Patents

Literature

75results about How to "Inhibition rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

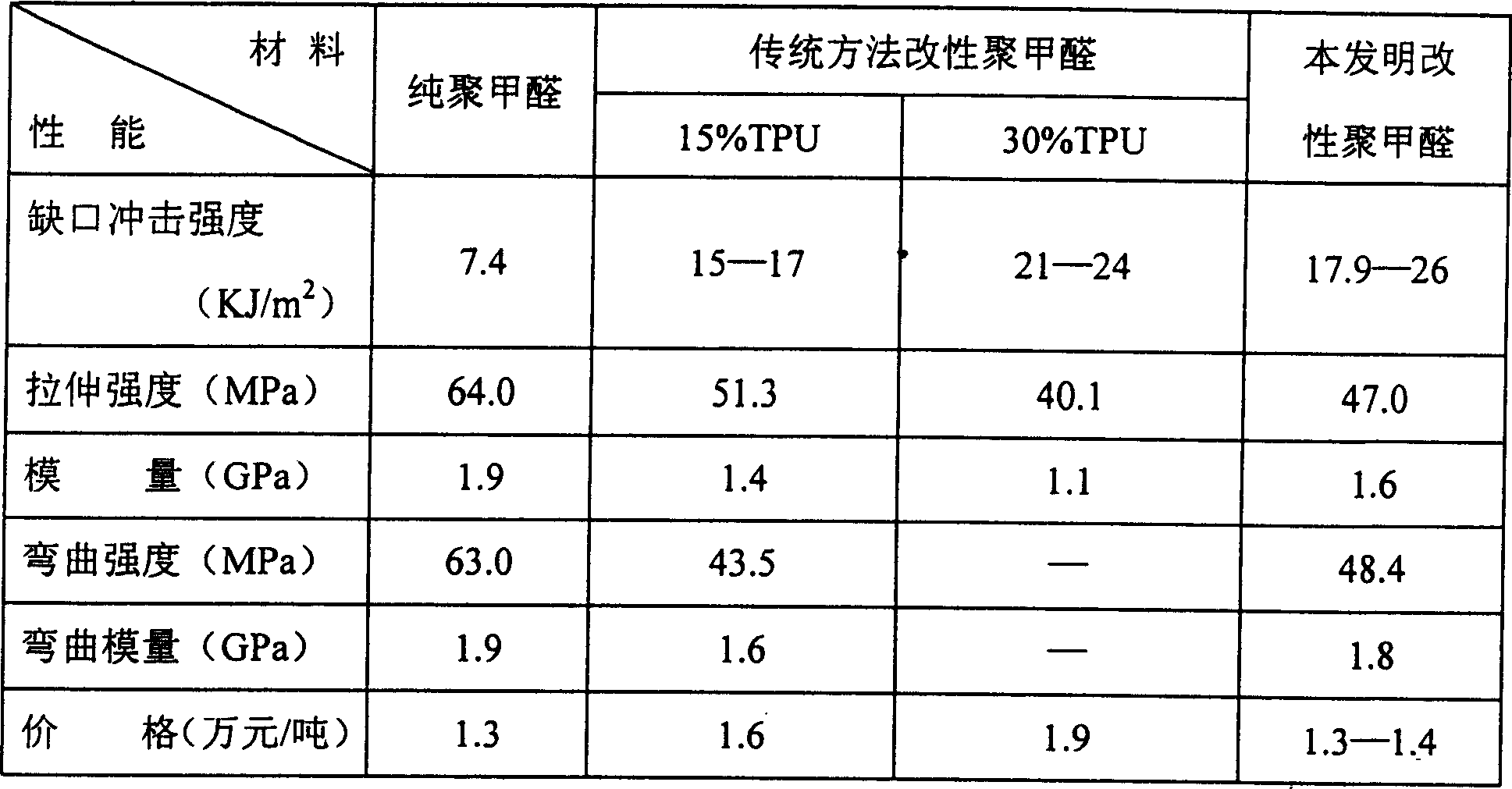

Nano composite polyformaldehyde material and its prepn

The present invention discloses one kind of nano composite polyformaldehyde material, and the composite contains polyformaldehyde 55-90 wt% and elastomer 2.5-30 wt% as well as characterized inorganicnano stuffing 0.1-10 wt% and compatibilizing agent 0.1-10 wt%. During the preparation, inorganic nano stuffing, compatibilizing agent and elastomer in certain proportion are smelted and mixed to obtain agglomerate; and the agglomerate is then diluted and dispersed in polyformaldehyde or polyformaldehyde / elastomer to obtain the product through further smelting and mixing. The present invention canstrengthen and toughen polyformaldehyde while reducing cost.

