Machine for packing aquatic product into bag

An aquatic bag and bag filling machine technology, applied in the directions of packaging, packaging protection, transportation and packaging, can solve the problems of difficult commercial operation, increase the external box, increase the cost, etc., to prevent transportation risks and achieve high production efficiency. , The effect of stable packaging specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

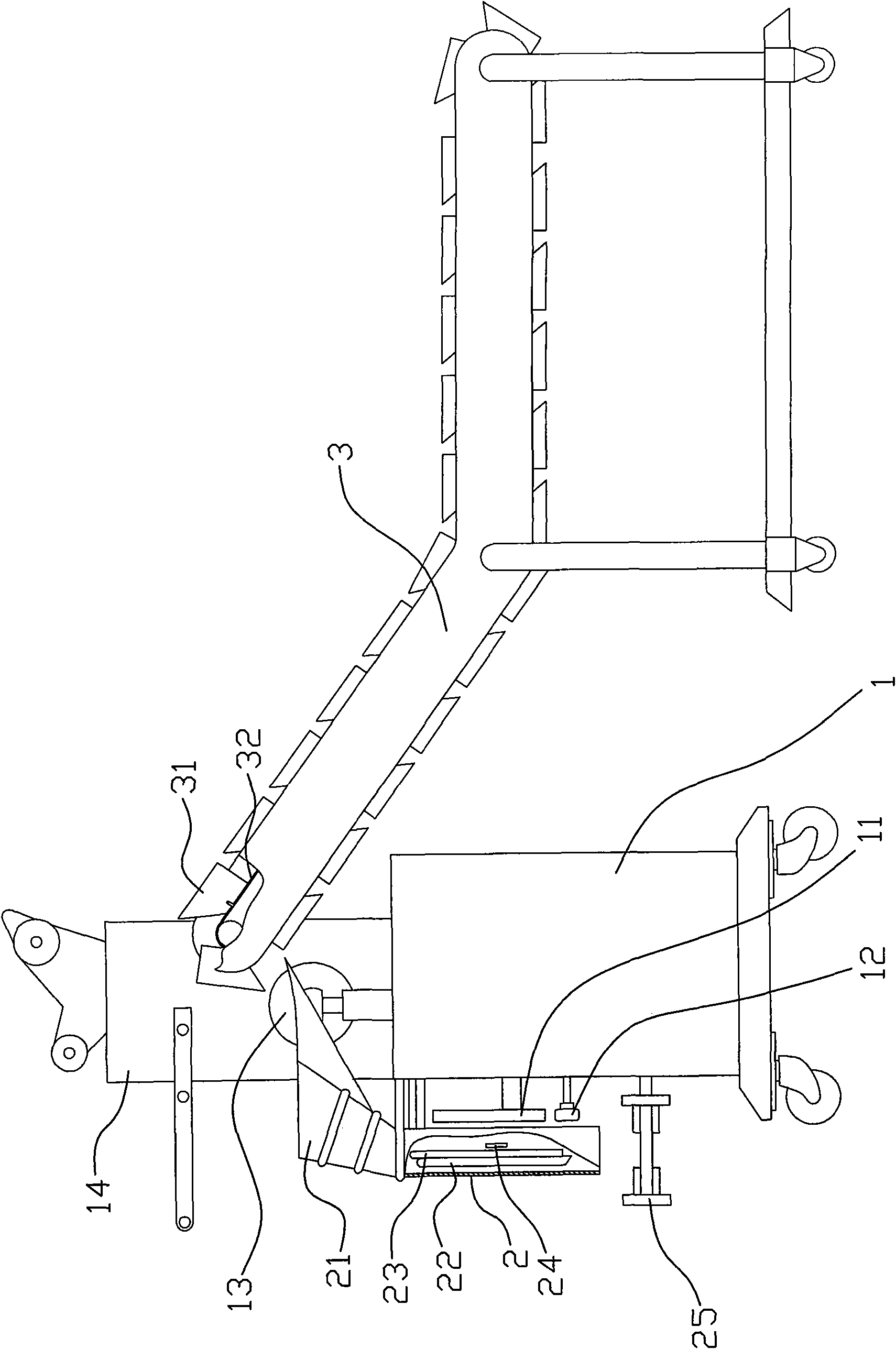

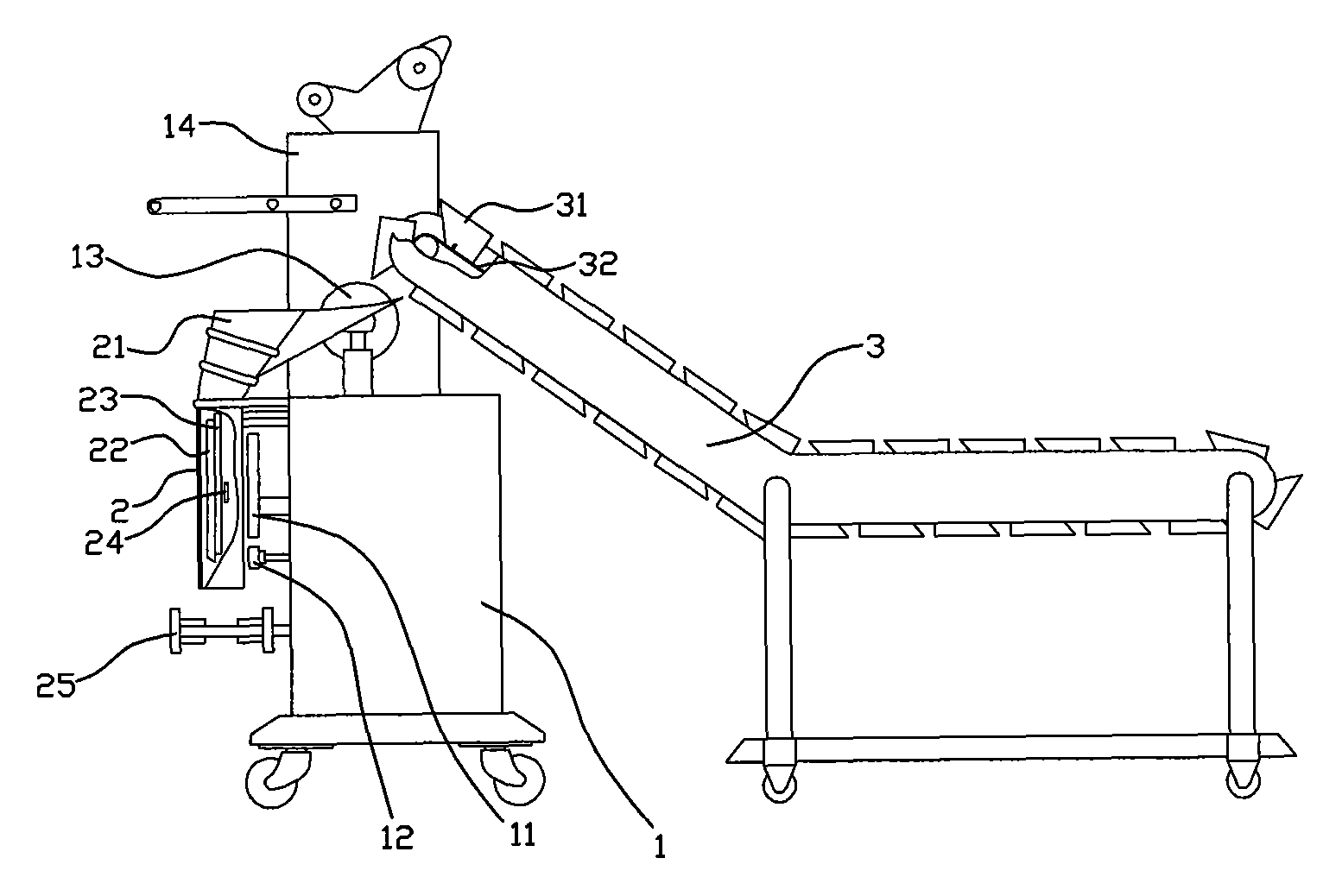

[0017] Embodiment 1: refer to figure 1 , Aquatic product bagging machine, including the packaging machine host 1 and the conveying device 3 with a bag-making cylinder 2 on the side, wherein: the inner side of the bag-making cylinder 2 is formed with a water injection pipe 22 and an inflation pipe 23; the water injection pipe 22 is connected to an external water source, and the inflation pipe 23 Connect to an external oxygen source; a heater 11 is installed on one side of the main machine 1 of the packaging machine; a pair of rollers 12 are provided in the gap under the heater 11, and the shafts of the rollers 12 are connected to the main machine 1; one side of the main machine 1 of the packaging machine is also provided with Cutting machine 25, and the working end gap of this cutting machine 25 is located at the lower end of the bag-making cylinder 2; the packaging machine host 1 has a console 14, and the control device installed in the console 14 can control the water injectio...

