Patents

Literature

52results about How to "Avoid air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

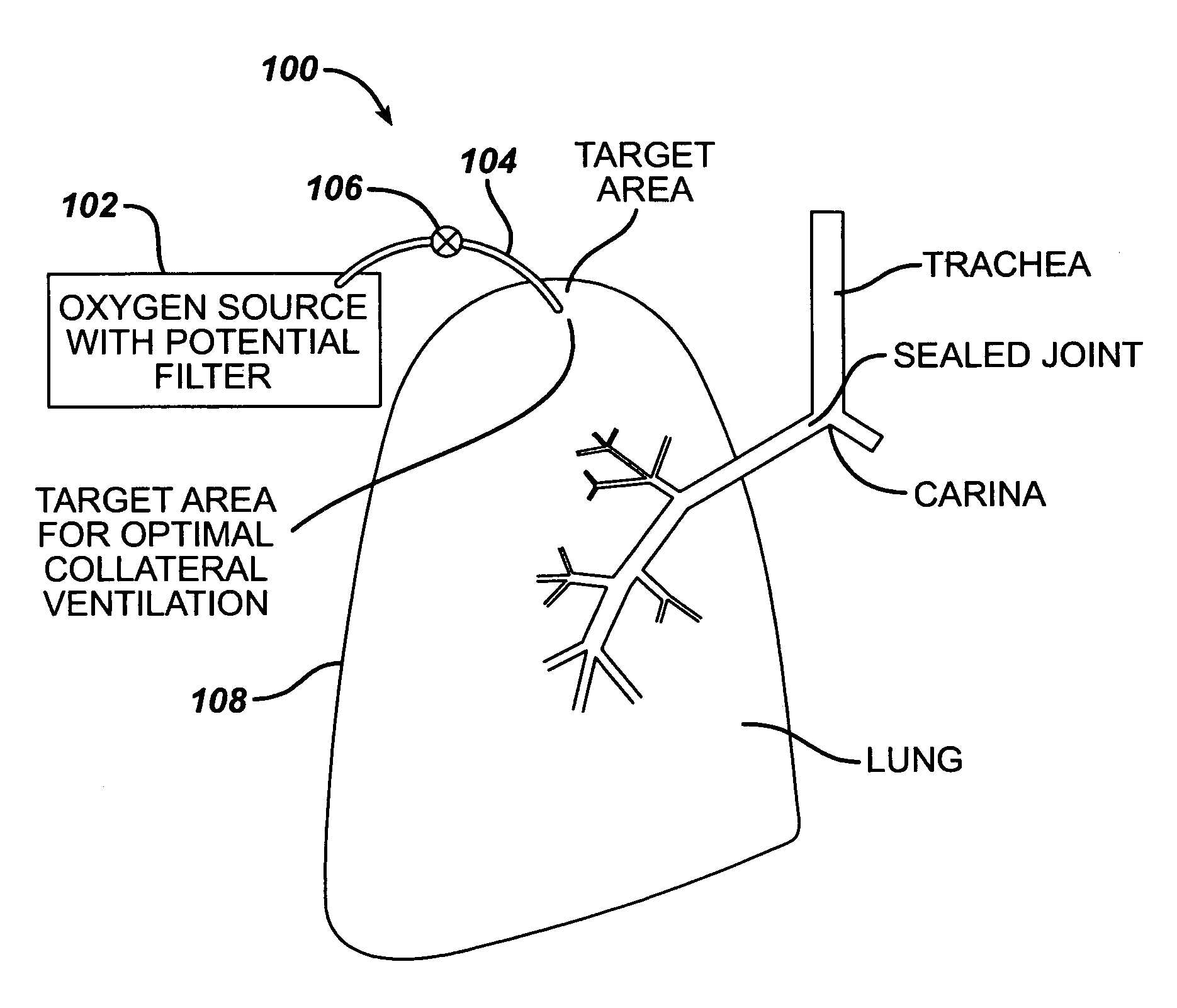

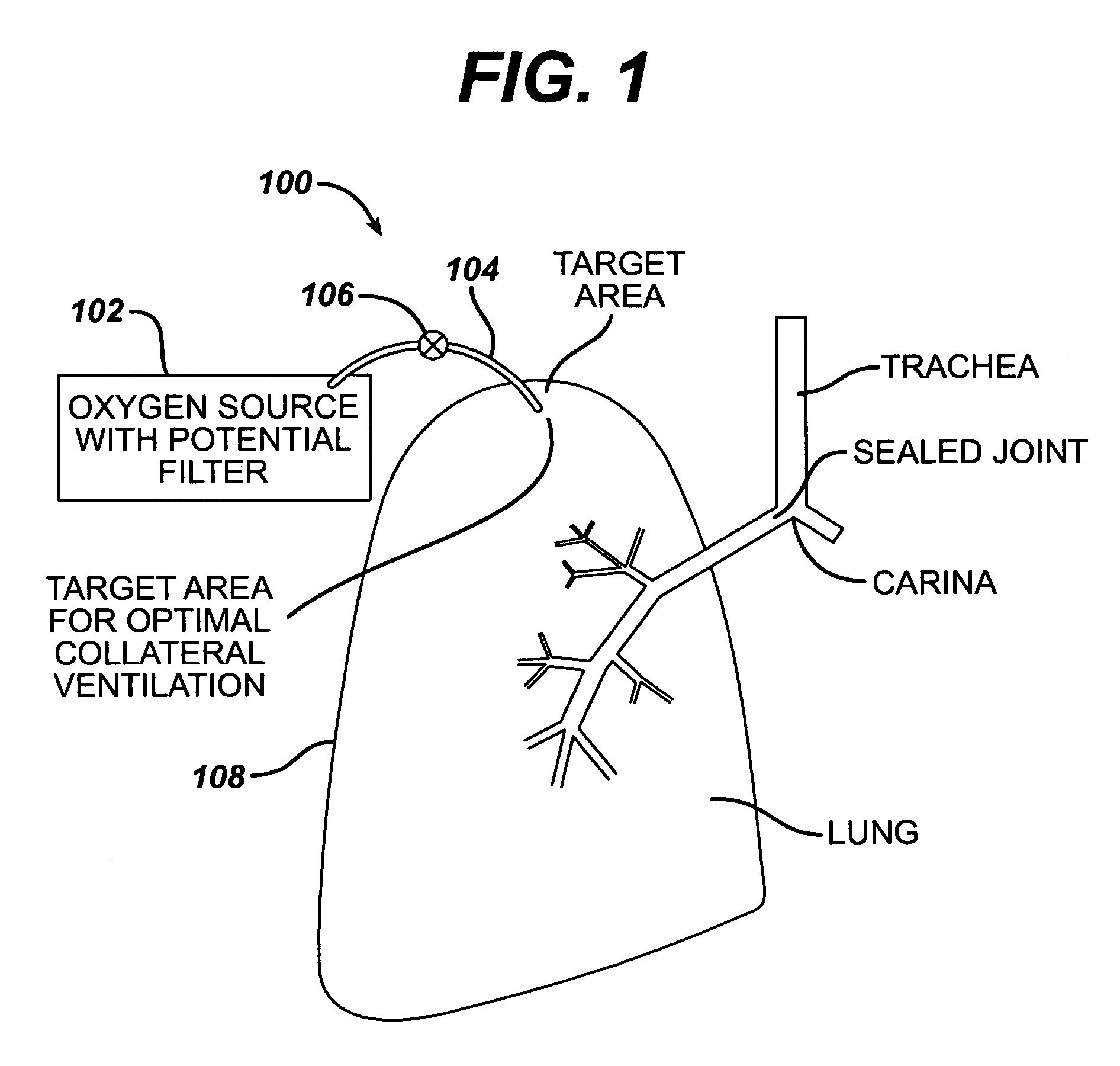

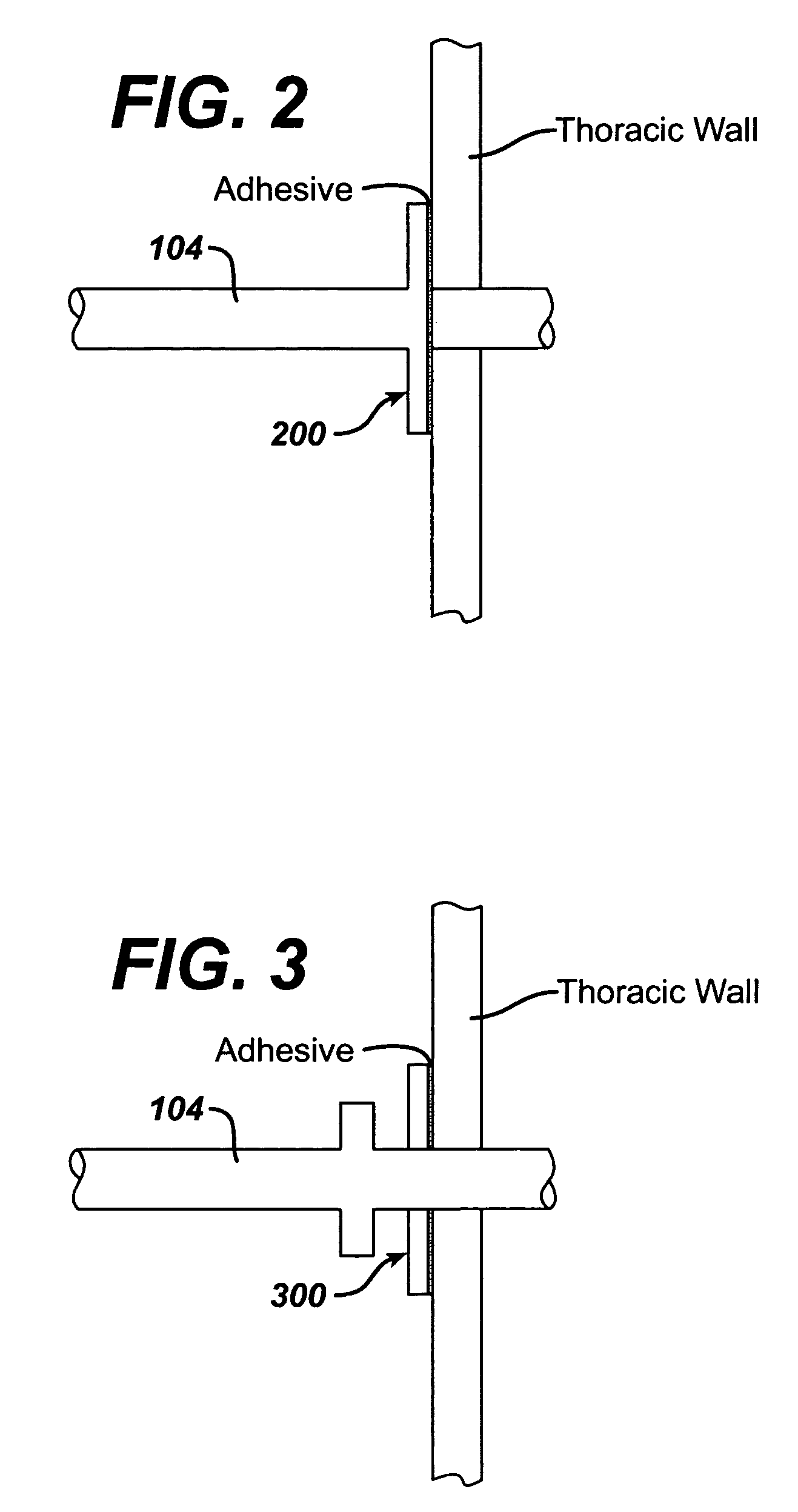

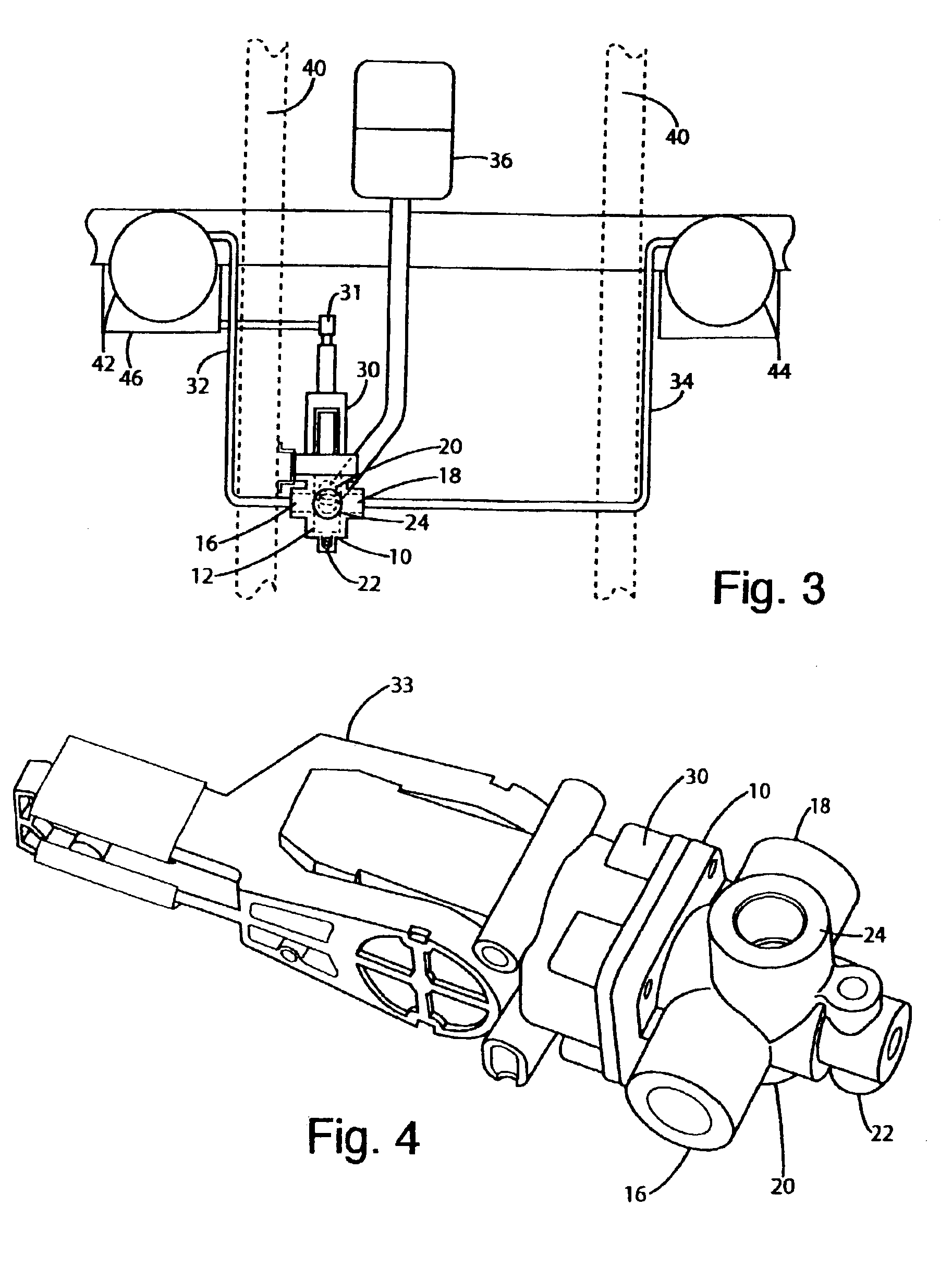

Lung reduction system

InactiveUS7252086B2Speed up the flowLower the volumeTracheal tubesBronchiLung tissueIntensive care medicine

