Patents

Literature

41results about How to "Suitable for packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

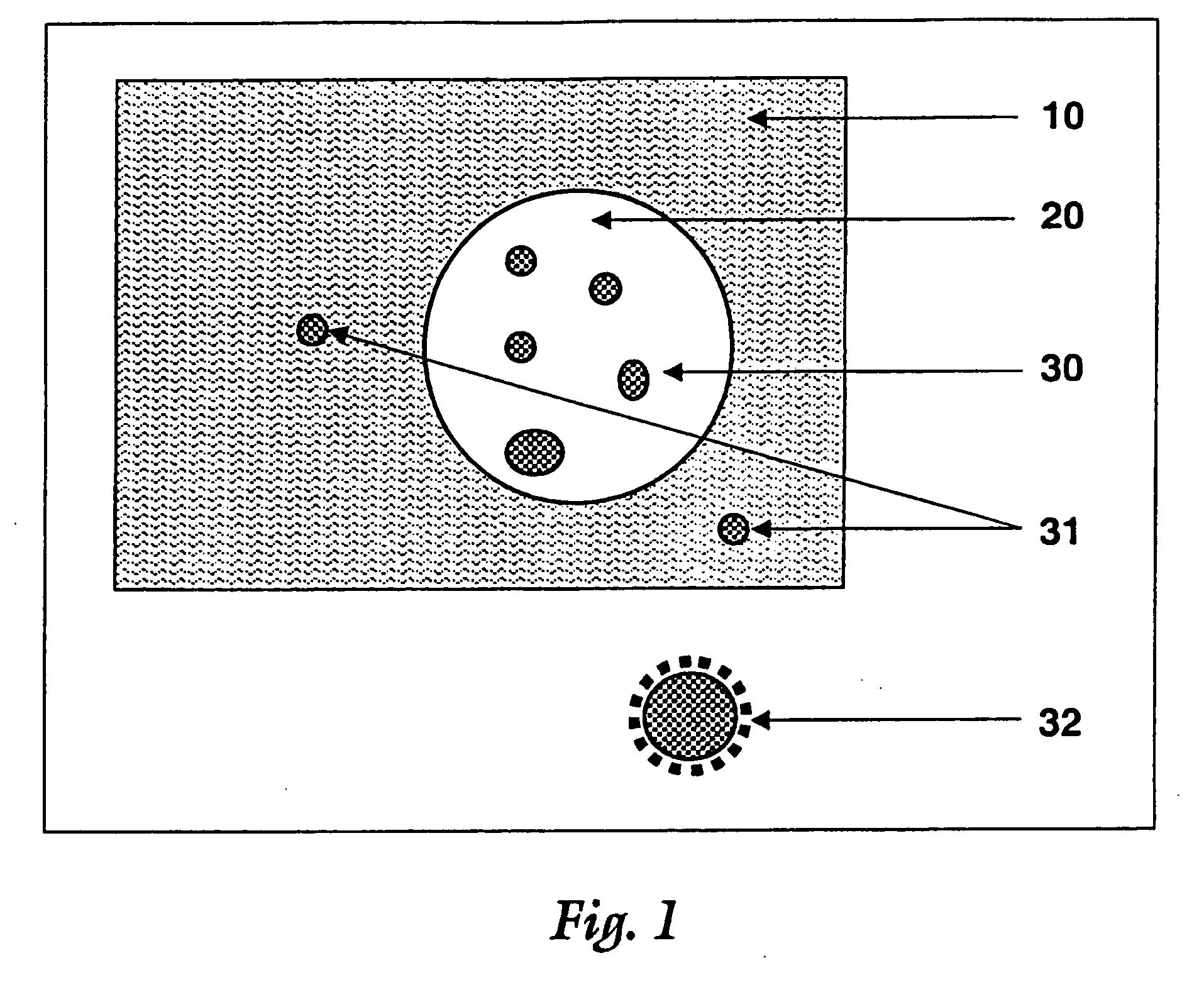

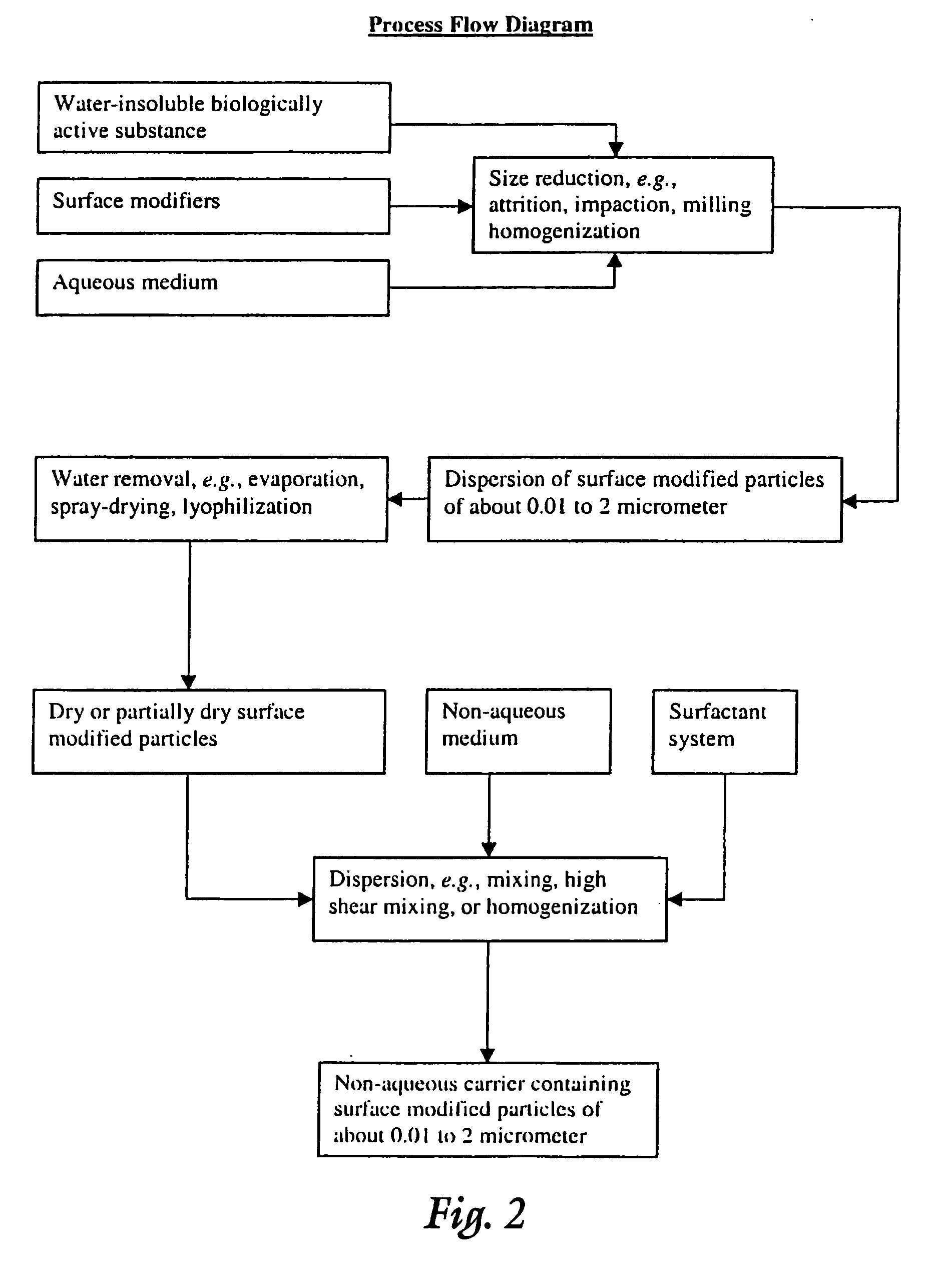

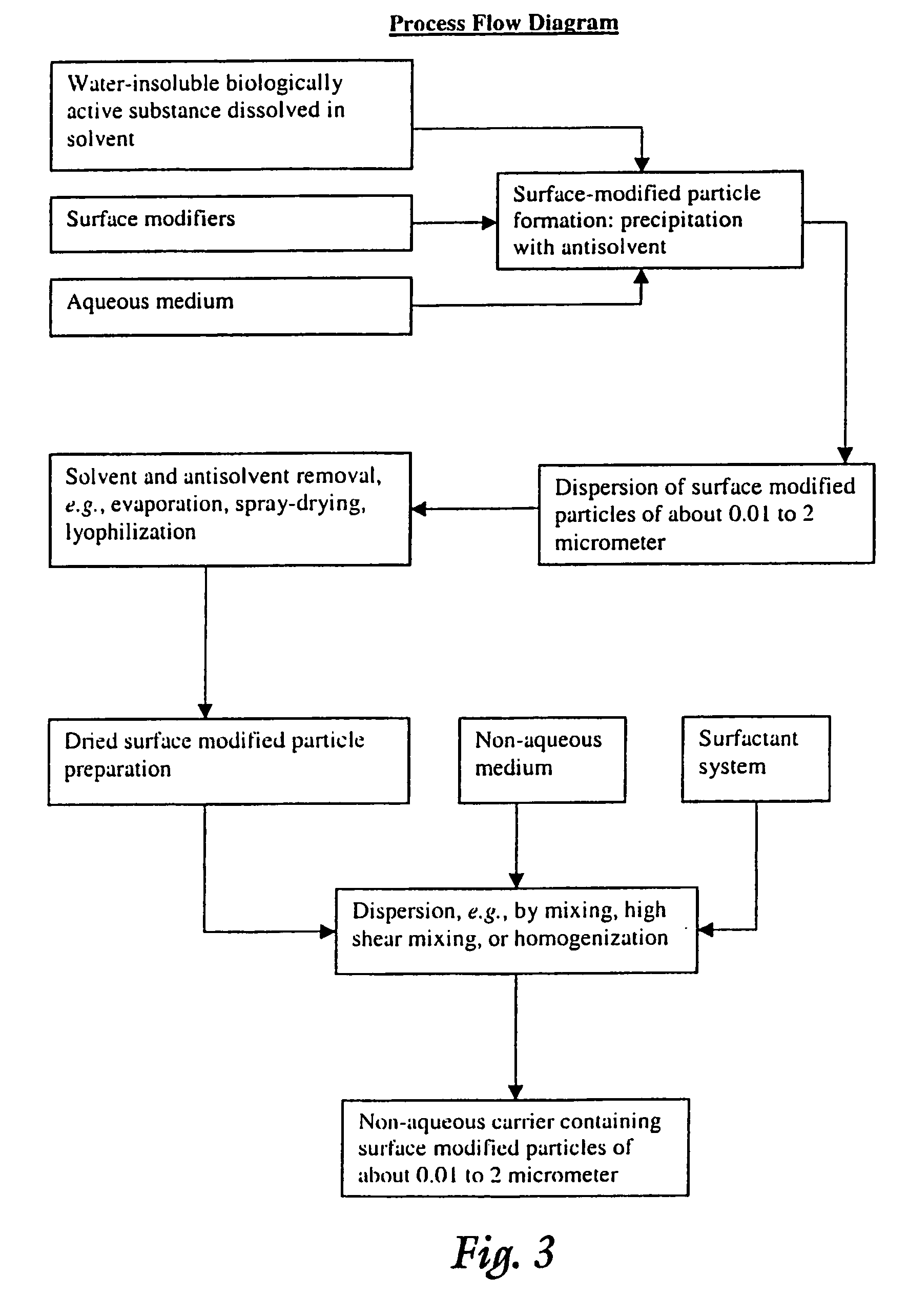

Surface modified particulate compositions of biologically active substances

InactiveUS20060210622A1Easy to useEfficient deliveryPowder deliveryOrganic active ingredientsParticulatesWater insoluble

This invention disclosure relates to compositions for the delivery of stable surface modified sub-micron and micron sized particles of water-insoluble biologically active substances from a non-aqueous medium that self-disperses on exposure to an aqueous environment.

