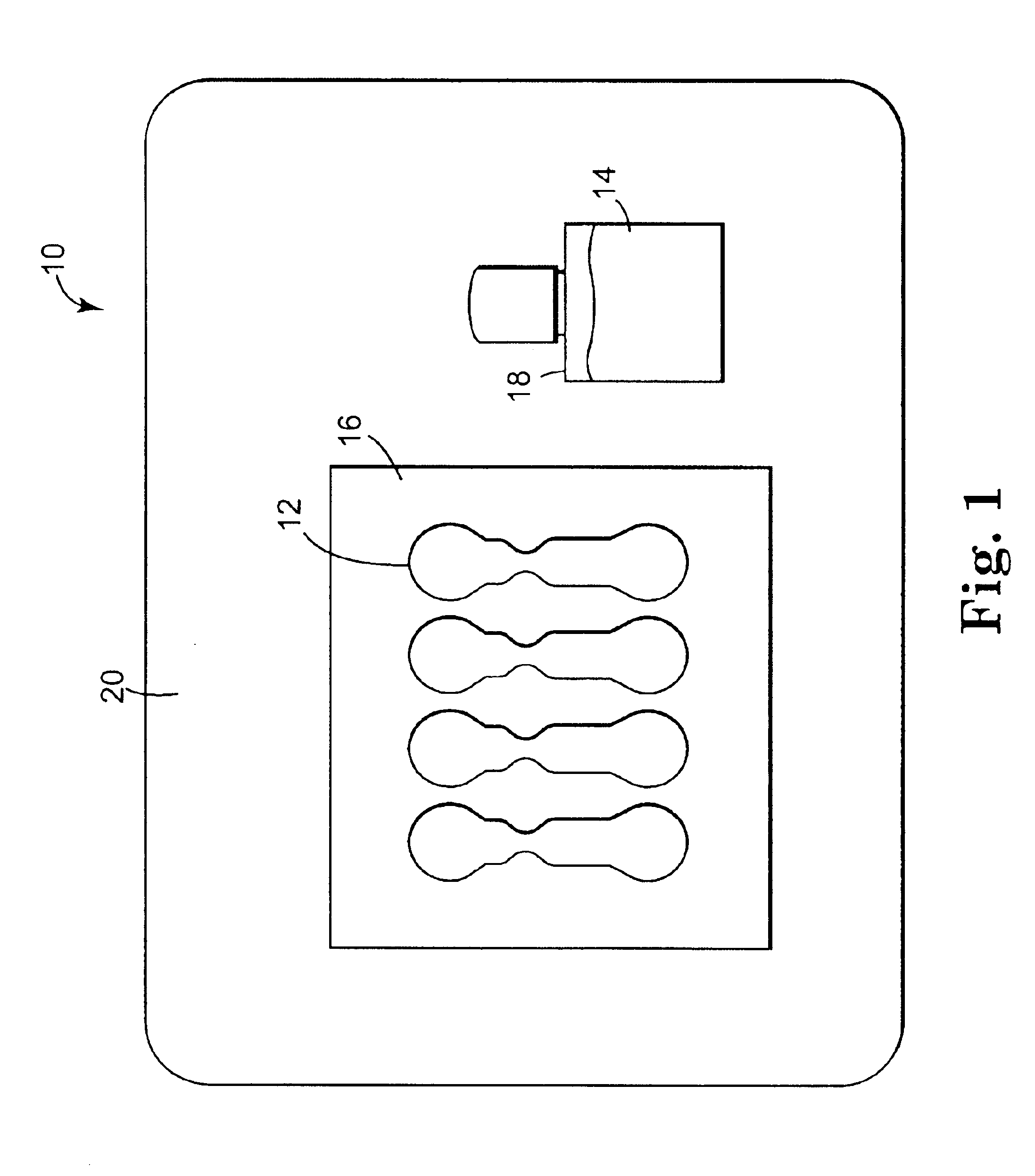

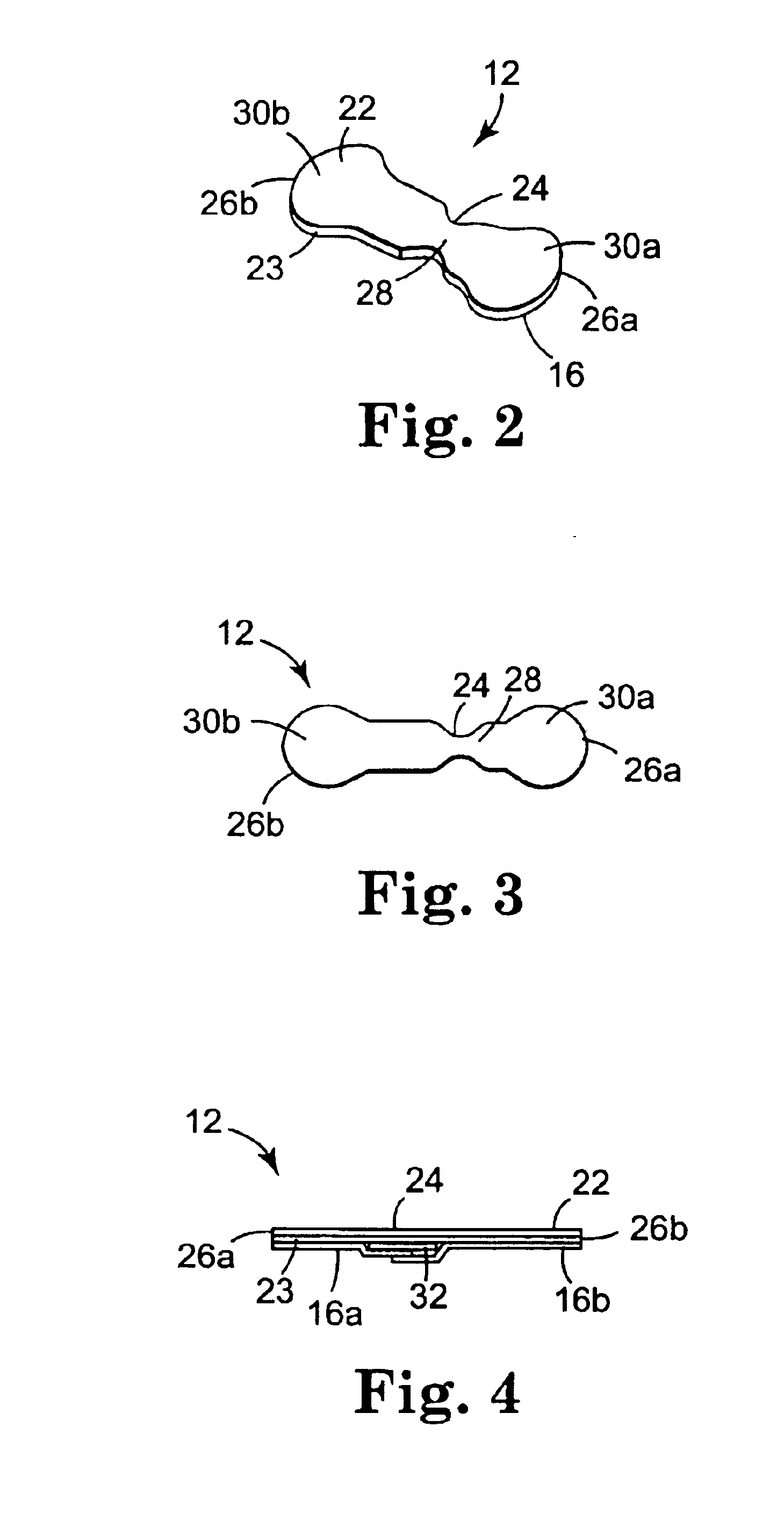

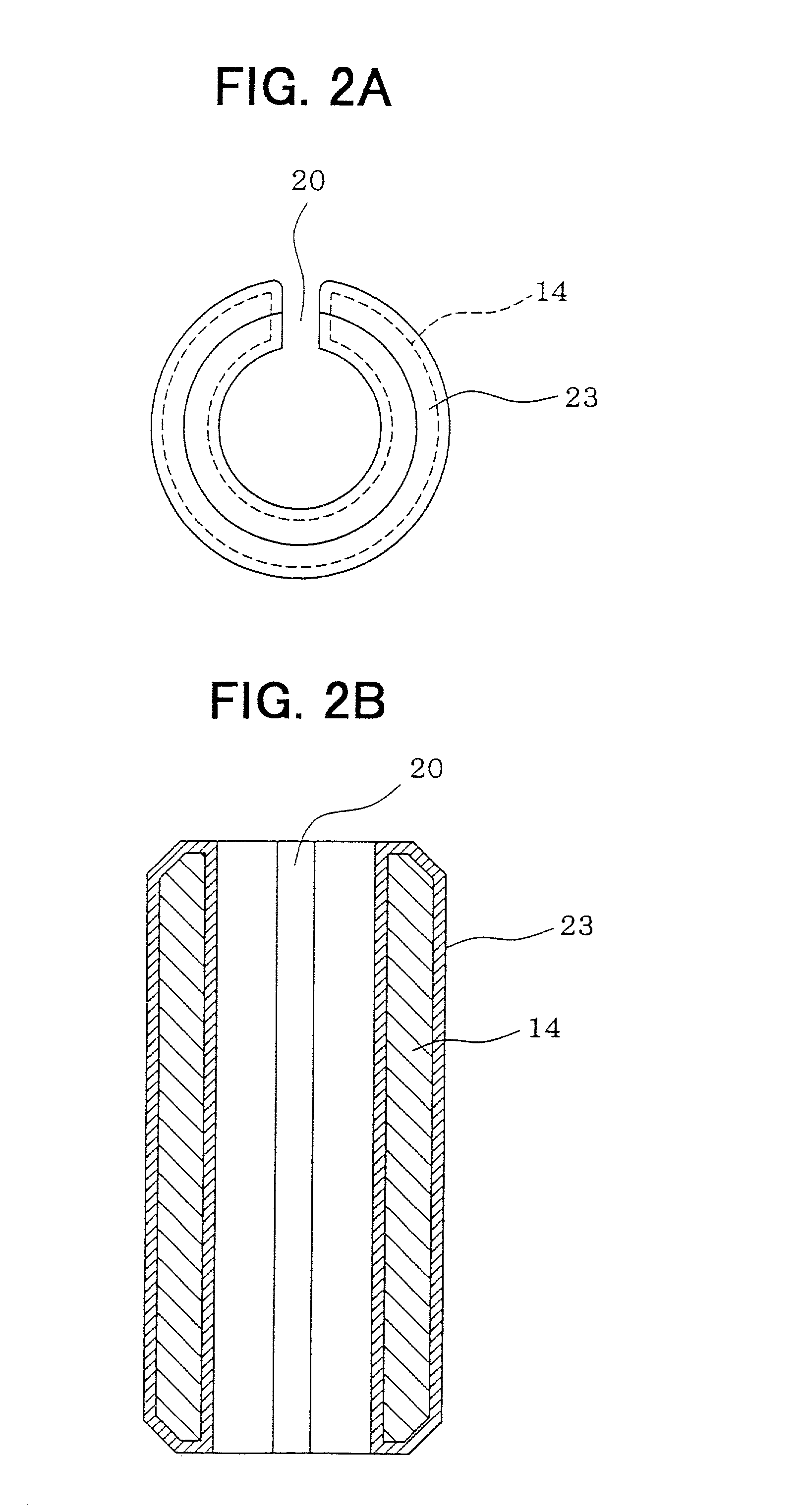

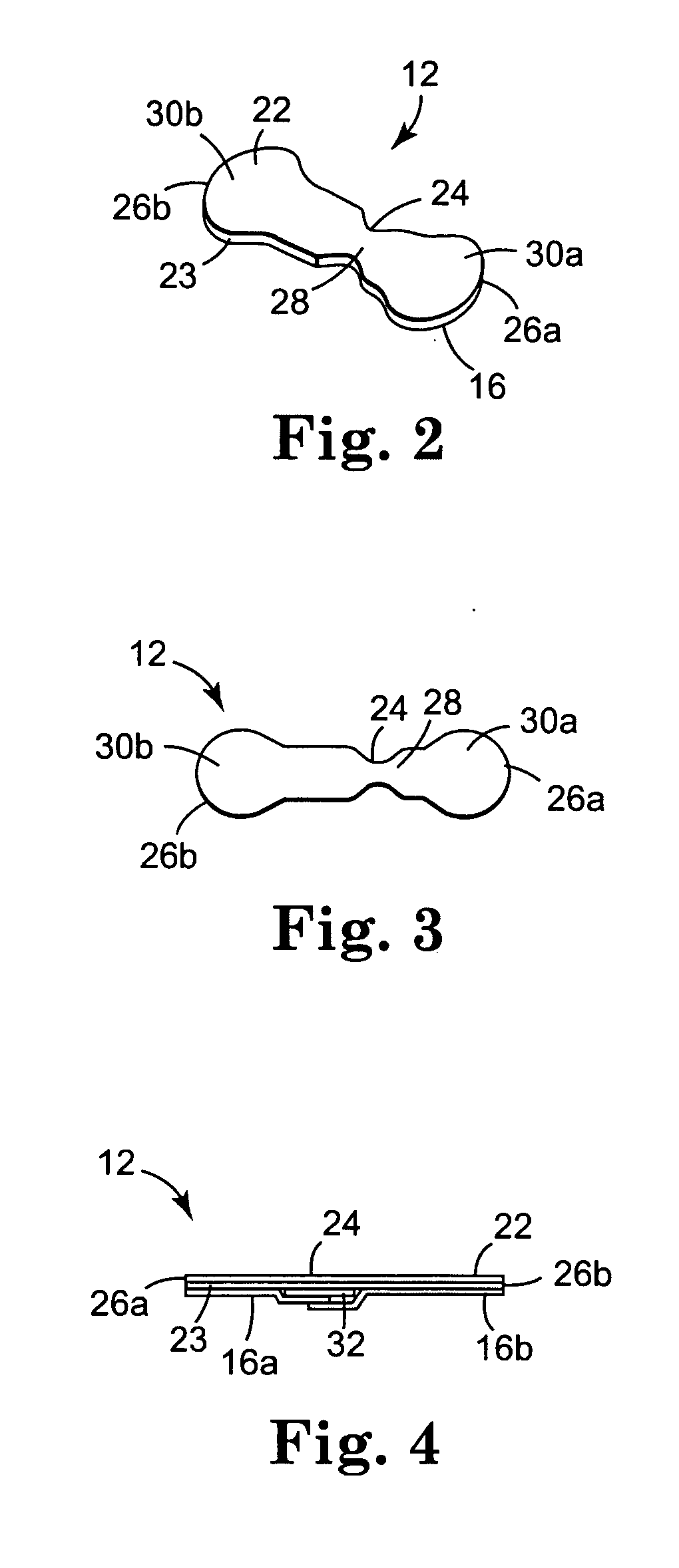

Wound closure system and method

InactiveUS6942683B2Good wound edge oppositionAvoid skin irritationSurgical adhesivesSurgical furnitureSolventIrritation

Methods and systems for closing wounds using wound closures and a flowable adhesive skin paint are disclosed. The flowable adhesive does not adhere the wound closures to the skin over the wound to reduce irritation. In some embodiments, the skin paint may include 1-40% of a siloxane-containing polymer; 60-99% of an Alkane-Based Siloxane Polymer Reaction Solvent; and 0-15% of adjuvants. The wound closures used with such a skin paint may include a wound bridging portion of microporous polypropylene film.

Owner:3M INNOVATIVE PROPERTIES CO

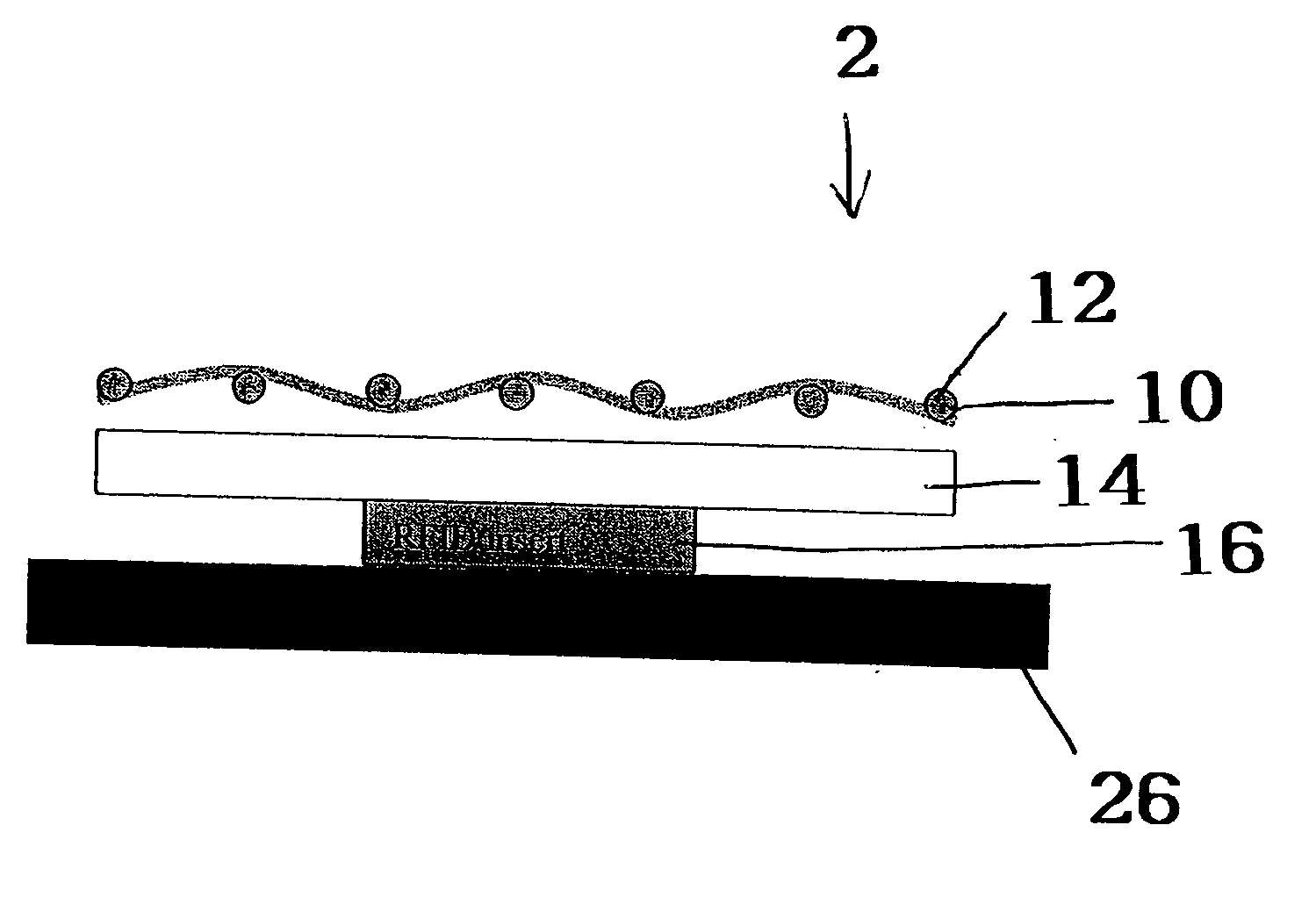

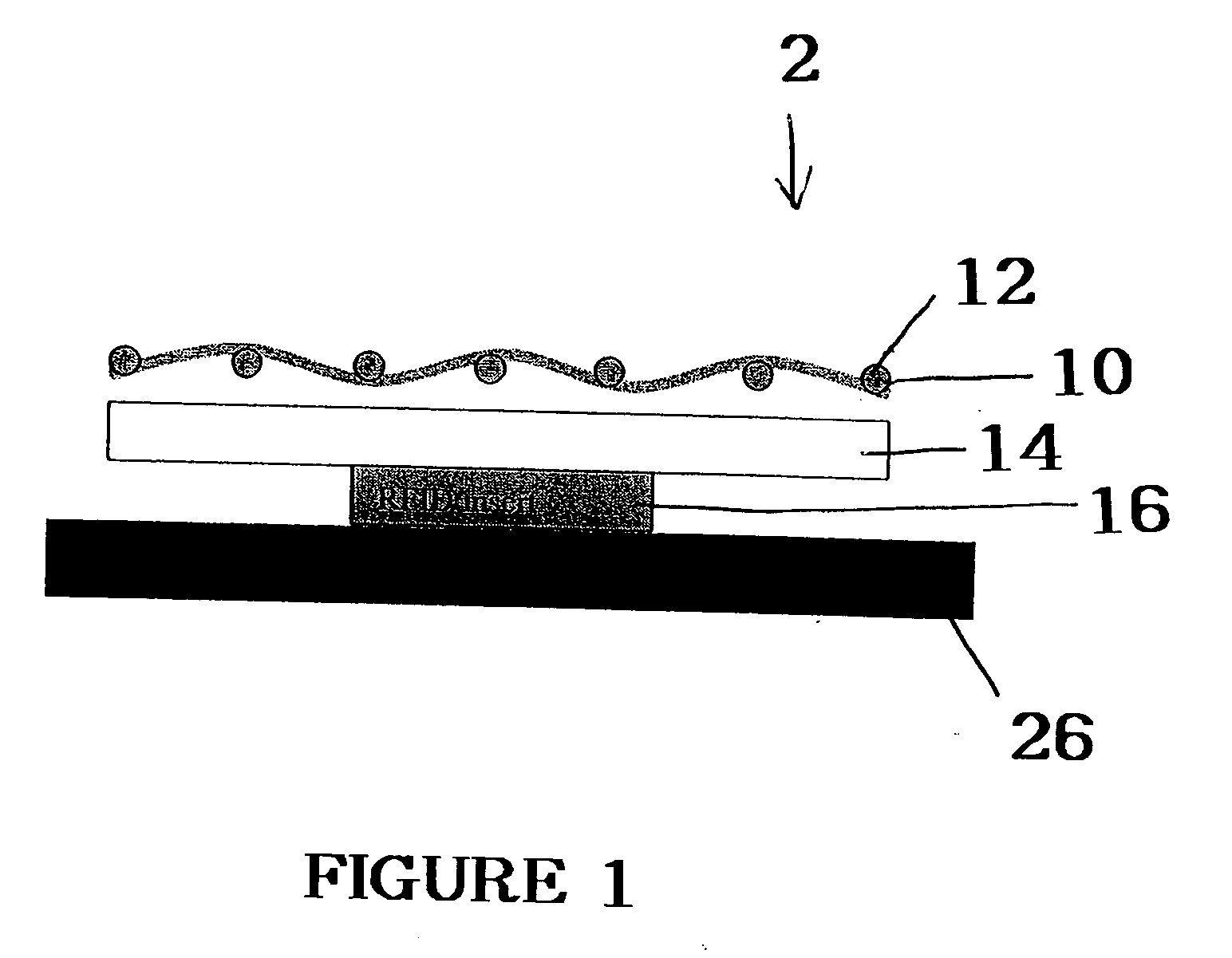

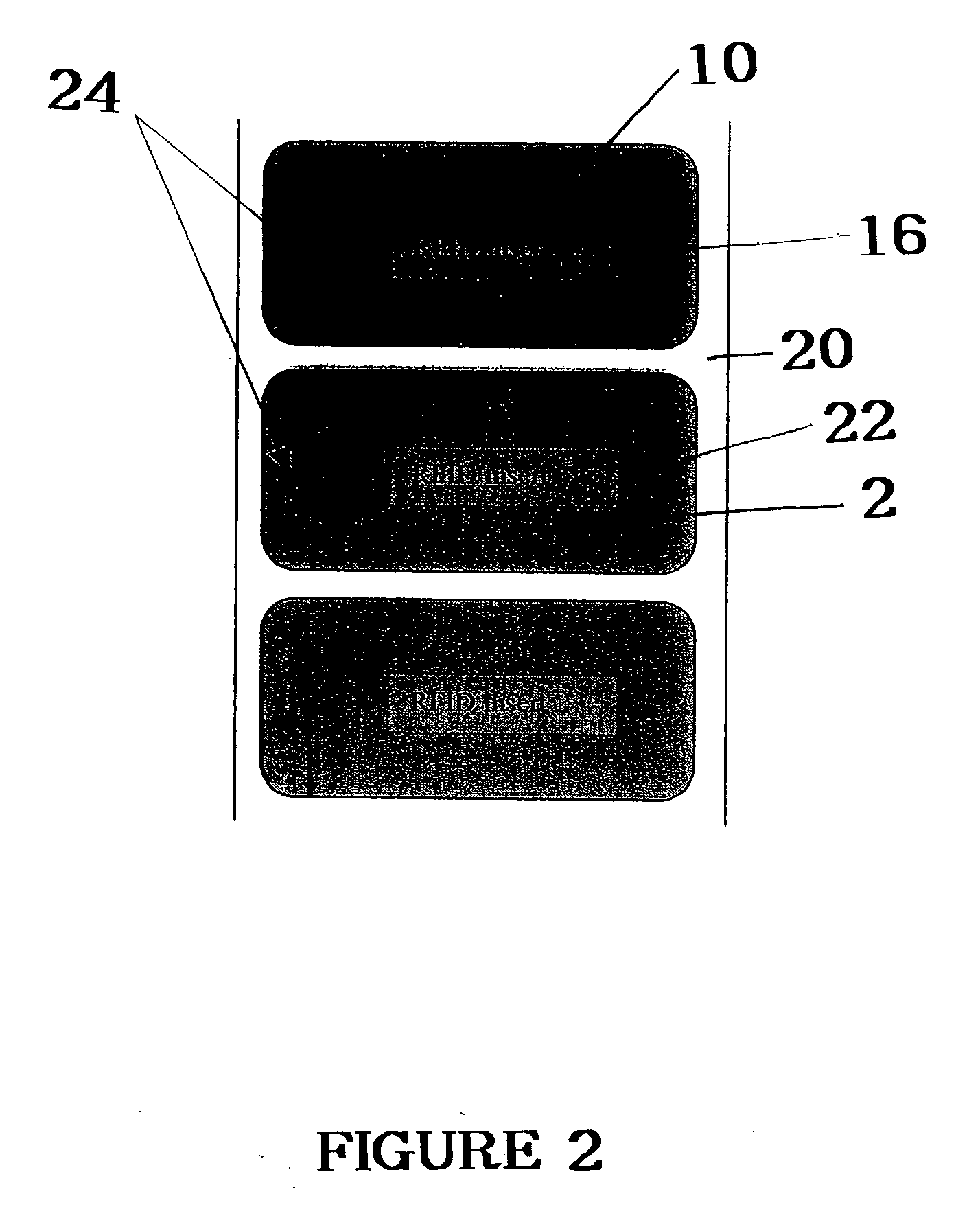

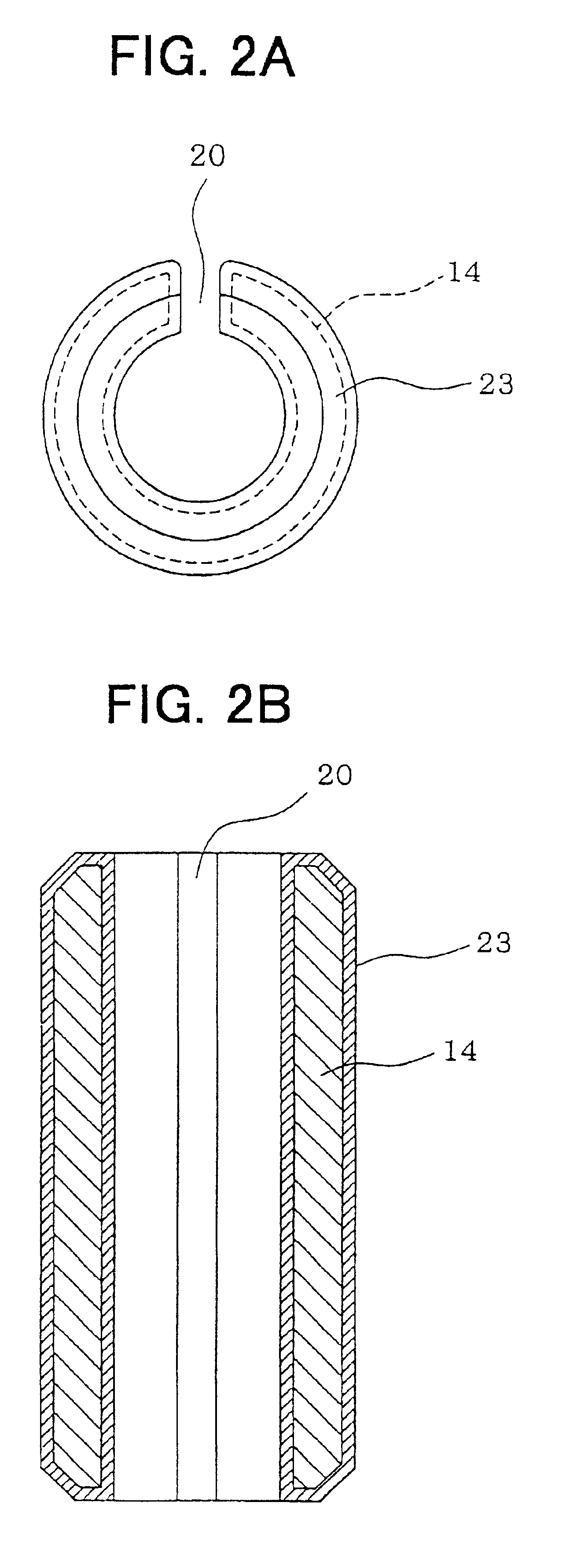

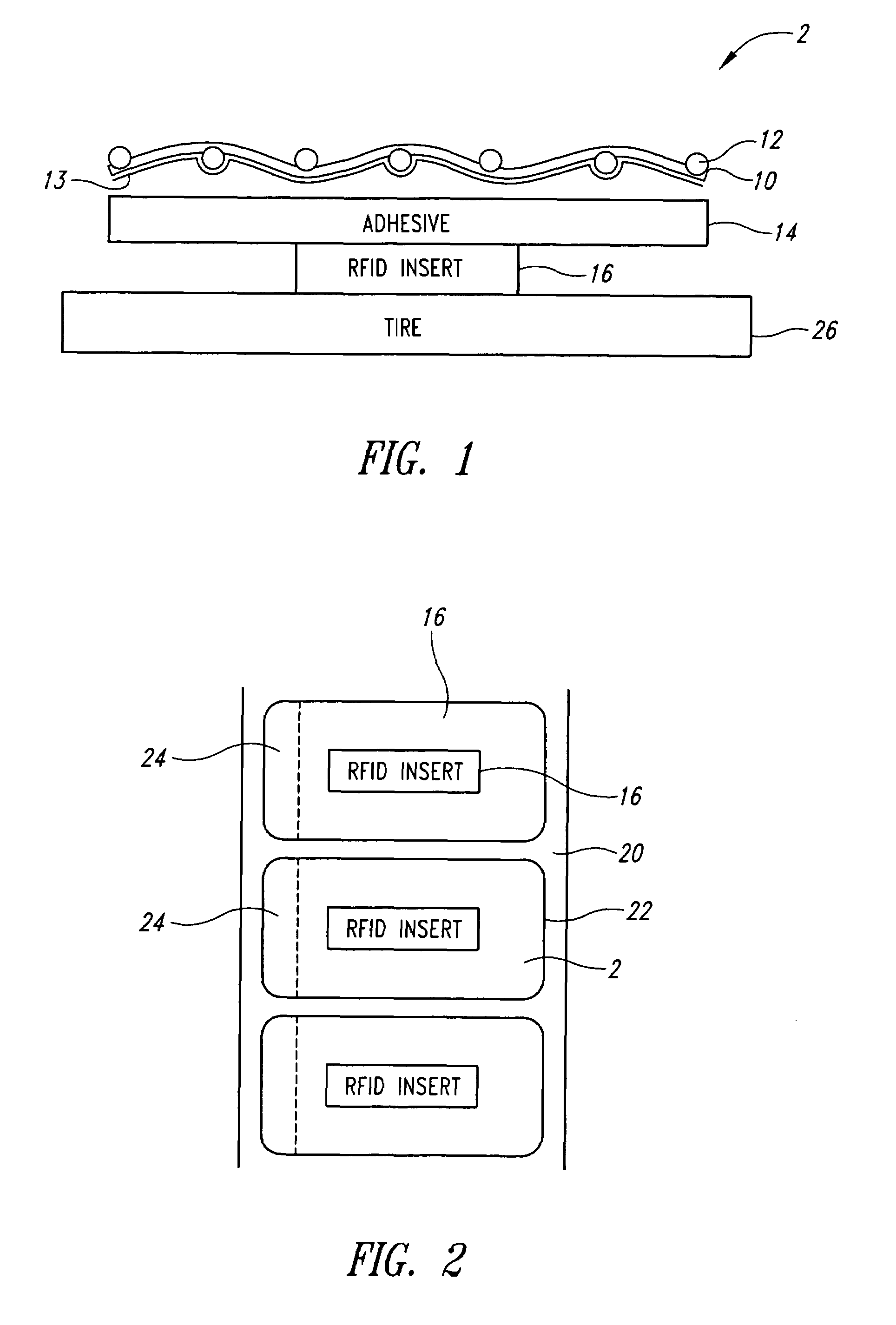

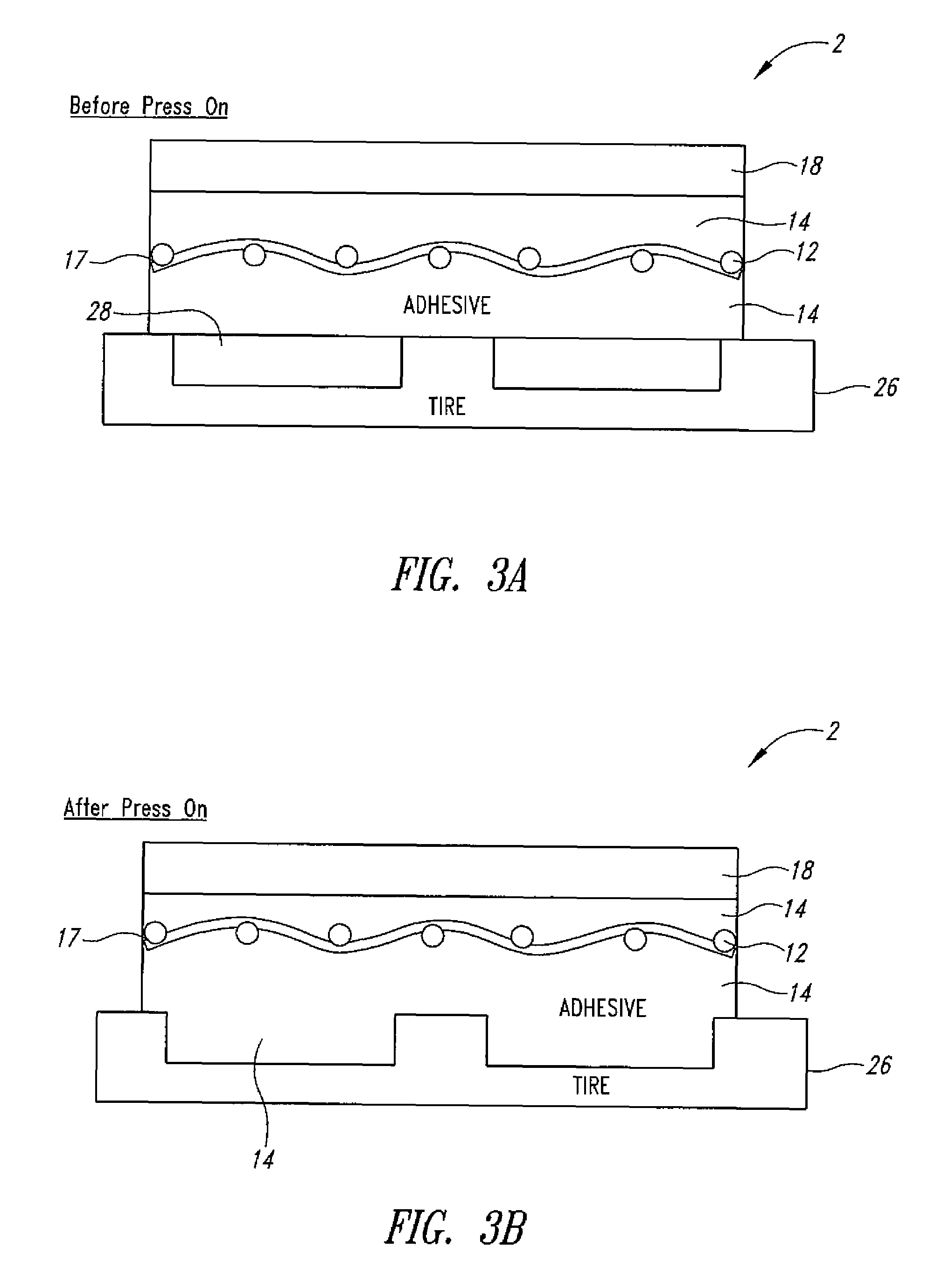

RFID tire label

ActiveUS20050221704A1Easy to disassembleLose tensile strengthStampsSynthetic resin layered productsEngineeringTyre label