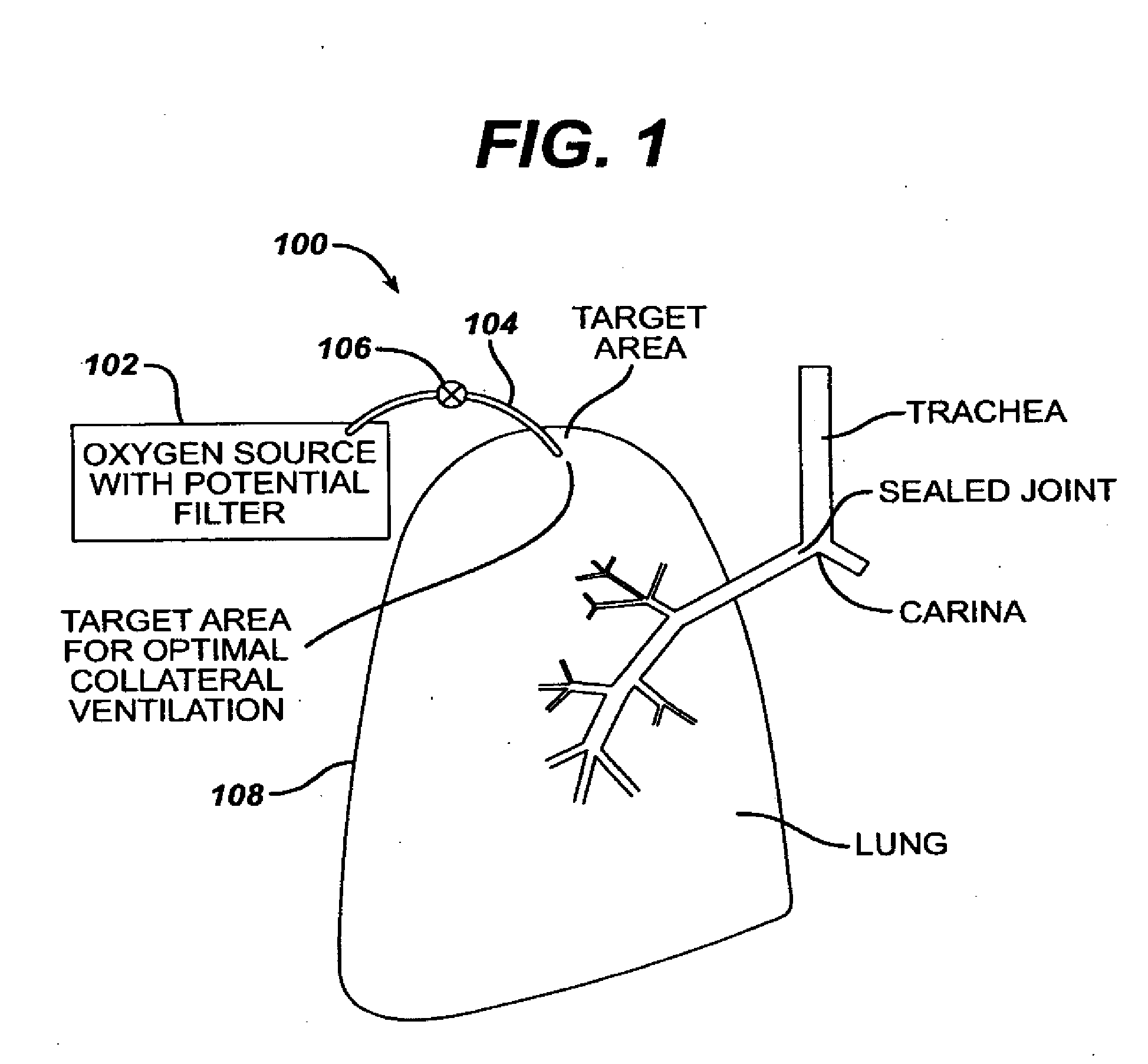

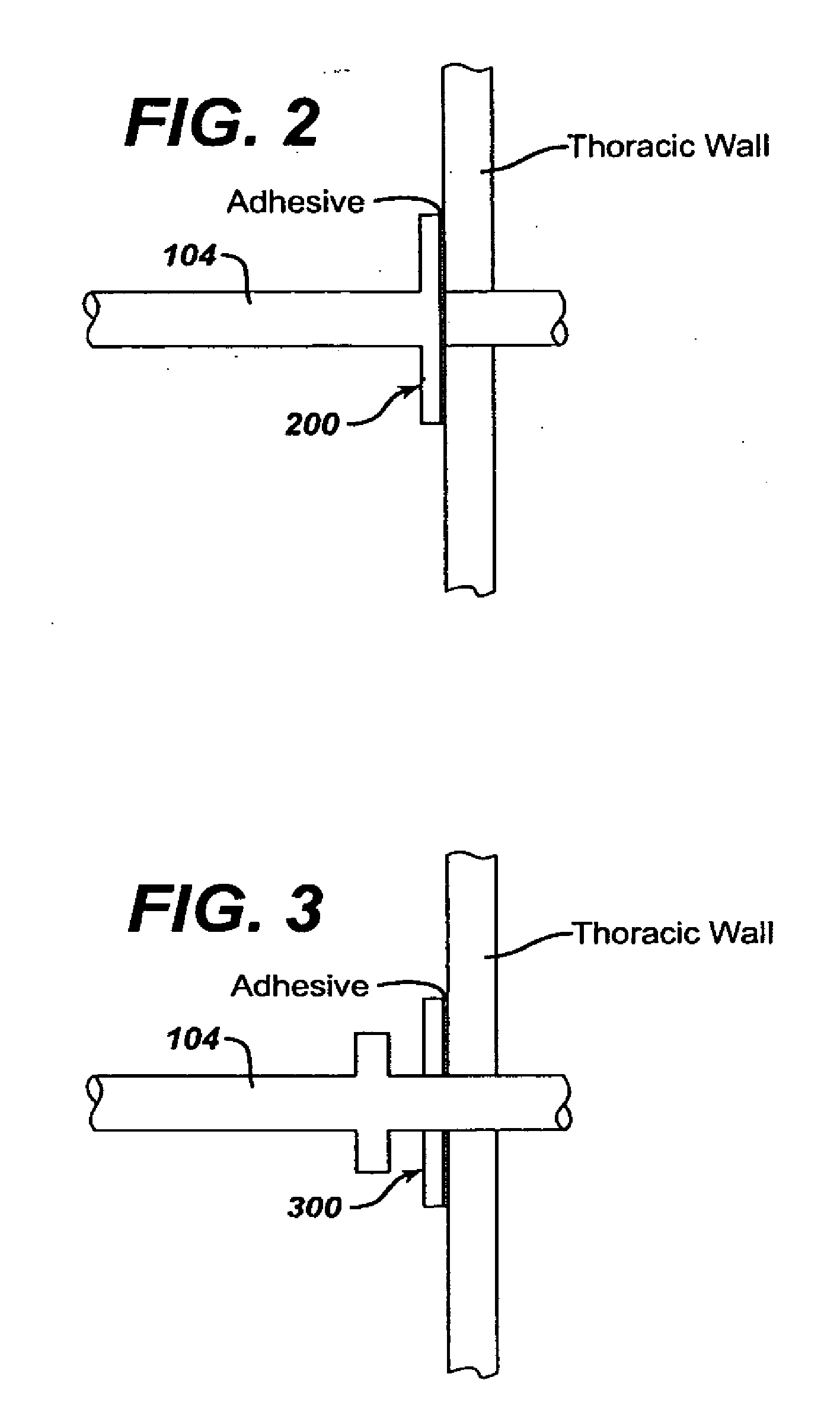

A pulmonary decompression device may be utilized to remove trapped air in the lung or lungs, thereby reducing the volume of diseased lung tissue. A lung reduction device may passively decompress the lung or lungs. In order for the system to be effective, an airtight seal between the parietal and visceral pleurae is required. Chemical pleurodesis is utilized for creating the seal.

