Glue solution injector driven by electromagnetic expulsive force

A technology of electromagnetic repulsion and injectors, which is applied in the direction of liquid injection devices, injection devices, electric solid devices, etc., can solve the problem of inability to adjust the movement stroke and spring preload, difficulty in realizing the gap between the electromagnet and the armature, and no design preload Adjust the knob and other issues to achieve the effects of shear thinning and micro glue injection, size reduction and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

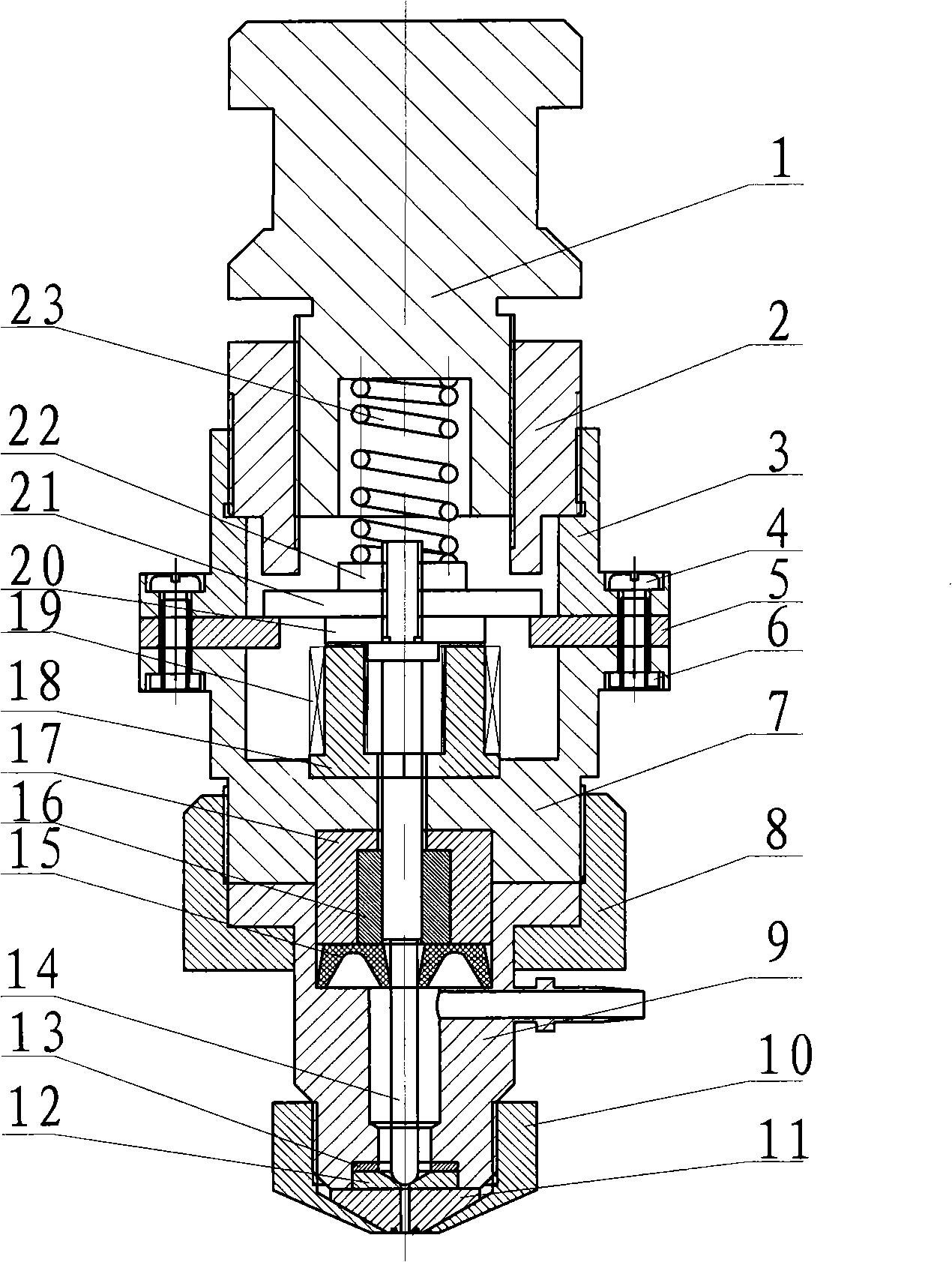

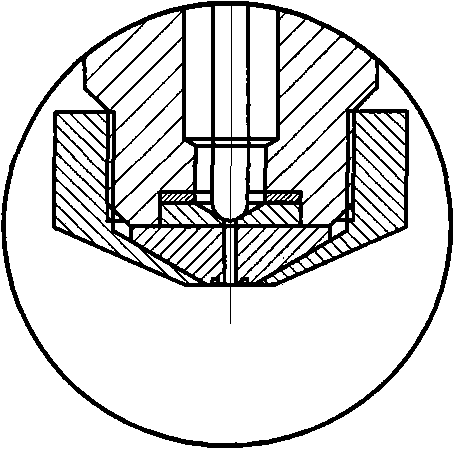

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] See attached figure 1 , 2 , the present invention --- a glue injector driven by electromagnetic repulsion, including a nozzle 11, a spray needle 14, a glue cavity 9, a thermal control body 10, a spring pretensioning device for a spray needle, and an electromagnet,

[0028] The needle spring pre-tensioning device includes a pre-tightening force adjustment knob 1, a stroke adjustment knob 2, and a pre-tightening spring 23; the lower end of the pre-tightening force adjustment knob 1 is provided with a cavity for placing the pre-tightening spring 23, and the outer peripheral surface Threads are provided on the top and screwed into the internally threaded hole of the stroke adjustment knob 2, and the outer circumference of the stroke adjustment knob 2 is provided with threads;

[0029] The electromagnet includes an upper conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com