Owner:INTERMEC IP

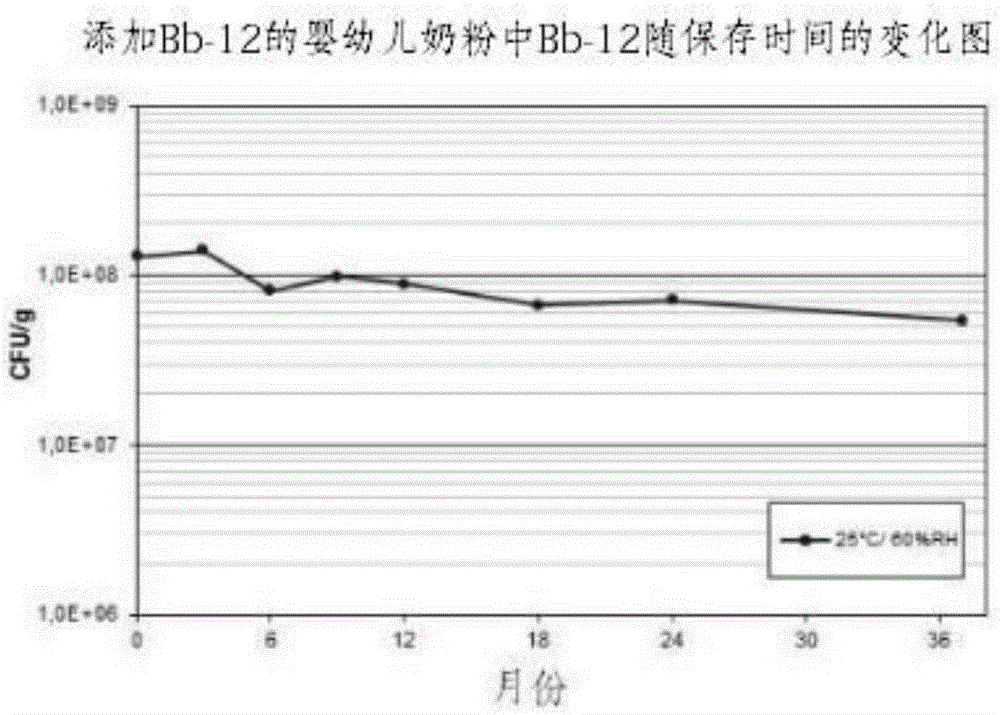

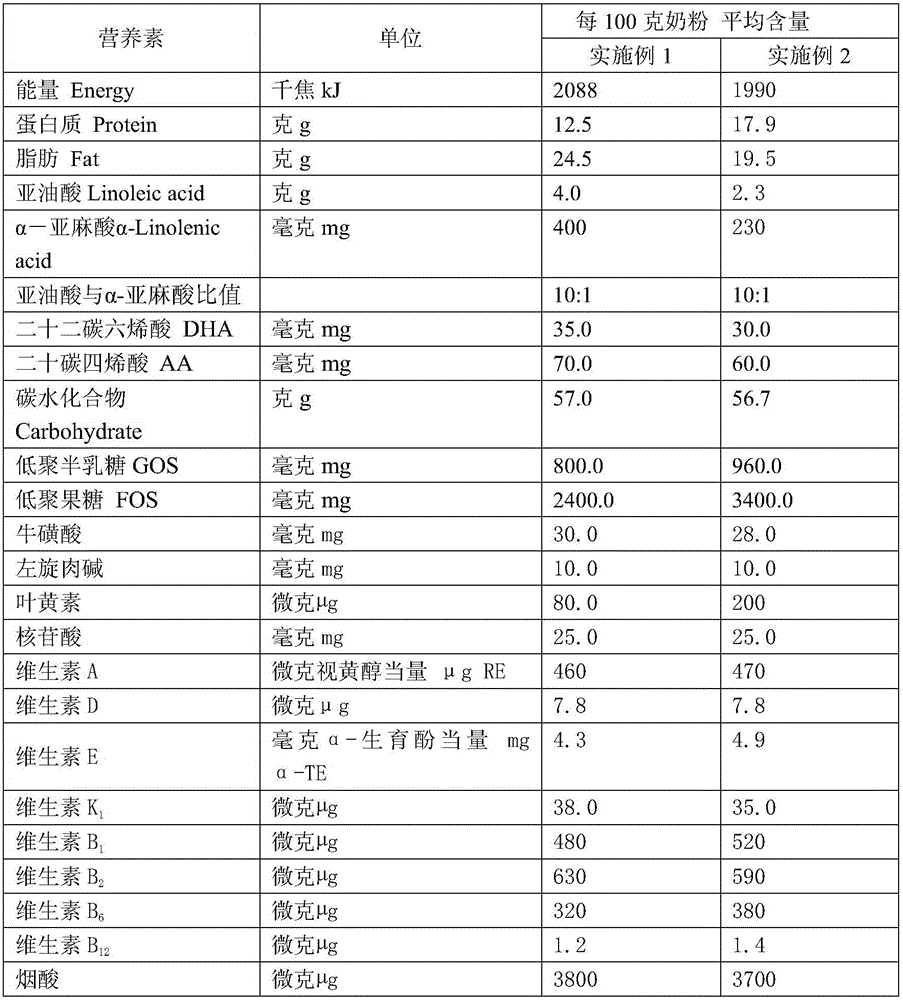

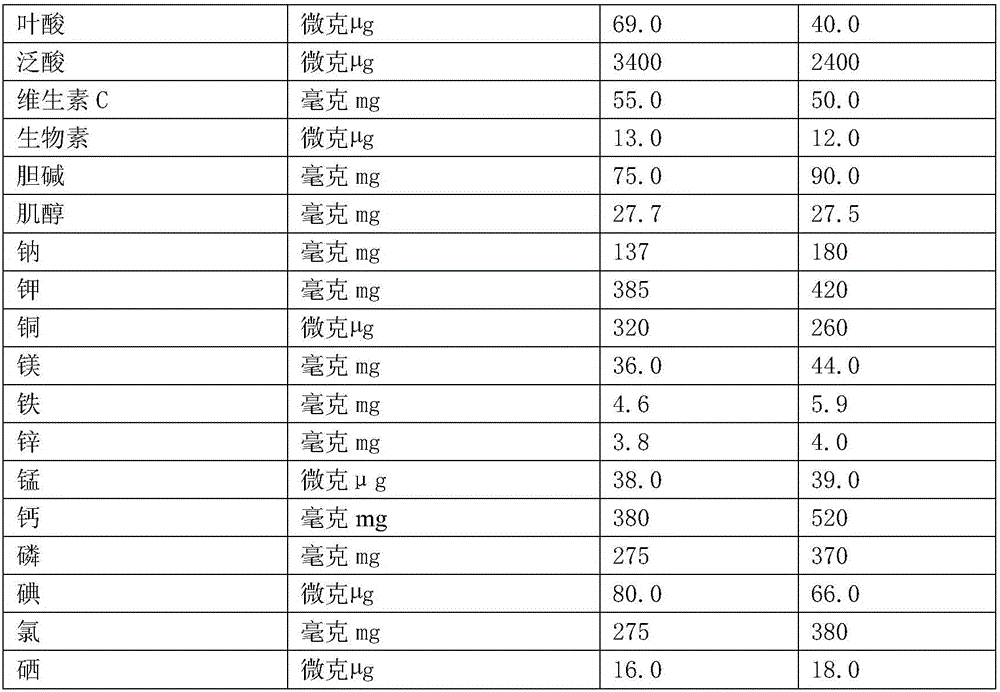

Infant formula milk powder with prebiotics and probiotics and method for preparing infant formula milk powder

InactiveCN105724584APromote value-addedPromote absorptionMilk preparationChemistryDocosahexaenoic acid

The invention discloses infant formula milk powder with prebiotics and probiotics and a method for preparing the infant formula milk powder. The infant formula milk powder comprises, by weight, base powder, galacto-oligosaccharides, fructo-oligosaccharides, bifidobacterium animalis (Bb-12), bifidobacterium lactis (Bi-07), docosahexaenoic acid, eicosatetraenoic acid, choline, nucleotide, lutein, L-carnitine, taurine, inositol and L-sodium ascorbate. The infant formula milk powder and the method have the advantages that the activity of the probiotics can be preserved to the greatest extent owing to technologies for controlling the activity of water in a product and residual oxygen in a package and the like, accordingly, severe decrease of the probiotics in production and storage procedures can be effectively reduced, and the shelf life of the product can be prolonged; intestinal flora can be regulated by the infant formula milk powder, intestinal environments can be optimized, stable superior intestinal flora can be formed, nutrient absorption can be promoted, the defecation speeds can be promoted, feces can be softened, constipation can be improved, and the probability that healthy infants suffer from acute diarrhea can be effectively reduced.

Owner:SHANGHAI CHENG GUAN DAIRY CO LTD

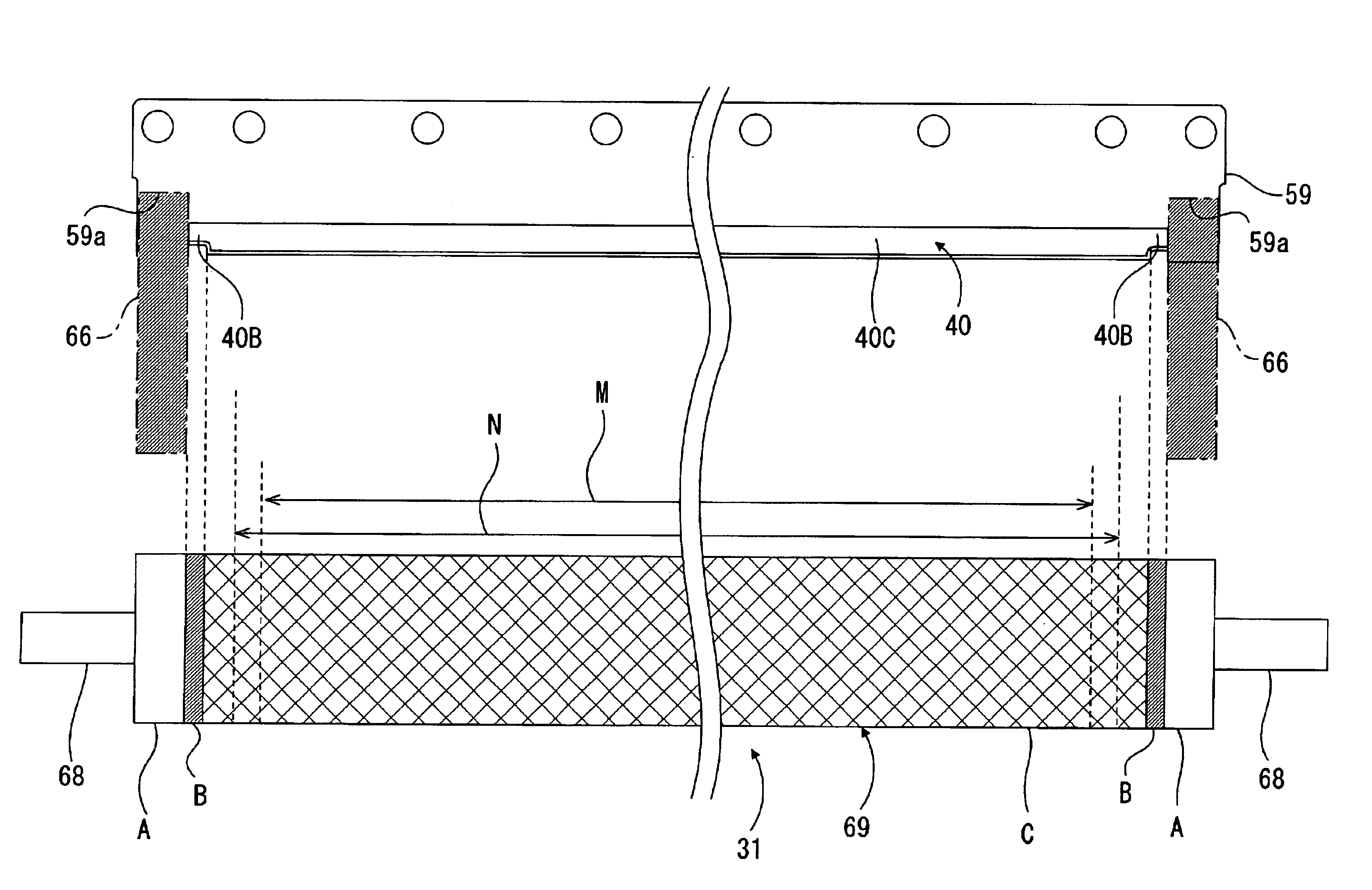

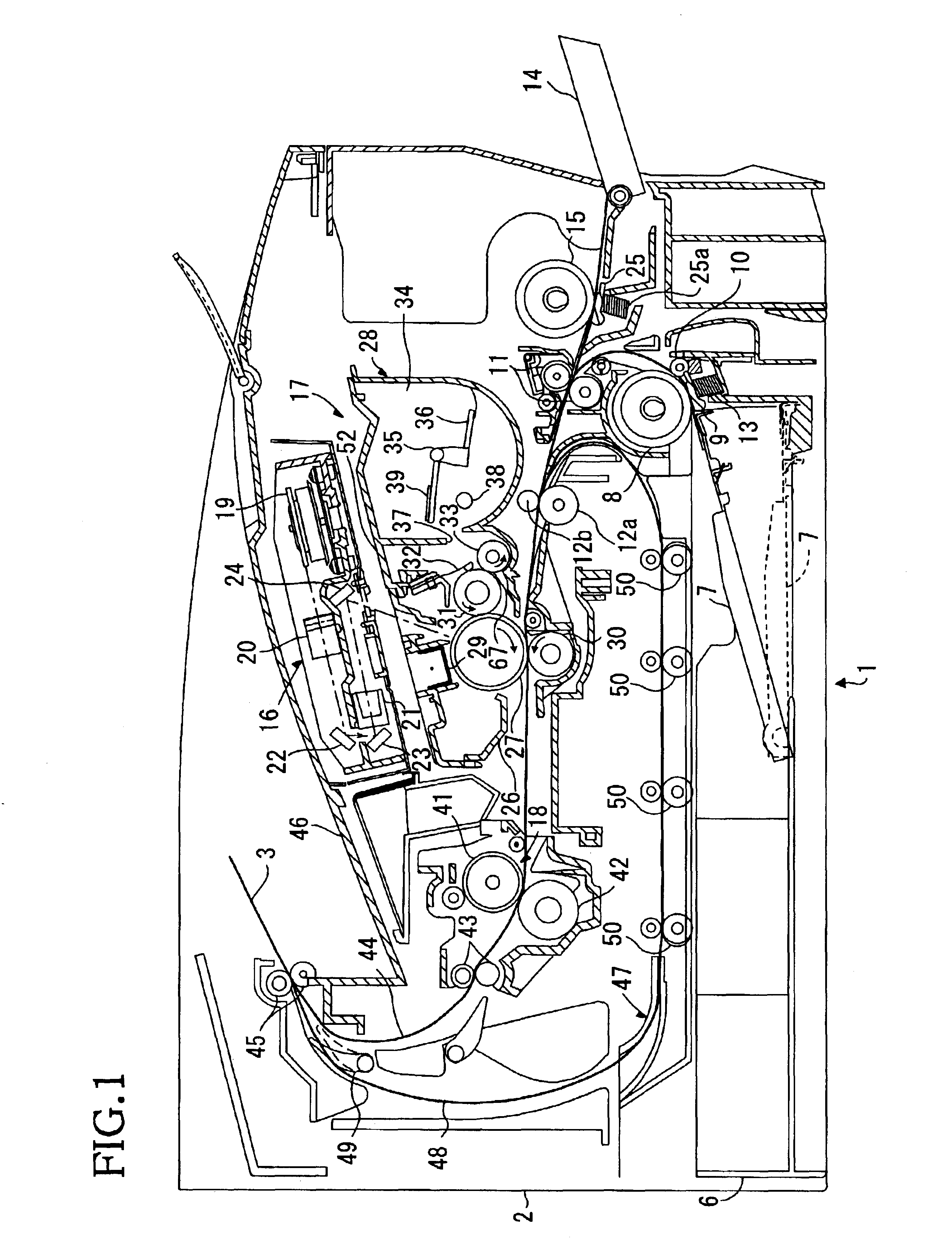

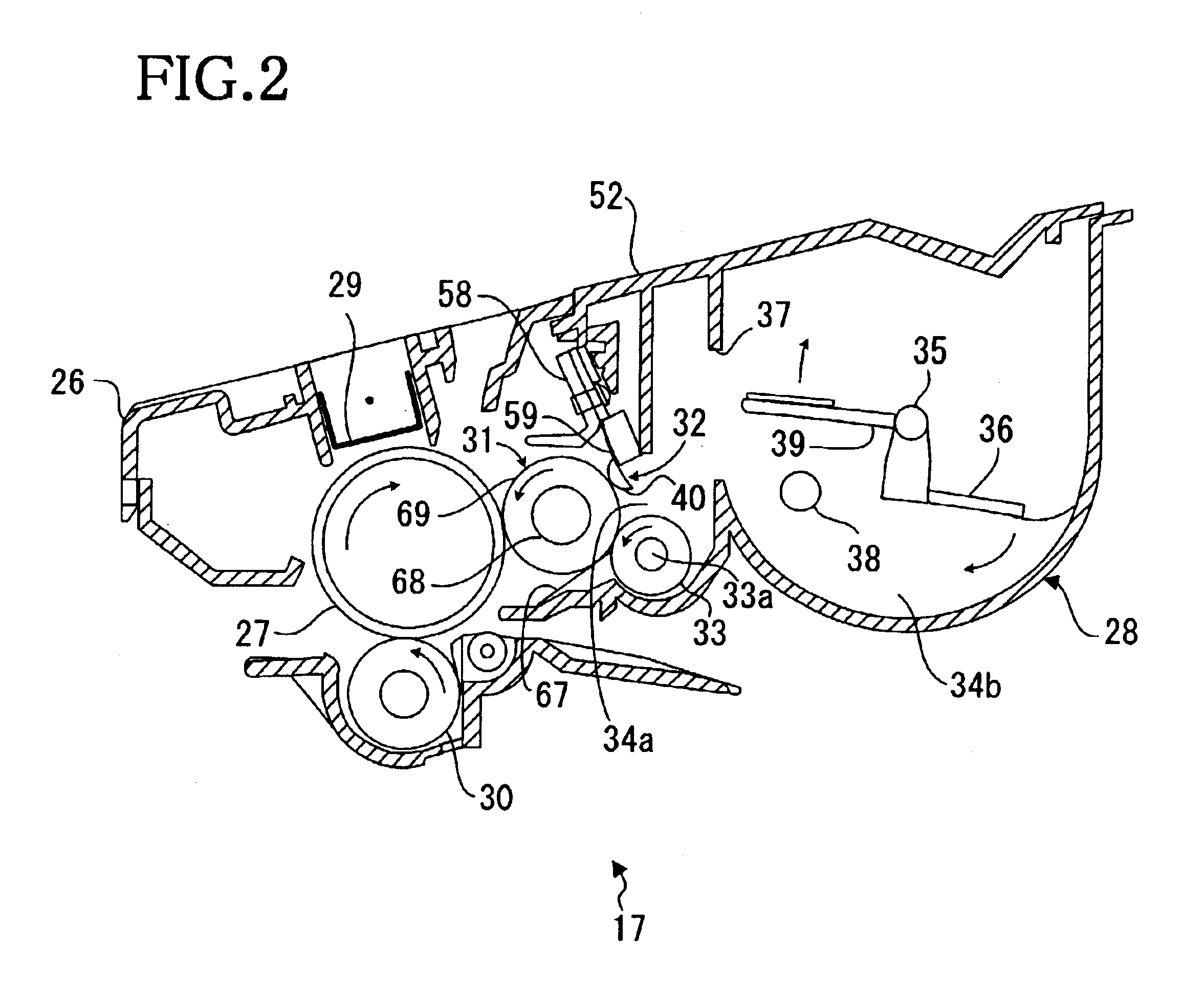

Developing cartridge

InactiveUS6980752B2Prevent leakageLimited adhesionElectrographic process apparatusMechanical engineeringEngineering

A developing cartridge has a housing that accommodates developer therein. Rotatably mounted in the housing is a developing roller. The housing has side seals provided at each end of the developing roller that oppose the circumferential ends of the developing roller. The developing roller itself is divided into a seal region, a side-end region and a center region. A portion of the seal region and the side-end region found at each end of the developing roller with the seal region portions being at the ends of the roller and the side end region portions being between the seal region portions and the center region. Opposing the developing roller is a toner thickness regulating blade having a presser portion. The presser portion has a discontinuous cross-section such that a greater portion of the presser member contacts the developer roller in each portion of the side-end region then contacts the developer roller in the center region. As a result, a greater pressure is applied between the presser portion and the developer roller at the side-end region thereby resulting in less toner being applied to the developing roller to be carried to a photosensitive member. To further the minimize the amount of toner applied to the developing roller, the roughness in the side end region of the developing roller is smaller than the roughness in the center region and the hardness in the side end region of the developing roller is greater than the hardness in the center region. This combination of factors prevents toner from leaking from the housing at the ends of the developing rollers.