Owner:SICHUAN UNIV

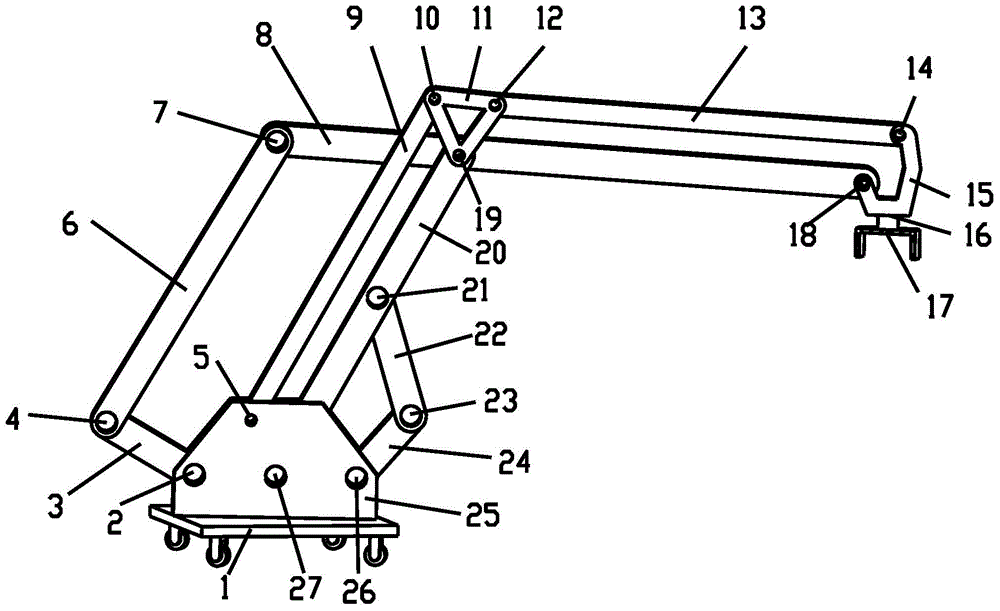

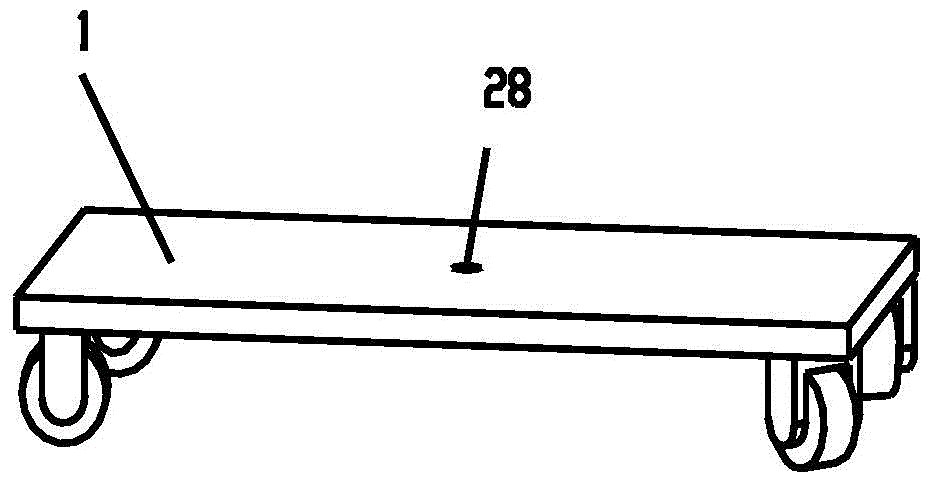

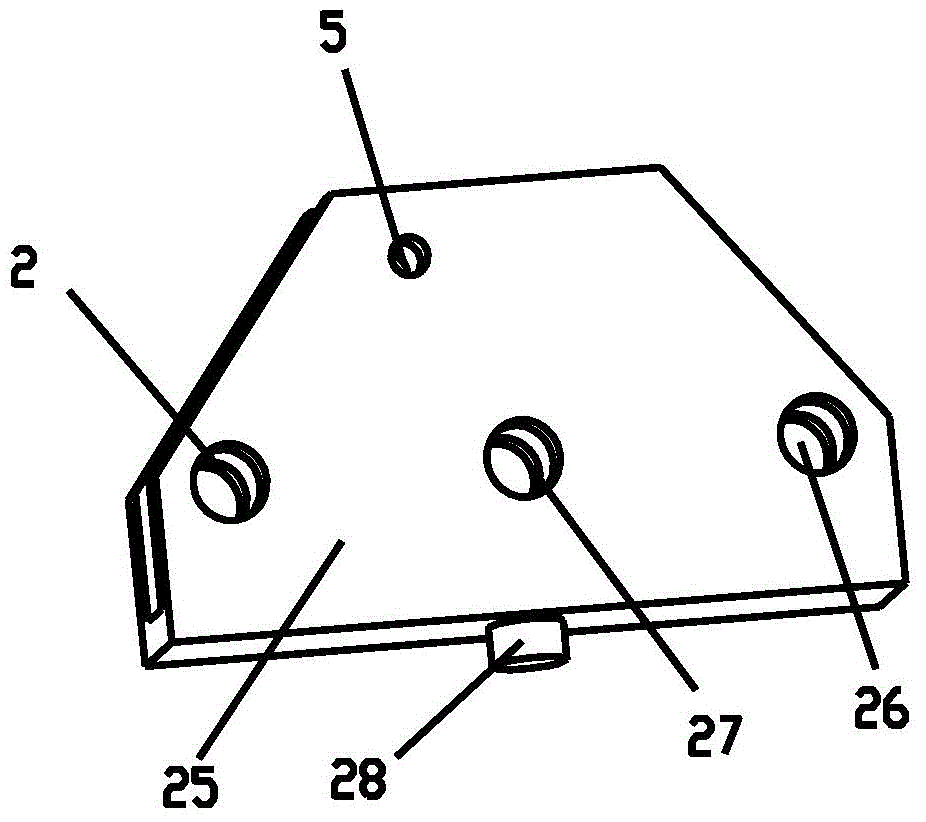

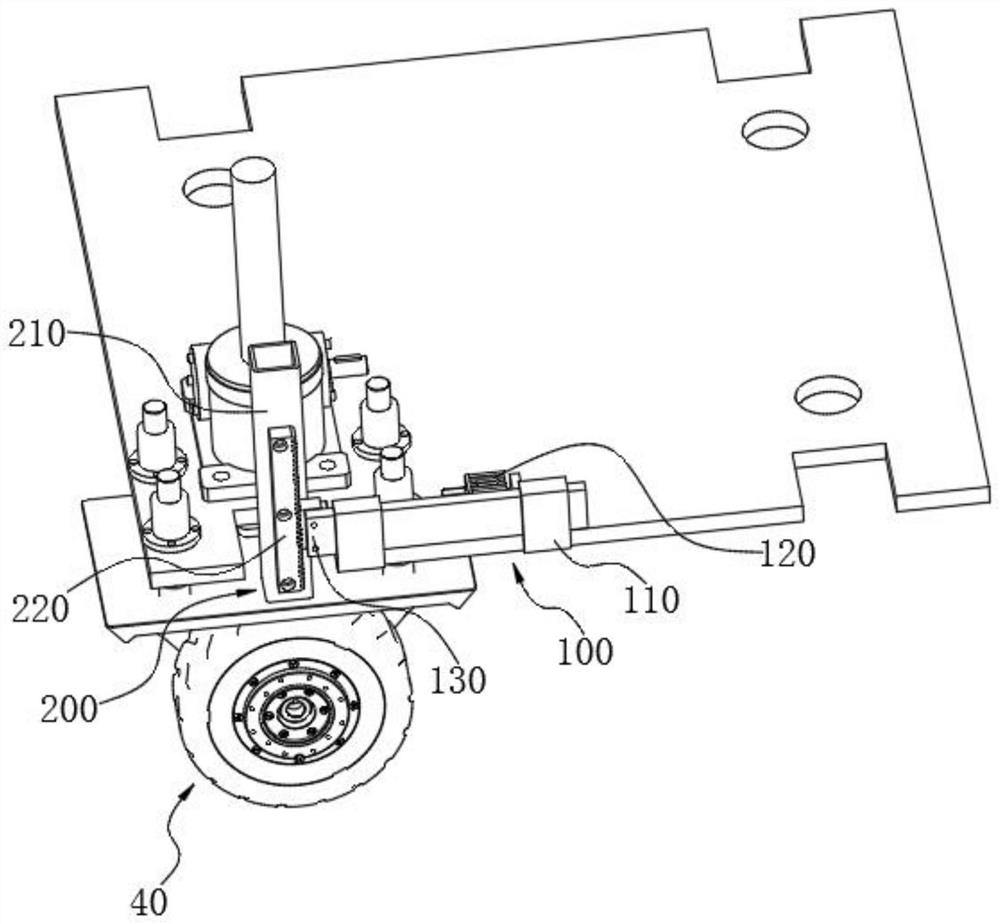

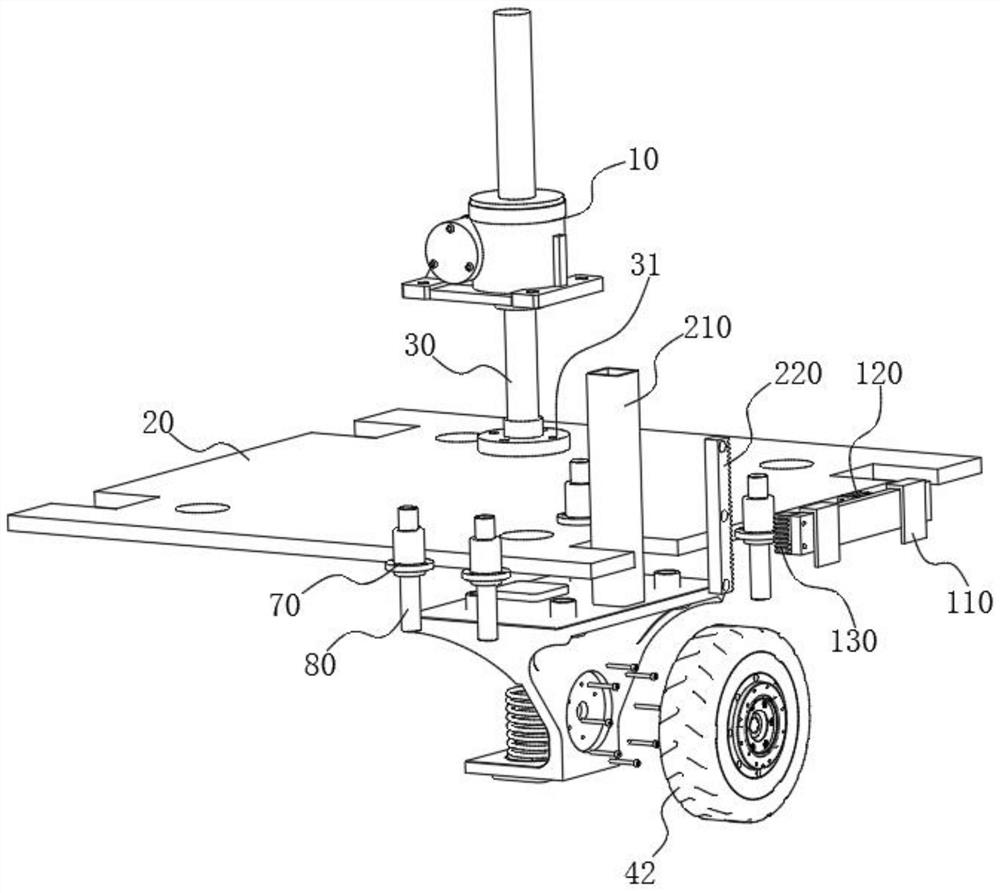

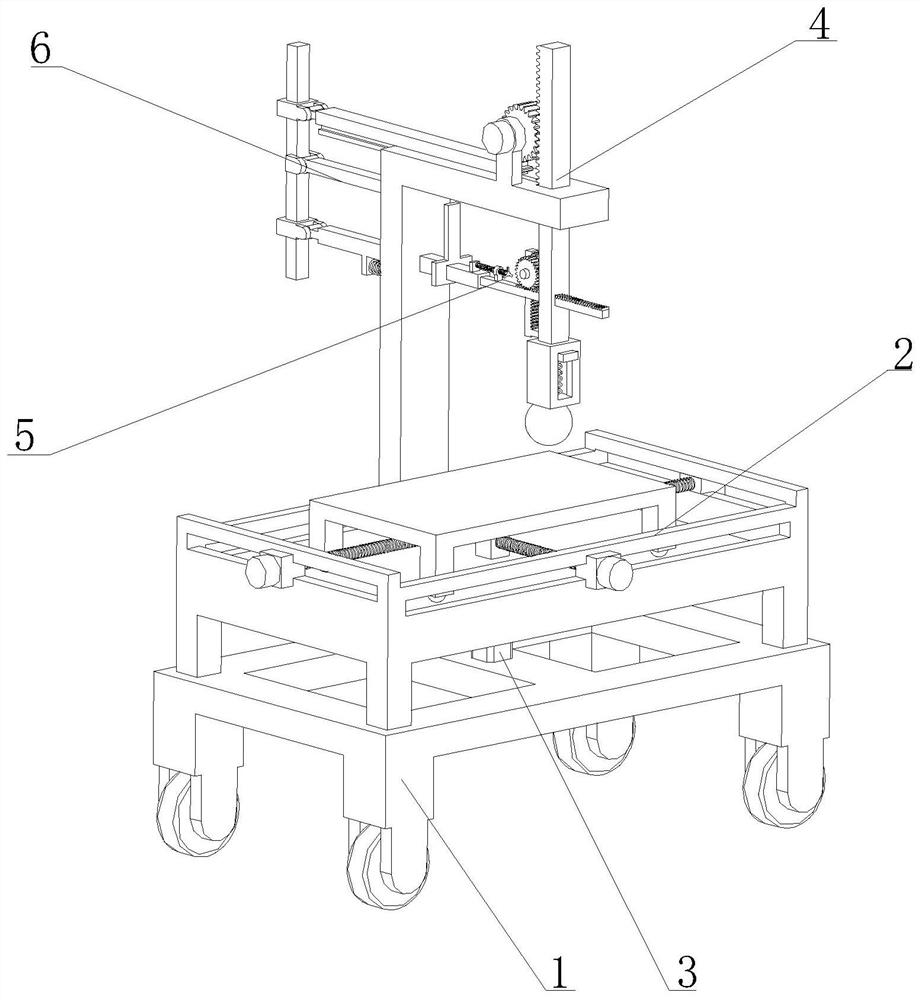

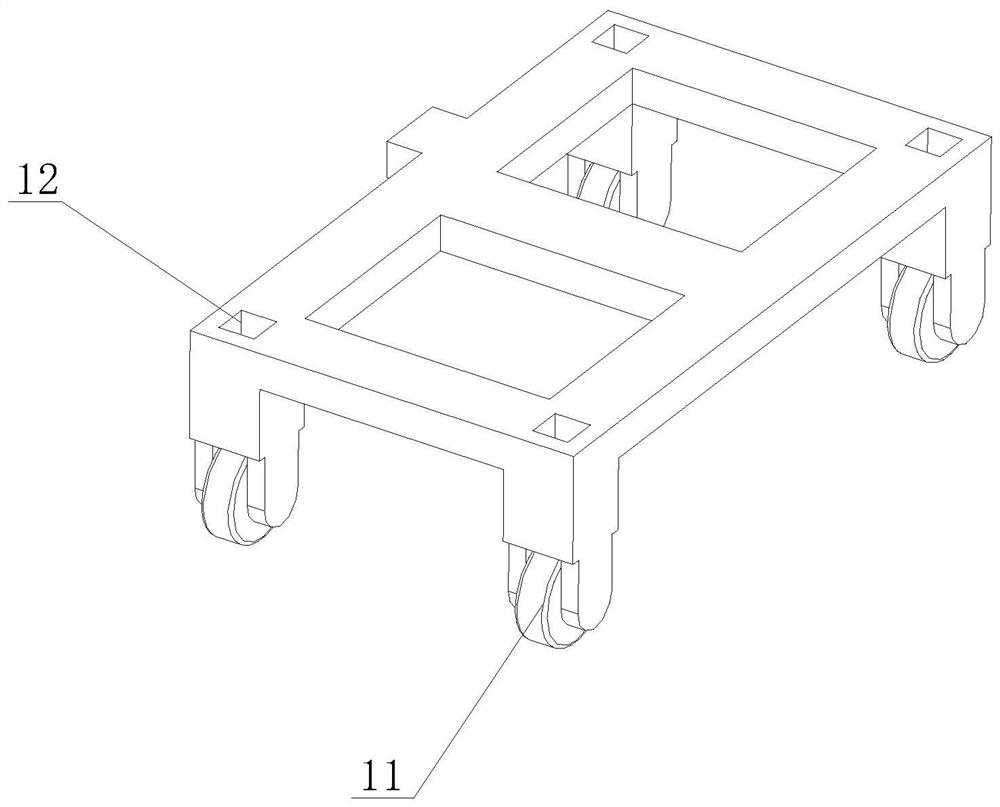

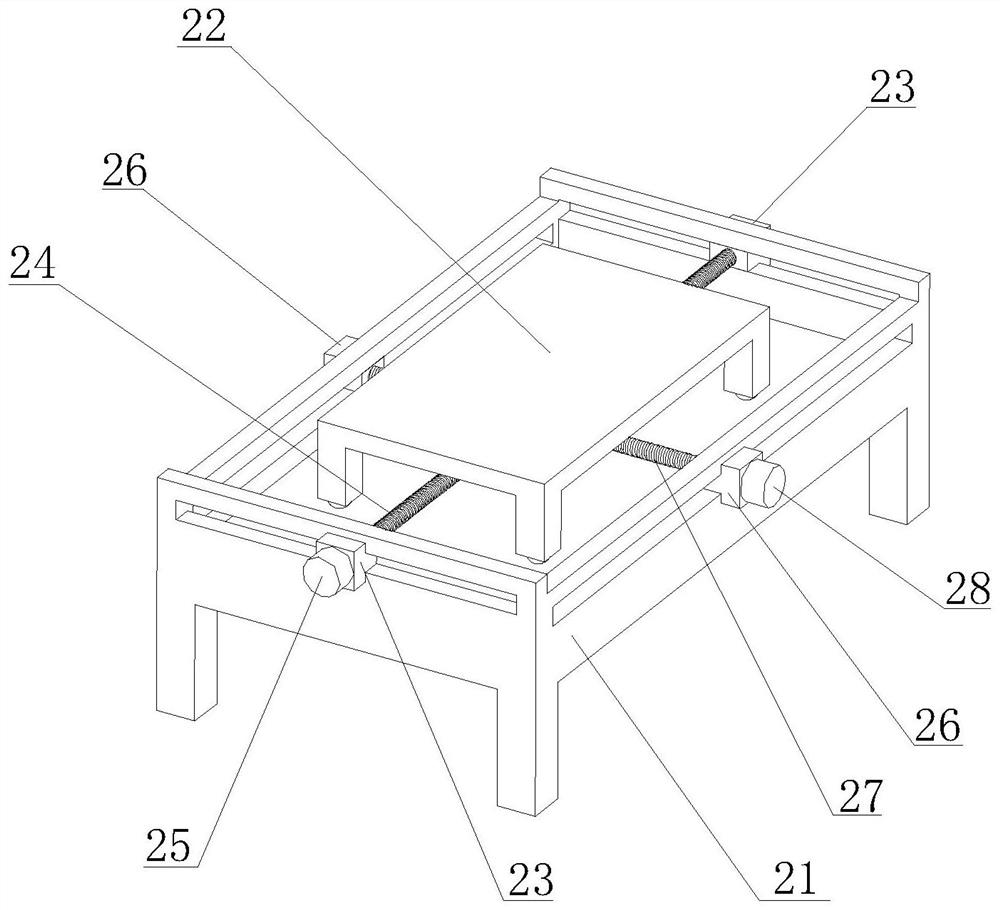

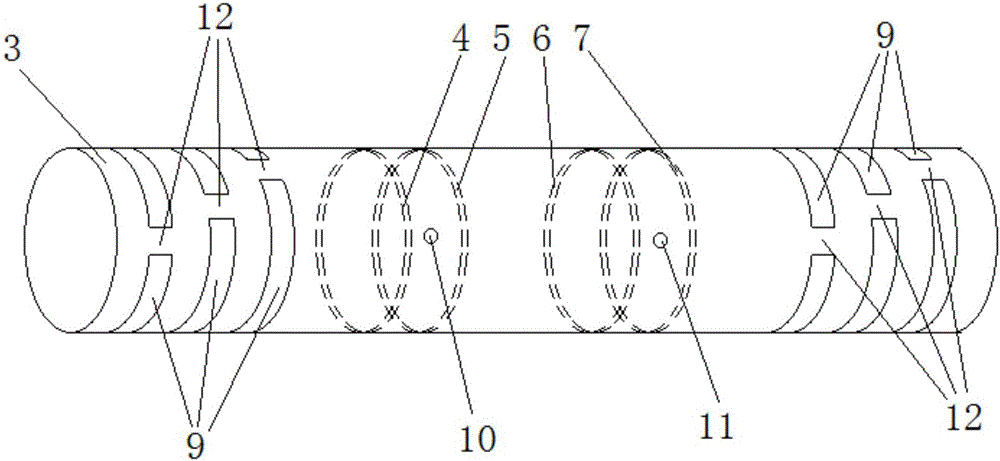

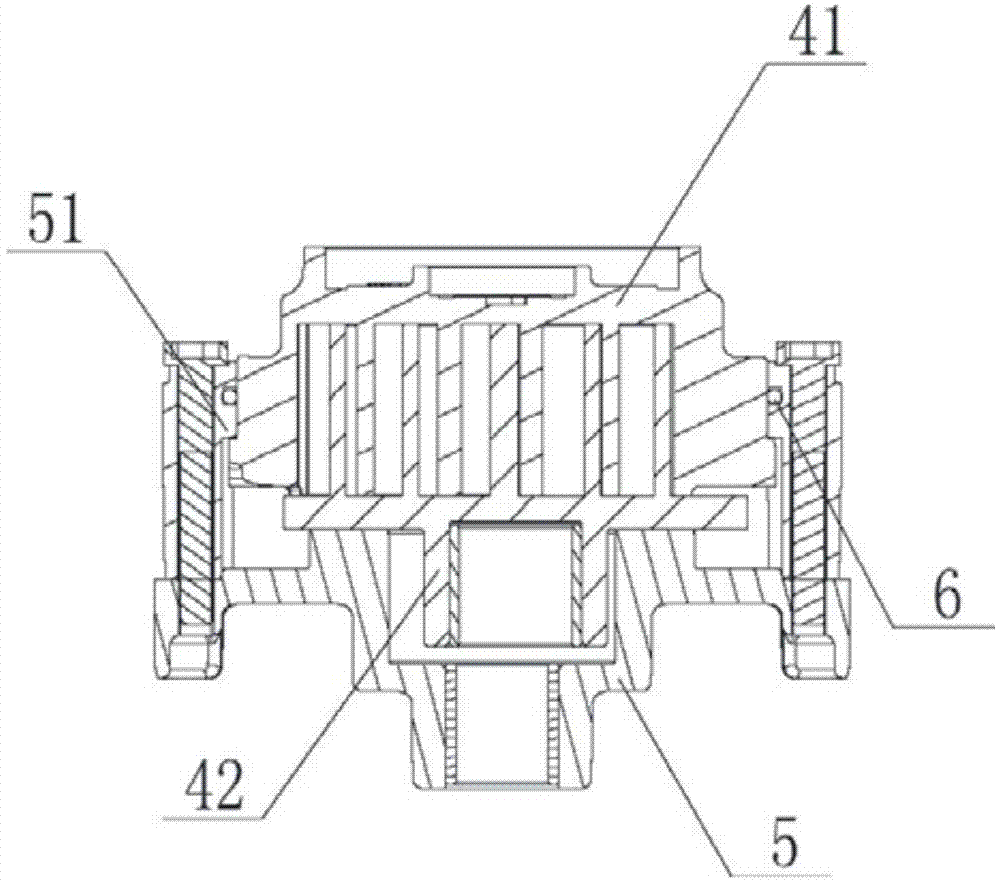

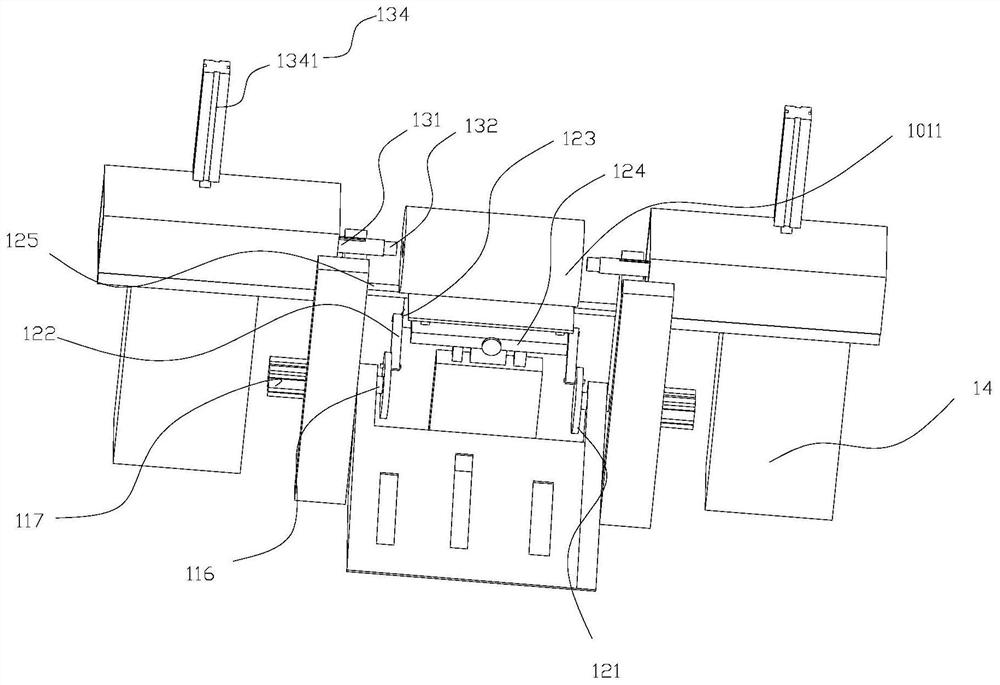

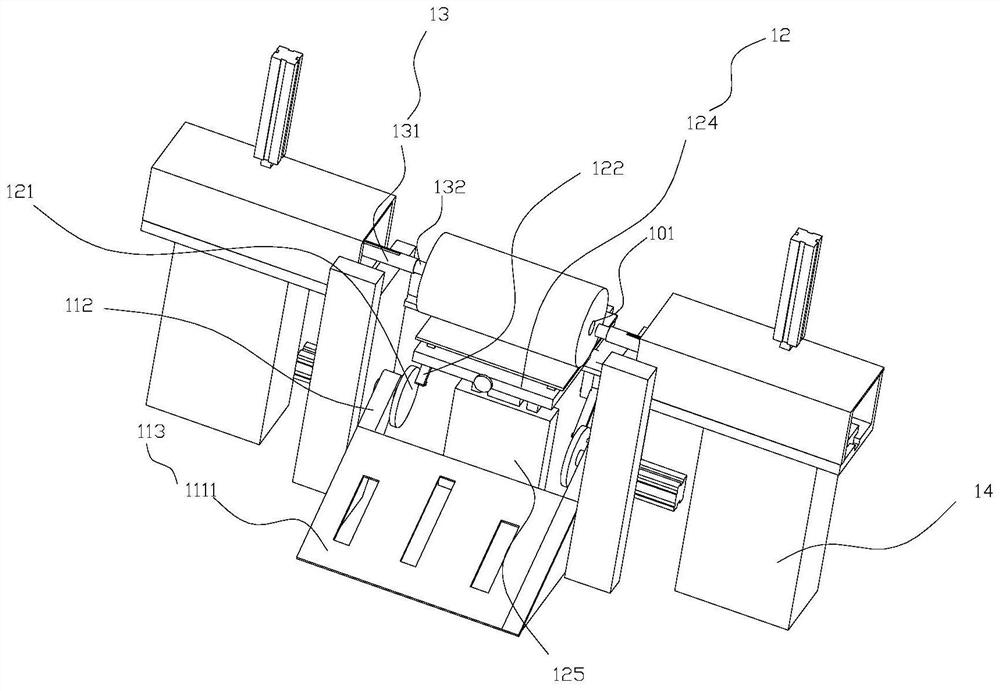

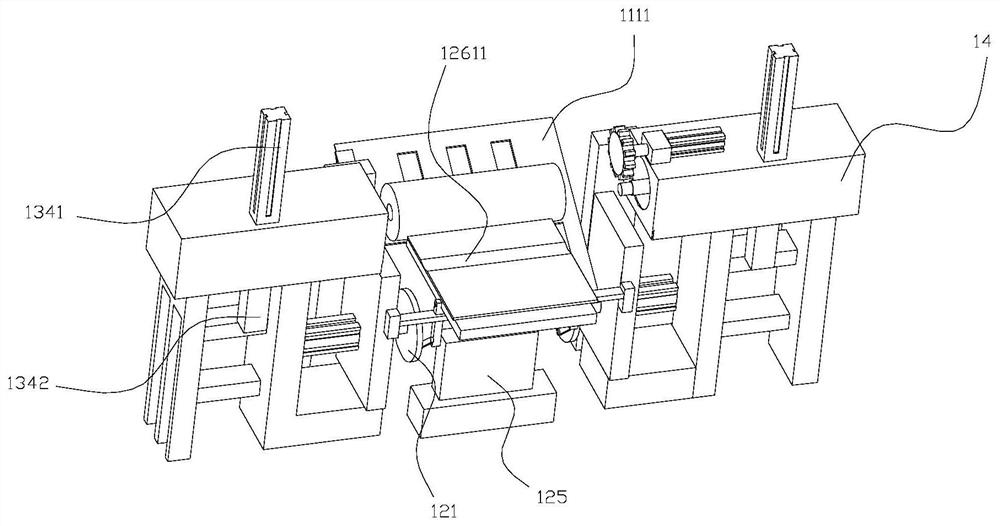

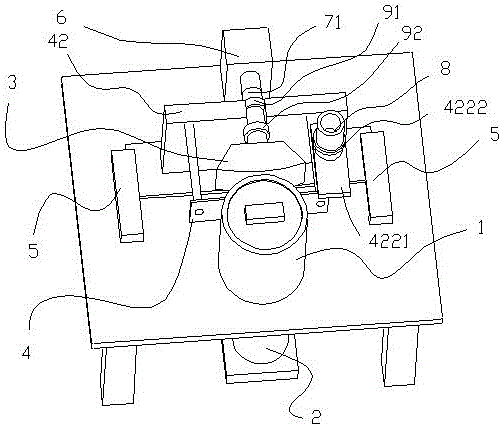

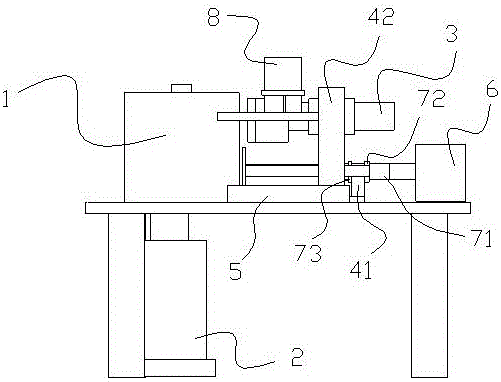

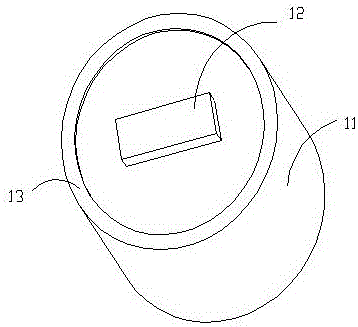

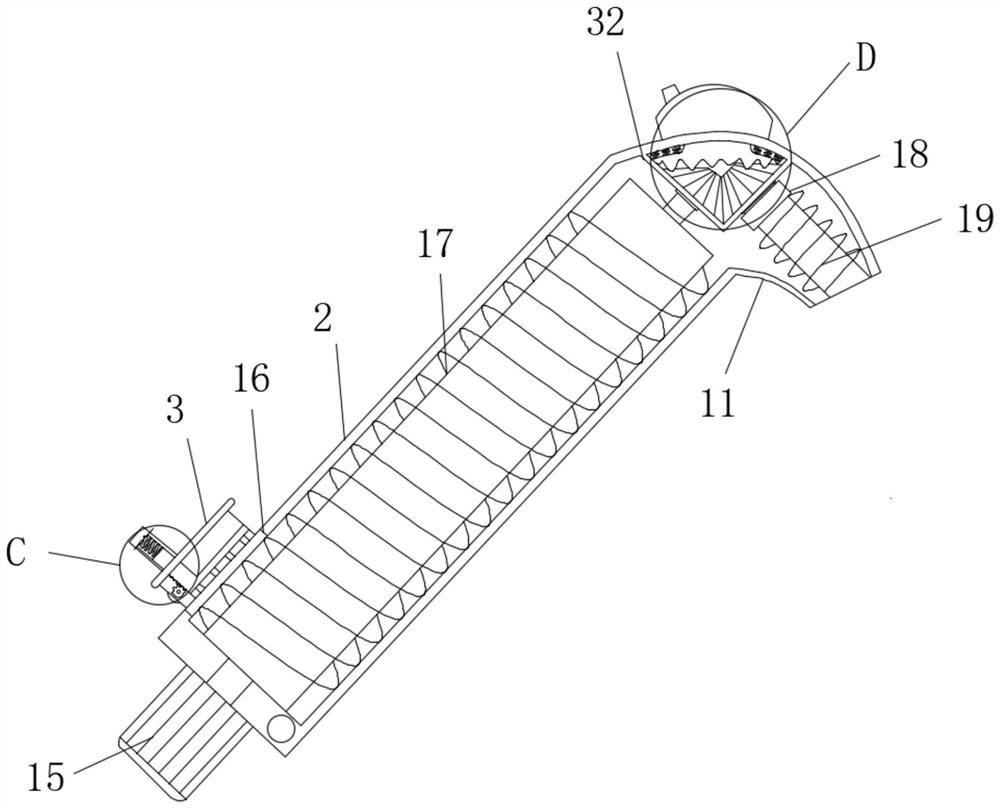

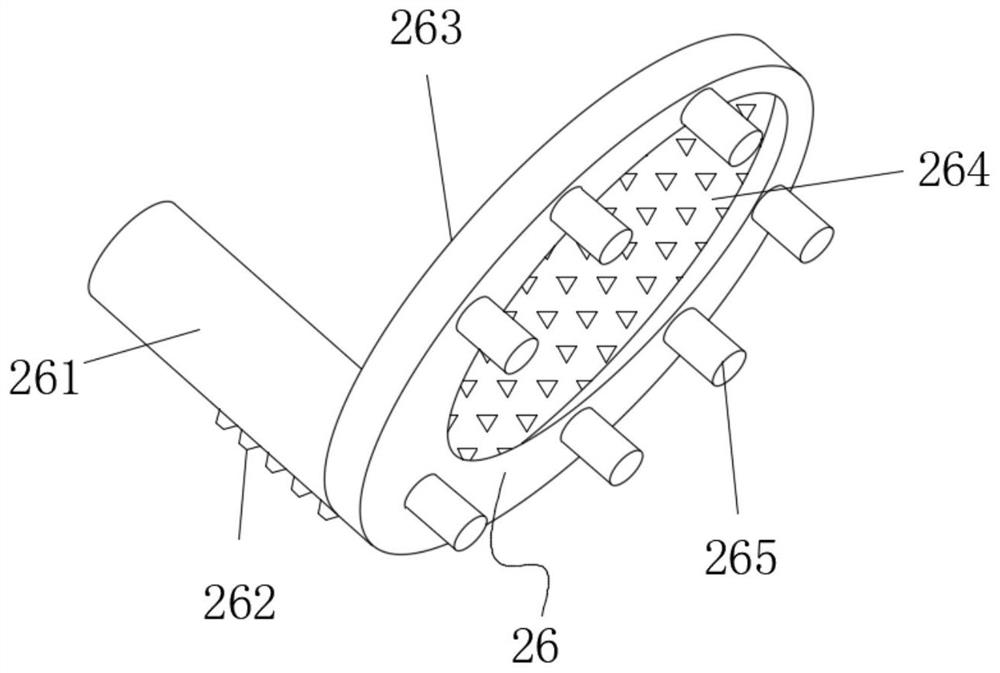

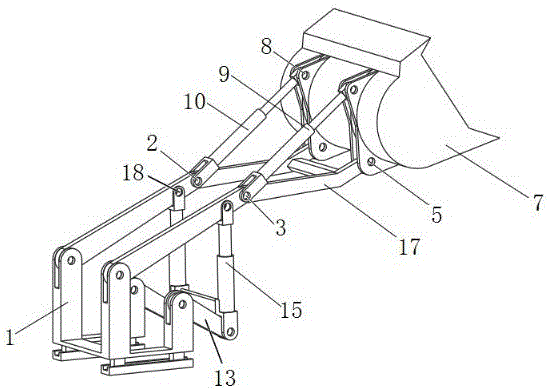

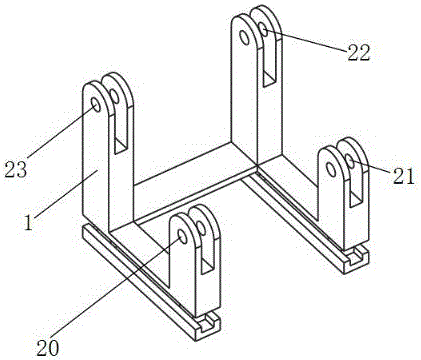

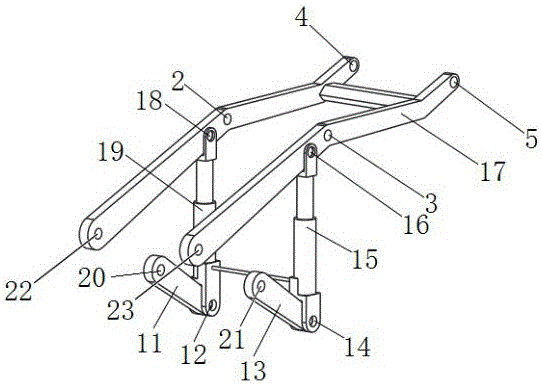

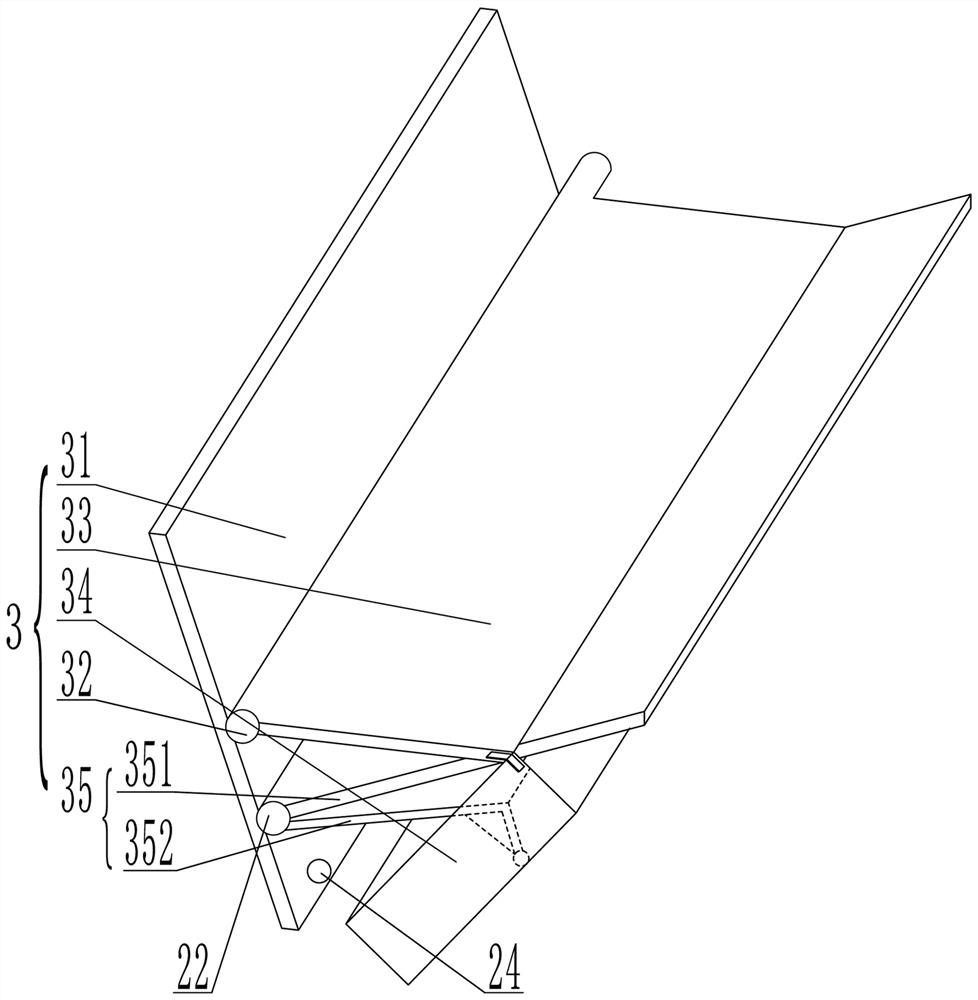

Multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism

InactiveCN104476535AGuaranteed to always translateInhibition rigidityProgramme-controlled manipulatorMulti degree of freedomActuator

The invention relates to a multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism. The multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism comprises an arm lifting mechanism and a movable platform. The arm lifting mechanism is composed of a plane five-bar mechanism and a branched chain. The planar motion of the arm lifting mechanism is realized through the synthetic motion of the plane five-bar mechanism and the branched chain; the spatial motion of the whole mechanism is realized through the motion of the movable platform. Two serial parallelogram structures are utilized for guaranteeing that an end actuator transversely moves all the time. Due to the mechanism, the robot has motion redundancy of almost infinite work space and height, has moving and operating functions at the same time, can realize complicated motion output, preferably realizes various palletizing actions, and is suitable for more occasions.