Owner:PORTAERO

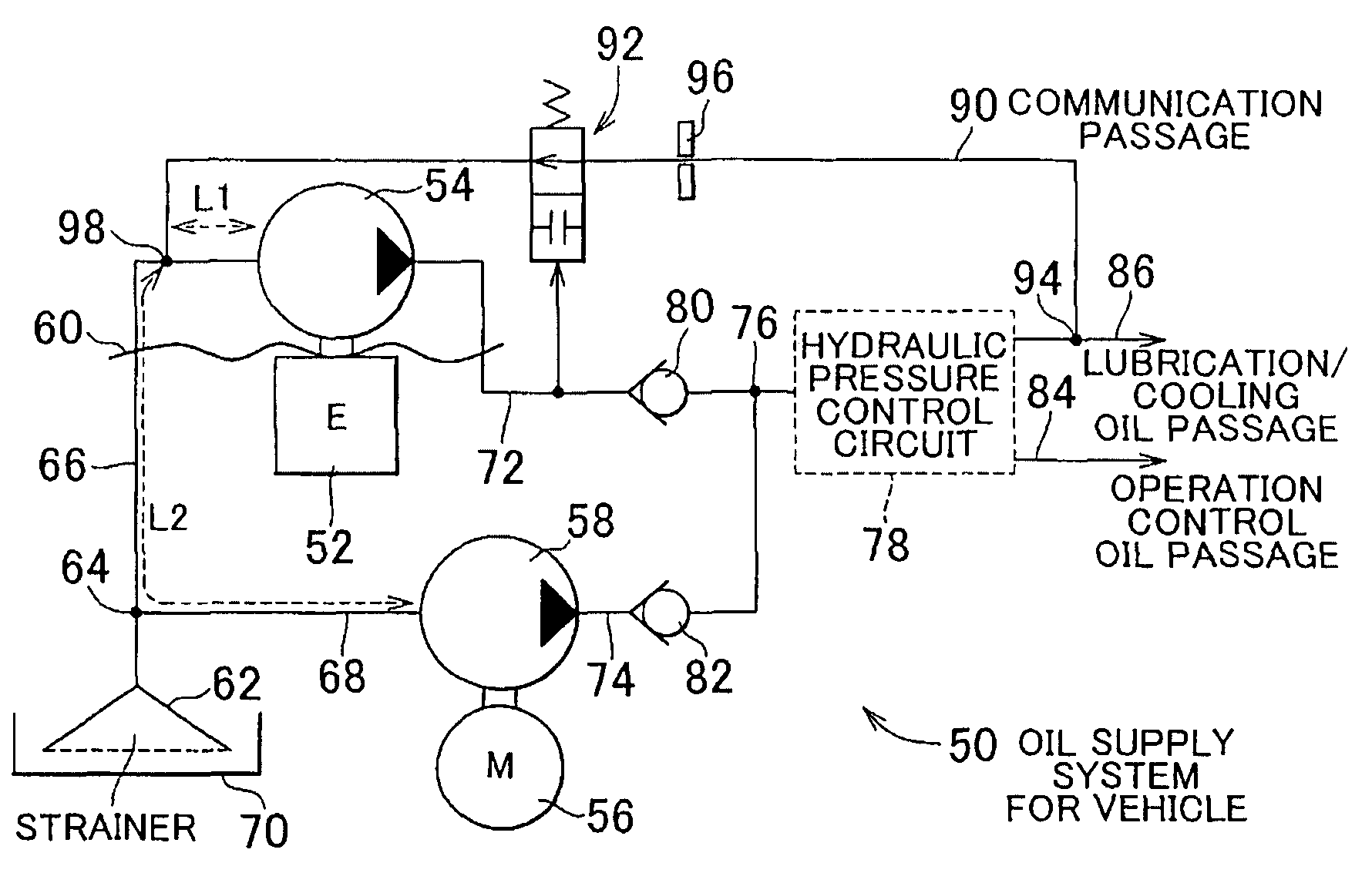

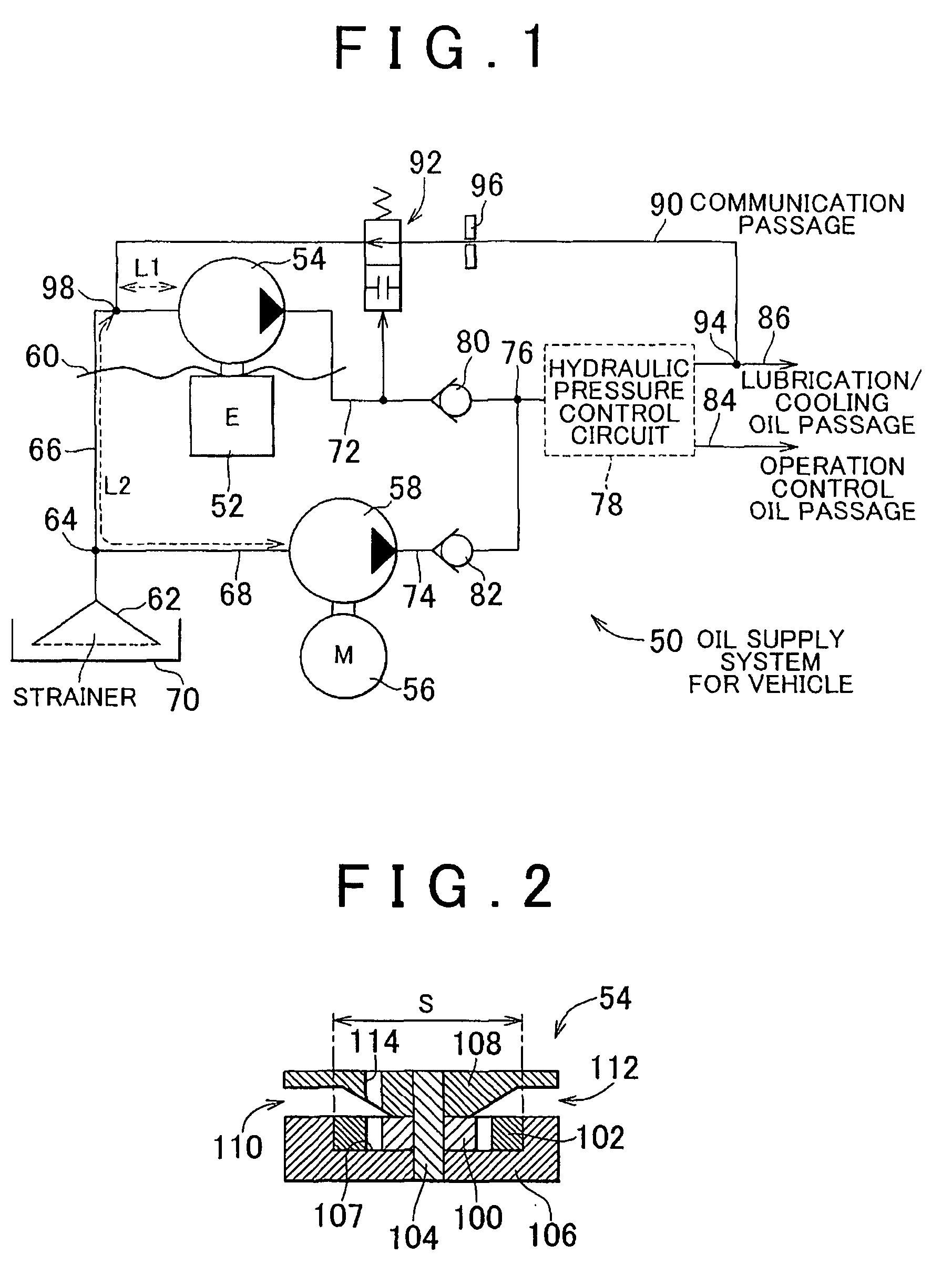

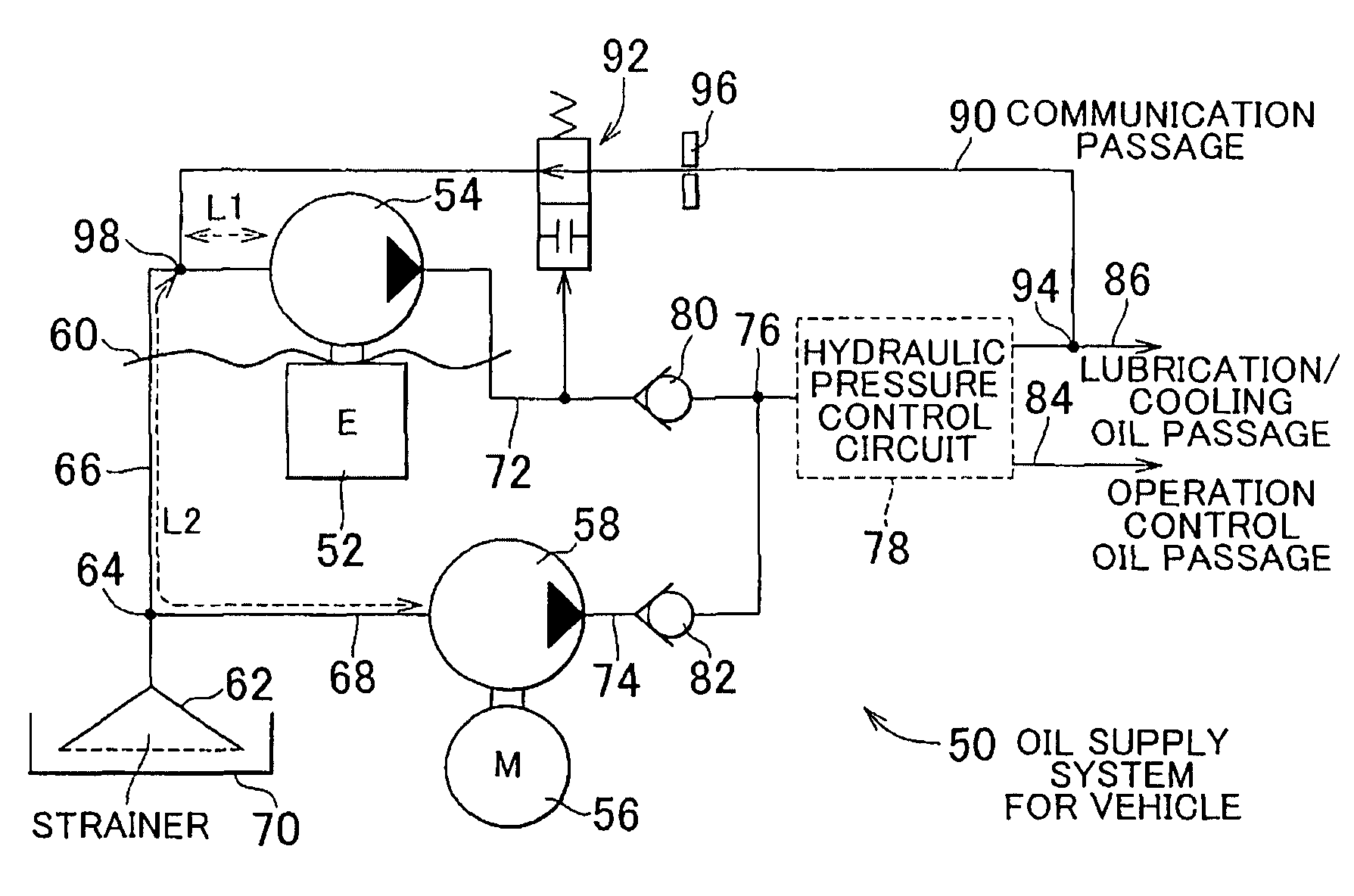

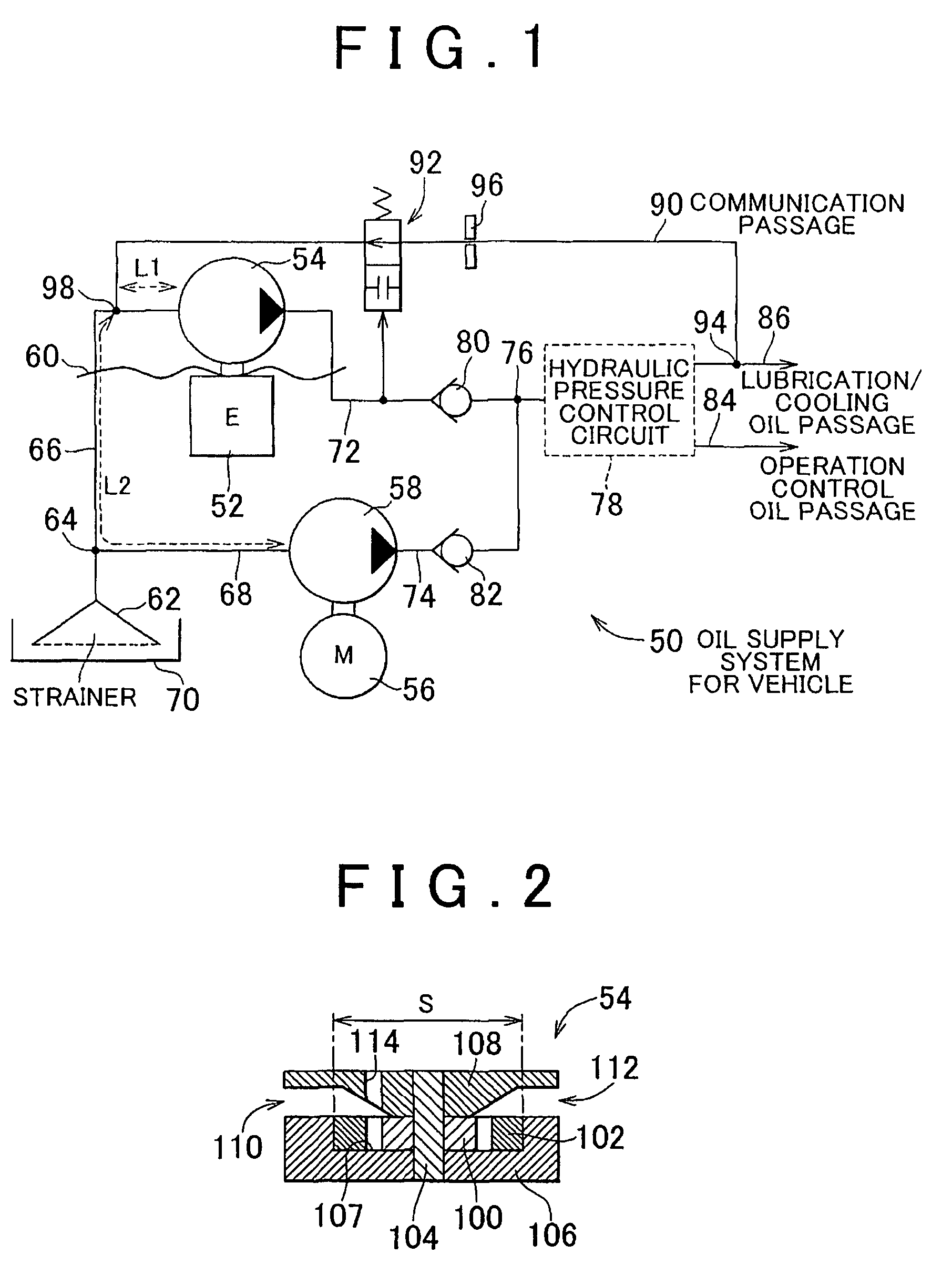

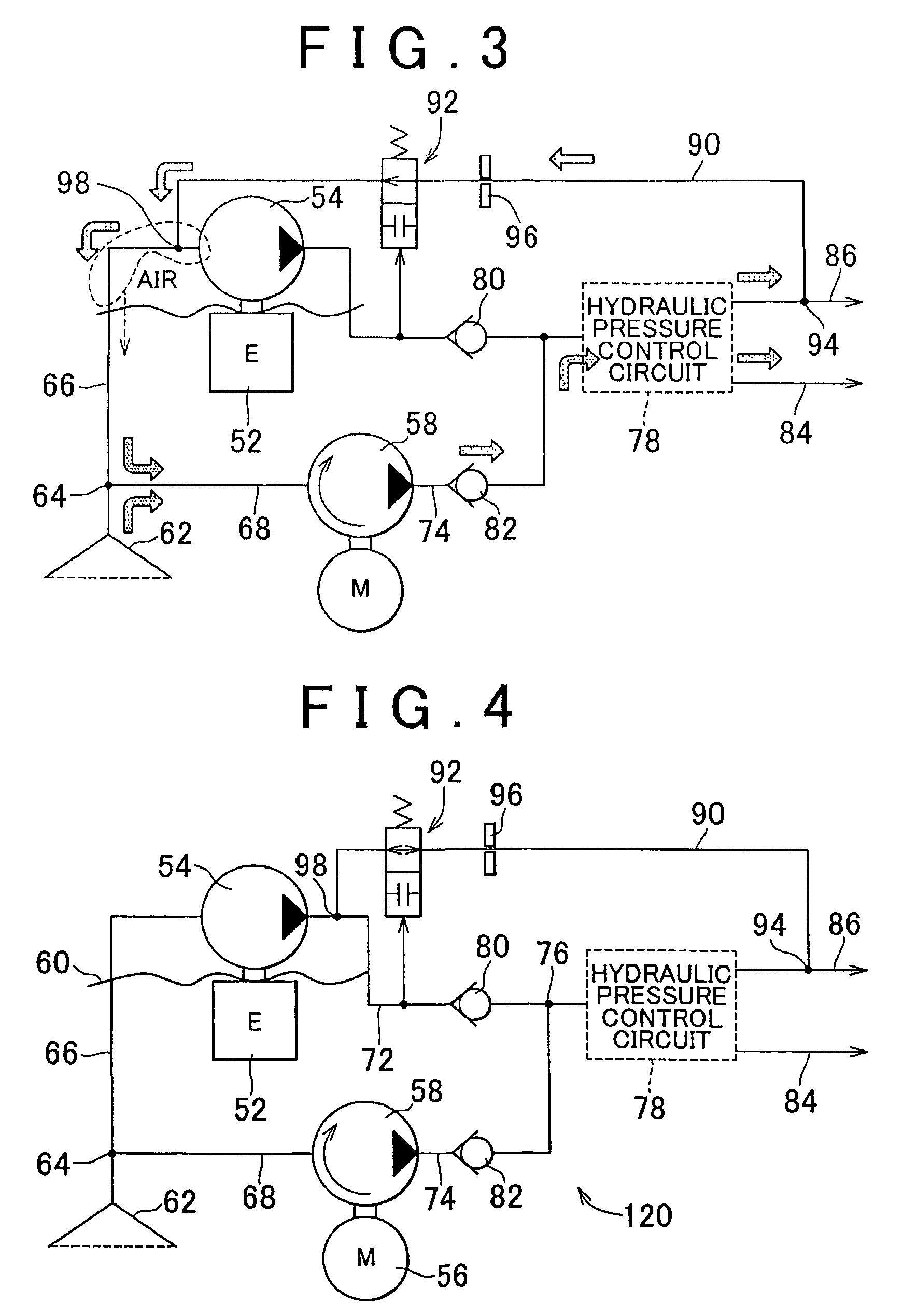

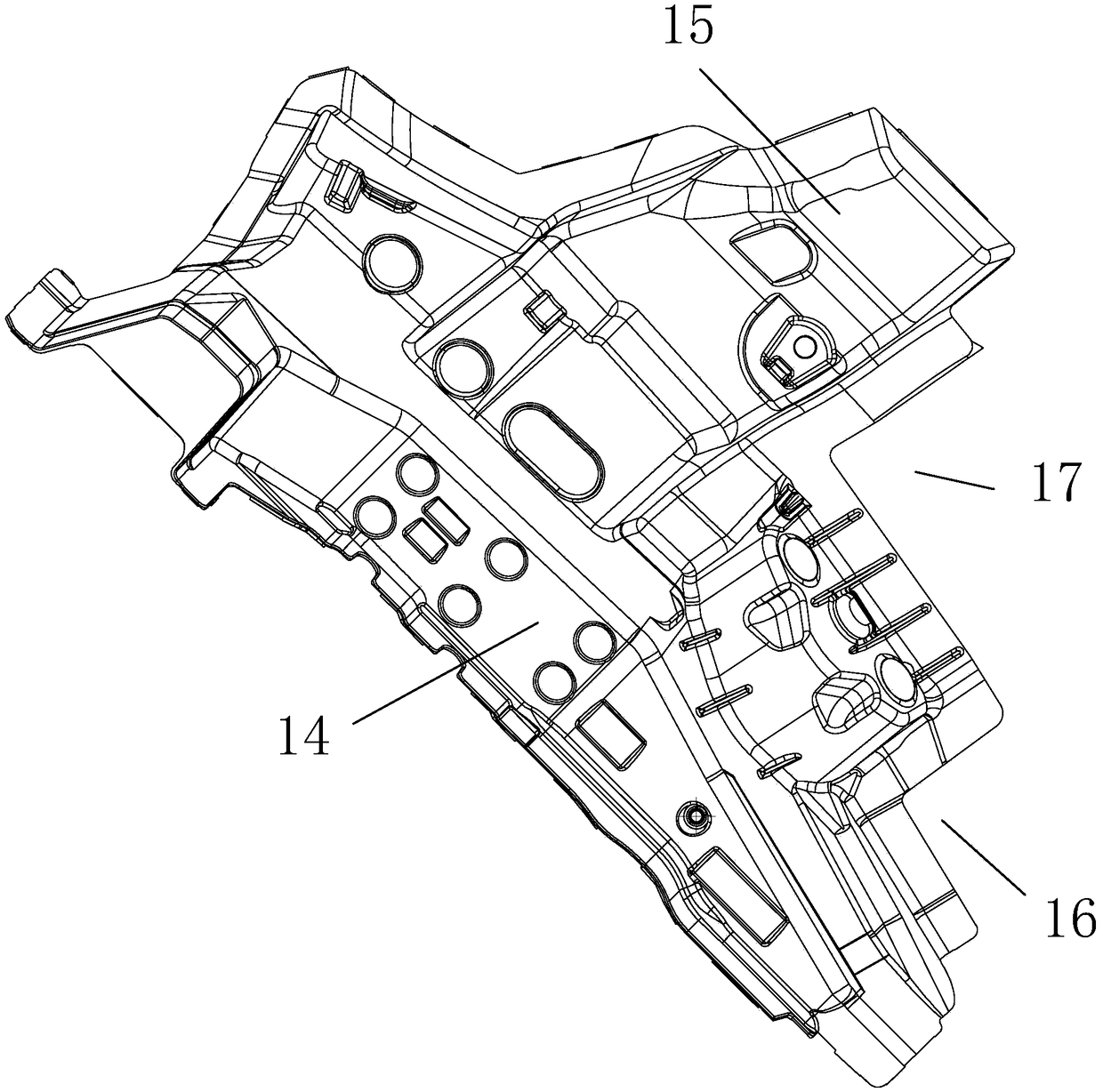

Oil supply system for vehicle

InactiveUS20080308355A1Deterioration of characteristicAvoid airGearboxesGear lubrication/coolingControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

Oil supply system for vehicle

InactiveUS7946389B2Avoid airEasy to disassembleLubrication of auxillariesGearboxesControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