Owner:SKYEPHARMA CANADA INC

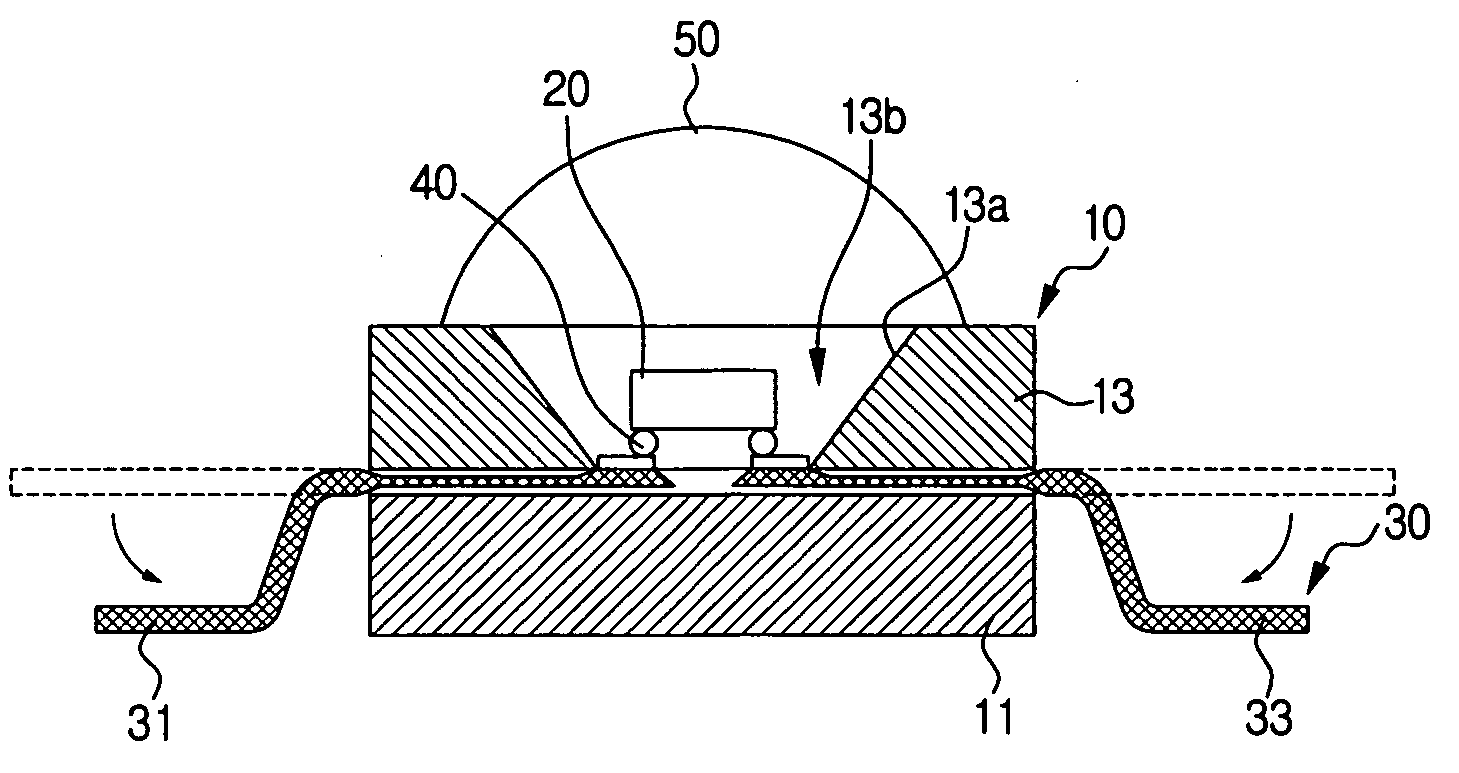

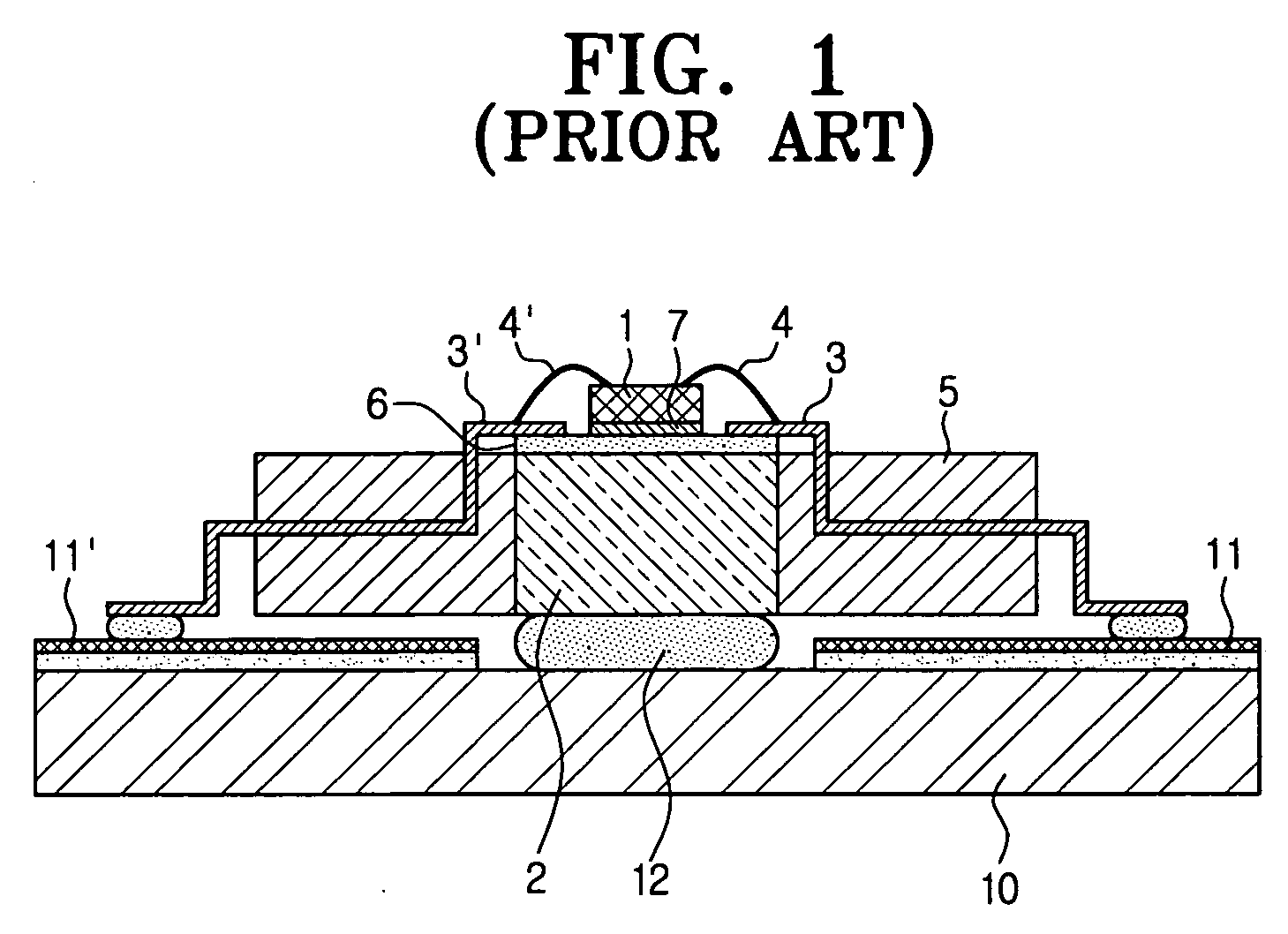

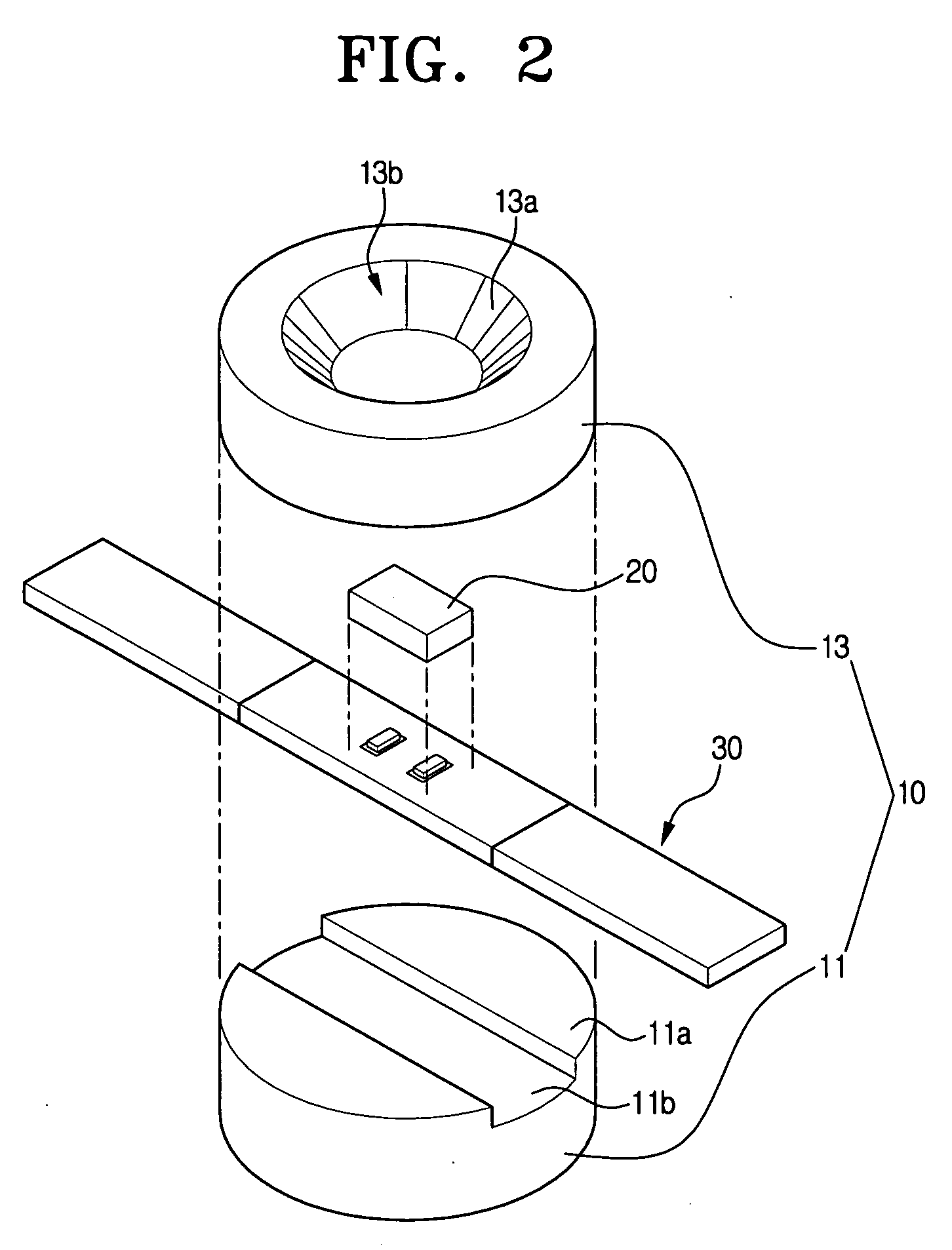

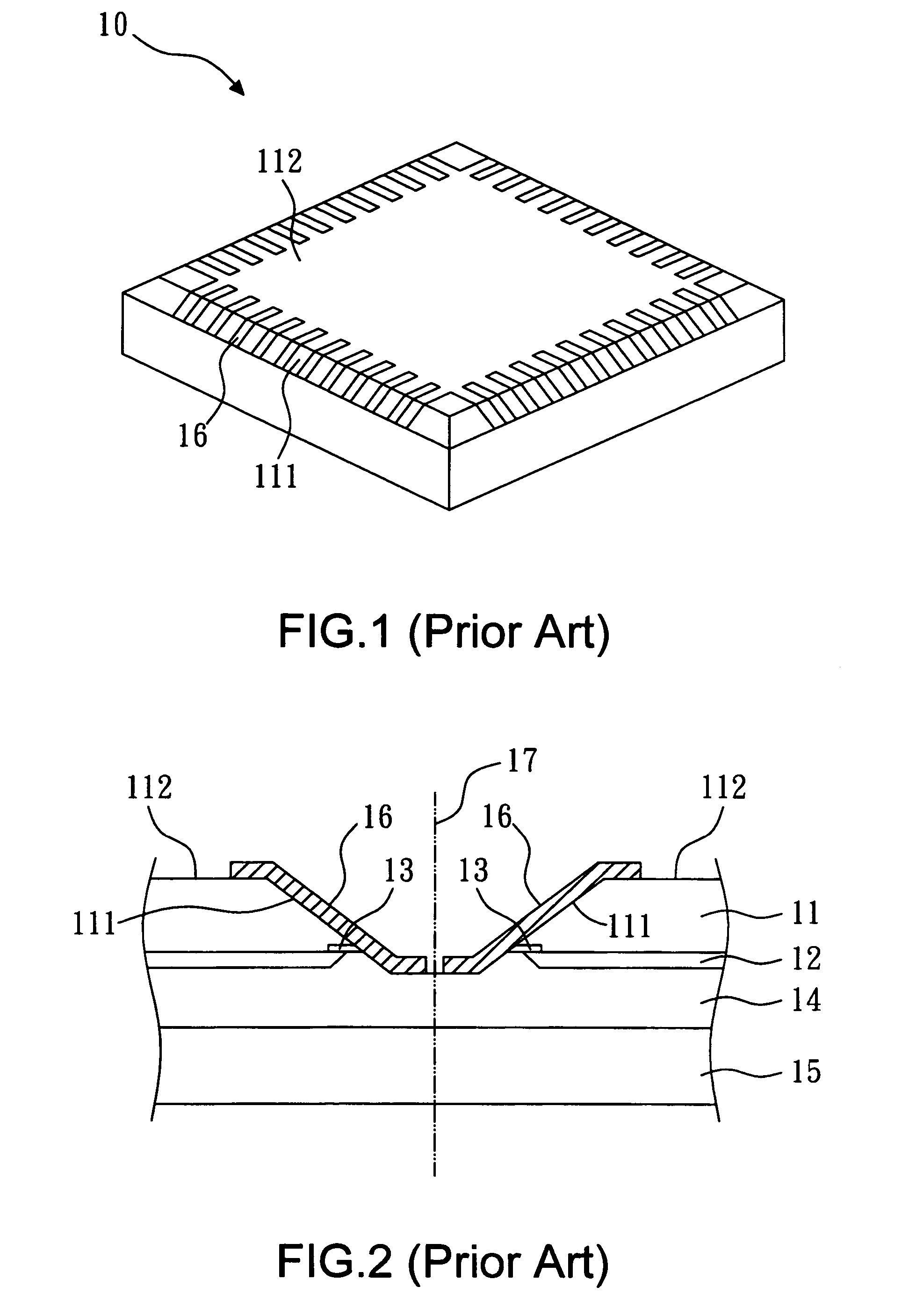

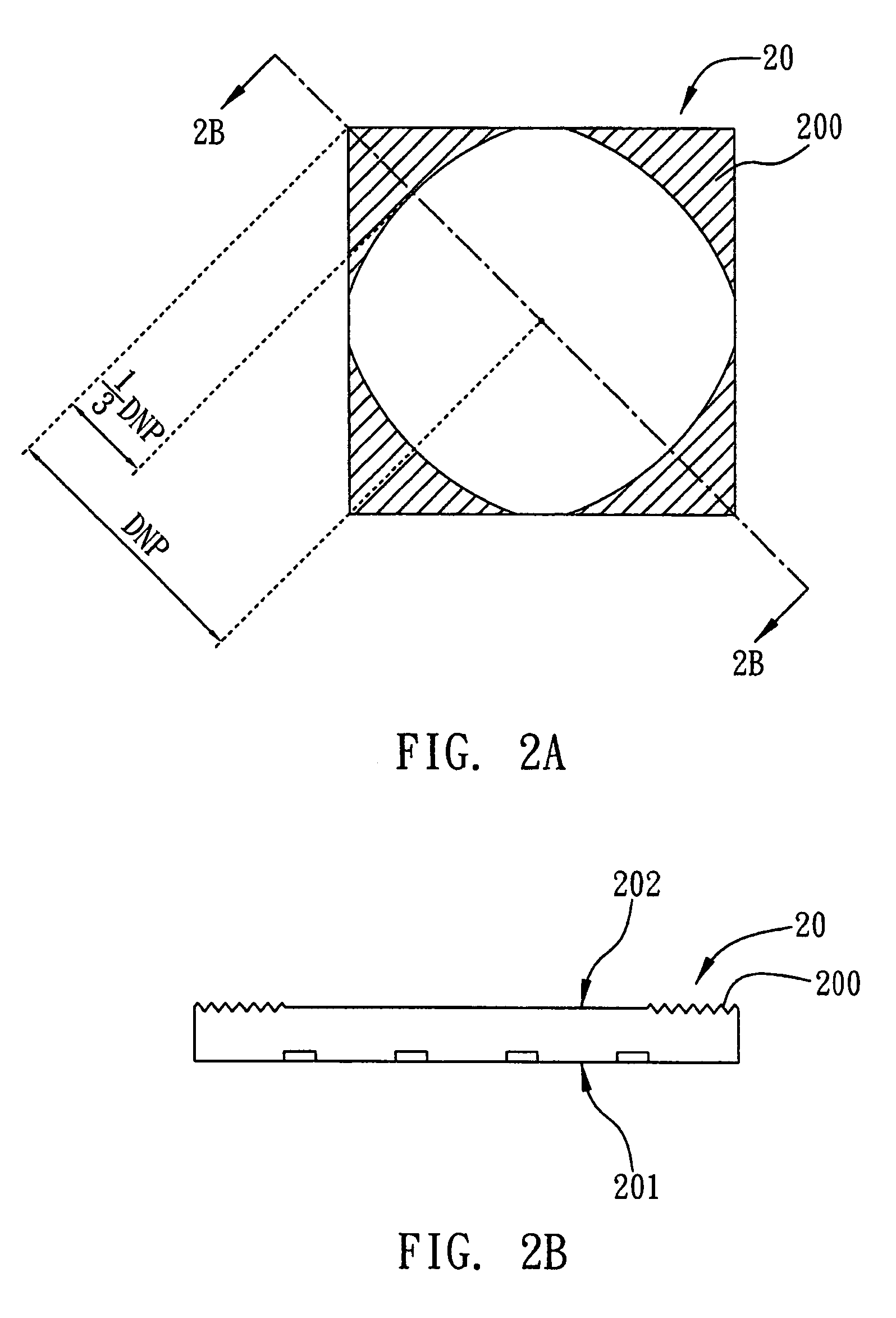

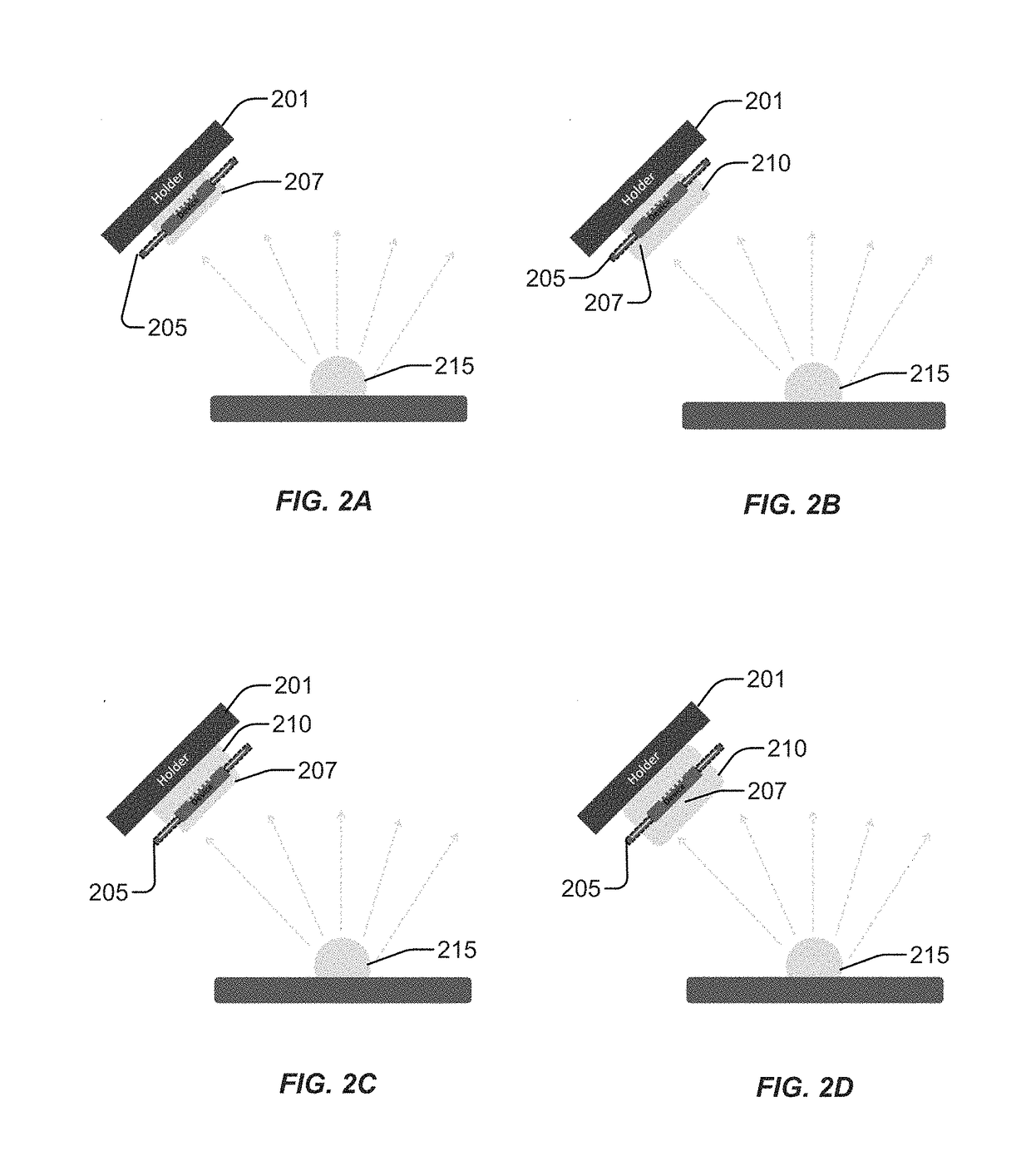

LED package and method for fabricating the same

InactiveUS20070029570A1Improve cooling effectEasy constructionSolid-state devicesSemiconductor devicesEngineeringElectrical and Electronics engineering

An LED package comprises: a package body having therein a LED receiving part including a reflecting surface; an LED mounted within the LED receiving part; a lead mounted within the package body such that first and second ends of the lead are exposed to the outside of the package body. The lead includes first and second conductive parts which are electrically connected to the LED and a non-conductive part which insulates the first and second conductive parts from each other.

Owner:SAMSUNG DISPLAY CO LTD

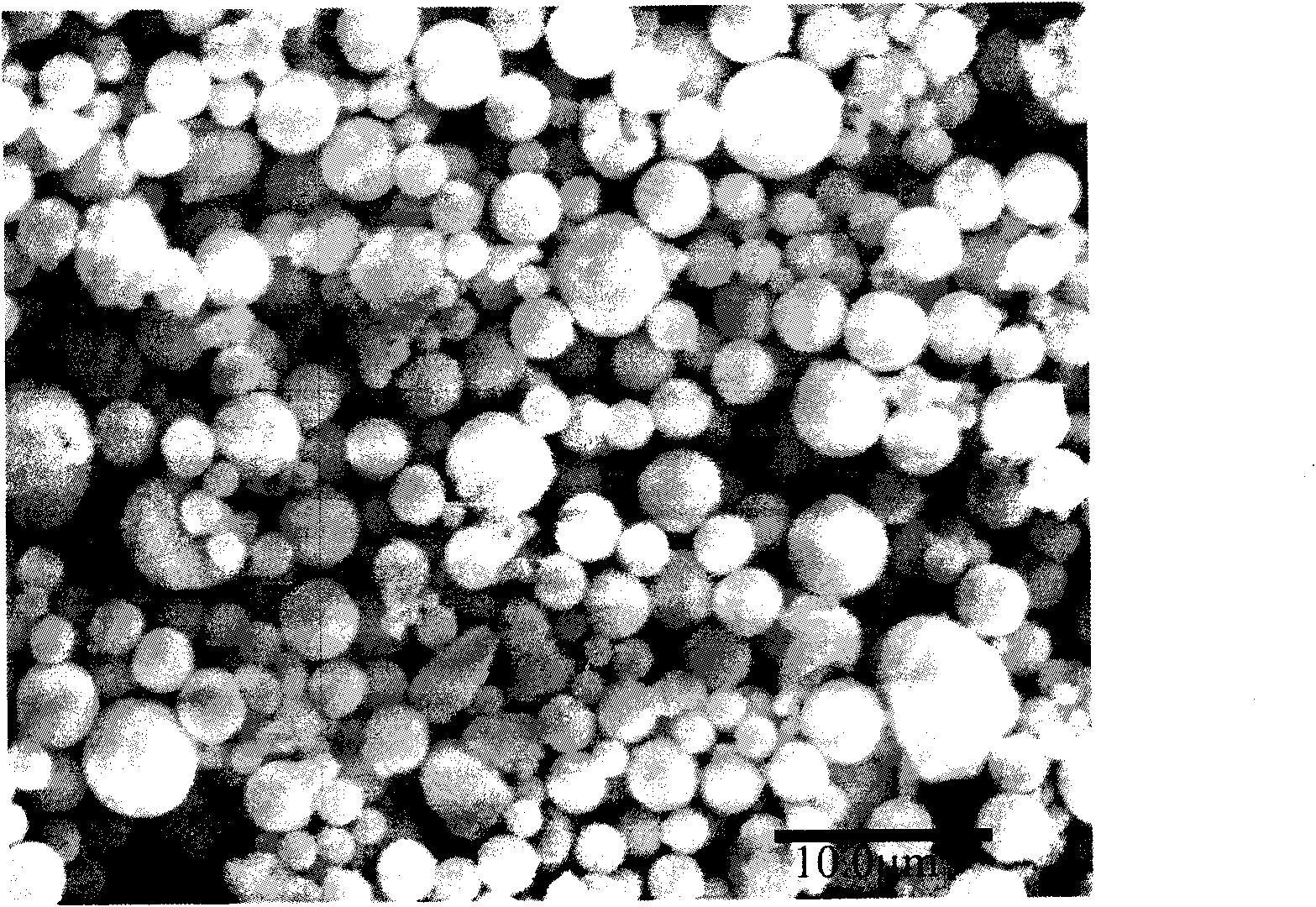

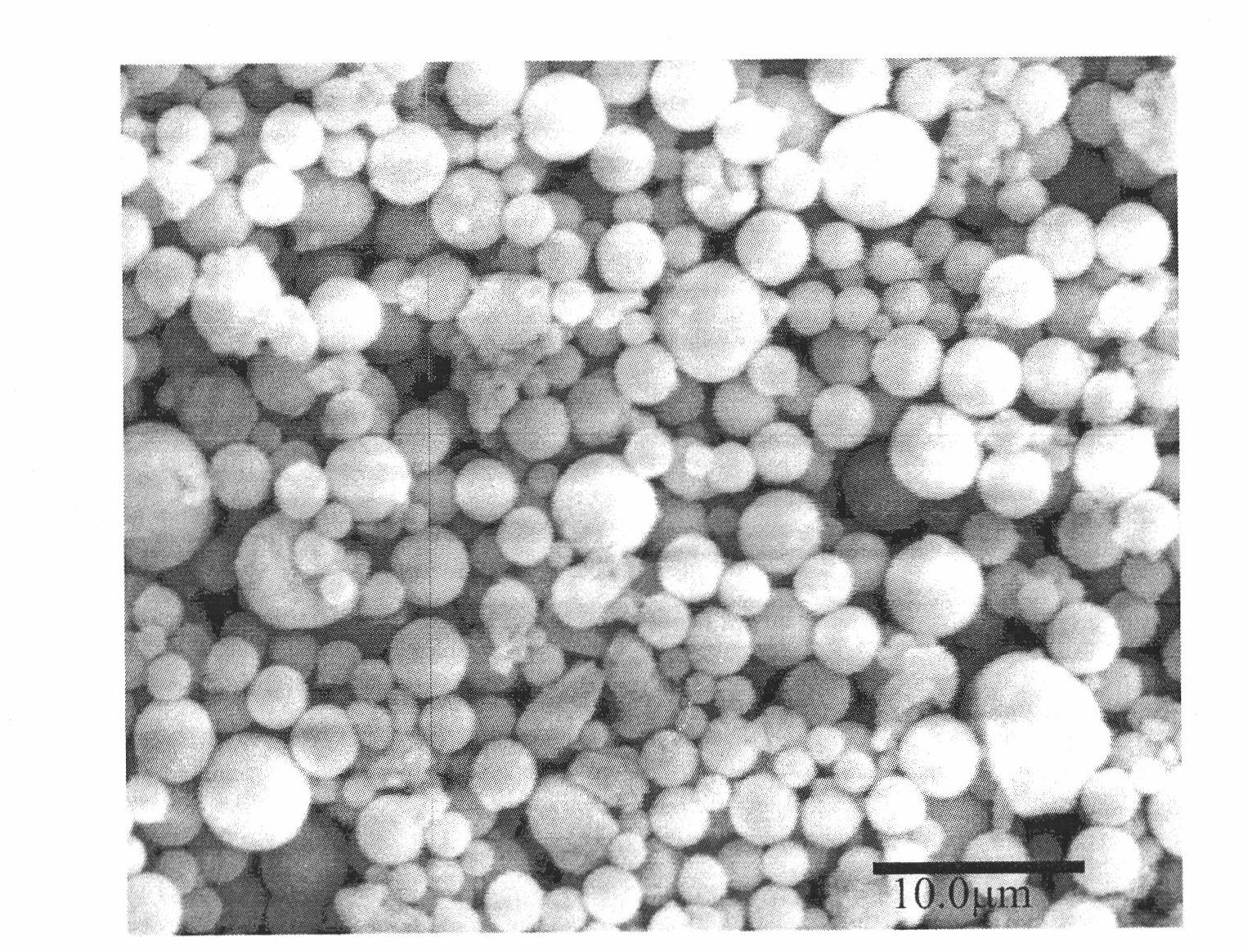

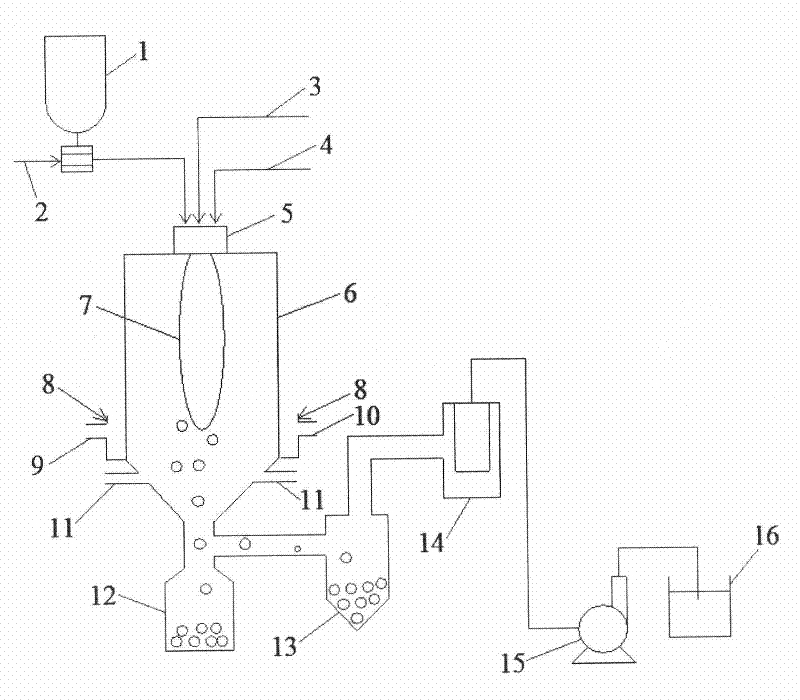

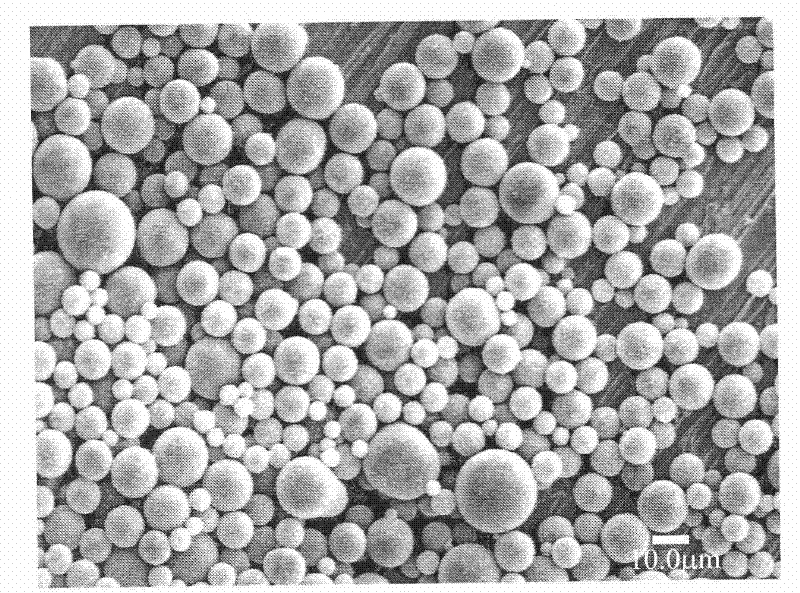

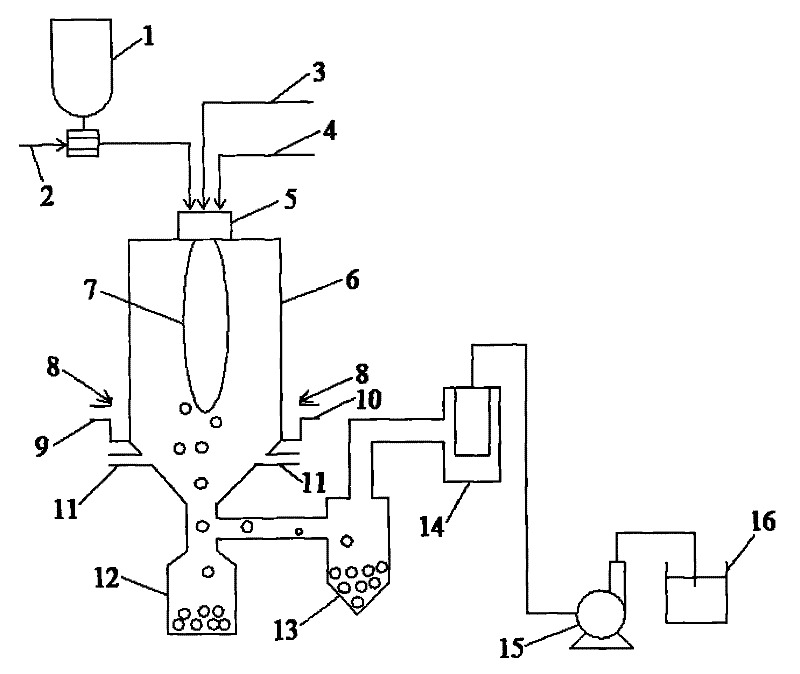

High-purity low-radioactivity spherical silicon micropowder and preparation method thereof

The invention discloses high-purity low-radioactivity spherical silicon micropowder. In the silicon micropowder, the content of SiO2 is not lower than 99.90 percent, the content of radioelement U is less than or equal to 1*10g / g, sphericization ratio is between 90 and 100 percent, and non-crystalline ratio is between 99 and 100 percent. The method for preparing the silicon micropowder comprises the following steps: preparing stable silica sol which has purity not lower than 99.90 percent and the ion content of an arbitrary impurity less than or equal to 5*10g / g by a silicon source with the content of radioelement U being less than or equal to 1*10g / g; concentrating the silica sol to lead the solid content of the silica sol to be between 41 and 70 percent; granulating the concentrated silica sol to lead grain diameter of the silica sol to be between 0.5 and 60 mu meters; roasting the granulated silicon oxide micropowder at a temperature of between 500 and 1,100 DEG C; and carrying out sphericization treatment on the micropowder in a flame burner and a sphericizing furnace, and classifying and collecting the micropowder after cooling to obtain the high-purity low-radioactivity spherical silicon micropowder. The spherical silicon micropowder of the invention can meet the requirement of a large-scale integrated circuit on capsulation packing, and the invention has simple process, low cost, simple required equipment, and is applicable to industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

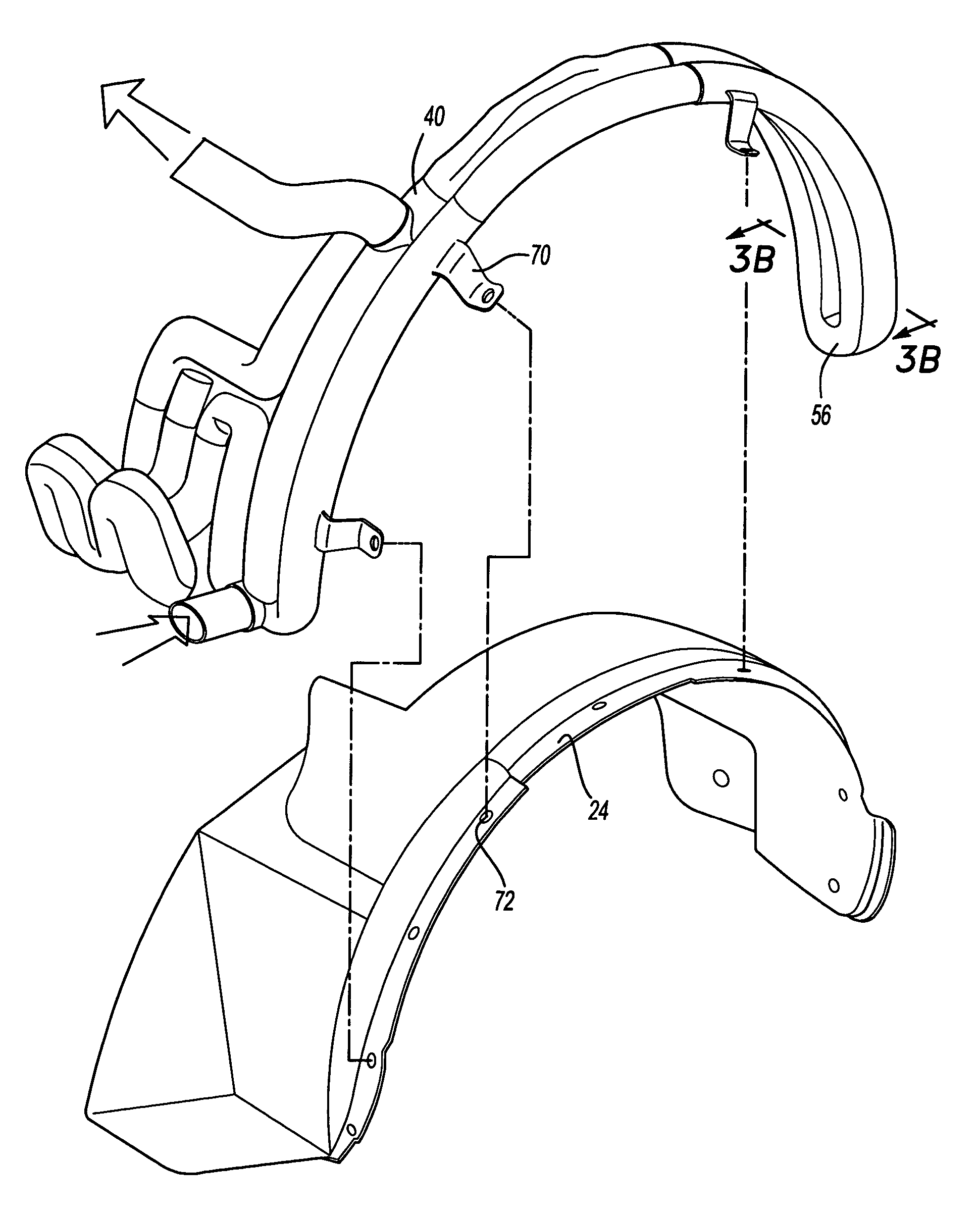

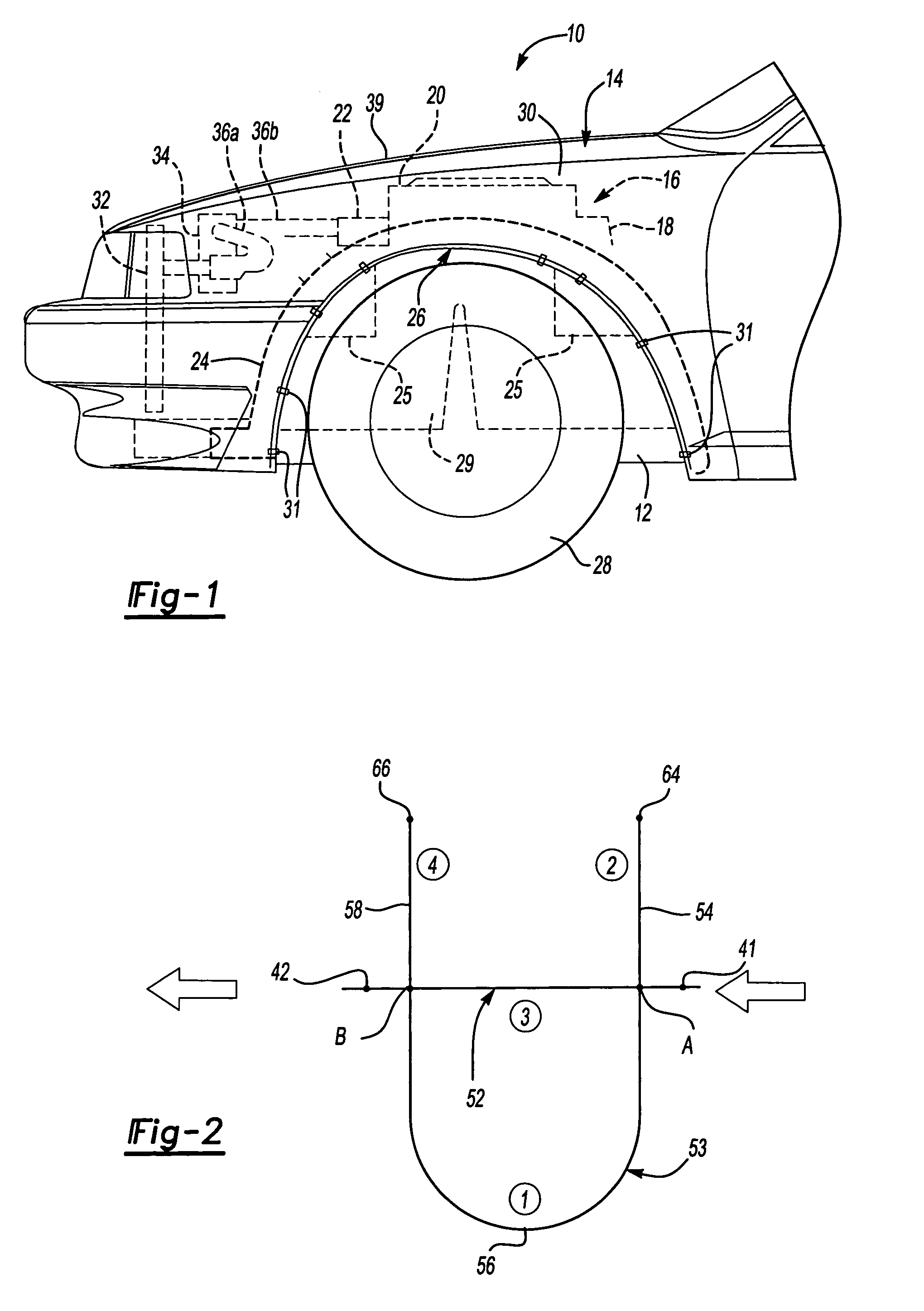

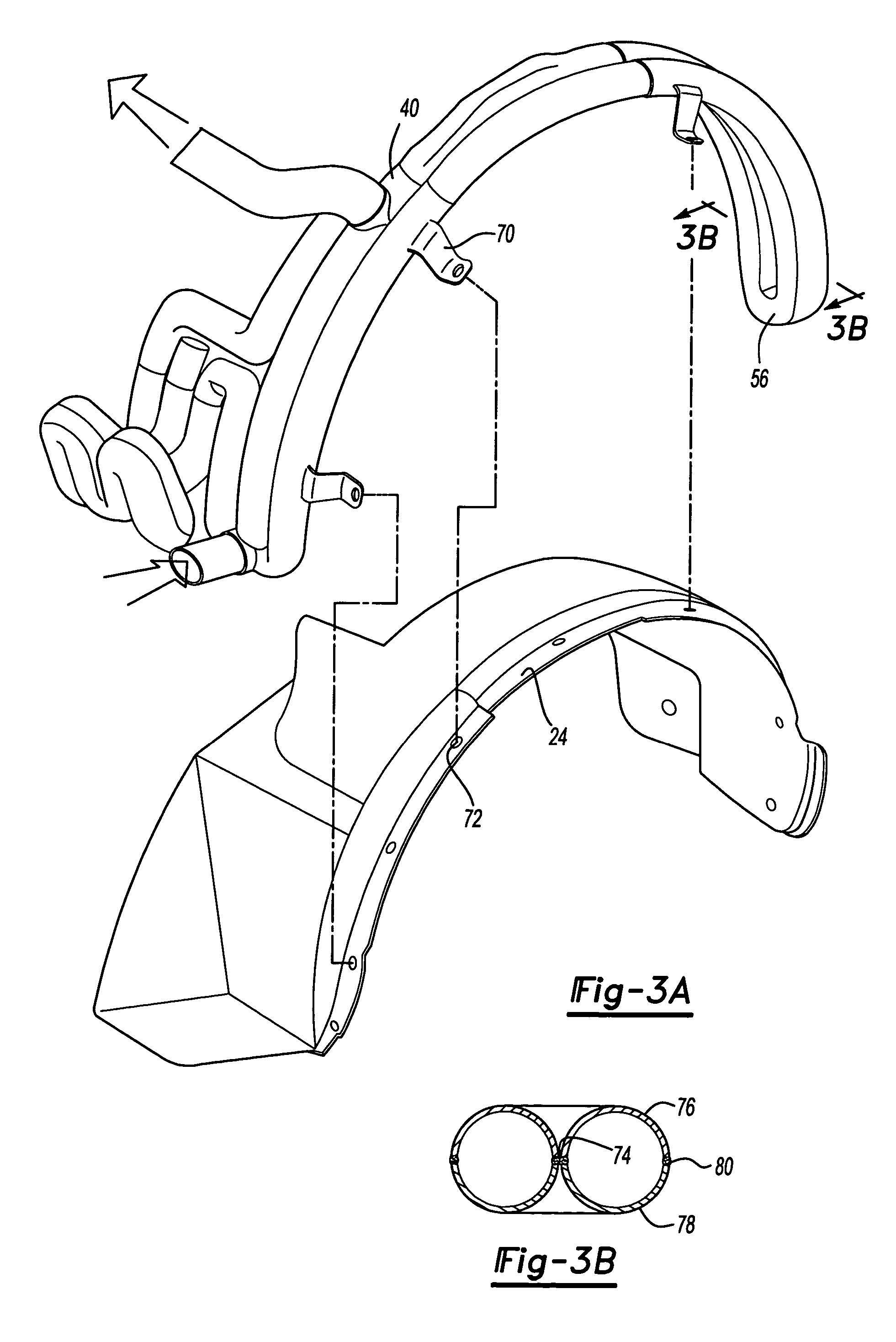

Herschel-Quincke tube for vehicle applications

InactiveUS7017707B2Easy to packSuitable for packagingCombustion-air/fuel-air treatmentSilencing apparatusMathematical modelEngineering