Owner:BROTHER KOGYO KK

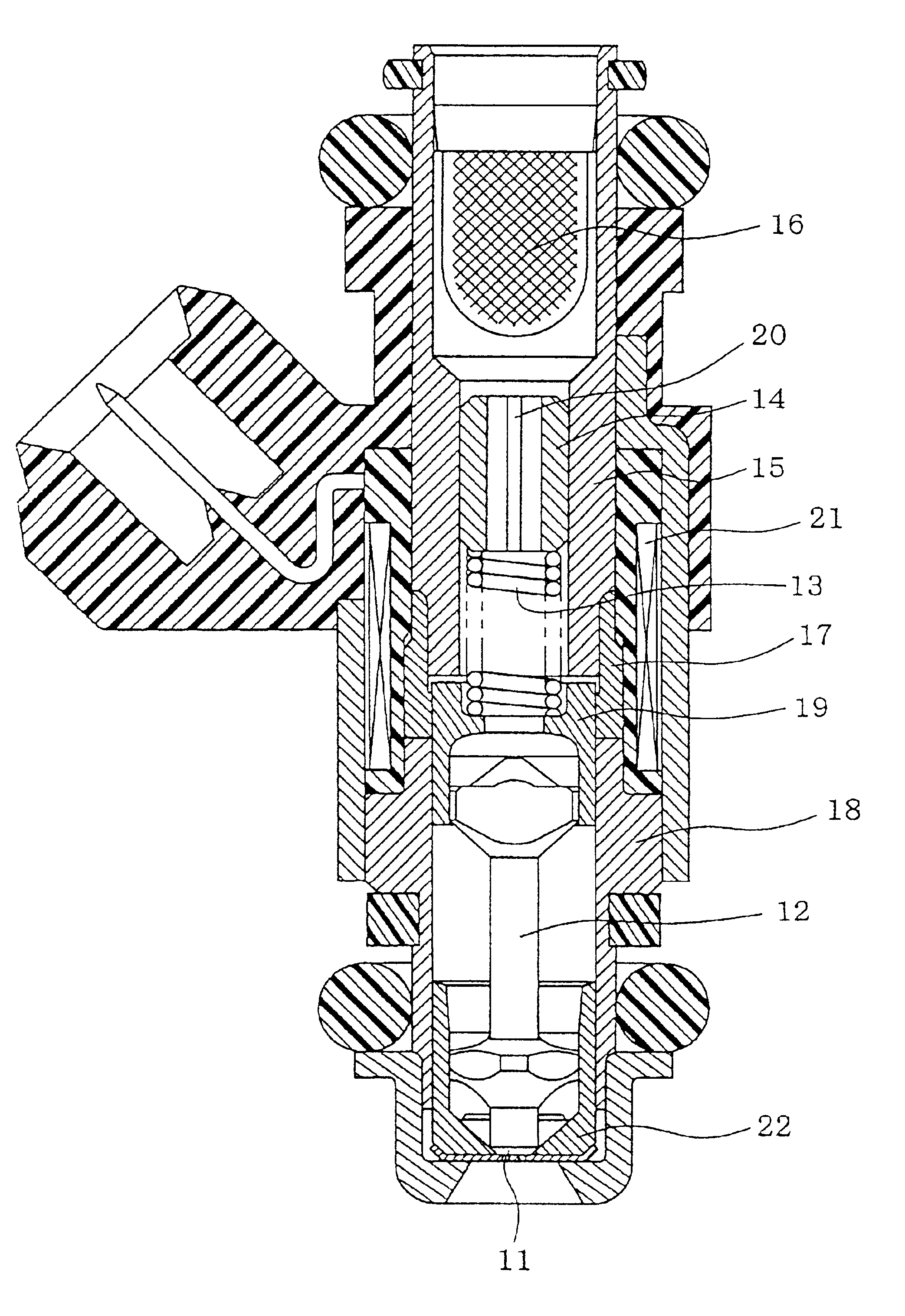

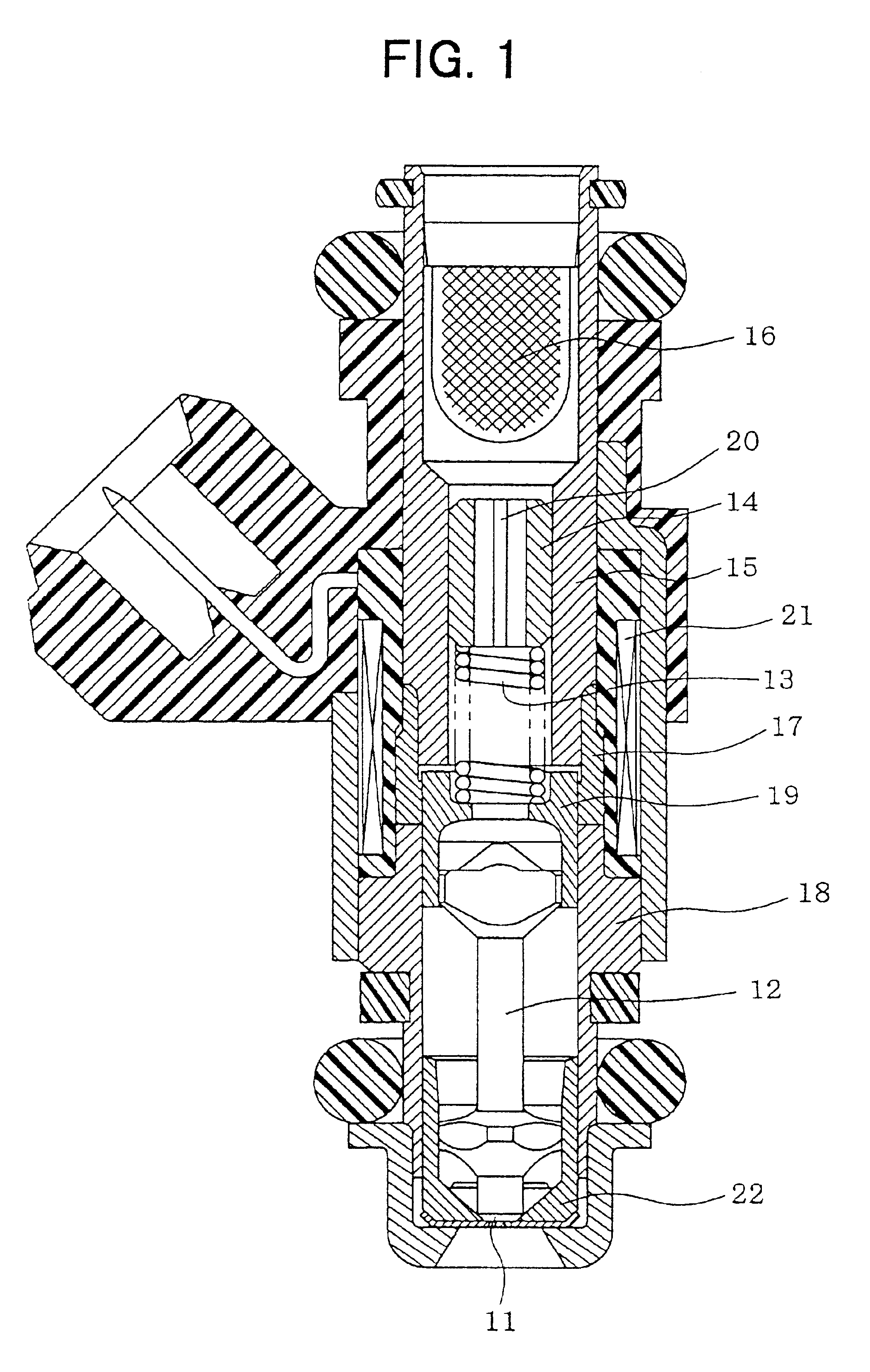

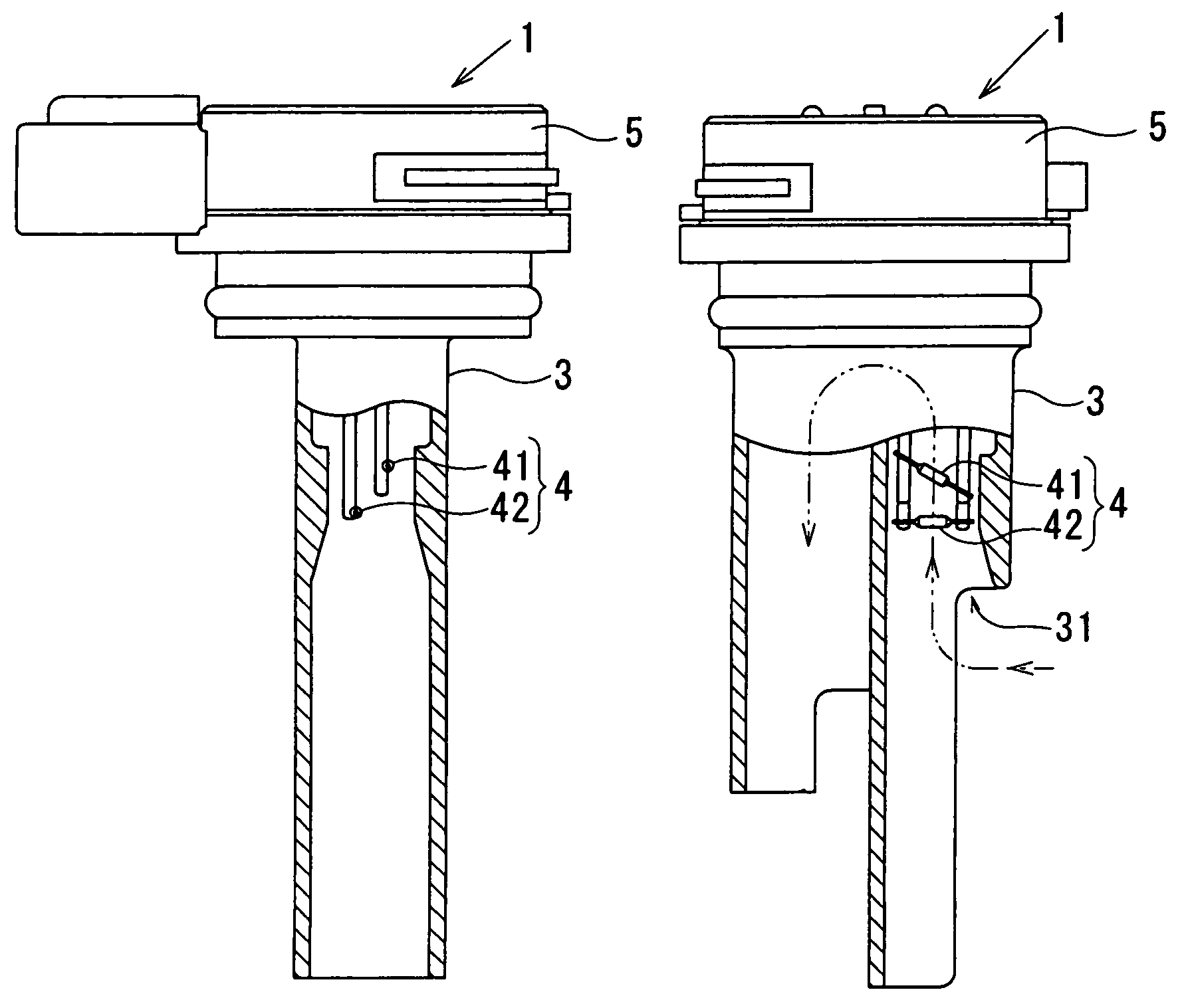

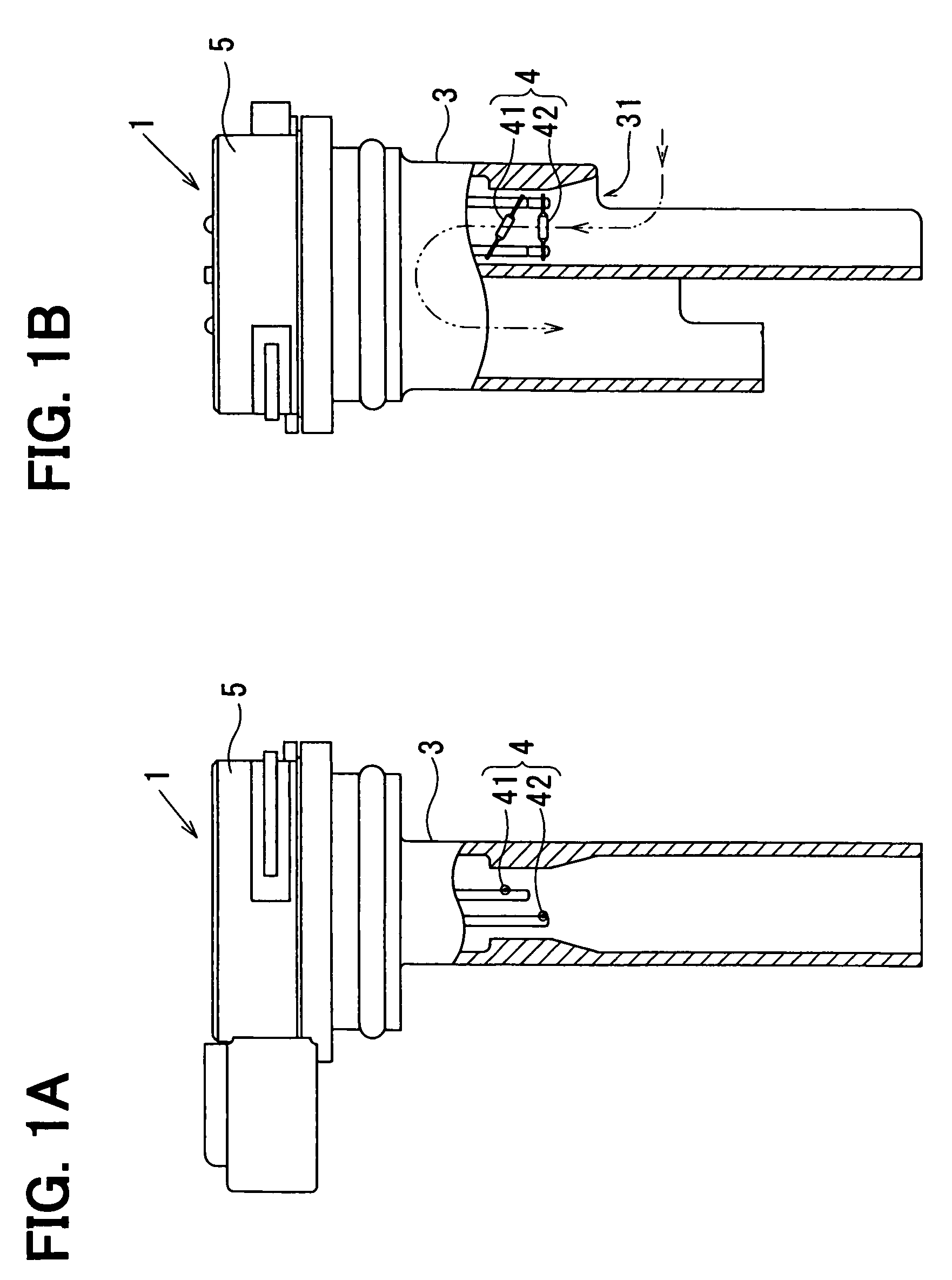

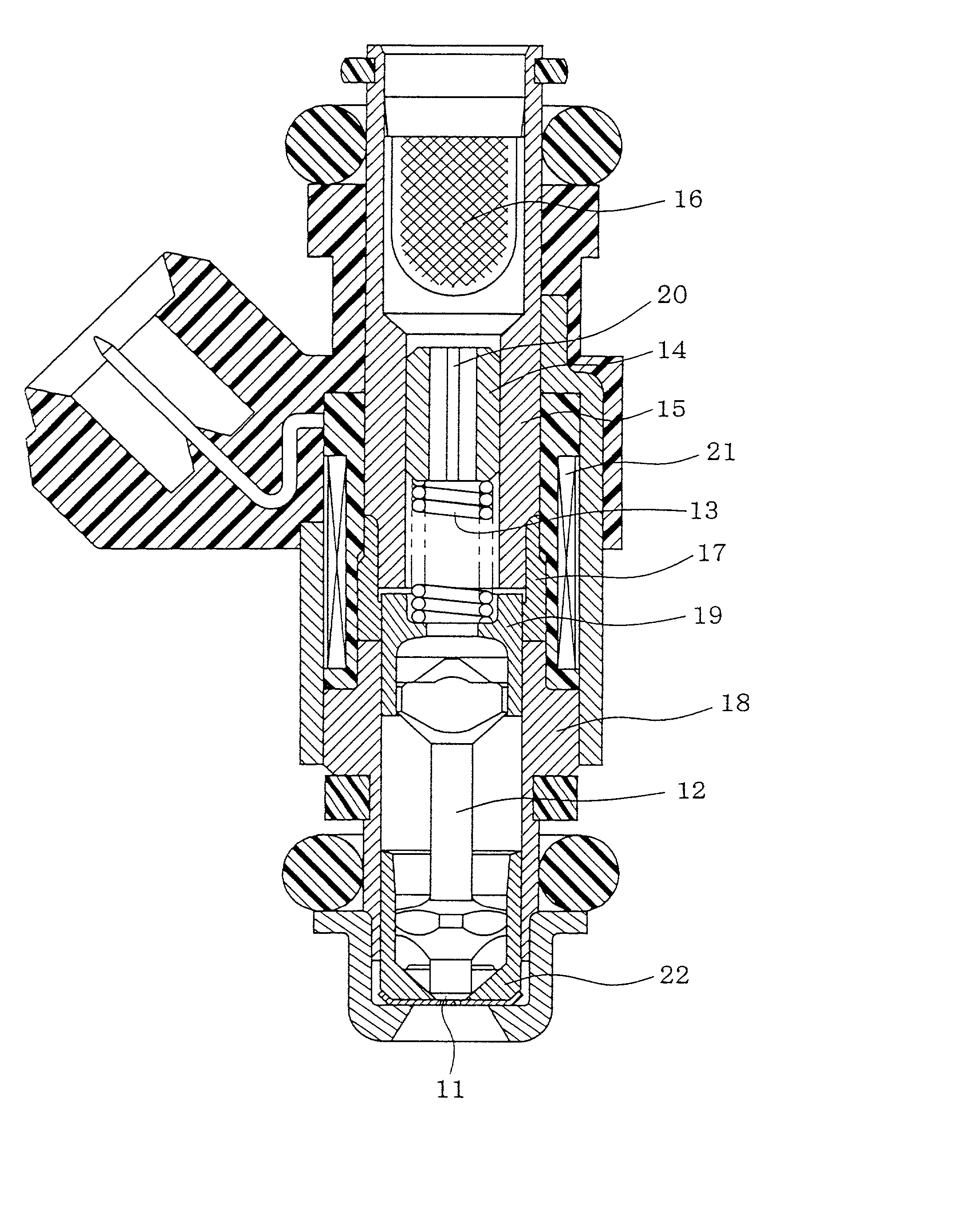

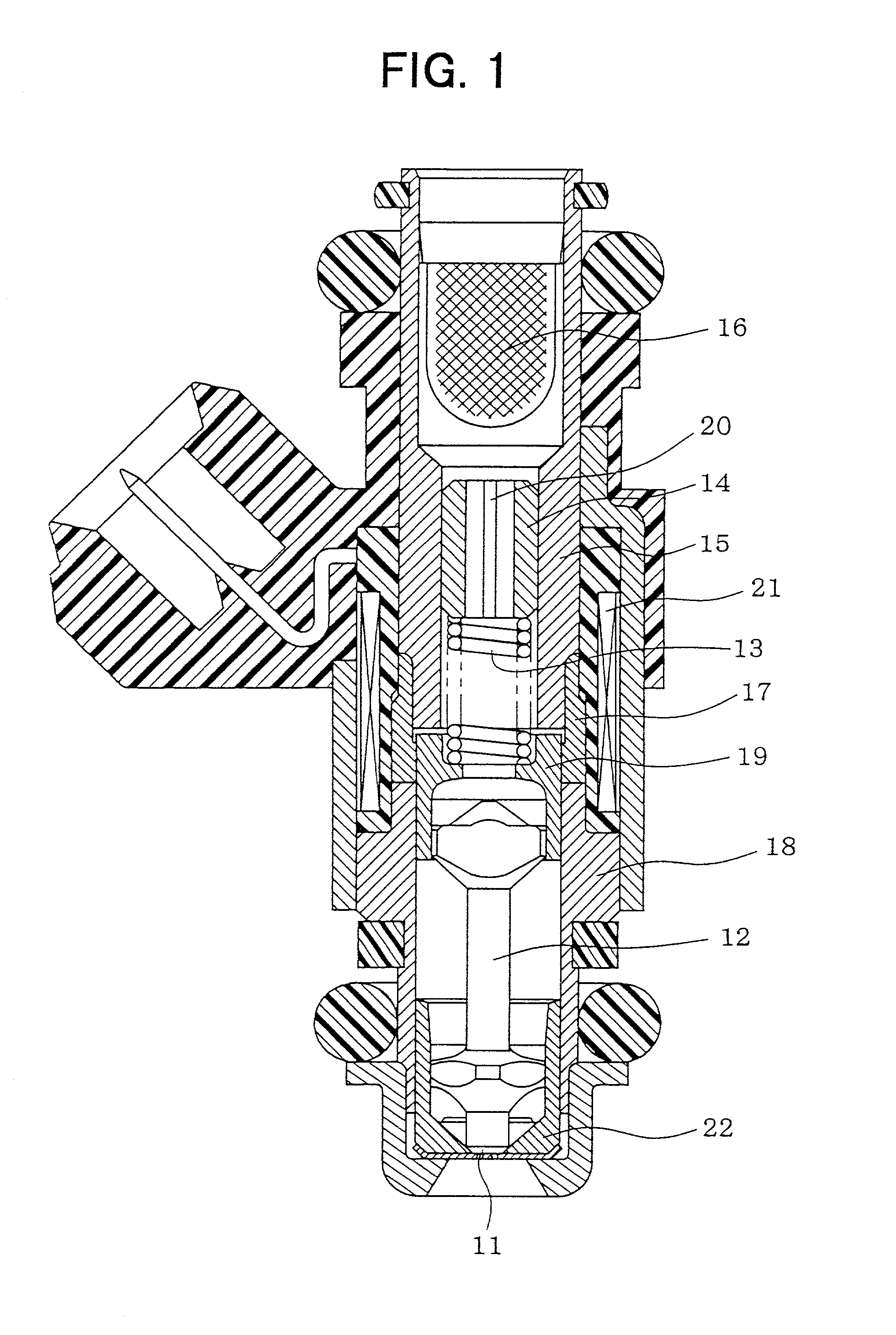

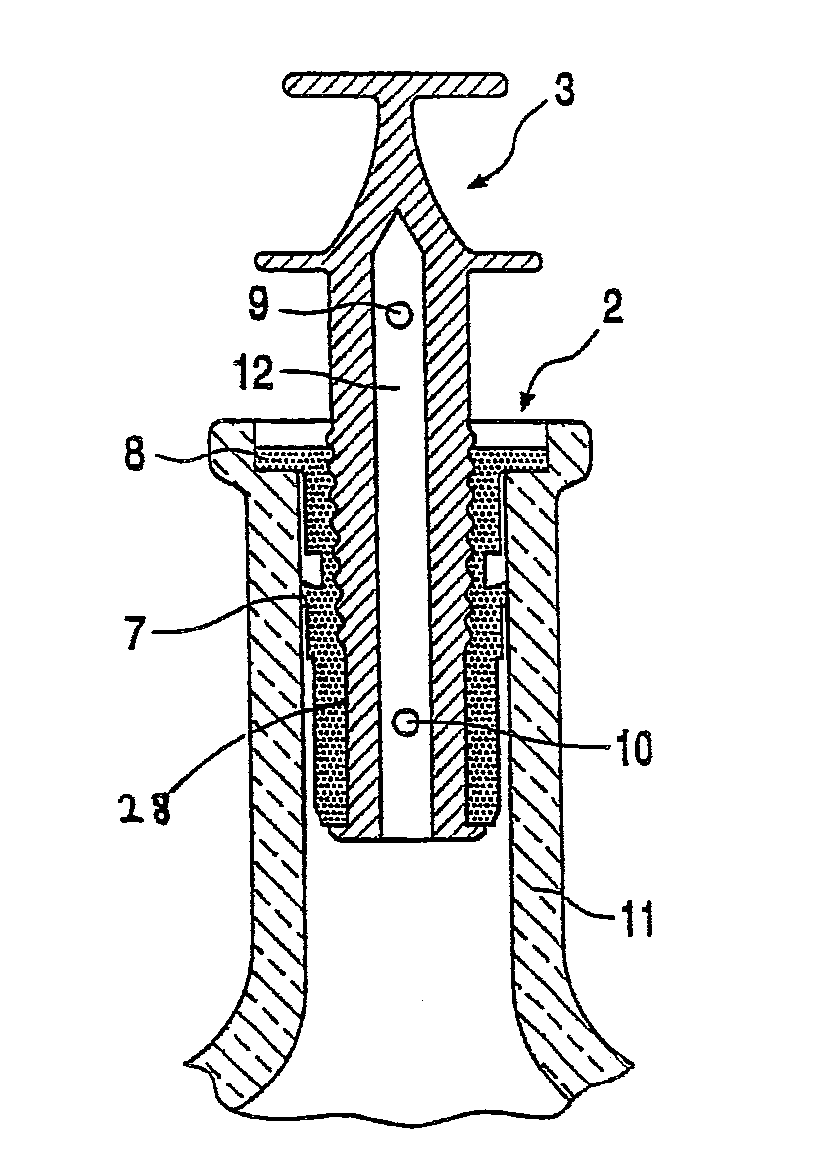

Adjustment pipe for fuel injection valve, and press-fitting structure and press-fitting method for the same

InactiveUS6834667B2Control deformationEasy to adjustVolume/mass flow measurementPipe elementsSpring forceEngineering

In a fuel injection valve, an adjustment pipe made of stainless steel and for adjusting a compression amount of a spring biasing a valve member is press-fitted into a cylindrical housing made of stainless steel, and a fuel injection amount is adjusted by adjusting a spring force of the spring in accordance with a press-fitted amount of the adjustment pipe. The adjustment pipe is immersed in an oxalic acid solution so that an oxalate film is formed thereon before being press-fitted into the cylindrical housing. Therefore, the oxalate film prevents a direct press-contact between an outer peripheral surface of the adjustment pipe and an inner peripheral surface of the cylindrical housing.

Owner:DENSO CORP

RFID tire label

ActiveUS7338914B2Excellent label conformance and adhesionQuickly conform to tire surface irregularitiesStampsSynthetic resin layered productsEngineeringTyre label

Owner:INTERMEC IP

Use of recycled packaging in polymer composite products

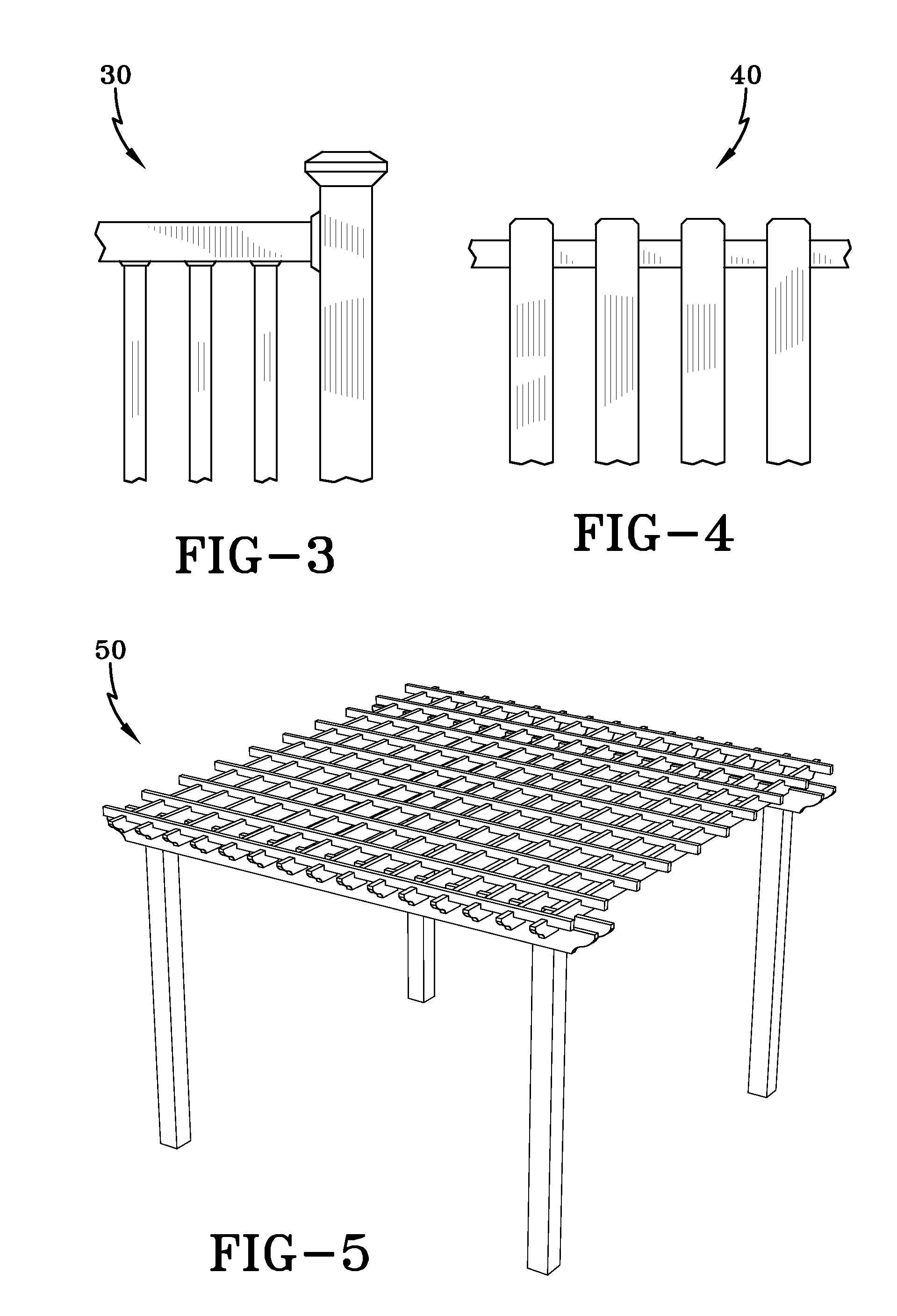

InactiveUS20140061967A1Improve manufacturabilityLimited adhesionPackage recyclingProductsPolymer compositesAluminium

A polymer composite and its method of manufacture using a recycled multilayer material. An example of the recycled multilayer material is comprised of a polyethylene / polyethylene terephthalate / aluminum film that may be extruded with organic filler to obtain desirable performance in wood-substitute products such as deck boards, railing, fencing, pergolas, residential cladding / siding, sheet products, and other applications.

Owner:CPG INT

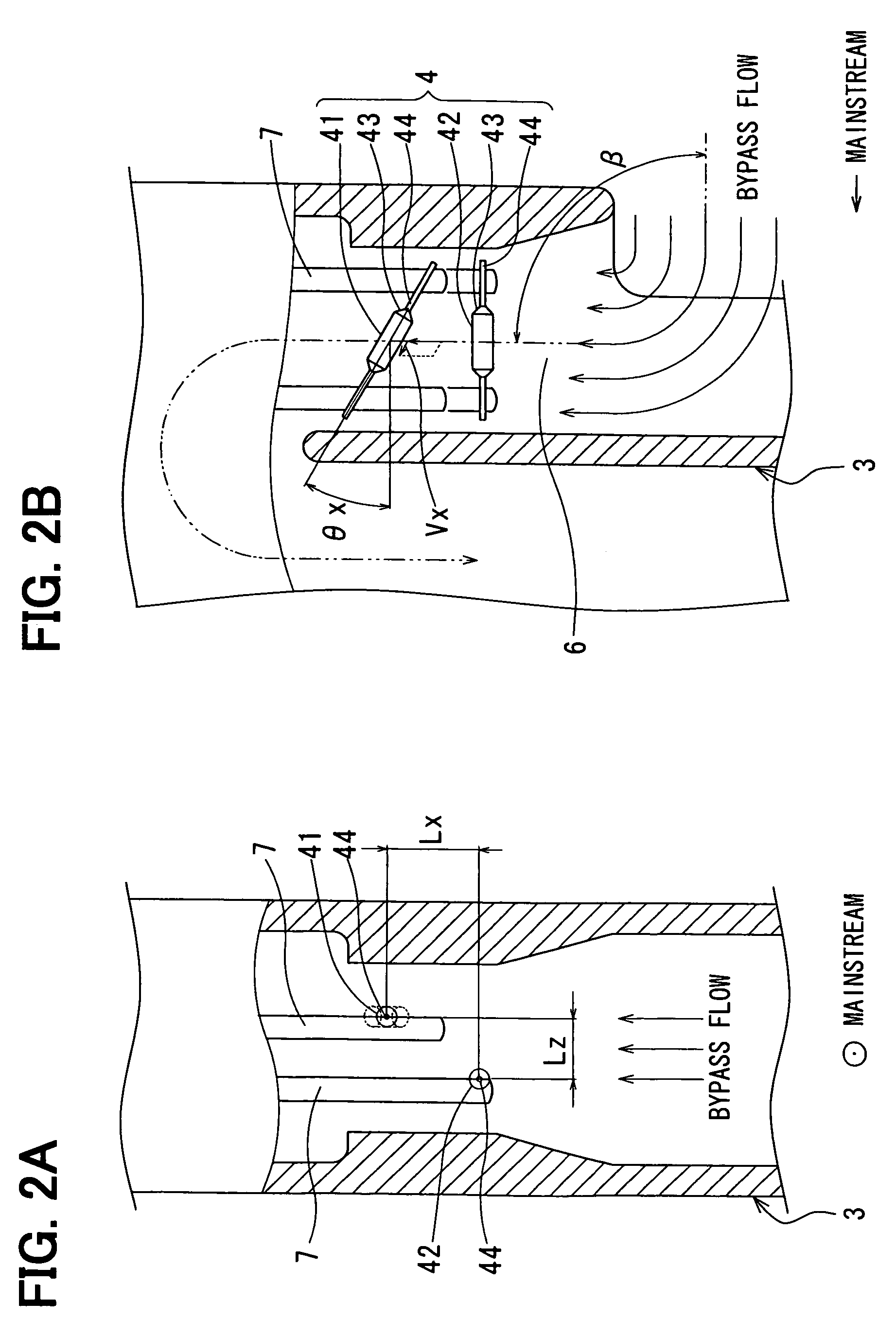

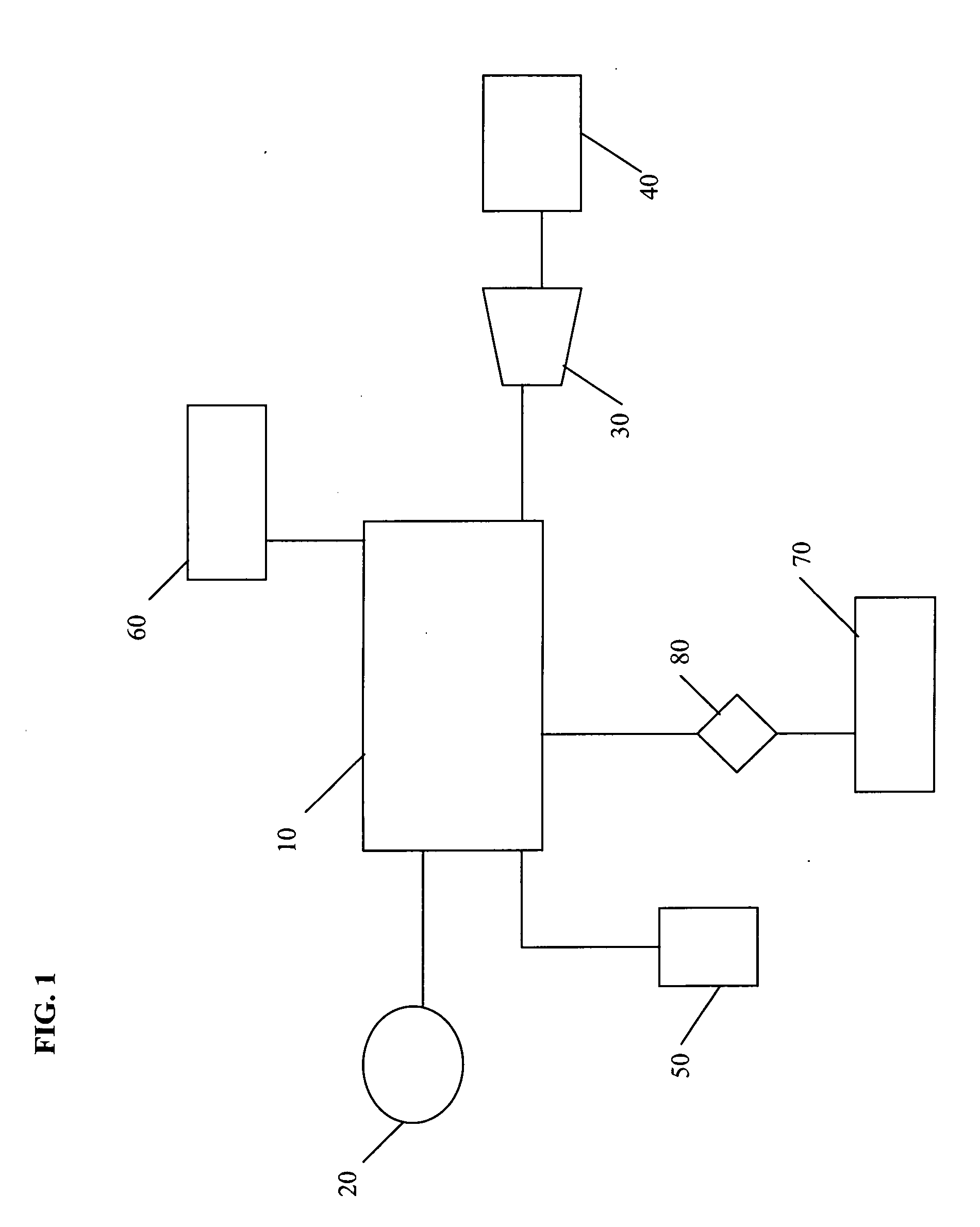

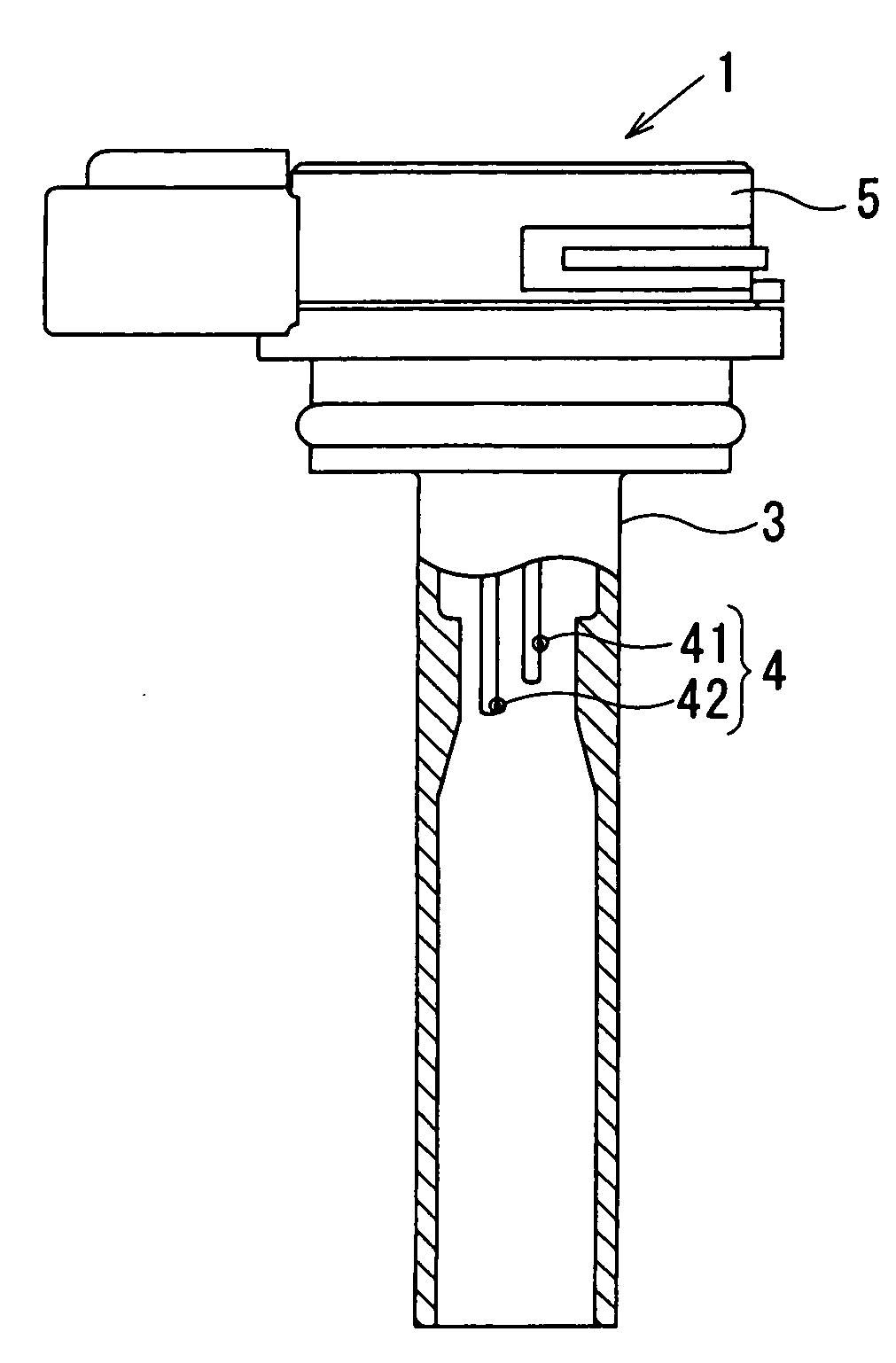

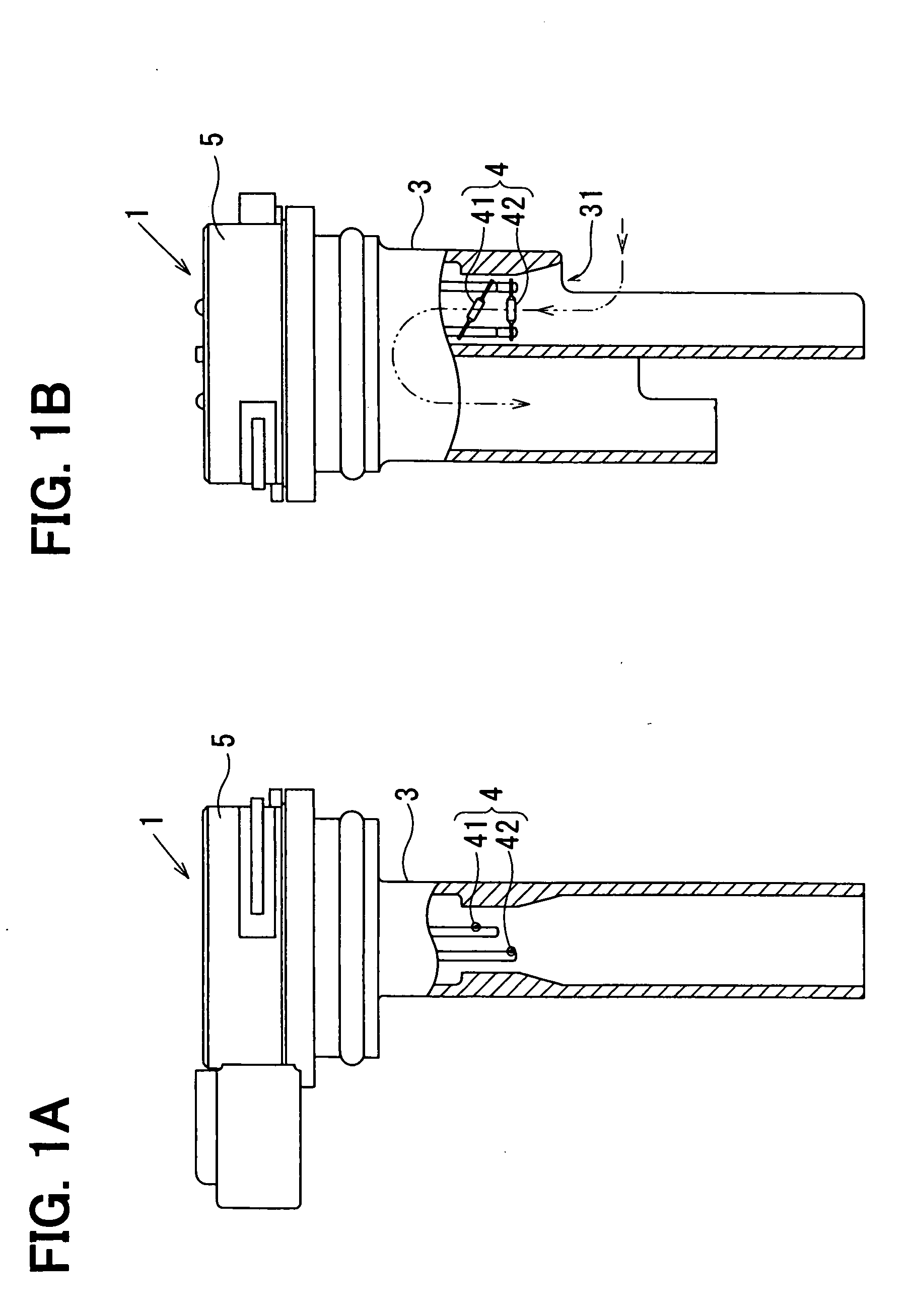

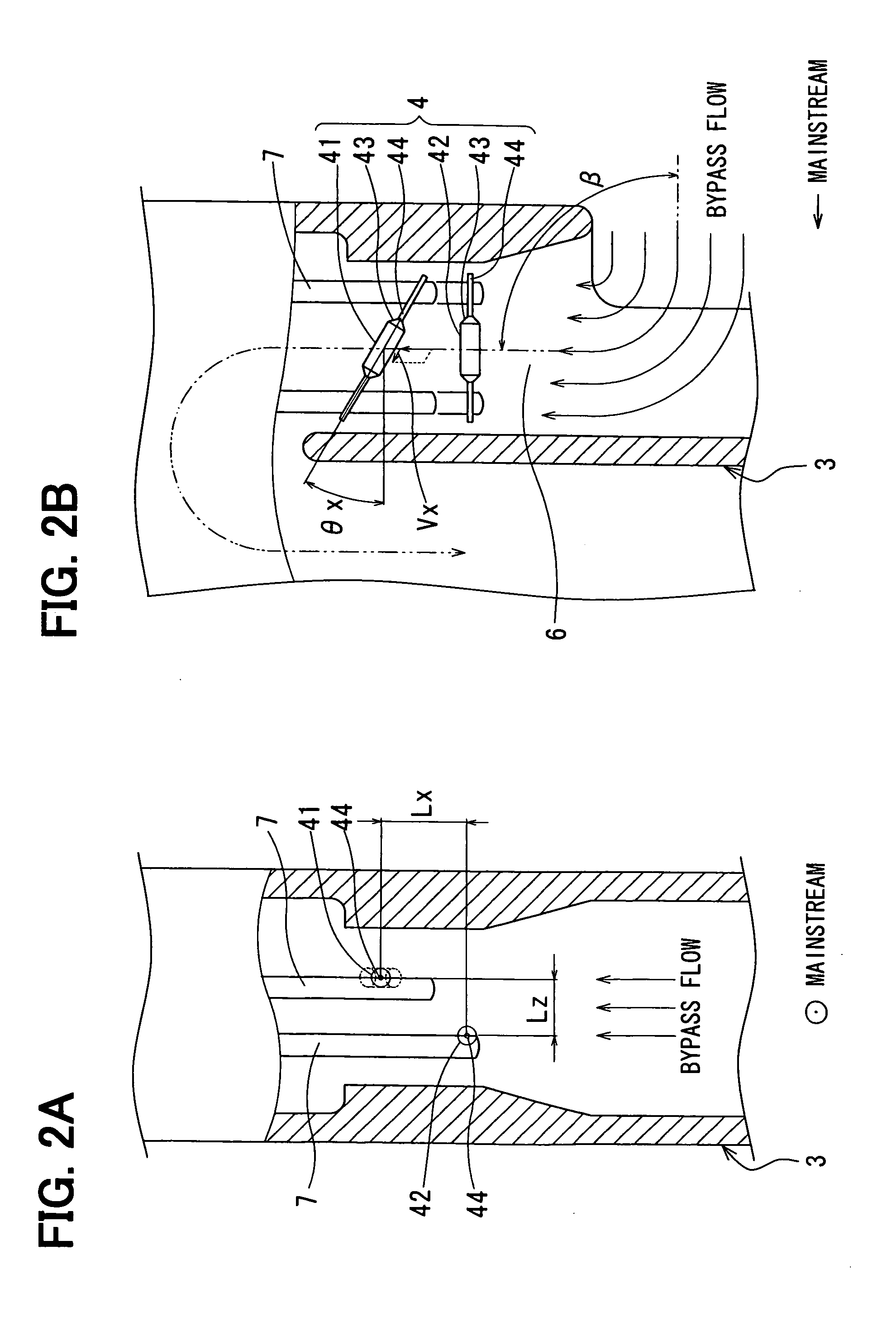

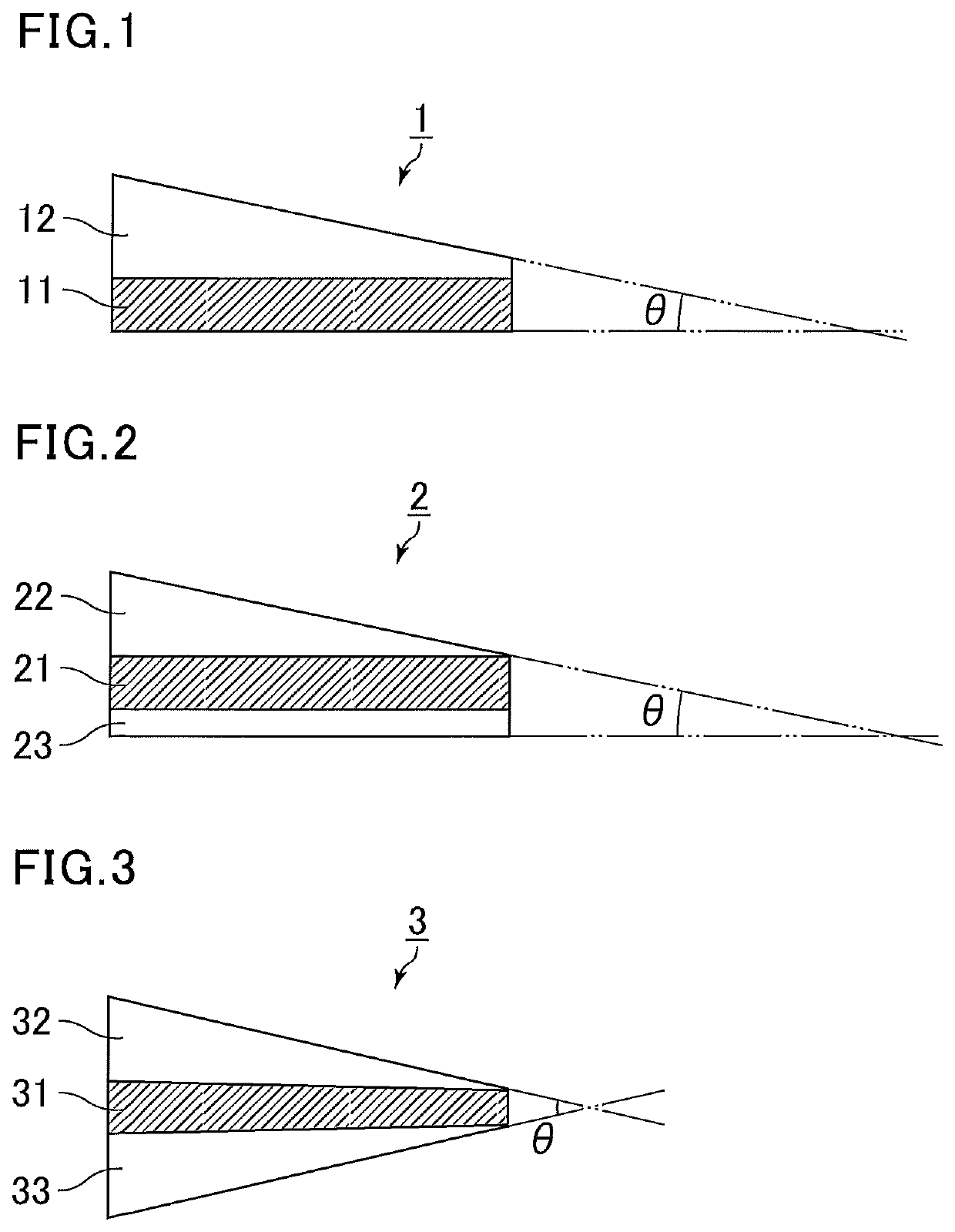

Flow measuring device having heating resistor in inclined position with respect to the flow direction

ActiveUS7661303B2Accurate detectionLimited adhesionVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringThermal radiation

An airflow measuring device includes a sensing portion provided in a bypass passage, which perpendicularly deflects part of air from a main passage to therethrough bypass the part of air. The sensing portion includes a heating resistor energized and dissipate heat to airflow. The sensing portion is configured to measure airflow in the bypass passage based on the heat radiation. The sensing portion further includes a pair of support members erected in the bypass passage to support the heating resistor. The heating resistor of the sensing portion is inclined at a first inclination angle with respect to a direction, which is perpendicular to a flow direction of air in the bypass passage. The heating resistor is inclined toward downstream at an outer streamline of the airflow in the bypass passage.