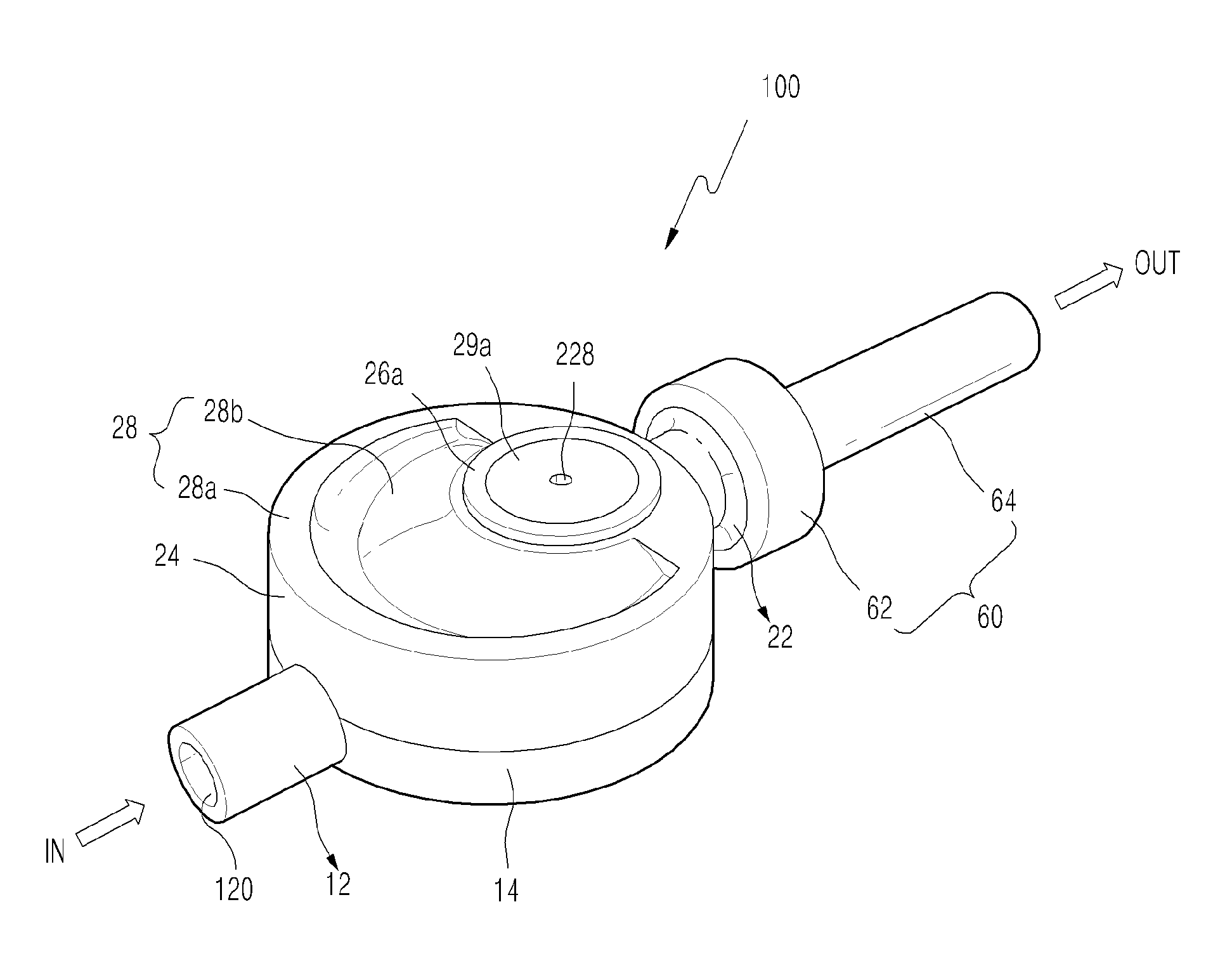

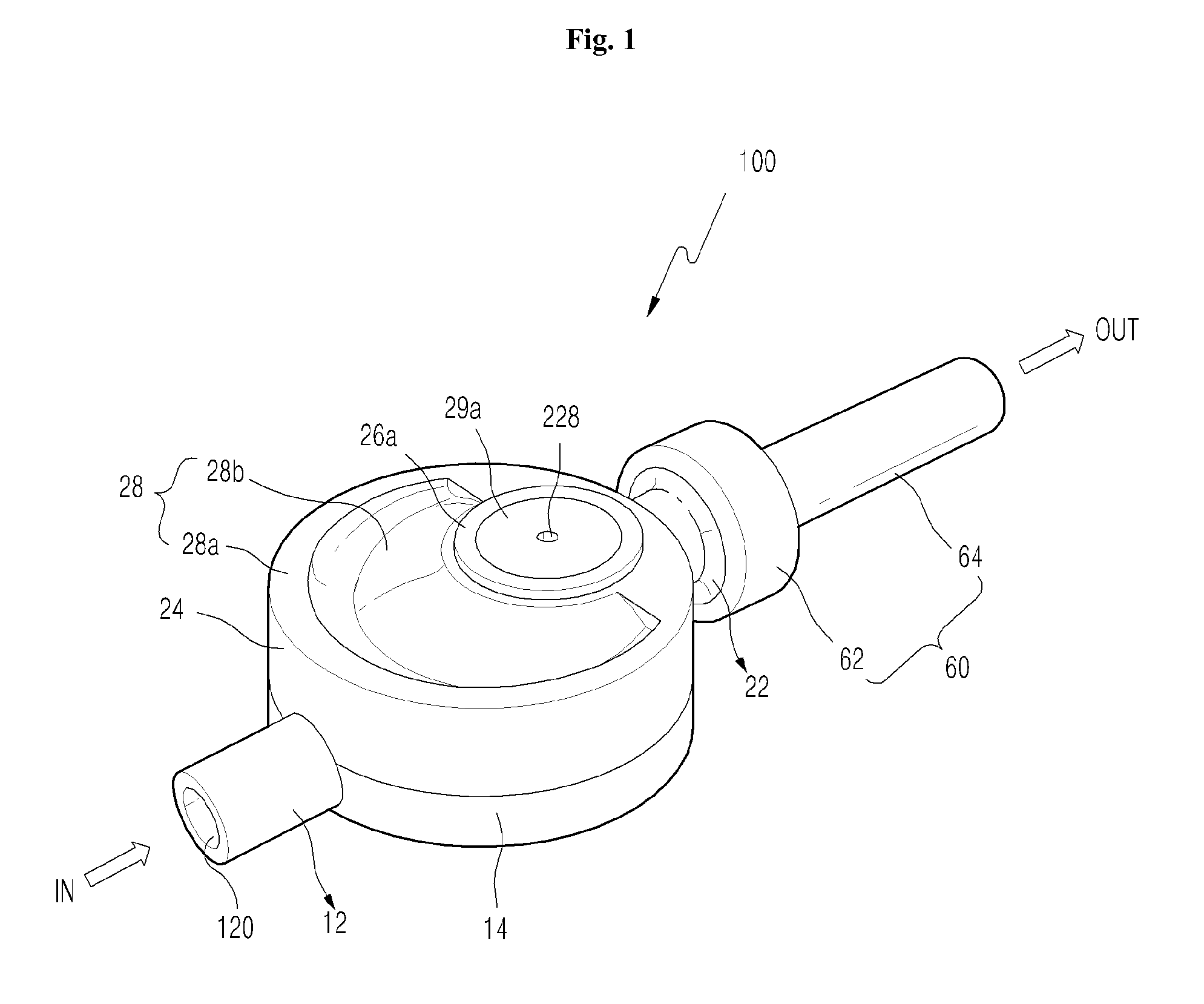

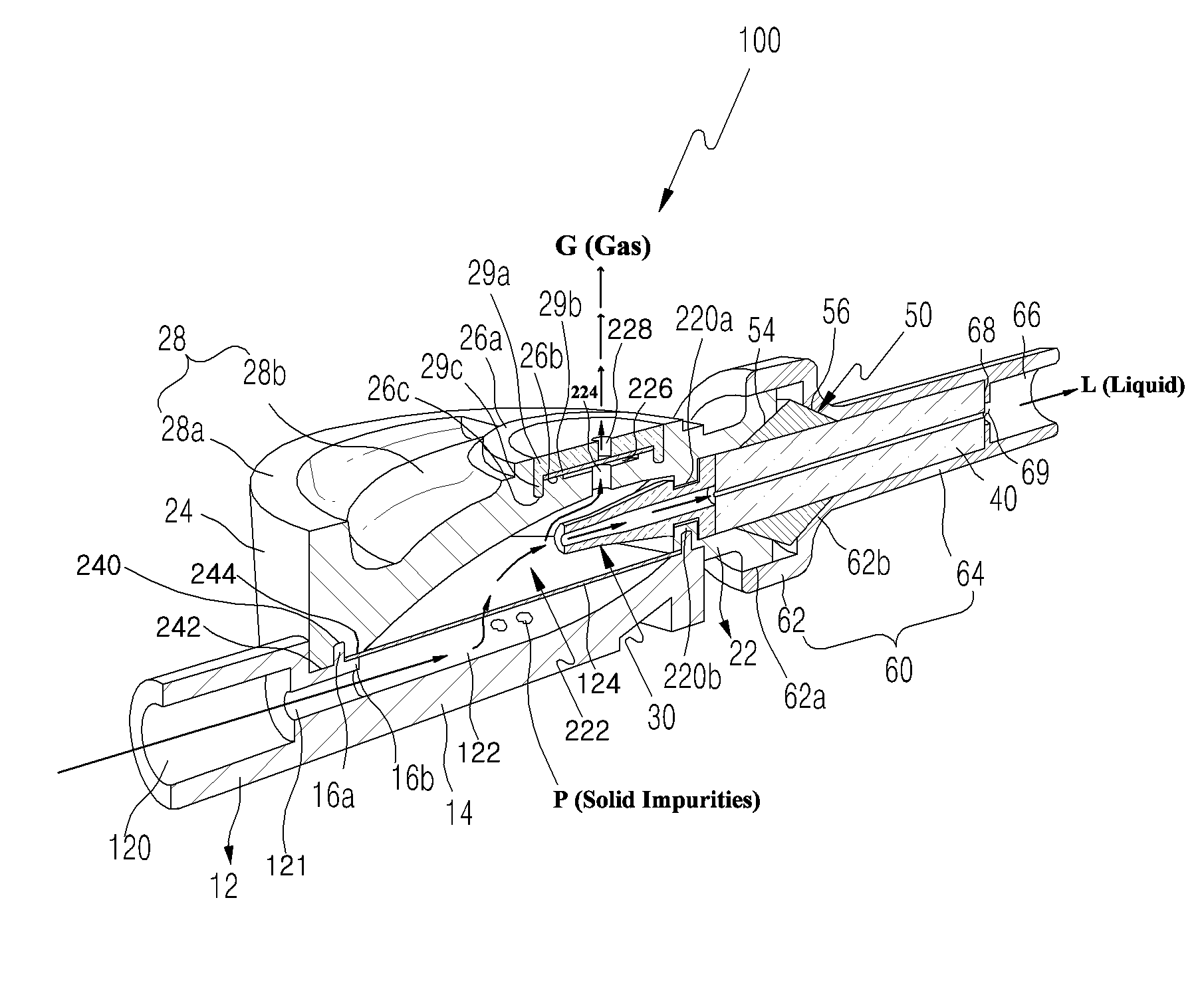

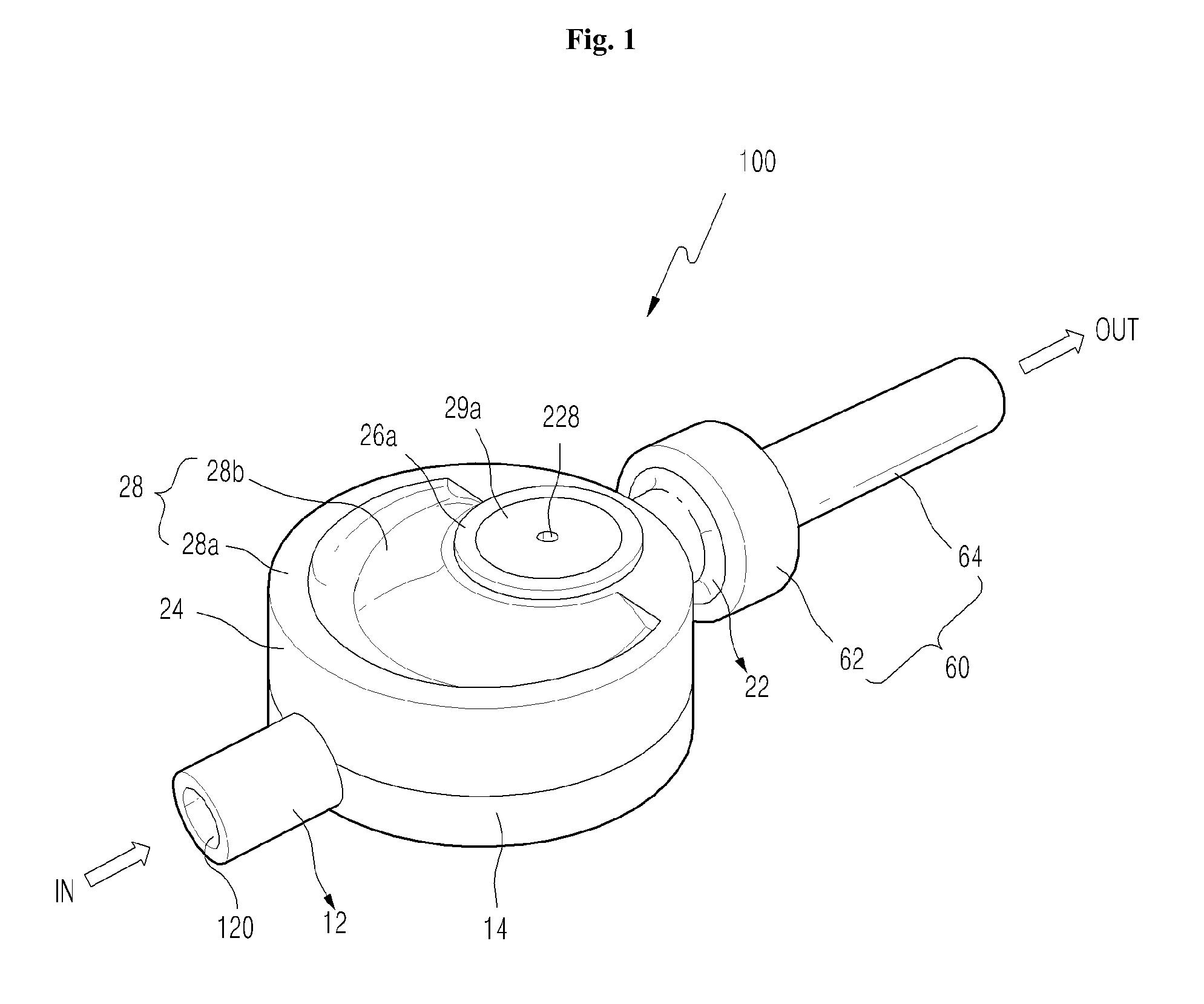

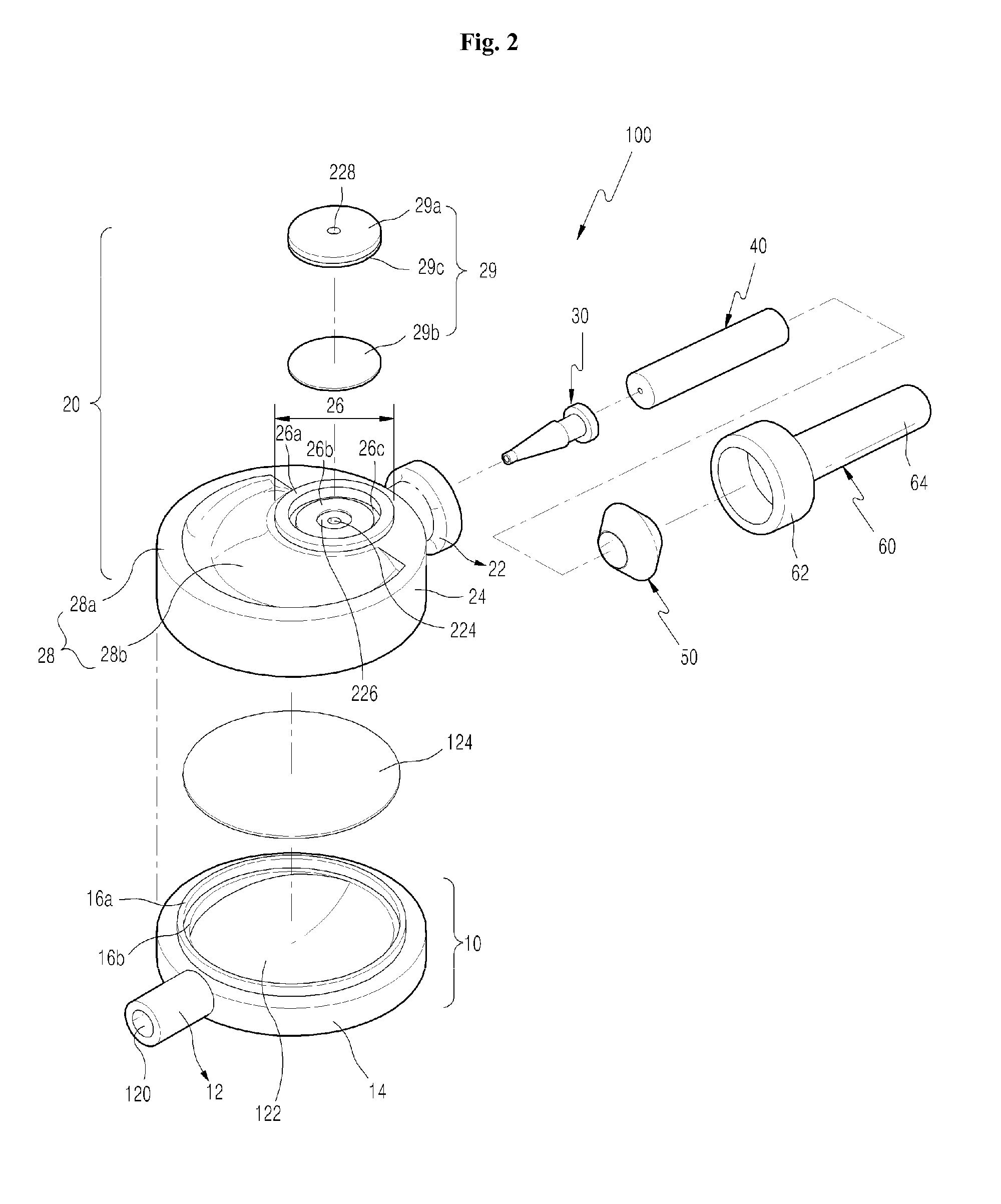

Filter device and liquid injection apparatus having the same

InactiveUS8382712B2Efficient removalAvoid airLiquid degasificationFiltering accessoriesSolid particleGlass fragment