An HQ tube arrangement suitable for packaging within a vehicle may be designed by creating a mathematical model representing a tube arrangement having a first passageway and a second passageway fluidly connected to the first passageway at first and second junctions. The second passageway is divided by the junctions into first, second, and third passages. Lengths are associated with each of the first passageway and the first, second, and third passages. A filter parameter, based upon an average transmission loss for a particular frequency over a standard deviation, is analyzed as a function of the lengths. Lengths are chosen based upon analysis of the filter parameter. Portions of the outer walls of the first and second passageways may be secured to or common to one another so that lengths of the passageways run along side of each other to provide a more compact HQ tube arrangement.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Fill-finish proces for peptide solutions

Owner:3 D MATRIX

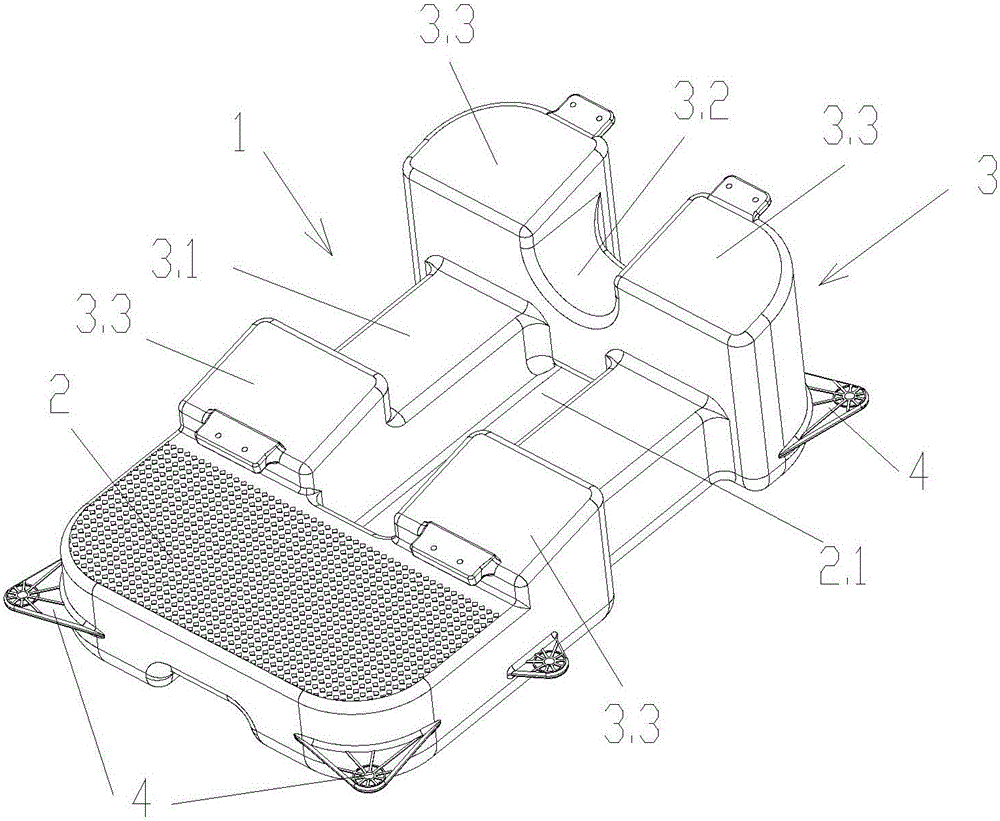

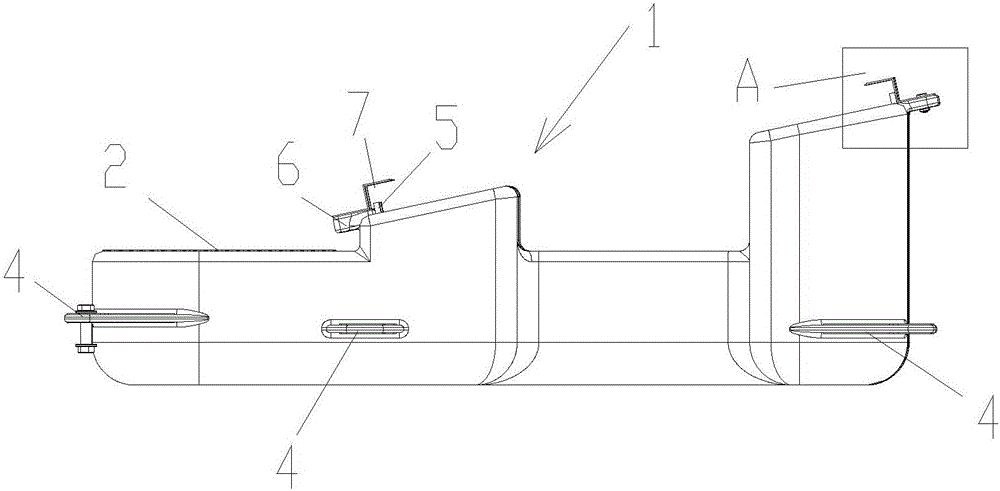

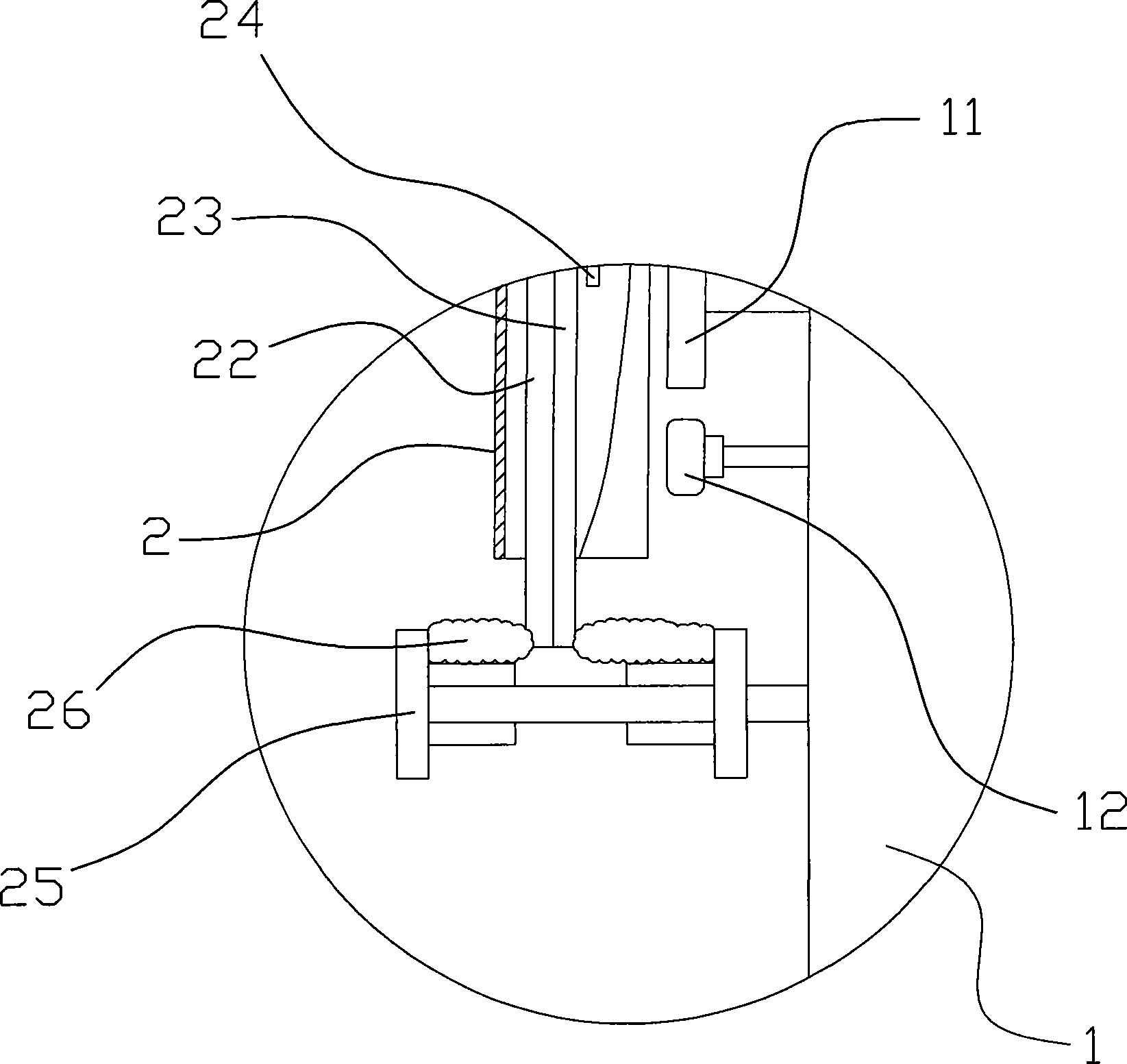

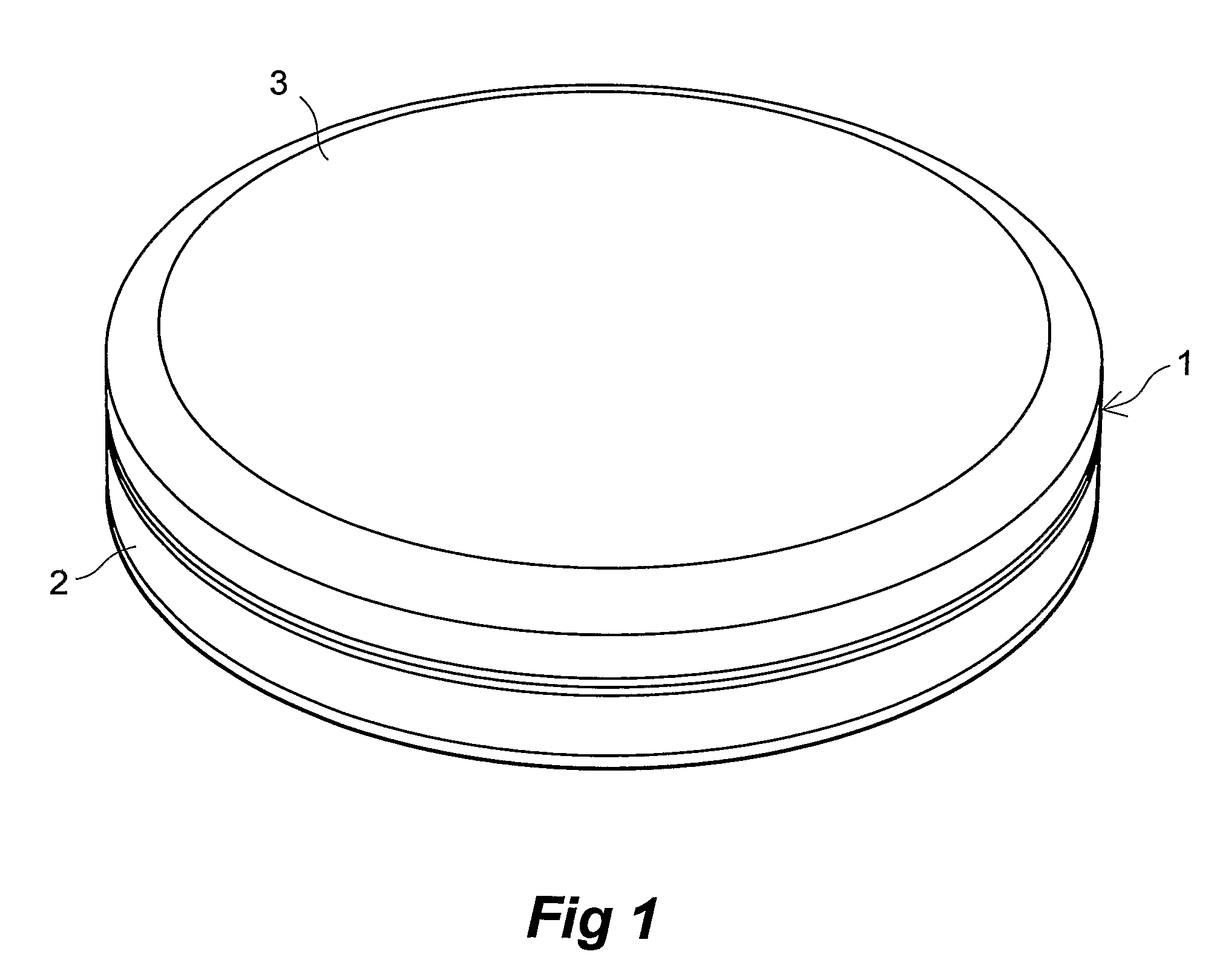

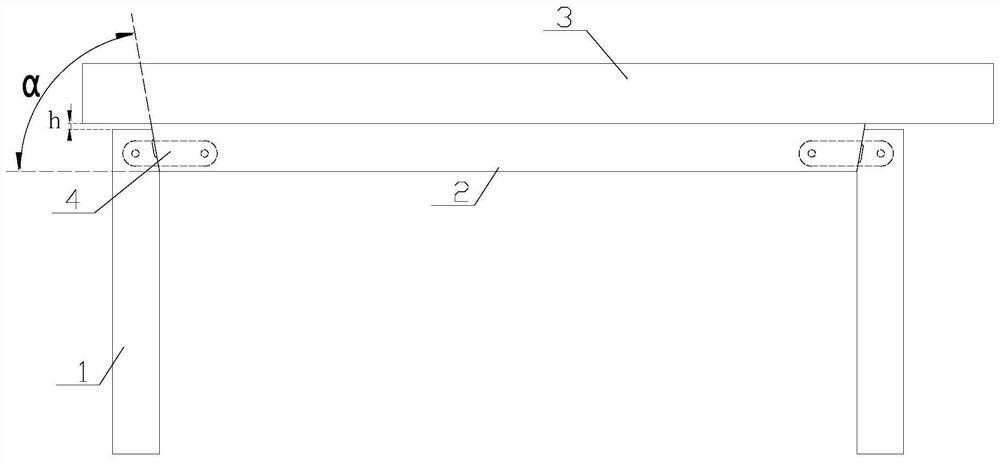

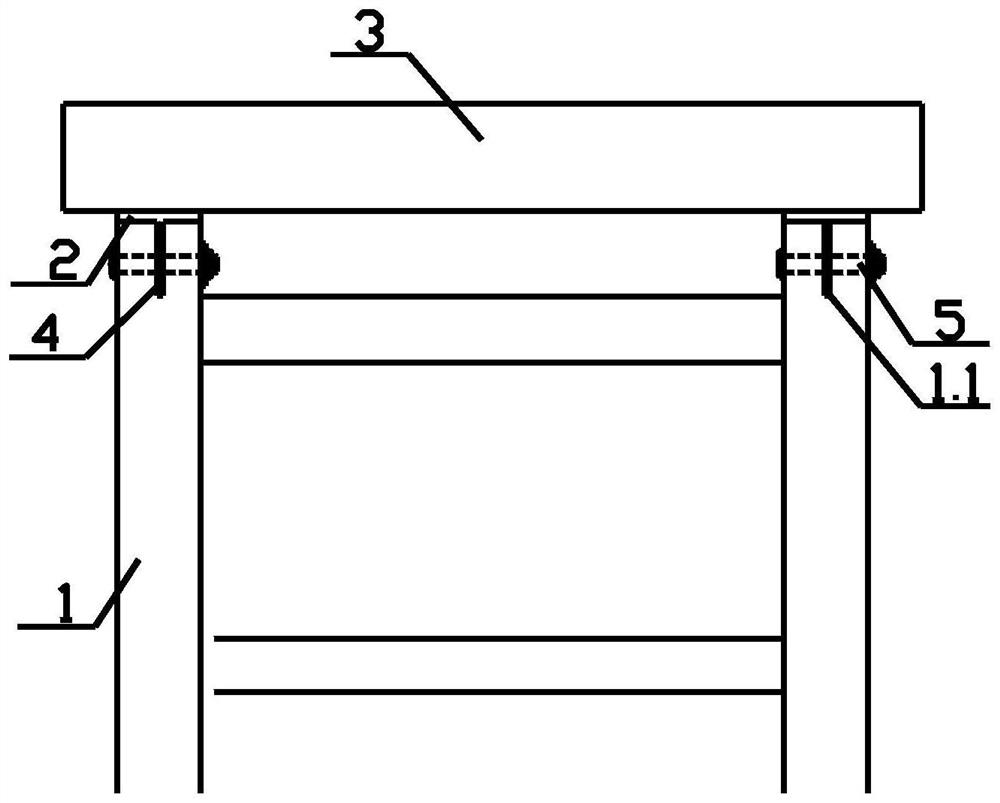

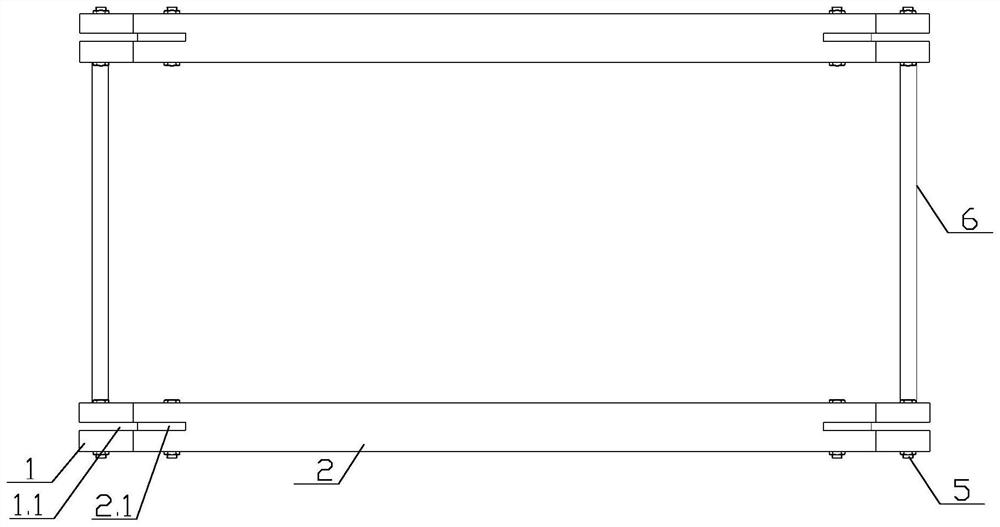

Integral double-hull floating platform device for offshore water-floating type photovoltaic power station

ActiveCN105099342AIncrease the amount of solar radiationEasy to installPV power plantsPhotovoltaic energy generationOffshore waterModularity

The invention discloses an integral double-hull floating platform device for an offshore water-floating type photovoltaic power station. The integral double-hull floating platform device comprises a plurality of floating bodies (1) employing a modulation design, wherein the plurality of floating bodies (1) are connected to form a sheet. The integral double-hull floating platform device is characterized in that each floating body (1) comprises a floating platform (2) and a rear component support slope (3), wherein each floating platform (2) is horizontally arranged at the front part; a hollow cavity (2.1) is formed between each floating platform (2) and the corresponding rear component support slope (3); each component support slope (3) comprises two parallel hulls (3.1); and a U-shaped connecting body (3.2) is arranged at one transverse side of the two hulls (3.1). According to the integral double-hull floating platform device, the defects that the device in the prior art is adverse to modular construction of a water photovoltaic power station and does not have the feasibility for lake surfaces, reservoirs and the like with relatively large water level change are overcome; application in water areas with different latitudes and different types can be realized; and the scale effect can be realized.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

