Polyurethane composite board with high light weight, high strength and high sound absorption, and full adhesive film forming technology of polyurethane composite board

A molding process and high-strength technology, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, lamination, etc., can solve the problems of unsatisfactory sound absorption, unsatisfactory sound absorption, and excellent sound absorption performance of PU composite boards. Improved rigidity and peel strength, reduced weight, and excellent bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

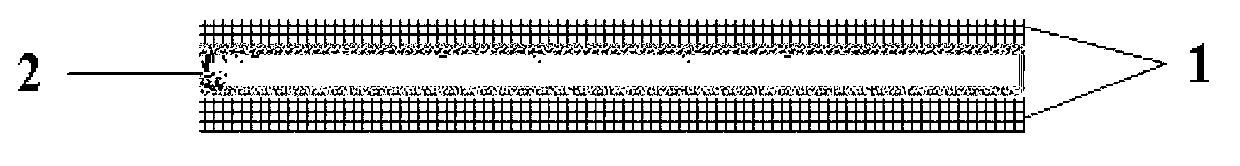

[0039] (1) First add 15 g / m 2 The ethylene-acrylic acid copolymer reticular hot melt adhesive film 1 is unrolled and laid flat on the crawler of the compound machine (the reticular film is a spider web film, the hole shape is rhombus, the length of the hole is 15mm, and the opening ratio is 2 %), then spread glass fibers with length-to-diameter ratios of 1000, 500, and 200 on the film, and the mass ratios of the three glass fibers are 7:2:1, and then unwind and spread 30 g / m 2 The ethylene-acrylic acid copolymer reticulated hot-melt adhesive film 1, the grammage of the reticulated hot-melt adhesive film 1 on both sides of the glass fiber is not consistent, hot-compression compounding is carried out at 230°C and 0.3 MPa, cooled, and rolled up. A film-type fiber mat 3 was obtained, wherein the glass fiber content was 20 wt%. The speed of the laminating machine at this stage is 15 m / min.

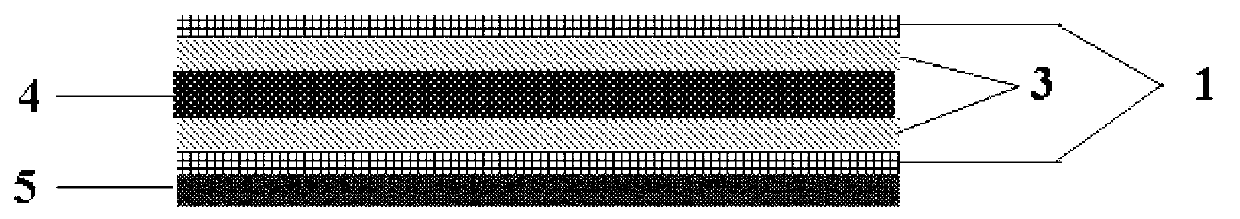

[0040] (2) On the crawler of the compound machine, unwind, lay flat, and stack 40 g / m in ...

Embodiment 2

[0044] (1) First add 20g / m 2 The modified polyethylene mesh hot-melt adhesive film 1 is unrolled and laid flat on the crawler of the compound machine (the mesh is a knife-cut film, the shape of the hole is circular, the length of the hole is 5mm, and the opening rate is 20% ), then spread basalt fibers with length-to-diameter ratios of 200, 2000 and 400 on the film, and the mass ratio of the three basalt fibers is 7:2:1, and then unwind and spread 35g / m 2 Modified polyethylene reticular hot-melt adhesive film 1, the grammage of the reticular hot-melt adhesive film 1 on both sides of the basalt fiber is inconsistent, hot-compression compounding is carried out at 200 ° C, 0.6MPa, cooling, winding, and obtain Film-type fiber felt 3, in which the content of basalt fiber is 50 wt%. The speed of the laminating machine at this stage is 12 m / min.

[0045] (2) On the crawler of the compound machine, unwind, lay flat, and stack 55 g / m in sequence from bottom to top 2 Needle-punched f...

Embodiment 3

[0048] (1) First add 25 g / m 2 The modified ethylene-vinyl acetate copolymer mesh hot melt adhesive film 1 is unrolled and laid flat on the crawler of the compound machine (the mesh is a spider web film, the shape of the hole is rhombus, the length of the hole is 25mm, and the opening rate of 40%), and then spread bamboo fibers with length-to-diameter ratios of 3000, 1000 and 200 on the film. / m 2 Modified ethylene-vinyl acetate copolymer reticular adhesive film, the weight of the reticular hot-melt adhesive film 1 on both sides of the bamboo fiber is inconsistent, at 160 ° C, 1MPa, carry out hot-compression compounding, cooling, winding, and obtain Film-type fiber mat 3, wherein the glass fiber content is 80 wt%. The production speed at this stage is 16 m / min

[0049] (2) On the crawler of the compound machine, unwind, lay flat, and stack 80 g / m in sequence from bottom to top 2 The hot-rolled non-woven fabric and the film-type fiber mat 3 are placed, and then the PU foam b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com