Owner:GUANGXI UNIV

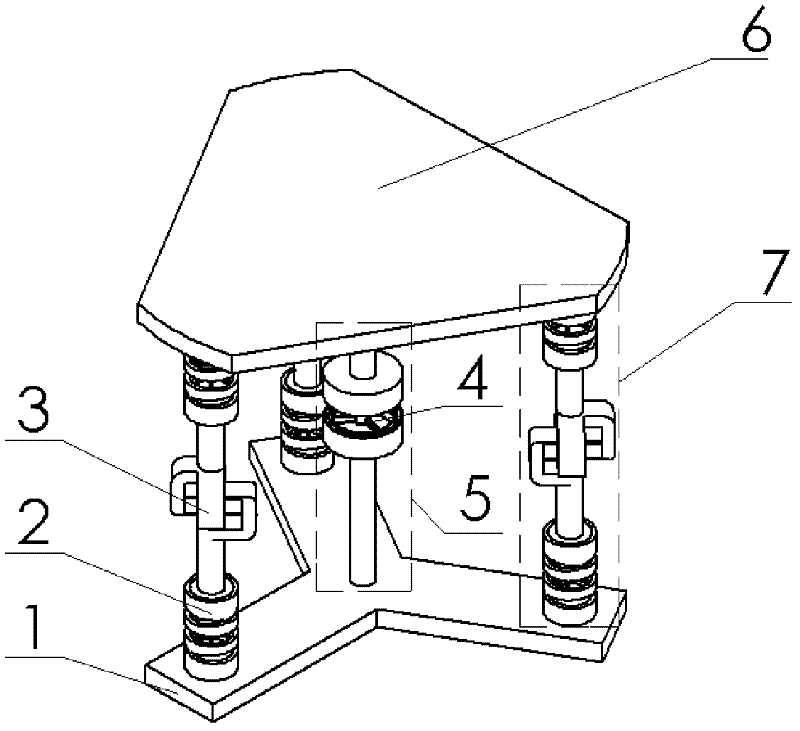

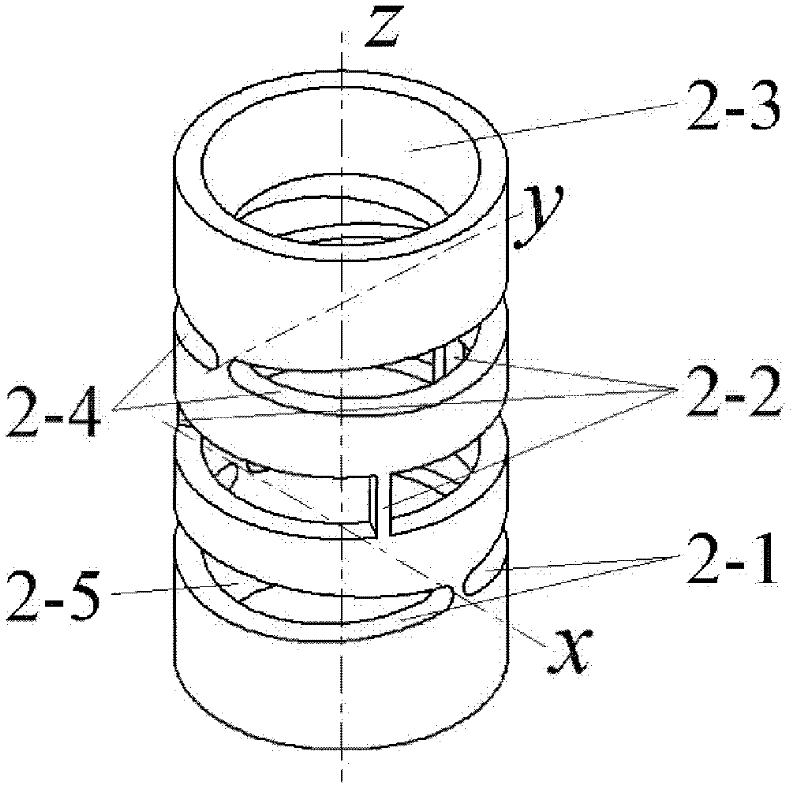

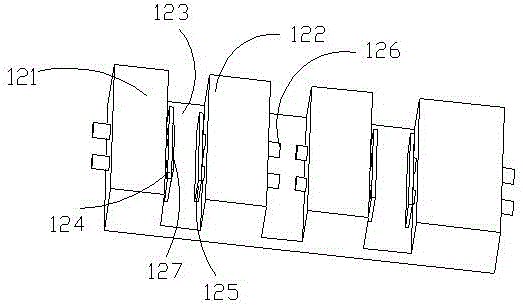

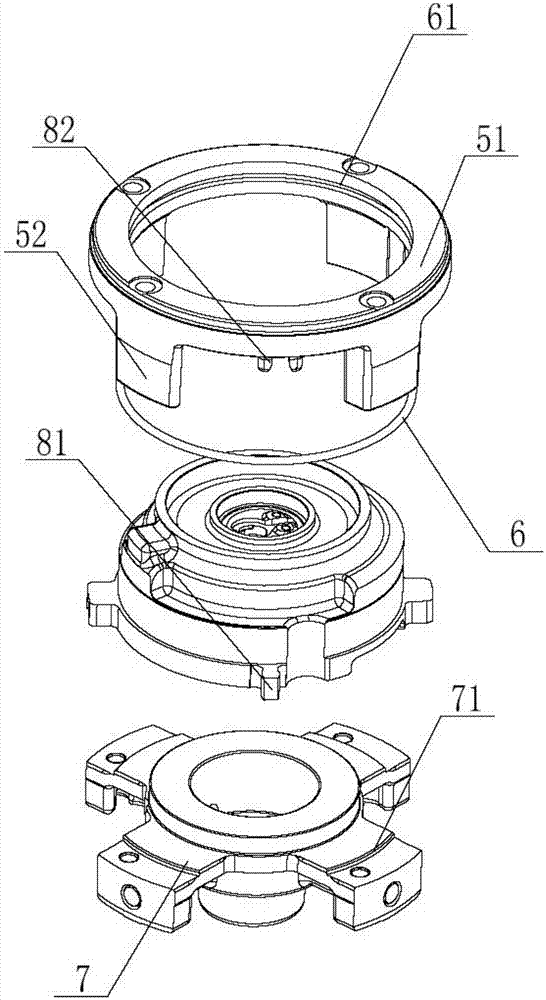

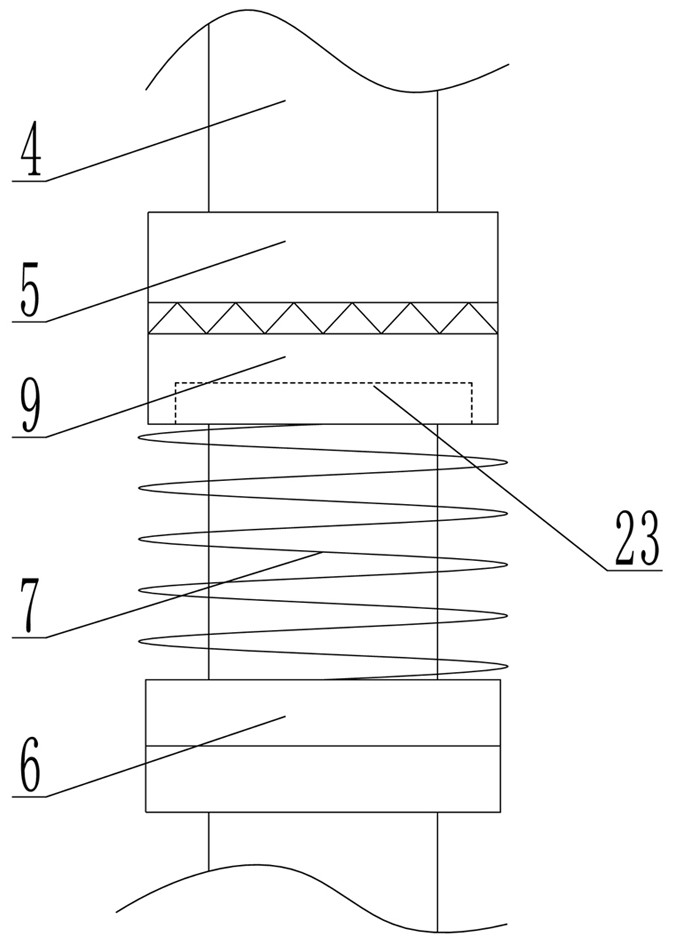

Intermediate branch chain of fully-flexible fine operation platform

ActiveCN102501245ASimple structureImprove operating precisionProgramme-controlled manipulatorEngineeringDegrees of freedom

The invention discloses an intermediate branch chain of a fully-flexible fine operation platform, wherein a four-degree-of-freedom (DOF) flexible hinge is disposed at the middle part of the intermediate branch chain, and the four-DOF flexible hinge comprises an upper connection ring, a lower connection ring and a central column; a three-branch Y-shaped connection sheet is disposed in the upper connection ring; the three branches of the Y-shaped connection sheet are disposed on the same horizontal plane, the first branch is arranged along x-axis, the second branch is arranged along y-axis, and the third branch is arranged along a direction in an angle of 135 degrees with x-axis; three radial sheet-shaped beams uniformly distributed along a circumference are disposed in the lower connection ring; the three radial sheet-shaped beams are installed at the lower end of the central column; and the upper end of the central column is connected with the bottom surface of the Y-shaped connection sheet. The intermediate branch chain of a fully-flexible fine operation platform has a fully-flexible joint and four degrees of freedom, so that the rigid collision and damage generated by the fully-flexible fine operation platform can be avoided.

Owner:HUNAN UNIV

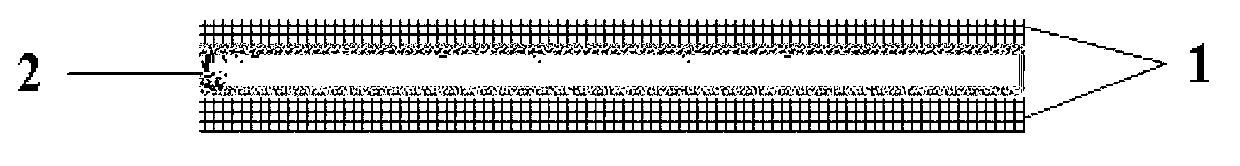

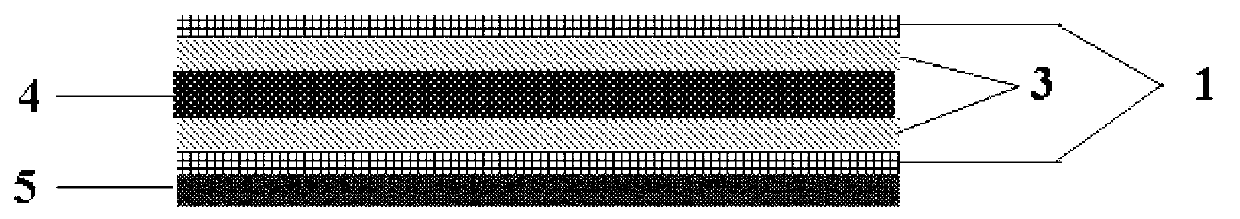

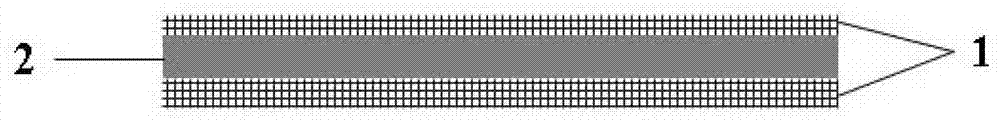

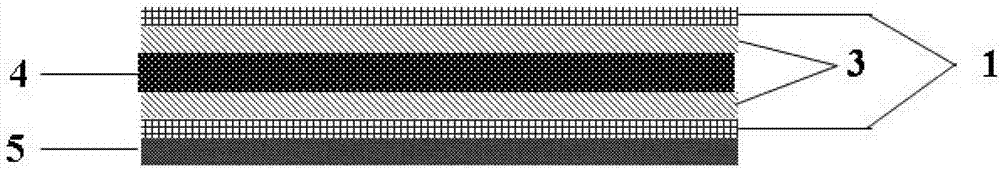

Polyurethane composite board with high light weight, high strength and high sound absorption, and full adhesive film forming technology of polyurethane composite board

ActiveCN103101256ASolve pollutionImprove wettabilitySynthetic resin layered productsLaminationFiberGlass fiber

The invention relates to a forming technology of a PU (polyurethane) composite board and particularly relates to a full adhesive film forming technology of a PU composite board with high light weight, high strength and high sound absorption for a high-grade car roof. The polyurethane composite board with high light weight, high strength and high sound absorption is compounded of a bottom fabric, adhesive film type fiber felt, a PU foaming board, adhesive film type fiber felt and net-shaped hot melt adhesive films which are sequentially laminated from bottom to top; according to the adhesive film type fiber felt, a central core layer is made of reinforce fibers and the upper surface and the lower surface of the central core layer are respectively composited with net-shaped hot melt adhesive films with different gram weights. The dust pollution problem caused by the use of adhesive powder is avoided; besides, fibers and the adhesive film are compounded firstly; and the invasion of the adhesive film to glass fibers is improved, so that the rigidity and the peeling strength of the polyurethane composite board are improved.

Owner:浙江华江科技股份有限公司

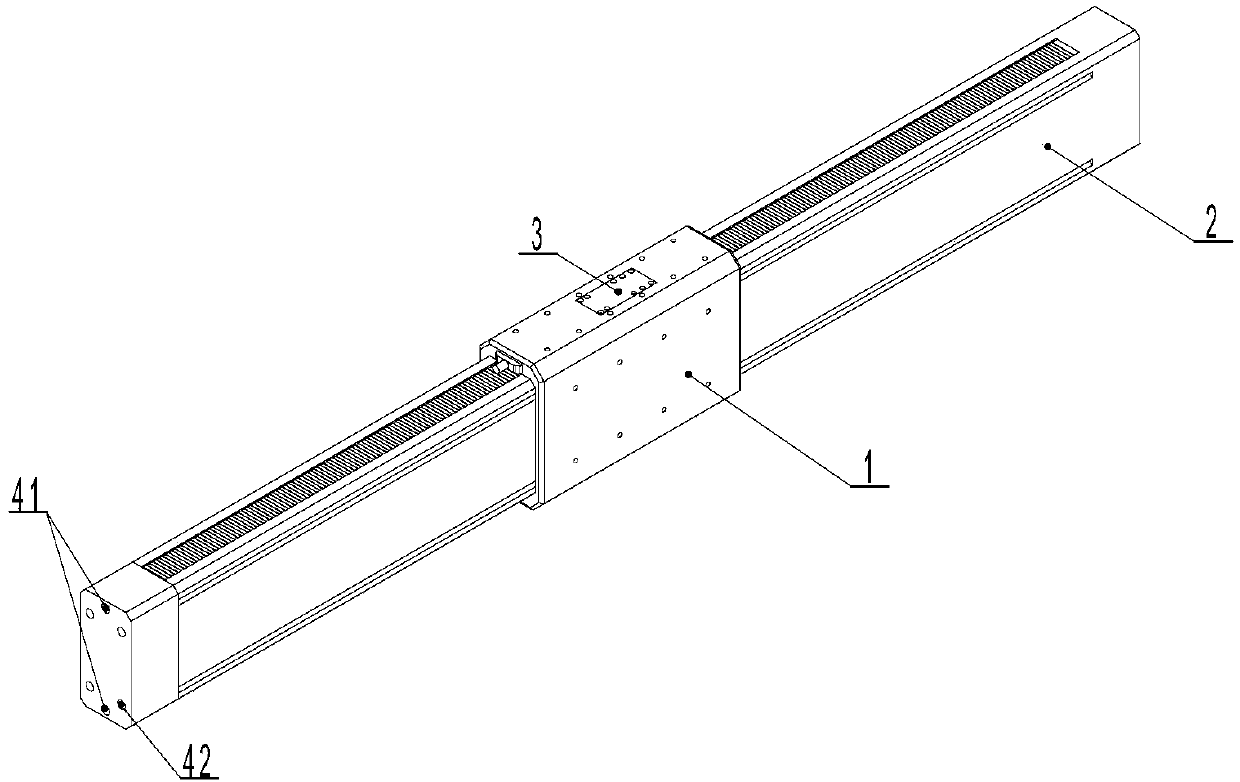

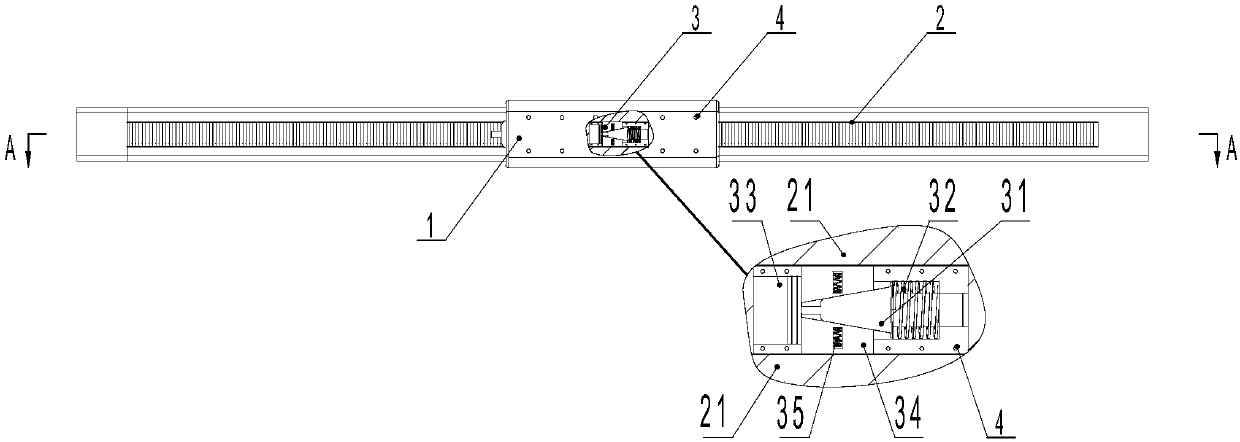

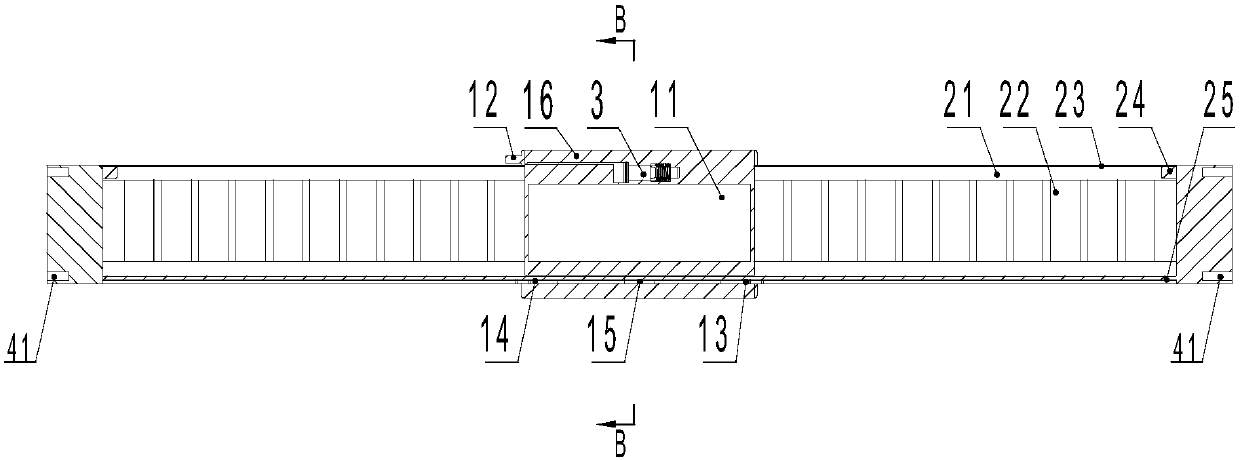

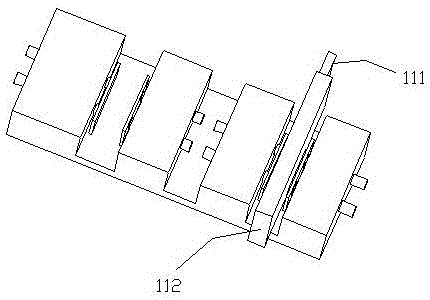

Linear motor module for robot splicing

PendingCN107733204ACompact structureReduce power lossProgramme-controlled manipulatorMechanical energy handlingElectric machineControl engineering

The invention relates to a linear motor module for robot splicing. The linear motor module comprises a rotor assembly, a stator assembly, a brake and a controller, wherein the brake is connected to the rotor assembly, the rotor assembly sleeves the stator assembly, connection holes are formed in both of the rotor assembly and the stator assembly, the rotor assembly comprises a shell, a coil, a connector, a grating reading head, a first limit switch and a second limit switch, the stator assembly comprises a stator body, a permanent magnet and a grating, the brake comprises a wedge-shaped block,a braking spring, a piston, a braking block and an extrusion spring, and the grating reading head, the first limit switch, the second limit switch and the piston all are electrically connected with the controller.