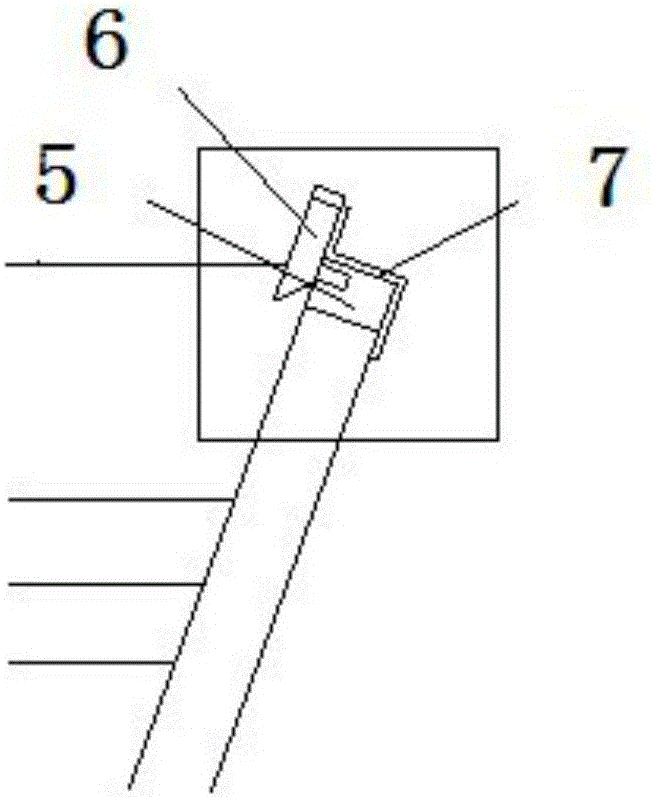

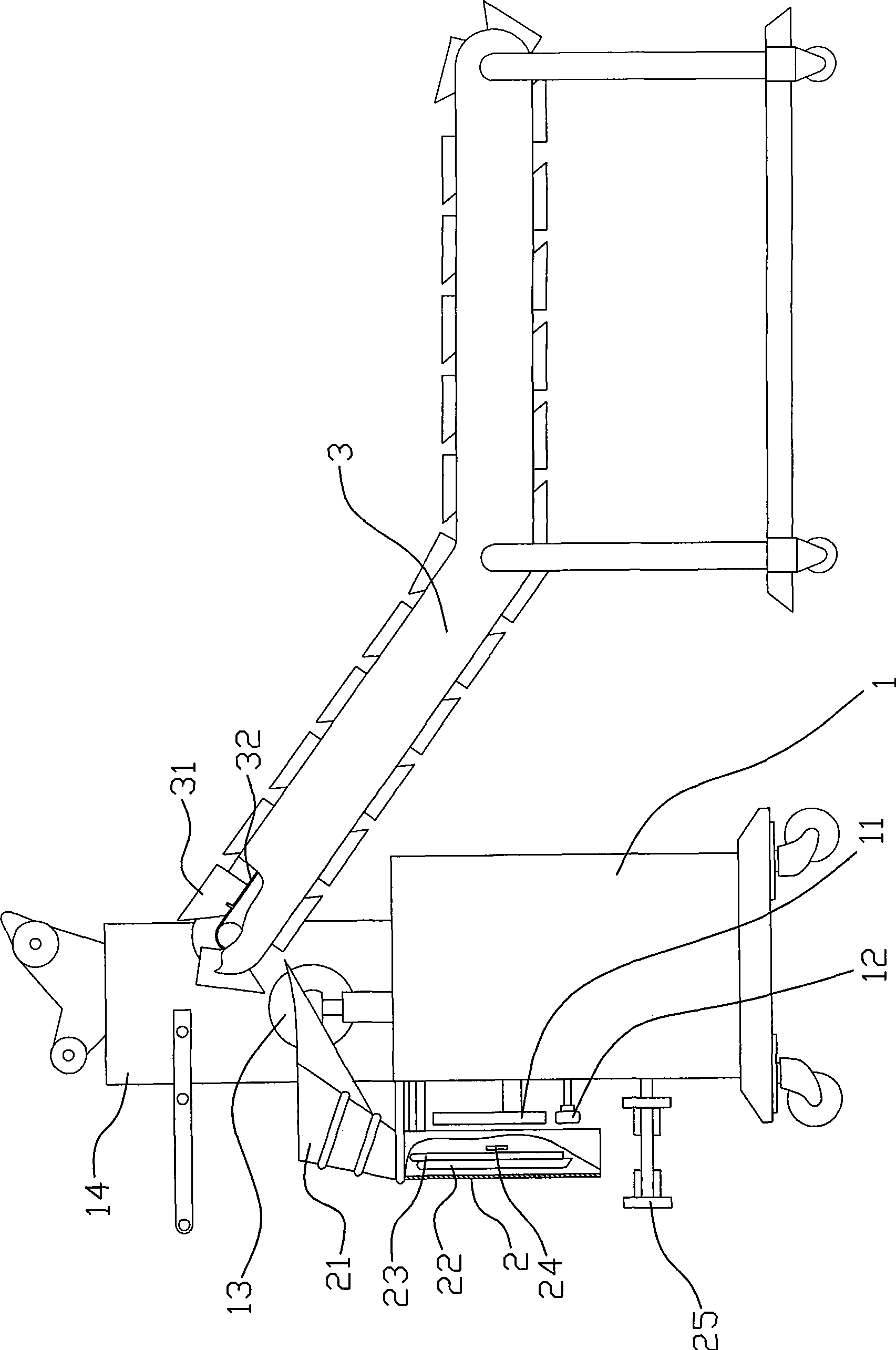

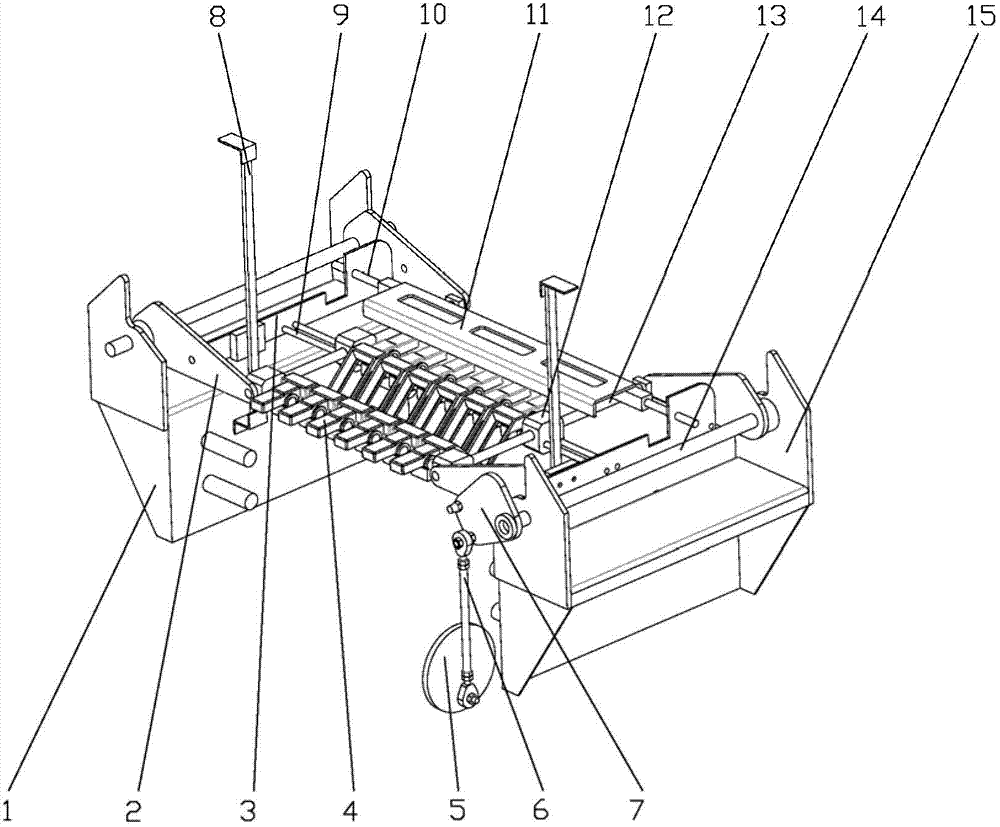

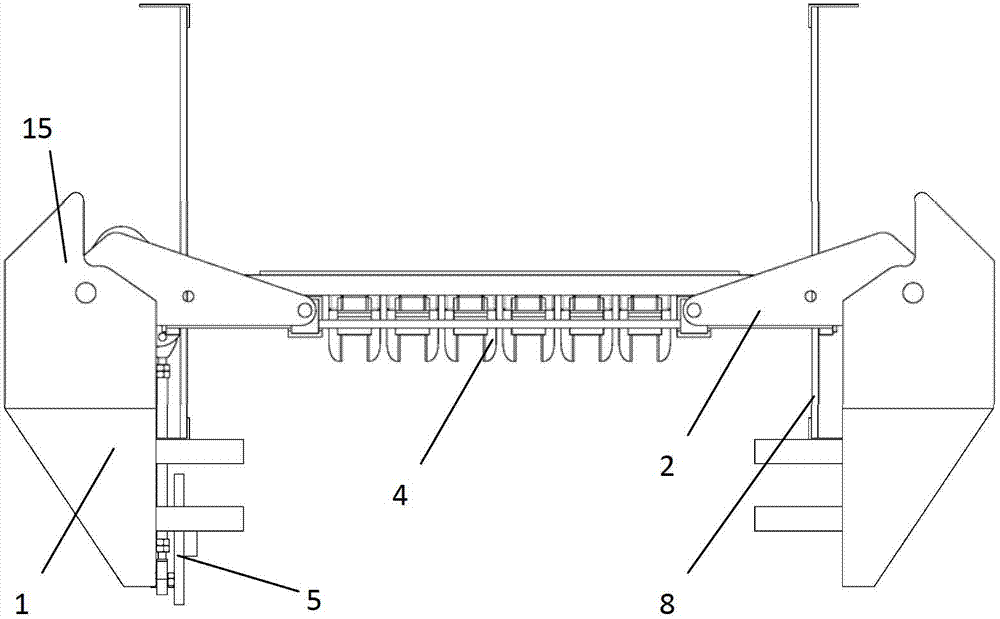

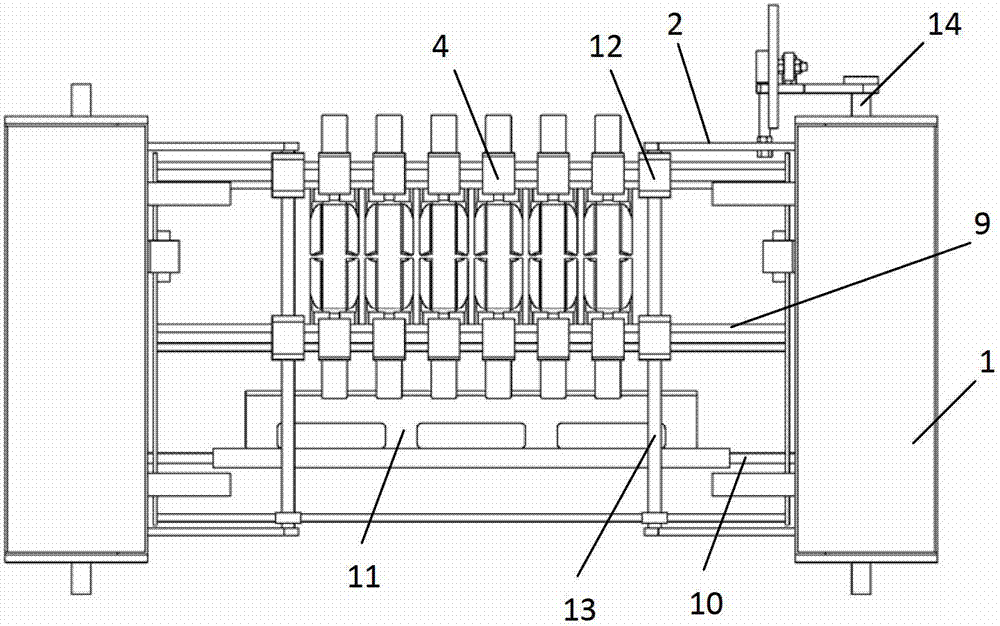

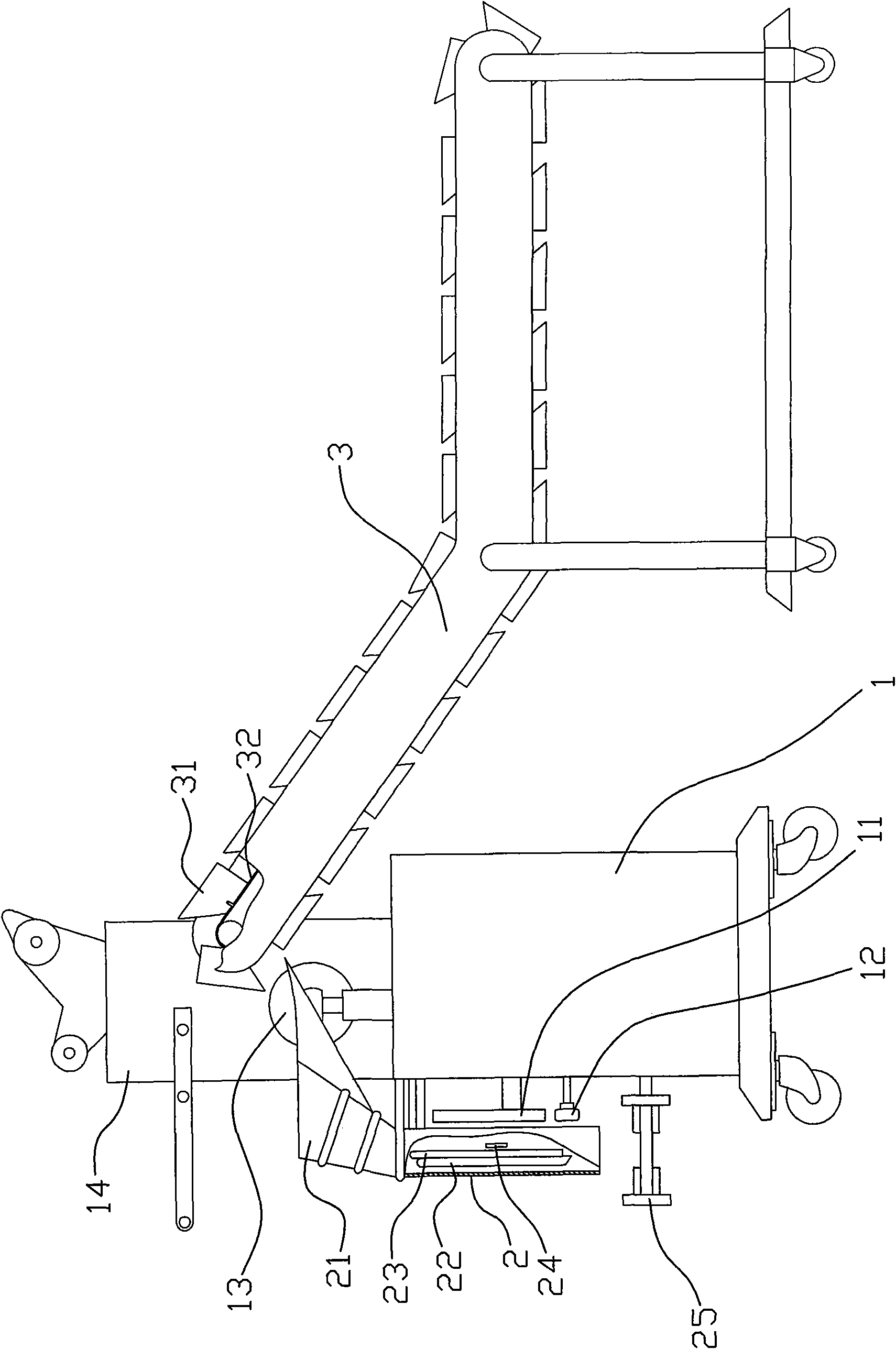

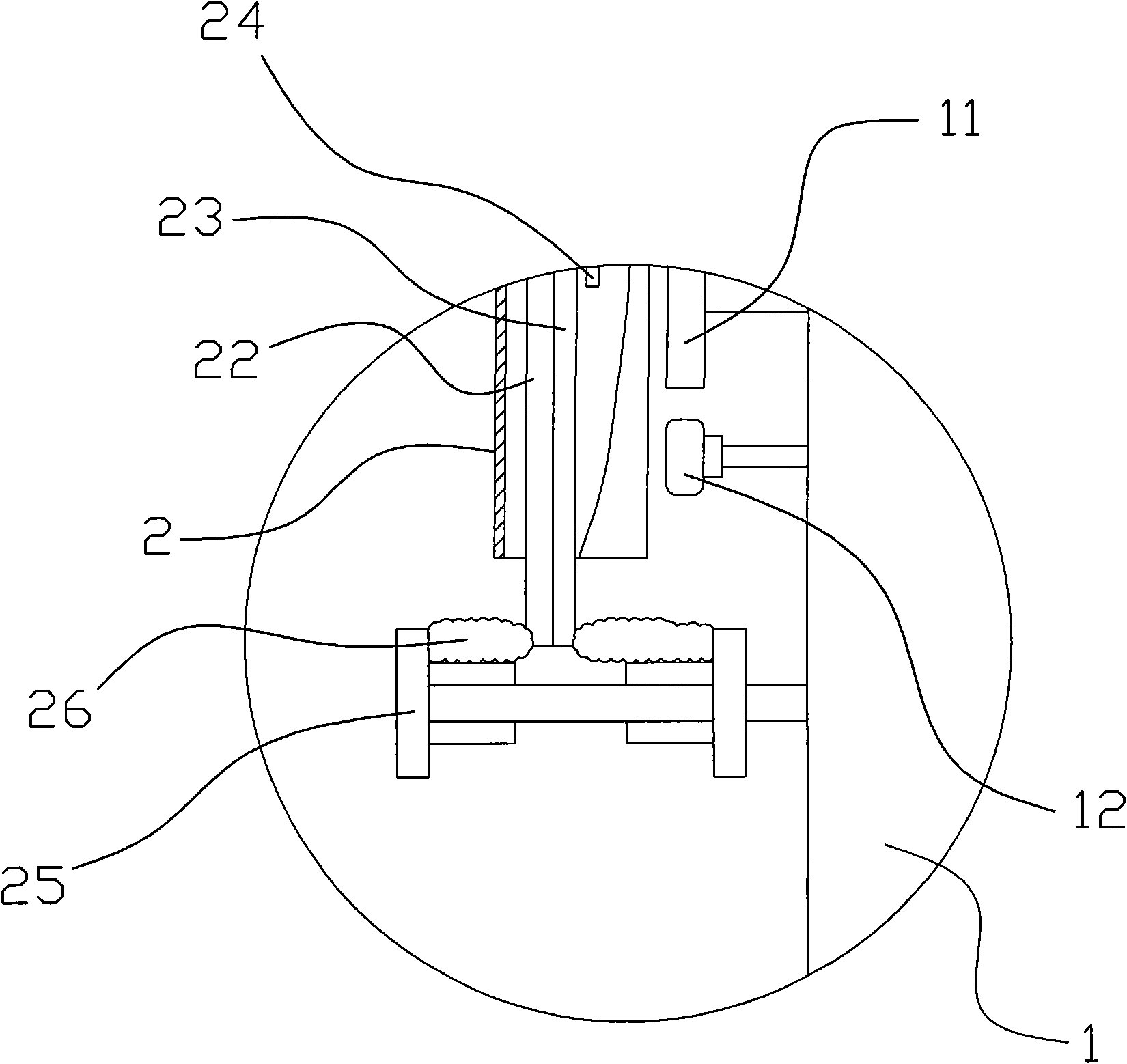

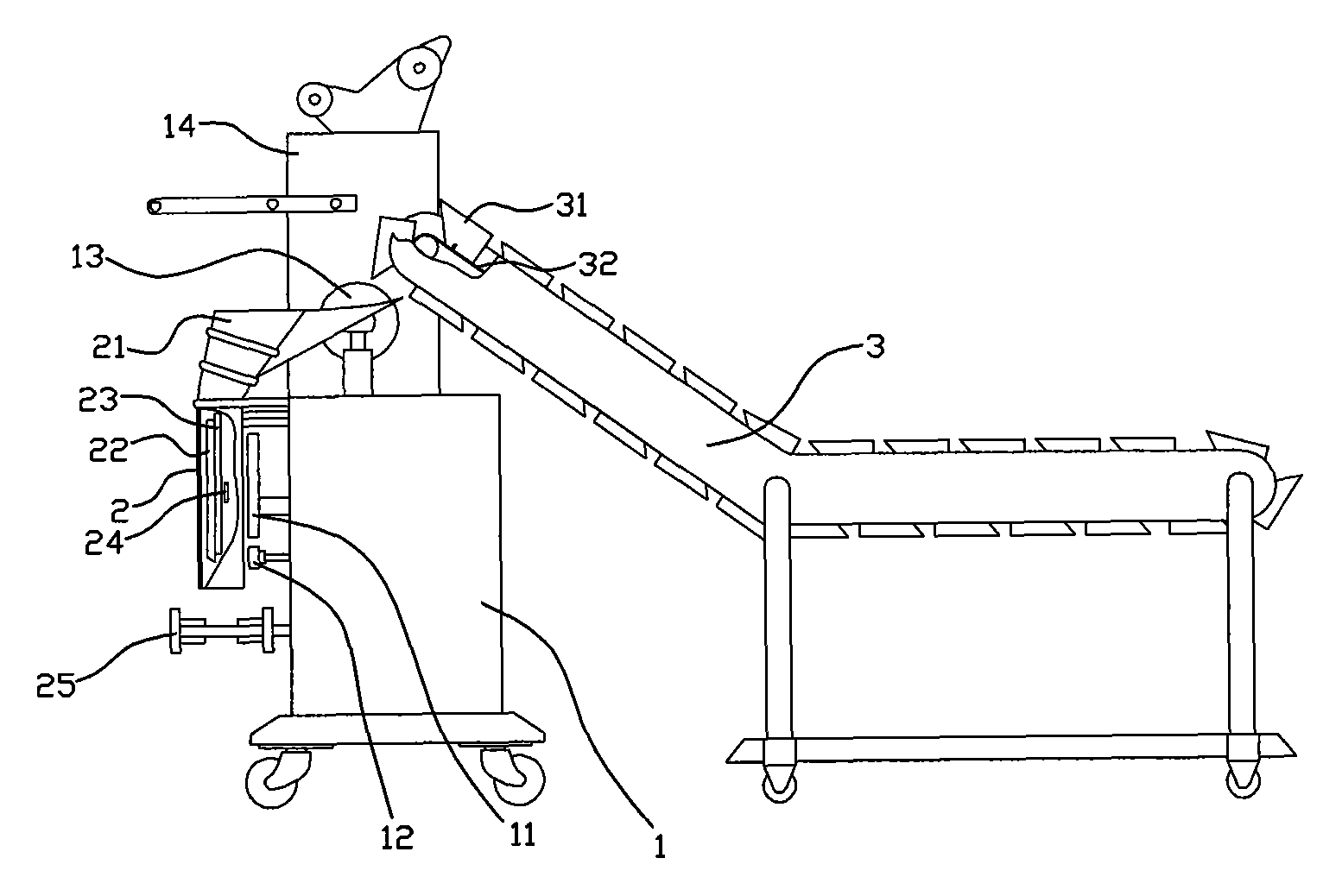

Machine for packing aquatic product into bag

InactiveCN101481022ASuitable for packagingIncrease productivityPackaging by pressurising/gasifyingPackaging automatic controlAutomatic controlWater source

The invention discloses an aquatic product bagging machine which comprises a packer host machine and a transporting device, wherein the side surface of the packer host machine is provided with a bag preparing cylinder, the inner side of the bag preparing cylinder is provided with a water injecting pipe and a gas filling pipe, the water injecting pipe is connected with an external water source, the gas filling pipe is connected with an external oxygen source, one side of the packer host machine is provided with a heater, a pair of rolling wheels is arranged below the heater in the clearance way, the shaft of the rolling wheels is connected with the host machine, one side of the packer host machine is also provided with a cutting-off machine, an operating end of the cutting-off machine is arranged on the lower end of the bag preparing cylinder in the clearance way, the packer host machine is provided with a control table, a control device arranged in the control table can automatically control the water injecting rate of the water injecting pipe and the gas filling rate of the gas filling pipe according to presetting parameters, the upper end of the bag preparing cylinder is provided with a loading hopper, and the packer host machine is connected with the transporting device which can feed the loading hopper through a driver. The invention has the advantages that the machine can continuously and quantificationally pack the aquatic products in a gas filling mode and an oxygenating mode, the packing of the aquatic product bagging machine has proper size, firm sealing and attractive bag body and is suitable for scale production, and the like.

Owner:ZHEJIANG OCEAN UNIV

Box and Lid

InactiveUS20090008391A1Easy transferFacilitate correct fittingTobacco devicesLidsEngineeringClosed state

In one embodiment of the present invention, a box including an open container and a lid for closing the open container is disclosed, the box in a closed state comprising two base surfaces, one of which consists of the bottom wall of the open container and the other of the top wall of the lid, together with at least one lateral surface, which is formed by a container side and a lid side. When the box is in the closed state the container side and the lid side at least partial overlap one another. An inward facing, inclined slide surface is furthermore arranged on the inside of the top wall of the lid in order, when closing the open container, to allow displacement of the lid into the correct closing position relative to the container. The slide surface runs along and adjacent to the lid side at an angle relative to the top wall and the lid side and is remote from the lid side.

Owner:JTI SNUS

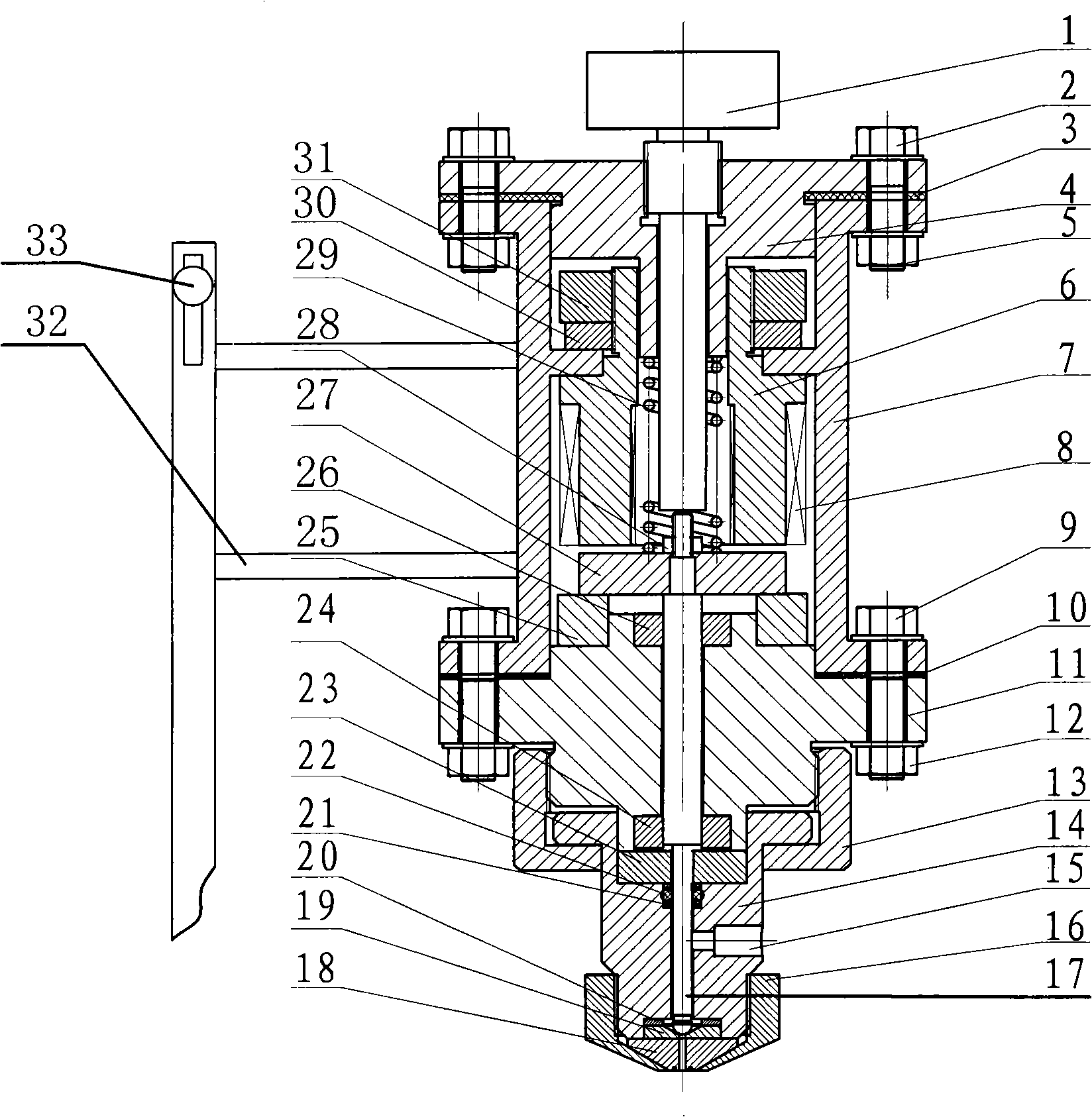

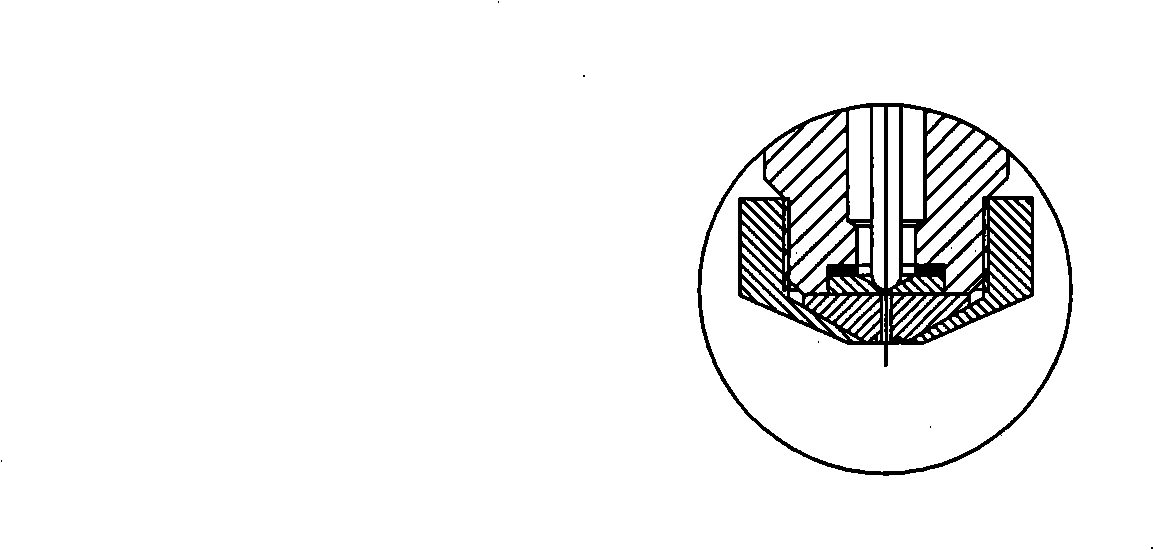

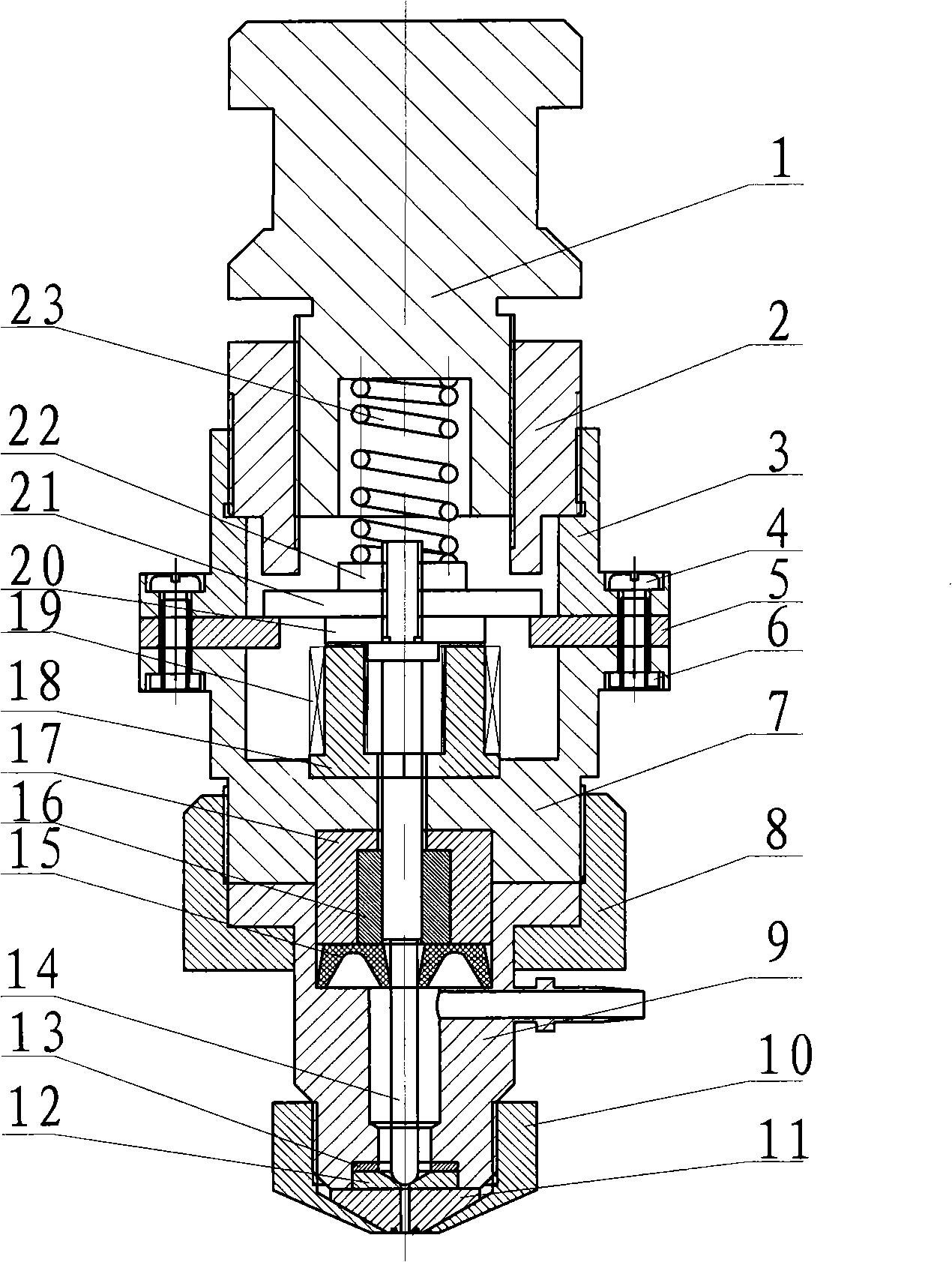

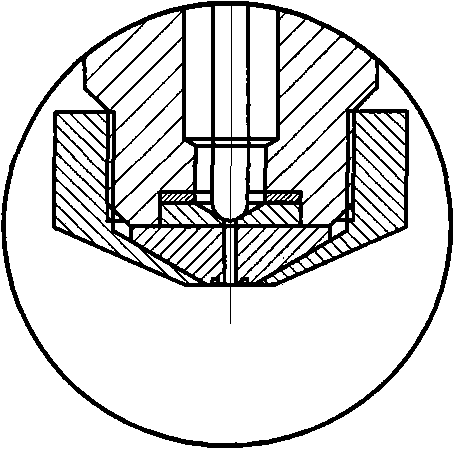

Glue solution injector driven by electromagnetic attraction

InactiveCN101279305AOvercoming the drawbacks of fragileReduced strength requirementsSemiconductor/solid-state device detailsSolid-state devicesEngineeringViscosity

A glue ejector driven by electromagnetic suction includes a nozzle, a glue cavity, a thermal cavity, a spray needle spring pretightening device, an electric magnetic body and a stroke adjusting knob. One end of the glue cavity is rotationally provided with the nozzle through the thermal cavity and the other end is connected with the lower end of the spray needle spring pretightening device through a nut; the electromagnetic body is arranged inside a housing; the top part is rotationally provided with the stroke adjusting knob and arranged below the spray needle spring pretightening device. The present invention utilizes an electromagnetic force to realize a larger drive force and adopts a chock block to remove the collision between the spray needle and the nozzle so as to improve the service life of the spray needle and realize a small-sized spray needle, thereby reaching the goal of micro-amount glue spraying and large viscosity glue spraying. The glue ejector provided by the present invention has the advantages of simple structure, convenient use, adjustable spraying speed and glue spraying amount, long service life, being suitable for industrialization manufacture, being able to replace the existing spring- pneumatic drive glue spraying system and being suitable for the sealing and packaging of micro-electric chips in particular.

