Flow choking strip for printed circuit board

A technology for printed circuit boards and flow resistance, which is applied to printed circuit components, electrical connection printed components, etc., can solve problems such as thickening and affecting forming quality, and achieve the effects of reducing board damage and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

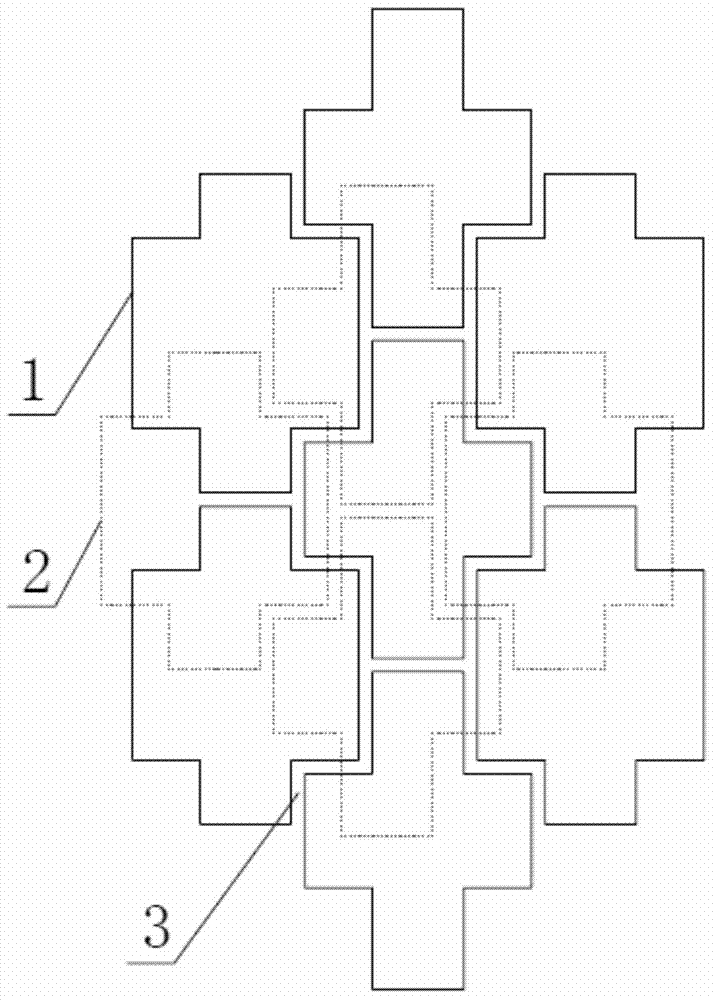

[0021] Example 1 as Figure 1-Figure 3 Shown: figure 1 It is a schematic diagram of the design structure of the choke bar of the present invention. In the figure, the choke bar includes two cross-shaped choke blocks of different sizes, and a flow guide gap 3 of a fixed size is designed between the two cross-shaped choke blocks 1 . The peripheral dimensions of the cross-shaped choke block 1 are 10-12mm wide and 13-15mm long, and two cross-shaped choke blocks of different sizes are arranged in a cross cycle; between the cross-shaped choke blocks 1 The diversion gap 3 has a size of 0.5-1.0mm; the cross-shaped flow blocking block 1 and the reverse cross-shaped flow blocking block 2 are arranged in a cross-dislocation on both sides of the core material of the printed circuit board, and the displacement size is 2-3mm.