Owner:DENSO CORP

Adjustment pipe for fuel injection valve, and press-fitting structure and press-fitting method for the same

InactiveUS20020062866A1Control deformationEasy to adjustVolume/mass flow measurementPipe elementsSpring forceEngineering

In a fuel injection valve, an adjustment pipe made of stainless steel and for adjusting a compression amount of a spring biasing a valve member is press-fitted into a cylindrical housing made of stainless steel, and a fuel injection amount is adjusted by adjusting a spring force of the spring in accordance with a press-fitted amount of the adjustment pipe. The adjustment pipe is immersed in an oxalic acid solution so that an oxalate film is formed thereon before being press-fitted into the cylindrical housing. Therefore, the oxalate film prevents a direct press-contact between an outer peripheral surface of the adjustment pipe and an inner peripheral surface of the cylindrical housing.

Owner:DENSO CORP

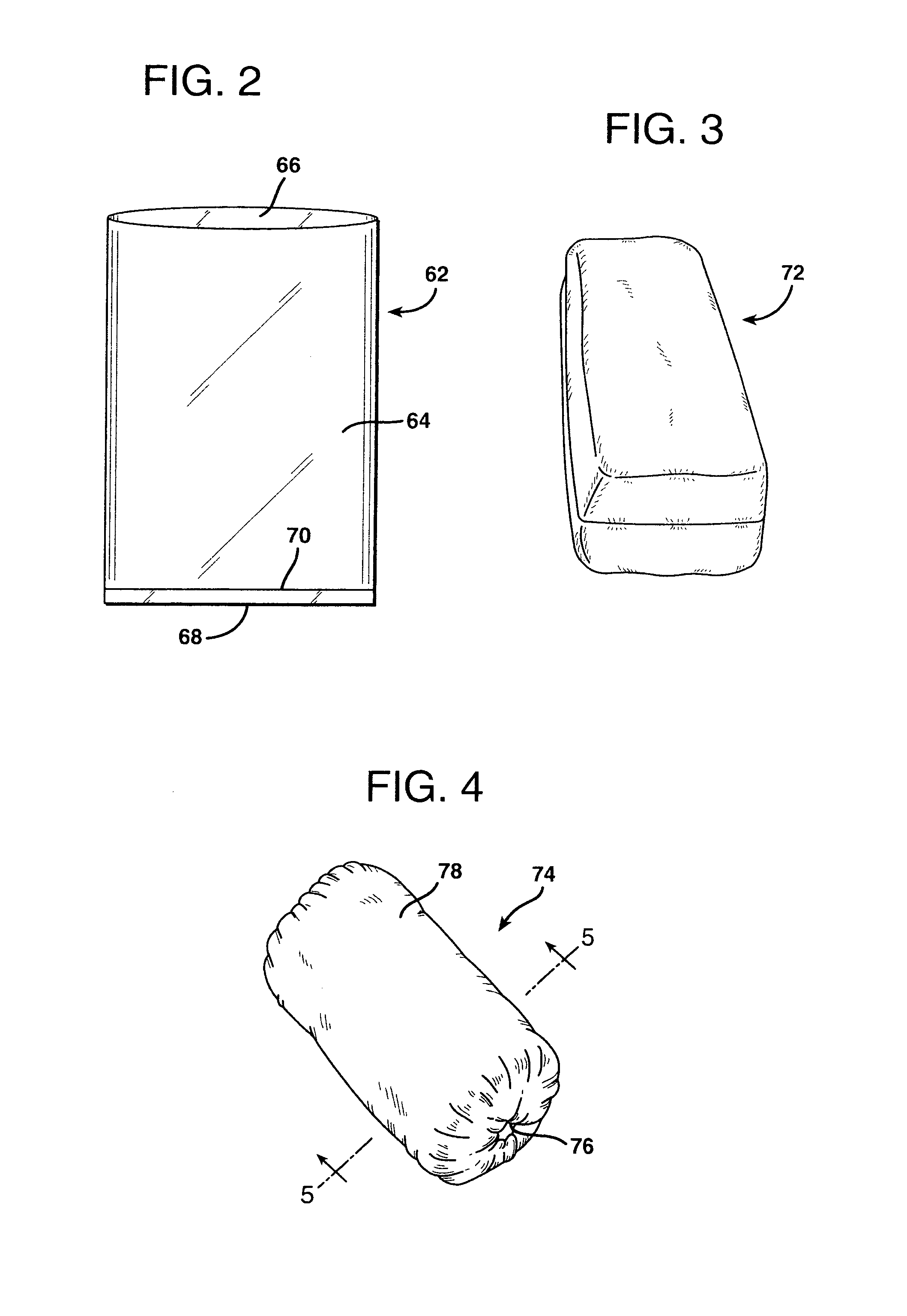

Additive transfer film suitable for cook-in end use

InactiveUS7183006B2Avoid handlingAvoid wastingThermoplastic sausage casingsWrappersPolyesterPolyolefin

A multilayer film has a first layer and a second layer. The first layer comprises an additive, a binder, and a crosslinking agent. The additive is a flavor, fragrance, colorant, antimicrobial agent, antioxidant, chelating agent, and / or odor absorbent. The binder is a polysaccharide and / or a protein. The crosslinking agent comprises a compound with at least two carbonyl groups. The second layer comprises a non-water-soluble thermoplastic polymer comprising at least one member selected from the group consisting of polyolefin, polyamide, polyester, polyvinylidene chloride, polyvinyl chloride, and polystyrene. Each of the additive, binder, and crosslinking agent are present throughout a thickness of the first layer. Preferably, the first layer is coated onto the second layer, which is preferably a non-water-soluble thermoplastic polymer, e.g., polyolefin, polyamide, and / or polyester. The film is especially useful for cook-in applications, in which a food product (preferably comprising uncooked meat) is packaged in the film with the coated layer against the meat. The meat is then cooked and the additive transfers to the meat, and purge can be very low. The invention also pertains to a process for preparing a cooked food product, process for making a coated film, and articles formed from the film, such as bags and casings.

Owner:CRYOVAC INC

Wound closure system and method

InactiveUS20050240221A1Good wound edge oppositionAvoid skin irritationSurgical furnitureSurgical adhesivesClose woundsAlkane

Methods and systems for closing wounds using wound closures and a flowable adhesive skin paint are disclosed. The flowable adhesive does not adhere the wound closures to the skin over the wound to reduce irritation. In some embodiments, the skin paint may include 1-40% of a siloxane-containing polymer; 60-99% of an Alkane-Based Siloxane Polymer Reaction Solvent; and 0-15% of adjuvants. The wound closures used with such a skin paint may include a wound bridging portion of microporous polypropylene film.

Owner:3M INNOVATIVE PROPERTIES CO

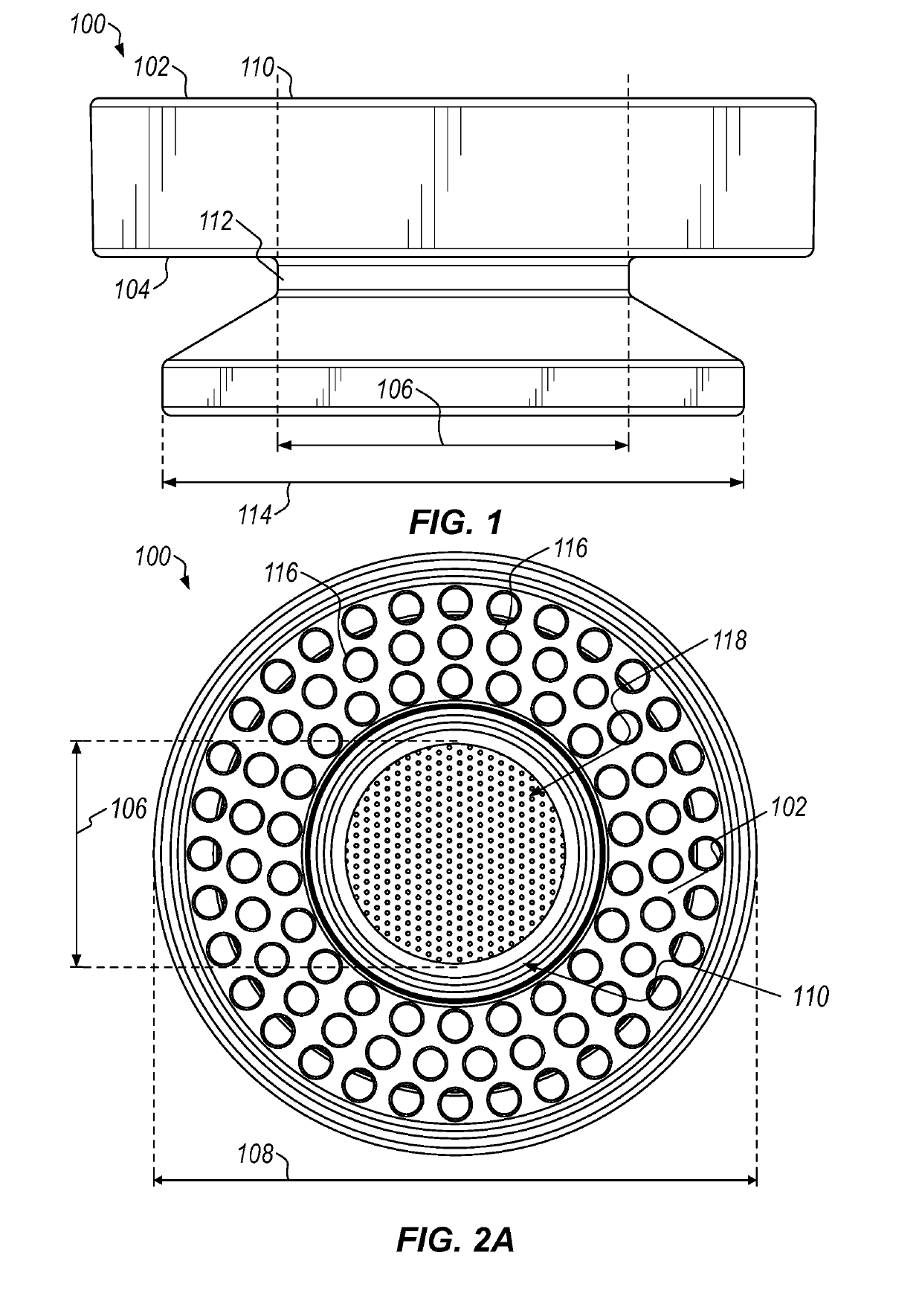

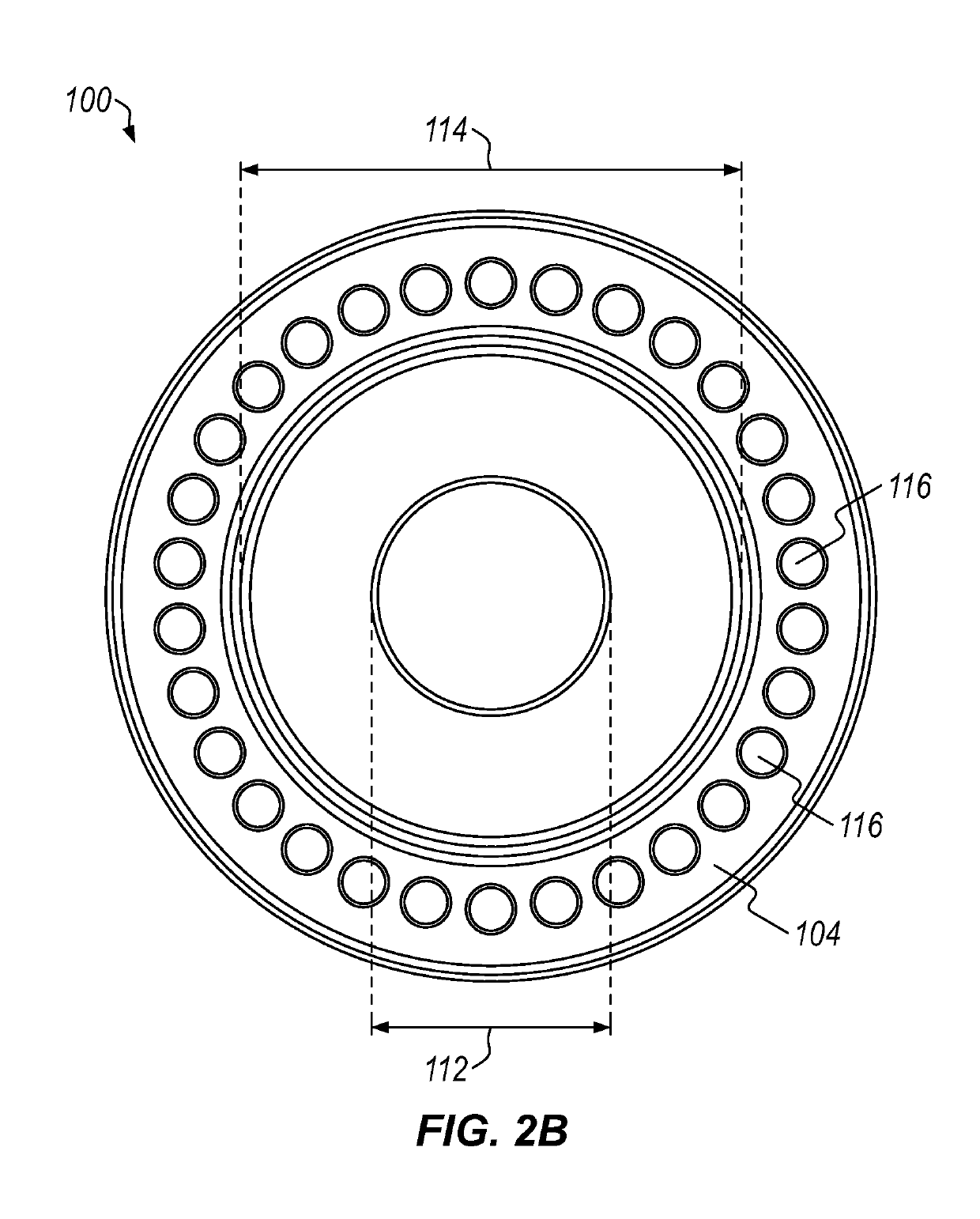

Beverage Preparation Apparatus

A beverage preparation apparatus comprising a platform section having a plurality of attachment points for additional components. The platform is adapted to releasably secure in a wide variety of target beverage vessels. The additional components include, but are not limited to, a large volume filter means, a temperature regulator, or a gravity-fed brewer. The platform may also be incorporated into a vacuum-insulated, stainless-steel beverage vessel.

Owner:TSIGOUNIS MARK

Multilayer film

InactiveUS20080081183A1Improve rigiditySuitable for packagingSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

An blow-extrudable film that ensures a reclosing ability after a first opening consists of a support layer on which a connecting layer and an overlying cover layer are arranged. The connecting layer essentially consists of a pressure sensitive hot melt adhesive. Both the support layer and the cover layer are essentially composed of polyethylene. The support layer may e.g. be made of low density and / or high density polyethylene (LD-PE respectively HD-PE). The cover layer consists of up to 100% LLD-PE (linear low density polyethylene) or of a blend of LLD-PE and polyethylene. Due to the LLD-PE content, the cover layer has a higher adhesion on the connecting layer than the support layer. In this manner it is ensured that in the first opening process, during which a portion of the support layer is separated, the connecting layer remains on the cover layer. Pressing the separated portion onto the connecting layer restores the bond between the separated portion and the film and recloses a container that is sealed by the film.

Owner:STANIPAC

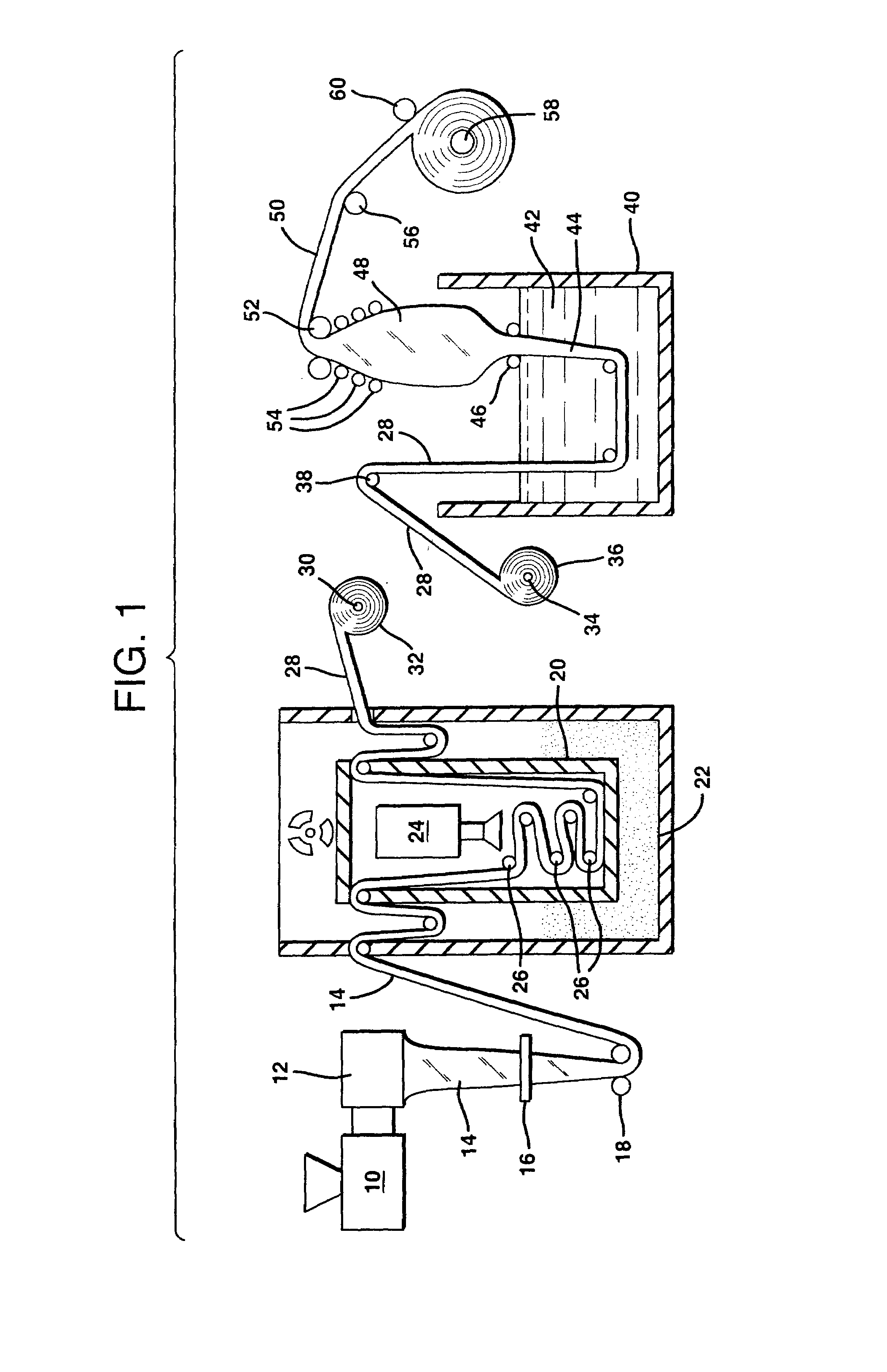

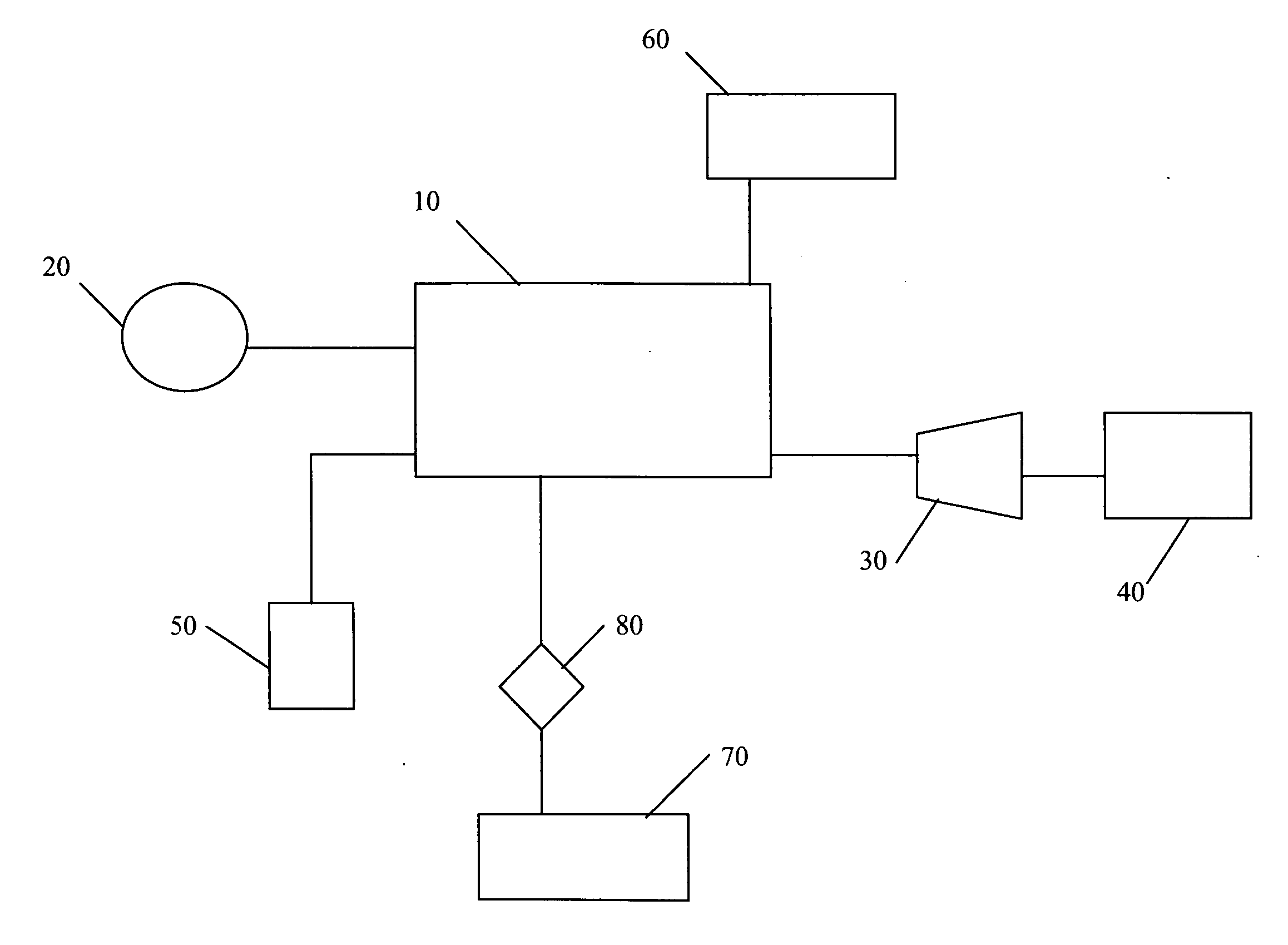

Nuclear fusion containment complex and systems network for the thermal durational enhancement of contained heat processes

InactiveUS20070172015A1Extended service lifeReduce wasteNuclear energy generationReaction to electrical energyDetonationHydrogen

A systems network for harnessing nuclear fusion power and, more particularly, a complex for containment of a nuclear fusion detonation reaction, in which the nuclear detonation reaction is used to heat water for application in a steam turbine system that is used to drive a generator. The systems network include a feedwater plant, a steam turbine system, an oxygen producing plant, and a thermal recovery plant, connected to a containment complex having a hydrogen detonation chamber encased in a series of thermal containment chambers having electromagnetically charged walls and an outer structure.