Owner:E WHA FRESENIUS KABI

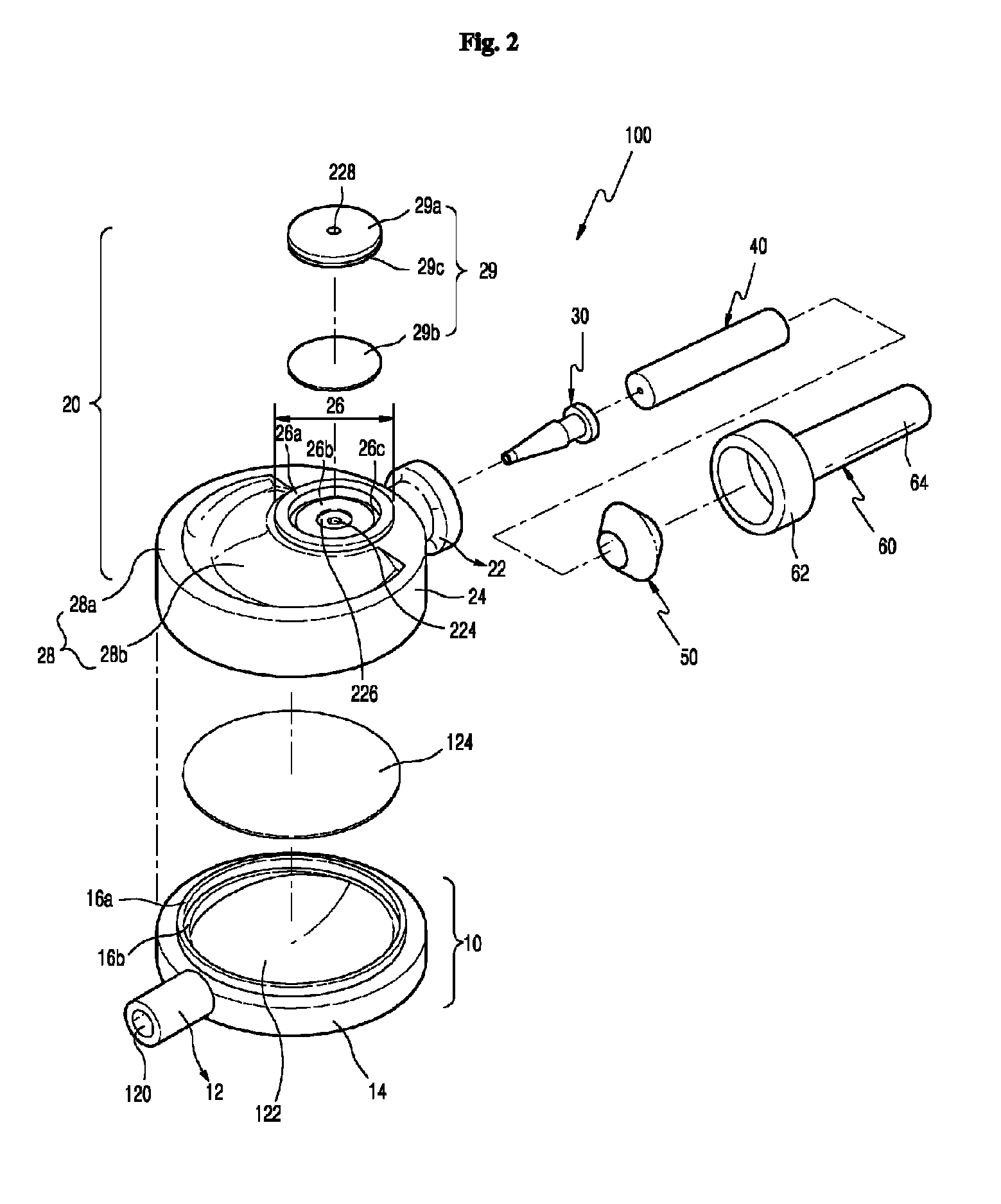

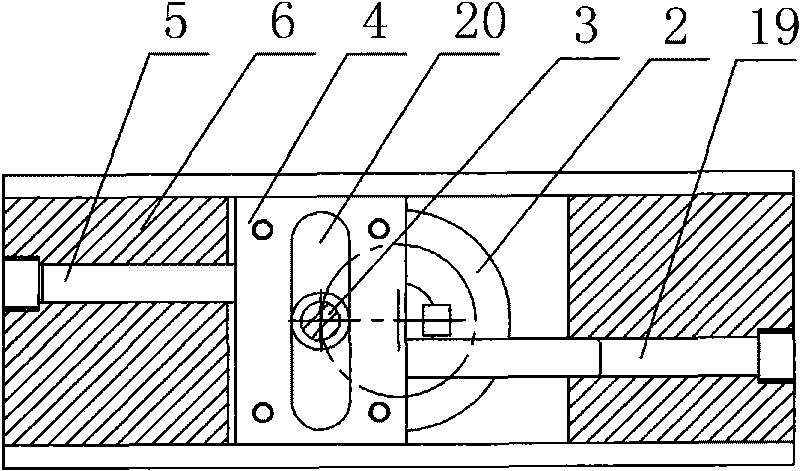

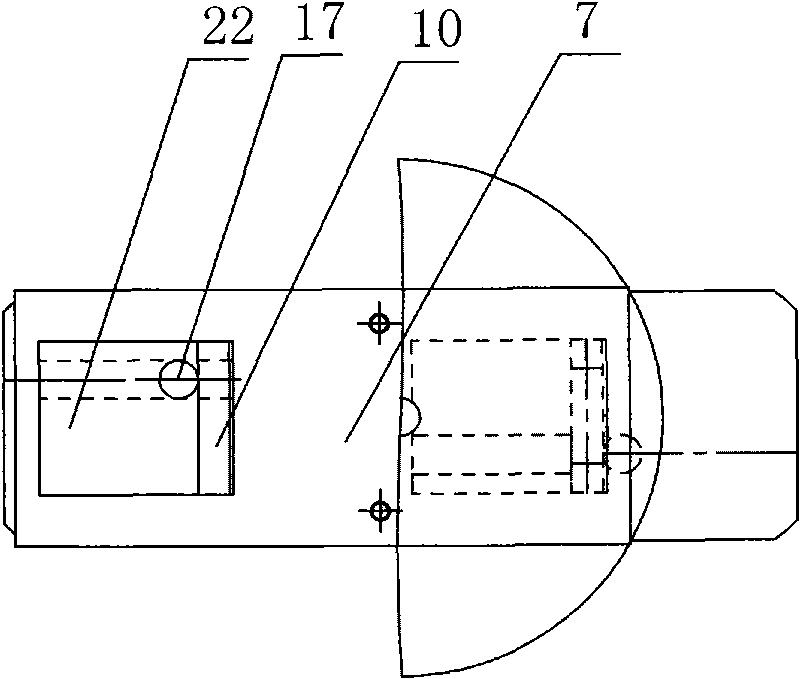

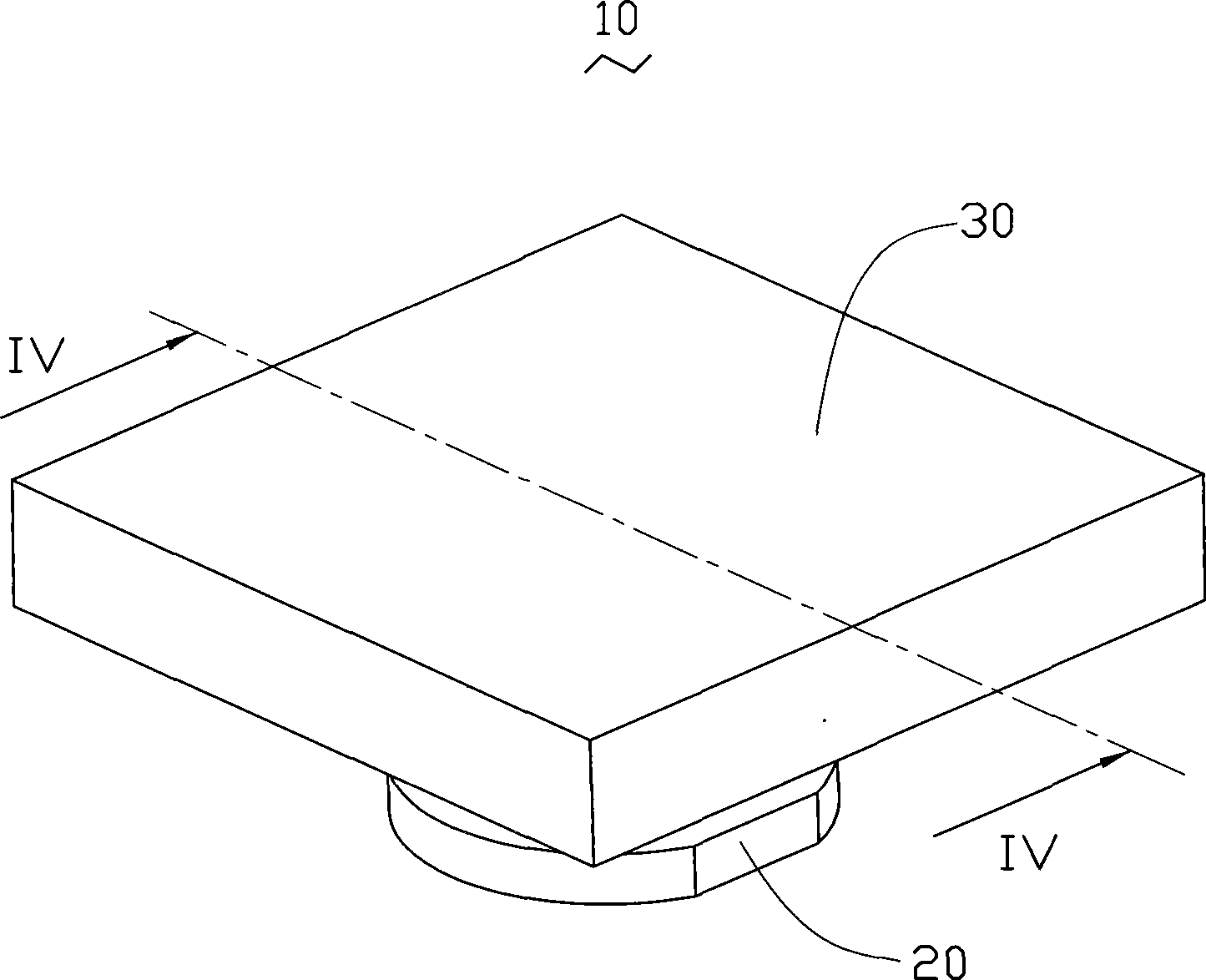

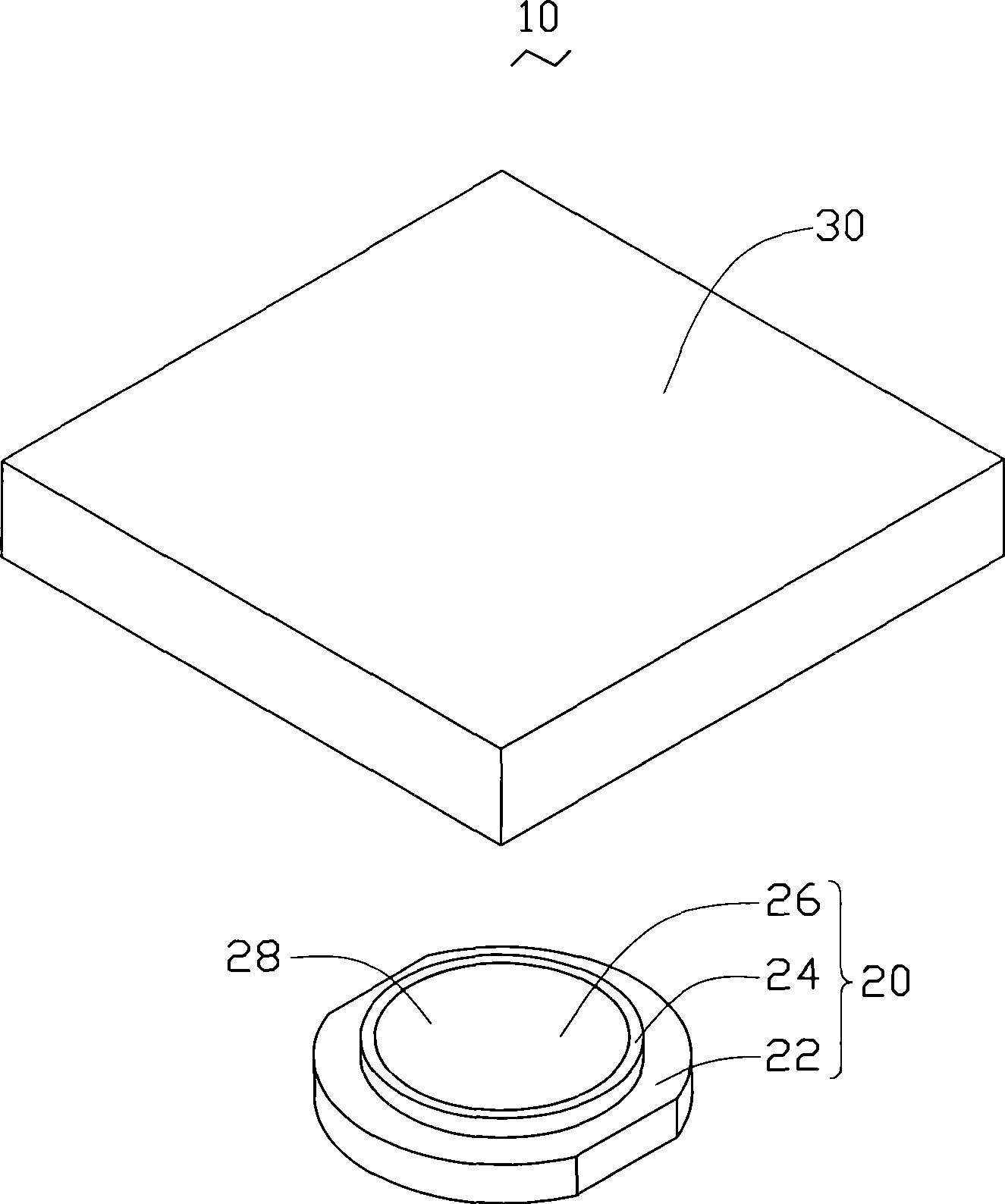

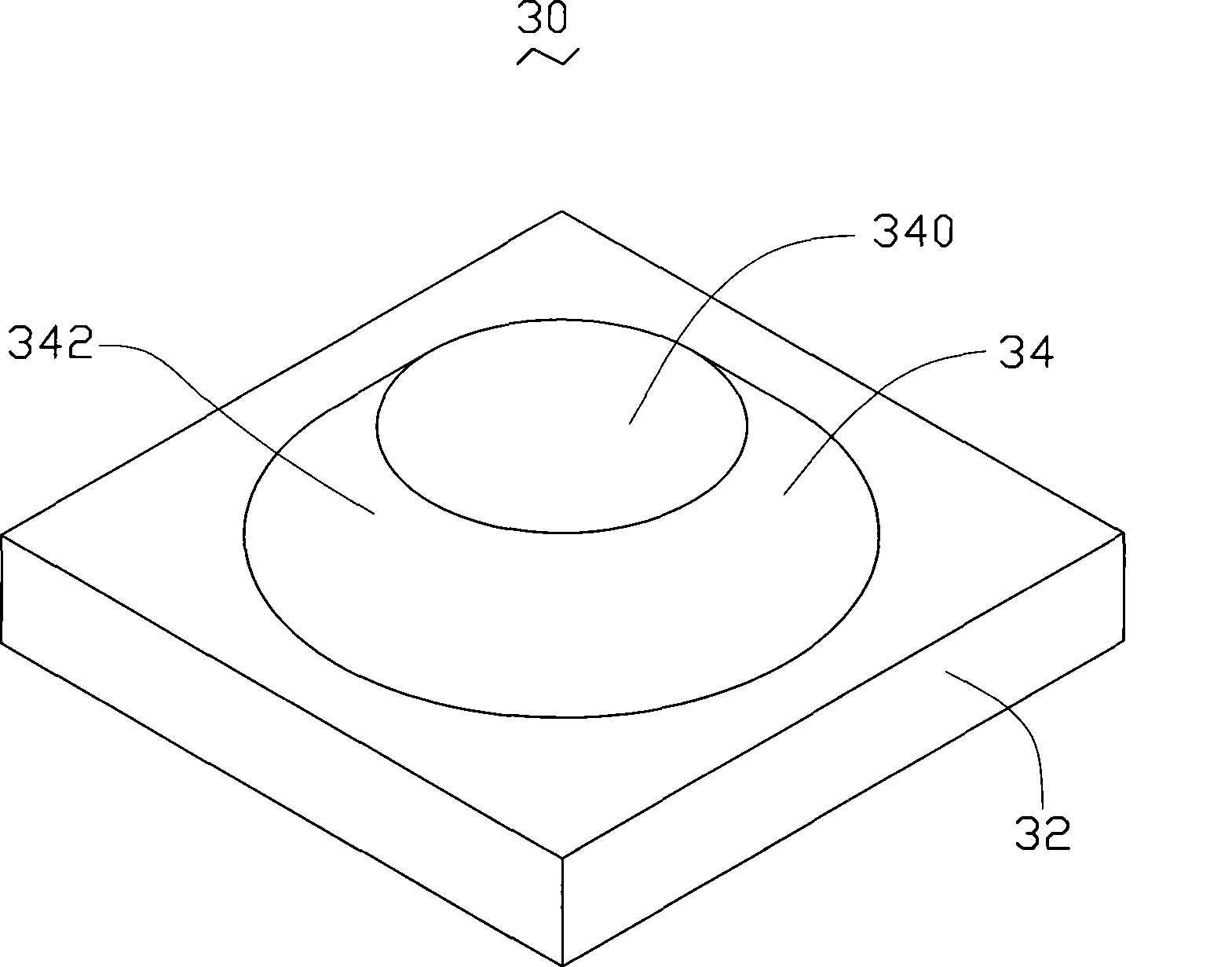

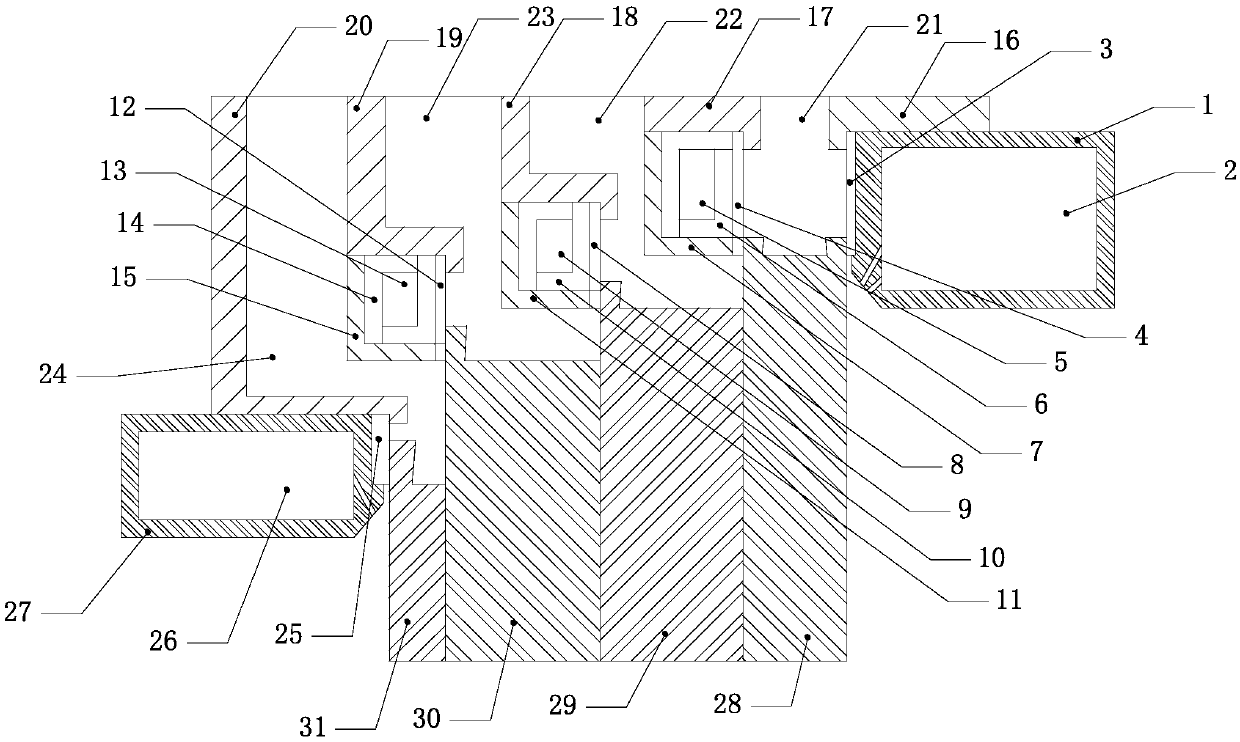

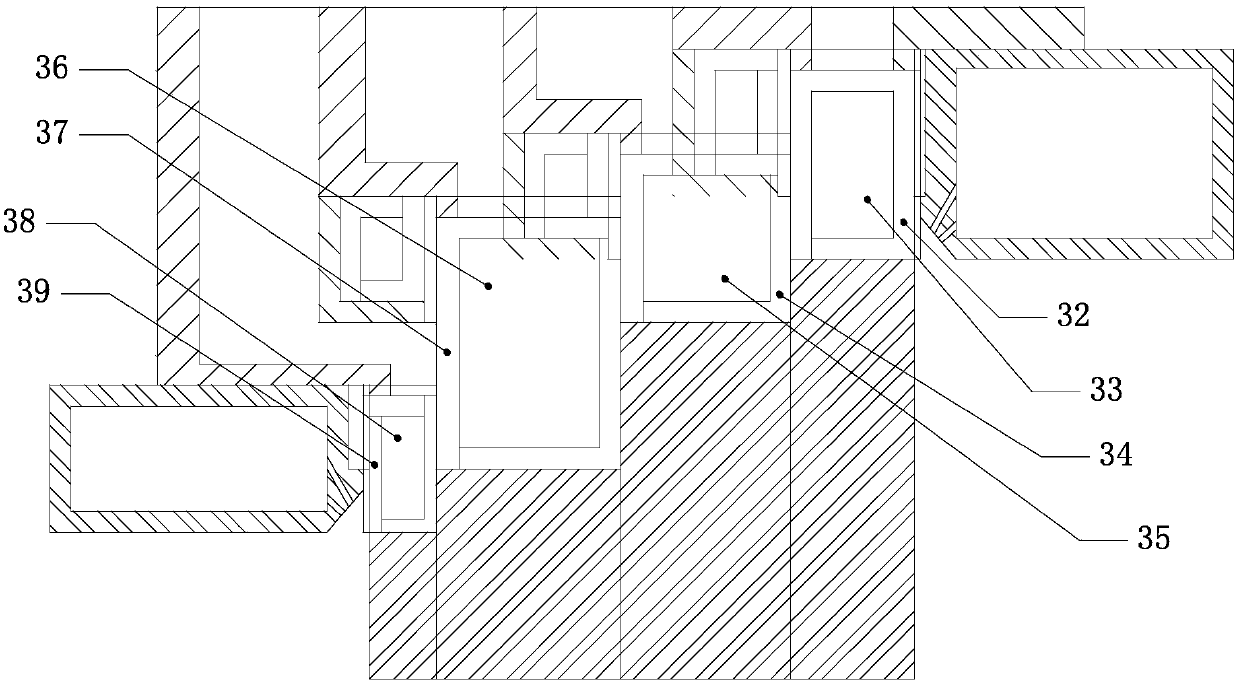

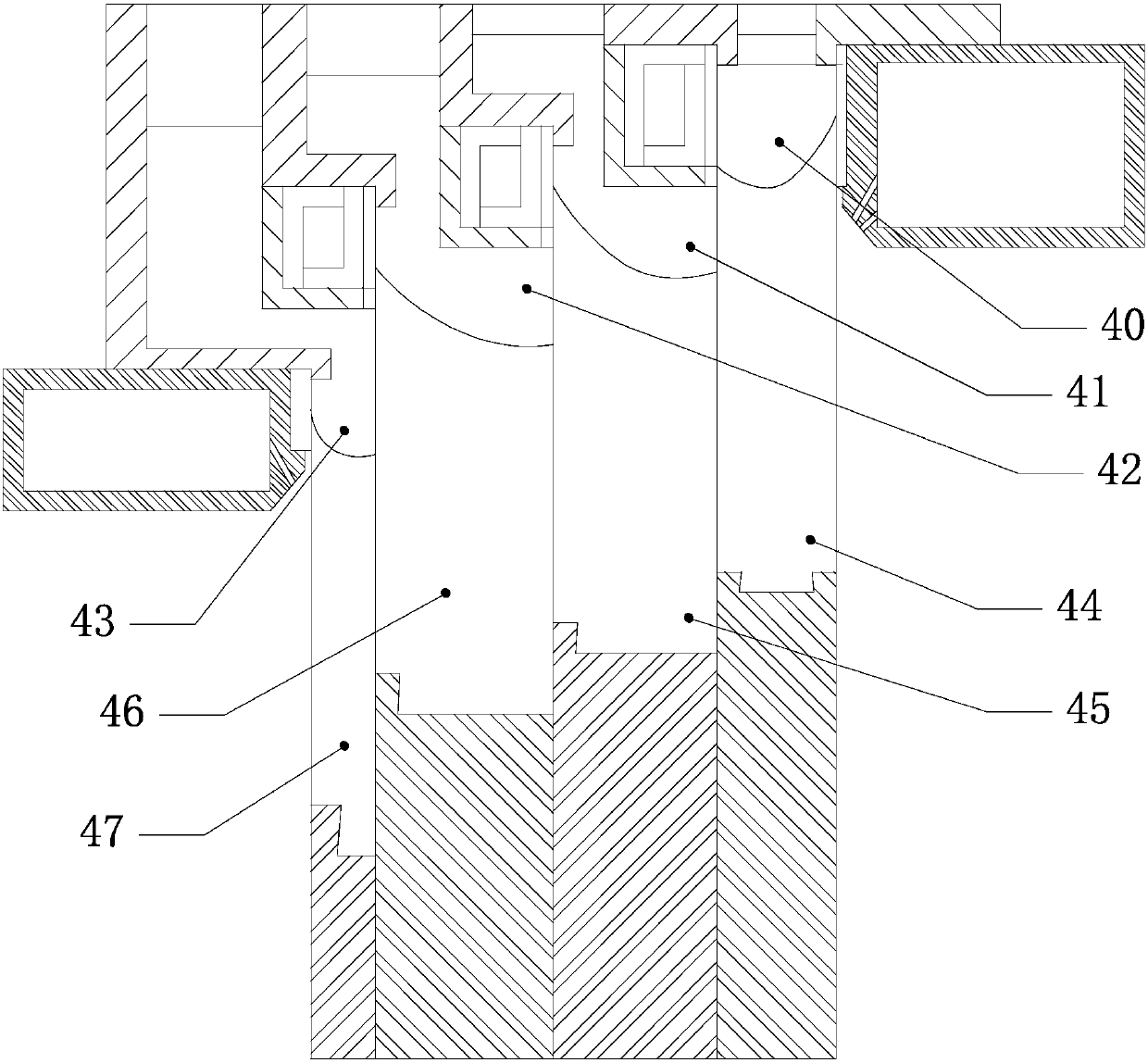

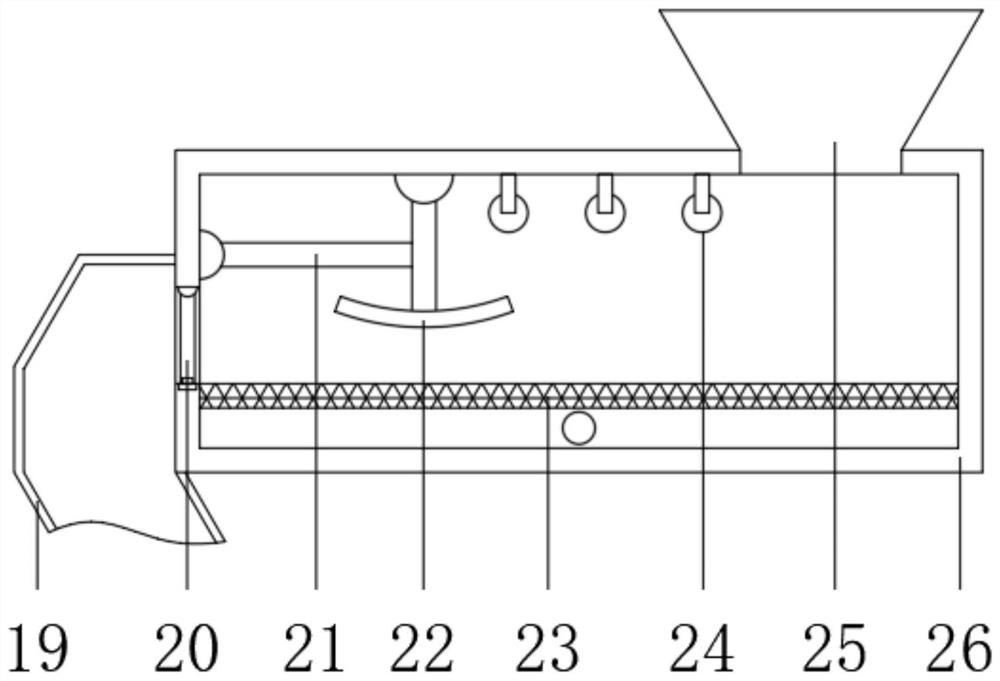

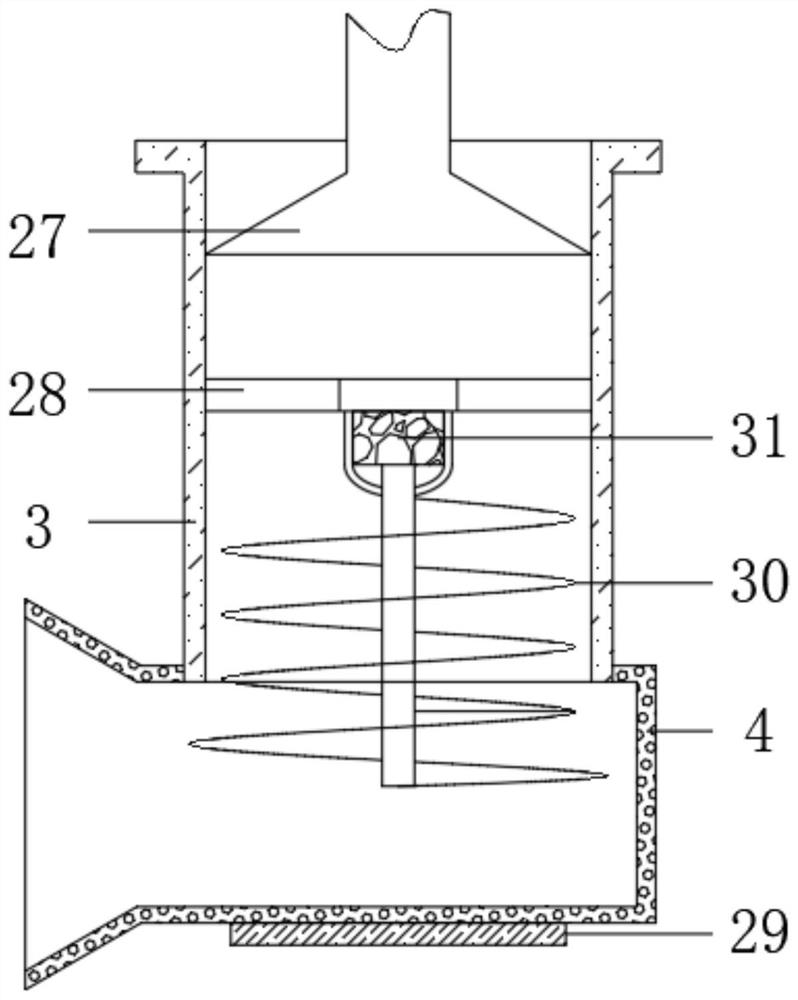

Electrical grease filling machine

The invention relates to an electrical grease filling machine which belongs to the technical field of mechanical equipment, in particular to an electrical grease filling machine. The electrical grease filling machine comprises a speed reducer shaft, an eccentric disc, a driving shaft, a