Owner:GSK CNC EQUIP

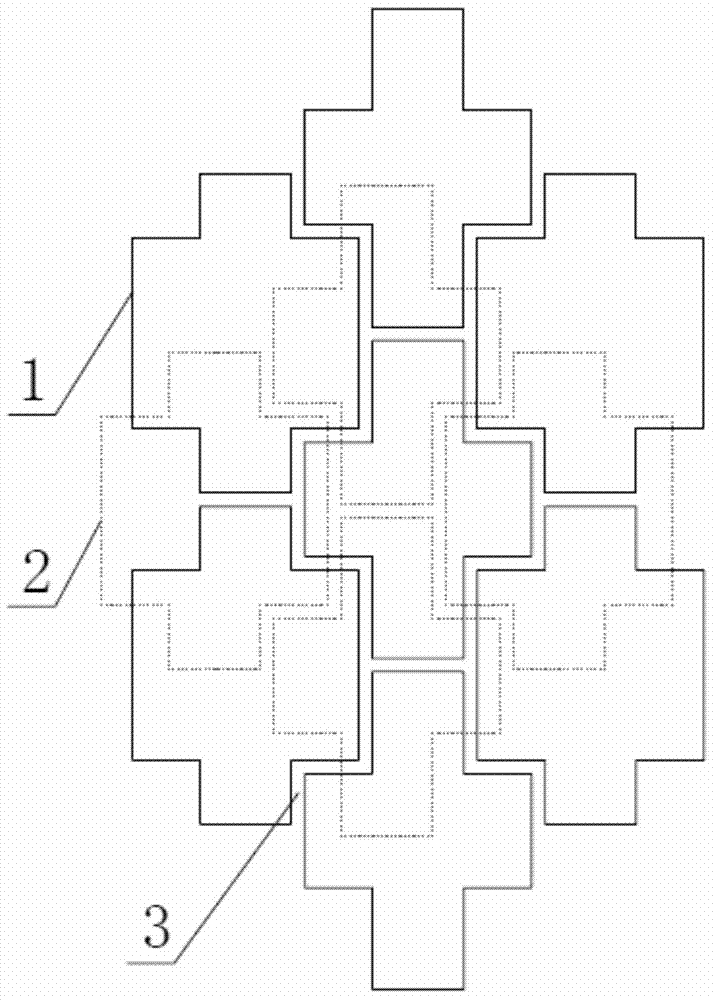

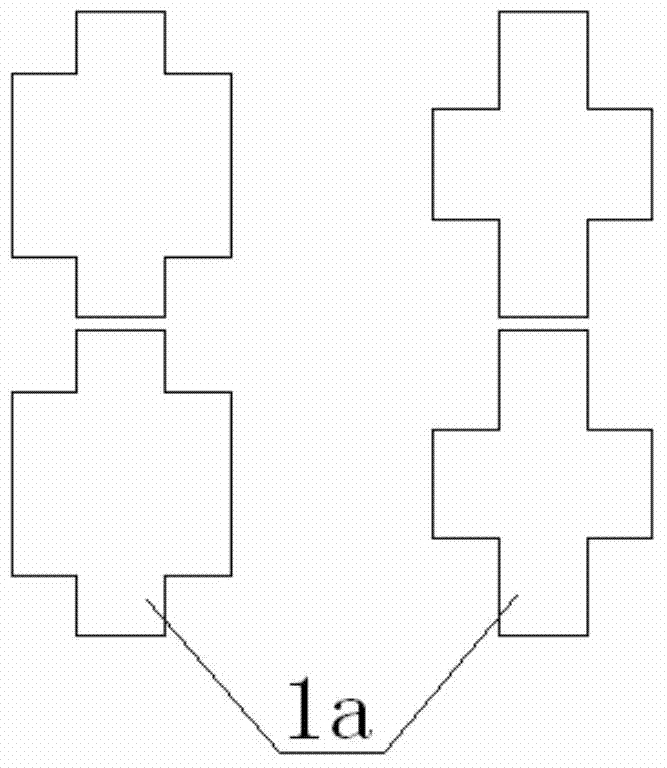

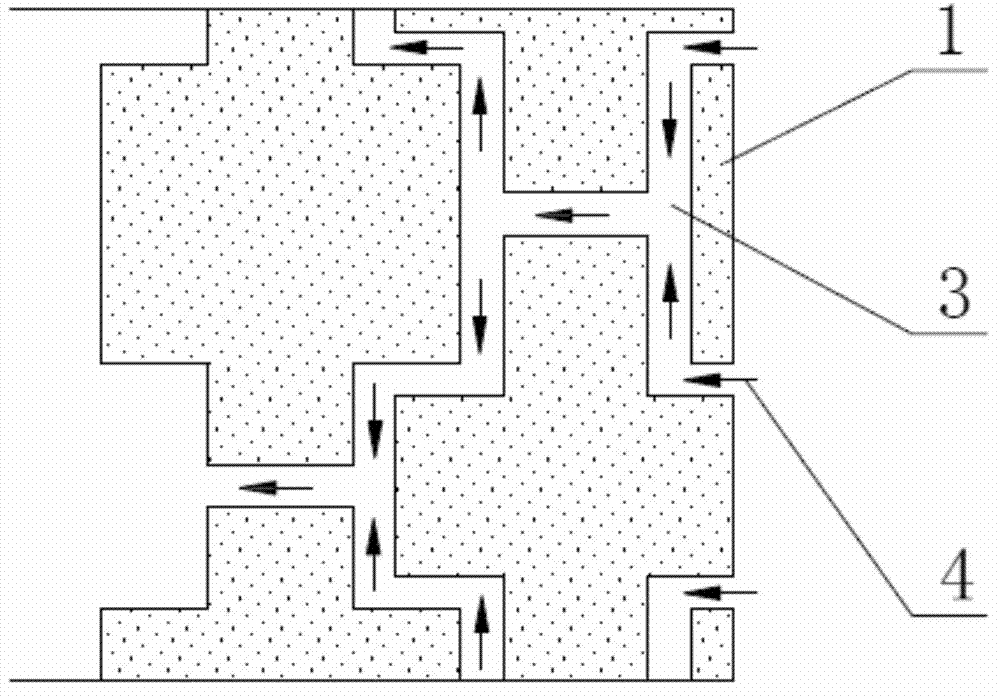

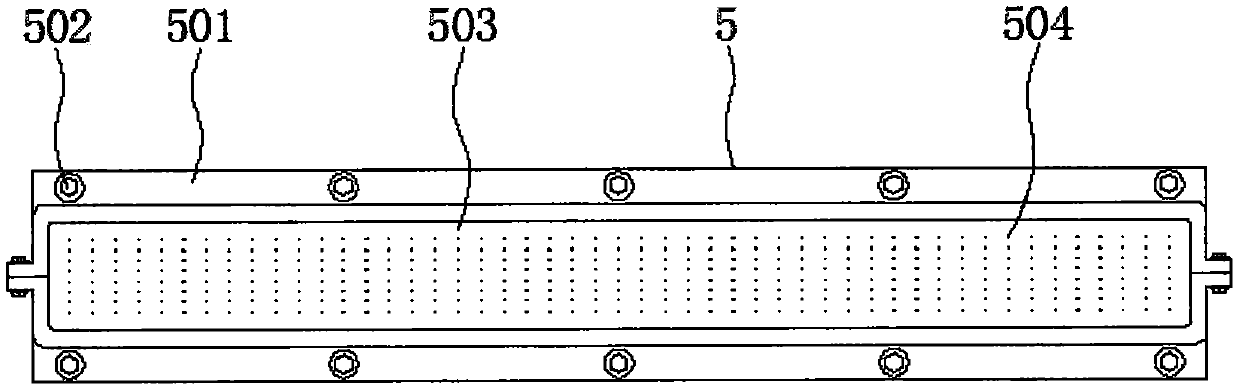

Flow choking strip for printed circuit board

InactiveCN103596361AImprove rigidityReduce board damage defectsElectrical connection printed elementsEngineeringPrinted circuit board

The invention discloses a flow choking strip for a printed circuit board, which is arranged at the edges of the two sides of a printed circuit board core material. The flow choking strip comprises a plurality of flow choking blocks with the cross section being cross-shaped, wherein the plurality of flow choking blocks form a bar-shaped flow choking strip through arrangement and combination, and the flow choking blocks are provided with diversion clearances with the same size therebetween. As adoption of the technical scheme, the flow choking strip provided by the invention for the printed circuit board avoids problems that core materials of traditional bar-shaped flow choking strips, wall-shaped flow choking strips, dot-shaped flow choking strips are low in rigidity, and that the air or resin overflow speed is too high or too low, and enables an empty area of the board side of the printed circuit board core material to be uniformly dispersed without large continuous empty areas, thereby obviously improving the rigidity of the core material, and significantly reducing board damage defects of the core material in the processing and manufacturing process.

Owner:DALIAN PACIFIC ELECTRONICS

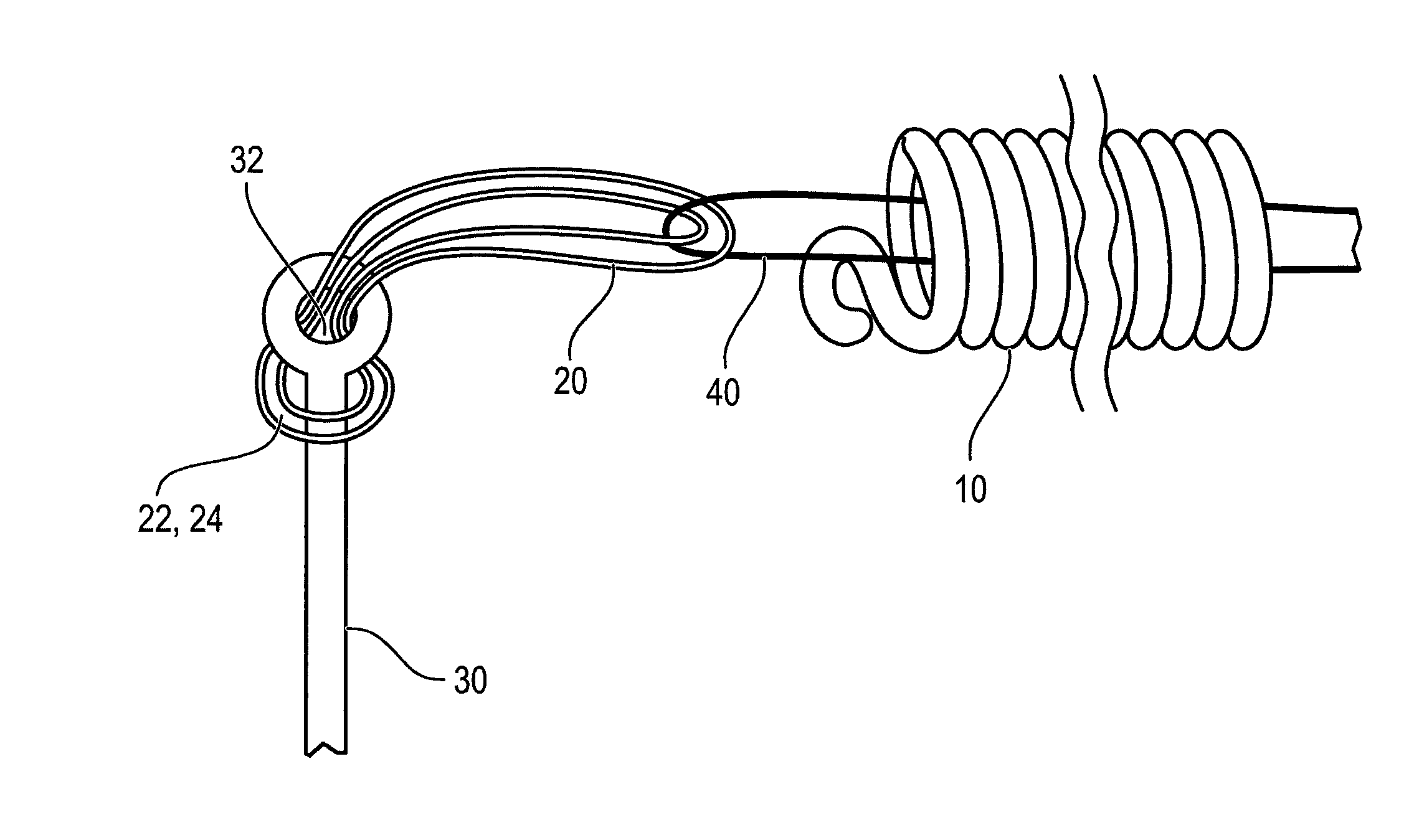

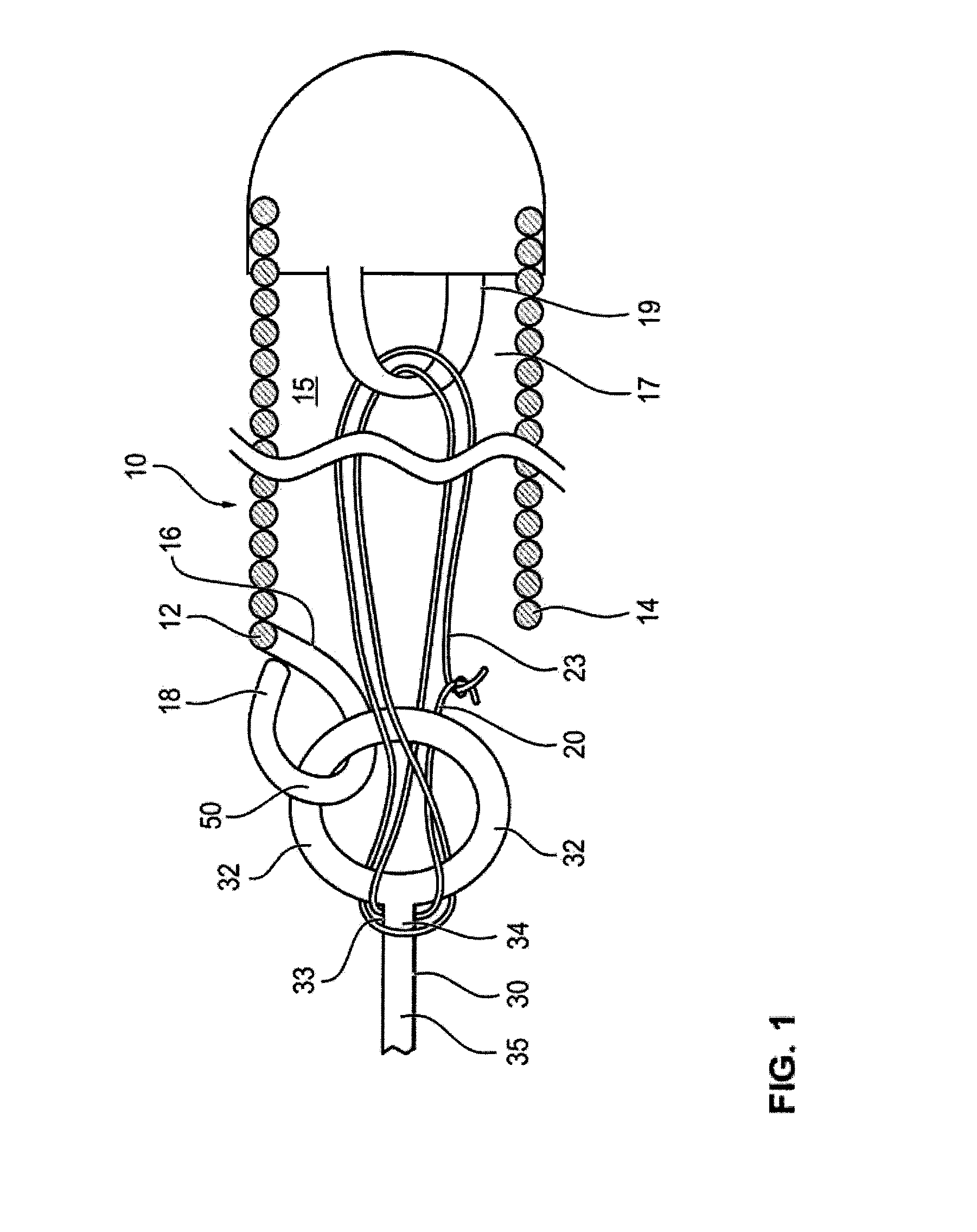

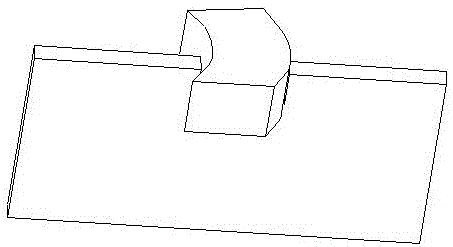

System for delivering a stretch resistant vaso-occlusive device and a method of producing same

InactiveUS20130325054A1Inhibition rigidityStretch resistant vaso-occlusive deviceDilatorsOcculdersProximal pointSurgery

A system for delivering a vaso-occlusive device for release within vasculature of a patient, the device containing an outer helically wound primary coil having a proximal end and distal ends, defining a lumen between them. The proximal end is detachably mounted to the distal end of an elongated delivery means. Further, the system also comprises an attachment element, at the distal end of the vaso-occlusive device and a stretch resisting member with two proximal ends and a distal end, extending at least partially through the lumen and passing through the attachment element, the distal end being releasably attached to the distal attachment element. The device has the advantage that the device is not damaged during manipulation by a physician, reducing the risk of injury to a patient.

Owner:ACANDIS

Nano composite polyformaldehyde material and its preparation

The present invention discloses one kind of nano composite polyformaldehyde material, and the composite contains polyformaldehyde 55-90 wt% and elastomer 2.5-30 wt% as well as characterized inorganic nano stuffing 0.1-10 wt% and compatibilizing agent 0.1-10 wt%. During the preparation, inorganic nano stuffing, compatibilizing agent and elastomer in certain proportion are smelted and mixed to obtain agglomerate; and the agglomerate is then diluted and dispersed in polyformaldehyde or polyformaldehyde / elastomer to obtain the product through further smelting and mixing. The present invention can strengthen and toughen polyformaldehyde while reducing cost.

Owner:SICHUAN UNIV

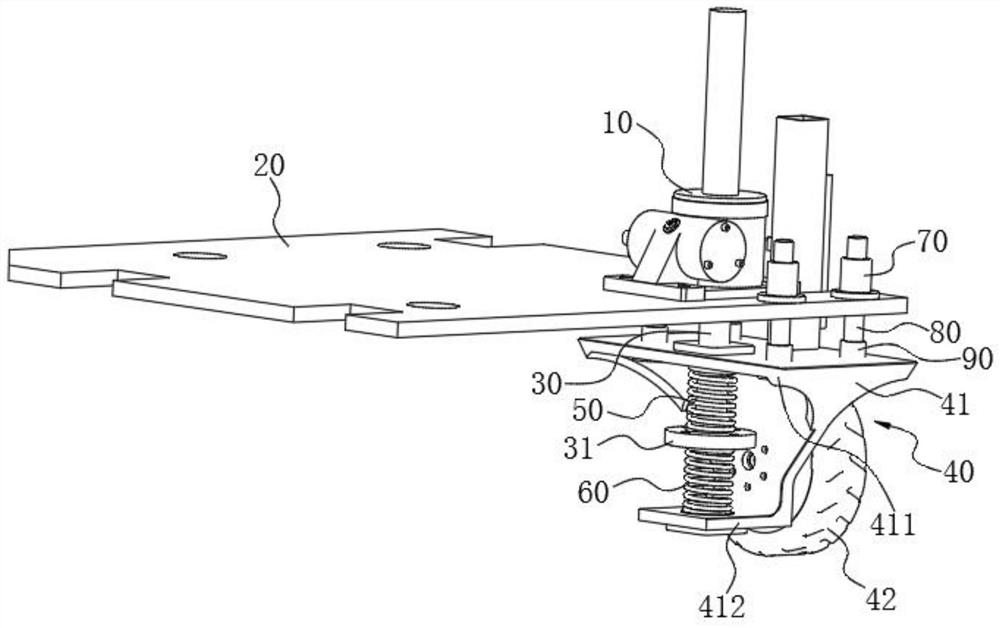

Suspension device, movable chassis and robot

ActiveCN112319168AImprove stabilityImprove adaptabilityResilient suspensionsControl theoryRolling chassis

The invention relates to a suspension device, a mobile chassis and a robot, and the suspension device comprises a driver which is used for being installed on a chassis body; a height adjustment executing part which is in driving connection with the driver, and the driver can drive the height adjustment executing part to move up and down; and a walking wheel system which is movably installed on thechassis body and movably connected with the height adjustment executing piece, and the height adjustment executing piece can drive the walking wheel system to be away from or close to the chassis body. According to the scheme, the suspension device is applied to a robot, is specifically used for being installed on a movable chassis, and can achieve the effect that the height of the chassis body is adjustable. According to the suspension device, lifting adjustment of the movable chassis can be achieved, the passing capacity and safety of the robot for different uneven road surfaces are improved, the service life is prolonged, and the working reliability is guaranteed.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

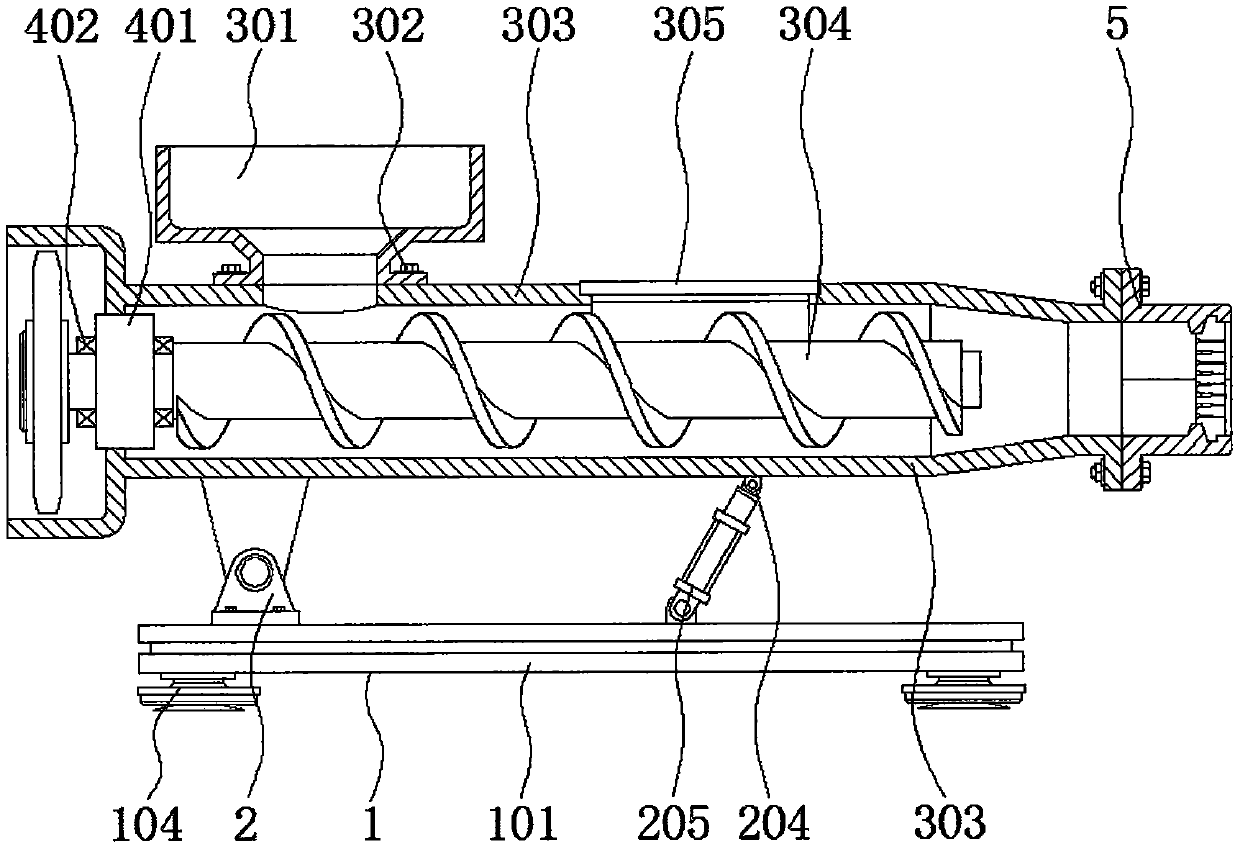

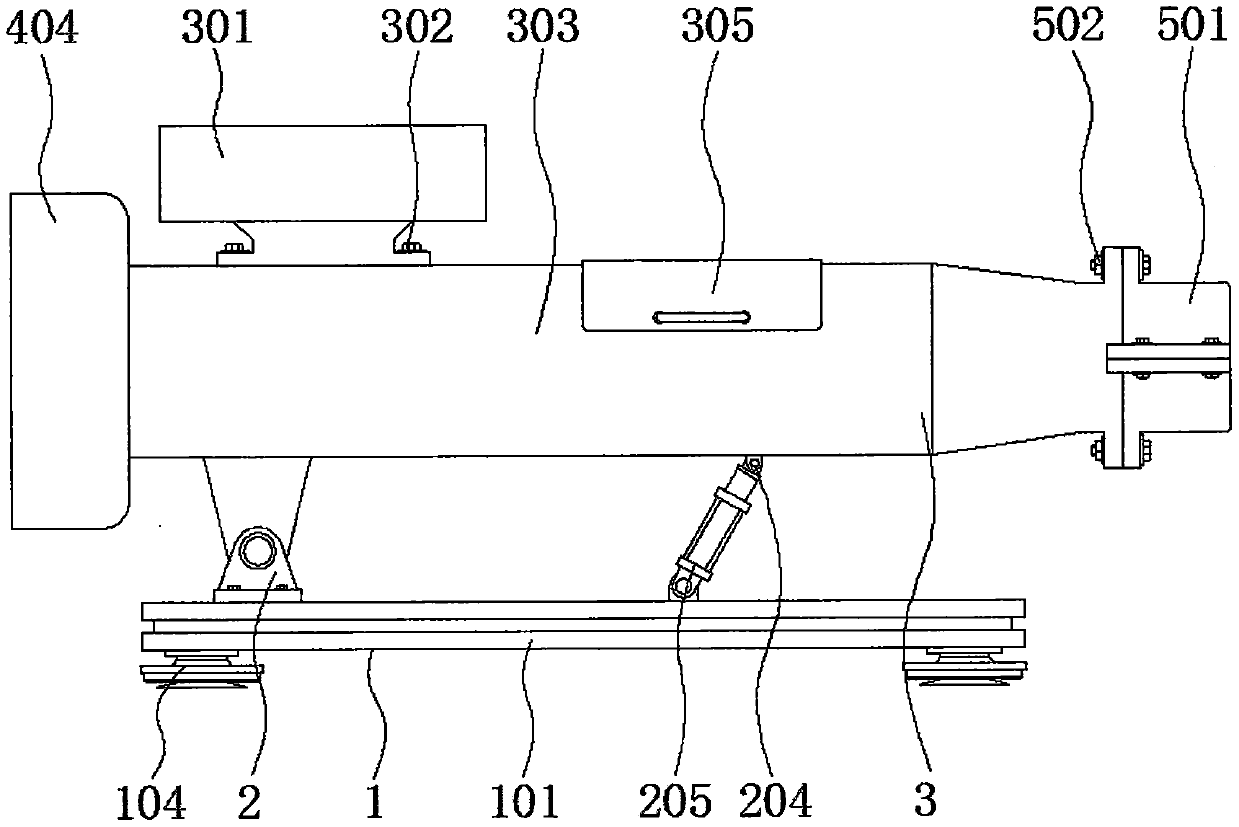

Wire spraying device with anti-residue heating structure for non-woven fabric production

InactiveCN110499534AGuaranteed stabilityAvoid direct contactSpinnerette packsSpinning head liquid feederEngineeringNonwoven fabric

The invention discloses a wire spraying device with an anti-residue heating structure for non-woven fabric production, and relates to the technical field of non-woven fabric production equipment. Thedevice comprises a composite base and a wire spraying mechanism. A support adjusting mechanism is arranged at the upper part of the composite base, and a power transmission mechanism is arranged on the left side of an extrusion molding pressurizing mechanism. The wire spraying mechanism comprises a side frame, bolts, a wire spraying plate and wire spraying guide holes. The side frame is internallyprovided with the wire spraying plate. According to the wire spraying device with the anti-residue heating structure for non-woven fabric production, the structure is increased, and meanwhile the performance of the whole device is greatly improved. The improved device not only has a smooth wire spraying effect, but also additionally achieves the ability of continuous internal heating, correspondingly the shape of raw materials in the process of extrusion is maintained, the generation of residues of internal materials in the device is avoided, and people's needs for use are effectively met.

