Rotary workbench

A technology of rotary table and sliding table, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems affecting the production efficiency and quality of PCD/CBN tools, raising the threshold, etc., so as to achieve flexibility, motion accuracy and The effect of improving stability and reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

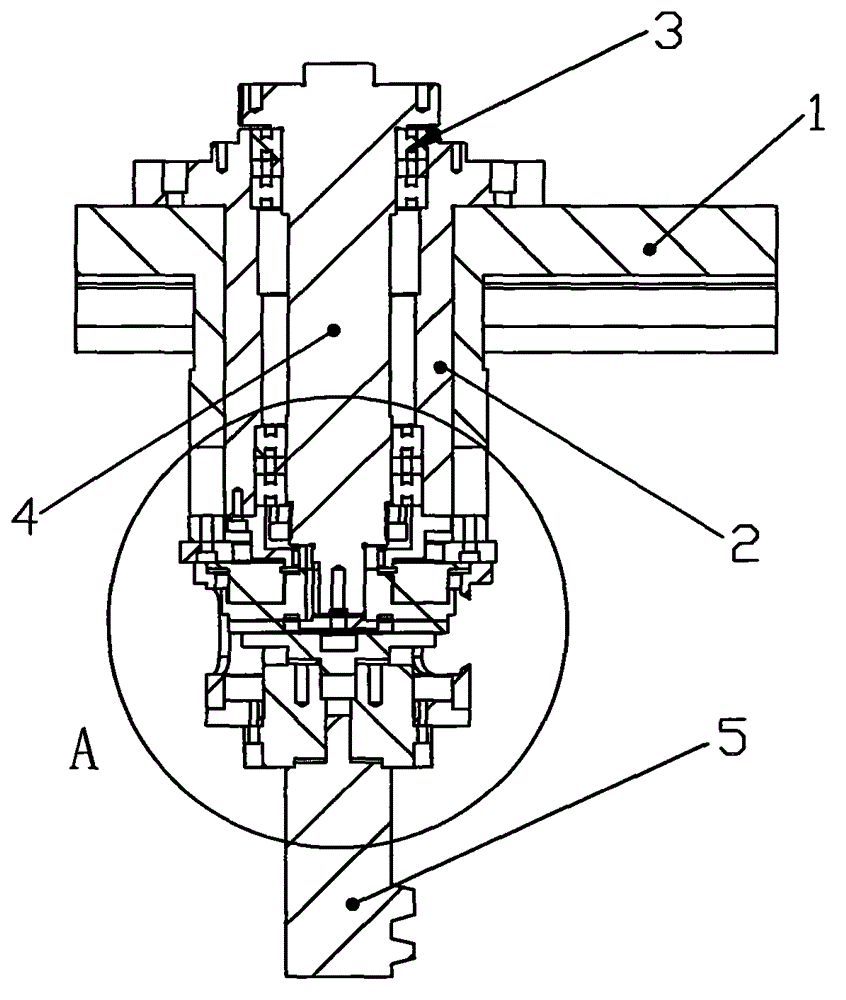

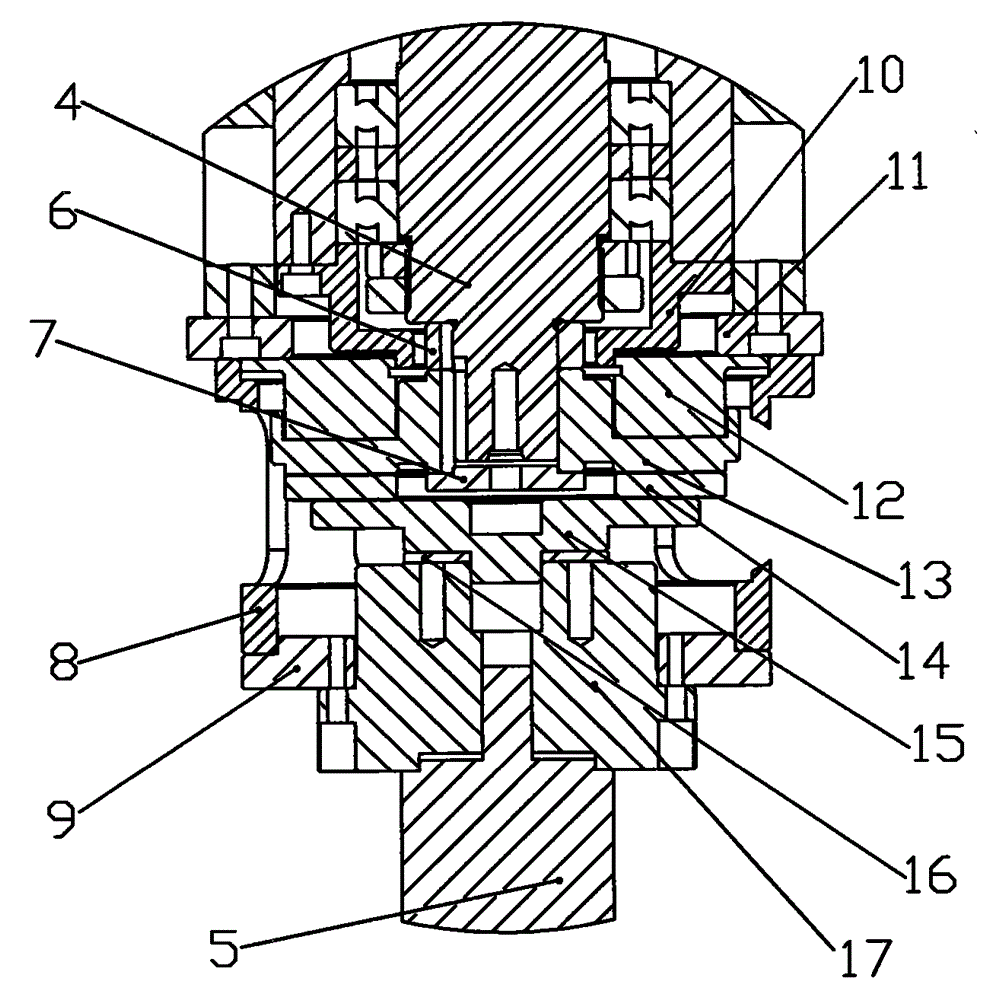

[0013] like figure 1 and figure 2 Shown: a rotary table according to an embodiment of the present invention, including a feed slide 1, one side of the feed slide 1 is provided with a cylindrical convex part with a through hole inside, and a vertical shaft 4 is provided in the through hole , the vertical shaft 4 is provided with a vertical shaft sleeve 2, and the two ends between the vertical shaft 4 and the vertical shaft sleeve 2 are respectively provided with a bearing group 3, the bearing group 3 is a high-precision bearing group, and the vertical shaft 4 The lower end is provided with a reducer 17 and a servo motor 5 in turn, the servo motor 5 is arranged at the lower end of the reducer 17, the lower end of the vertical shaft sleeve 2 is provided with a lower end cover 10, and the vertical shaft 4 runs through the lower end cover 10 , an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com