slide block, a piston, a cylinder, a moving block, an oil stirring piece, an oil press plate, a fixed block, a bottom plate, a connecting block, a spiral oil press device driving shaft, a bearing, an outer flange, an inner flange, an oil inlet, an oil tank, a piston hole, a through groove, an oil outlet hole, a square hole and an oil press piece. The electrical grease filling machine can suck grease having higher viscosity and prevent air appearing in oil.

Owner:扬州市晨辉机械有限公司

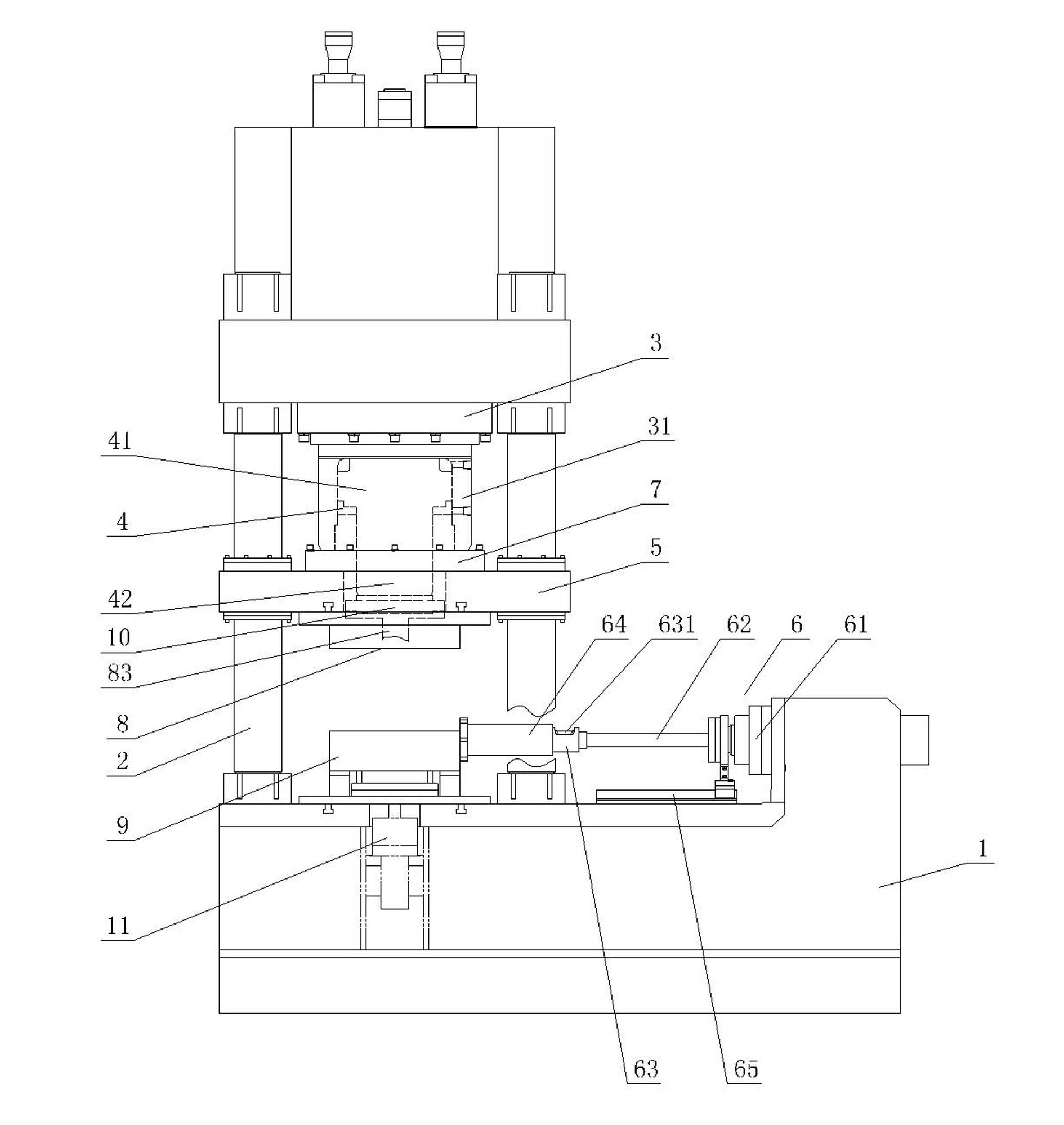

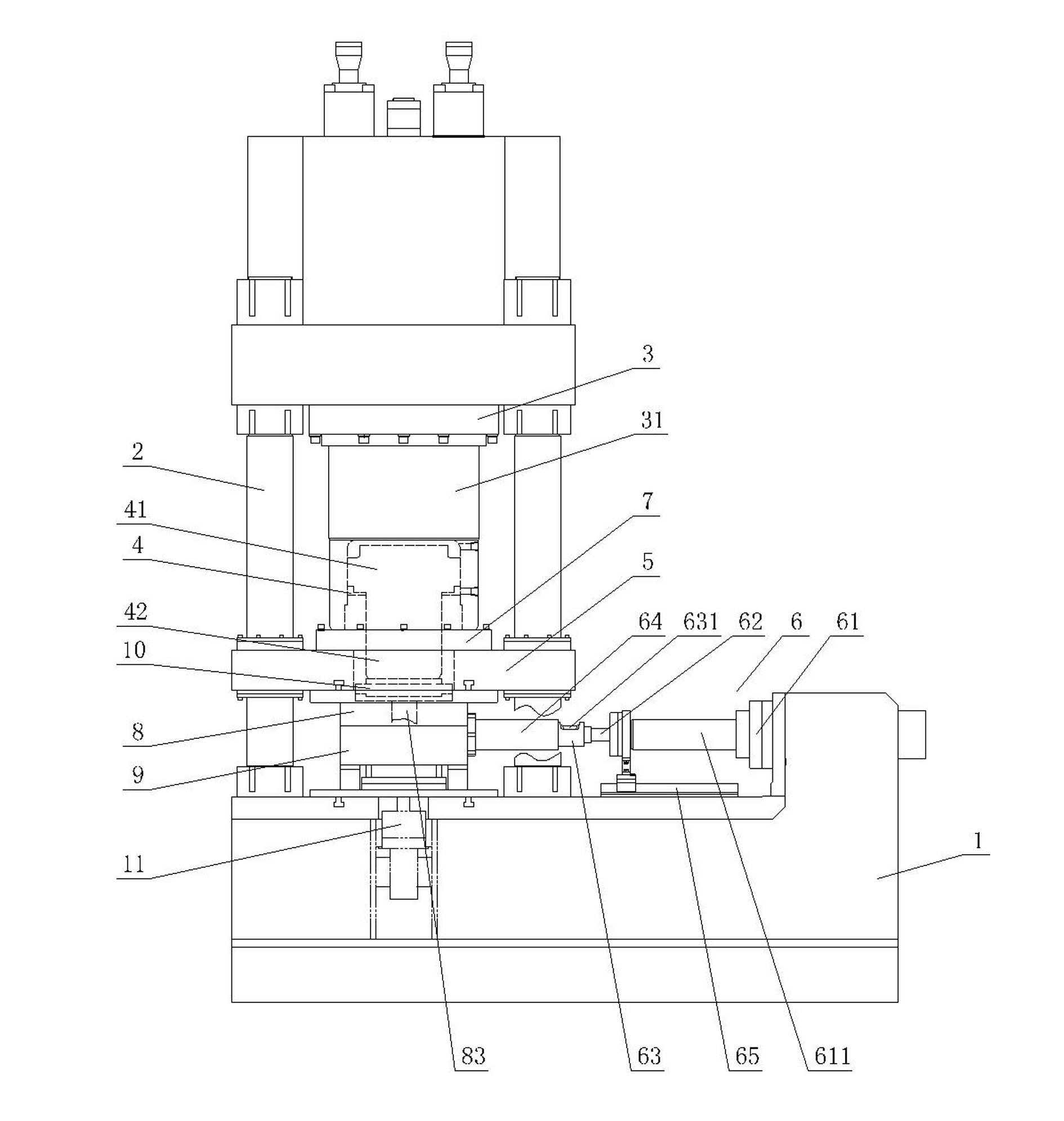

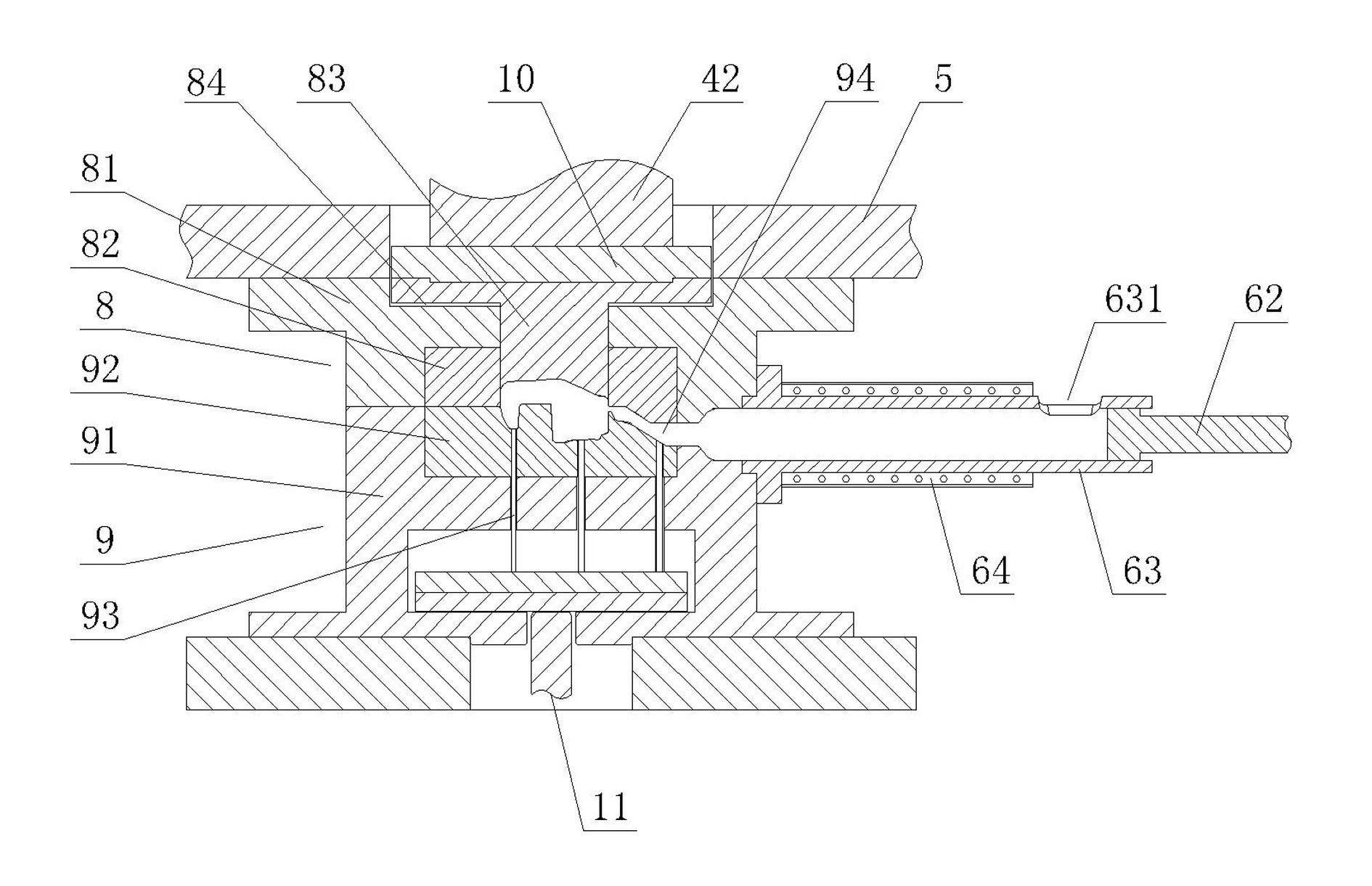

Casting-forging hydropress and method for casting and forging product thereof

InactiveCN102554628AEasy to fillFlexible adjustment of filling speedOther manufacturing equipments/toolsPressure castingEngineering