Owner:湖南欣龙非织造材料有限公司

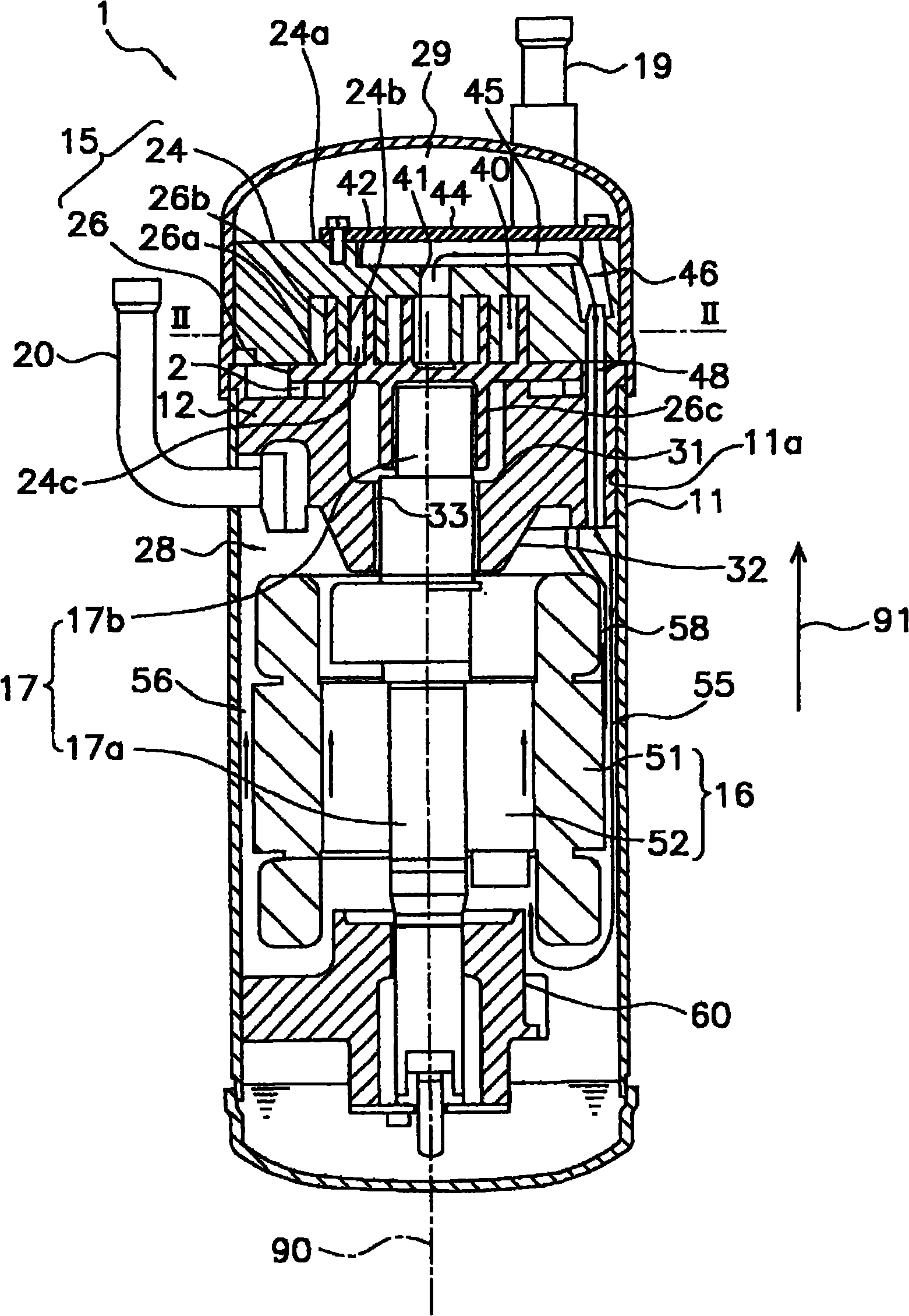

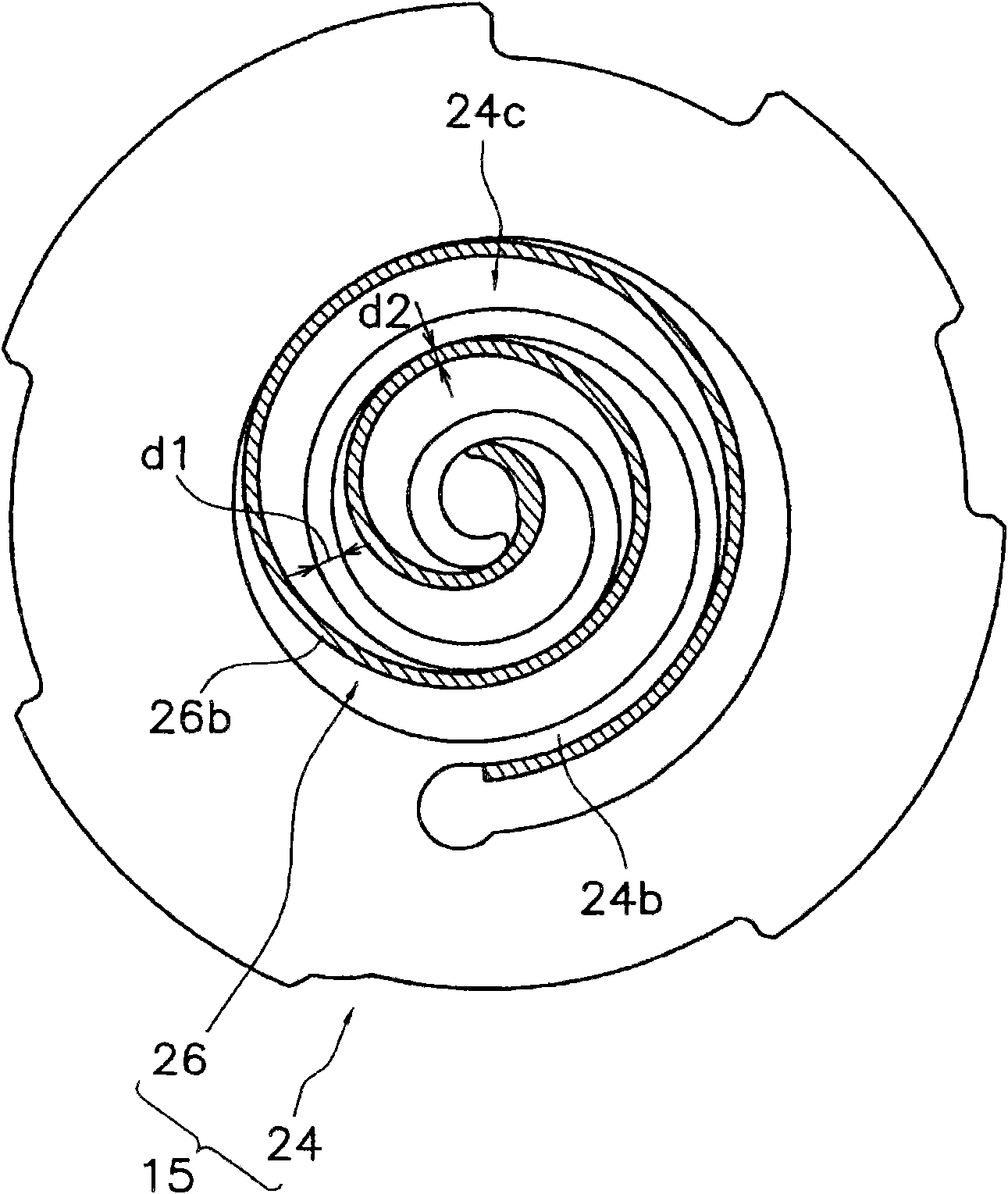

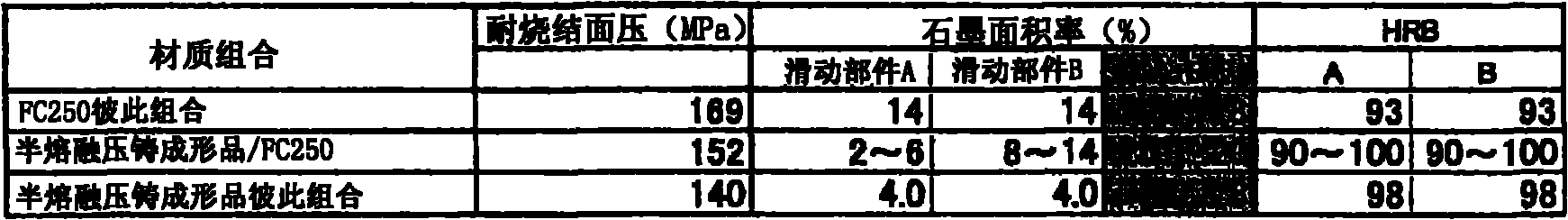

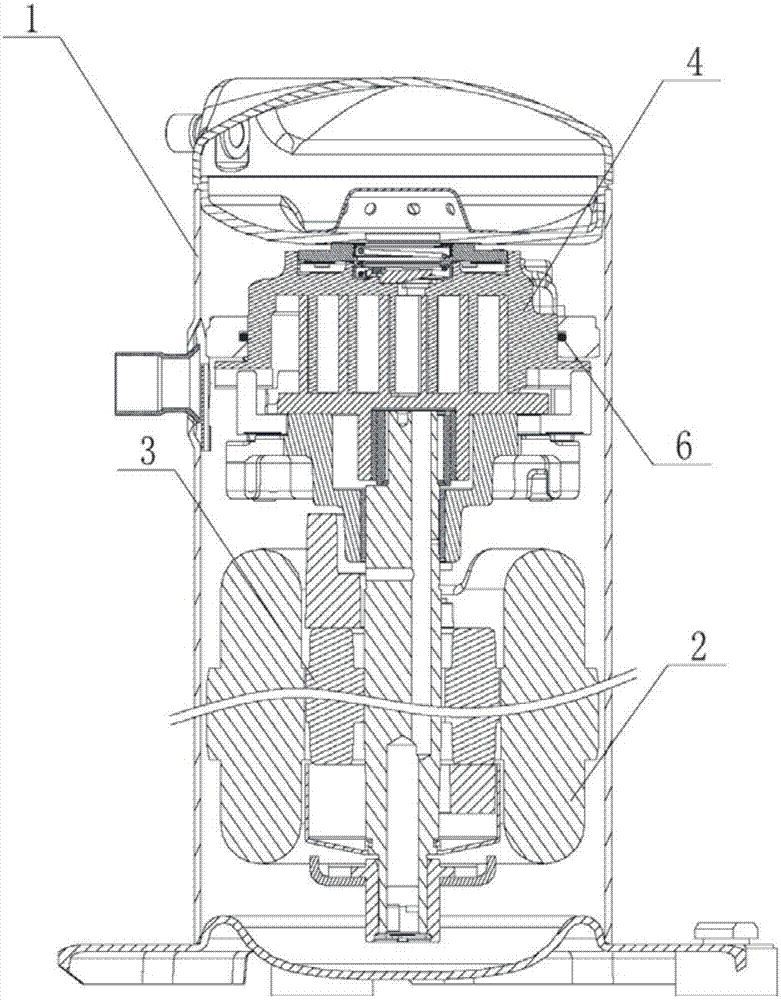

Compression mechanism and scroll compressor

ActiveCN101772647ADifficult to sinterEasy to prevent sinteringRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDie castingEngineering

A compression mechanism that has increased strength and rigidity and in which seizure is prevented. A scroll compressor (1) has the compression mechanism (15). The compression mechanism (15) has a stationary scroll (24) and a movable scroll (26) and compresses refrigerant. The stationary scroll (24) and the movable scroll (26) use different materials. Specifically, either of the stationary scroll (24) and the movable scroll (26) is a die cast molding produced by molding cast iron by semi-molten die casting. The other is a gray pig cast iron product. A gray pig cast iron product having a tensile strength in the range of not less than 250 N / mm2 but not more than 300 N / mm2 can be used.

Owner:DAIKIN IND LTD

Medical ultrasonic detection device

InactiveCN113545804AHigh degree of automationReduce laborPatient positioningInfrasonic diagnosticsMedical staffEngineering

The invention discloses a medical ultrasonic detection device, and belongs to the field of medical ultrasonic detection. The medical ultrasonic detection device comprises a workbench, a first lead screw, a second lead screw, a supporting plate, a detection mechanism, a limiting mechanism and a clamping mechanism; the first screw rod and the second screw rod are arranged at the upper end of the workbench, universal balls are arranged at the lower end of the supporting plate, the position of the supporting plate on the workbench can be changed at will in cooperation with detection of the detection mechanism, so that ultrasonic detection on multiple body parts of a patient is achieved, the automation degree of the ultrasonic detection is greatly improved, and the workload of medical staff is reduced; the limiting mechanism and the clamping mechanism are arranged on the detection mechanism, so that the situation that a probe is driven by a fourth driving device to descend all the time, and the body surface of the patient is injured due to too large pressure is avoided; a first driving device is arranged at the upper end of a base to control the workbench to ascend and descend, so that the probe can ascend to an original position after detecting the patient.

Owner:陈明香

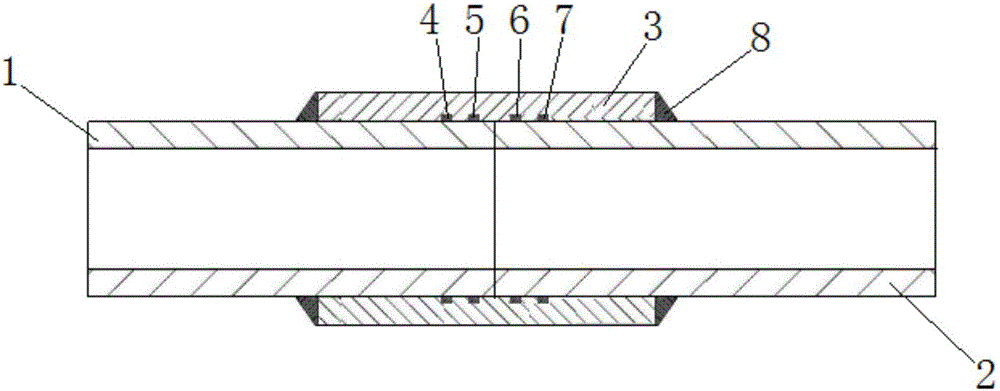

Pipeline welding structure for pull pipe construction method

InactiveCN105952992AGuaranteed welding fastnessAvoid the problem of unstable weldingPipe couplingsCouplingsArchitectural engineeringPipe welding

The invention discloses a pipeline welding structure for a pull pipe construction method. The pipeline welding structure comprises an outer sleeve at a pipeline joint, more than one welding slot is arranged at each of two ends of the outer sleeve, the welding slots do not run through the pipe wall of the outer sleeve; at two sides of the outer sleeve and in the welding slots, the outer sleeve is welded with a pipeline in the outer sleeve; on the inner wall of the outer sleeve, a first welding rod, a second welding rod, a third welding rod and a fourth welding rod are arranged in the middle of the outer sleeve; the pipeline joint is located between the second welding rod and the third welding rod; and the first welding rod, the second welding rod, the third welding rod and the fourth welding rod are connected between the outer sleeve and the pipeline in a sealed way by adopting a hot melting manner. The pipeline welding structure is simple in structure, and the arrangement of the outer sleeve structure ensures the firmness and tightness of welding of two pipelines in long-distance traction and drawing.

Owner:江苏中达建设工程有限公司

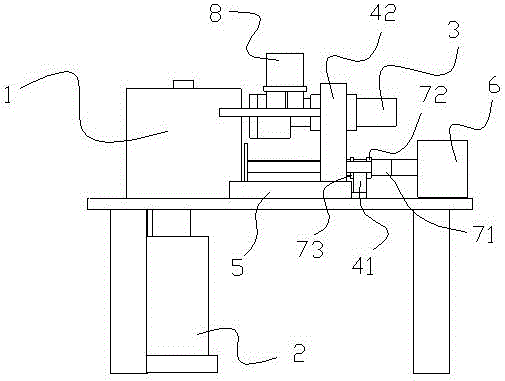

Piston processing method

The invention discloses a piston processing method which comprises the following steps of material selecting and smelting; pouring; thermal treatment; metal processing: carrying out neck ring turning, pinhole base hole processing and oil coating in sequence, wherein a neck ring turning device is adopted to carry out neck ring turning on a piston, a pinhole base hole processing device is adopted to carry out pinhole base hole drilling on the piston, and an automatic oil coating mechanism is adopted to carry out oil coating on the piston; and roundness test: adopting a piston roundness test device to test surface roundness of the piston. The piston processing method disclosed by the invention has the advantage of being high in strength and modulus, stable and precise in neck ring turning, stable in clamping, uniform in oil coating, high in oil coating efficiency, free of manual handheld measuring and wide in measuring position selectivity, and being capable of reducing tool abrasion, avoiding occurrence of oval holes during drilling, improving product quality, reducing a rejection rate and realizing simultaneously measuring roundness of the skirt part and the top part of the piston.

Owner:ANHUI HIGH TECH POWER TECH

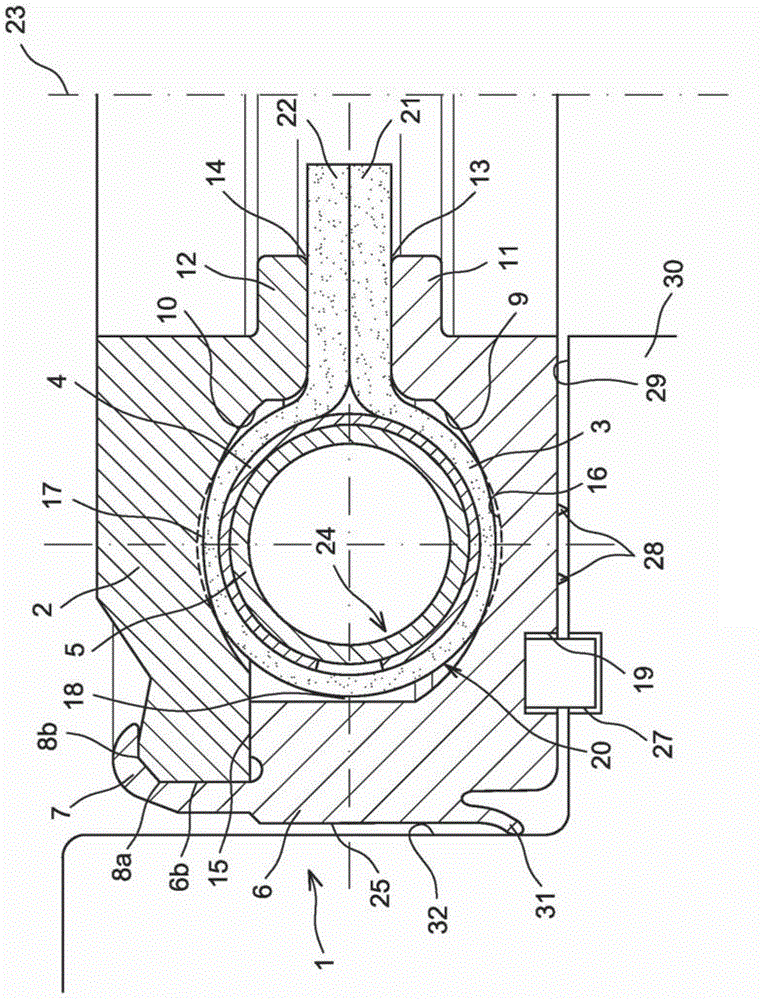

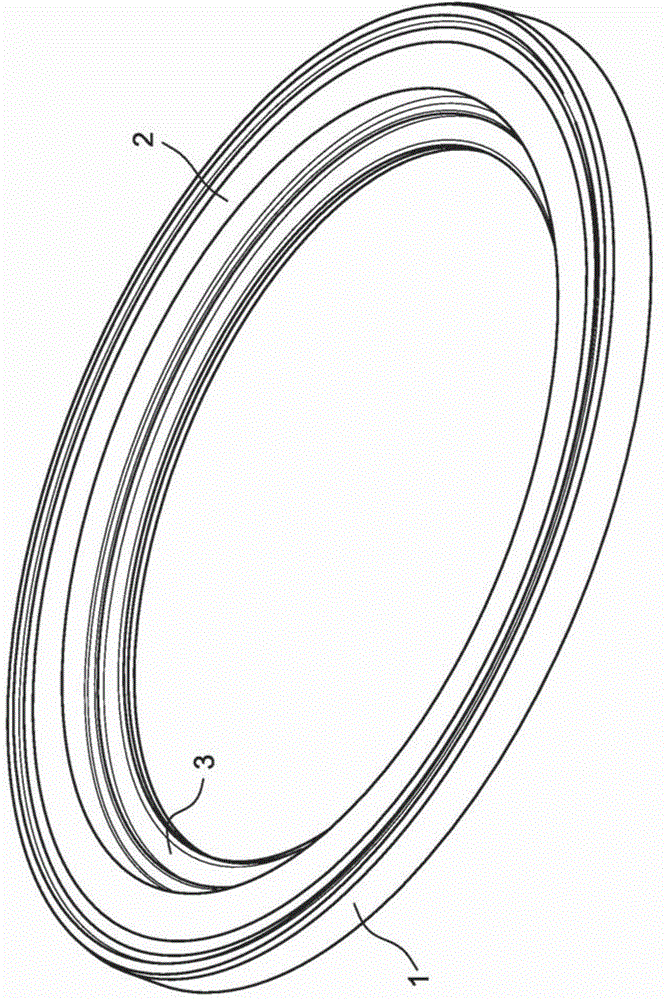

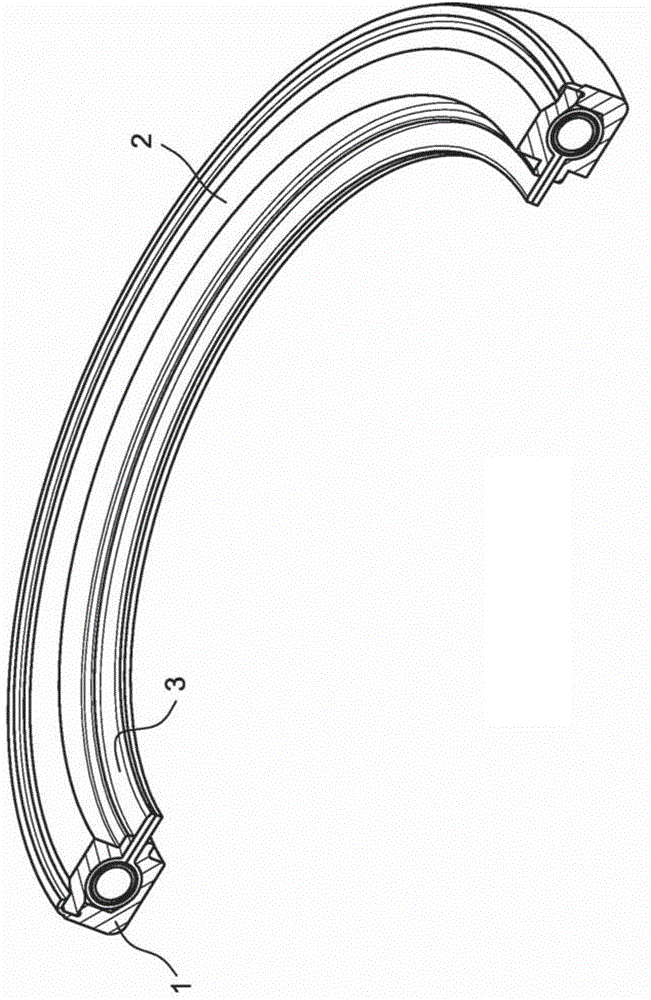

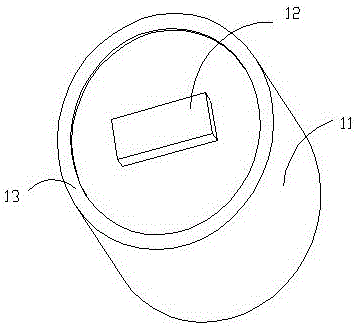

Brush-type circular seal

ActiveCN104603508AReduce shear stressSpin hold improvementEngine sealsFlanged jointsBristleConductor Coil

The seal comprises a housing made up of two portions (1, 2) clamped together as a close and fluid tight fit at interfaces (15, 6b) and a composite structure comprising, inside the housing, a core (24) that is advantageously soft and elastic and a winding (20) of brush bristles. This structure extends directly facing the opposing internal faces (9, 10) of the housing, which compresses them and has an arched shape of slightly larger radius of curvature. The composite structure is kept in a precise position firmly but without stress.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Automatic piston oiling mechanism and method

InactiveCN106540845AShorten the timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an automatic piston oiling mechanism. The automatic piston oiling mechanism comprises a positioning installation base, a motor, a brush, a holding rack assembly, guide rails and an air cylinder, wherein the motor is arranged at the bottom of the positioning installation base, and an output shaft of the motor is connected with the positioning installation base; the positioning installation base is used for storing a piston to be oiled; the holding rack assembly is used for clamping the brush and is in sliding fit with the guide rails; the oil brushing end of the brush can be attached to the surface of the piston to be oiled; and the piston rod end of the air cylinder is connected with the clamping rack assembly so that the clamping rack assembly can be driven to move close to or away from the positioning installation base along the guide rails. The invention further discloses an automatic piston oiling method. The automatic piston oiling mechanism and method have the advantages that the piston is installed stably and firmly, oiling is even, and the oiling efficiency is high.