Owner:CENT SOUTH UNIV

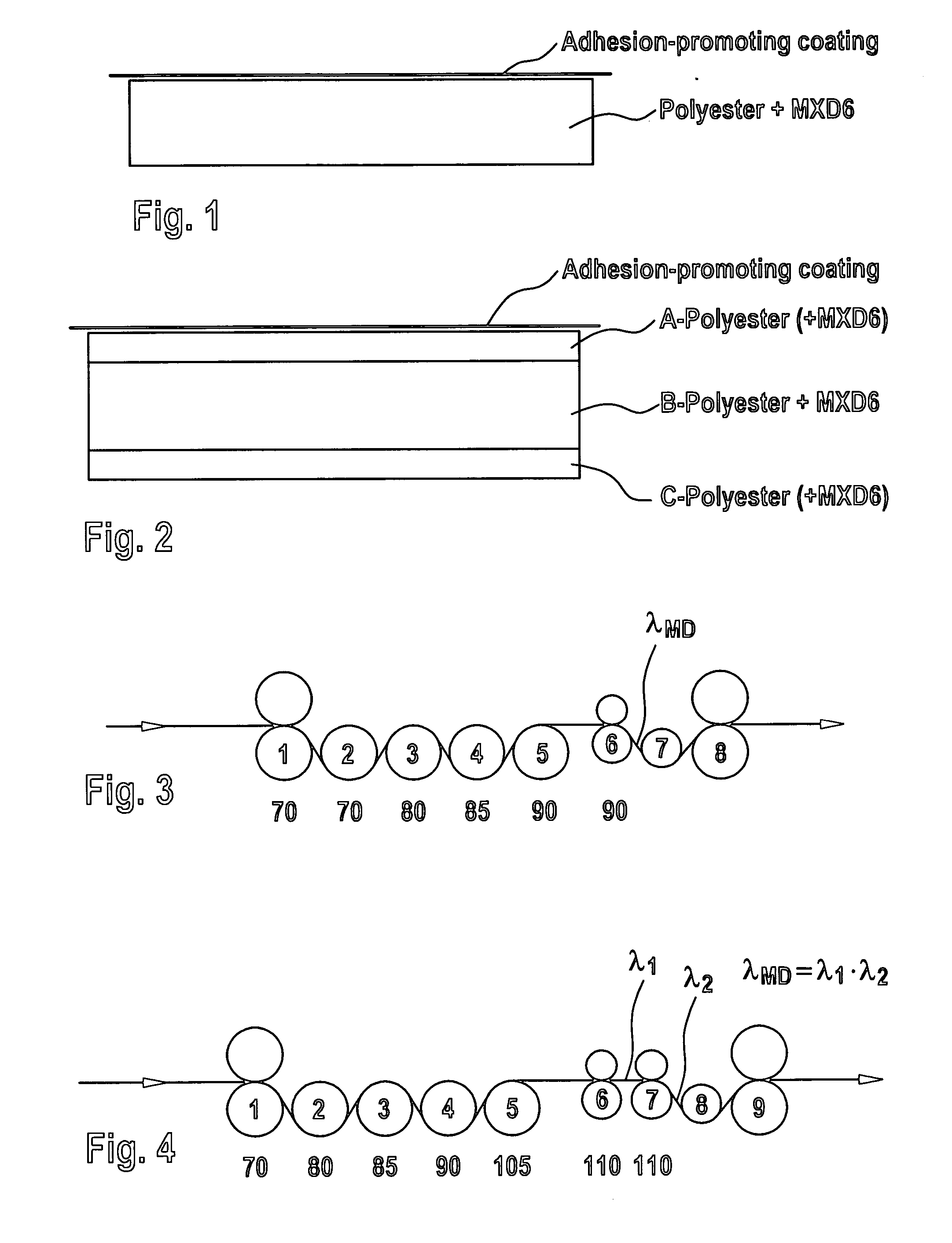

Extrusion-coatable polyester film comprising poly(m--xyleneadipamide)

InactiveUS20050287382A1Improve applicabilityImprove barrier propertiesLayered product treatmentSynthetic resin layered productsPolyesterXylylene

Polyester films which comprise not only thermoplastic polyester, e.g. polyethylene terephthalate, but also from 5 to 45% by weight of poly(m-xyleneadipamide) and optionally from 0.02 to 1% by weight of fillers, and which have, on at least one surface, an adhesion-promoting layer comprised of a hydrolyzed amino-functional silane. The films of the invention are produced by a sequential stretching process, and feature improved mechanical properties, such as a modulus of elasticity greater than 3500 N / mm2 in both orientation directions, high gloss, low haze, and very good barrier properties with respect to oxygen transmission. Films of the invention are therefore a suitable packaging material for foods and other consumable items, and as starting material for production of laminates via extrusion coating.

Owner:MITSUBISHI POLYESTER FILM

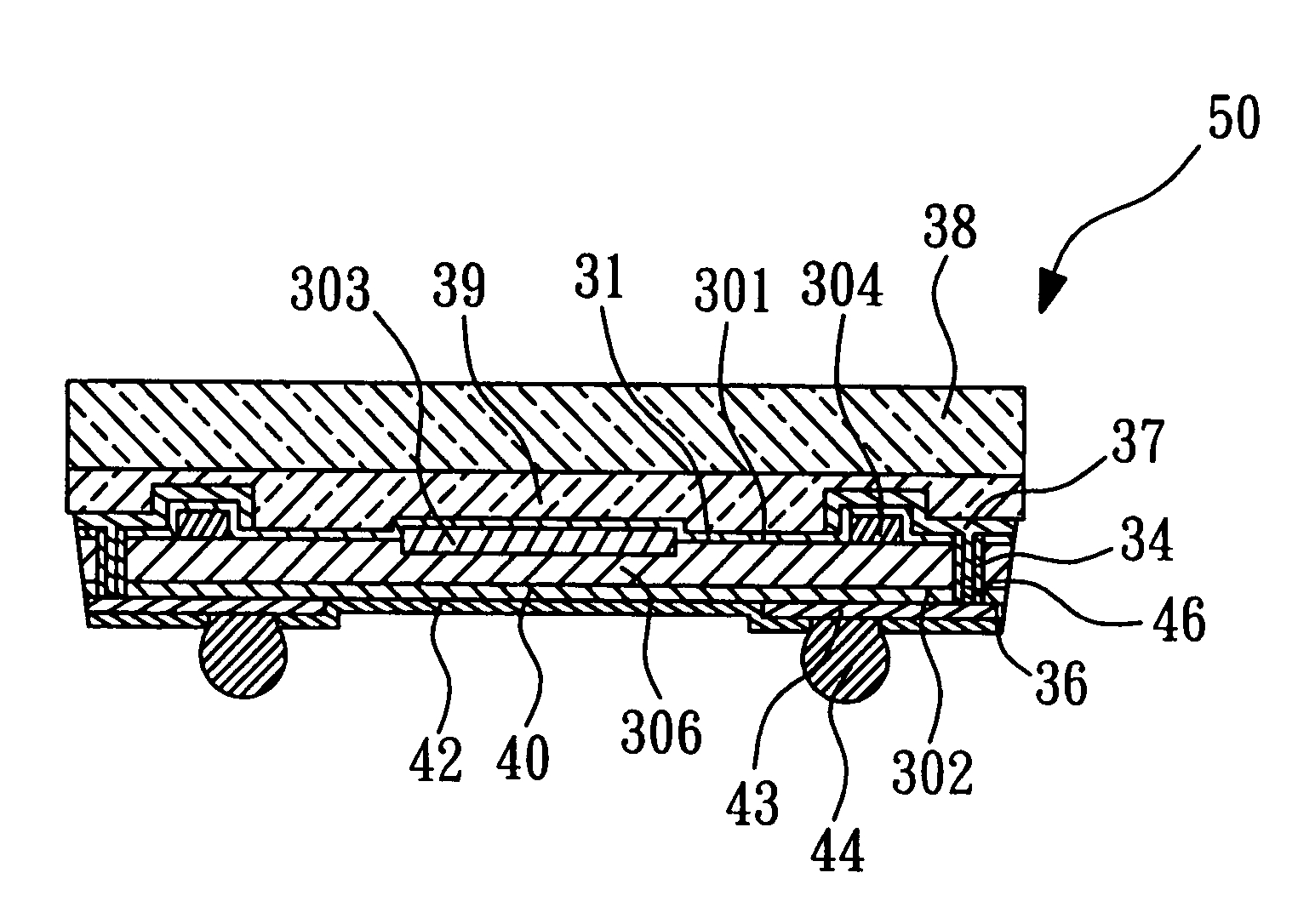

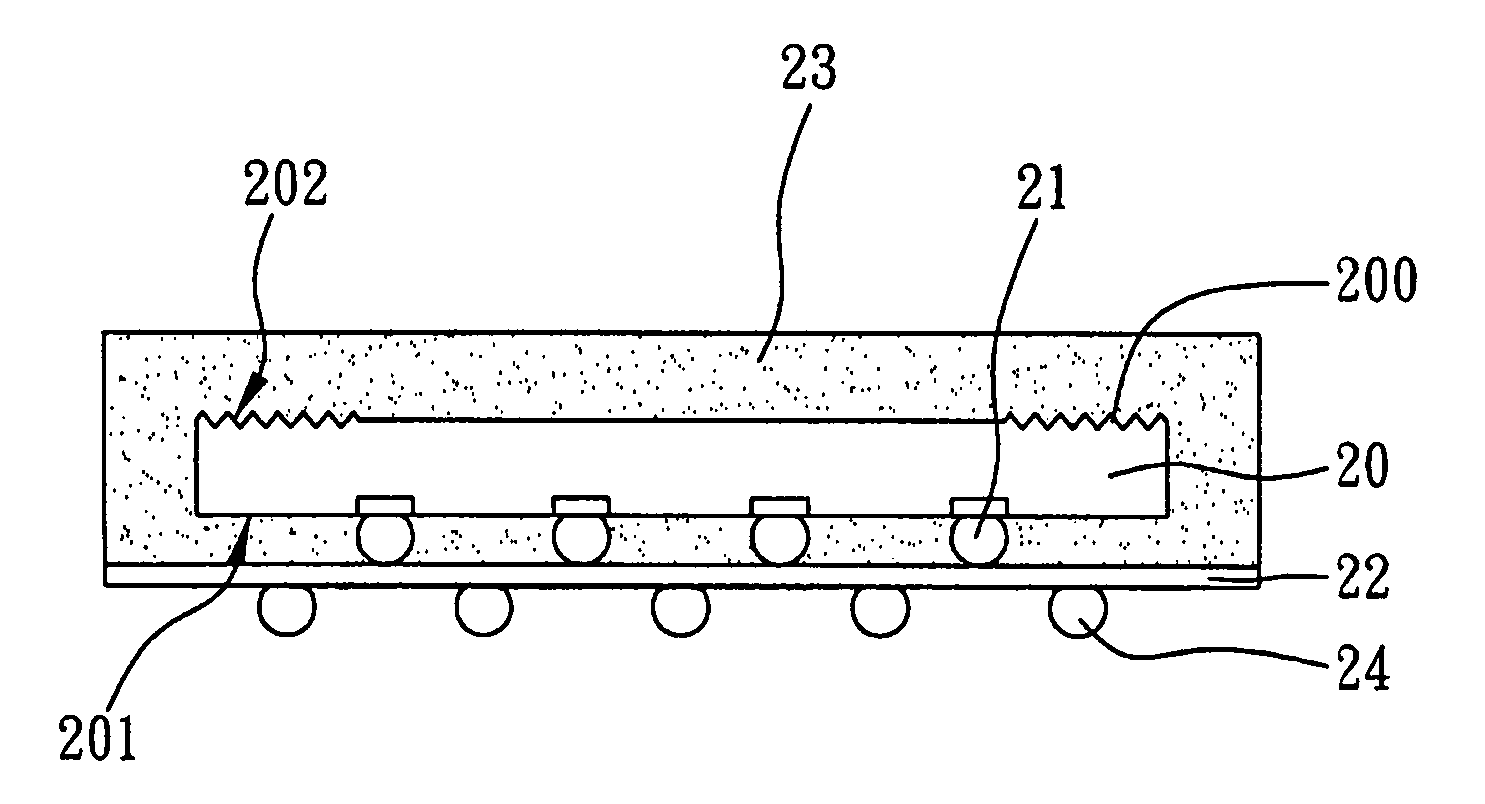

Semiconductor package having an optical device and a method of making the same

ActiveUS7229846B2Simple processSuitable for packagingSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor package

The present invention relates to a semiconductor package having an optical device and a method of making the same. The package comprises a chip, an upper metal redistribution layer, a transparent insulating layer, and a lower metal redistribution layer. The chip has an active surface, a back surface, at least one through hole, an optical device, and at least one upper pad, wherein the optical device is electrically connected to the upper pad, and the through hole is filled with a metal post. An insulating layer is disposed between the wall of the through hole and the metal post. The upper metal redistribution layer is disposed on the active surface of the chip, and is used for connecting the upper pad and the metal post. The transparent insulating layer is disposed on the active surface of the wafer. The lower metal redistribution layer is disposed on the back surface of the chip, and is connected to the metal post. Whereby, the optical device is packaged, and the manufacturing process is simplified, and the cost is reduced.

Owner:ADVANCED SEMICON ENG INC

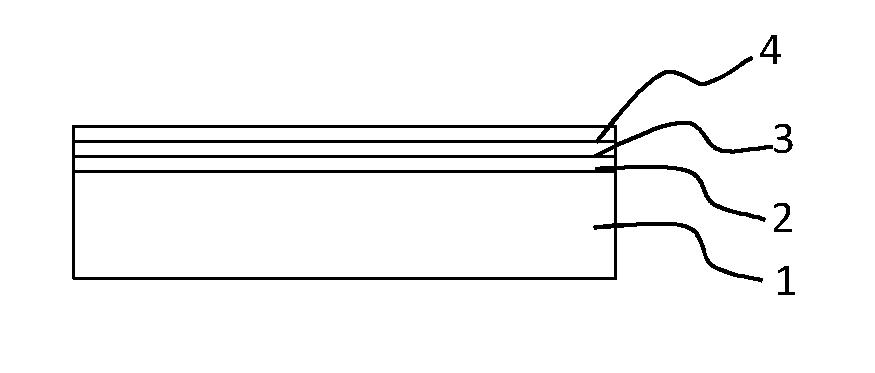

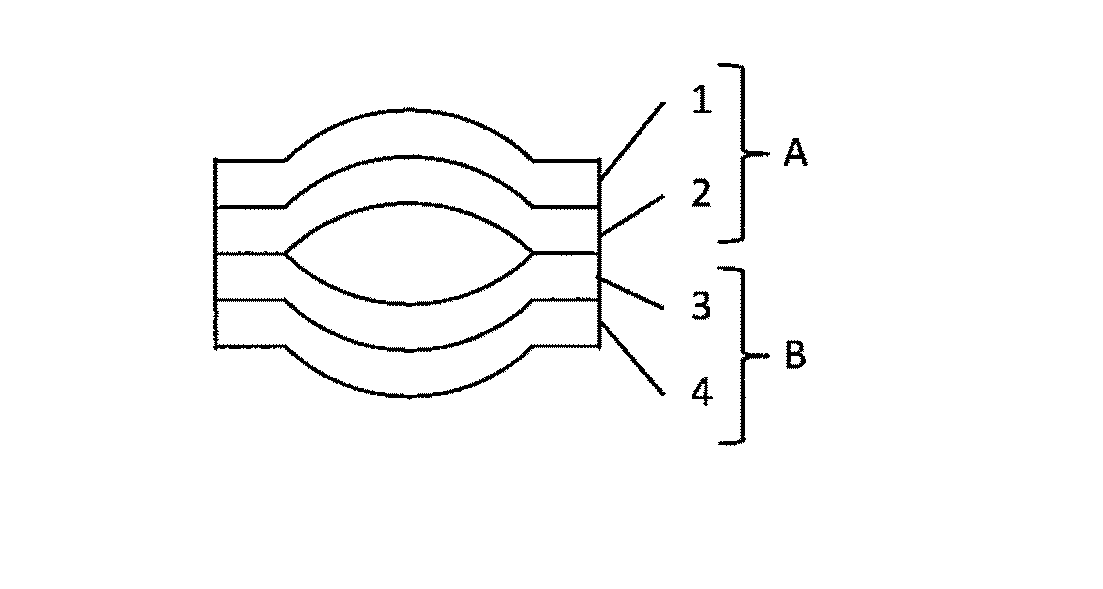

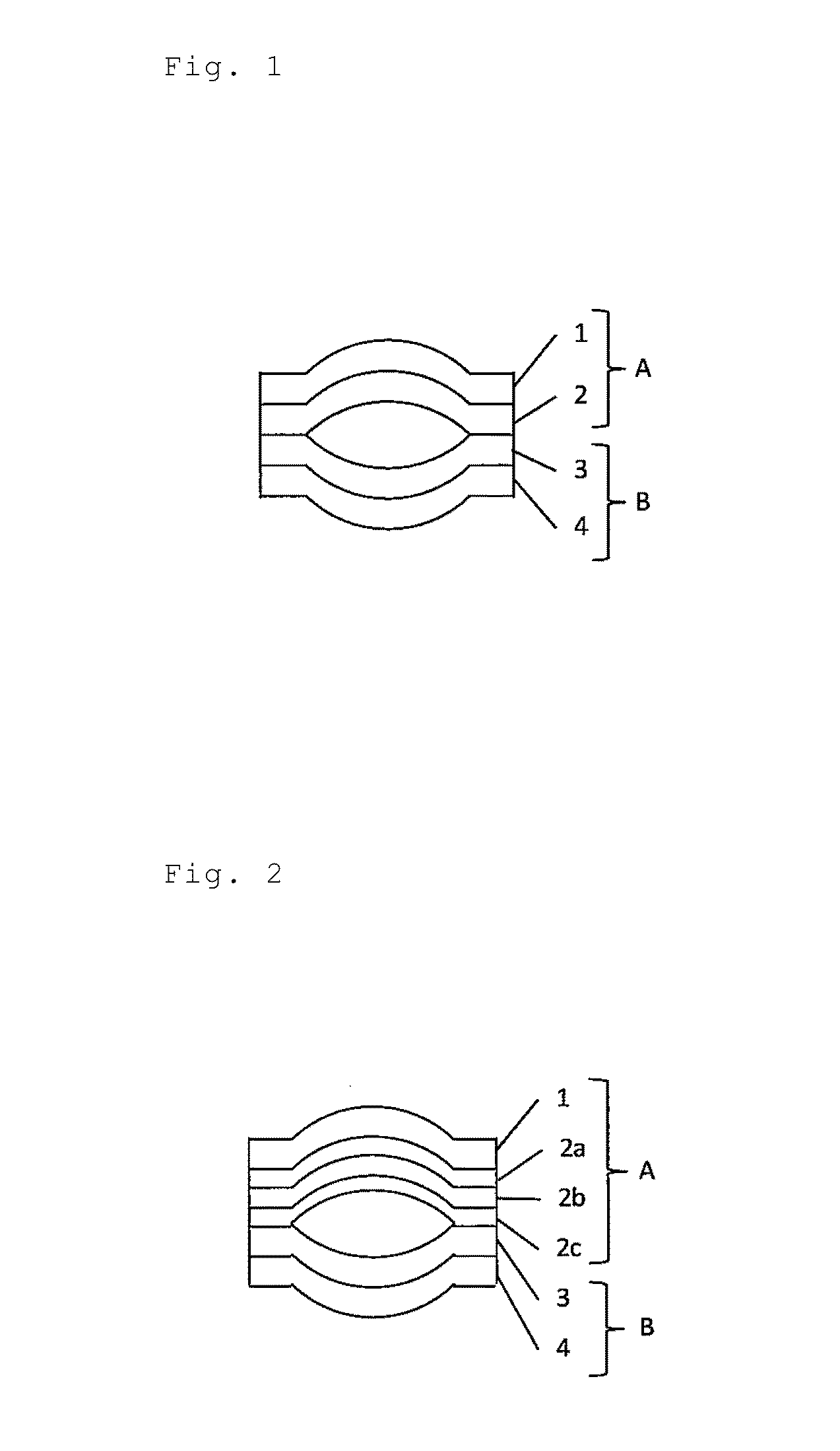

Multilayer film

InactiveUS20080081183A1Improve rigiditySuitable for packagingSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

An blow-extrudable film that ensures a reclosing ability after a first opening consists of a support layer on which a connecting layer and an overlying cover layer are arranged. The connecting layer essentially consists of a pressure sensitive hot melt adhesive. Both the support layer and the cover layer are essentially composed of polyethylene. The support layer may e.g. be made of low density and / or high density polyethylene (LD-PE respectively HD-PE). The cover layer consists of up to 100% LLD-PE (linear low density polyethylene) or of a blend of LLD-PE and polyethylene. Due to the LLD-PE content, the cover layer has a higher adhesion on the connecting layer than the support layer. In this manner it is ensured that in the first opening process, during which a portion of the support layer is separated, the connecting layer remains on the cover layer. Pressing the separated portion onto the connecting layer restores the bond between the separated portion and the film and recloses a container that is sealed by the film.

Owner:STANIPAC

A method for manufacturing a packaging material and a packaging material made by the method

ActiveUS20160376750A1Improve barrier propertiesImprove adhesionWrappersReinforcing agents additionPaperboardPolymer

The invention refers to a method to produce a packaging material comprising the steps of; treating at least one surface of a paperboard substrate with a binder and with a metal salt, printing at least a part of said treated surface with ink, and applying at least one polymer layer on said printed surface. The packaging material produced in accordance with the invention shows good printability and simultaneously good adhesion of the applied polymer layer.

