Liquid controlled multi-way valve

A multi-way valve and hydraulic control technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of high labor intensity, fixed oil pump flow, low efficiency, etc., to reduce labor intensity, reversing The effect of fast speed and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

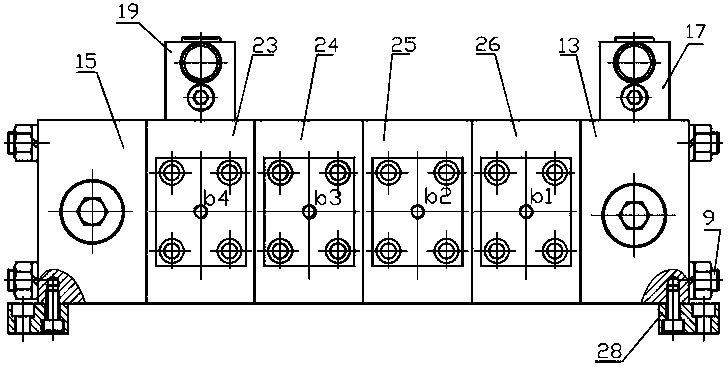

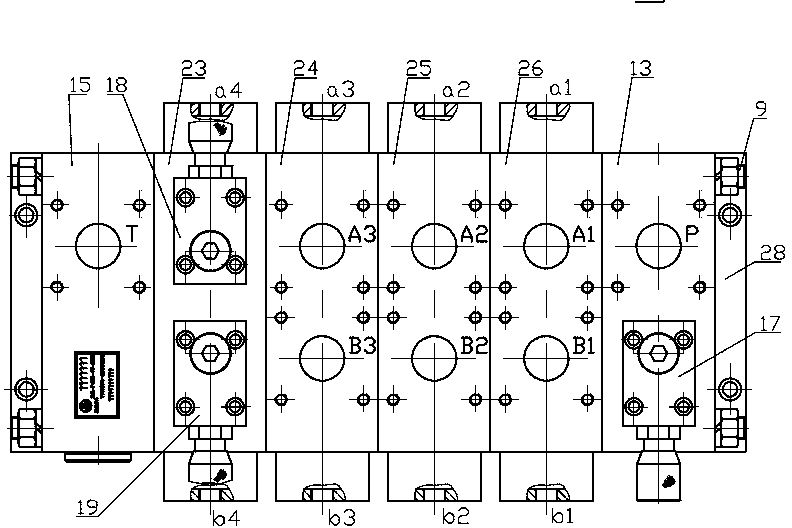

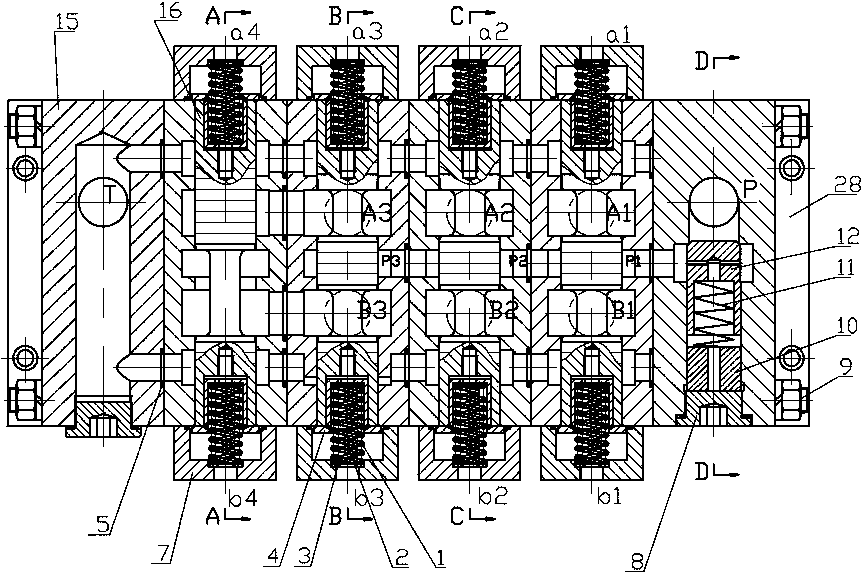

[0030] Embodiment: a kind of hydraulic control multi-way valve (see attached figure 1 attached figure 2 attached image 3 ), including the valve body. The valve body is composed of 6 pieces of valve pieces interconnected to form an integral structure. The valve body is in a rectangular parallelepiped structure. The oil passage is processed, and the four corners of the valve plate are connected by a string screw 9. The lower part of the valve body is fixed with a connecting seat 28, and the 6 valve plates include the oil inlet valve plate 13 and the oil return valve plate 15 at both ends and from the The loose / pile valve plate 23, the pile pressure valve plate 24, the quick pressure pile pressure valve plate 25 and the differential valve plate 26 are arranged in sequence from right to left. The oil inlet and oil outlet of each valve plate are connected to each other. It is sealed by NBR90 hardness NBR O-ring 5, and the differential valve is differentially connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com