Owner:GORDON EDWARD CADY II

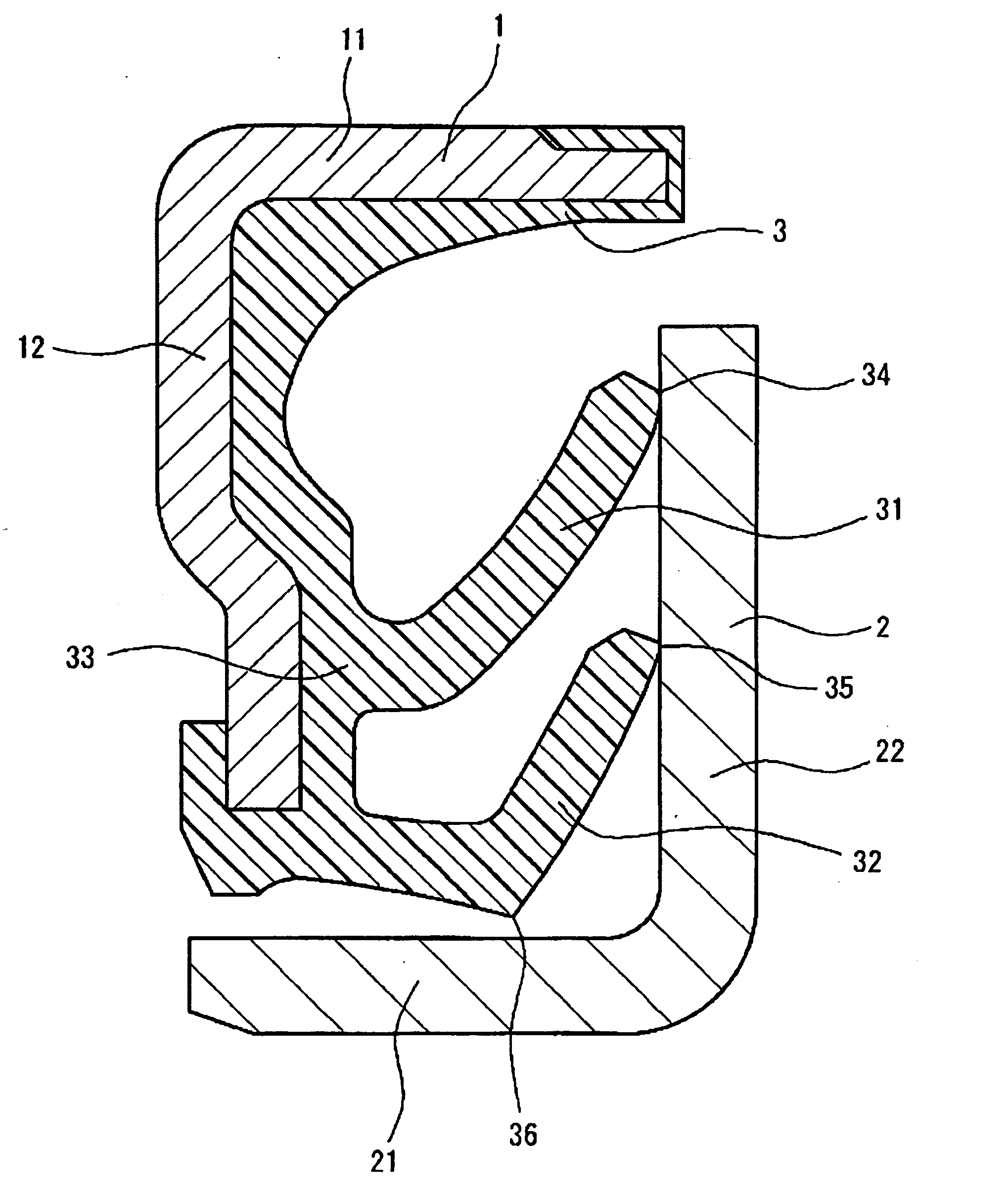

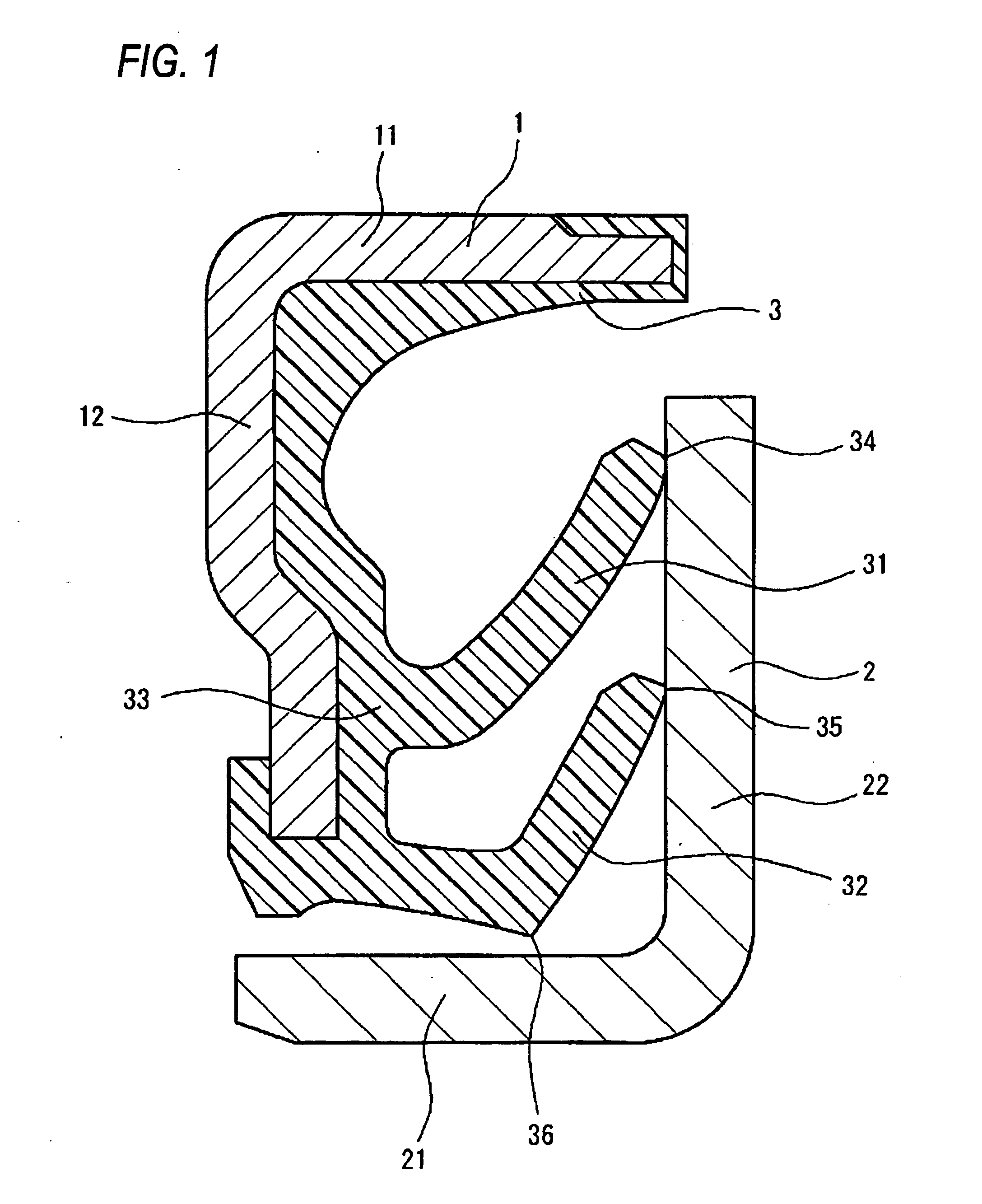

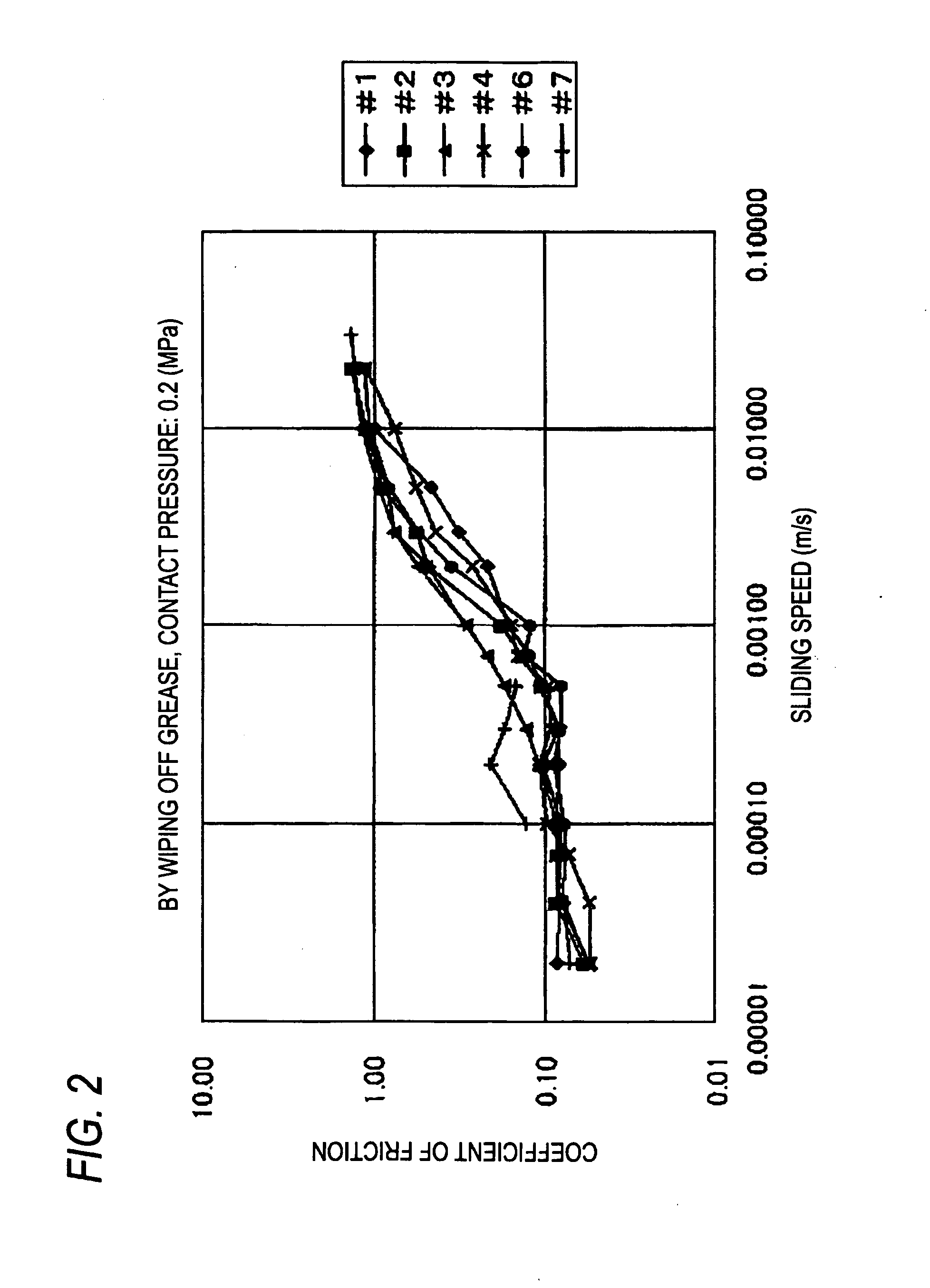

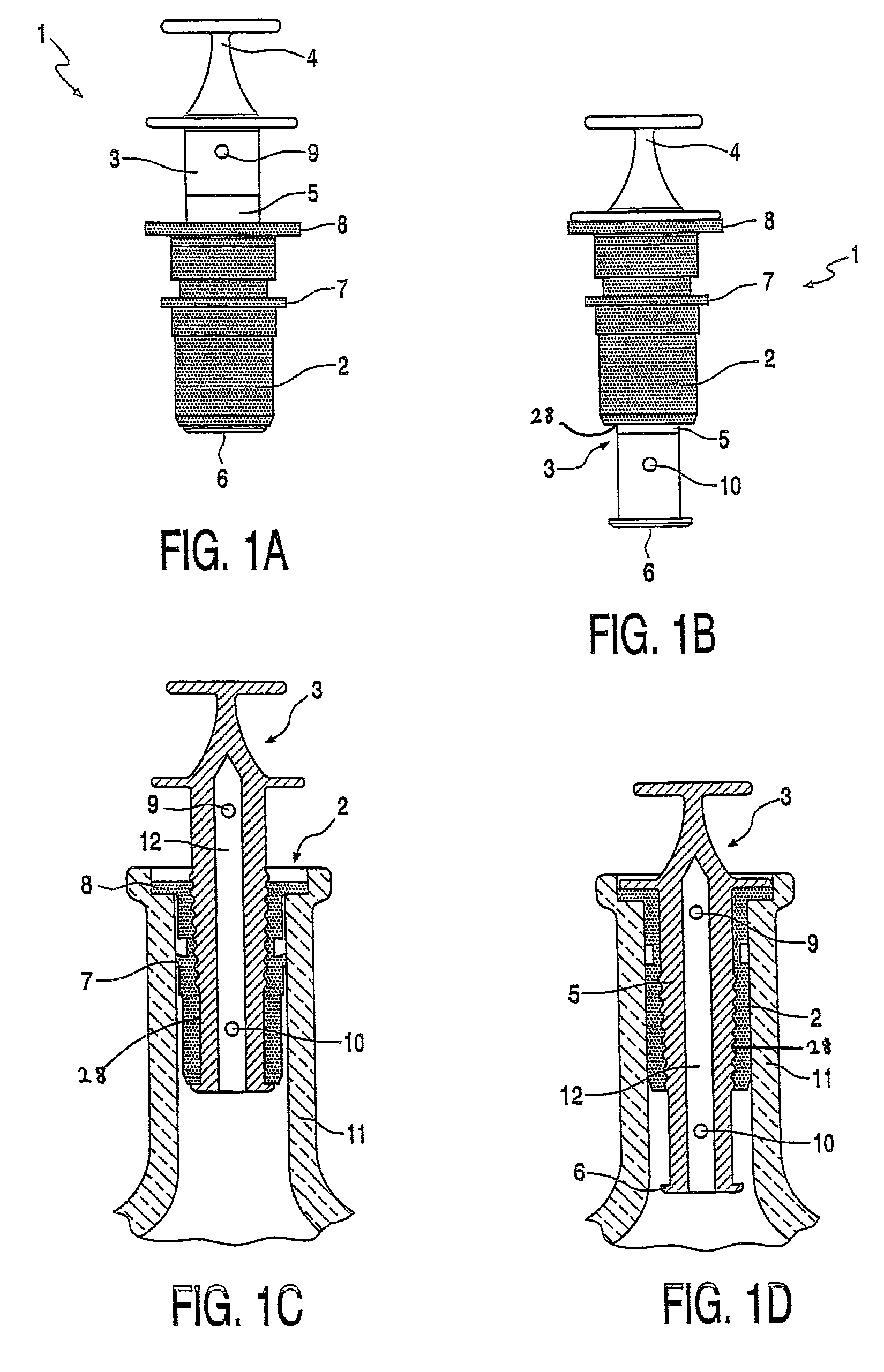

Sealing device

InactiveUS20100295254A1Reduce coefficient of frictionLimited adhesionEngine sealsAlkaline-earth metal silicatesOrganic acidEngineering

The invention provides a sealing device in which adhesion of an elastic member used for the sealing device is controlled, and a coefficient of friction against a member sliding against the sealing device is reduced.A sealing device includes a first member 1, a second member 2 moving relative to the first member, and an elastic member 3 fixed to the first member 1 and sliding against the second member 2, and is characterized in that: the elastic member 3 is made of a rubber composition containing a metal soap, an organic acid amide and an oil-containing particle.

Owner:JTEKT CORP +1

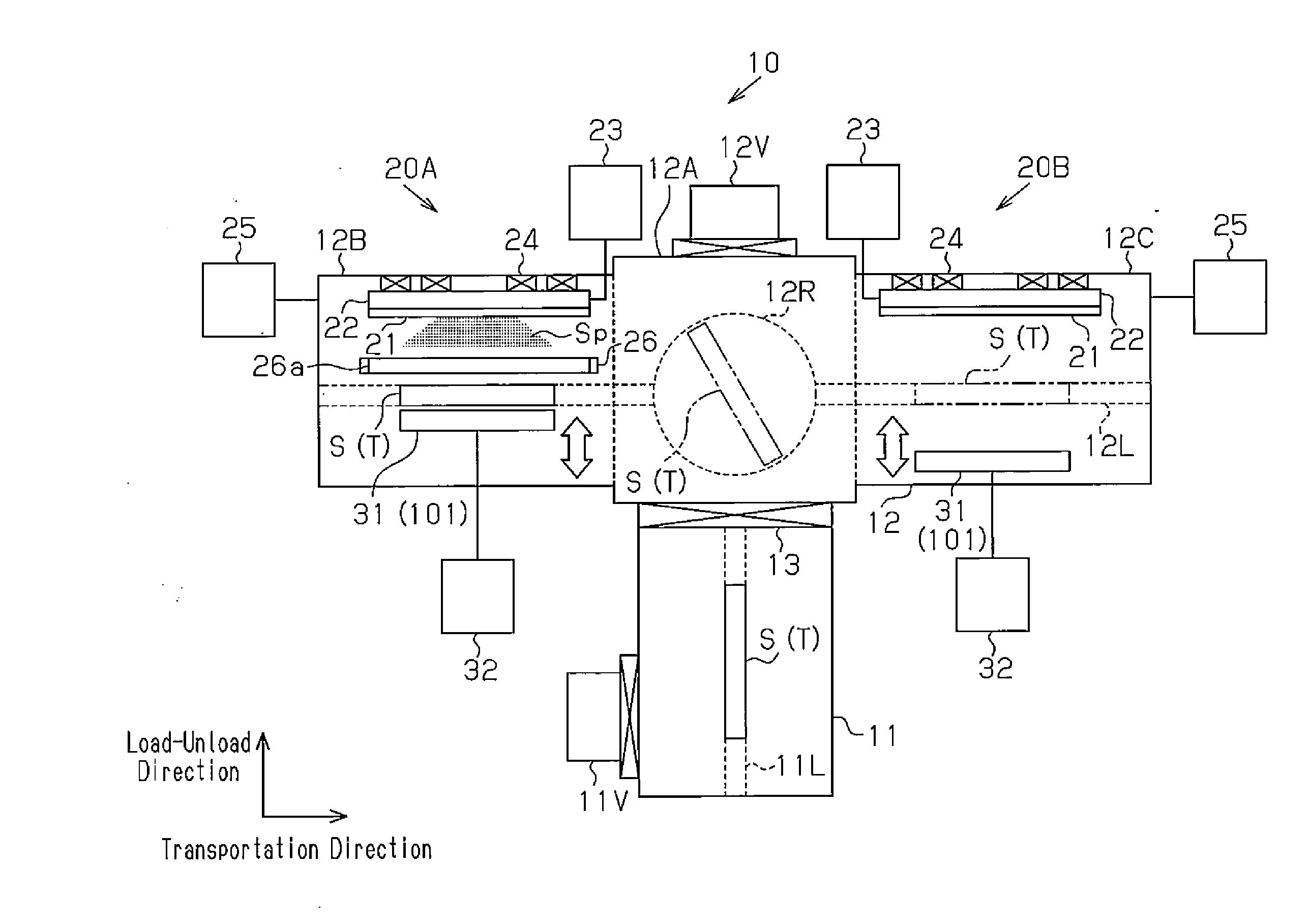

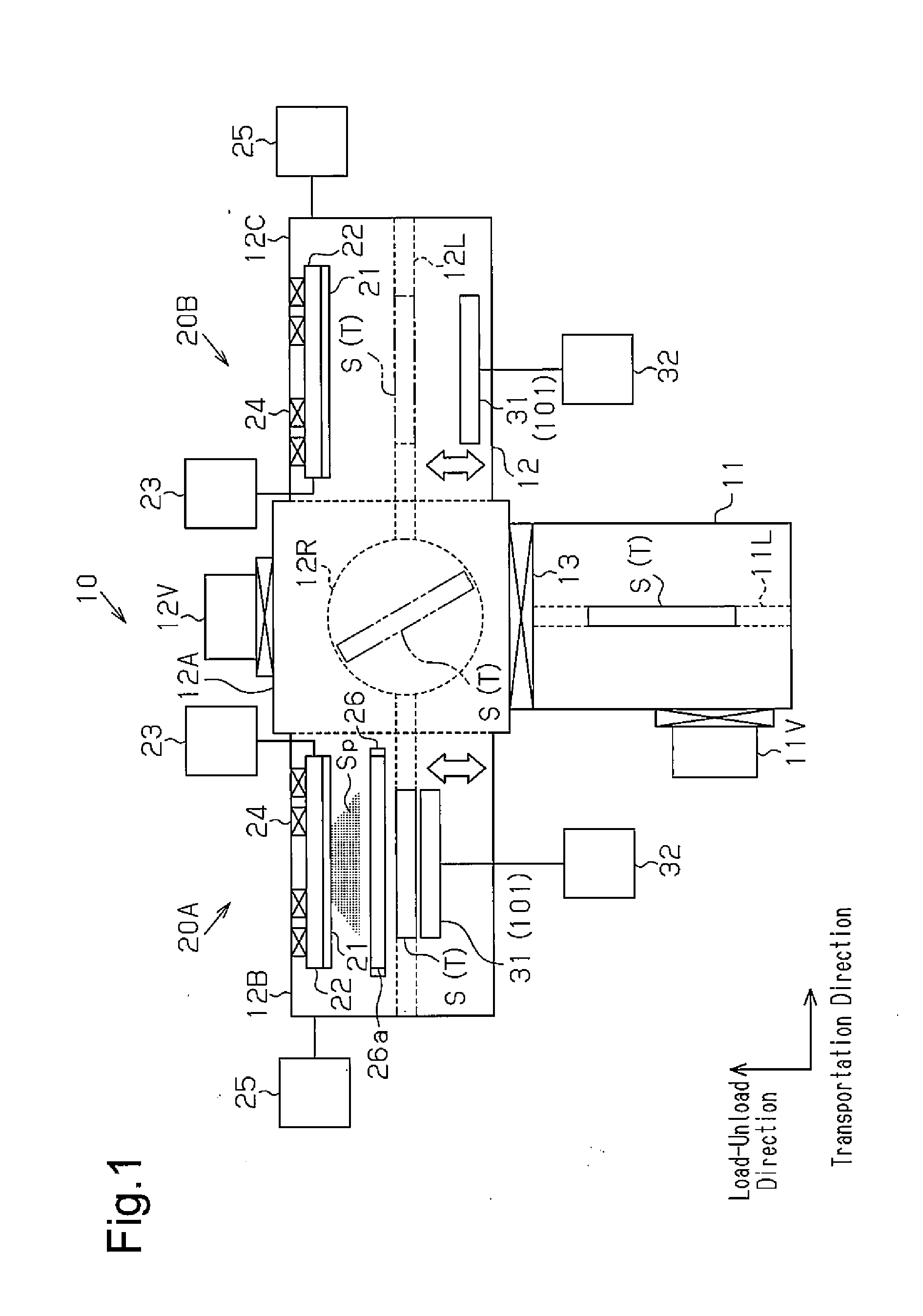

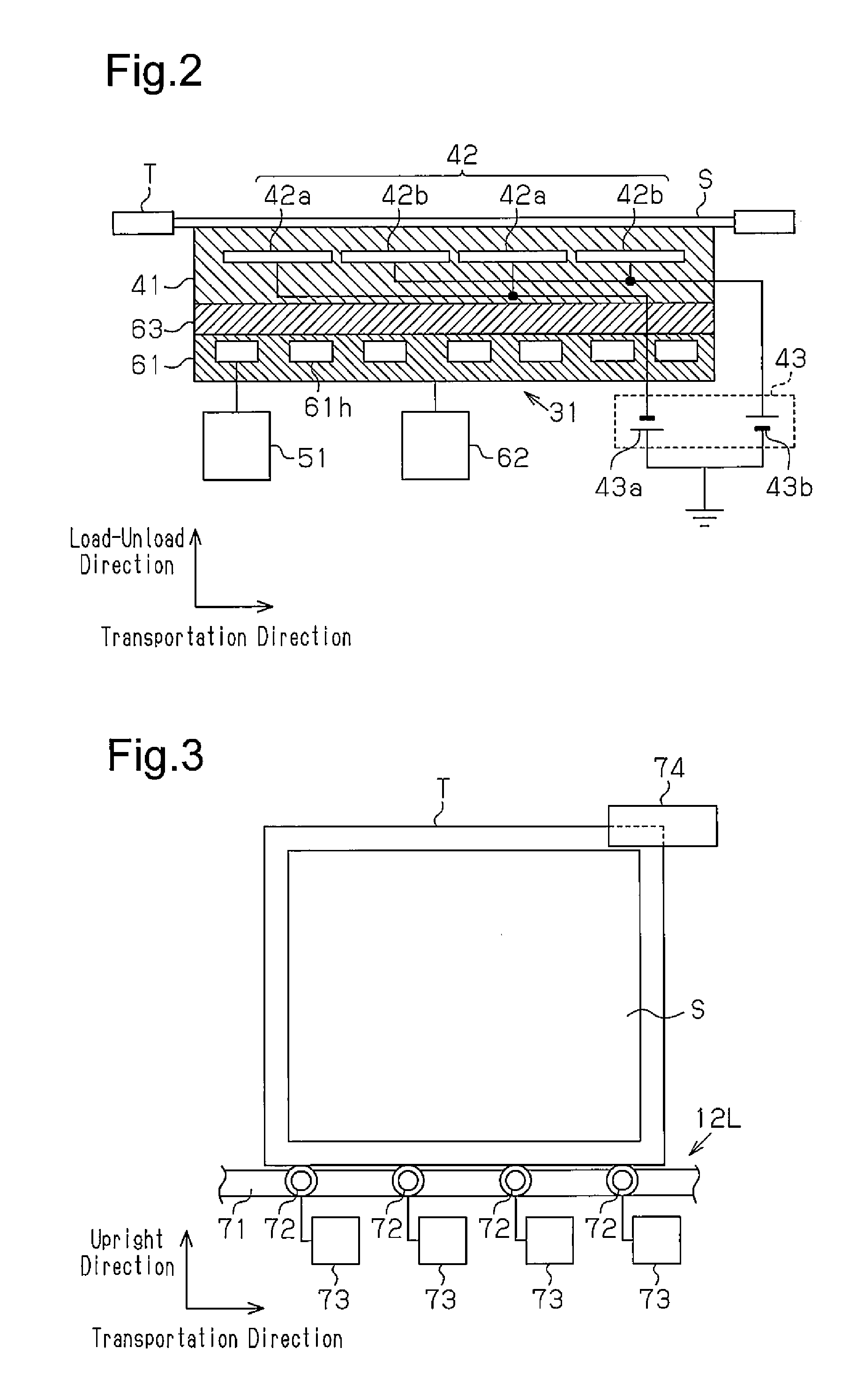

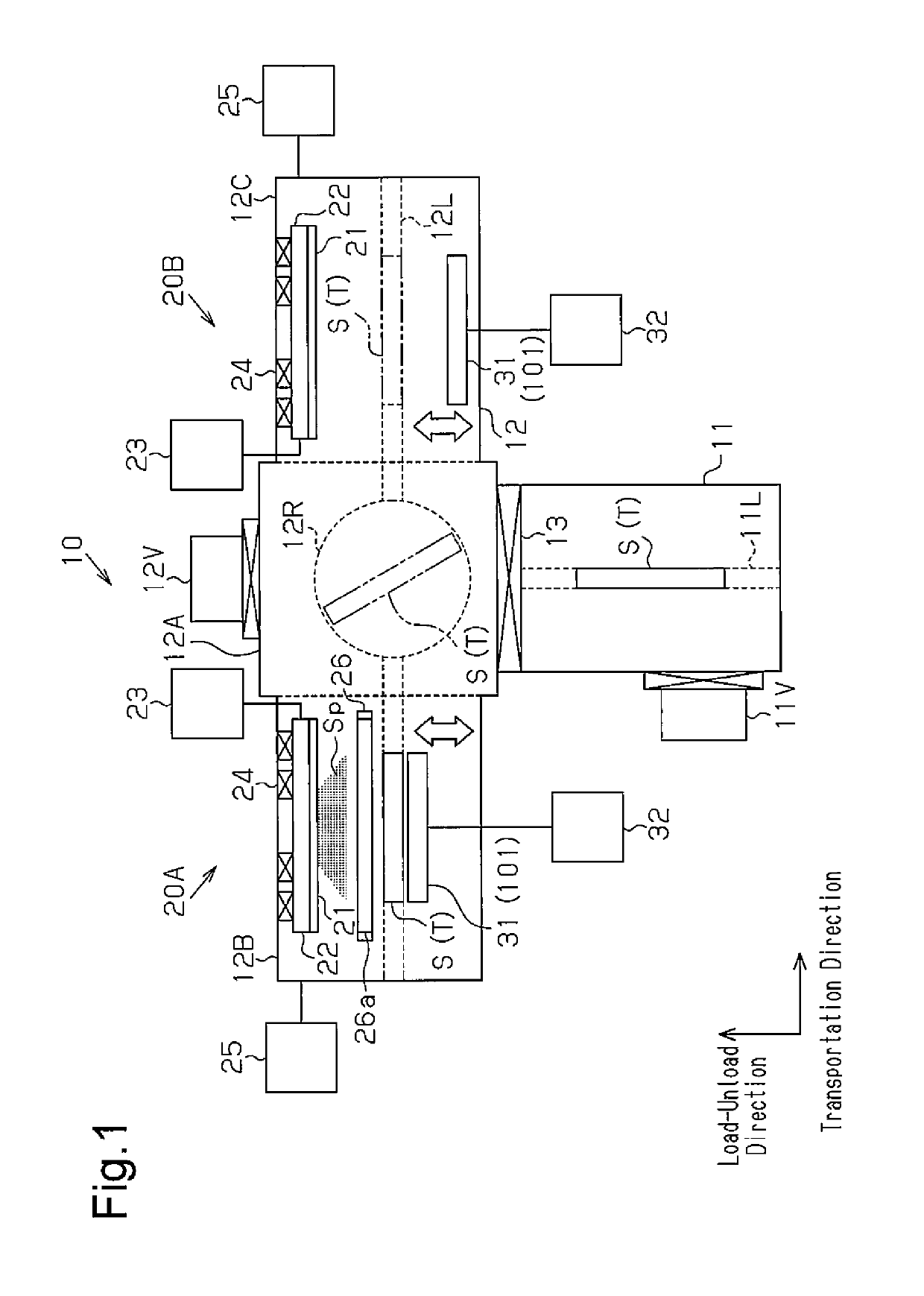

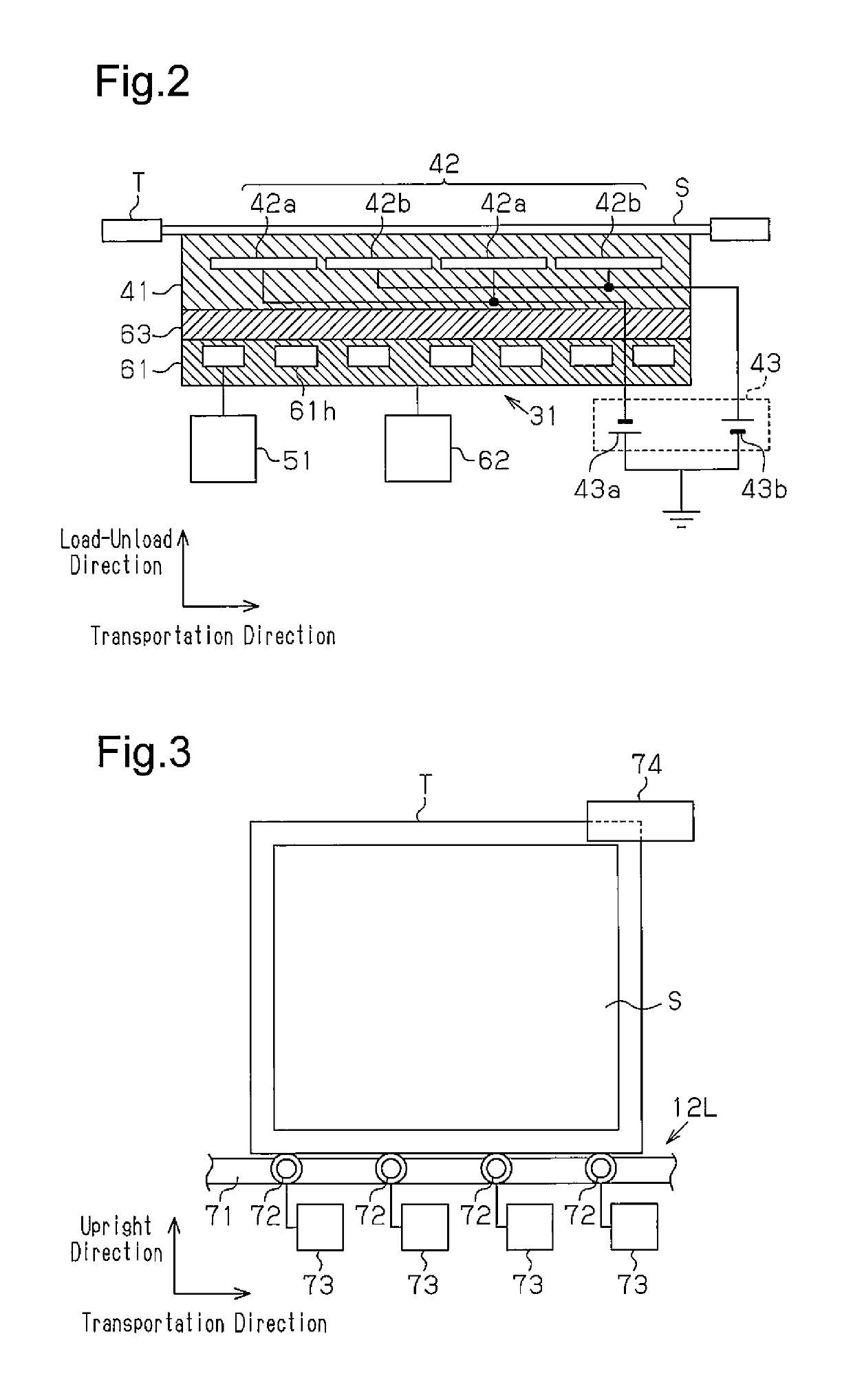

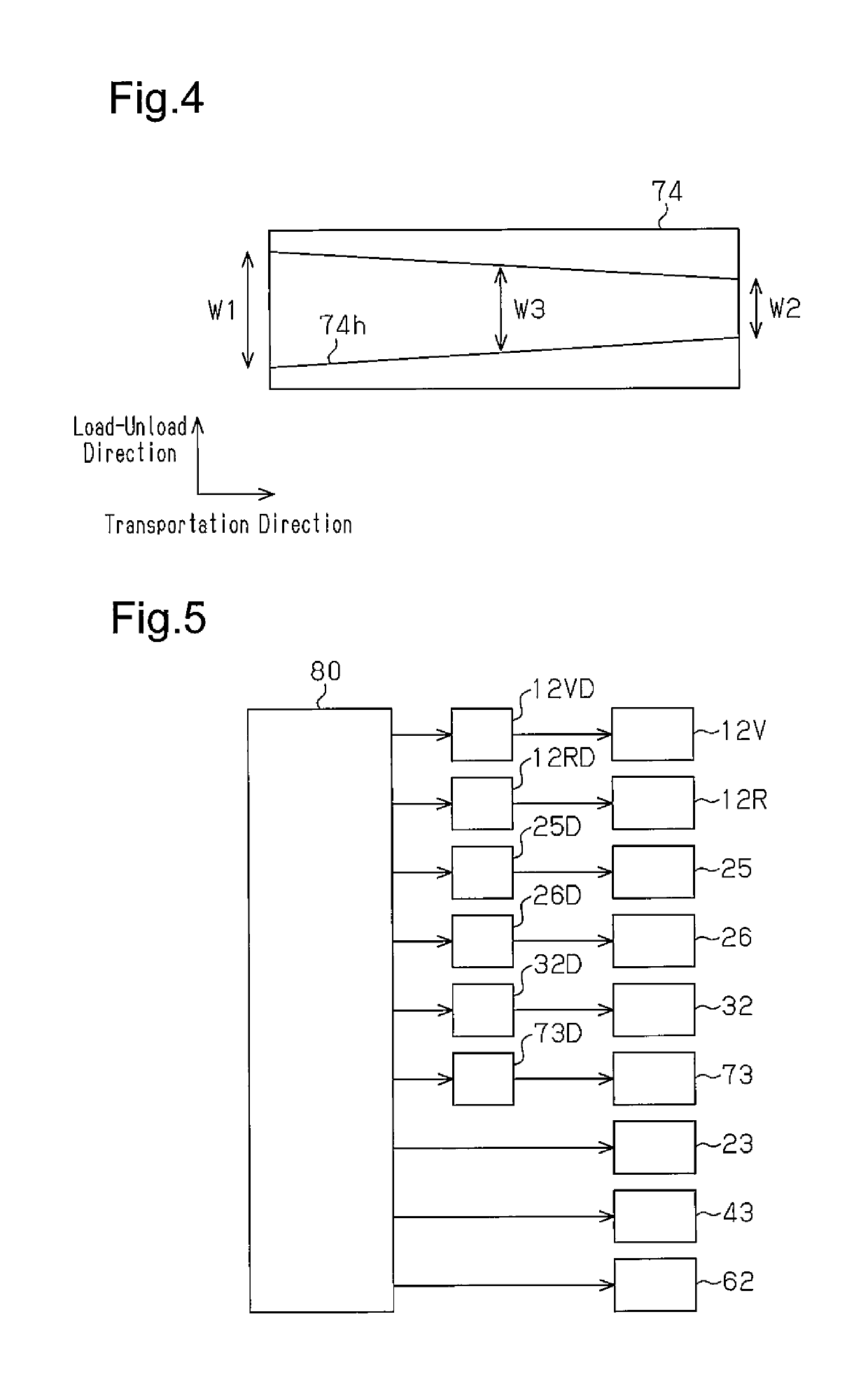

Thin substrate processing device

ActiveUS20160376697A1Improve cooling effectControl damageCellsElectric discharge tubesMaterials science

A thin substrate processing device includes a substrate processing unit configured to process a thin substrate, and a cooling unit configured to cool the thin substrate when the substrate processing unit is processing the thin substrate.

