Nano composite polyformaldehyde material and its preparation

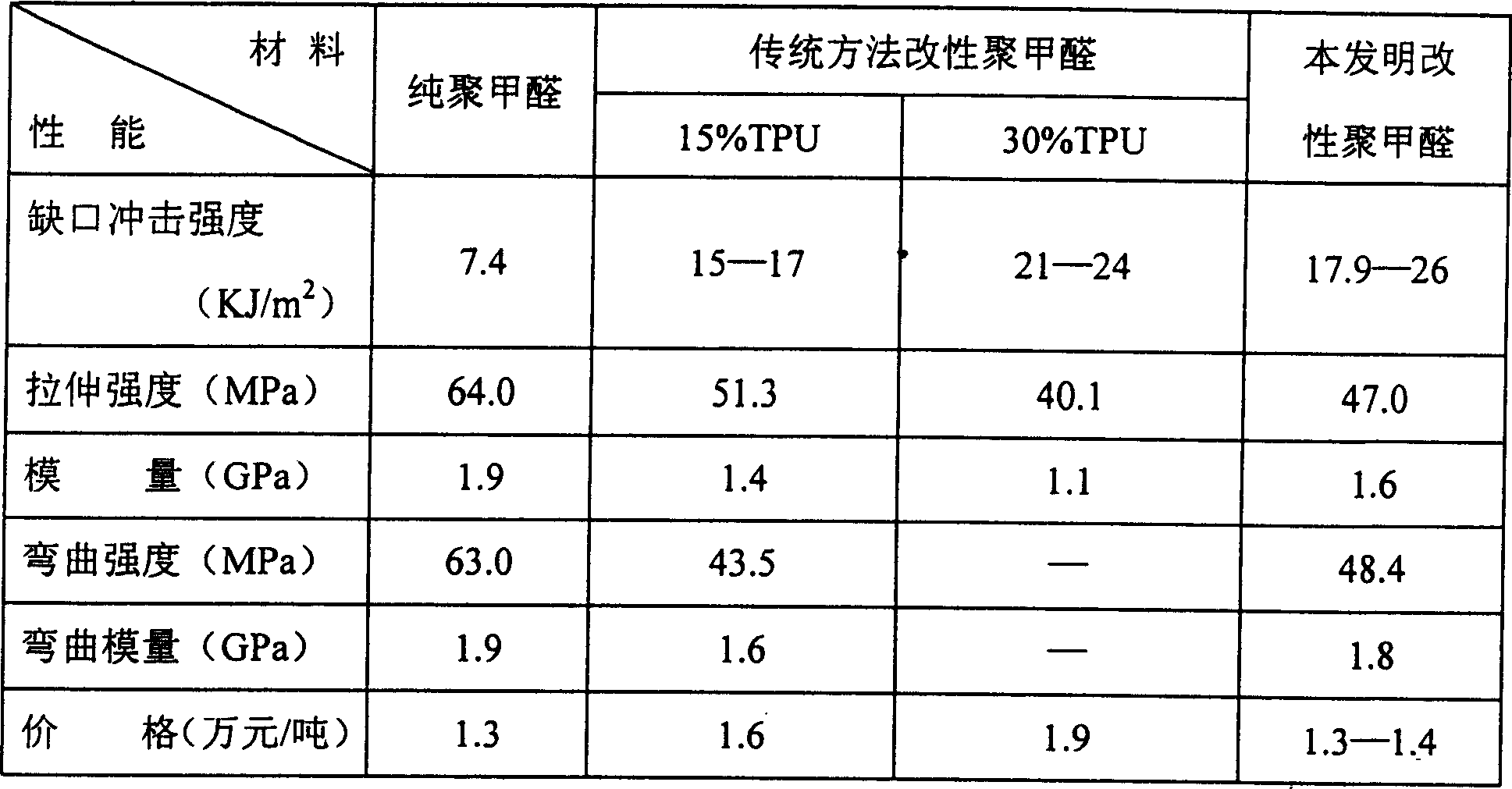

A nano-composite material and technology of composite material, applied in the field of polyoxymethylene nano-composite material and its preparation, can solve the problems of reduced modulus, reduced rigidity, increased cost, etc., and achieve cost reduction, solve processing problems, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After drying 200 grams of calcium carbonate with a particle size of 50 nanometers at 100°C for 6 hours, stir and mix with 10 grams of isopropyl trioleoyl phthalate at room temperature in a high-speed mixer; then mix with 200 grams at 90°C The polyurethane that has been dried for 5 hours is continuously stirred and mixed evenly in a high-speed mixer at a speed of 1000 rpm, and then melted and blended and extruded through a twin-screw extruder at 130-210°C to obtain a masterbatch: mix 8 grams of the masterbatch with ethylene - Dilute and disperse 10 grams of vinyl acetate copolymer in 382 grams of polyoxymethylene so that the calcium carbonate content is 1.0%, and then melt and blend at 140-200 ° C on a twin-screw extruder to obtain a polyoxymethylene nanocomposite material.

Embodiment 2

[0023] After drying 40 grams of silicon dioxide with a particle size of 80 nm at 130°C for 6 hours, stir and mix with 2 grams of γ-(methacryloxypropyl)trimethoxysilane in a high-speed mixer at room temperature and then continue to mix with 360 grams of polyurethane dried at 90°C for 5 hours in a high-speed mixer at a speed of 1000rpm, and then melt blending and extruding at 130-210°C through a twin-screw extruder to obtain a parent Material: 120 grams of masterbatch and 20 grams of grafted polyurethane are diluted and dispersed in 260 grams of polyoxymethylene, so that the silicon dioxide content is 3%, and then melted and blended at 140-200 ° C on a twin-screw extruder to obtain polyoxymethylene Formaldehyde nanocomposites.

Embodiment 3

[0025] After drying 160 grams of montmorillonite with a particle size of 150 to 200 nanometers at 110 ° C for 6 hours, stir and mix with 2 grams of hexadecyltrimethylammonium bromide in a high-speed mixer at room temperature; then mix with 240 grams of The acrylonitrile-butadiene rubber dried at 90°C for 5 hours is continuously stirred and mixed evenly at a speed of 1000rpm in a high-speed mixer, and then melted and blended and extruded at 130-210°C by a twin-screw extruder to obtain a masterbatch; 50 grams of masterbatch and 20 grams of phenolic resin are diluted and dispersed in 330 grams of polyoxymethylene, so that the content of montmorillonite is 5%, and then melted and blended on a twin-screw extruder at 140-200 ° C to obtain a polyoxymethylene nanocomposite material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com