Preparation method of high-purity ultrafine spherical quartz powder

A spherical quartz powder, high-purity technology, applied in the direction of silicon oxide, etc., to achieve the effect of simple process flow, simple equipment, and large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

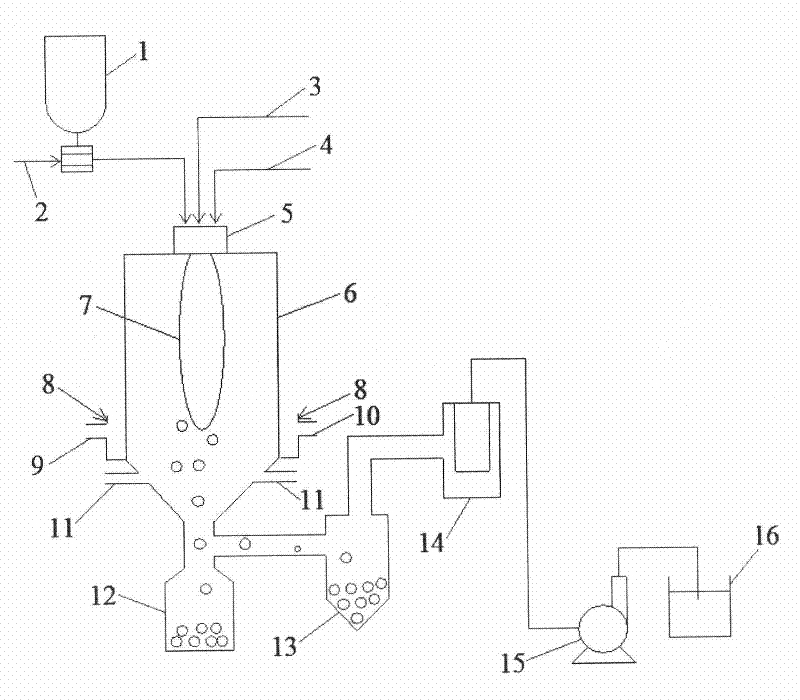

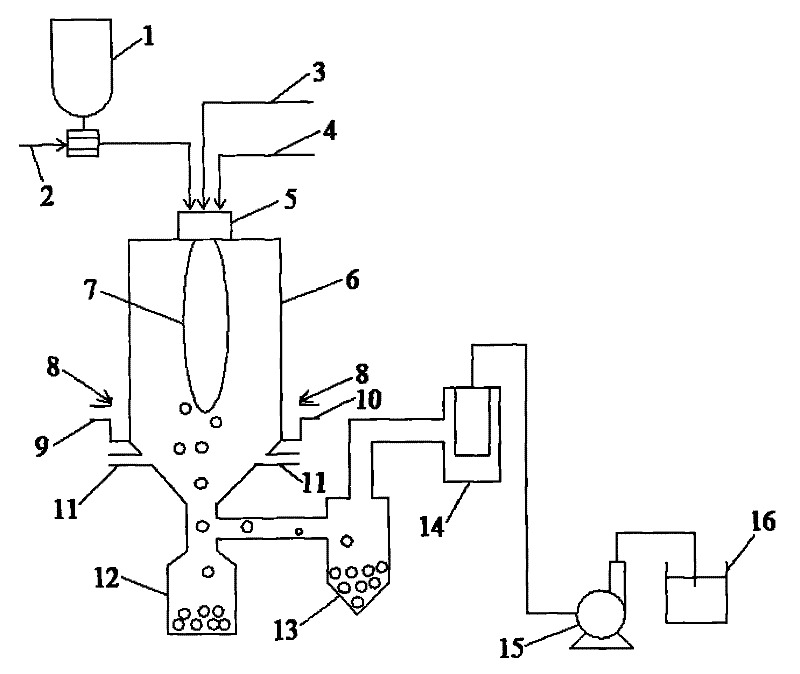

Method used

Image

Examples

Embodiment 1

[0036] SiO 2 Angular quartz powder with a content of 99.92% and a median particle size of 5 μm is used as raw material, liquefied petroleum gas (LPG) is used as fuel gas, oxygen is used as supporting gas, and oxygen is used as carrier gas for powder delivery. After adjusting the pressure and flow rate of oxygen and LPG, it is ignited and spheroidized The furnace is preheated (generally, the preheating temperature is not lower than 1500°C) for 50 minutes, and the powder feeding rate is 300g / min. Analysis of SiO in products by gravimetric method 2 content, laser particle size analyzer test particle size and SEM and XRD analysis of the product, SiO in the obtained spherical quartz powder 2 The content is 99.84%, the median particle size is 2.2μm, the spheroidization rate is 99%, and the amorphous rate is 99%.

Embodiment 2

[0038] SiO 2 Angular quartz powder with a content of 99.96% and a median particle size of 10 μm is used as raw material, acetylene is used as gas, oxygen is used as supporting gas, and oxygen is used as carrier gas for powder delivery. After adjusting the pressure and flow rate of oxygen and acetylene, ignite, and preheat the spheroidizing furnace for 50 minutes , The powder feeding rate is 50g / min. Analyze by the method identical with embodiment 1, obtain SiO 2 Spherical quartz powder with a content of 99.90%, a median particle size of 5.3 μm, a spheroidization rate of 97%, and an amorphous rate of 98%.

Embodiment 3

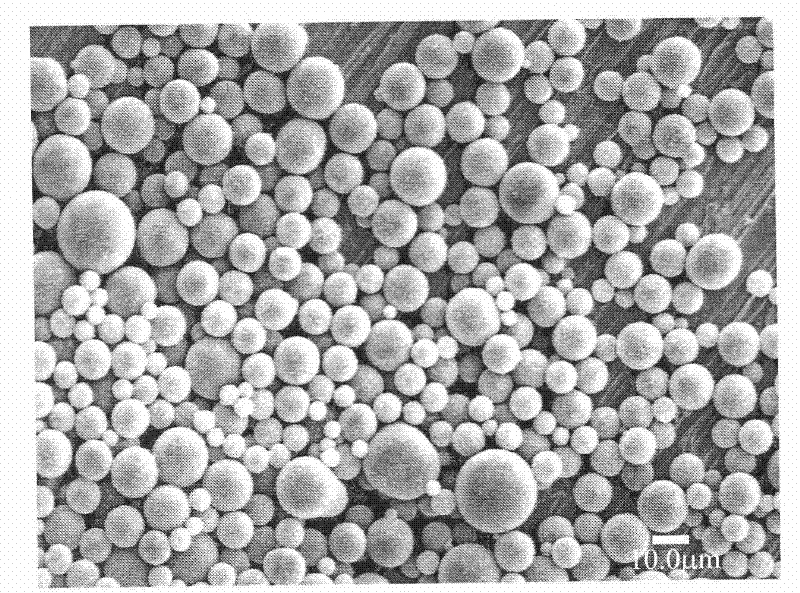

[0040] SiO 2Angular quartz powder with a content of 99.88% and a median particle size of 20 μm is used as raw material, LPG is used as fuel gas, oxygen is used as supporting gas, and oxygen is used as carrier gas for powder delivery. After adjusting the pressure and flow rate of oxygen and LPG, ignite and preheat the spheroidizing furnace for 50 minutes , The powder feeding rate is 100g / min. Analyze by the method identical with embodiment 1, obtain SiO 2 Spherical quartz powder with a content of 99.84%, a median particle size of 11 μm, a spheroidization rate of 94%, and an amorphous rate of 100% (the SEM image of which is shown in figure 2 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com