Owner:ULVAC INC

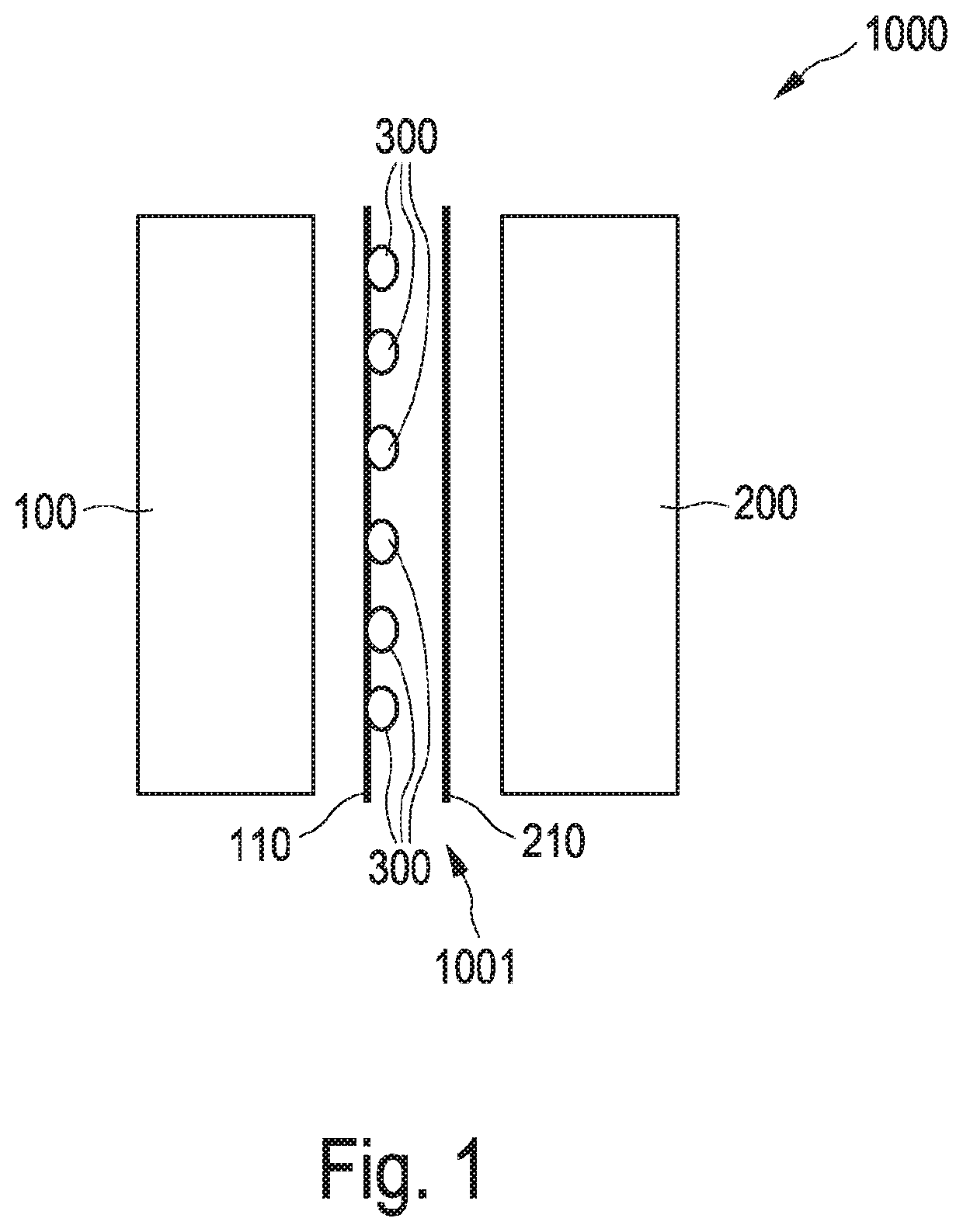

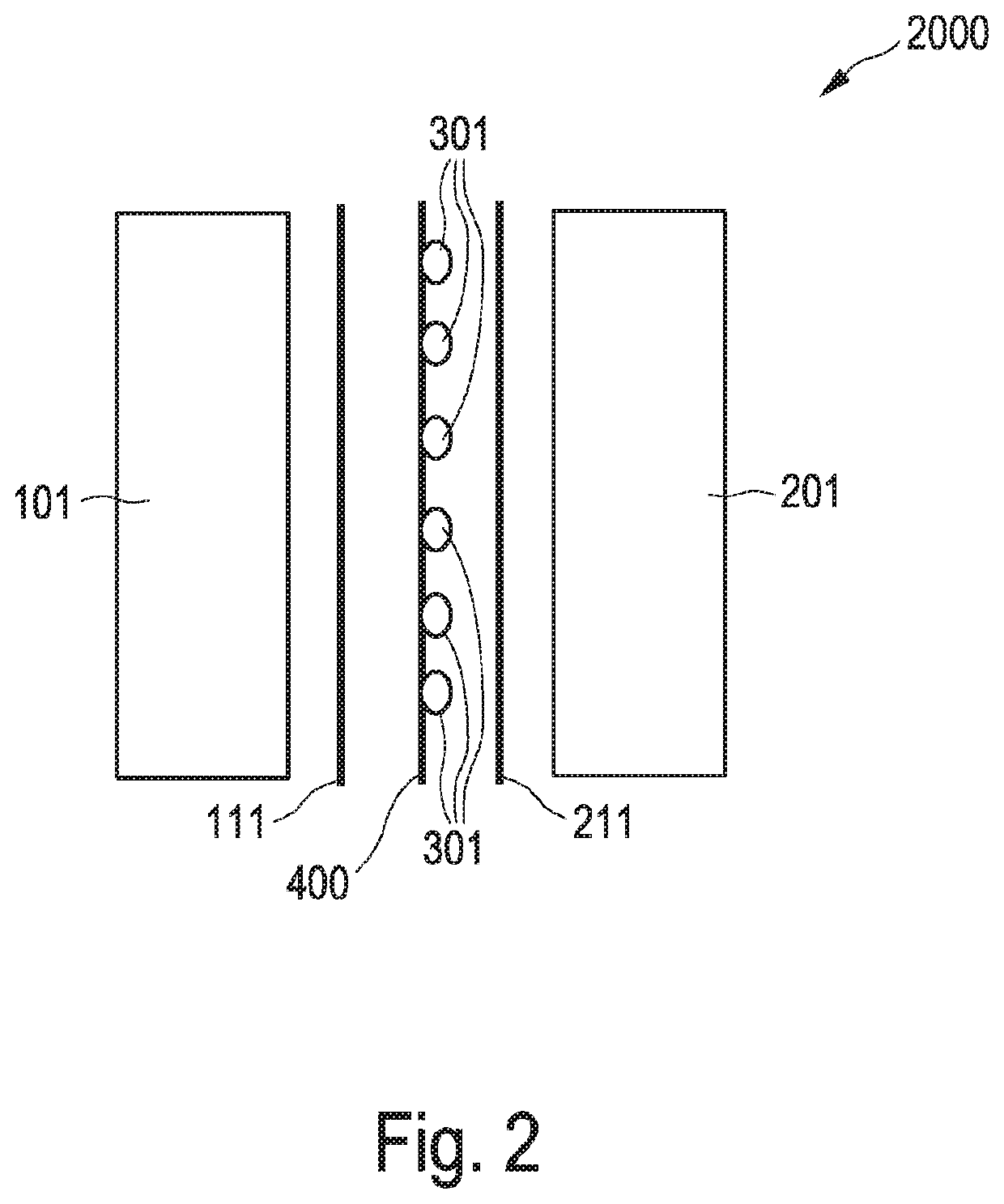

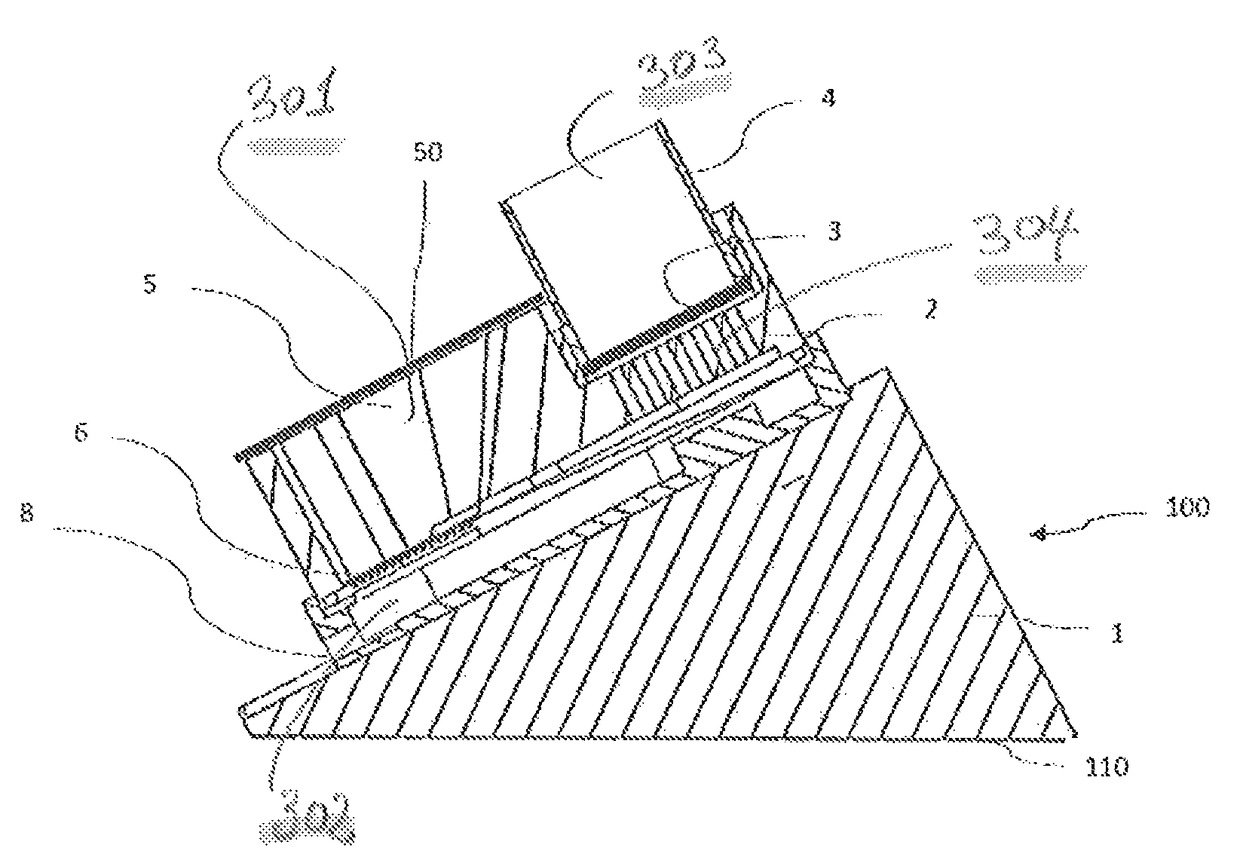

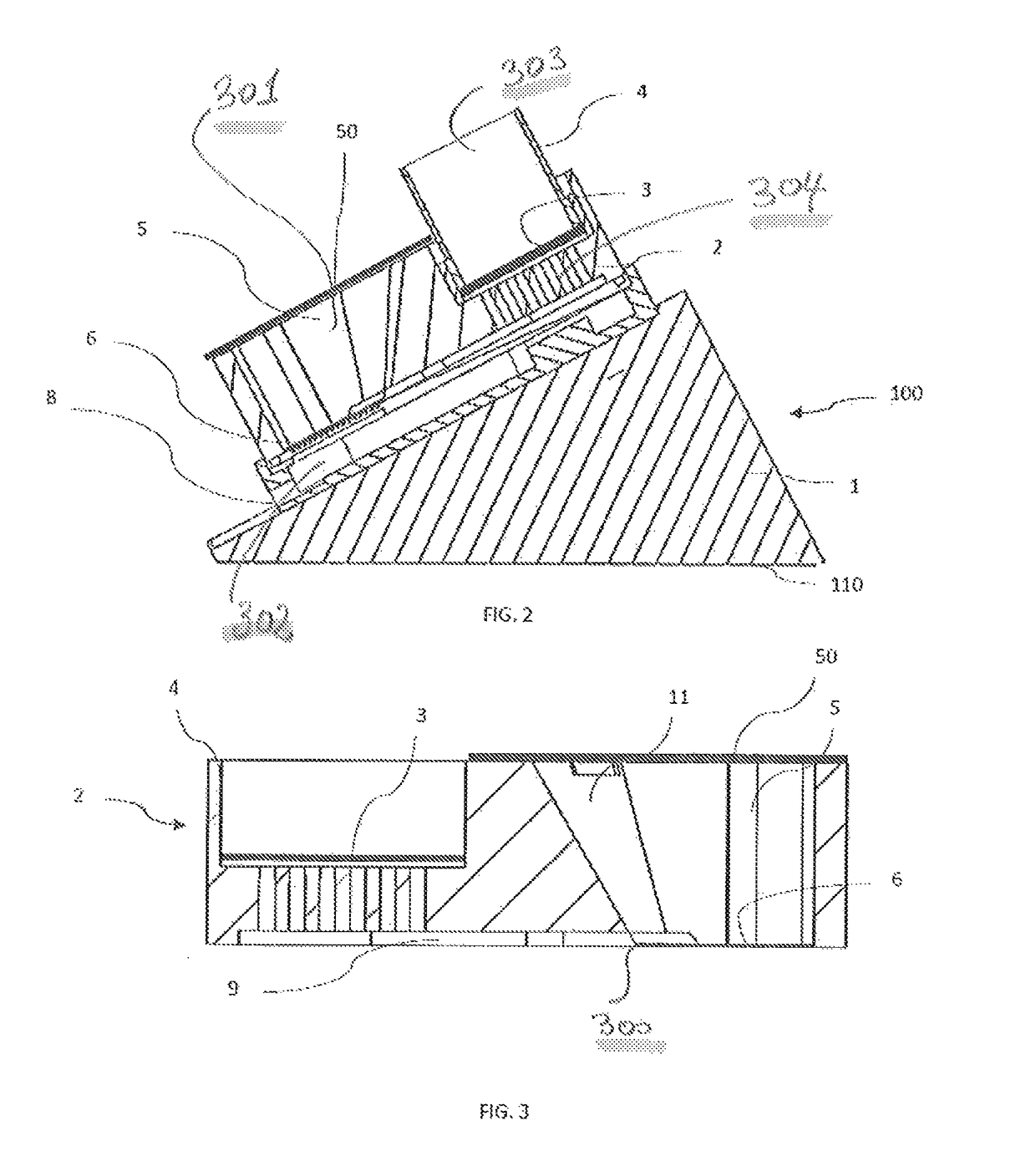

Laminated glass, laminated safety glass, and method for the production thereof

ActiveUS20200262185A1Optimizes freedomLimited adhesionProtective equipmentSynthetic resin layered productsOptical reflectionEngineering

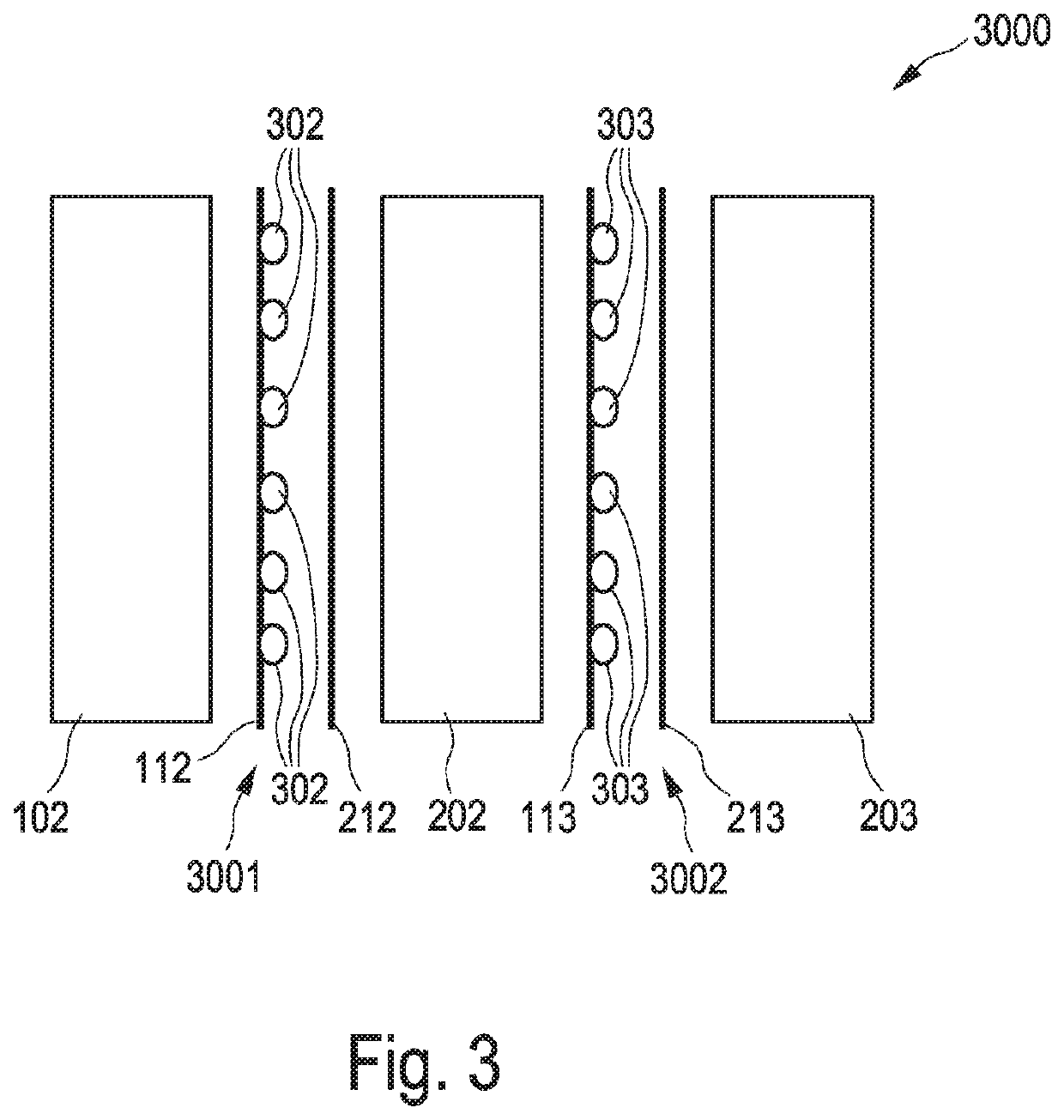

A one-way laminated glass (1000, 2000, 3000, 4000, 5000, 6000A, 6000B, 6000C, 6000D) for installation in facades (6000, 7000) or for interior design, comprising a first and a second glass pane (100, 101, 102, 200, 201, 202), and also comprising, arranged between the first and second glass pane and bonded to these, a lamination foil composite (1001, 3001, 3002) with a first lamination foil (110, 111, 112, 113) and with a second lamination foil (210, 211, 212, 213), wherea large number of paillettes (300, 301, 302, 303, 304, 305, 500, 600A, 600B, 600C, 600D, 700) with a first light-absorbing surface (501) is arranged between the first lamination foil and second lamination foil, and a visual effect (E) is concomitantly achieved, wherethe light-absorbing surface (501) of the paillettes faces toward the first lamination foil, and the paillettes are arranged at distances from one another such that when the laminated glass is viewed from the side corresponding to the light-absorbing surface (501) of the paillettes it appears transparent,where a second surface (502) of the paillettes, which faces toward the second lamination foil, is optically reflective, and when the laminated glass is viewed from the side corresponding to the optically reflective surface (502) of the paillettes it appears less transparent.

Owner:SEEN AG

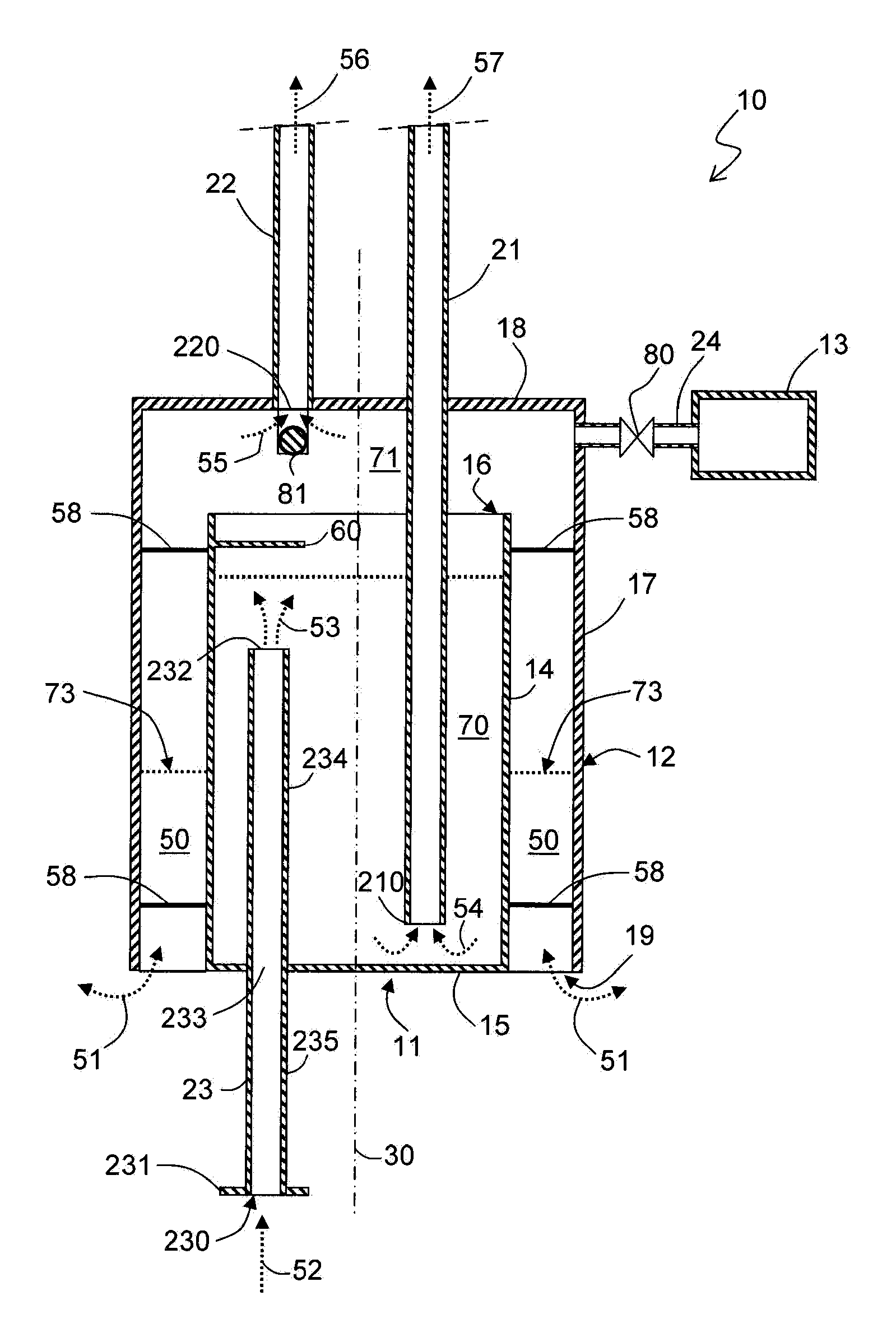

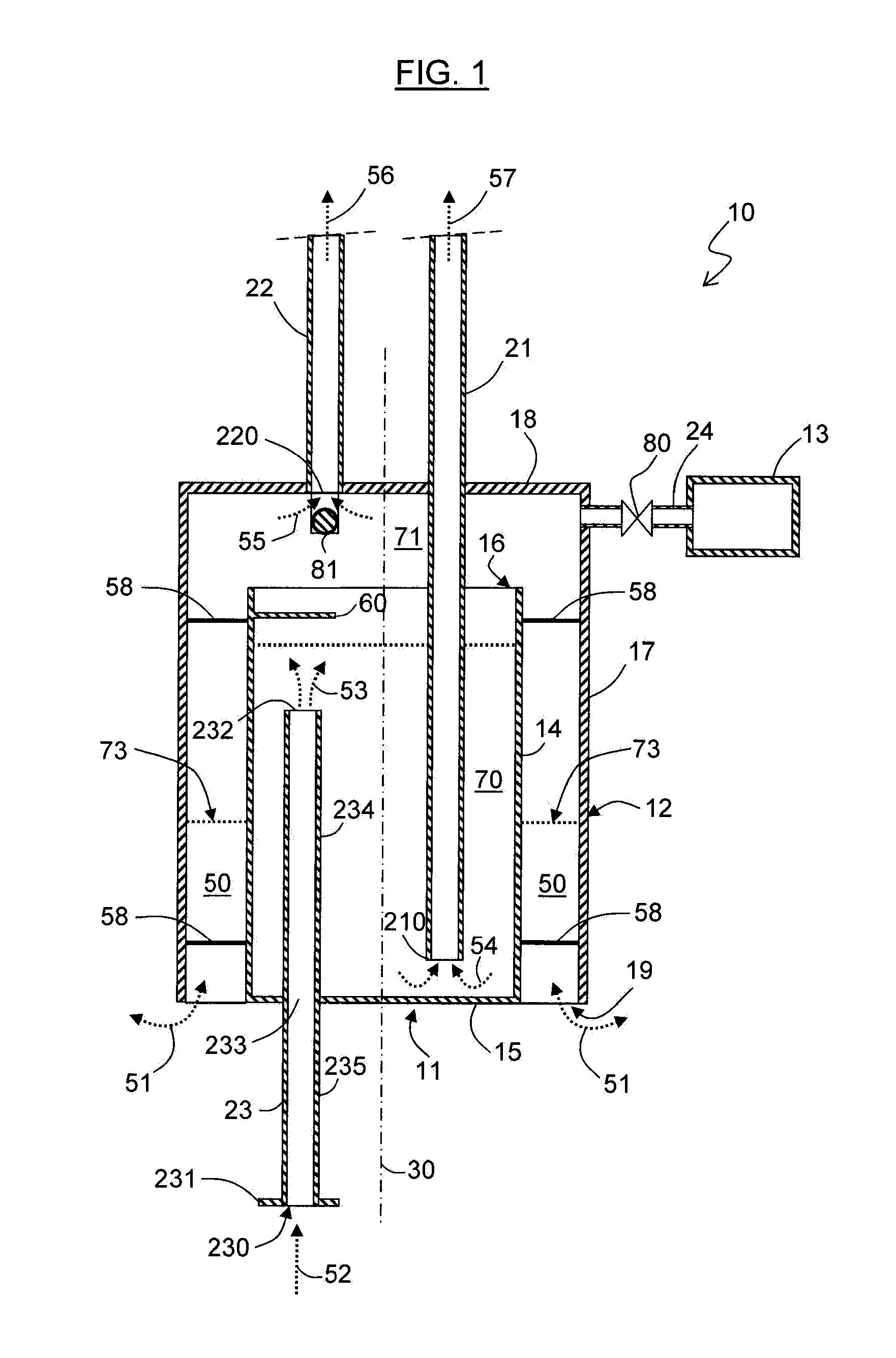

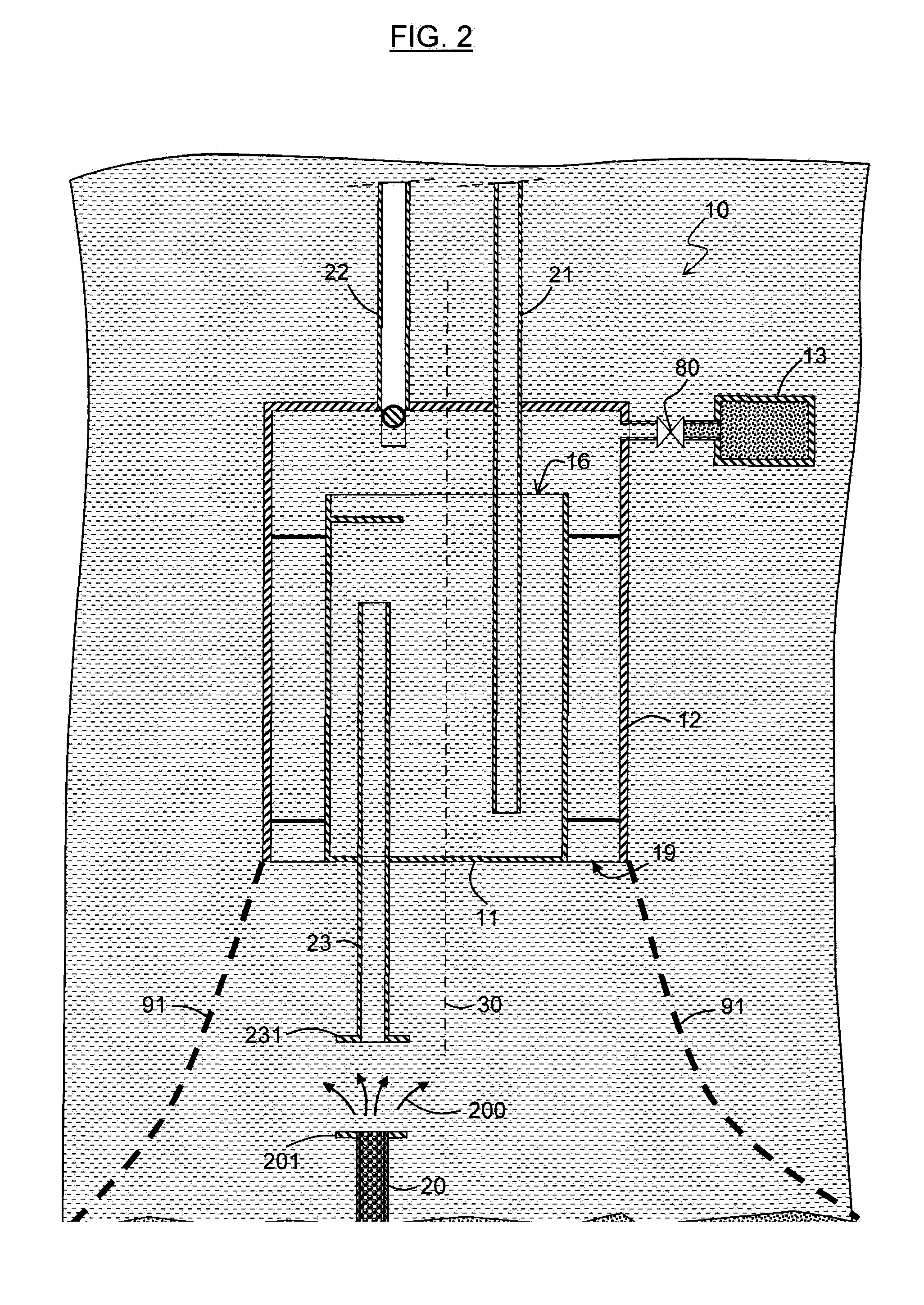

Method and device for collecting a light underwater fluid such as fresh water or hydrocarbons

InactiveUS20150247386A1Easy to implementLow mechanical strengthWater cleaningSeawater treatmentHydrocotyle bowlesioidesFresh water

The invention relates in particular to a device for undersea collection of a light fluid the device comprising:a first tank that is provided with a first opening and a second opening;a second tank covering the first opening, surrounding a portion of the first tank, and provided with a third opening putting the second tank, into communication with the medium surrounding the device;connection means connecting together the first and second tanks:a first pipe opening out into the first tank in order to provide density transport of a phase of the fluid to the surface;a structure for guiding and introducing the fluid into the first tank, which structure extends inside the first tank and separates a first portion of the first tank in which the second opening is provided from a second portion of the first tank in which the open end of the first pipe extends; anda structure for collecting the fluid, which structure extends outside the first tank, is secured to the first tank, and surrounds the second opening.

Owner:NYMPHEA ENVIRONNEMENT

Flow measuring device

ActiveUS20080236274A1Accurate detectionLimited adhesionVolume/mass flow by thermal effectsVolume flow proportion measurementThermal radiationResistor

An airflow measuring device includes a sensing portion provided in a bypass passage, which perpendicularly deflects part of air from a main passage to therethrough bypass the part of air. The sensing portion includes a heating resistor energized and dissipate heat to airflow. The sensing portion is configured to measure airflow in the bypass passage based on the heat radiation. The sensing portion further includes a pair of support members erected in the bypass passage to support the heating resistor. The heating resistor of the sensing portion is inclined at a first inclination angle with respect to a direction, which is perpendicular to a flow direction of air in the bypass passage. The heating resistor is inclined toward downstream at an outer streamline of the airflow in the bypass passage.

Owner:DENSO CORP

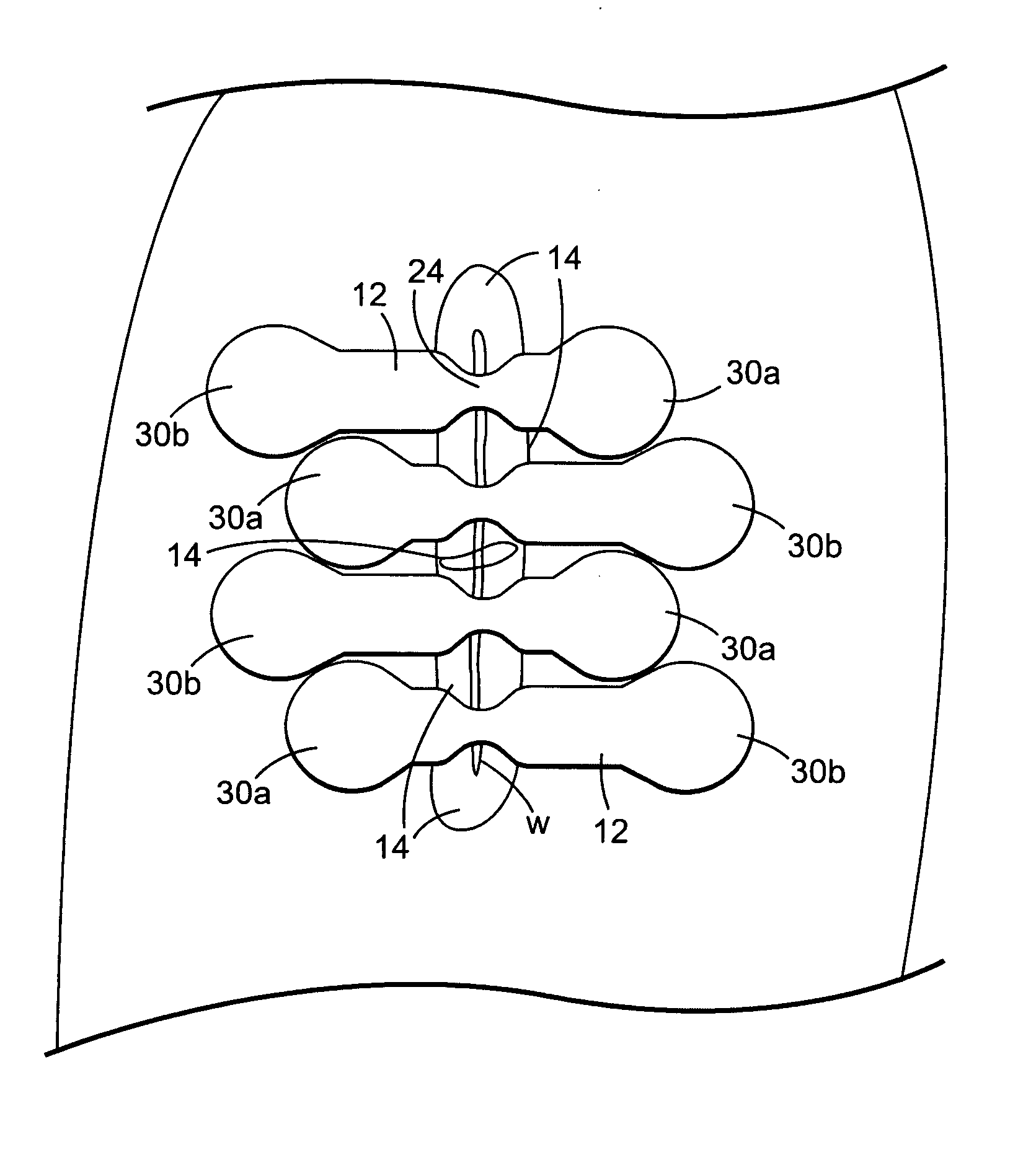

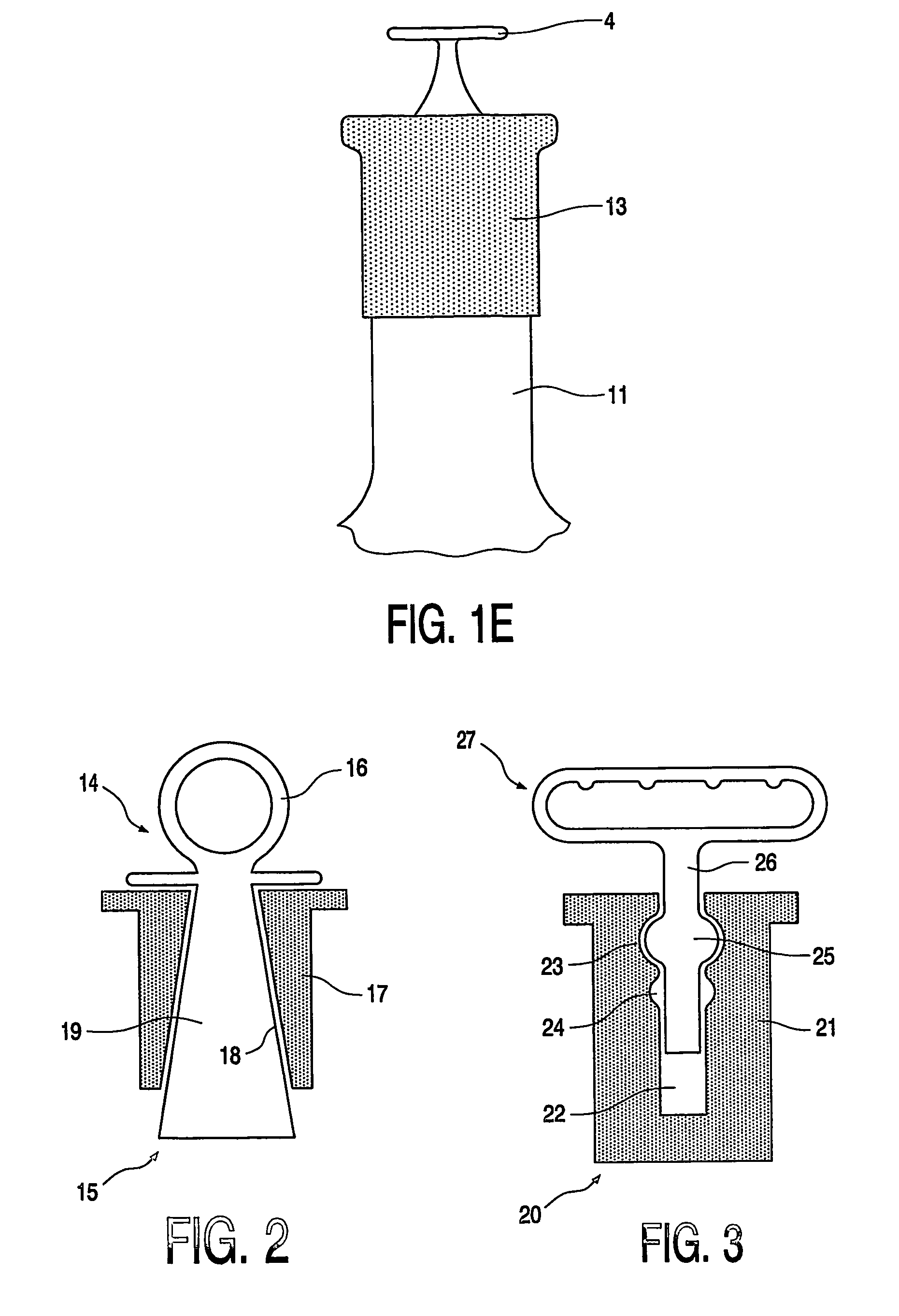

Closure and methods for placing and removing such a closure

InactiveUS7832581B2Simplify placing and removalImprove fitCapsPulse automatic controlEngineeringBung