Embodiment 2

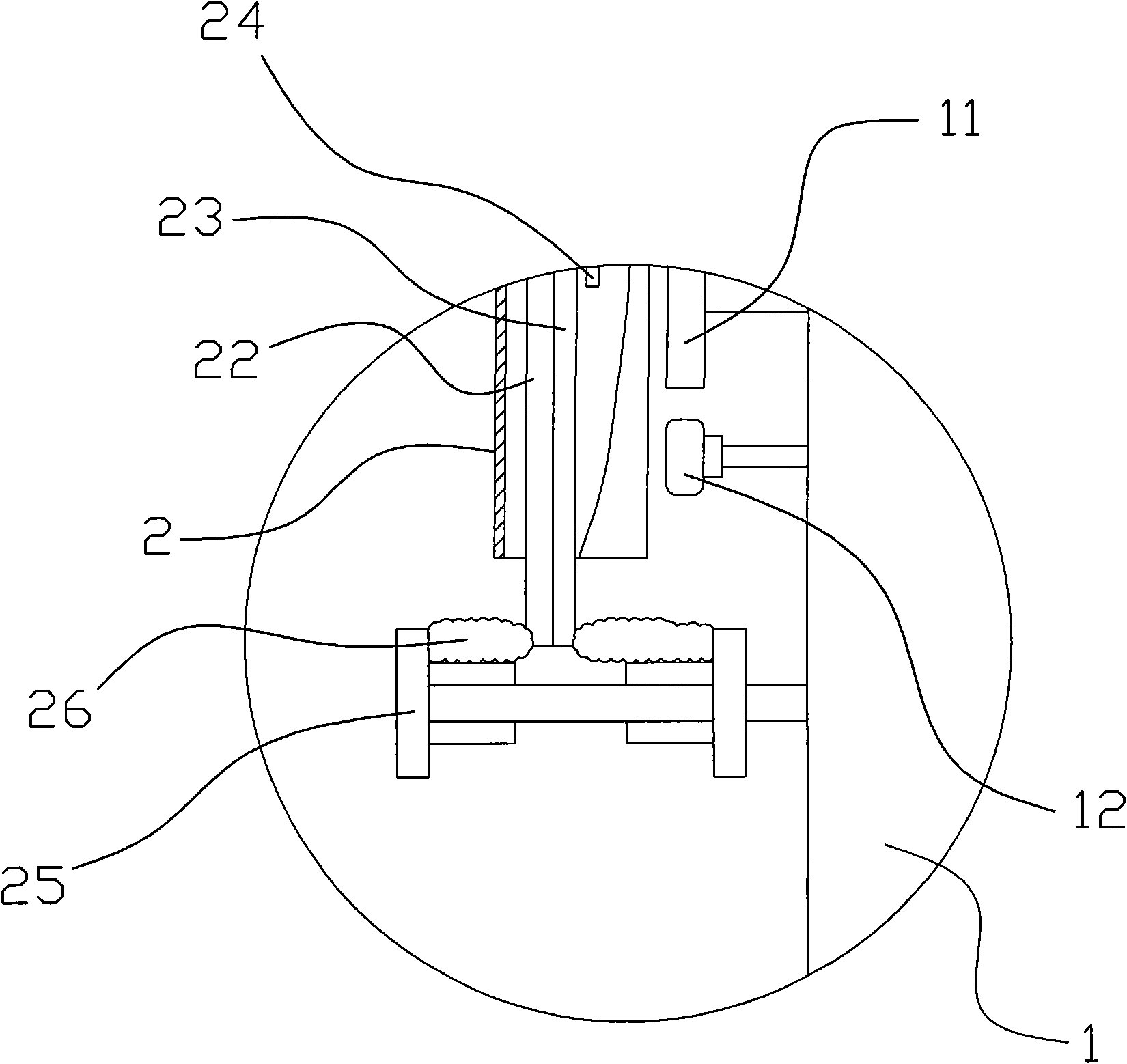

[0022] Embodiment 2: refer to figure 2 , most of the parts of the aquatic product bagging machine of the present embodiment are the same as that of Embodiment 1, except that the end of the inflation tube 23 stretches out from the bag-making cylinder 2; the upper edge of the cutting machine 25 is provided with a flexible clamping member 26, and the The clamping member 26 can wrap the water injection pipe 22 and the side circumference of the inflation pipe 23 when clamping. Its function is to seal the bag body below the clamping piece 26 in the process of inflating the inflation tube 23 through the flexible clamping piece 26 to form a certain air pressure in the bag, which can further improve the effect of oxygenation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com