Owner:ANHUI HIGH TECH POWER TECH

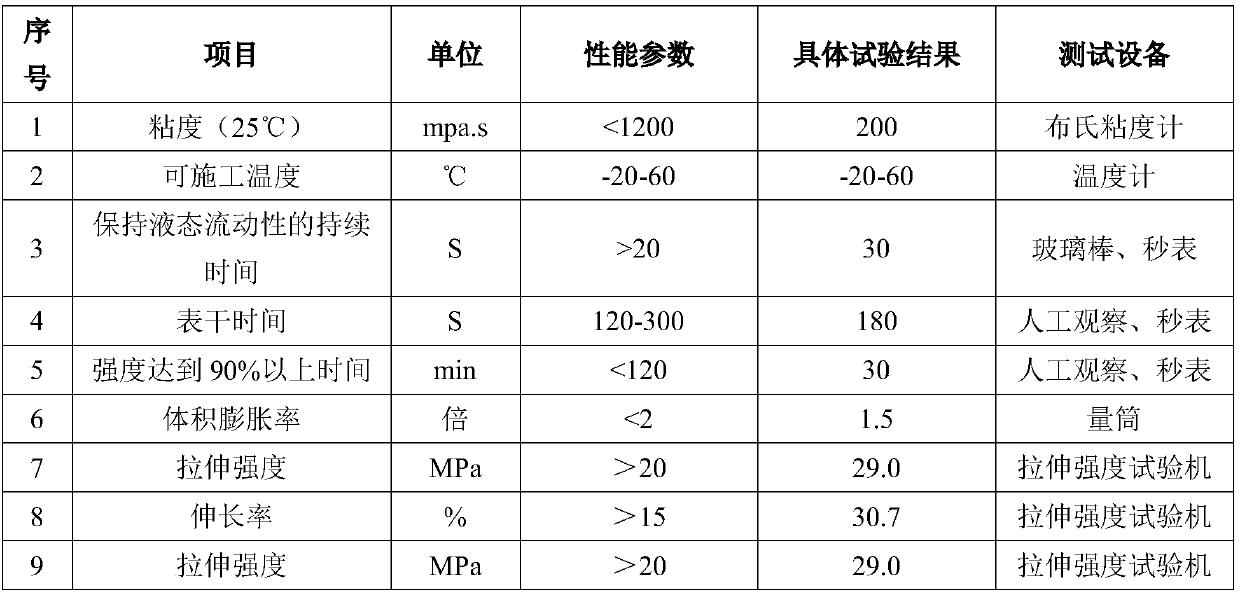

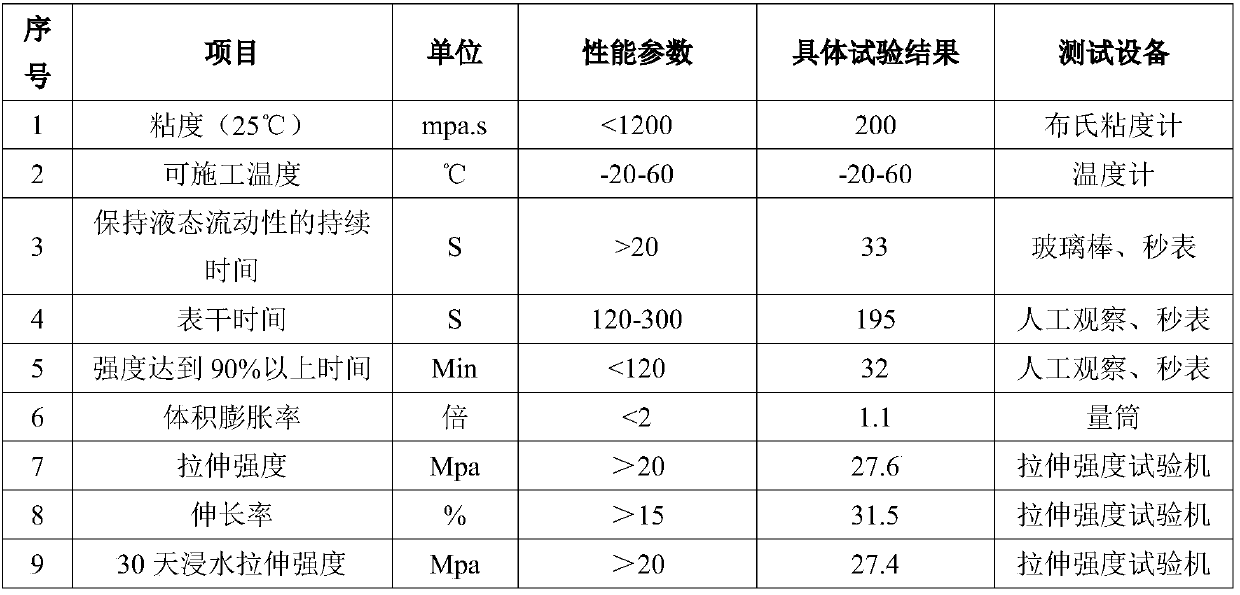

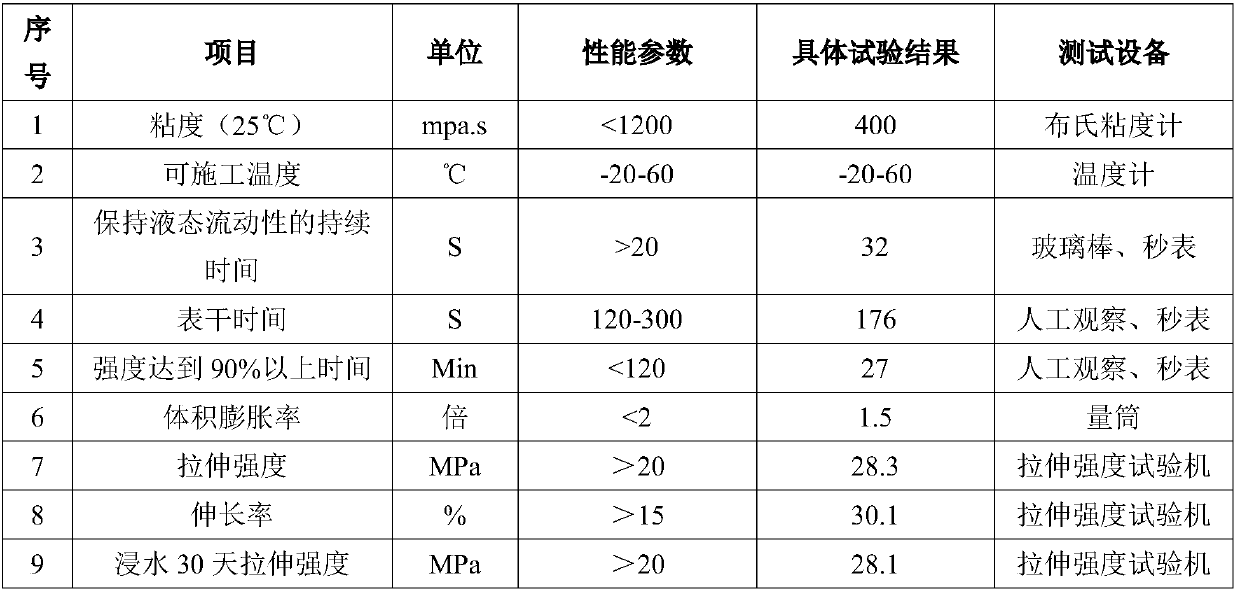

Waterproof organic grouting material for repairing semi-rigid base course cracks and preparing method thereof

InactiveCN109627420AImproves water sensitivityImproves resistance to water damageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyol

The invention discloses an organic grouting material, belongs to the technical field of road repairing, and aims at providing a waterproof organic grouting material for repairing semi-rigid base course cracks. The waterproof organic grouting material is prepared from an A component and a B component. The A component is prepared from a composite polyol, a moisture absorbent, a toughening agent, a catalyst, an antifoaming agent and a cross-linking agent. The B component is prepared from PAPI-2-type isocyanate. The composite polyol is a mixture of a hard-bubble polyol and a CASE-type polyol. Thewaterproof organic grouting material for repairing the semi-rigid base course cracks has the good water damage resistance, flowability, permeability, flexibility, durability and excellent mechanical performance, the semi-rigid base course cracks can be repaired, roads can be rapidly developed, and the influences of pavement construction on public travel can be lowered.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

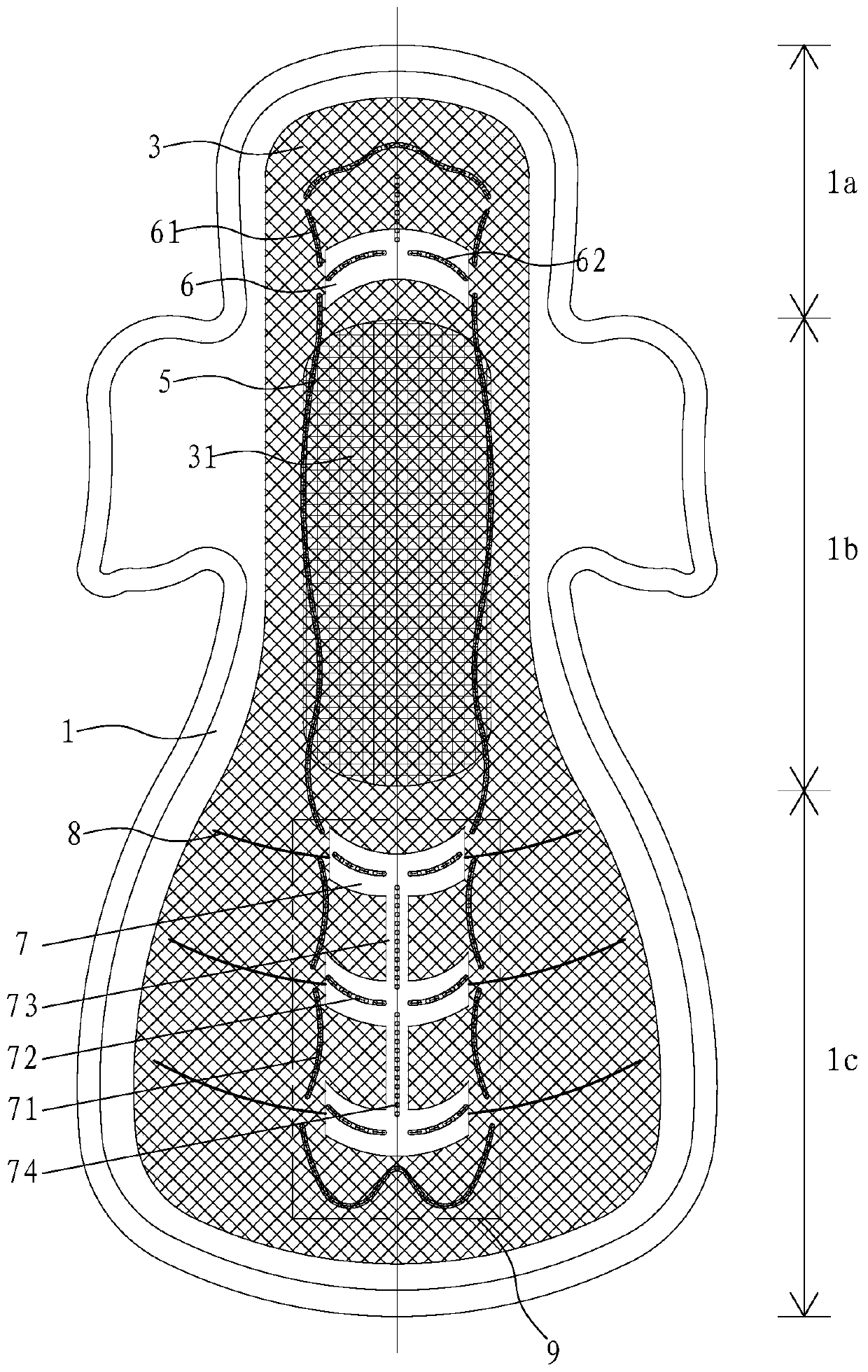

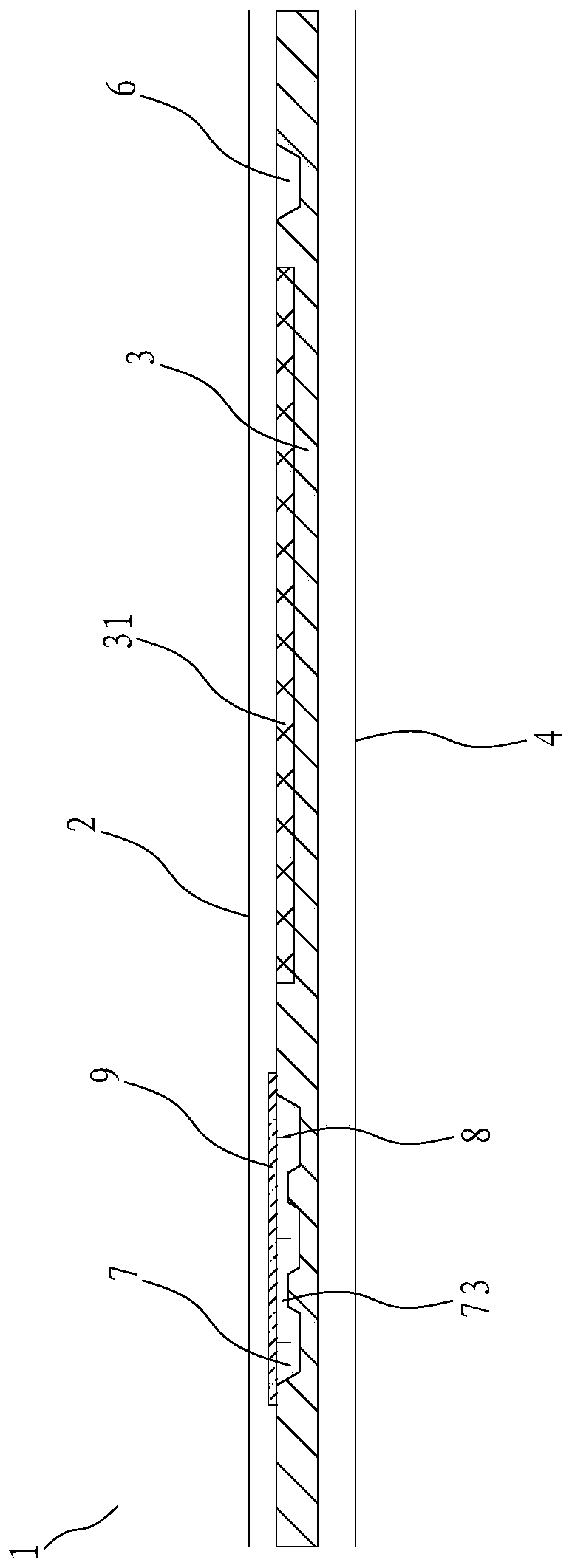

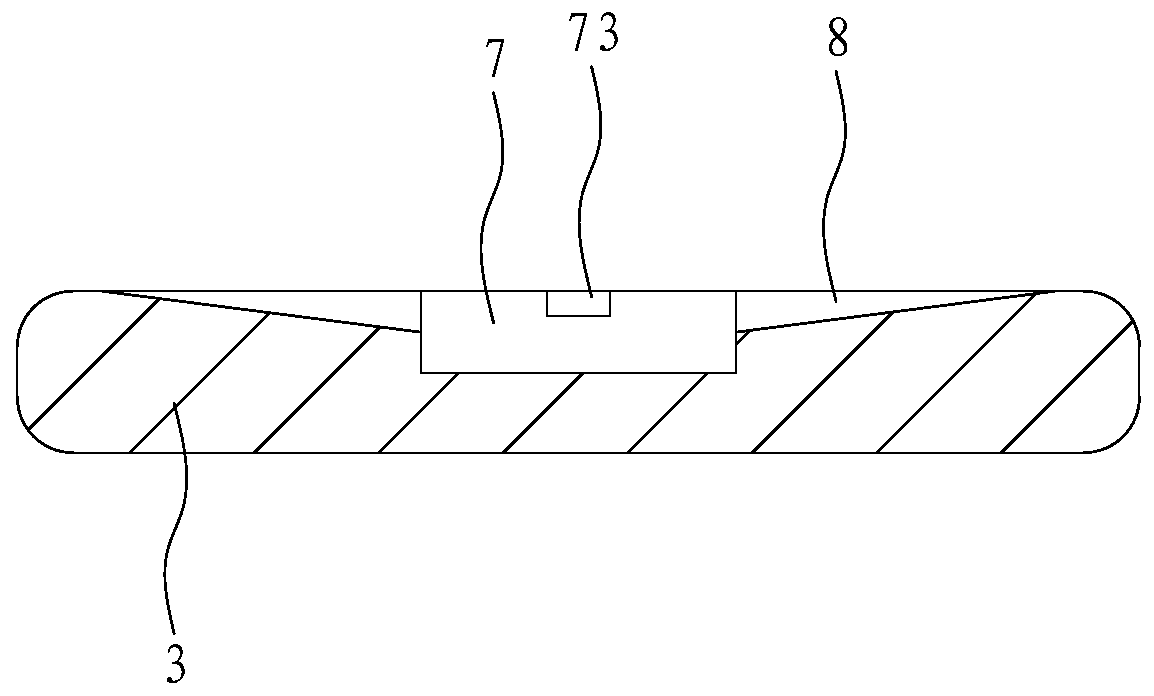

Disposable sanitary napkin in line with ergonomics

The invention relates to the field of disposable absorption articles and particularly relates to a disposable sanitary napkin in line with ergonomics. The disposable sanitary napkin comprises a body,wherein the body comprises a liquid-permeable surface layer, a liquid-impermeable bottom layer and an absorption core arranged between the liquid-permeable surface layer and the liquid-impermeable bottom layer, the body comprises a front end part, a middle part and a rear end part, the absorption core located on the front end part is provided with a plurality of front low-lying grooves formed along a width direction, the absorption core located on the rear end part is provided with a plurality of rear low-lying grooves formed along a width direction, side edges of the body located at each rearlow-lying groove are outwards provided with fold lines, the absorption core is provided with an elastic body for covering the rear low-lying grooves, a stretch ratio of the elastic body in a length direction of the body is 1.1 to 1.2 times, and a plurality of penetrating holes are formed in the elastic body. According to the disposable sanitary napkin, the technical problem of the existing sanitary napkins that the risk of menstruation leakage is caused due to the fact that the sanitary napkins cannot be in fit with a body during wearing is solved.