Owner:MARITA DE BEER HLDG

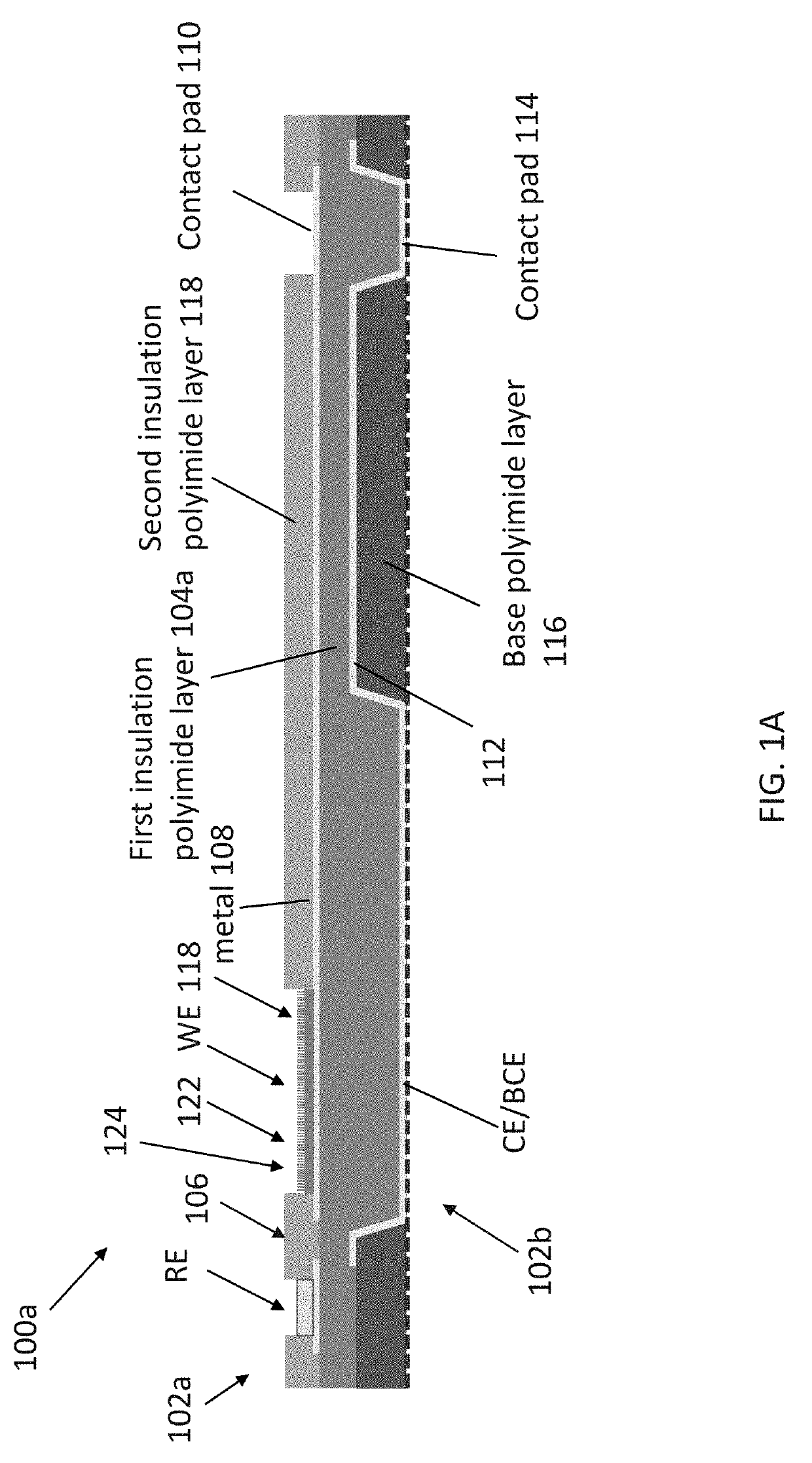

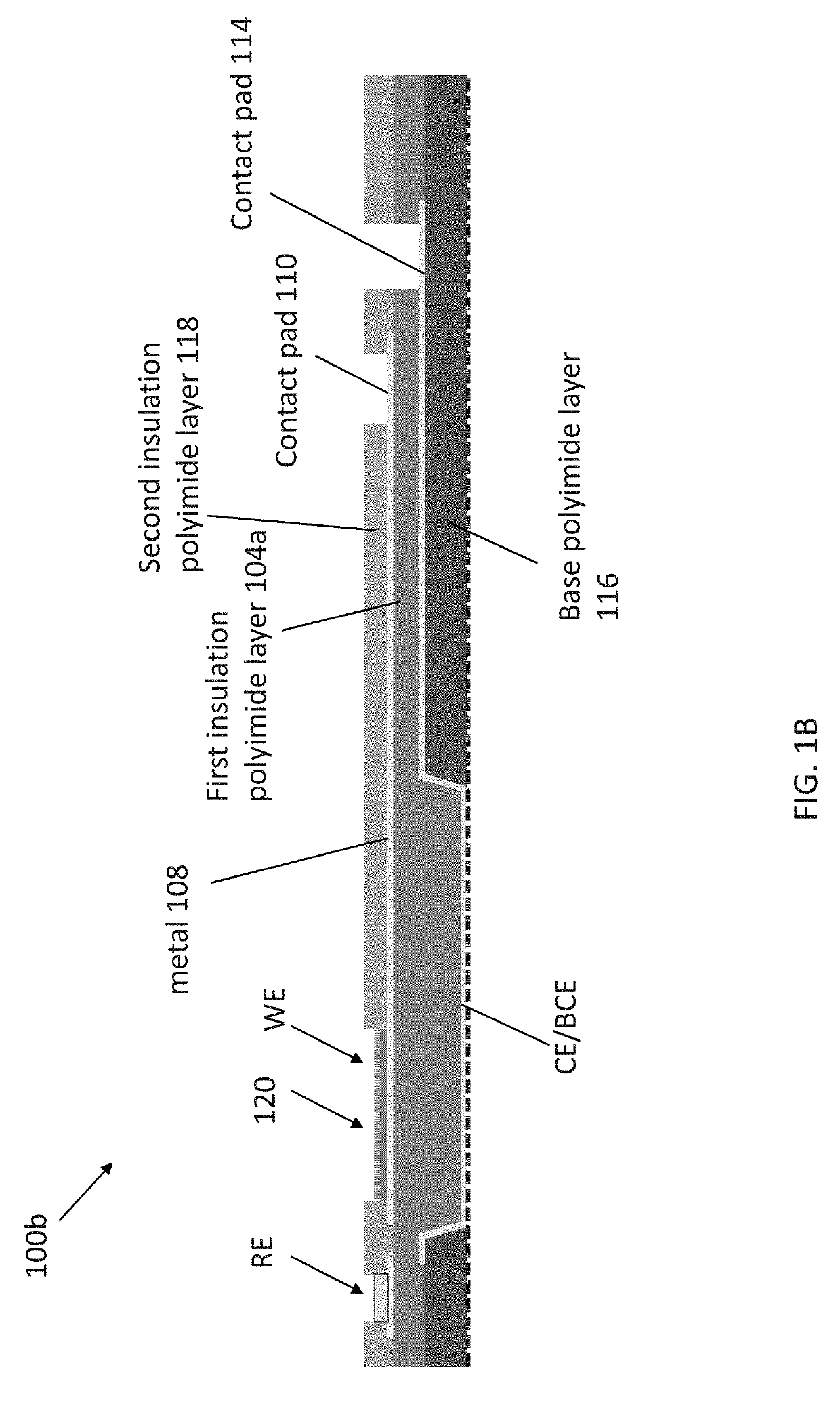

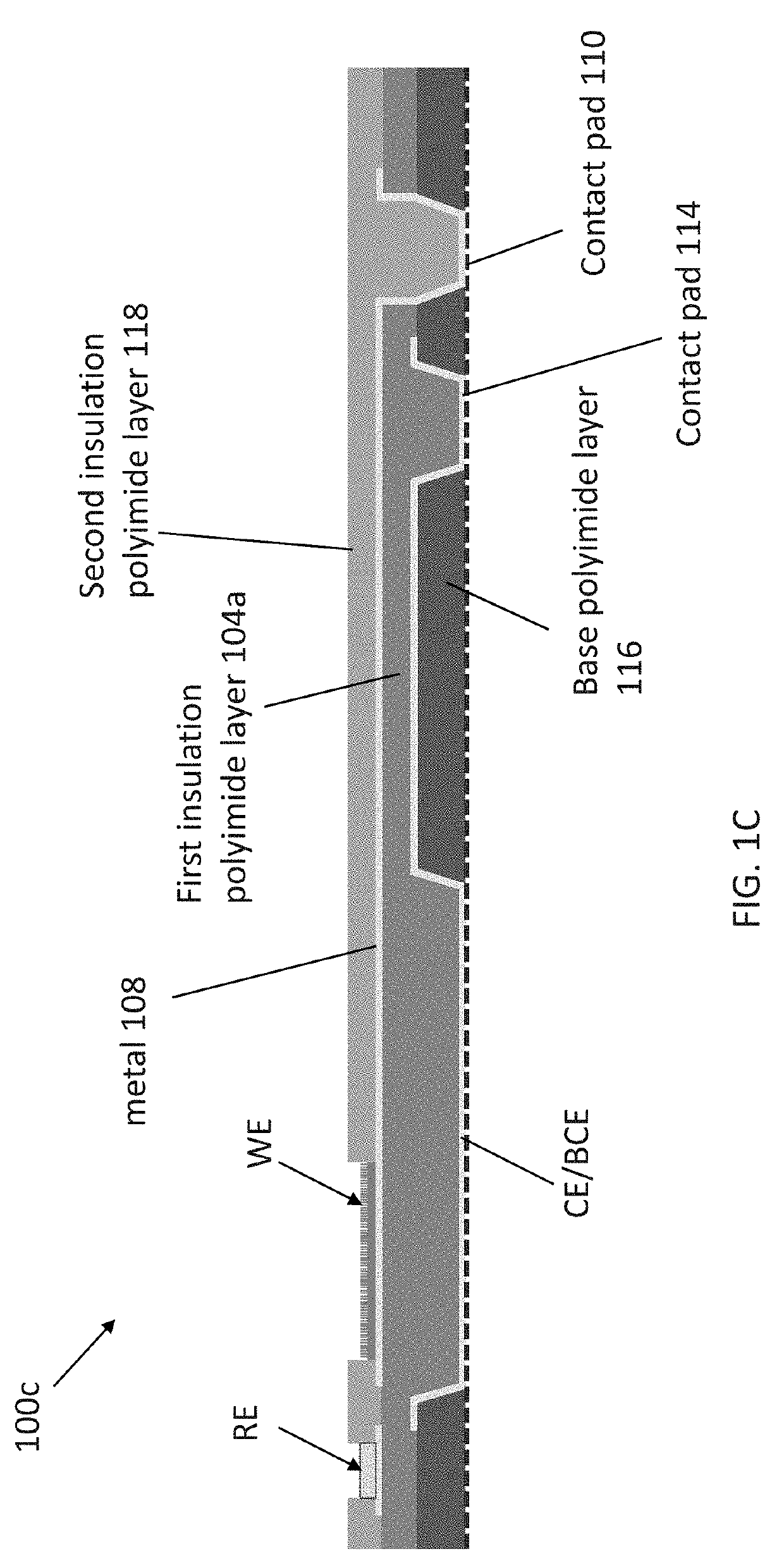

Methods for controlling physical vapor deposition metal film adhesion to substrates and surfaces

ActiveUS20190242010A1Reduce overall surface area contactLimited adhesionVacuum evaporation coatingMaterial analysis by electric/magnetic meansGas phaseMetal

A method of depositing of a film on a substrate with controlled adhesion. The method comprises depositing the film including metal, wherein the metal is deposited on the substrate using physical vapor deposition at a pressure that achieves a pre-determined adhesion of the film to the substrate. The pre-determined adhesion allows processing of the film into a device while the film is adhered to the substrate but also allows removal of the device from the substrate.

Owner:MEDTRONIC MIMIMED INC

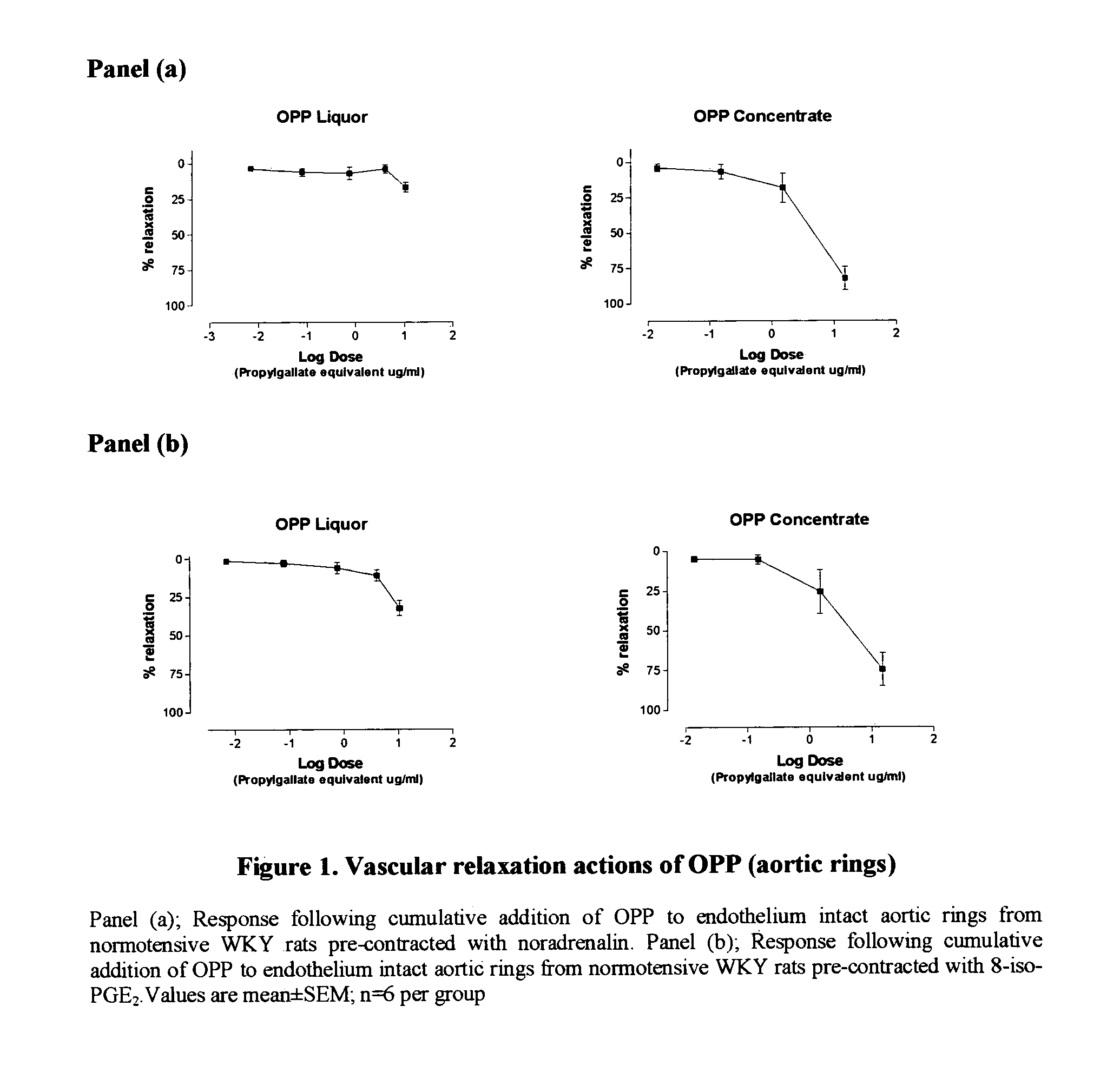

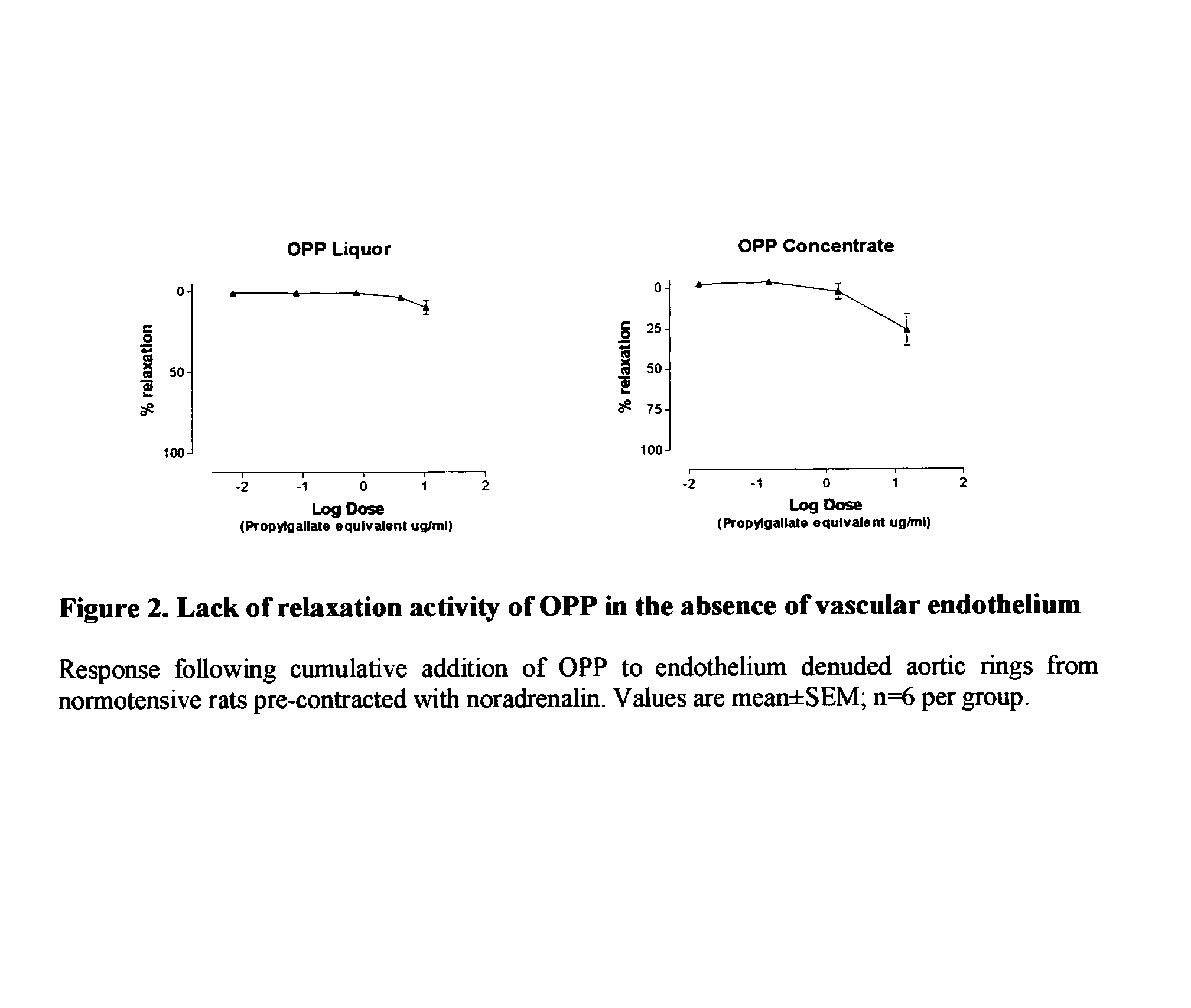

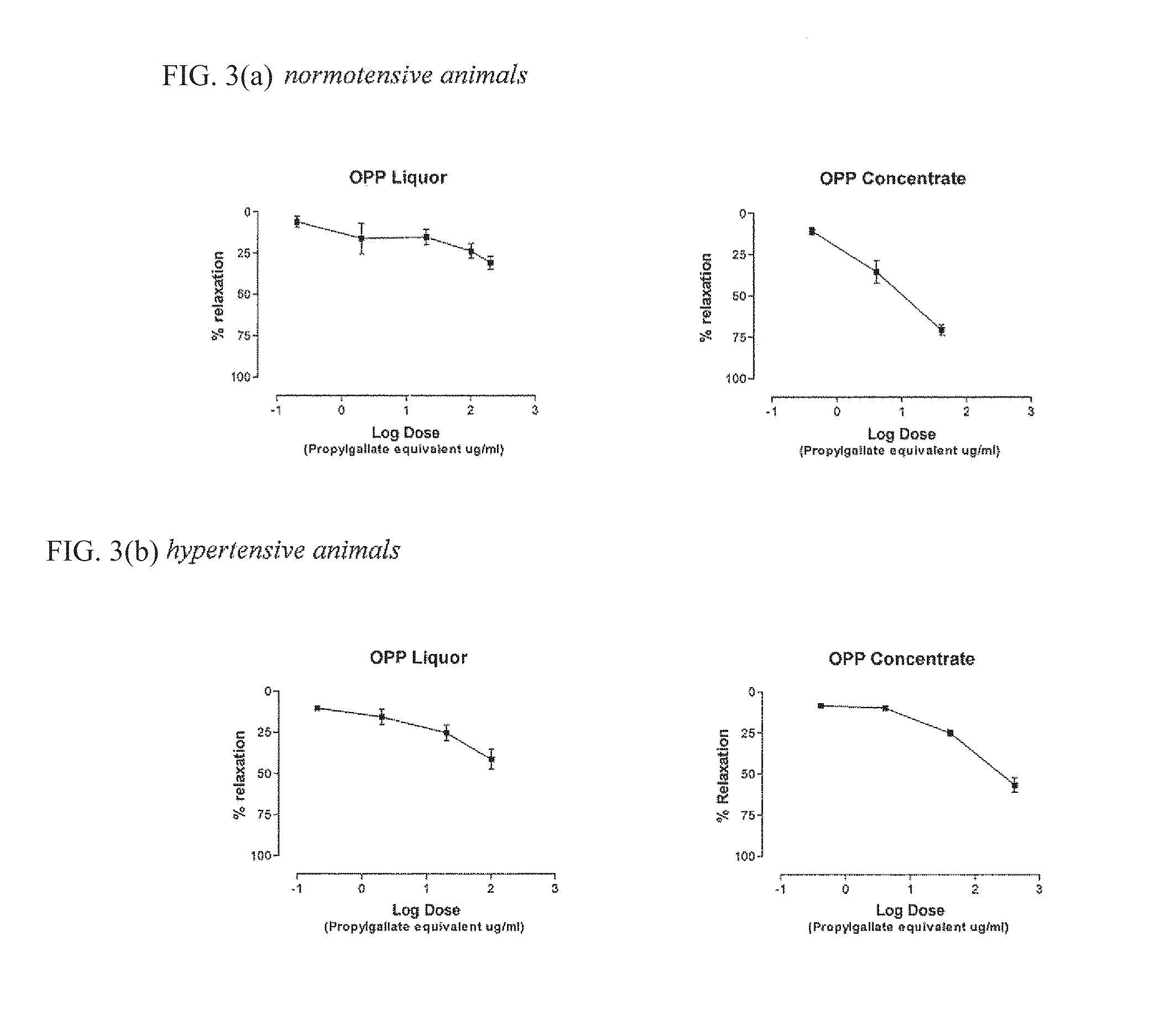

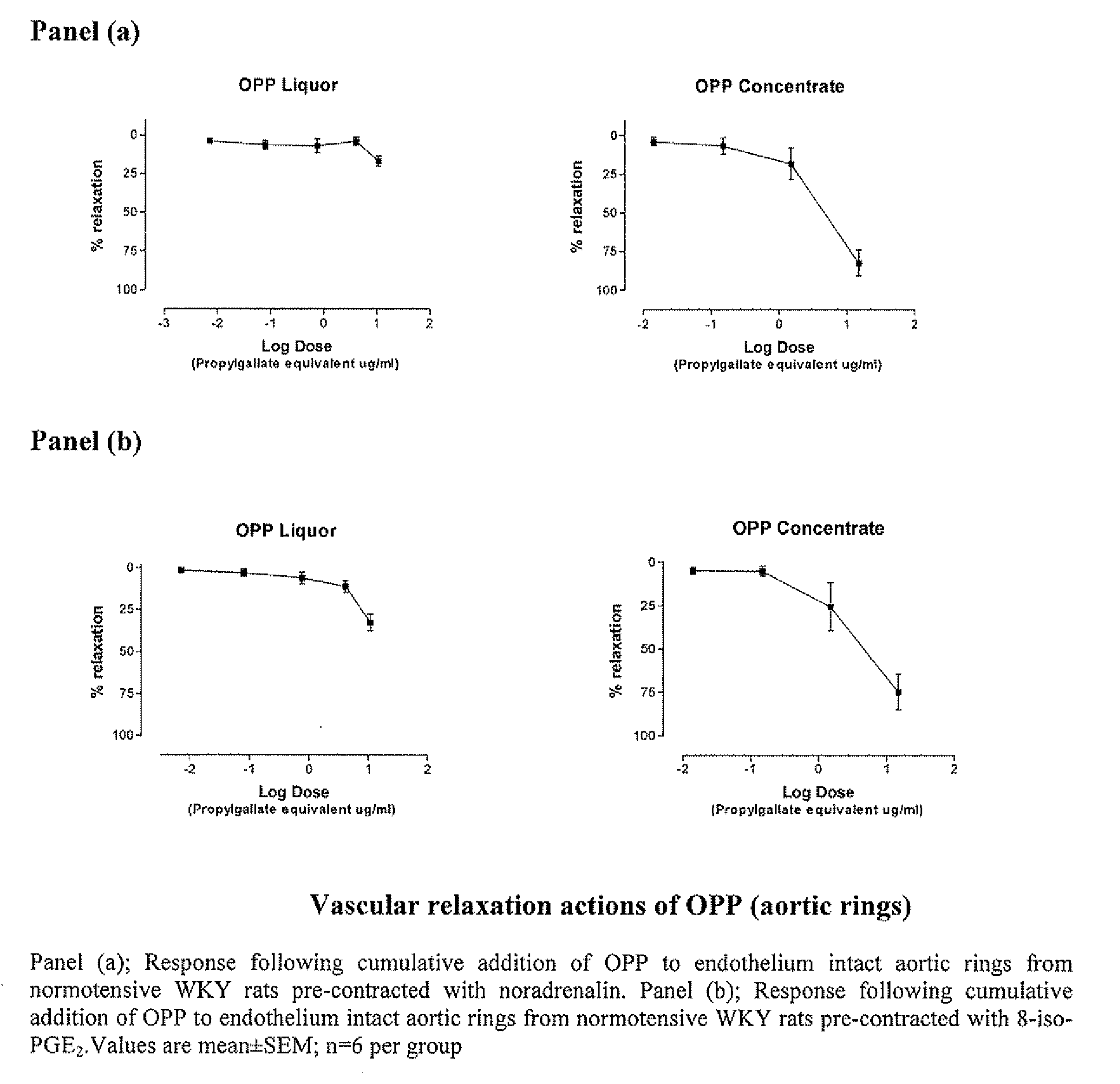

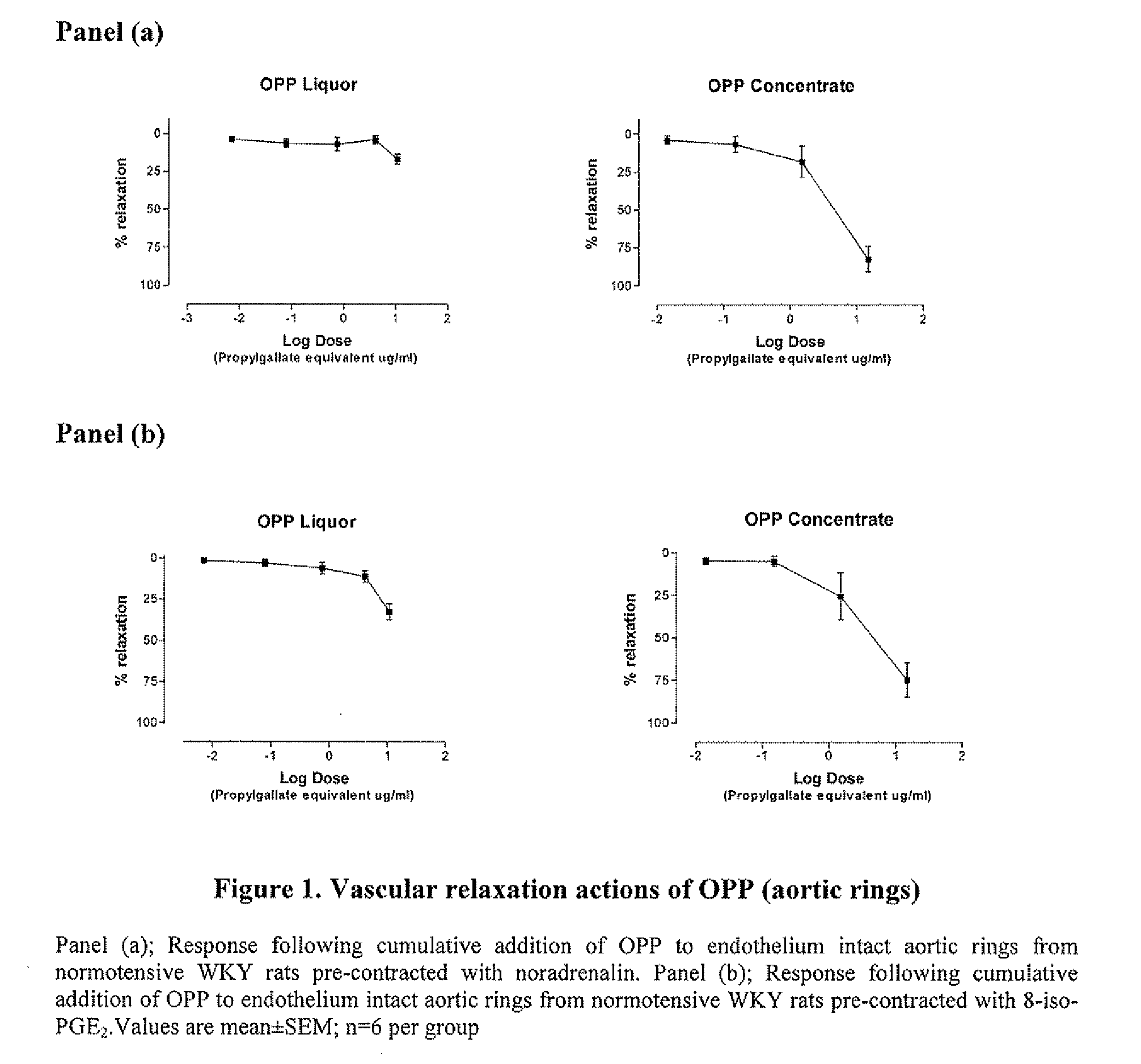

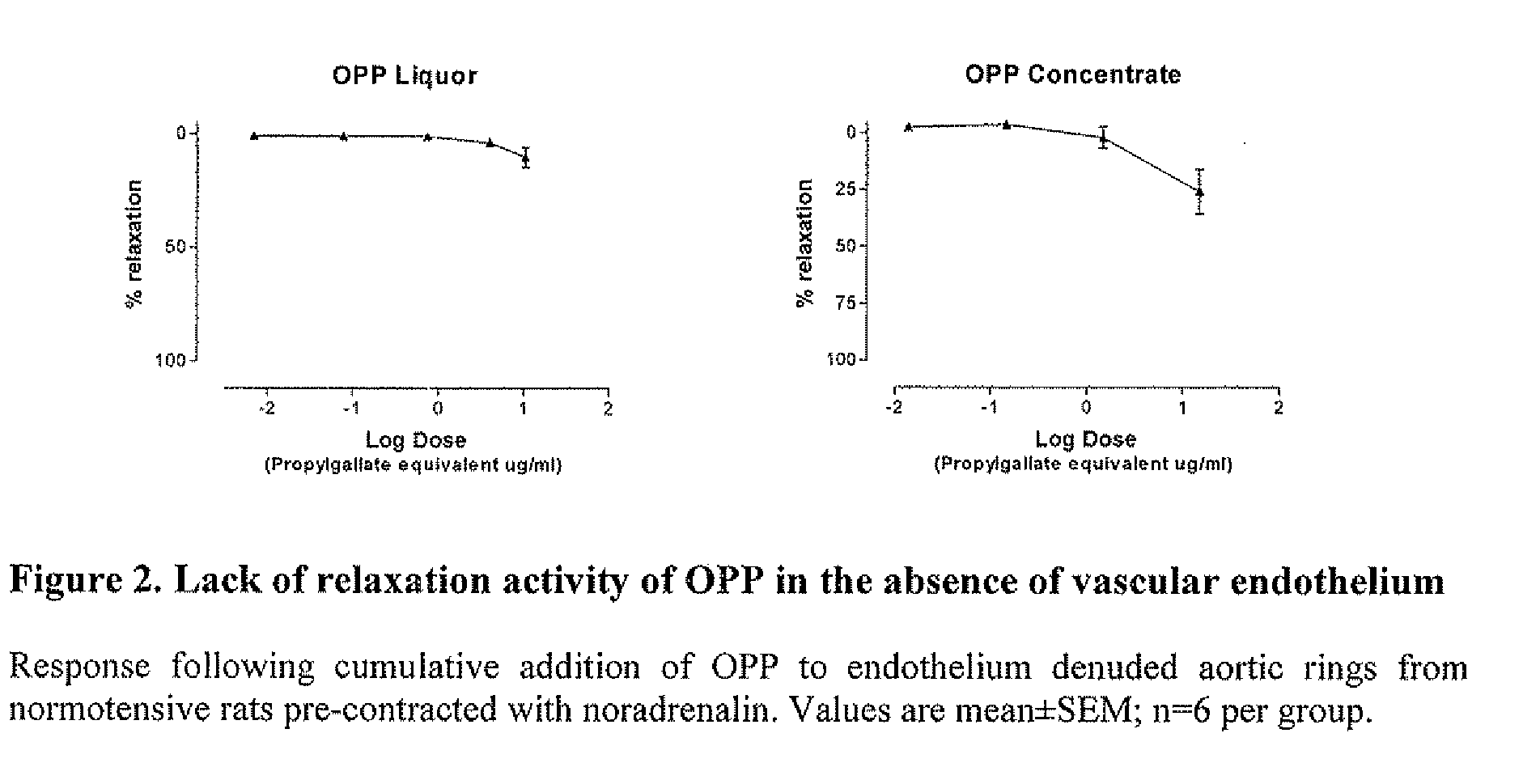

Composition and method for improving vascular health

ActiveUS8771764B2Limited adhesionImprove integrityOrganic active ingredientsBiocideVascular diseaseTraditional medicine

The present invention relates to a composition for the use in improving vascular health, including treating and preventing vascular diseases and diseases related thereto, using a botanical extract of oil palm vegetation liquor from the palm oil milling process.

Owner:MALASIAN PALM OIL BOARD

Composition and Method for Improving Vascular Health

ActiveUS20120141612A1Limited adhesionImprove integrityBiocideAnimal repellantsVascular diseaseVegetation

The present invention relates to a composition for the use in improving vascular health, including treating and preventing vascular diseases and diseases related thereto, using a botanical extract of oil palm vegetation liquor from the palm oil milling process.