Owner:STORA ENSO OYJ

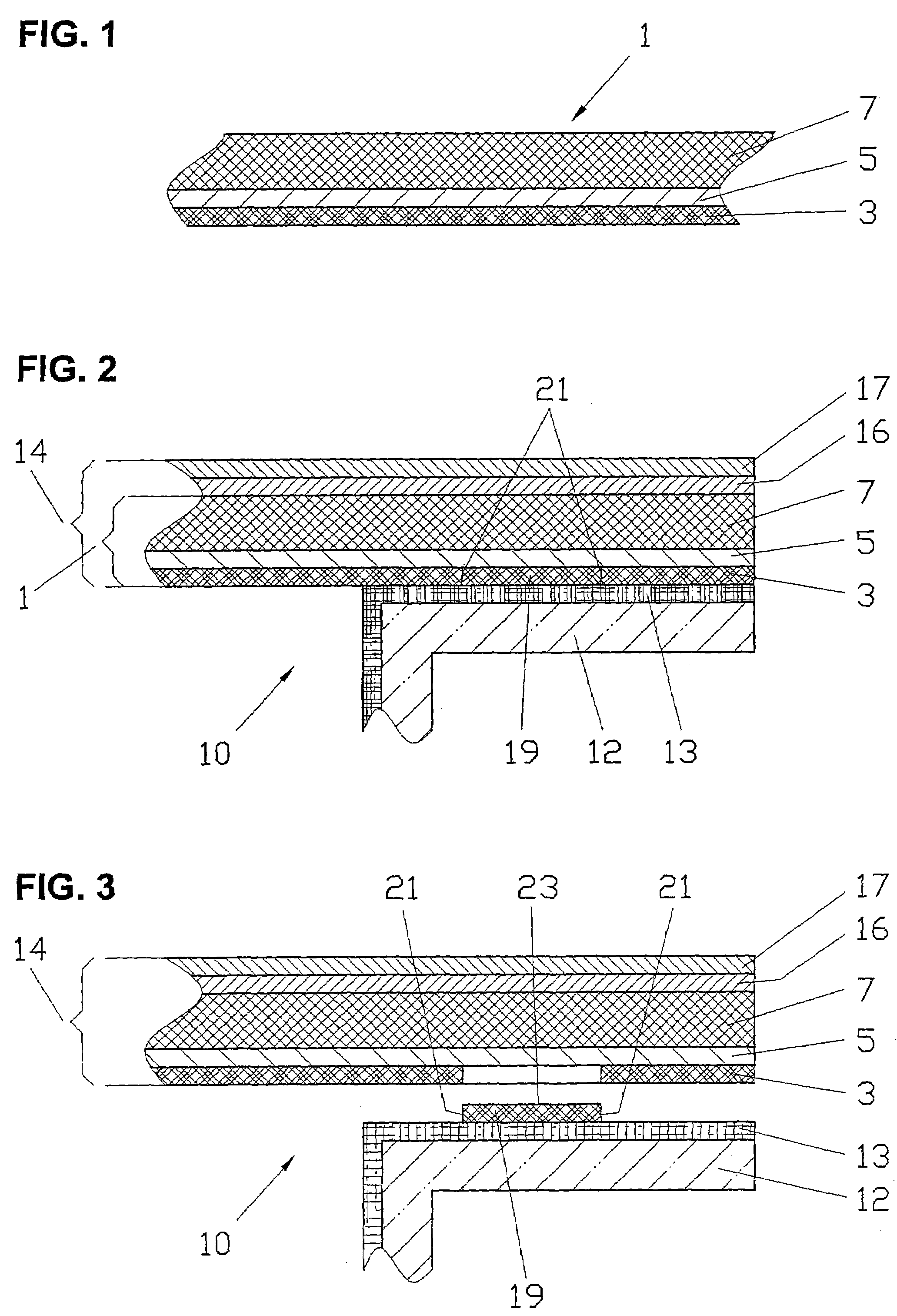

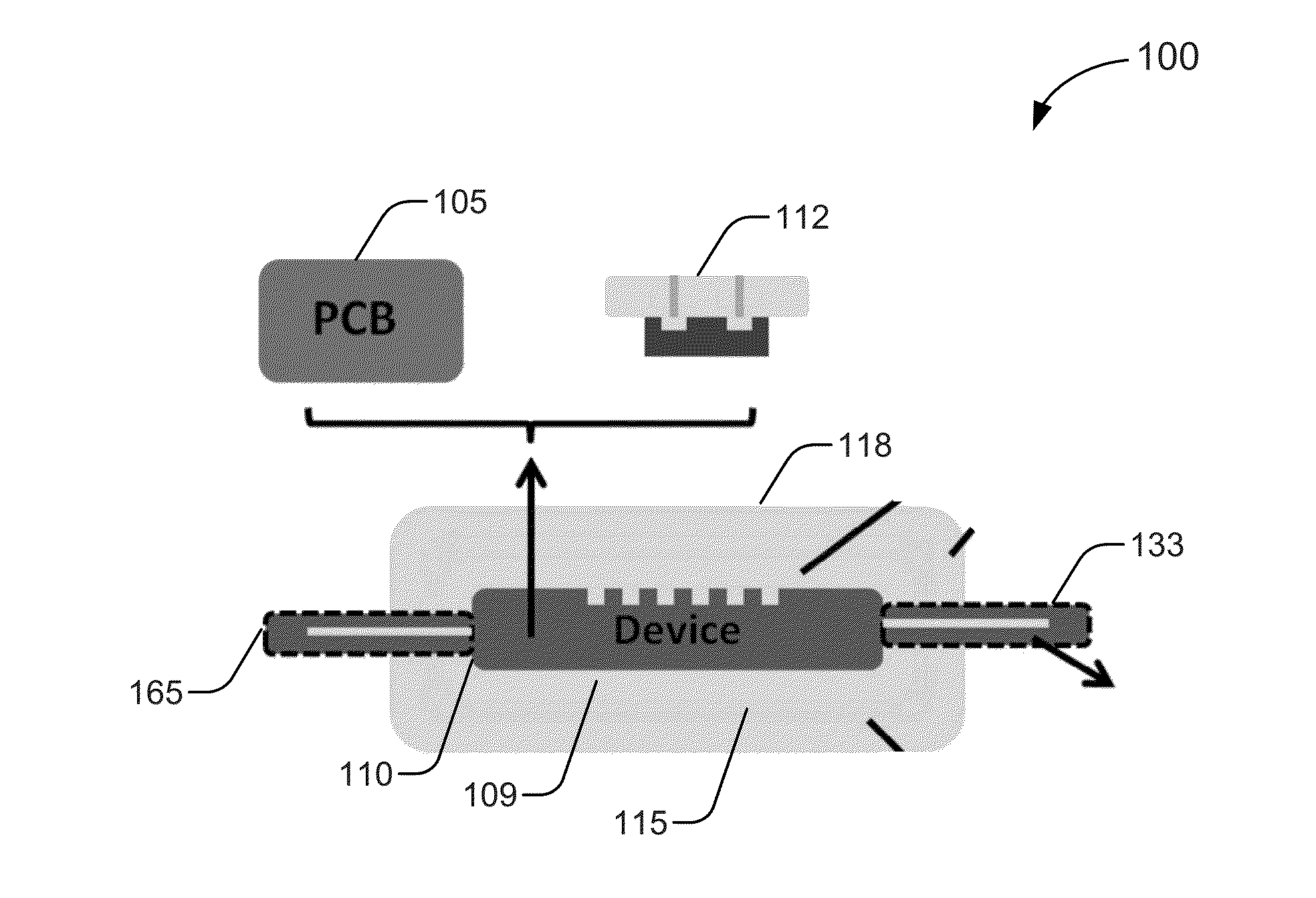

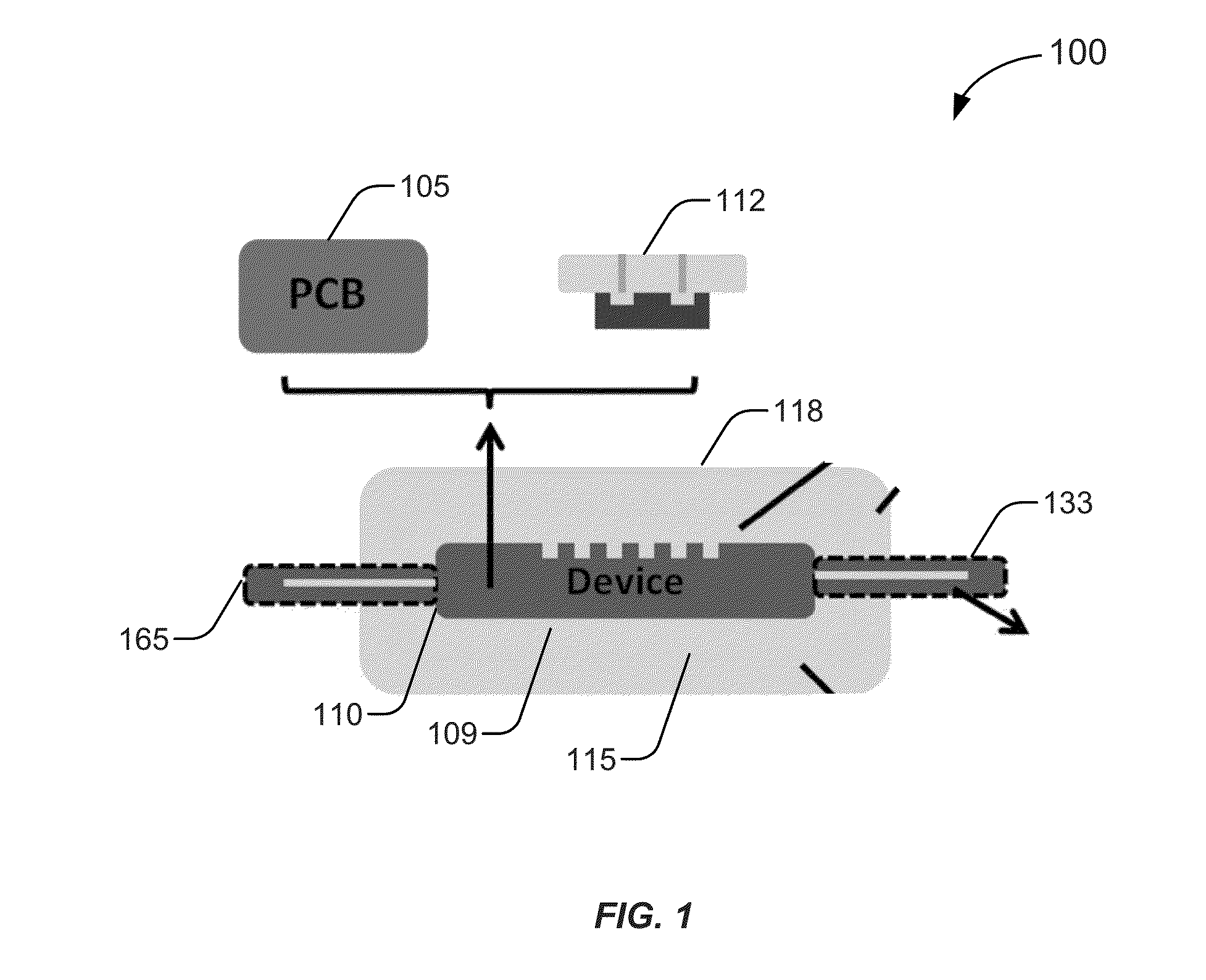

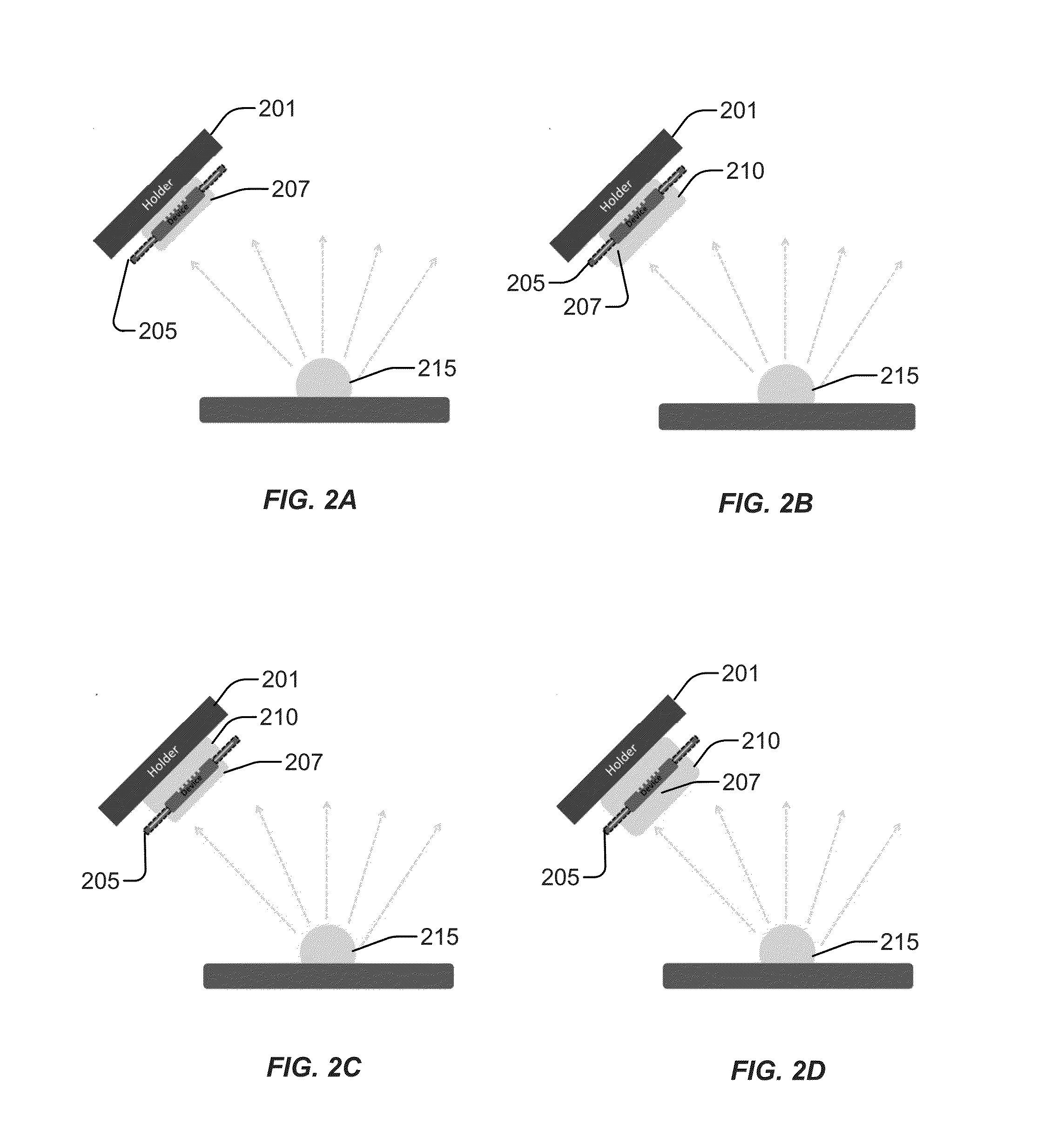

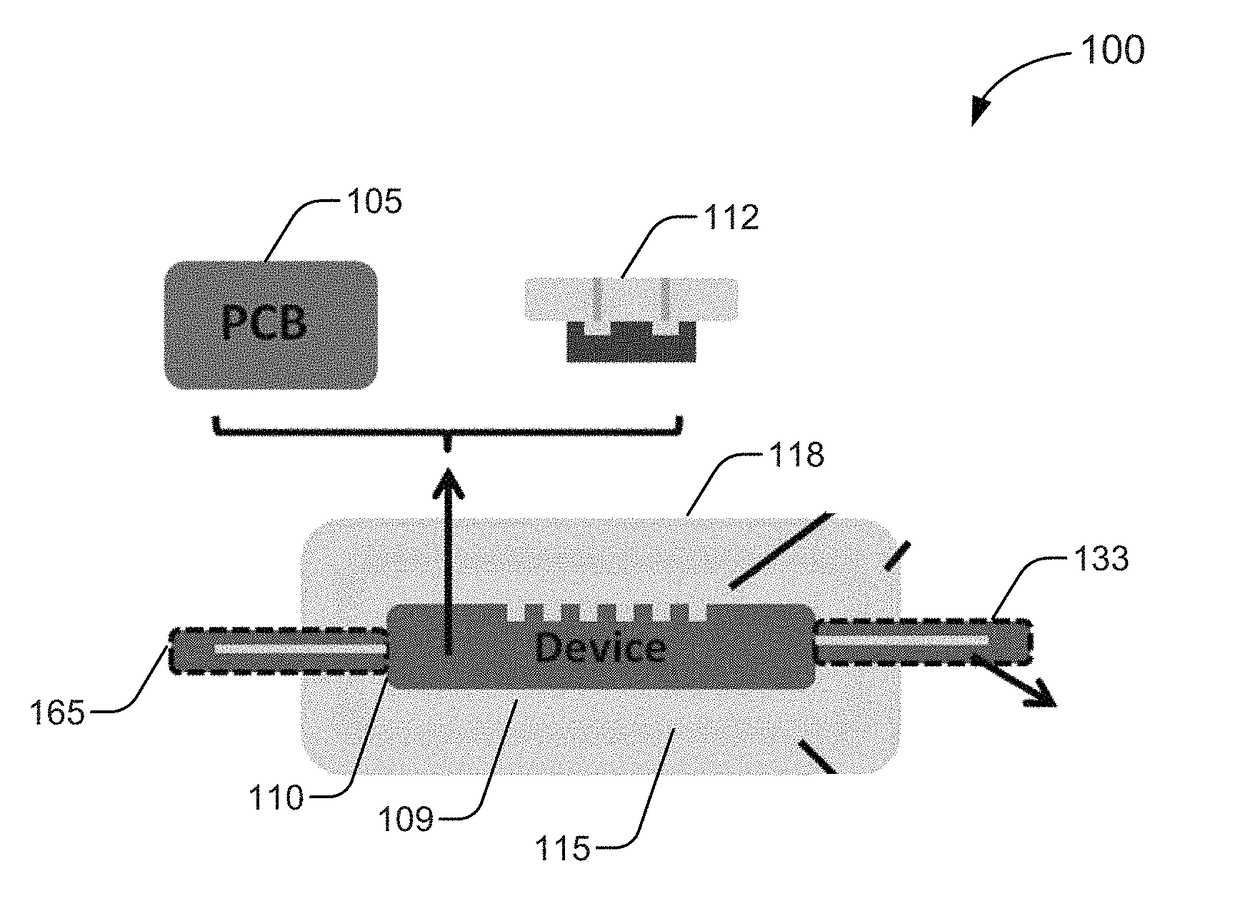

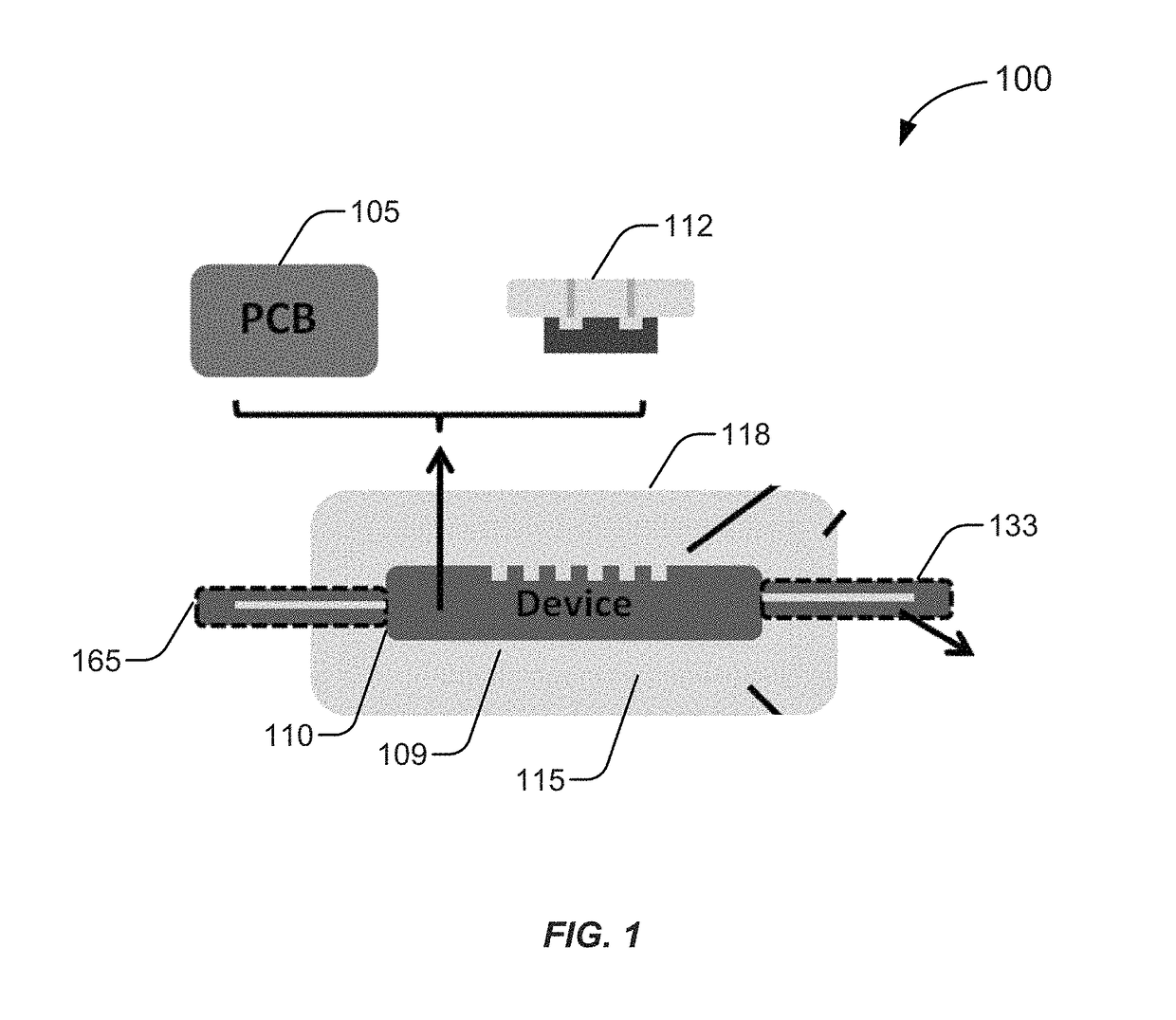

Multi-layer packaging scheme for implant electronics

ActiveUS20160133540A1Low water vapor transmission rateStay flexibleElectrotherapyEye implantsFilm-coated tabletBiomedical engineering

The present invention provides a micropackaged device comprising: a substrate for securing a device with a corrosion barrier affixed to the substrate, wherein the corrosion barrier comprises a first thin-film layer, a metal film coating the thin-film layer and a second thin-film layer to provide a sandwich layer; and optionally at least one feedthrough disposed in the substrate to permit at least one input and or at least one output line into the micropackaged device, wherein the micropackaged device is encapsulated by the corrosion barrier. Methods of producing the micropackaged device are also disclosed.

Owner:CALIFORNIA INST OF TECH

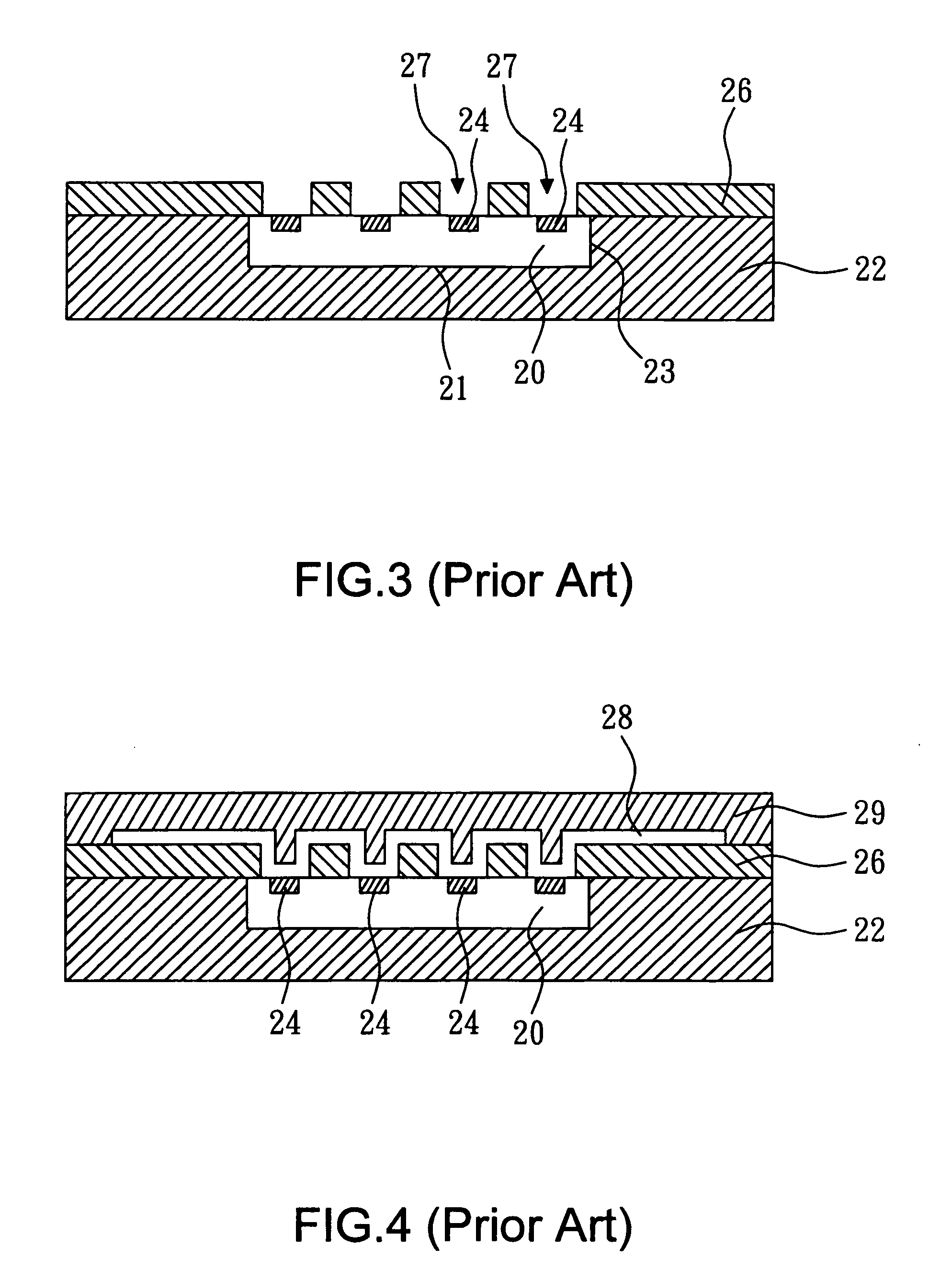

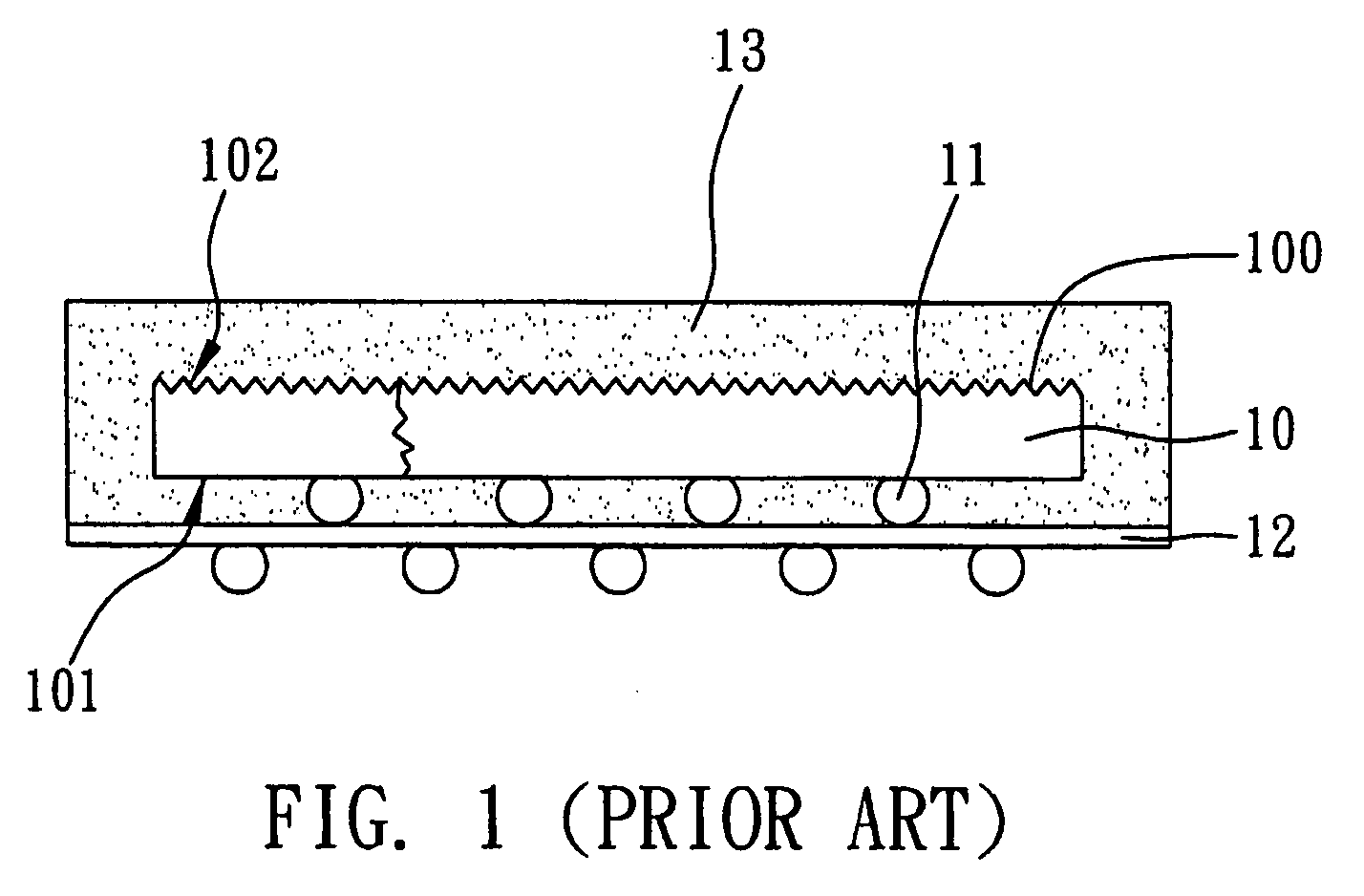

Semiconductor package and fabrication method thereof

InactiveUS8698326B2Avoid layeringAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package and a fabrication method thereof are disclosed. The fabrication method includes the steps of providing a semiconductor chip having an active surface and a non-active surface opposing to the active surface, roughening a peripheral portion of the non-active surface so as to divide the non-active surface into the peripheral portion formed with a roughened structure and a non-roughened central portion, mounting the semiconductor chip on a chip carrier via a plurality of solder bumps formed on the active surface, forming an encapsulant on the chip carrier to encapsulate the semiconductor chip. The roughened structure formed on the peripheral portion of the non-active surface of the semiconductor chip can reinforce the bonding between the semiconductor chip and the encapsulant, and the non-roughened central portion of the non-active surface of the semiconductor chip can maintain the structural strength of the semiconductor chip.