The invention discloses a casting-forging hydropress and a method for casting and forging a product thereof. The casting-forging hydropress comprises a worktable, a stand column, a die-assembling cylinder, a forging and pressing cylinder, a movable beam and a pressure casting device, wherein the stand column is arranged on the worktable, the die-assembling cylinder is arranged on the stand column, the movable beam is movably arranged on the stand column and connected with a piston rod of the die-assembling cylinder, the forging and pressing cylinder is arranged on the die-assembling cylinder, and the pressure casting device is arranged on the tabletop of the worktable. According to the invention, as the pressure casting device is arranged on the tabletop of the worktable, a die can be filled with metal liquid not just in the state of die opening, thereby facilitating the filling and pressure feeding of the metal liquid, and simplifying the operation process, so that the operating efficiency of the hydropress is effectively improved; meanwhile, as a cylinder body of the forging and pressing cylinder is formed by hollowing out the lower end of the piston rod of the die-assembling cylinder, the structure of the hydropress is simplified, and the hydropress has the advantages of high forging pressure and stable die-assembling pressure and the like, thereby effectively ensuring the forging performance of products.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

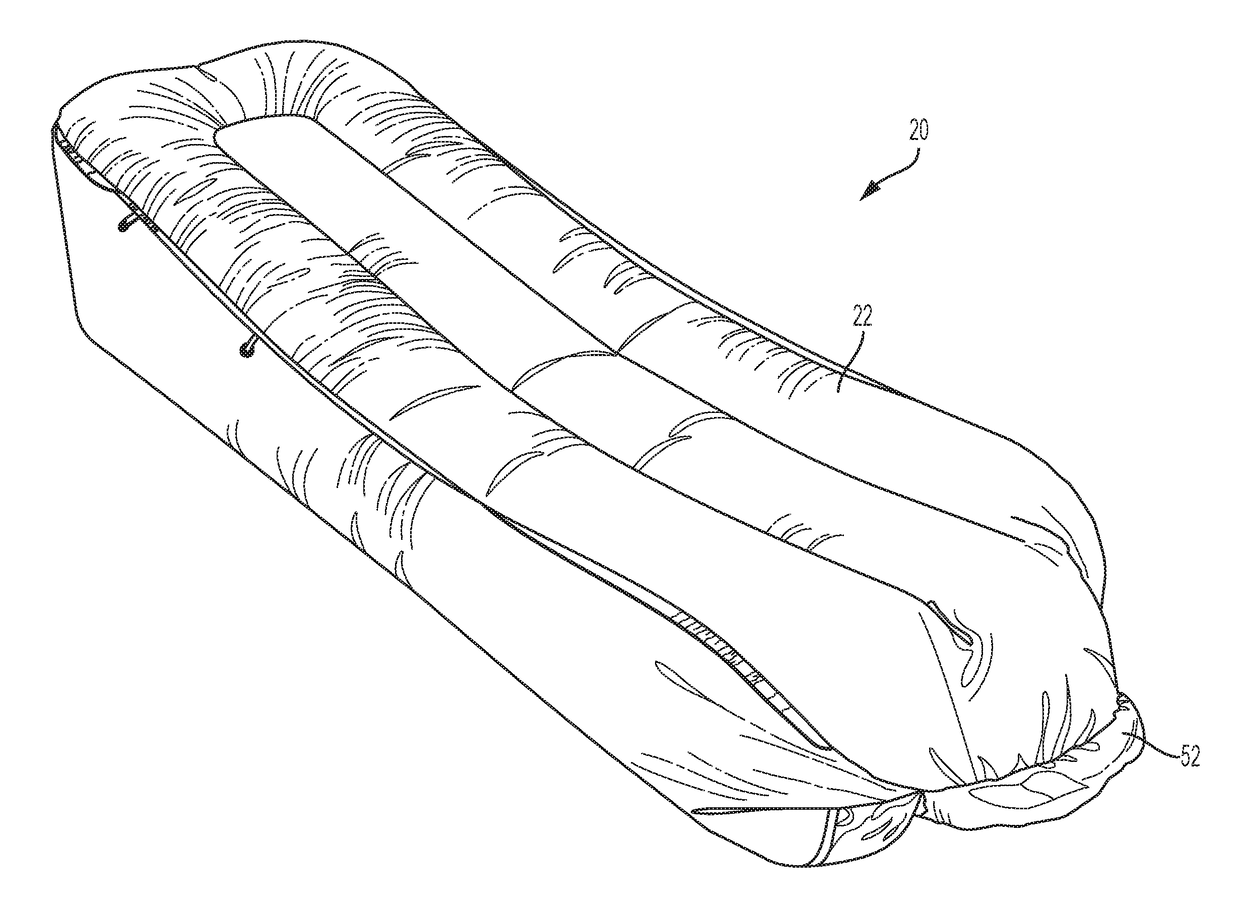

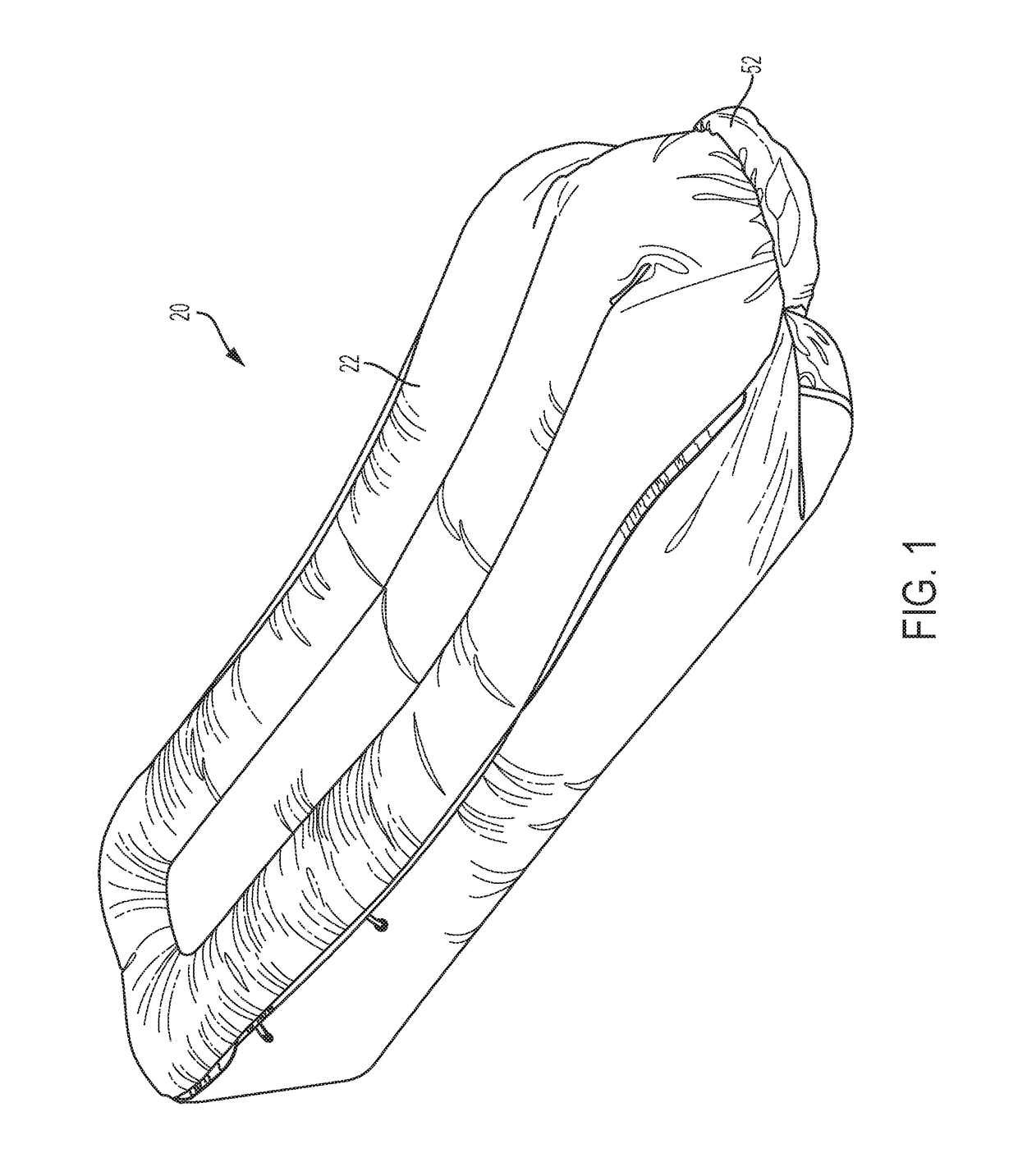

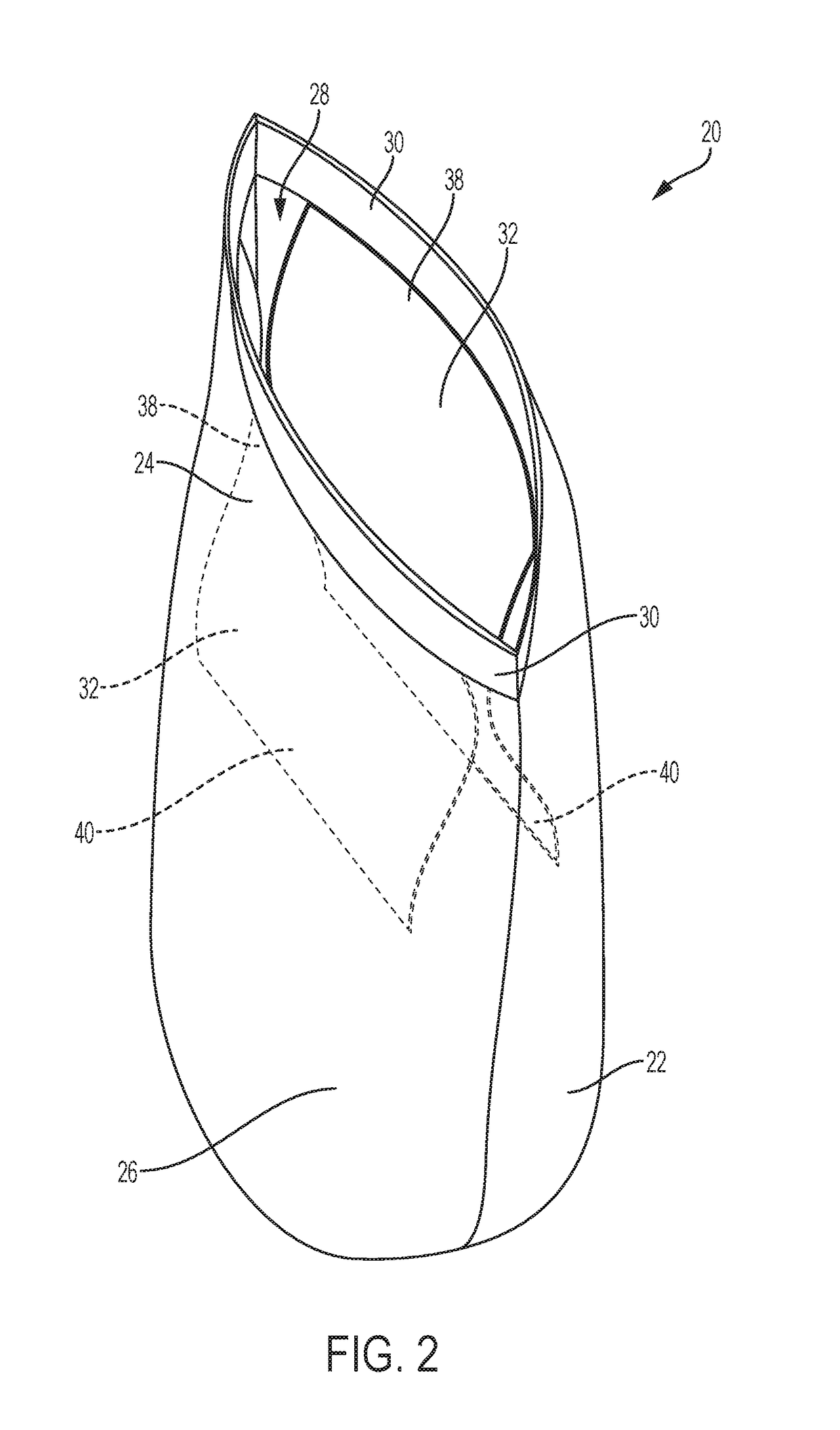

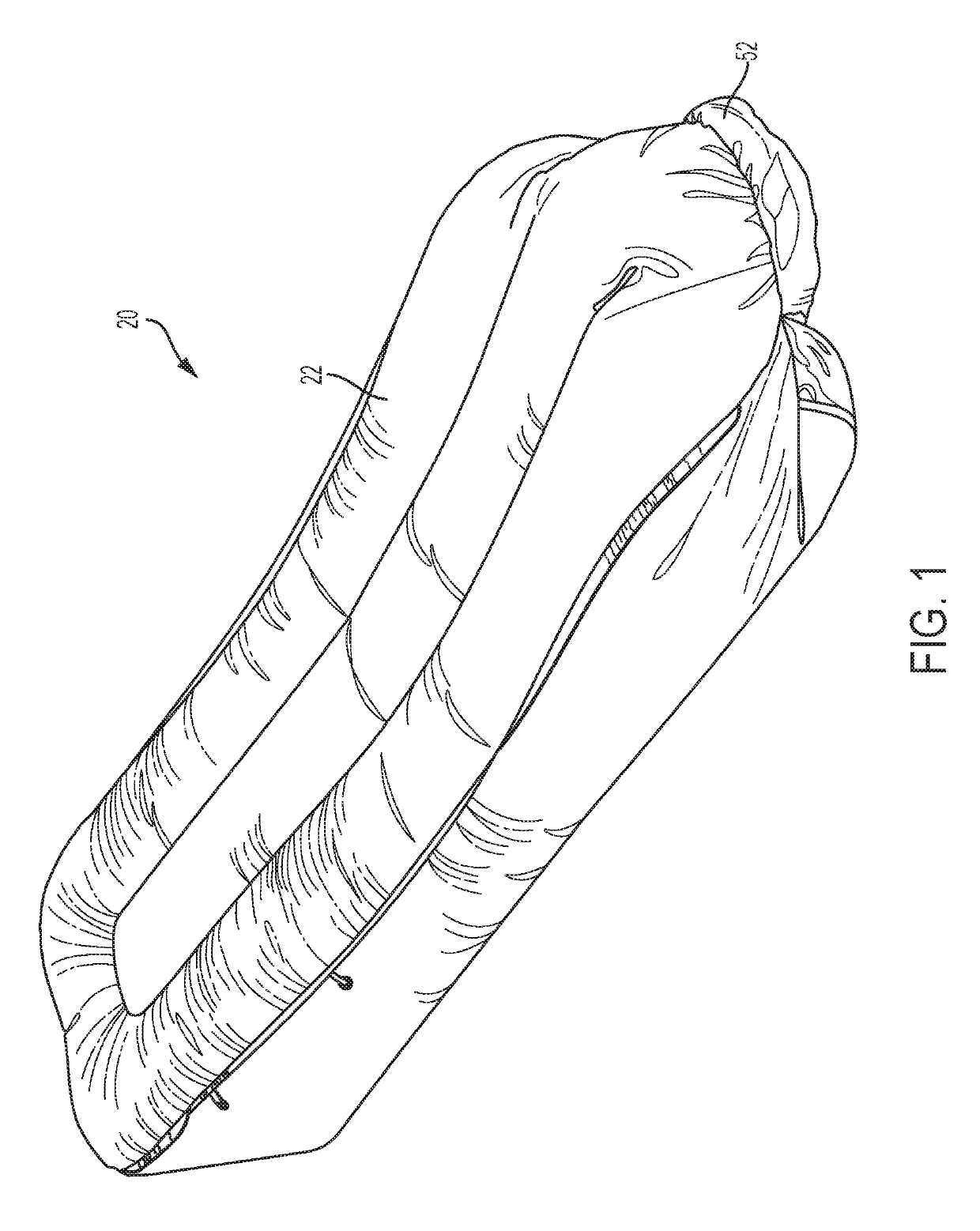

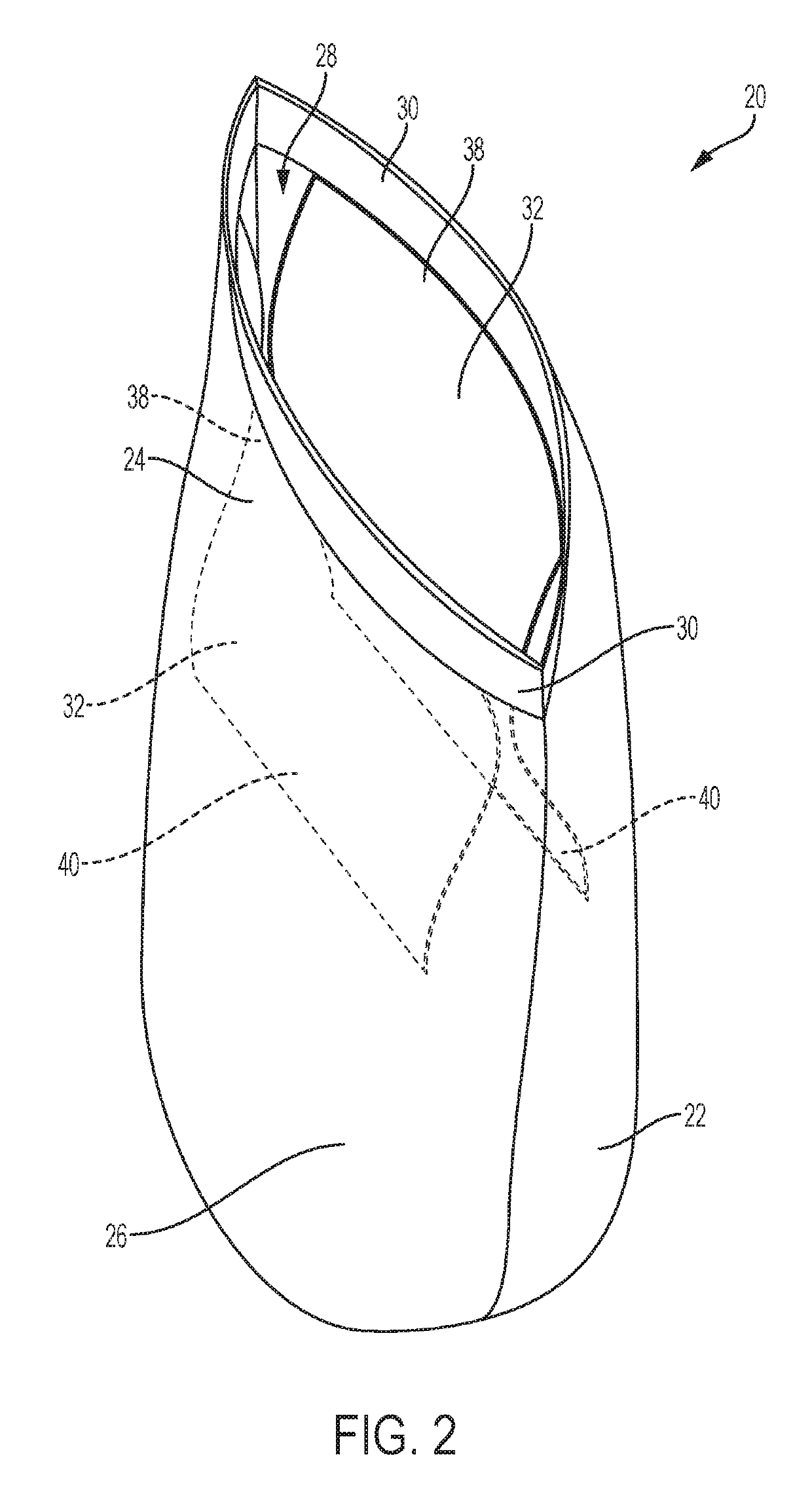

Air Inflation Device For Inflating Air Support Furniture And Method Of Using The Same

An air support article of air inflatable furniture comprises an air inflation device. The air inflation device provides an openable and closable opening into the sack that forms the majority of the article. The air inflation device comprises at least one pliable flap attached to the sack. The flap acts as a partial check valve that allows the article to be inflated simply by rapidly opening and closing the opening.