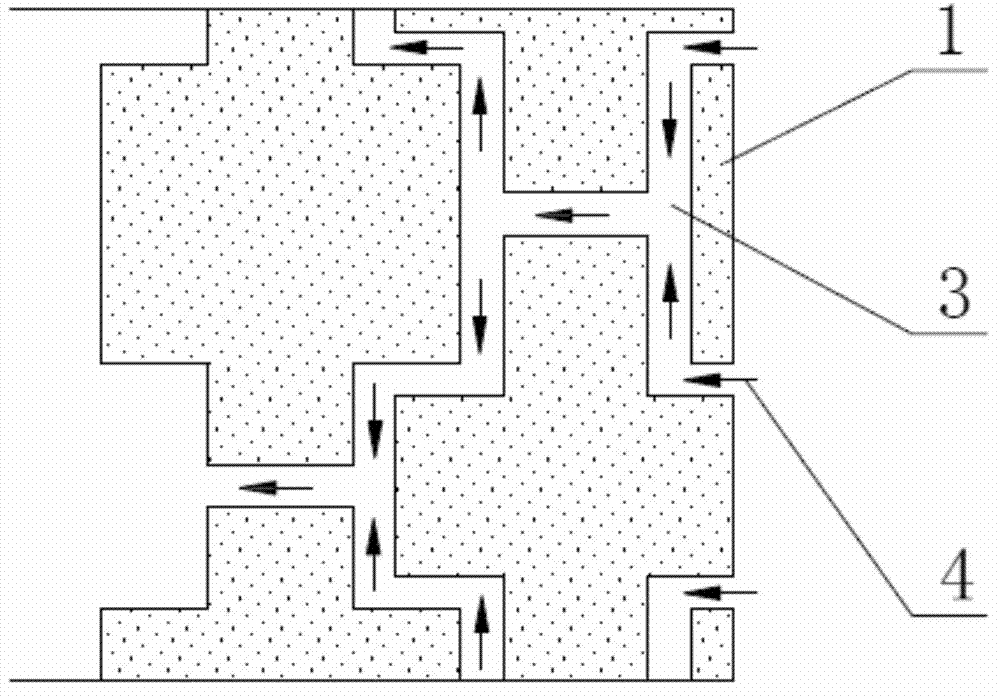

[0022] figure 2 It is a schematic diagram of the diversion effect of the cross-shaped spoiler of the present invention. During lamination, the air or resin 4 flo...

Embodiment 2

[0023] Example 2, such as Figure 7 Shown:

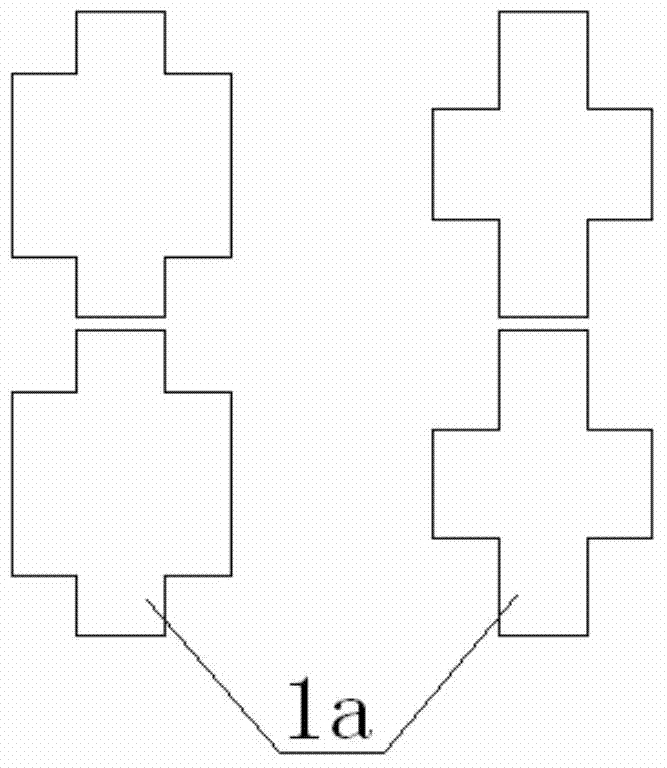

[0024] A choke strip formed by a combination of cross-shaped choke blocks 1, that is, a multi-row choke sub-strip 1a, the cross-shaped choke block 1 at the corresponding position in each choke sub-strip and the adjacent choke sub-strip The positions of the cross-shaped spoiler blocks 1 are the same, but the axis angle of each cross-shaped spoiler block 1 intersects with the trend of the spoiler sub-strips, that is, a certain angle is formed, and a diversion gap 3 with exactly the same size is also formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com