Owner:FUJIAN HENGAN HLDG CO LTD +2

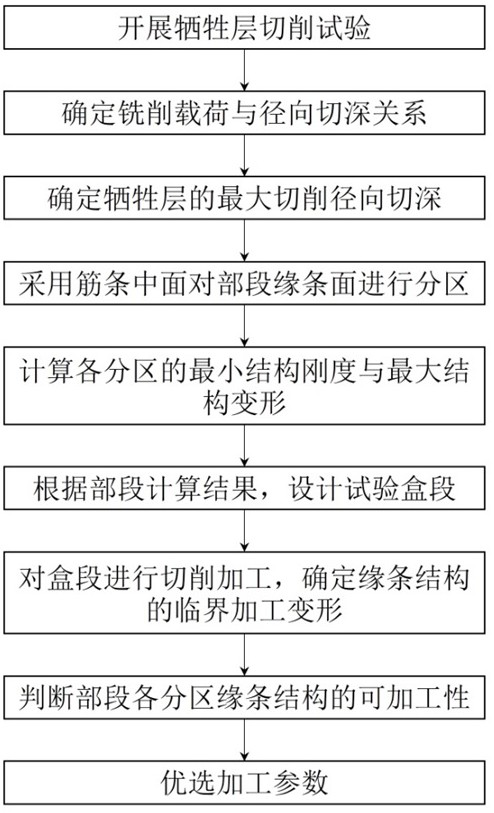

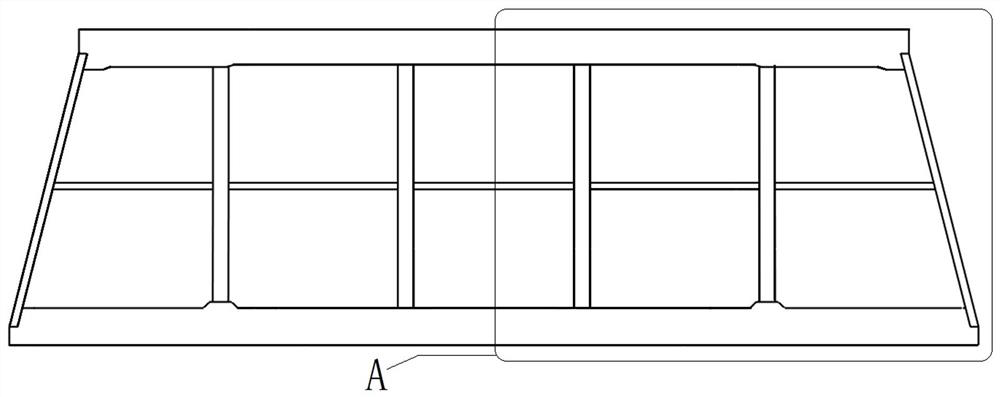

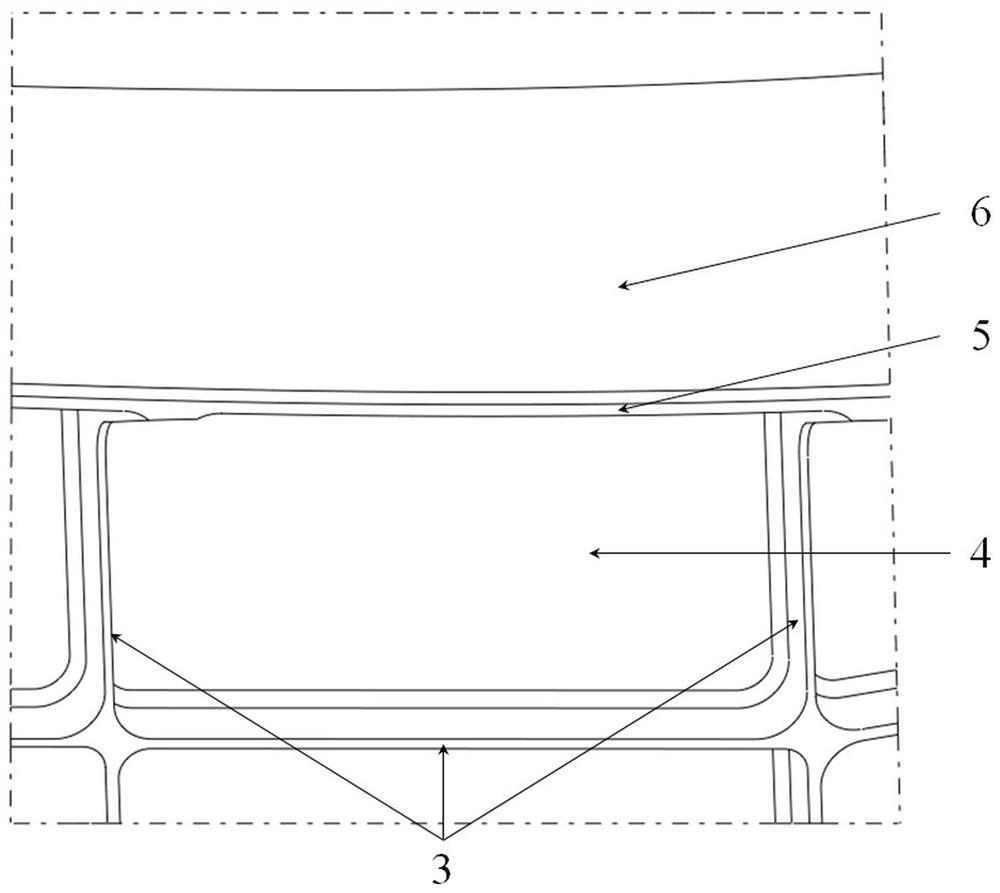

Method for judging machinability of aircraft component compensation layer

ActiveCN113378307AAvoid Scrap SituationsPrecise positioningGeometric CADSustainable transportationMachining vibrationsMachining deformation

The invention belongs to the technical field of aircraft component assembly, and particularly relates to a method for judging the machinability of an aircraft component compensation layer, which comprises the following steps of: obtaining a rule between a cutting load and a cutting parameter through a cutting test, and determining a limit cutting parameter; combining the structural characteristics of the section, partitioning the processing surface of the compensation layer, and calculating to obtain the deformation of all relative stiffness minimum points on the section and the minimum structural stiffness; designing a box section test piece according to requirements, performing partitioning according to box section structural characteristics, and obtaining deformation of all relative rigidity minimum points on a box section and the minimum structural rigidity through calculation; and determining critical machining deformation, and judging the machinability of the section compensation layer on the basis of the critical machining deformation in combination with rules among the parameters, so that optimization of the cutting parameters of all the partitions is achieved. According to the method, a process calculation and analysis method is provided for machinability judgment of the section compensation layer liner, the problems of machining vibration and debonding in the machining process can be predicted, and parts which cannot be machined can be accurately positioned.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

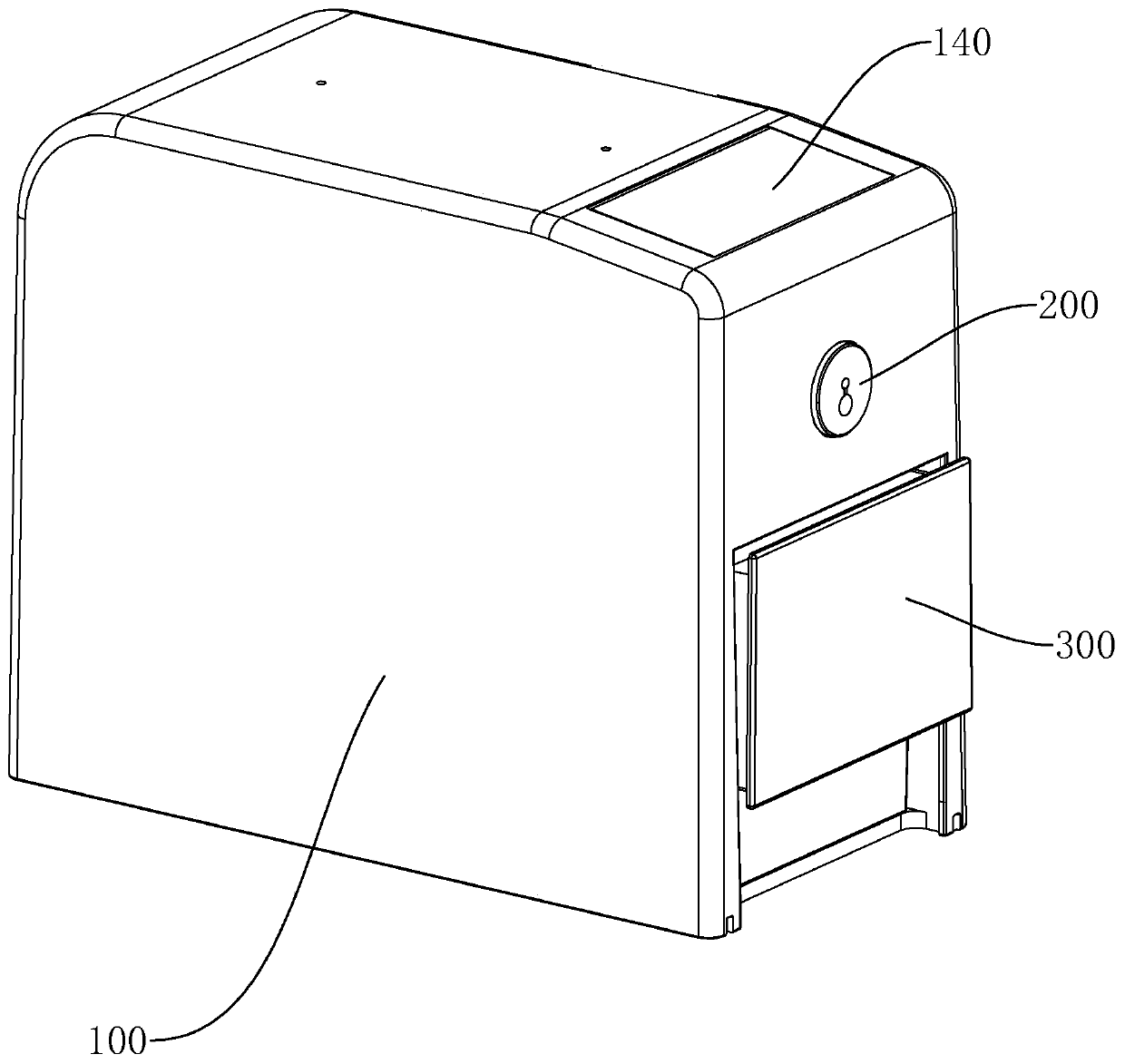

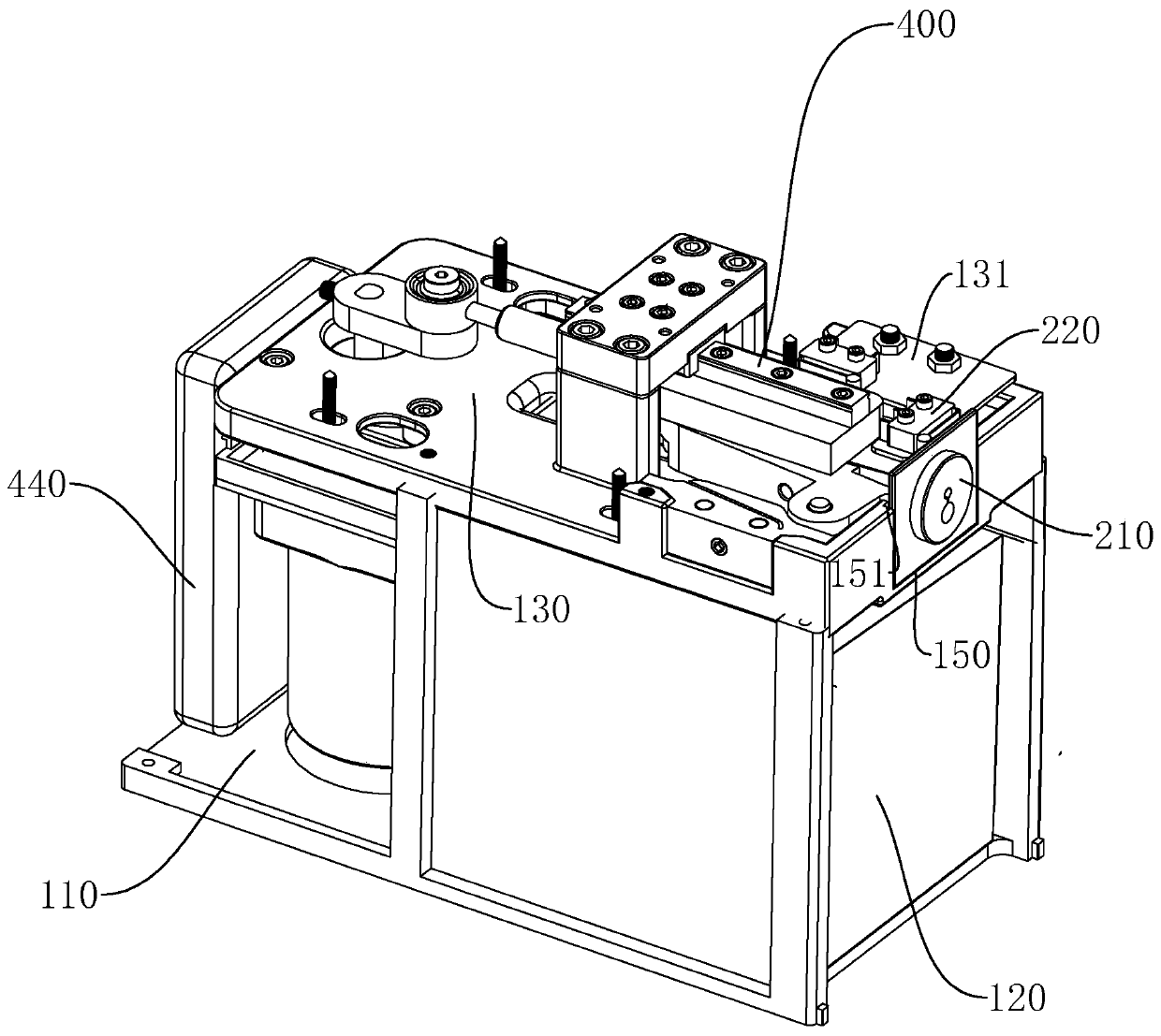

Novel noise-reducing scroll compressor

ActiveCN103867435ADoes not affect compressionInhibition rigidityRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention discloses a novel noise-reducing scroll compressor which comprises a vortex plate assembly and a bearing block, wherein the vortex plate assembly comprises a dynamic vortex plate and a static vortex plate which are jointed with each other; the bearing block is provided with an annular piece; the lower end of the vortex assembly is sleeved with the annular piece; the inner wall of the annular piece is in clearance fit with the side wall of the static vortex plate; at least one elastic element is arranged on the side wall of the static vortex plate or the inner wall of the annular piece. An existing vortex plate structure is improved in a simple and feasible manner on the premise that the compression of an existing scroll compressor is not changed and the compression effect of the scroll compressor is not influenced, and the problem that the noise caused by contact between the static vortex plate and the annular piece is high is solved.

Owner:SUZHOU INVOTECH SCROLL TECH

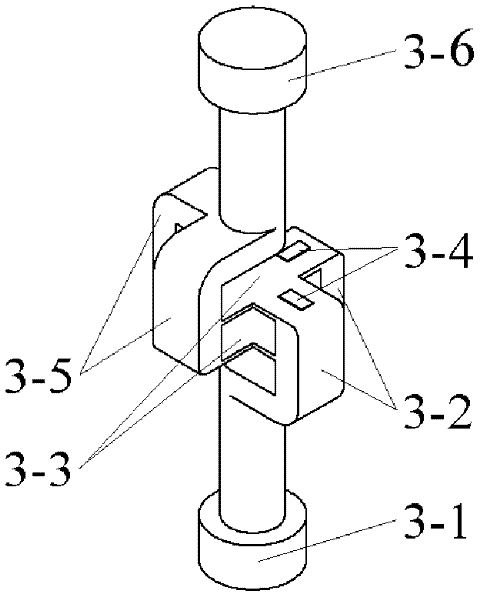

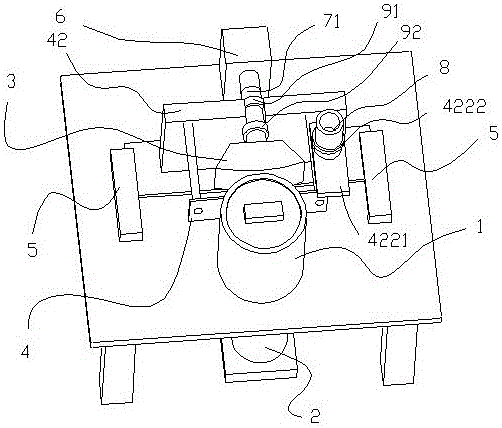

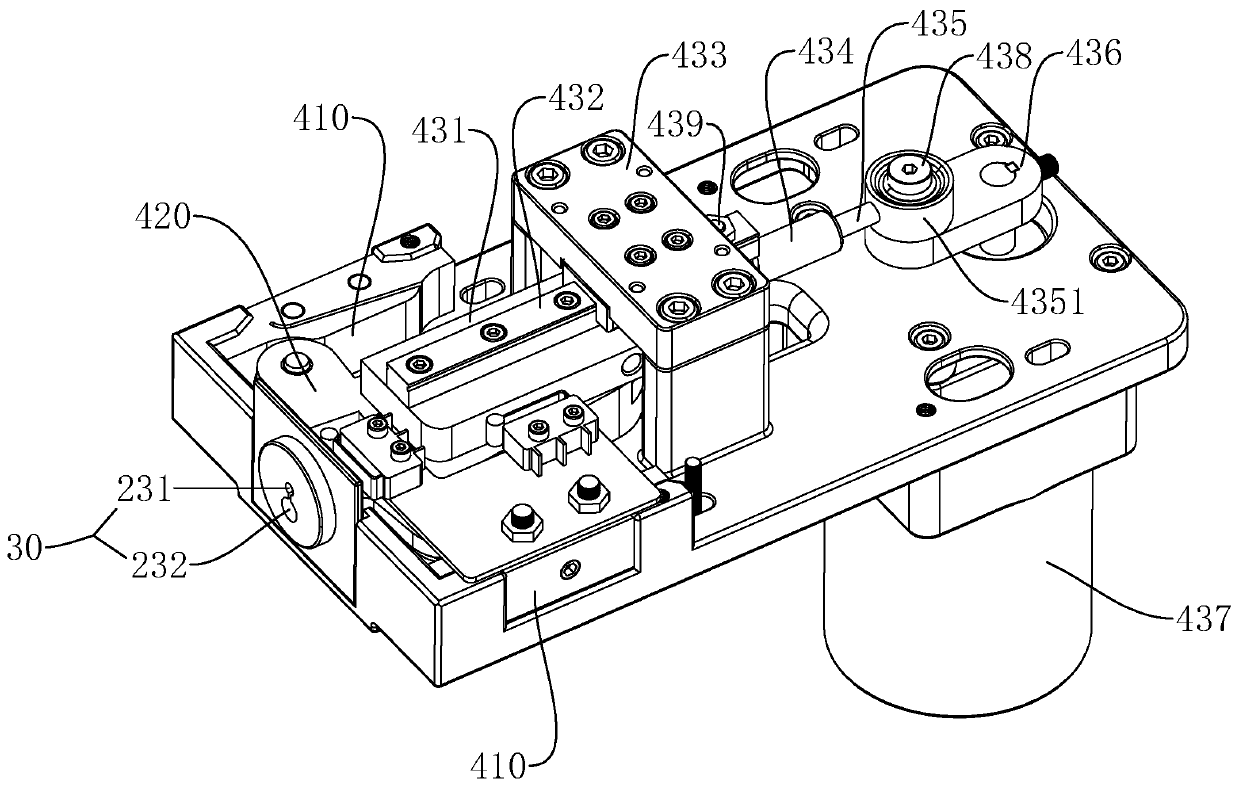

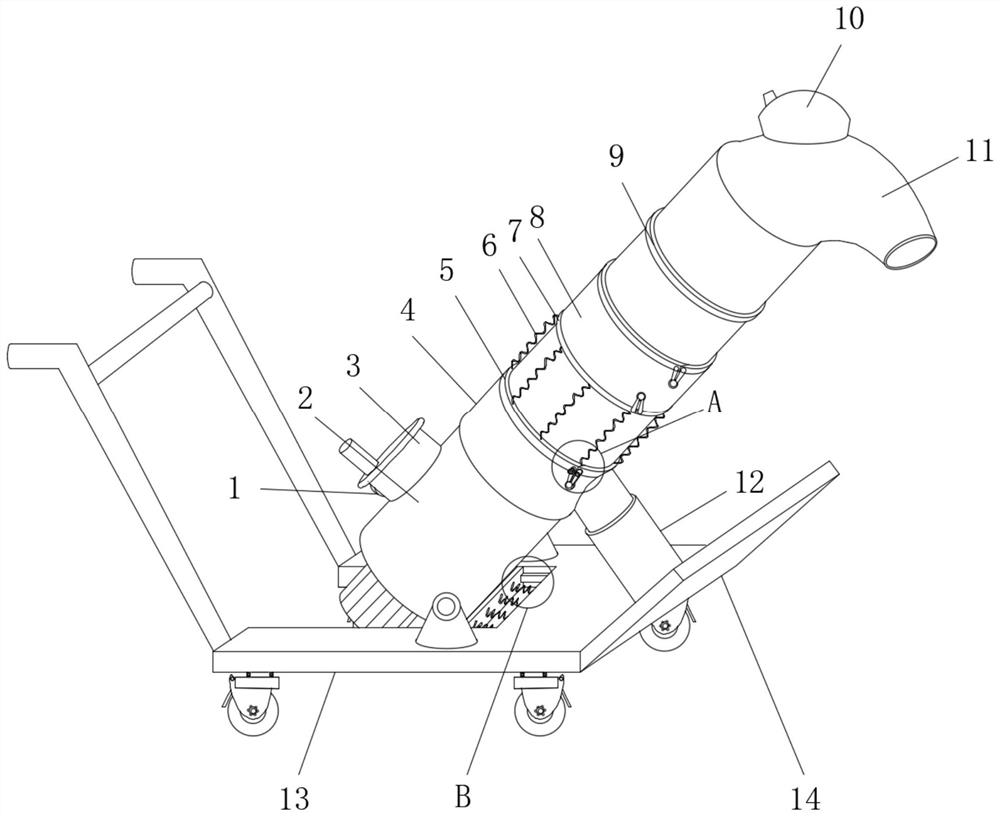

Needle head separating mechanism for automatic needle head separator

PendingCN109731189AInhibition rigidityReduced service lifeInfusion needlesSyringe needleBiomedical engineering

The invention discloses a needle head separating mechanism for an automatic needle head separator. The needle head separating mechanism comprises guide blocks, needle pulling-out tongs and a driving assembly. The driving assembly is connected with the needle pulling-out tongs. The needle pulling-out tongs comprise a first tong arm, a second tong arm and an elastic part. The first tong arm is hinged to the second tong arm, a needle pulling-out opening corresponding to a needle inserting opening is formed between the first tong arm and the second tong arm, and the elastic part is arranged in theneedle pulling opening and provides opening force for the needle pulling-out opening. Guide parts are arranged on the outer side of the second end of the first tong arm and the outer side of the second end of the second tong arm. The guide blocks are located on the two sides of the needle pulling-out tongs, elastic guide driving parts in sliding fit with the guide parts are arranged on the guideblocks, and when the guide parts move to pass through the elastic guide driving parts, the elastic guide driving parts drive the needle pulling-out opening to be clamped. In the guide fit process of the guide blocks and the needle pulling-out tongs, deformation can be generated, and the situation that the contact rigidity of the guide blocks and the needle pulling-out tongs is too large, so that the service life is shortened is avoided.

Owner:ZHEJIANG HUAFU MEDICAL EQUIP

Functional composite non-woven fabric preparation method and feeding method and device

ActiveCN112537678AHeight fine-tuningReduce frictionLiquid surface applicatorsCoatingsEngineeringStructural engineering

The invention discloses an inclined fastening feeding device. The top of a turnover feeding platform is a placing surface, the turnover feeding platform is rotated towards a lifting platform so that the lifting platform can move downwards, and a cloth roll on the placing surface can fall to the top of the lifting platform; the turnover feeding platform is rotated back to the lifting platform so that the lifting platform can move upwards until the cloth roll on the top of the lifting platform is opposite to aligning and fastening devices; and the two aligning and fastening devices are symmetrically distributed on two sides of the lifting platform, when two aligning roller bodies extend out to be aligned oppositely, two extrusion movable blocks extrude each other to move into inner cavitiesof the corresponding aligning roller bodies, and thus, a fastener partially extends out of the aligning roller bodies and abuts against the inner wall of a paper tube. The invention further disclosesa functional composite non-woven fabric preparation method, a feeding method and a feeding and conveying device. The inclined fastening feeding device has the advantage of improving the cloth production and processing efficiency.

Owner:福建智罗科技有限公司

Piston greasing device

InactiveCN106269385AShorten the timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a piston greasing device, which comprises a positioning installing seat, a motor, a hair brush and a clamping frame assembly, wherein the motor is arranged at the bottom of the positioning installing seat; an output shaft of the motor is connected with the positioning installing seat; the positioning installing seat is used for containing a piston to be greased; the clamping frame is used for clamping the hair brush; the greasing end of the hair brush can be attached onto the surface of the piston to be greased. The piston greasing device has the advantages that the installation of the piston is stable and firm; the greasing is uniform; the greasing efficiency is high.

Owner:ANHUI HIGH TECH POWER TECH

Feeding mechanism with anti-blocking function for injection molding machine

The invention discloses a feeding mechanism with an anti-blocking function for an injection molding machine, and belongs to the technical field of injection molding machines. The feeding mechanism comprises a material conveying outer cylinder, a first cleaning sleeve, a second cleaning sleeve, an air cylinder, a base, a material conveying screw rod, a fixing assembly, a vibrating screen dredging assembly and a driving bevel gear, wherein the material conveying outer cylinder is rotationally installed on the base through a mounting frame. According to the feeding mechanism, the vibrating screendredging assembly is installed in a feeding pipe, during feeding, a driving motor can be started, the driving motor can drive a driving half gear to rotate, the driving half gear can be meshed with meshing outer teeth of a top column, and the top column is driven to move; when the driving half gear can be disengaged from the meshing outer teeth of the top column, the vibrating screen dredging assembly can be reset due to the action of a second connecting spring, so that reciprocating vibration of the vibrating screen dredging assembly is realized; and a dredging bottom shaft is installed at the bottom of the vibrating screen dredging assembly, so that added materials can be screened at the same time, a feeding port can be effectively dredged, and the functionality of the device is improved.