Owner:SILICONWARE PRECISION IND CO LTD

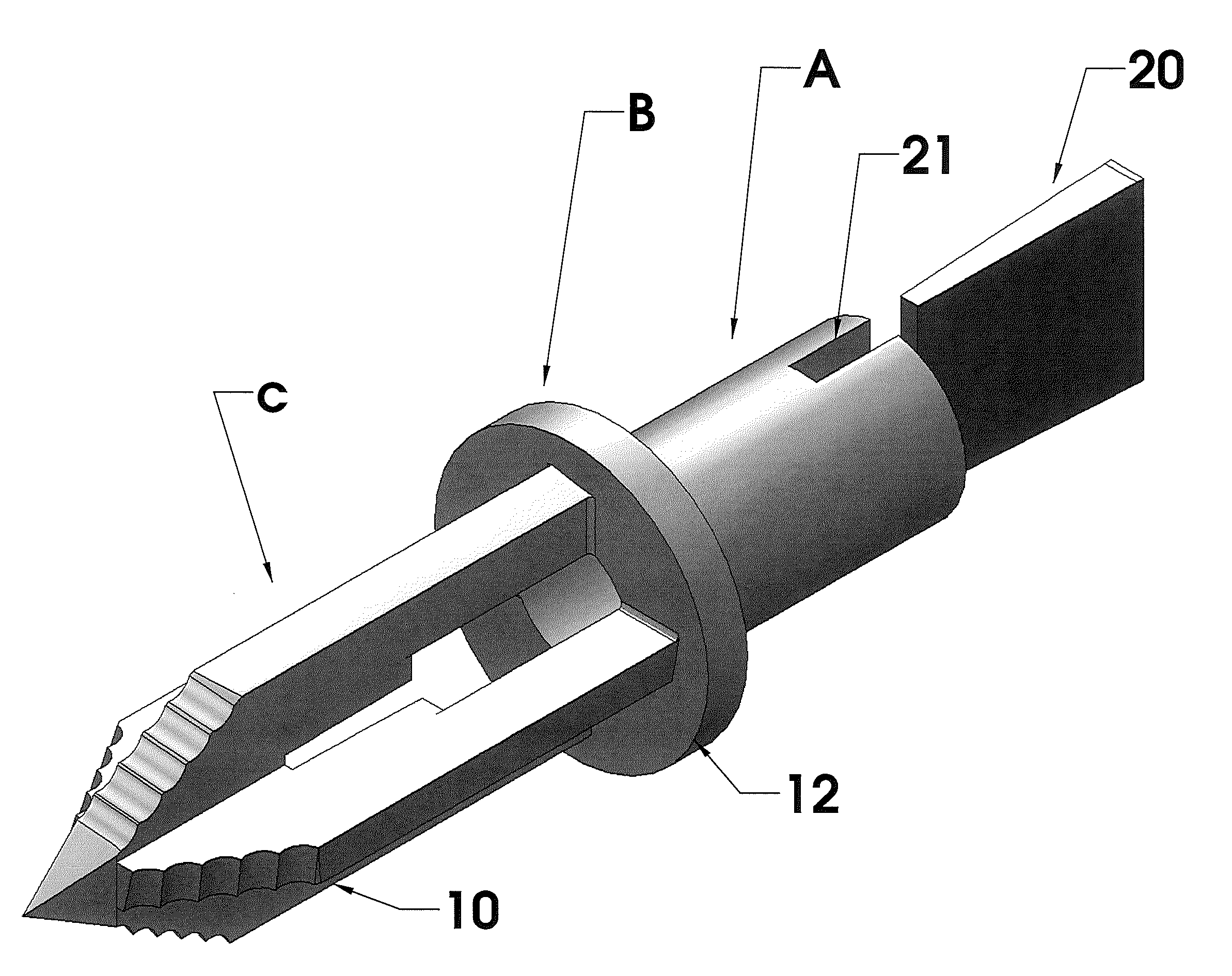

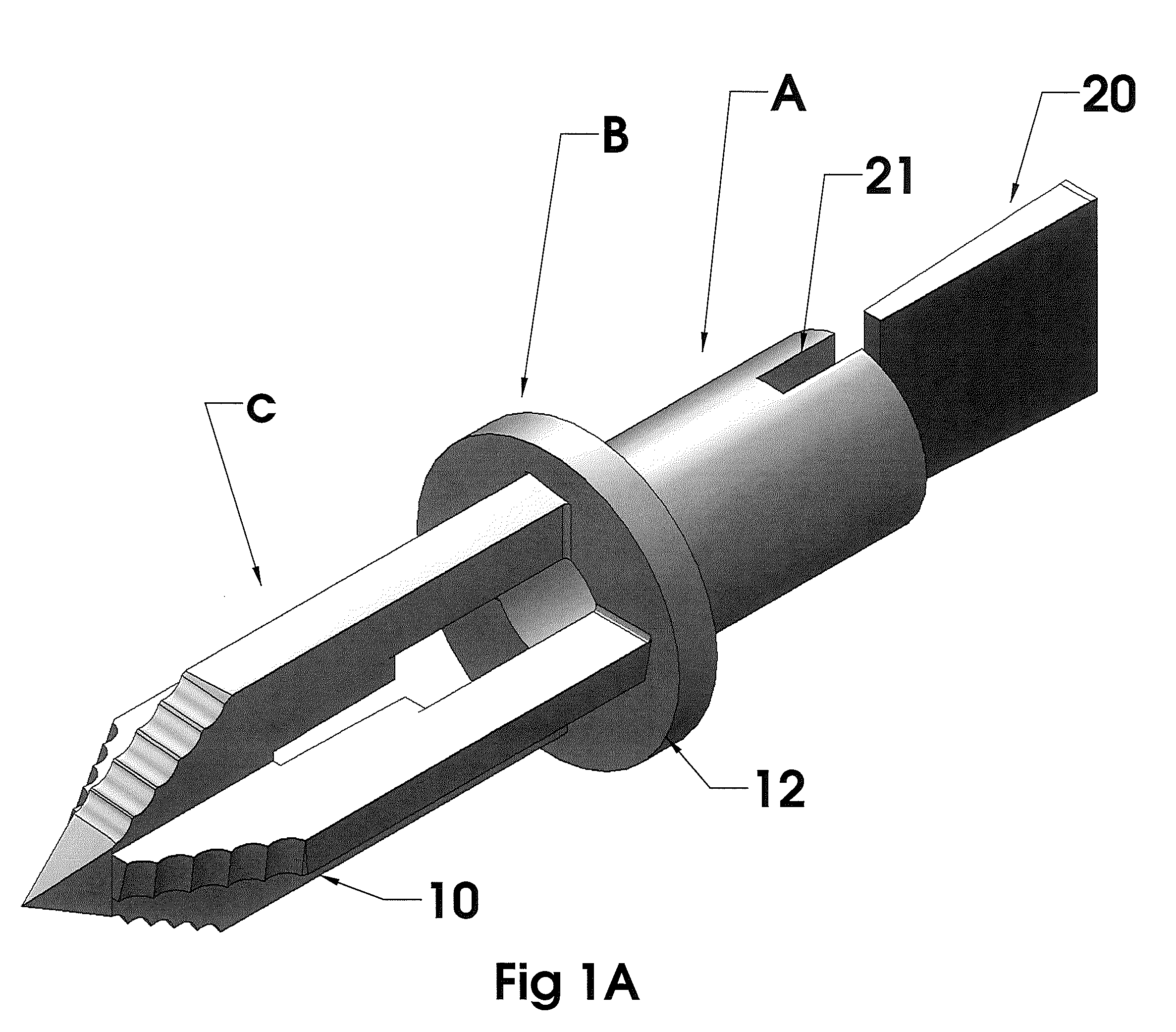

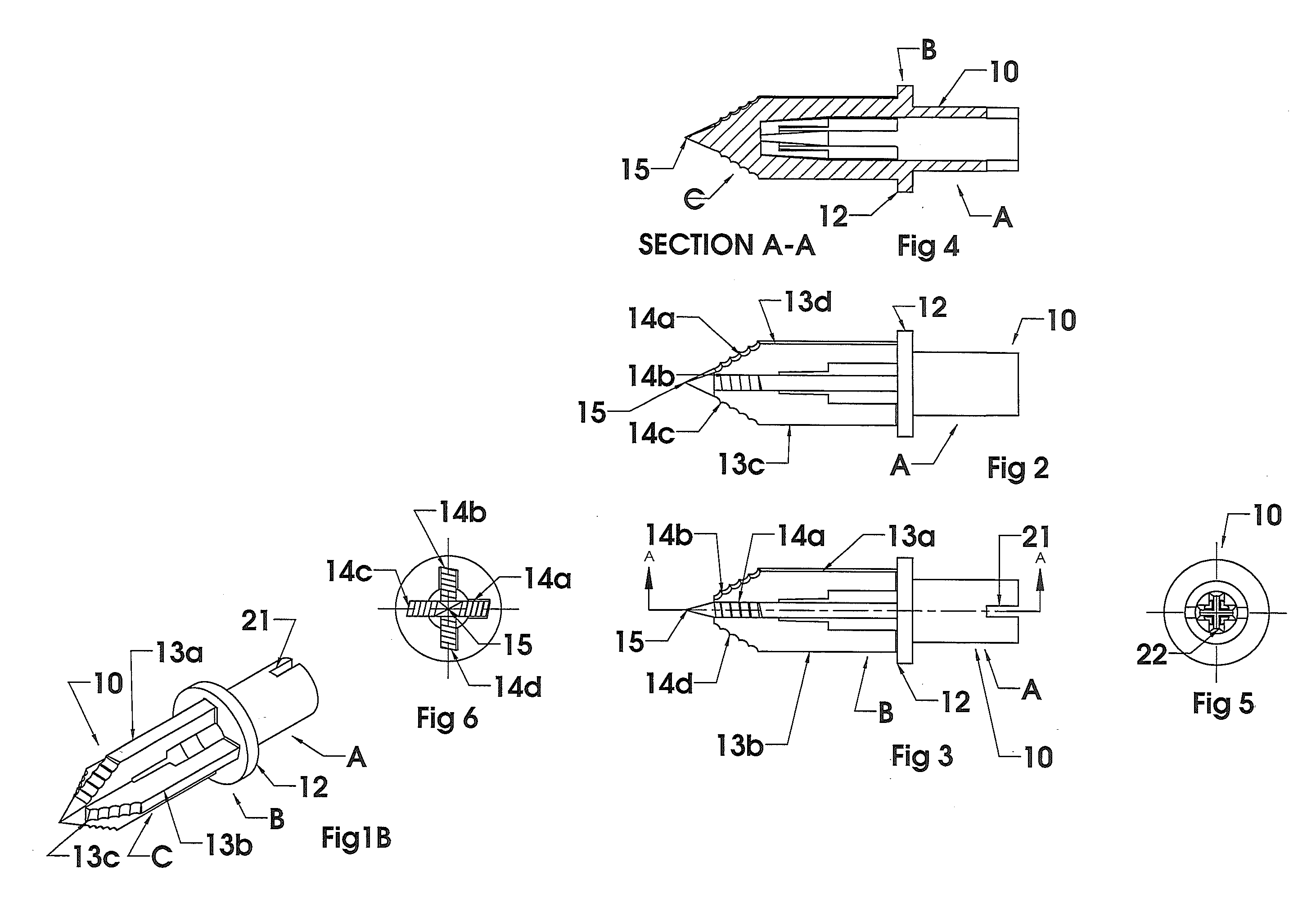

Reusable low cost drill for drywall

InactiveUS20110262235A1Low costStable and precise in perpendicular hole formationThread cutting machinesThread cutting auxillary apparatusDrill bitDrywall

Owner:GARFIELD THEODORE F +1

Fill-finish process for peptide solutions

ActiveUS10793307B2Suitable for packagingPeptide/protein ingredientsPackage sterilisationProcess engineeringOrganic chemistry

Owner:3 D MATRIX

Hygroscopic packaging container

ActiveUS20160221292A1Efficiently and rapidly absorbInhibit deteriorationFlexible coversWrappersEngineeringMoisture absorption

Provided is a hygroscopic packaging container which eliminates the necessity of filling a moisture absorbent and which has satisfactory working efficiency and is highly effective in moisture absorption. The hygroscopic packaging container is obtained from two gas-barrier multilayer films each comprising a gas-barrier layer and a heat-sealable layer, by stacking the gas-barrier multilayer films so that the surface of one of the heat-sealable layers overlies that of the other and heat-sealing the peripheral parts of the layers, at least one heat- sealable layer of the two gas-barrier multilayer films being a hygroscopic heat-sealable layer.

Owner:DAI NIPPON PRINTING CO LTD

Glue solution injector driven by electromagnetic expulsive force

InactiveCN101279306AControl clearanceAvoid collisionSemiconductor/solid-state device detailsSolid-state devicesReciprocating motionEngineering

A glue ejector driven based on electromagnetic expulsive force comprises a nozzle, a spray needle, a glue cavity, a thermal cavity, a spray needle spring pretightening device and an electromagnetic body. The pray needle spring pretightening device comprises a pretightening force adjusting knob, a stroke regulating knob and a pretightening spring; the electromagnetic body comprises an upper connection body, a location chock block, a lower connection body, a magnet core, a loop, a gag bit, an adjustable baffle and a pretightening nut; the invention leads an electromagnet and the gag bit to exclude mutually by controlling the galvanizing voltage of the electromagnet to drive the spray needle to move upwards and compress the spring, then the spray needle restores under the action of the spring; thereby leading the spray needle to reciprocate, so as to reach the aim of spraying glue. The glue ejector of the invention has the advantages of simple structure, convenient use, adjustable spraying speed and glue spraying amount, long service life, which is suitable for industrialization manufacture, is capable of replacing the existing spring-pneumatic drive glue spraying system and is suitable for the sealing and packaging of micro-electric chips in particular.

Owner:CENT SOUTH UNIV

Elastomer composition, water-crosslinkable elastomer composition, and method for producing elastomer composition

There is provided an elastomer composition which can be molded like a thermoplastic resin by using a conventional plastics processing equipment, and has a very small compression set like a vulcanized rubber. The elastomer composition comprises: 100 parts by mass of an ethylene / α-olefin copolymer (A); 10 to 150 parts by mass of a propylene-based resin (B); and 5 to 150 parts by mass of a non-aromatic softener for rubber (C); 0.03 to 1 parts by mass of an organic peroxide (D); 0.5 to 7 parts by mass of a silane coupling agent (E); 0 to 2 parts by mass of a crosslinking aid (F); and 0 to 100 parts by mass of an inorganic filler (G).

Owner:RIKEN TECHNOS CORP

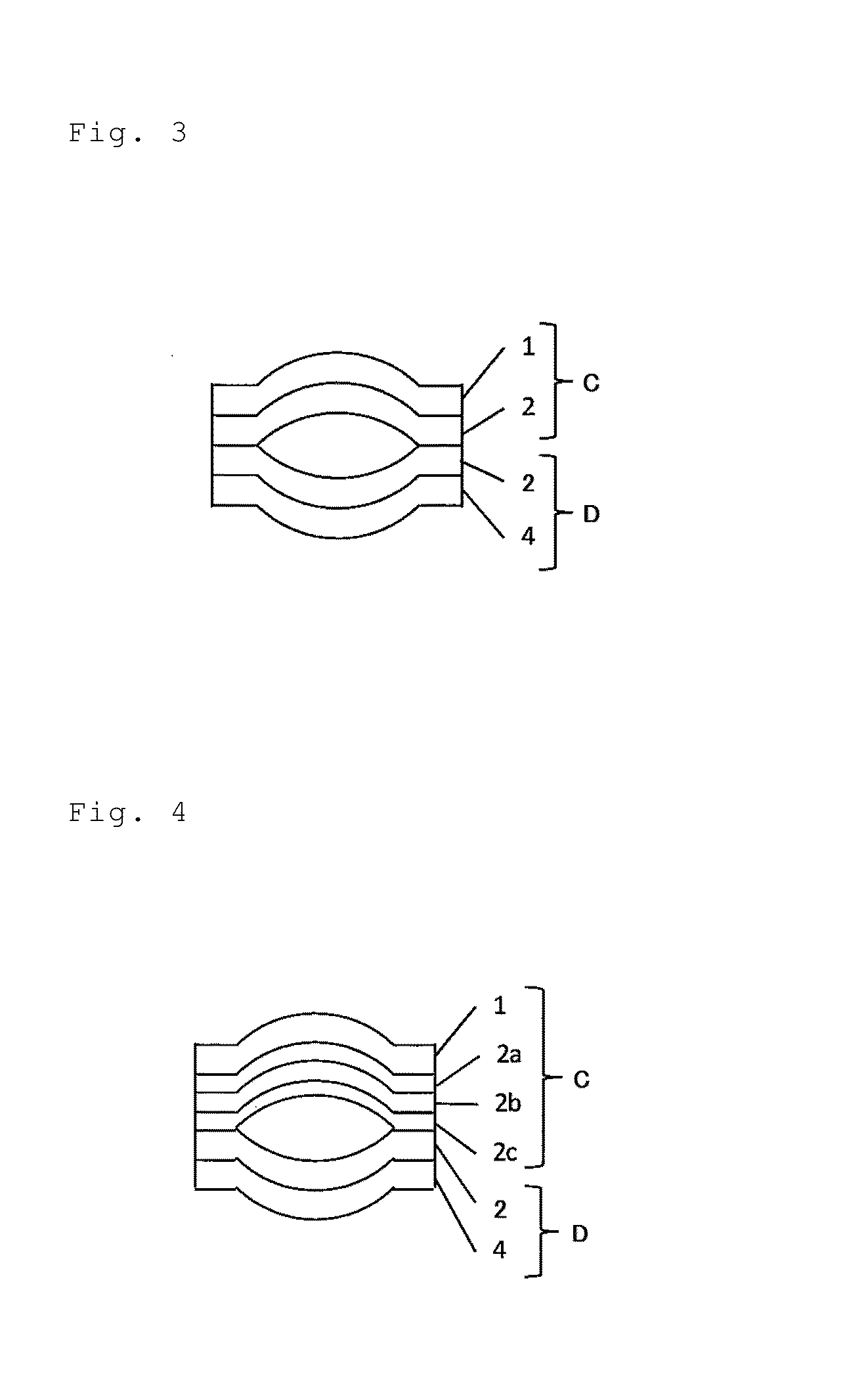

Multilayer, biaxially oriented polyester film, process for its production and its use

InactiveUS6962740B2Guaranteed reuseSuitable for packagingFlexible coversWrappersPolyesterPolyethylene terephthalate glycol

Three-layer, highly oriented polyester films having an A-B-C layer construction, preferably made of polyethylene terephthalate, which, in addition to a base layer B have a smooth surface layer A which contains no external particles and a rough surface layer C which contains external particles such as antiblocking agents or pigments, preferably SiO2, in defined amounts and particle sizes, and the surface layer C is additionally provided with an acrylate-containing layer D feature in particular good producibility and processibility, high gloss of the film surface A and low opacity. The very smooth surface A is suitable in particular for coating with materials, for example SiOx, by means of plasma polymerization of hexamethyldisiloxane by the CVD or PECVD method, which provides the film with a high oxygen barrier and is suitable in particular as packaging for light- and air-sensitive foods or other consumable items.