Owner:MALASIAN PALM OIL BOARD

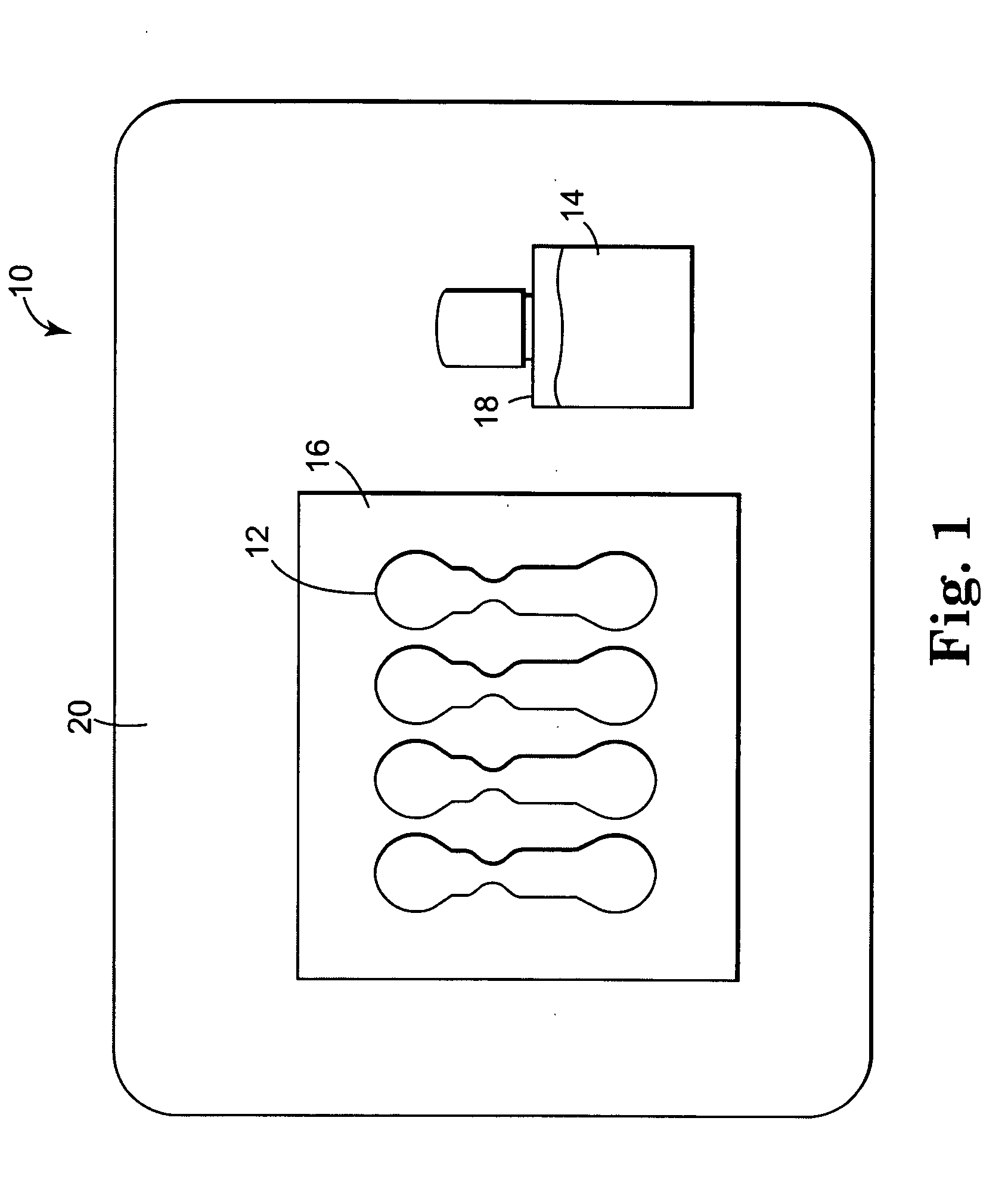

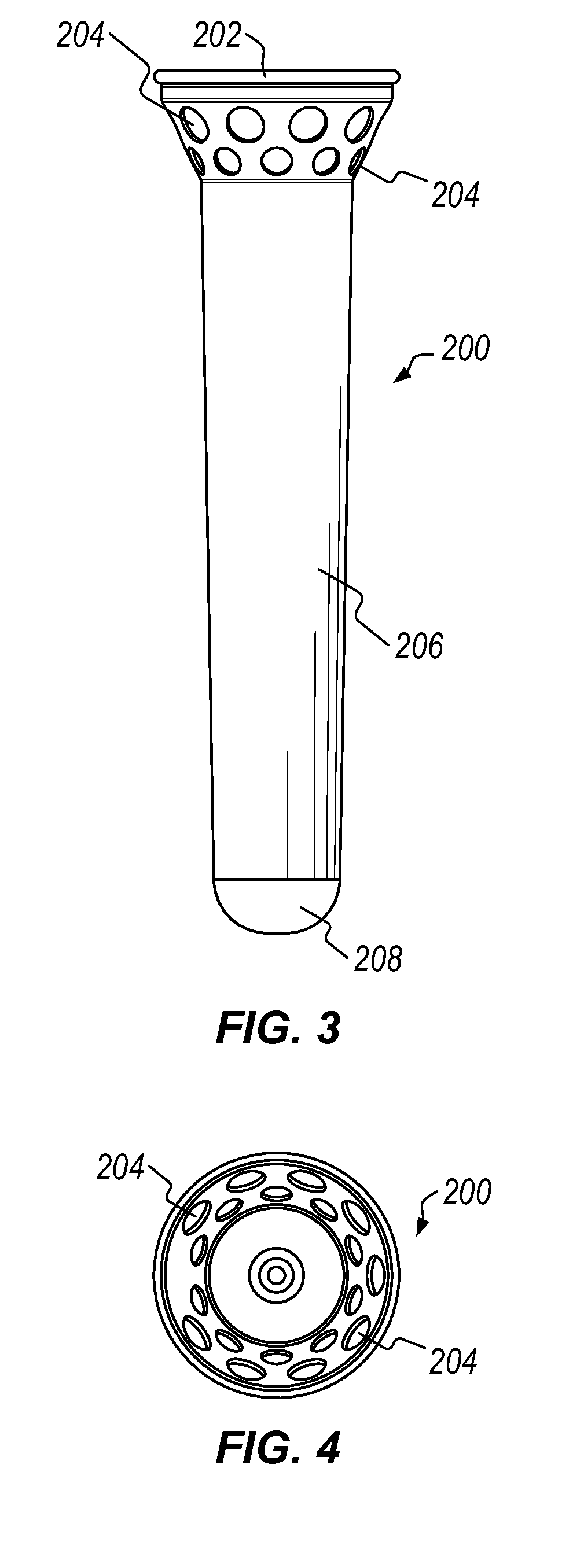

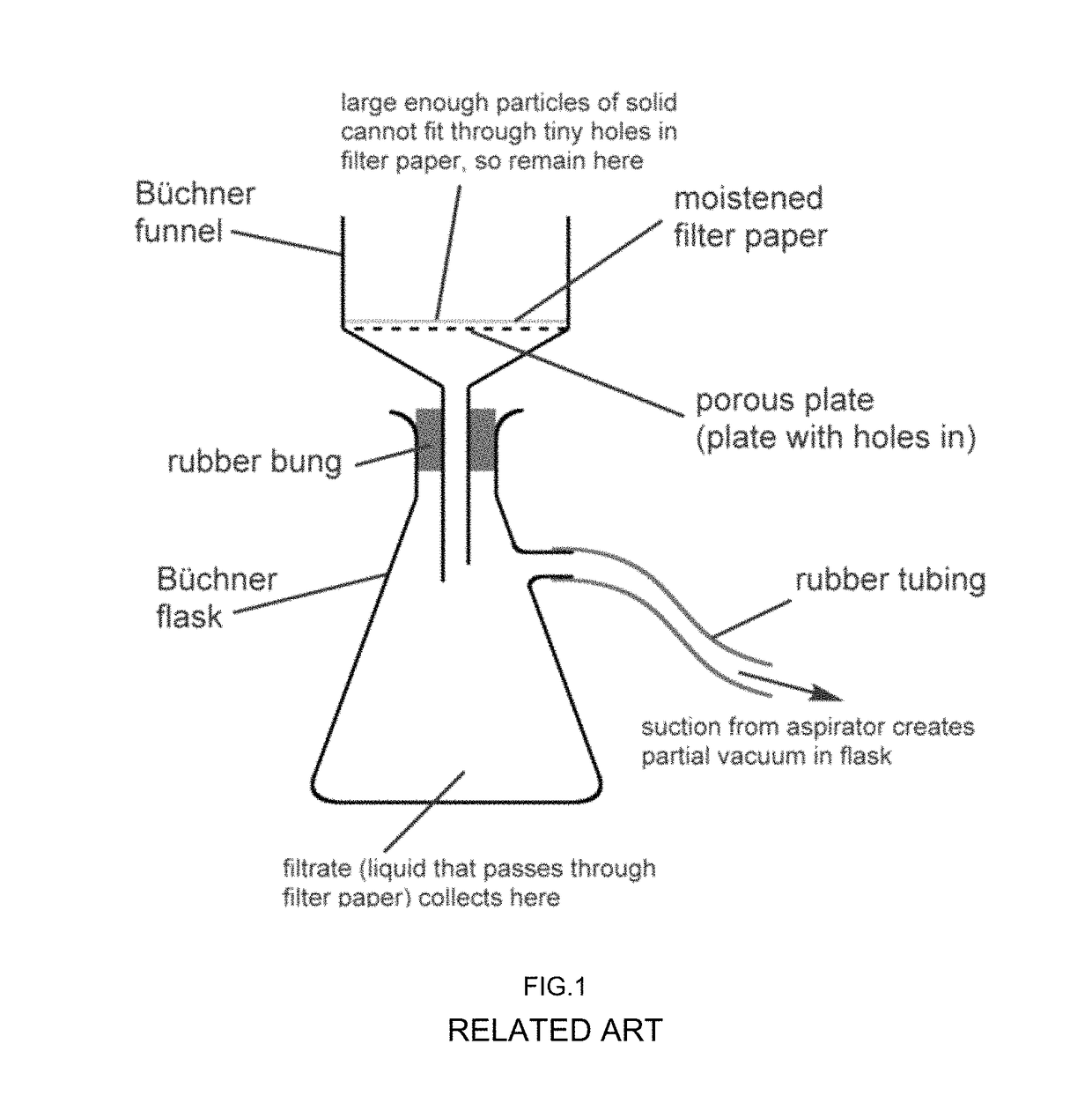

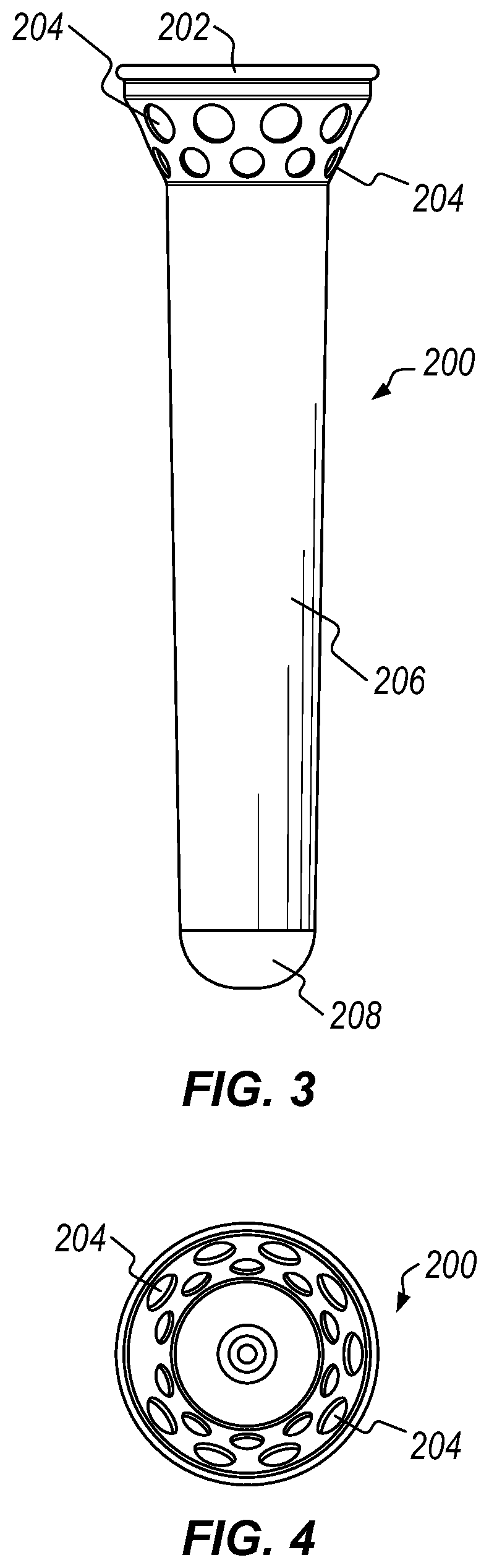

Device for preparing biological samples

ActiveUS9957473B2Limited adhesionSimple processPreparing sample for investigationBiological material testing proceduresFiltrationEngineering

A device for preparing biological samples including a fixed support of which the base extends in a first plane, a filtration block that can be removable, the filtration block including a collecting tank that itself includes a filtering device extending in a second plane and dividing the collecting tank into a collection area and a suction area, the suction area being designed to be connected to a suction device, the second plane of the filtering device being inclined relative to the plane of the base of the fixed support.

Owner:BIOMERIEUX SA

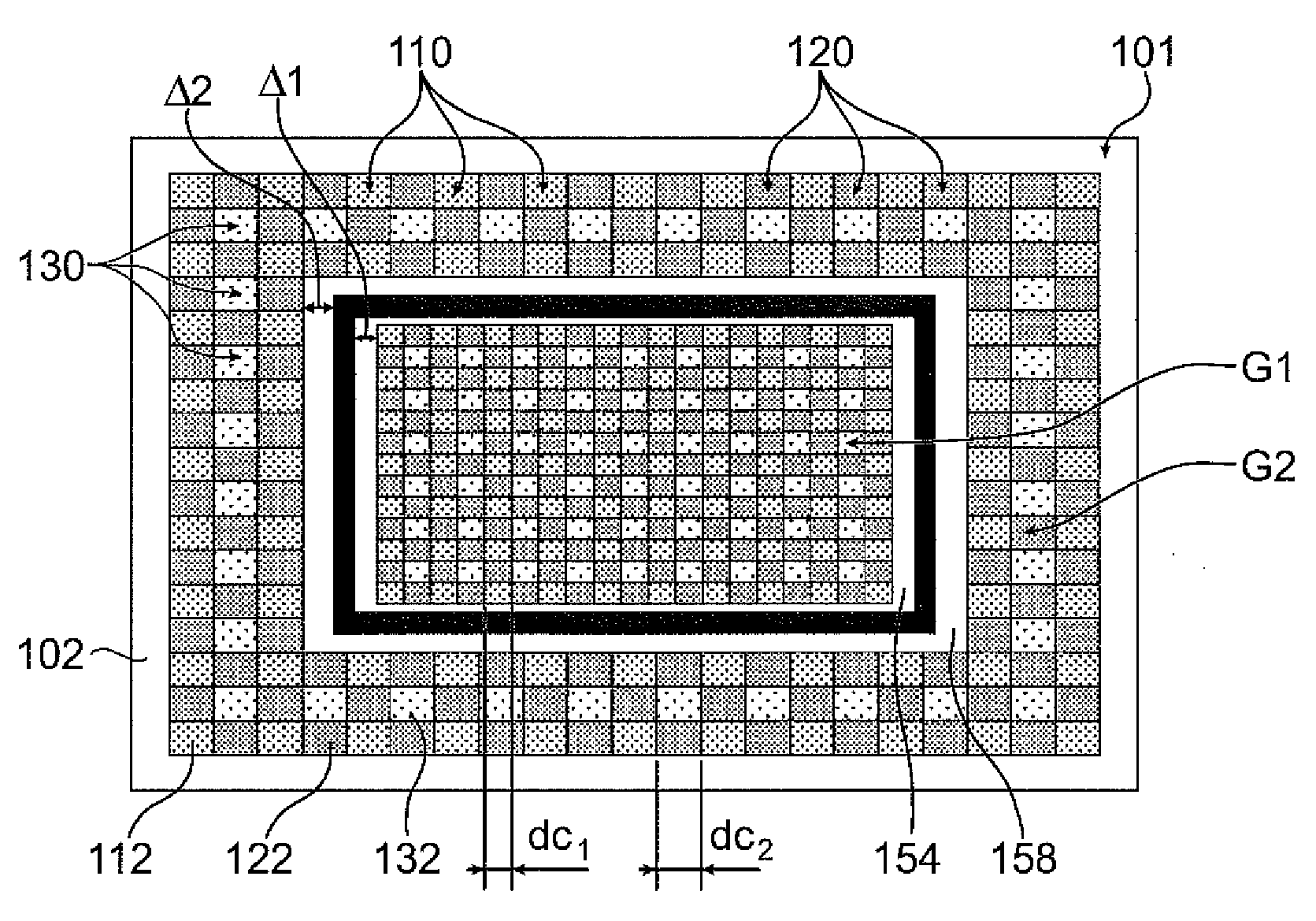

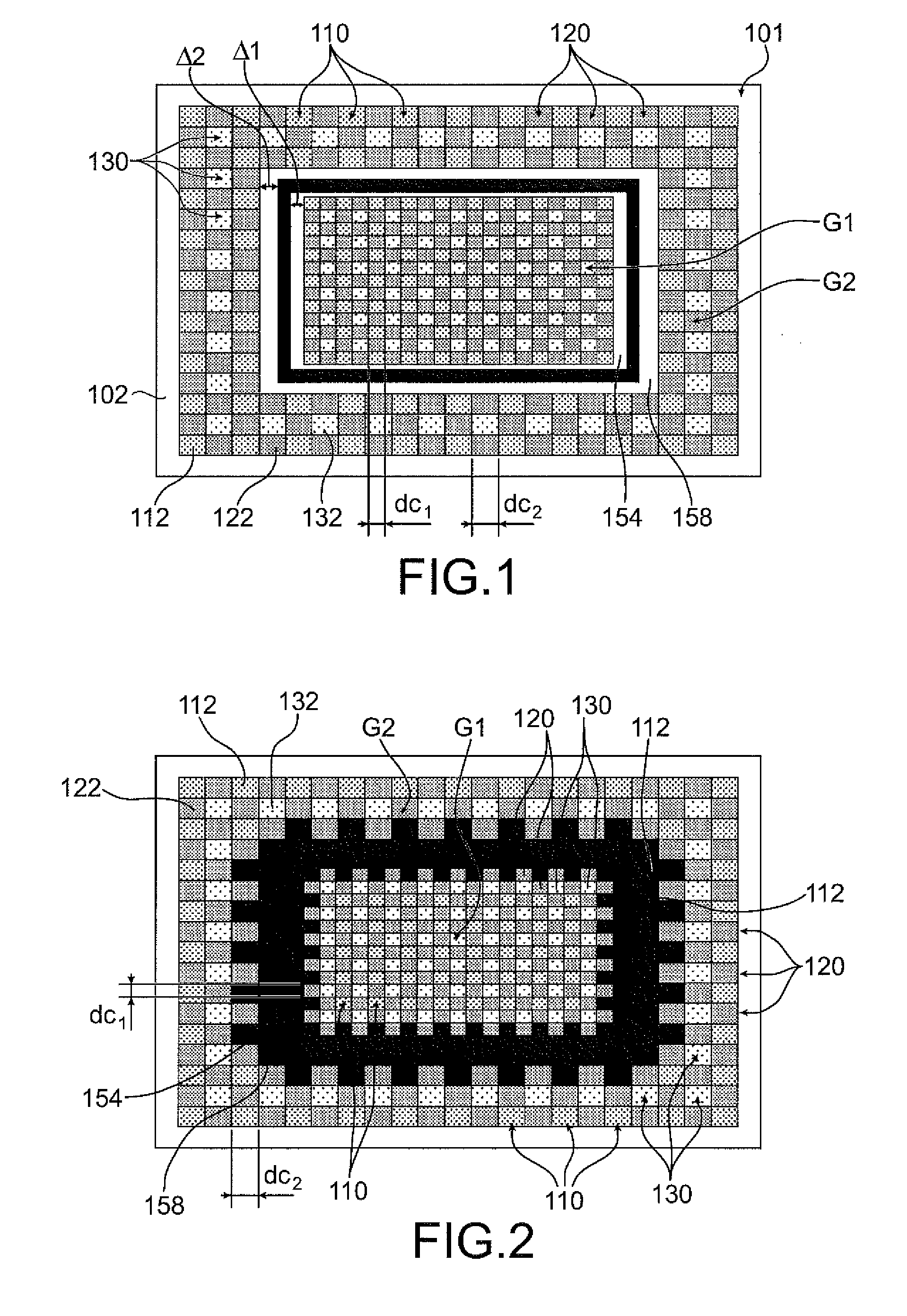

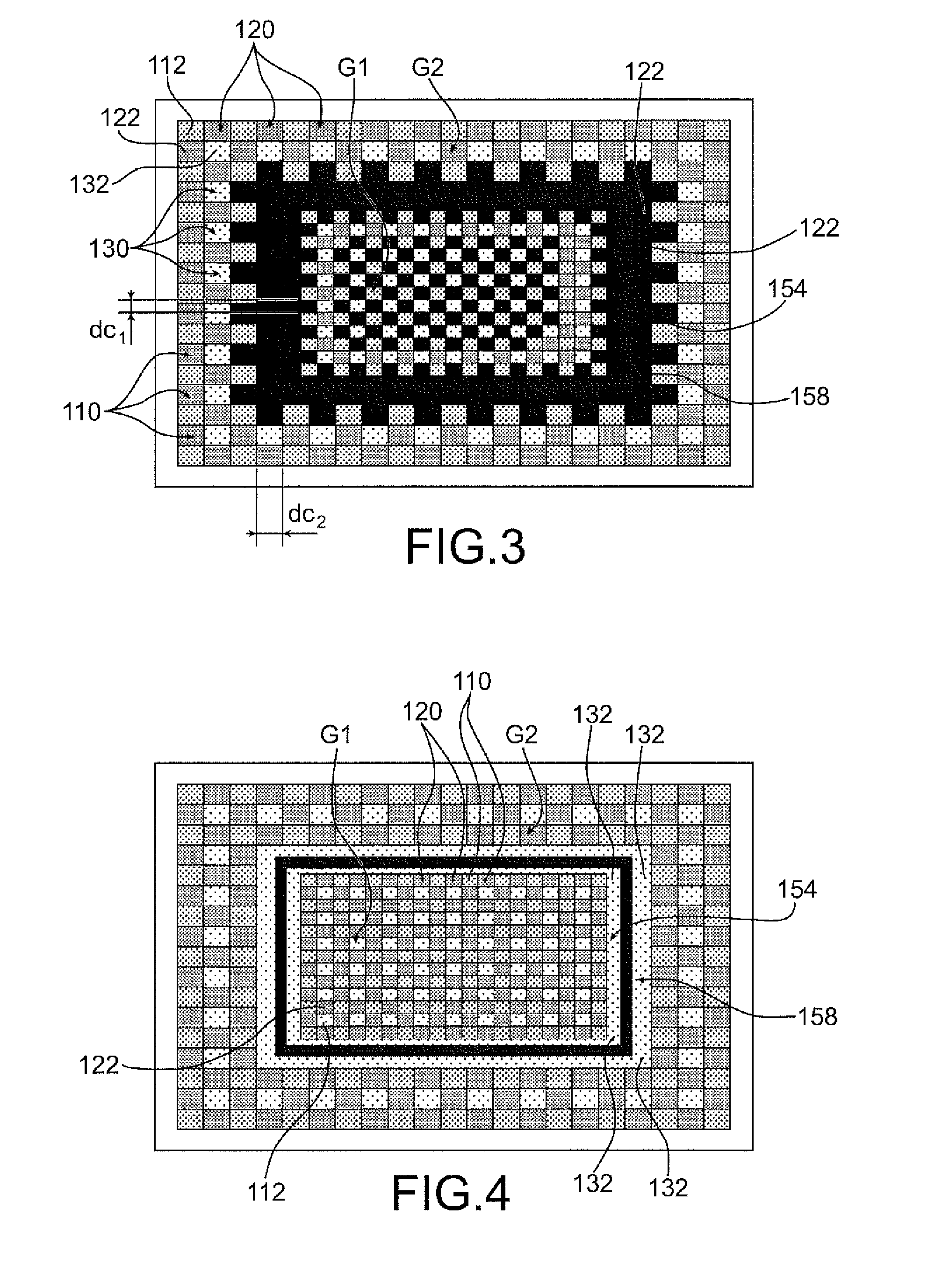

Production of an improved color filter on a microelectronic imaging device comprising a cavity

ActiveUS20070287217A1Limited adhesionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilter element

A microelectronic device includes a color filter equipped with a plurality of filtering elements, including several filtering elements. The device includes at least one first zone located inside a cavity and includes a first group of filtering elements having a first critical dimension, and at least one second zone at the periphery of the cavity, including a second group of filtering elements having a second critical dimension that is different from the first critical dimension.

Owner:STMICROELECTRONICS SRL

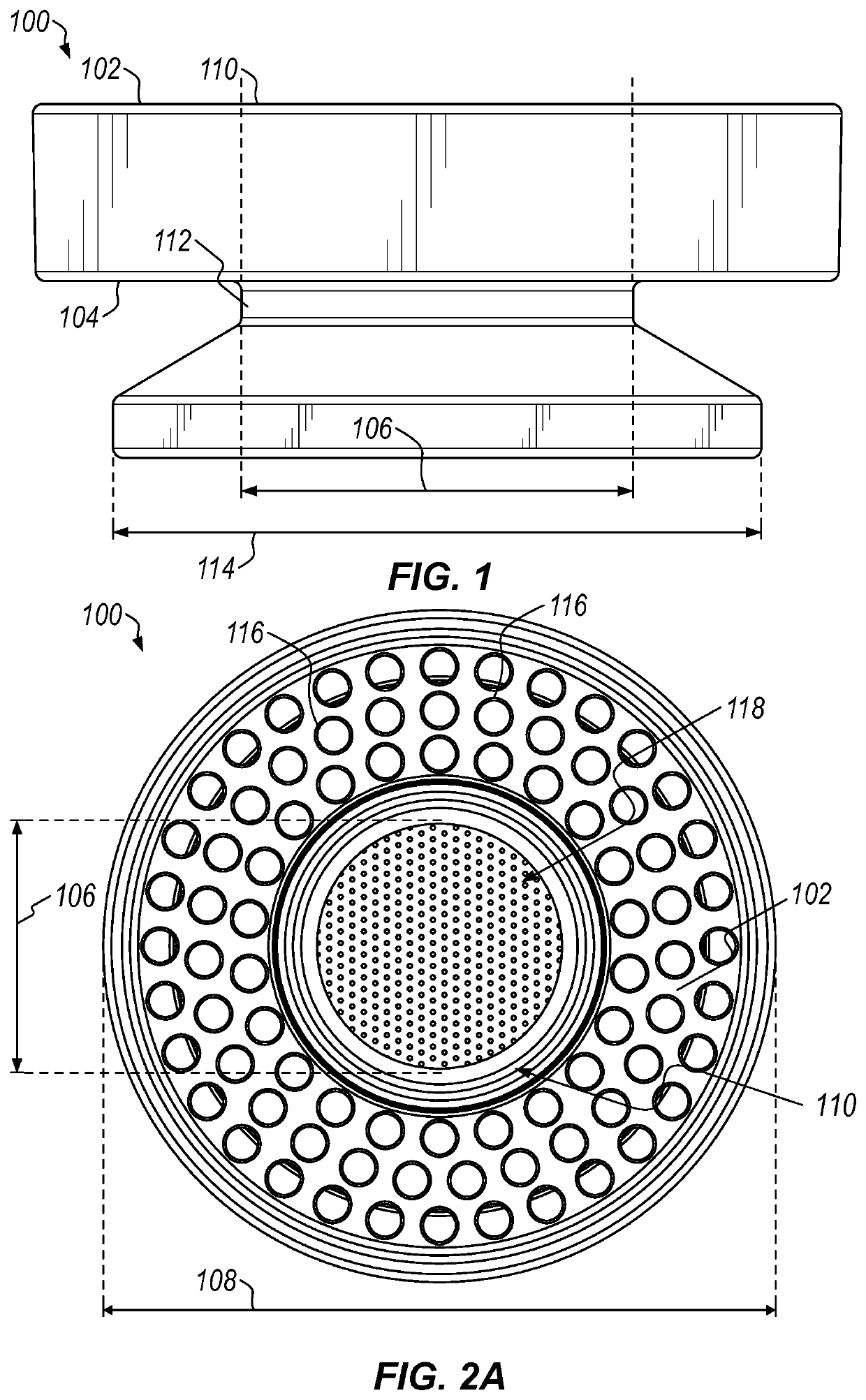

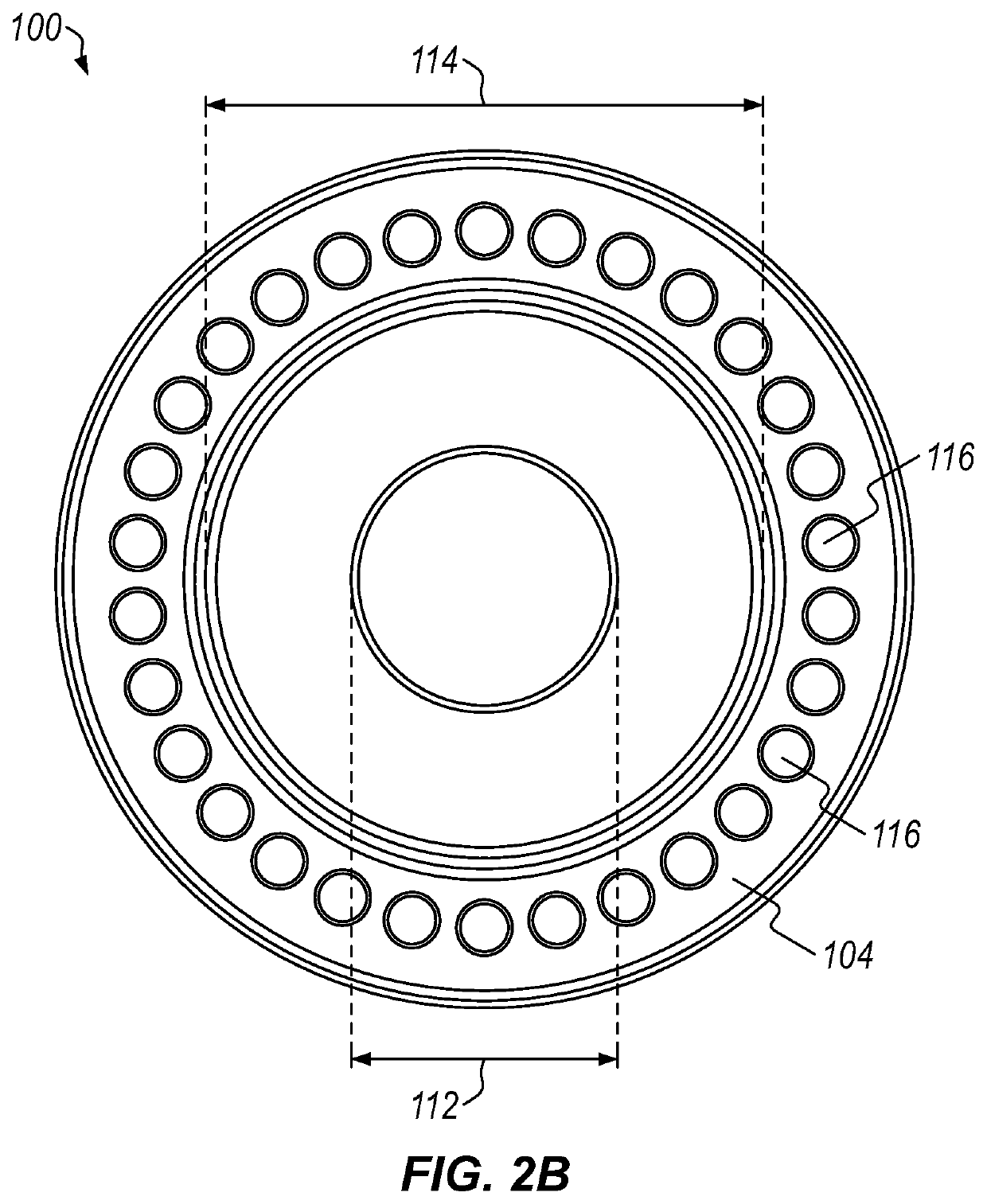

Beverage preparation apparatus

A beverage preparation apparatus including a platform section having a plurality of attachment points for additional components. The platform is adapted to releasably secure in a wide variety of target beverage vessels. The additional components include, but are not limited to, a large volume filter means, a temperature regulator, or a gravity-fed brewer. The platform may also be incorporated into a vacuum-insulated, stainless-steel beverage vessel.

Owner:TSIGOUNIS MARK

Thin substrate processing device

ActiveUS10370757B2Control damageLimited adhesionElectric discharge tubesVacuum evaporation coatingOptoelectronics

A thin substrate processing device include a substrate processing unit configured to process a thin substrate, and a cooling unit configured to cool the thin substrate when the substrate processing unit is processing the thin substrate.

Owner:ULVAC INC

Light-emitting sheet, interlayer for laminated glass, and laminated glass

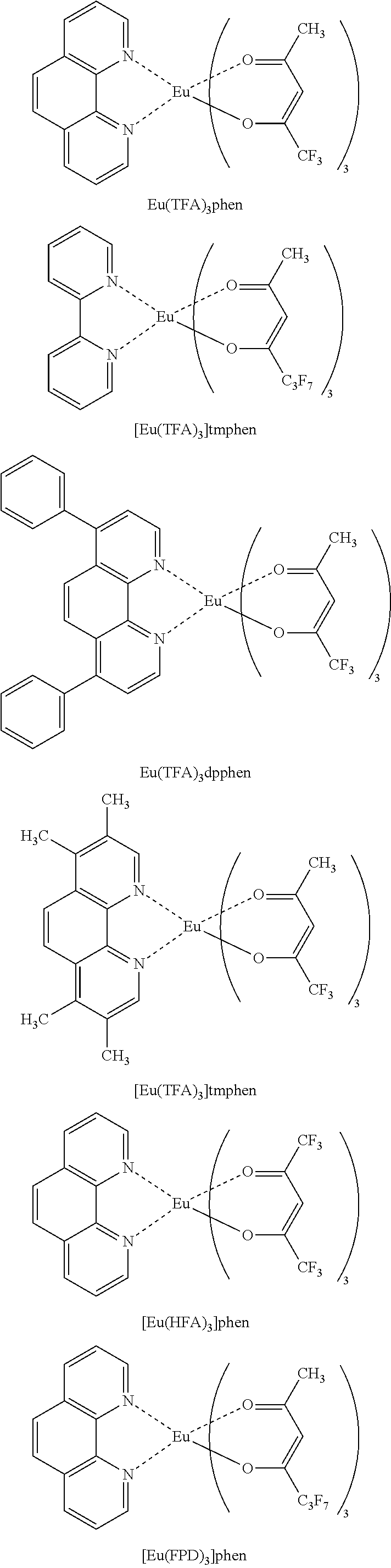

ActiveUS10800144B2Display imageLimited adhesionWindowsWindscreensAlkaline earth metalLight irradiation

The present invention aims to provide a luminescent sheet capable of displaying high-luminance images under irradiation with light and capable of controlling the adhesion to glass, and an interlayer film for a laminated glass and a laminated glass each including the luminescent sheet. Provided is a luminescent sheet including: a thermoplastic resin; a luminescent material; and a cyclic coordination metal compound having a five- or more-membered ring structure formed by coordinating an organic compound having in a molecule two or more atoms of at least one kind selected from oxygen, phosphor, nitrogen, and sulfur, to at least one metal selected from an alkali metal, an alkaline earth metal, and magnesium.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com