Owner:李香妹

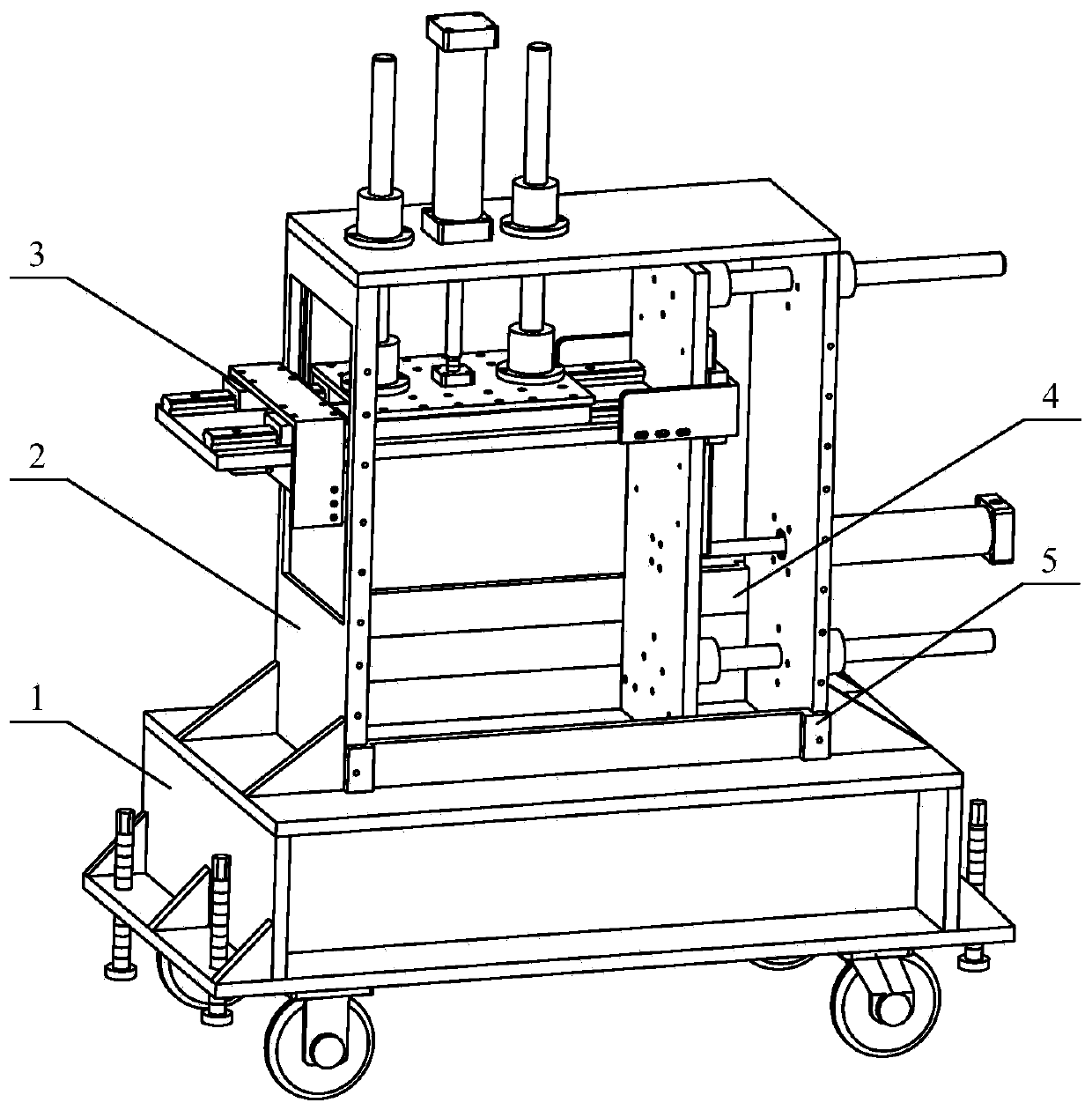

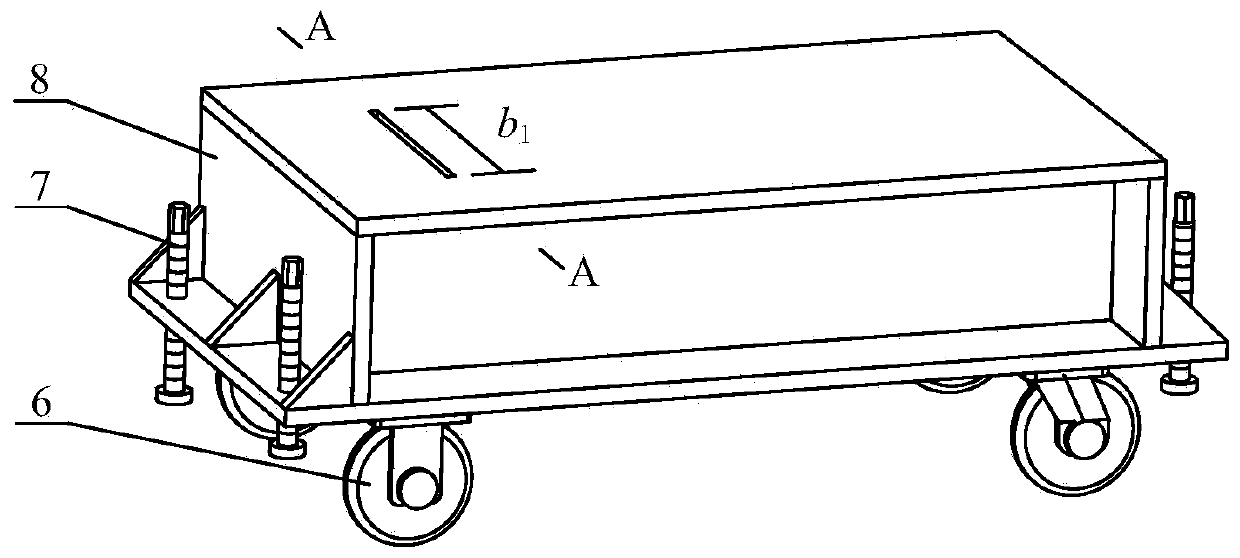

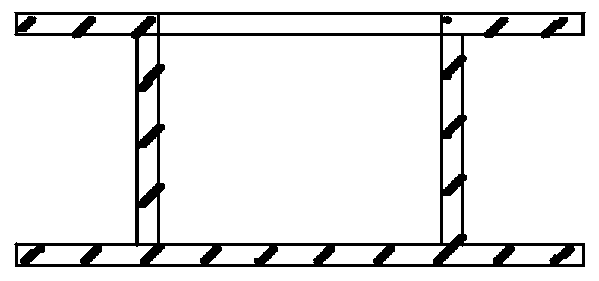

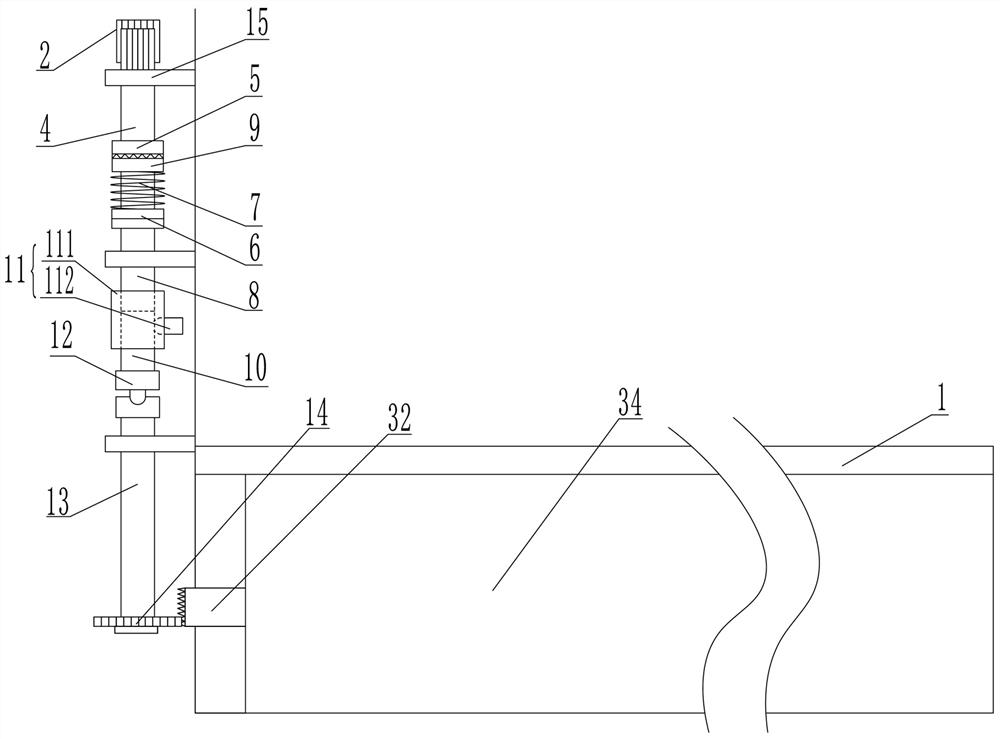

Analog simulation test loading device with adjustable model size

PendingCN110455635AAchieving adjustable sizeImprove applicabilityMaterial strength using tensile/compressive forcesEngineeringSimulation test

The invention relates to an analog simulation test loading device with adjustable model size. The technical scheme is as follows: upper ends of a left support frame (9) and a right support frame (18)are fixed with an upper fixing frame (12) to form a jack mounting rack (2) fixed on an upper plate of a base (1); the structure of a loading system (3) is that a right loading plate (30) is connectedwith an upper loading plate (27) through a vertical connecting plate (32), and the upper end of a left baffle (22) is connected with the upper loading plate (27) through a horizontal connecting plate(25); a work end of a horizontal hydraulic jack (20) of a right support frame (18) is connected with the right loading plate (30), a vertical hydraulic jack (14) of the upper fixing frame (12) is fixedly connected with a jack mounting plate (11), a strip-type slider (10) fixed on the lower plane of the jack mounting plate (11) is movably mounted on a horizontal guide rail (29), and the left baffle(22) is movably mounted in guide grooves of two stand columns of the left support frame (9). The analog model casting space size is adjustable and load application is controllable.

Owner:WUHAN UNIV OF SCI & TECH

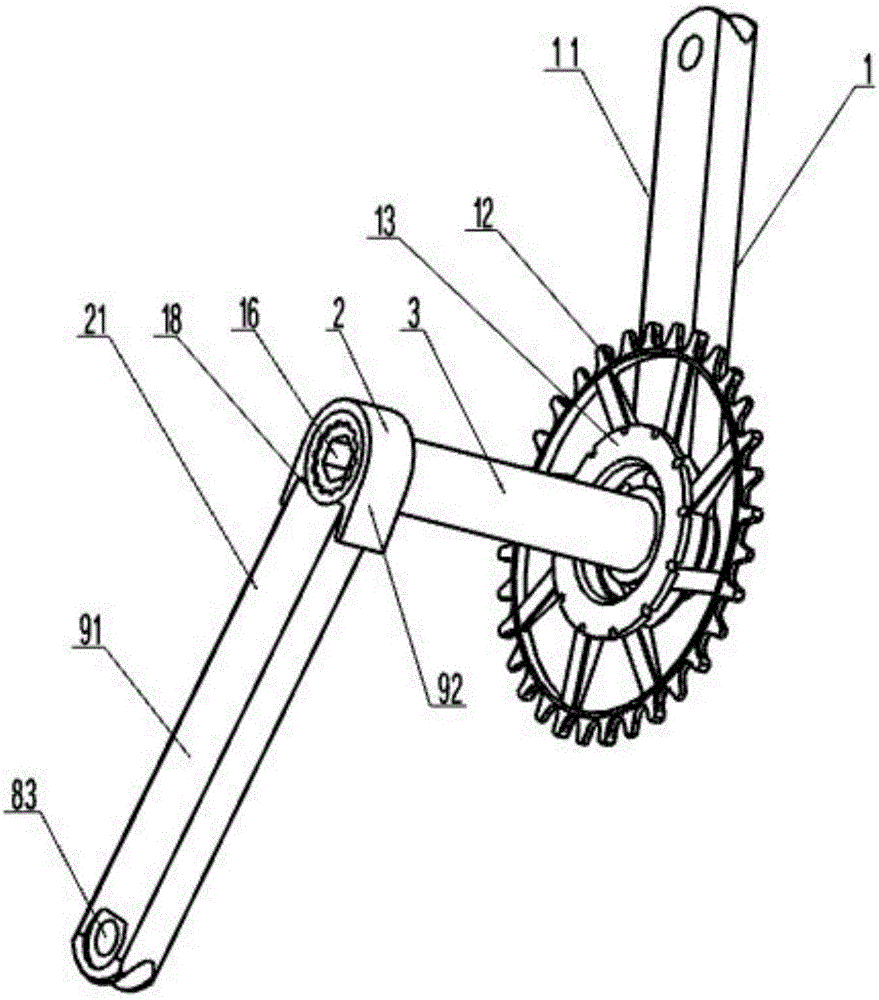

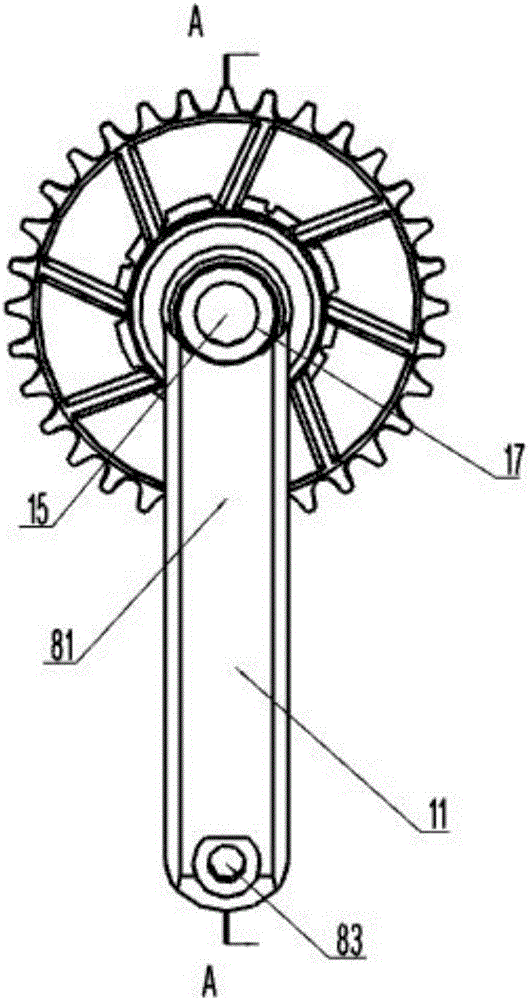

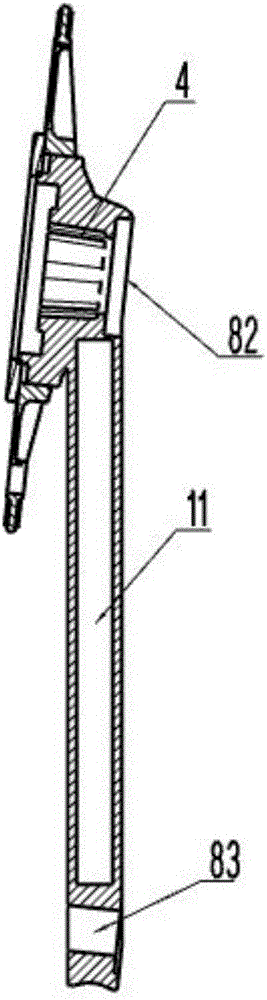

Direct-assembling type hollow crank assembly of bicycle and processing method of hollow crank

The invention relates to a bicycle direct-mounted hollow crank assembly and a processing method for the hollow crank, comprising a right crank device, a left crank device and a central axis shaft rod, the crank assembly can reduce the weight of the bicycle crank and ensure higher strength , to avoid the traditional bicycle crank cumbersome disassembly and low rigidity problems, and the processing difficulty of the right crank and left crank is greatly reduced, so that the yield has been greatly improved and the cost has been reduced.

Owner:雷明久

Plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot

InactiveCN106049576ANo emissionsReduce noiseMechanical machines/dredgersThree degrees of freedomElectro hydraulic

The invention relates to a plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot. The plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot comprises a movable arm lifting mechanism, a bucket control mechanism and the like. According to the sliding loading robot, hydraulic elements are introduced into the movable arm lifting mechanism, so that the pressure of two cylinders is the same, the problem of unbalanced stress of two driving chains for lifting movable arms of an existing controllable sliding loading mechanism is solved, and the bearing stability of the movable arms is increased. The sliding loading robot has the characteristics of high mechanical efficiency, high response speed, high moving accuracy, good controllability and the like of the existing controllable sliding loading mechanism, has the advantages of low noise, no exhaust gas emission, low energy consumption and the like and is suitable for construction engineering such as garbage collection, road maintenance and the like in cities and other densely populated places; and the hydraulic elements are introduced, so that the sliding loading robot has high bearing and antivibration performance, an overload protection function is easy to realize, the reliability and practicability of the sliding loading robot are greatly increased, and the loading robot can be operated in a harsh construction environment.

Owner:SHANDONG JIAOTONG UNIV

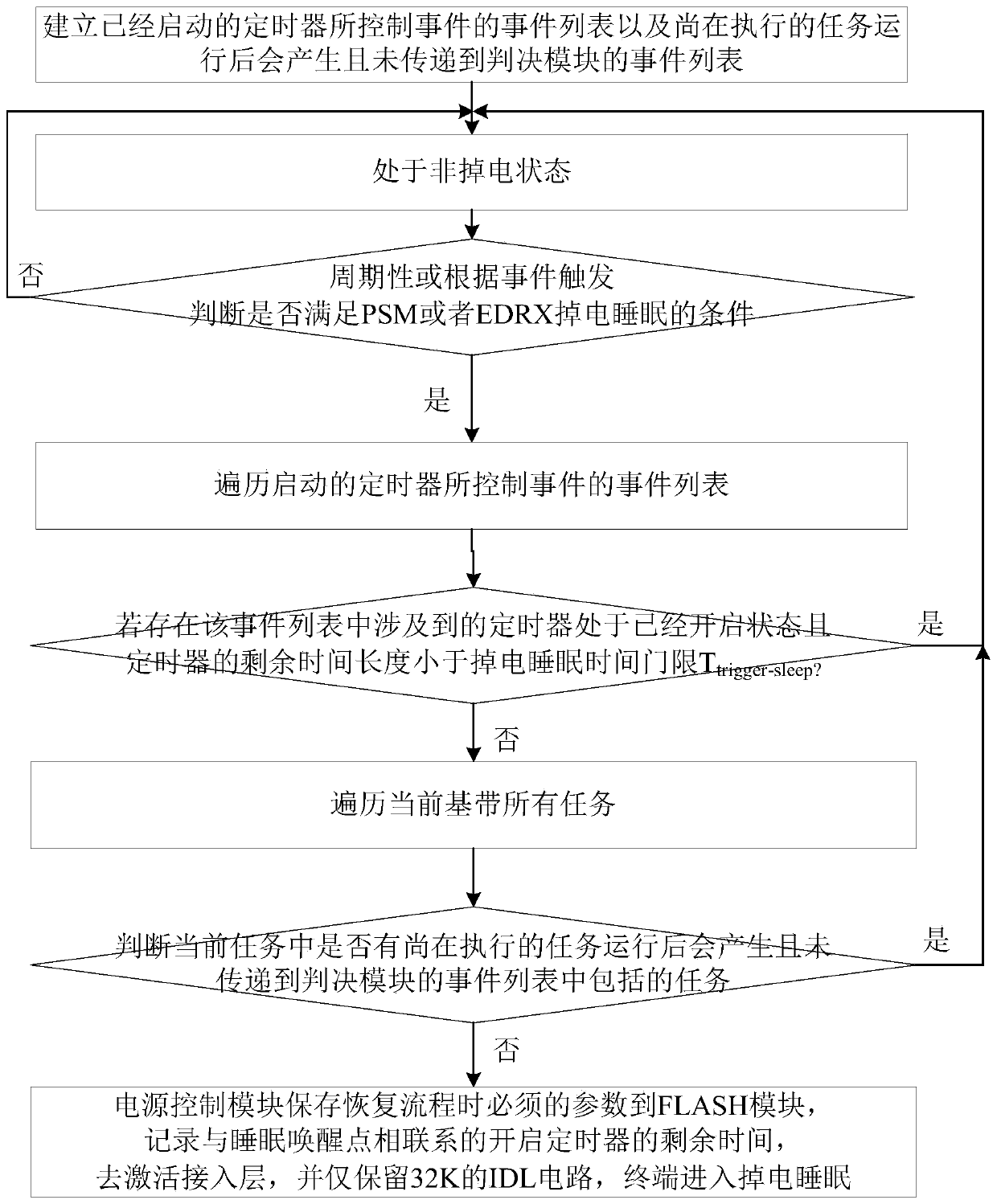

PSM and EDRX power-down sleep method and terminal thereof

ActiveCN111315003AImprove sleepingAvoid overheadPower managementConnection managementSleep timeThe Internet

The invention relates to a mobile communication system, in particular to a PSM and EDRX power-down sleep method and a terminal thereof, and the method comprises the steps: building an event list of events controlled by a started timer and an event list which is generated after an executed task runs and is not transmitted to a judgment module; if PSM or EDRX power-down sleep conditions are met, traversing an event list of events controlled by the started timer, and if the timer involved in the event list is started and the remaining time length of the timer is smaller than a power-down sleep time threshold, continuing to be in a non-power-down state; otherwise, traversing all tasks of the current baseband, and if the tasks which are still generated after the executed tasks run and are not transmitted to the event list of the judgment module exist in the tasks, continuing to keep a non-power-down state; otherwise, the power supply control module executes power-down sleep; according to the invention, power failure and power-on of the terminal and unnecessary expenditure of the Internet of Things terminal are greatly avoided, and a better low-power-consumption effect is obtained.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Automobile side skirt capable of being automatically opened and closed and corresponding high-end welcome automobile

The invention discloses an automobile side skirt capable of being automatically opened and closed, which belongs to the technical field of automobiles and comprises a side skirt body and a transmission device, wherein the side skirt body comprises a fixing plate connected with the lower edge beam, a fender and a dust shielding box, wherein the fender and the dust shielding box are rotationally connected to the fixing plate through rotating shafts; and a linkage device is rotationally connected to the fixing plate and comprises a first connecting plate and a second connecting plate, one side of the first connecting plate is movably connected with the dust shielding box, and one side of the second connecting plate is rotationally connected with the inner wall of the dust shielding box. The invention further discloses a high-end welcome automobile. The high-end welcome automobile comprises an automobile body, an automobile door rotationally connected to the automobile body and an automobile side skirt fixedly arranged on a lower edge beam of the automobile body. The automobile side skirt can be stored in the dust shielding box, cannot be exposed for a long time, can be kept clean for a long time, prevents trouser legs from being stained when a driver gets on or gets off a vehicle, can improve the experience feeling of a high-end vehicle, enables the driver to experience VIP-level treatment, and is convenient to use, low in manufacturing cost and suitable for manufacturing side skirts of all vehicles.

Owner:赵洪强

Polyurethane composite board with high light weight, high strength and high sound absorption, and full adhesive film forming technology of polyurethane composite board

ActiveCN103101256BSolve pollutionImprove wettabilitySynthetic resin layered productsLaminationFiberGlass fiber

The invention relates to a forming technology of a PU (polyurethane) composite board and particularly relates to a full adhesive film forming technology of a PU composite board with high light weight, high strength and high sound absorption for a high-grade car roof. The polyurethane composite board with high light weight, high strength and high sound absorption is compounded of a bottom fabric, adhesive film type fiber felt, a PU foaming board, adhesive film type fiber felt and net-shaped hot melt adhesive films which are sequentially laminated from bottom to top; according to the adhesive film type fiber felt, a central core layer is made of reinforce fibers and the upper surface and the lower surface of the central core layer are respectively composited with net-shaped hot melt adhesive films with different gram weights. The dust pollution problem caused by the use of adhesive powder is avoided; besides, fibers and the adhesive film are compounded firstly; and the invasion of the adhesive film to glass fibers is improved, so that the rigidity and the peeling strength of the polyurethane composite board are improved.

Owner:浙江华江科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com