Owner:MITSUBISHI POLYESTER FILM

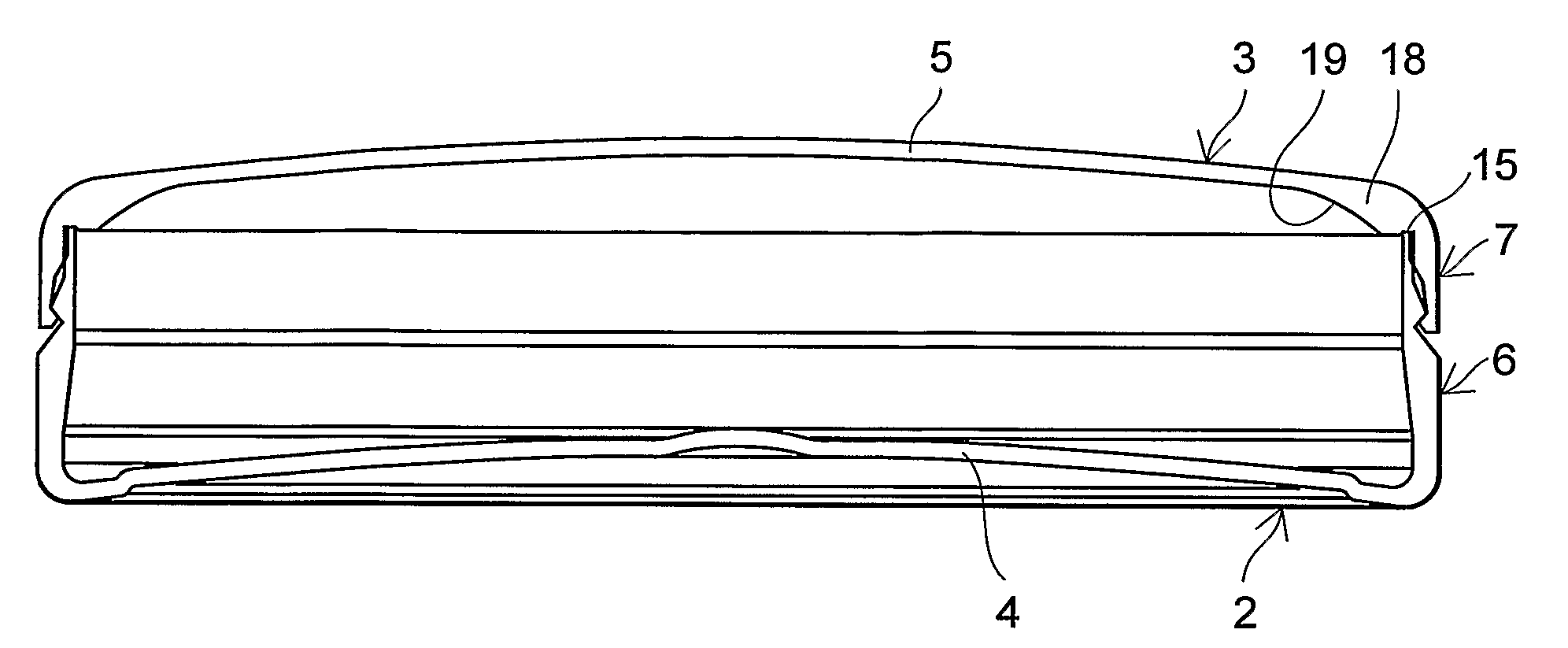

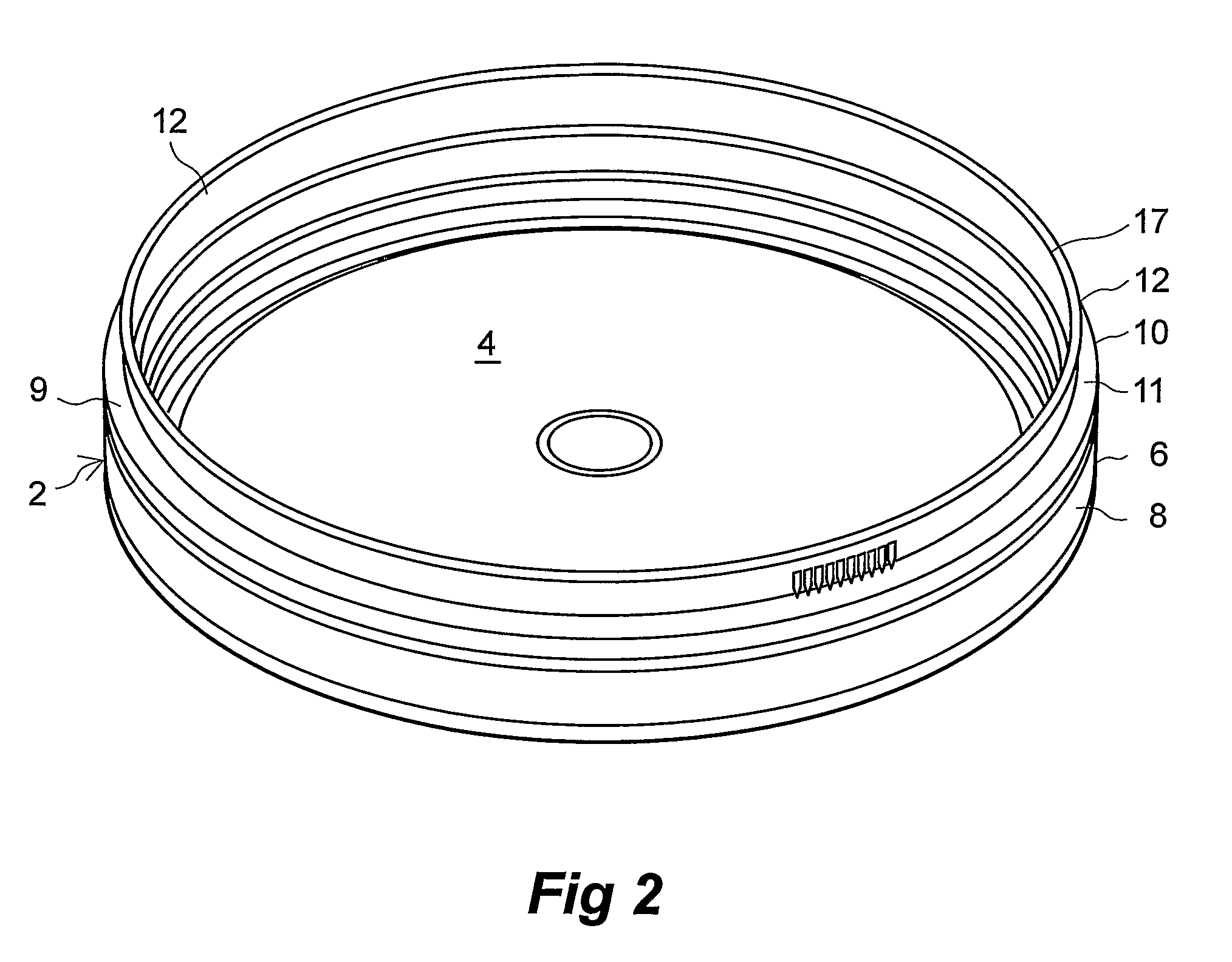

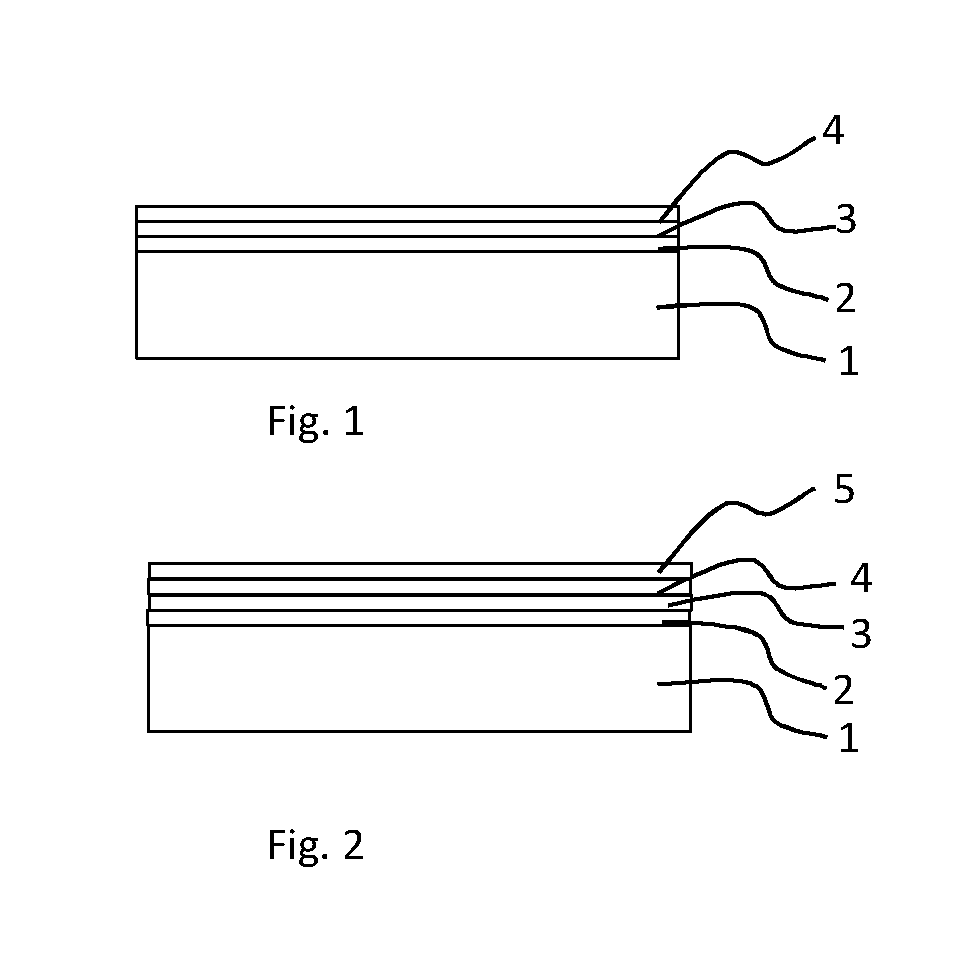

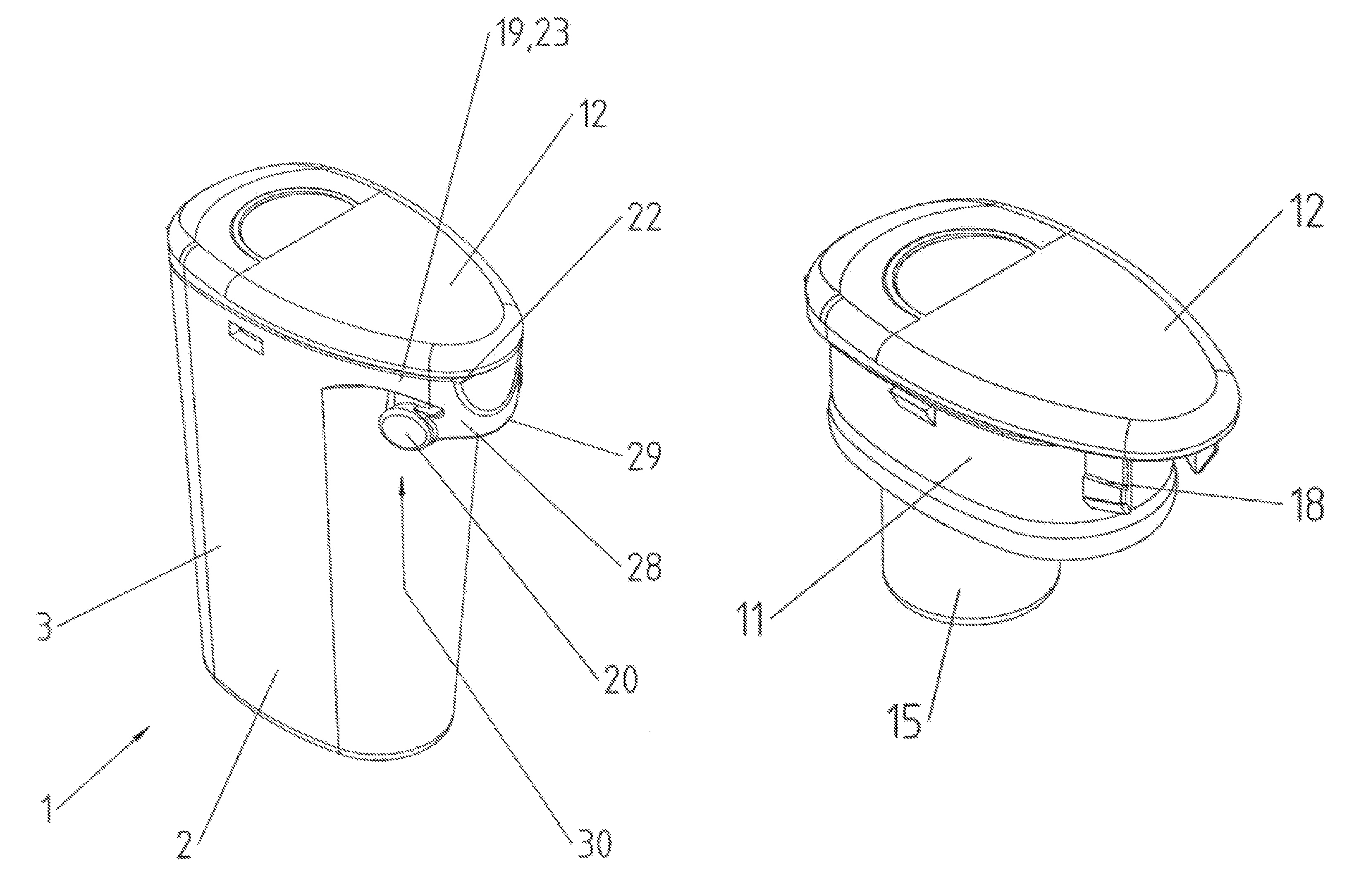

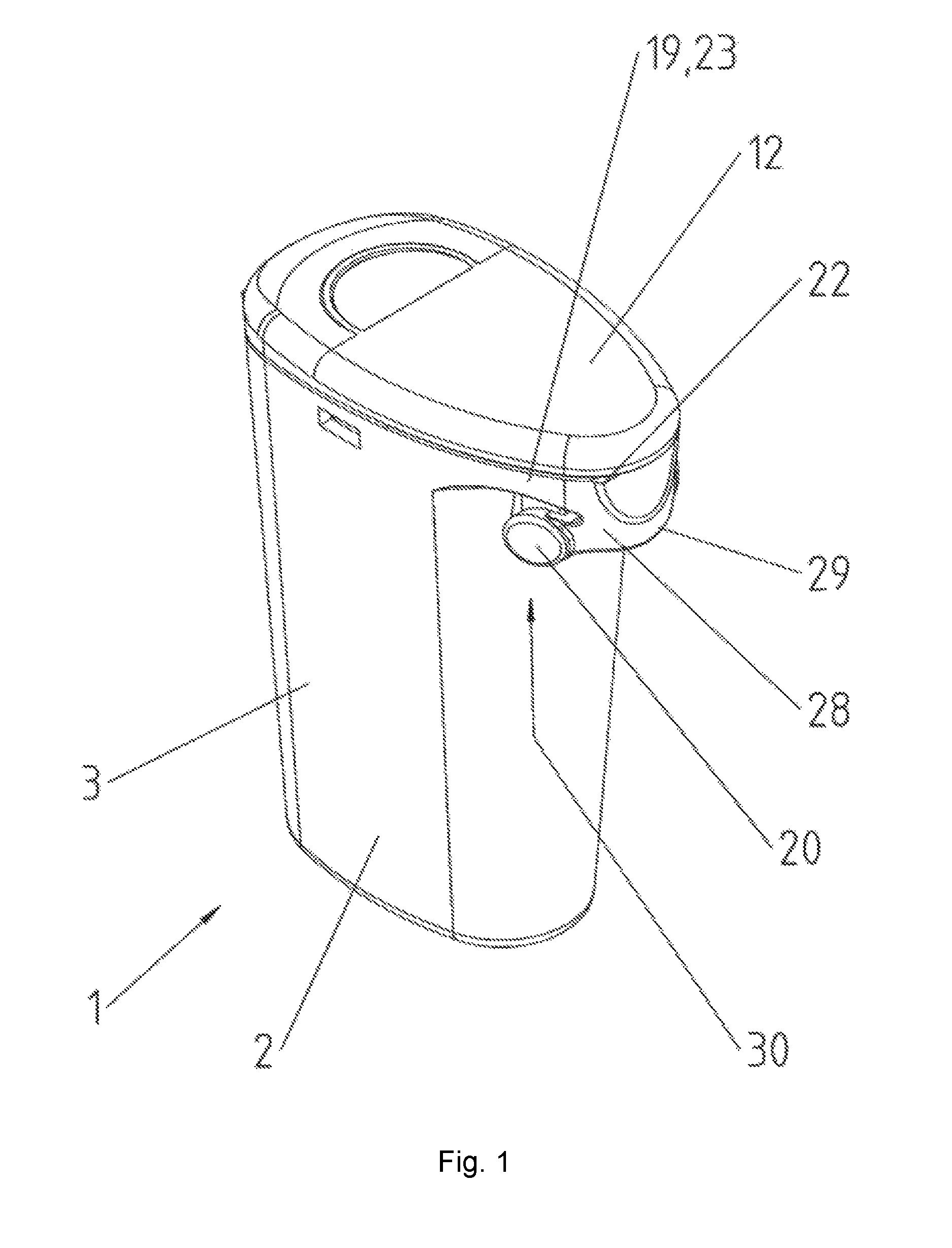

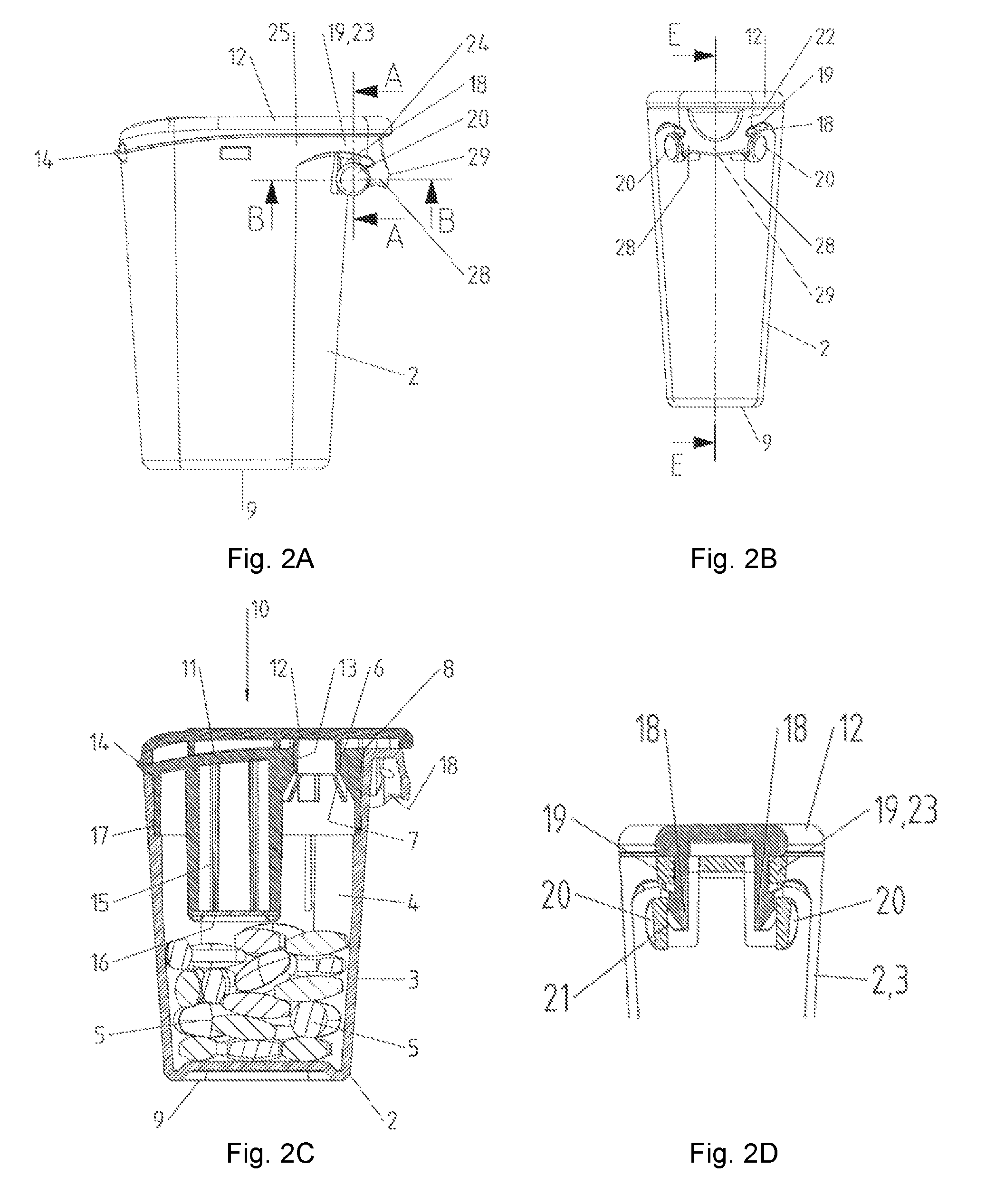

Container with a child-proof lock

ActiveUS9567141B2Easy to operateProduced cost-effectivelySmall article dispensingClosure with auxillary devicesEngineeringMechanical engineering

A container having a container body (2) comprises a container wall (3) and forms a receiving space (4) for goods to be packaged (5). The container comprises a discharge opening (6) for discharging the goods to be packaged (5) and a container closure (10) for closing the discharge opening (6). The container closure (10) comprises a lid (12) which can assume a closed position for closing the discharge opening (6) and an open position for opening the discharge opening (6). The container further comprises a child-proof lock (30) including first and second locking elements (18, 19). The first and second locking elements (18, 19) can assume a mutual locked position in which the lid (12) is fixed in the closed position, and wherein the first and second locking elements (18, 19) can be moved to a release position in which the lid (12) can be moved to the open position.

Owner:SANNER

Poultry egg packaging mechanism with changeable egg fall distance

Owner:ZHEJIANG UNIV

Multi-layer packaging scheme for implant electronics

ActiveUS9773715B2Low water vapor transmission rateStay flexibleElectrotherapyEye implantsElectronBiomedical engineering

The present invention provides a micropackaged device comprising: a substrate for securing a device with a corrosion barrier affixed to the substrate, wherein the corrosion barrier comprises a first thin-film layer, a metal film coating the thin-film layer and a second thin-film layer to provide a sandwich layer; and optionally at least one feedthrough disposed in the substrate to permit at least one input and or at least one output line into the micropackaged device, wherein the micropackaged device is encapsulated by the corrosion barrier. Methods of producing the micropackaged device are also disclosed.

Owner:CALIFORNIA INST OF TECH

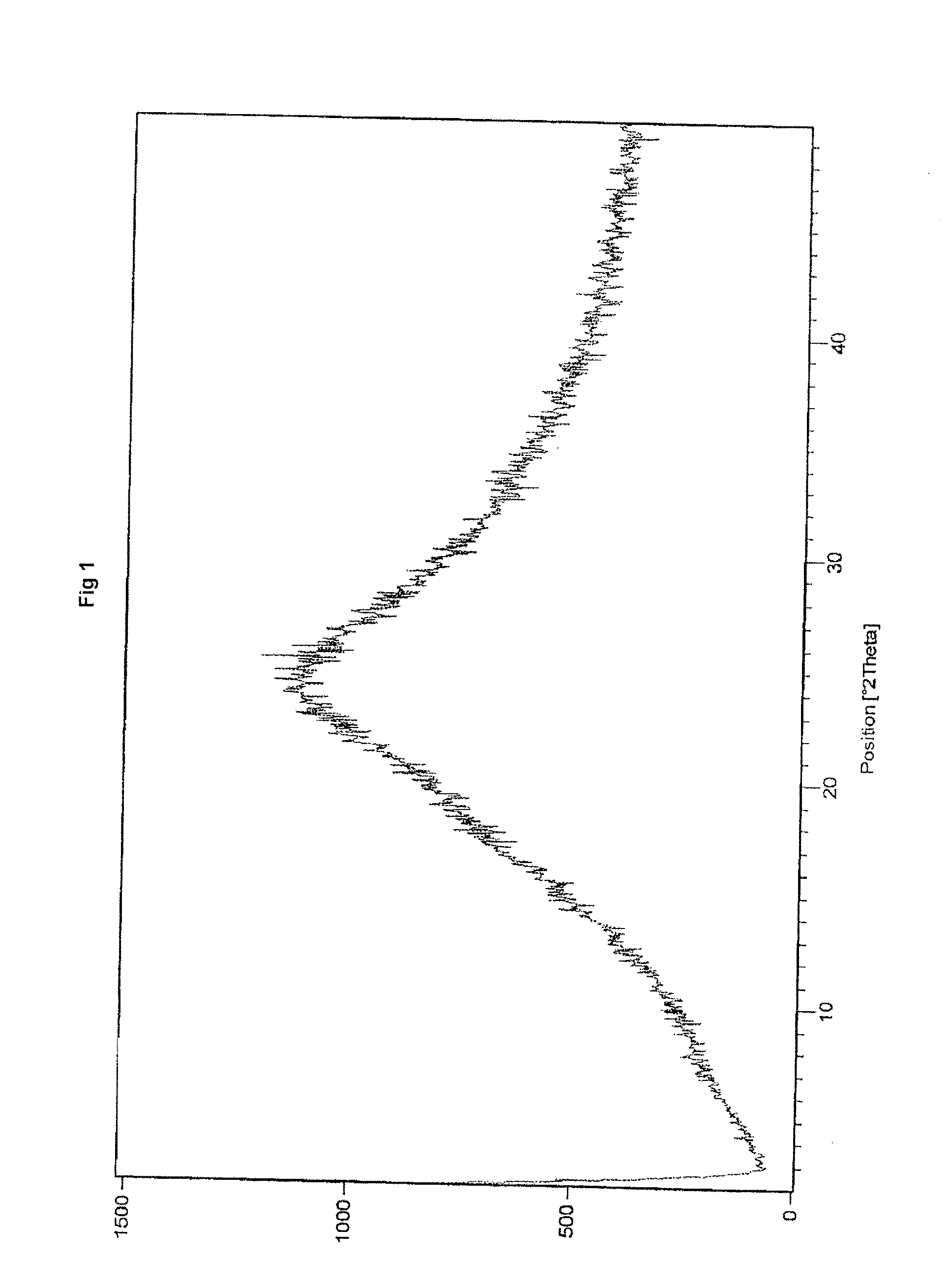

Preparation method of high-purity low-radioactivity spherical silicon micropowder

The invention discloses high-purity low-radioactivity spherical silicon micropowder. In the silicon micropowder, the content of SiO2 is not lower than 99.90 percent, the content of radioelement U is less than or equal to 1*10<-9>g / g, sphericization ratio is between 90 and 100 percent, and non-crystalline ratio is between 99 and 100 percent. The method for preparing the silicon micropowder comprises the following steps: preparing stable silica sol which has purity not lower than 99.90 percent and the ion content of an arbitrary impurity less than or equal to 5*10<-6>g / g by a silicon source with the content of radioelement U being less than or equal to 1*10<-9>g / g; concentrating the silica sol to lead the solid content of the silica sol to be between 41 and 70 percent; granulating the concentrated silica sol to lead grain diameter of the silica sol to be between 0.5 and 60 [mu]m; roasting the granulated silicon oxide micropowder at a temperature of between 500 and 1,100 DEG C; and carrying out sphericization treatment on the micropowder in a flame burner and a sphericizing furnace, and classifying and collecting the micropowder after cooling to obtain the high-purity low-radioactivity spherical silicon micropowder. The spherical silicon micropowder of the invention can meet the requirement of a large-scale integrated circuit on capsulation packing, and the invention has simple process, low cost, simple required equipment, and is applicable to industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Foldable massage bed

The invention belongs to the technical field of massage beds, and particularly relates to a foldable massage bed. In order to solve the technical problem that an existing foldable massage bed is prone to loosening and damage after being used for a long time, the technical scheme is as follows: the foldable massage bed comprises four connecting pieces and eight bolts; one side face of the upper end of each of four bed legs is an inclined face; furthermore, a first clamping groove is vertically formed in the middle of each inclined face; the two end faces of two cross beams are inclined faces matched with the inclined faces of the bed legs; second clamping grooves are perpendicularly formed in the middles of the inclined faces of the cross beams; the inclined faces of the bed legs make contact with the inclined faces of the cross beams; the four connecting pieces are arranged in communicating grooves formed by the first clamping grooves and the second clamping grooves; the connecting pieces are connected with the bed legs through bolts in the first clamping grooves; and the connecting piece is connected with the cross beam through a bolt in the second clamping groove. When the foldable massage bed disclosed by the invention is used, the cross beam is deeply embedded between the inclined faces of the bed legs under the action of gravity and pushing force; the friction force of the contact surfaces of the bed legs and the cross beam is larger; and the longer the time is, the more stable the structure is.

Owner:北京孤岛科技有限公司

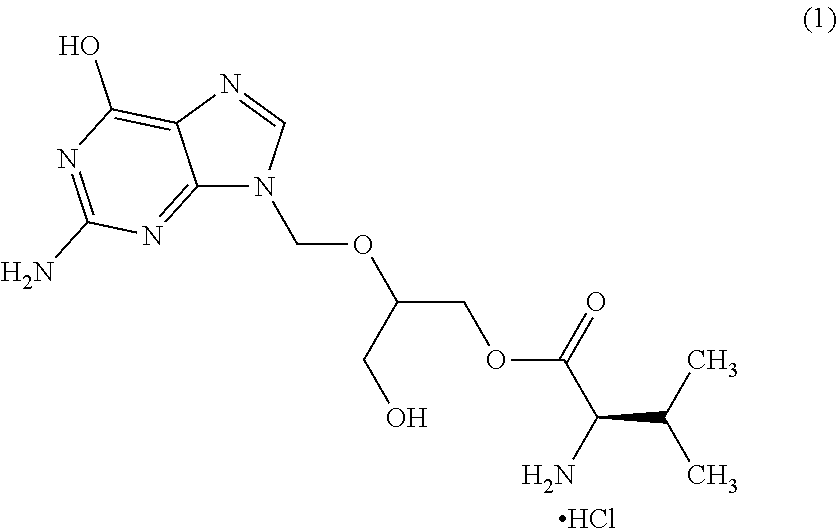

Process for the preparation of amorphus valgancyclovir hydrochloride

InactiveUS20130133289A1Maintain polymorphicMaintain chemical stabilityOrganic chemistrySynthetic resin layered productsValganciclovir HydrochlorideSolvent

Amorphous valgancyclovir hydrochloride has a median particle size of below 100 μm. A process for the preparation of the compound includes dissolving valgancyclovir hydrochloride in at least one solvent, removing the solvents under moisture controlled conditions, and drying the wet mass.

Owner:MYLAN LAB

Fill-finish process for peptide solutions

InactiveUS20210024236A1Suitable for packagingPeptide/protein ingredientsPackage sterilisationProcess engineeringOrganic chemistry

Owner:3 D MATRIX

Machine for packing aquatic product into bag

InactiveCN101481022BSuitable for packagingIncrease productivityPackaging by pressurising/gasifyingPackaging automatic controlAutomatic controlWater source

The invention discloses an aquatic product bagging machine which comprises a packer host machine and a transporting device, wherein the side surface of the packer host machine is provided with a bag preparing cylinder, the inner side of the bag preparing cylinder is provided with a water injecting pipe and a gas filling pipe, the water injecting pipe is connected with an external water source, the gas filling pipe is connected with an external oxygen source, one side of the packer host machine is provided with a heater, a pair of rolling wheels is arranged below the heater in the clearance way, the shaft of the rolling wheels is connected with the host machine, one side of the packer host machine is also provided with a cutting-off machine, an operating end of the cutting-off machine is arranged on the lower end of the bag preparing cylinder in the clearance way, the packer host machine is provided with a control table, a control device arranged in the control table can automatically control the water injecting rate of the water injecting pipe and the gas filling rate of the gas filling pipe according to presetting parameters, the upper end of the bag preparing cylinder is provided with a loading hopper, and the packer host machine is connected with the transporting device which can feed the loading hopper through a driver. The invention has the advantages that the machine cancontinuously and quantificationally pack the aquatic products in a gas filling mode and an oxygenating mode, the packing of the aquatic product bagging machine has proper size, firm sealing and attractive bag body and is suitable for scale production, and the like.

Owner:ZHEJIANG OCEAN UNIV

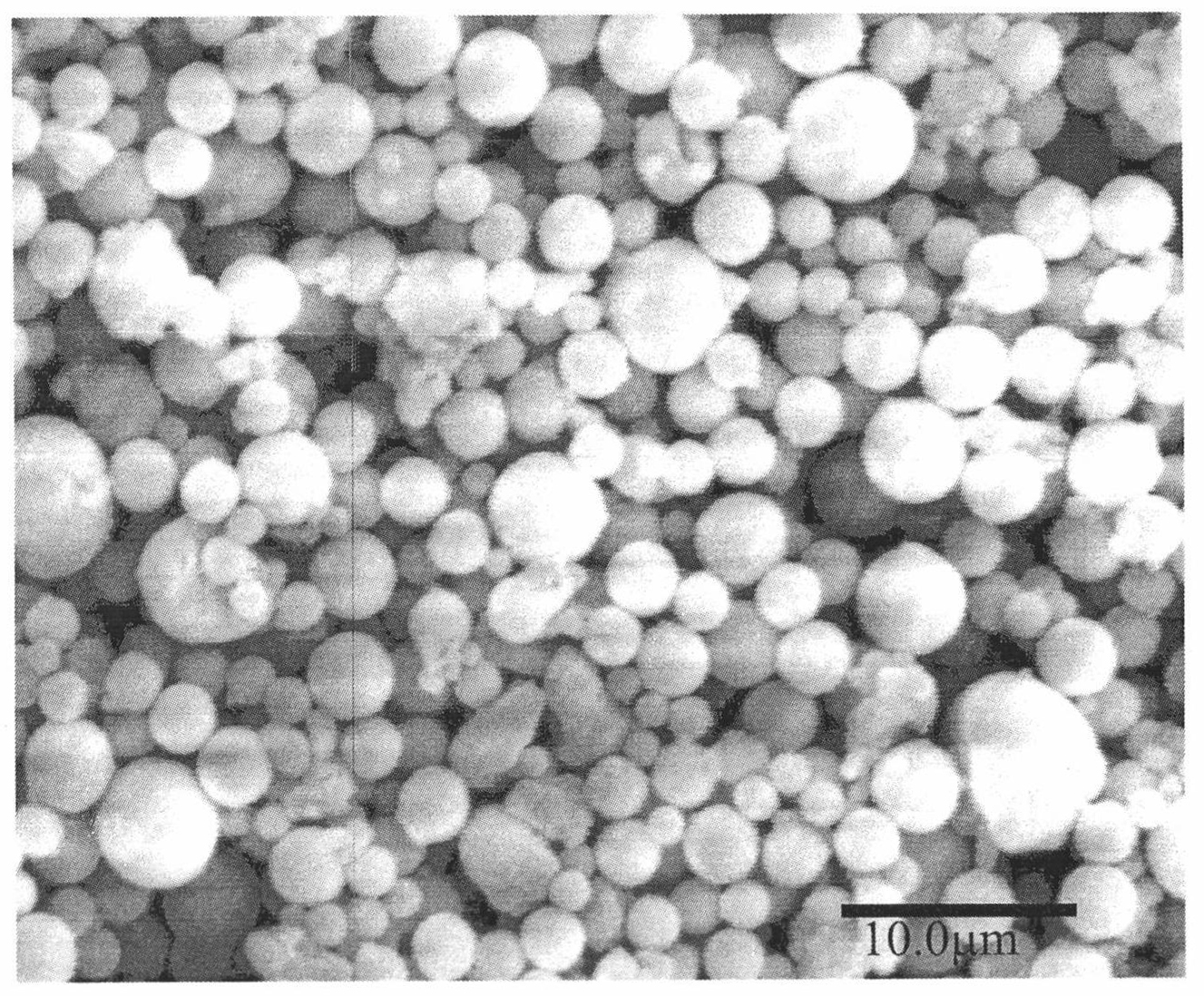

Preparation method of high-purity ultrafine spherical quartz powder

The invention discloses high-purity ultrafine spherical quartz powder, a preparation method and special equipment thereof. In the quartz powder, the content of SiO2 is not lower than 99.80 percent, granularity is between 1 and 40 mu meters, sphericization ratio is between 90 and 100 percent, and non-crystalline ratio is between 99 and 100 percent. The preparation method is to axially introduce a quartz raw material into flame at a temperature not lower than 1750 DEG C from a flame burner, melt the quartz raw material in a sphericizing furnace, and classify and collect the quartz powder after cooling to obtain a product. The equipment comprises a powder feeder, the flame burner connected with the powder feeder, a sphericizing furnace in axial connection with the flame burner, a water cooling device encircling the periphery of the lower part of the sphericizing furnace, a gravitational settler connected with the bottom of the sphericizing furnace, a cyclone collector communicated with the upper part of the sphericizing furnace, a cloth collector connected with the top part of the cyclone collector, an exhaust fan connected with the cloth collector, and a water tank connected with theexhaust fan. The quartz powder has high purity, high sphericization ratio, high non-crystalline ratio, simple equipment and process and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com