Owner:ZHEJIANG HENGFENG TOP LEISURE CO LTD

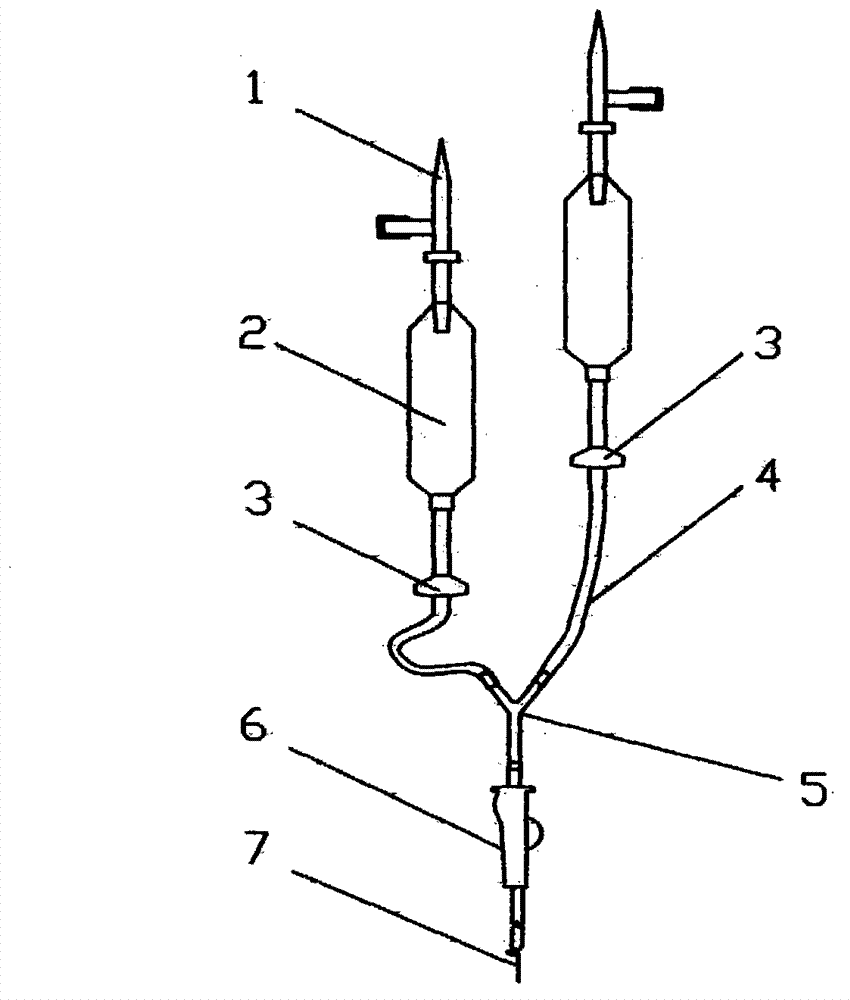

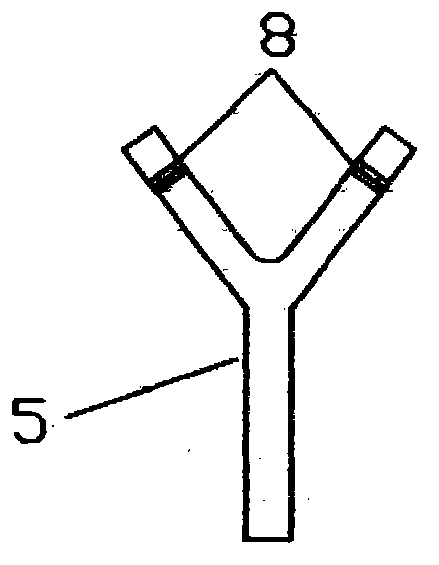

Double-way unintermittent infusion set

The invention relates to a double-way unintermittent infusion set and belongs to a medical infusion set. The double-way unintermittent infusion set comprises bottle plug puncture units, an air inlet pipe air filter, a dropper and a needle which are sequentially connected through a hose, and a flow adjuster is sleeved on the hose. The double-way unintermittent infusion set is characterized in that the infusion set further comprises a tee joint, two branch tubes of the tee joint are connected with two infusion tubes, each infusion tube is provided with one bottle plug puncture unit and a one-way valve. The double-way unintermittent infusion set has the advantages that when a patient is subjected to infusion of multiple bottles of liquor medicines continuously, infusion medicine bottles can be automatically switched, unintermittent infusion is realized, burden of medical staff is alleviated, infusion efficiency is improved, and the problems of waste of liquor medicine, air entering the tubes and blood return and the like are avoided. The double-way unintermittent infusion set can be widely used for one-off infusion of various patients.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

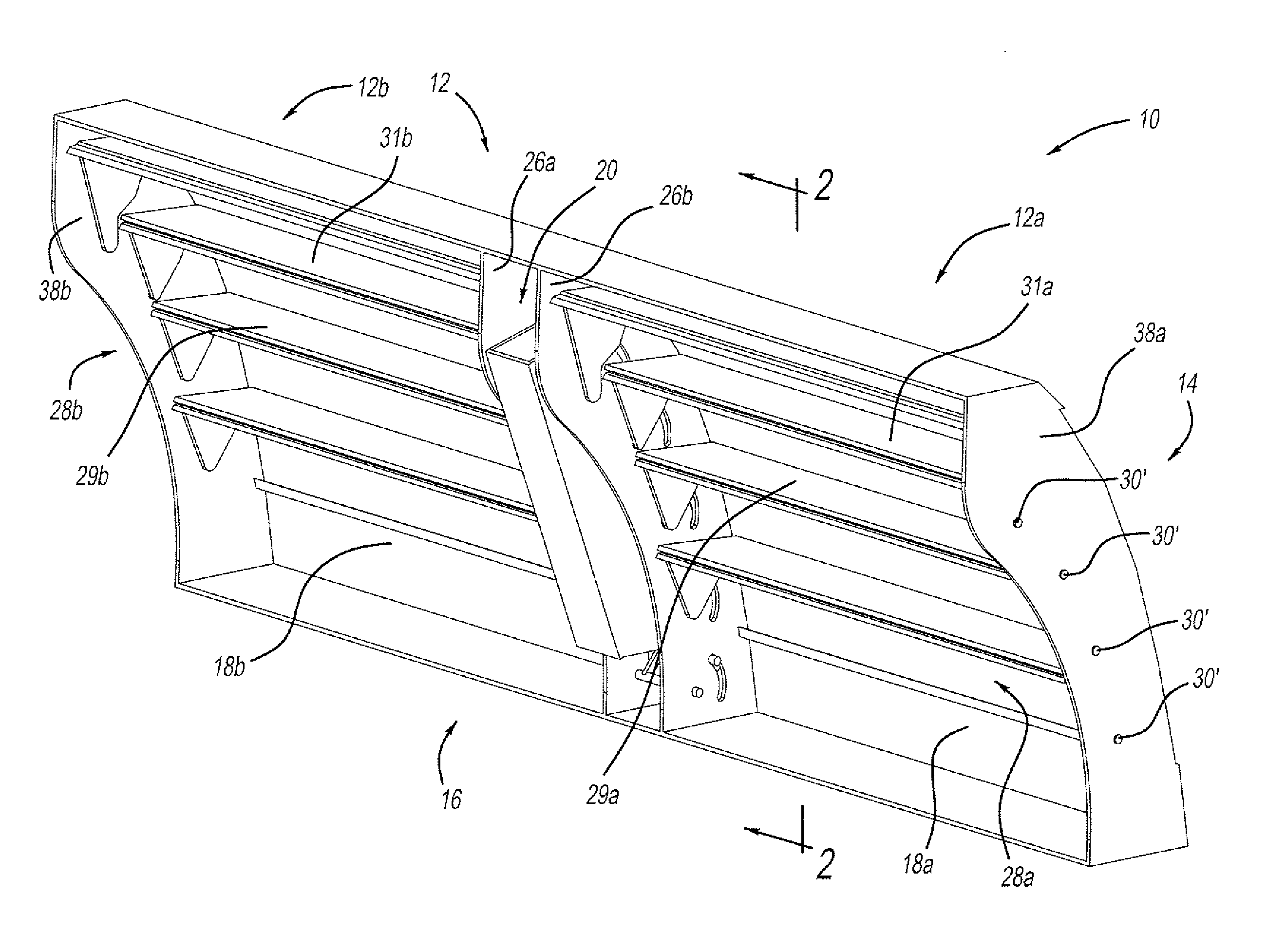

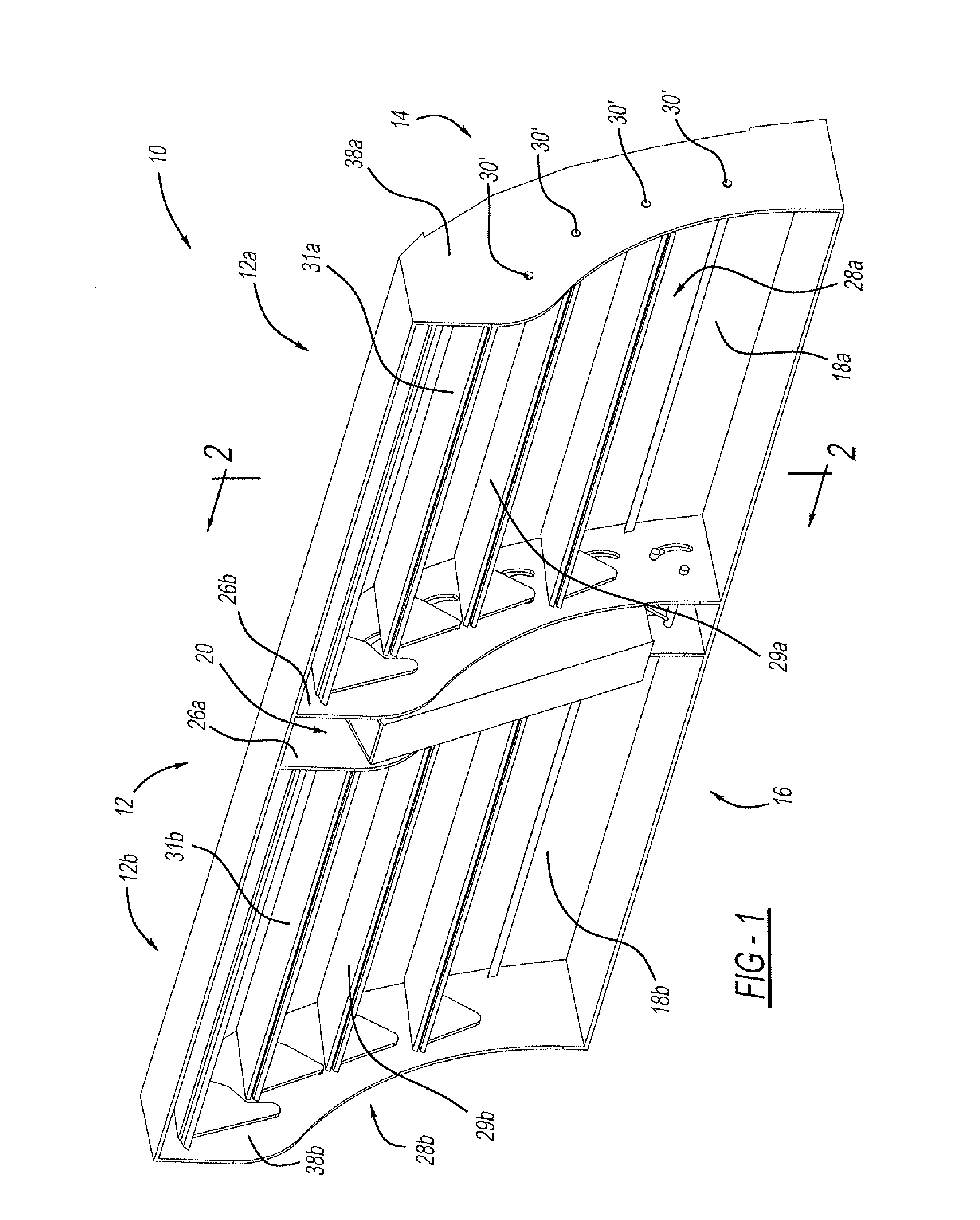

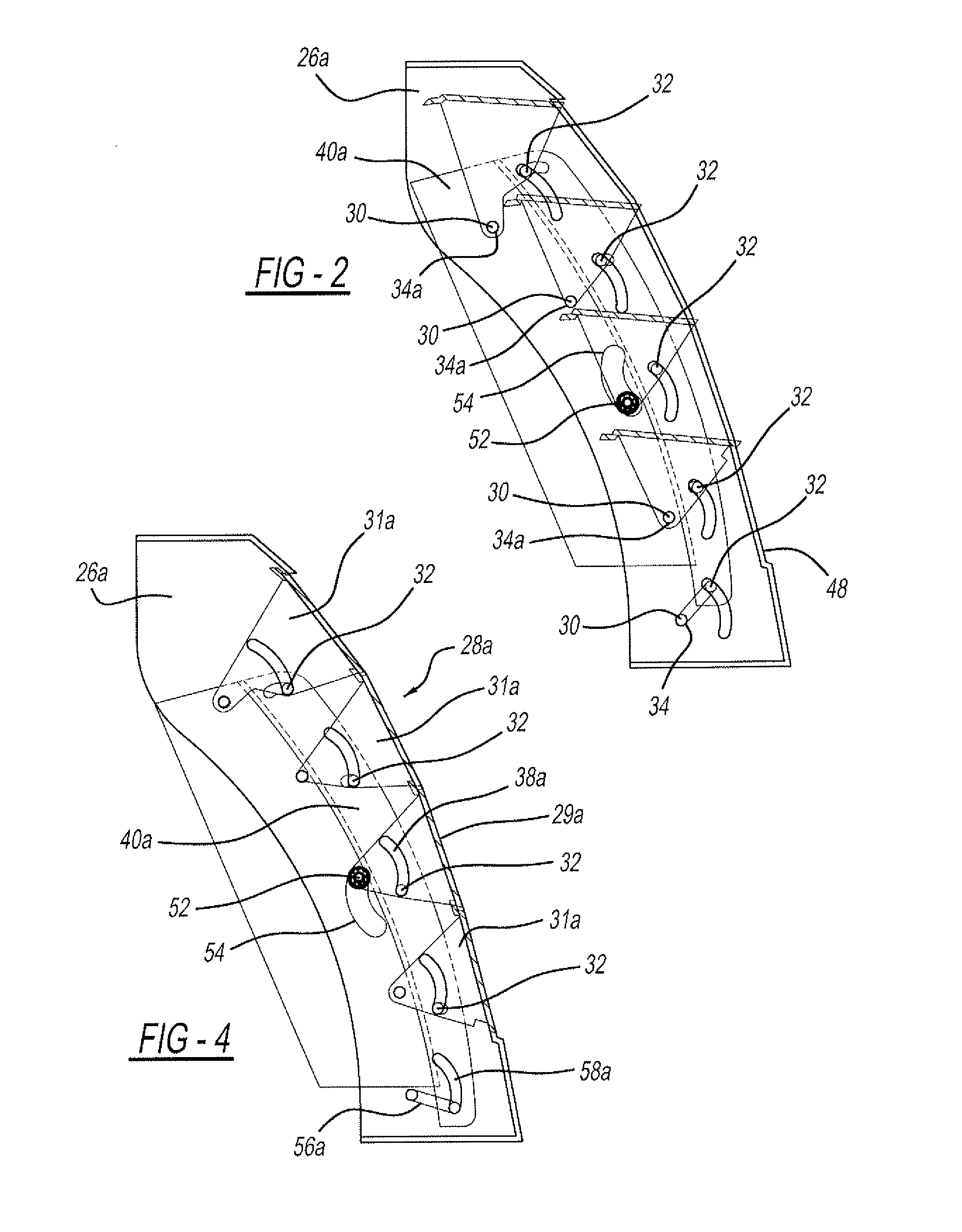

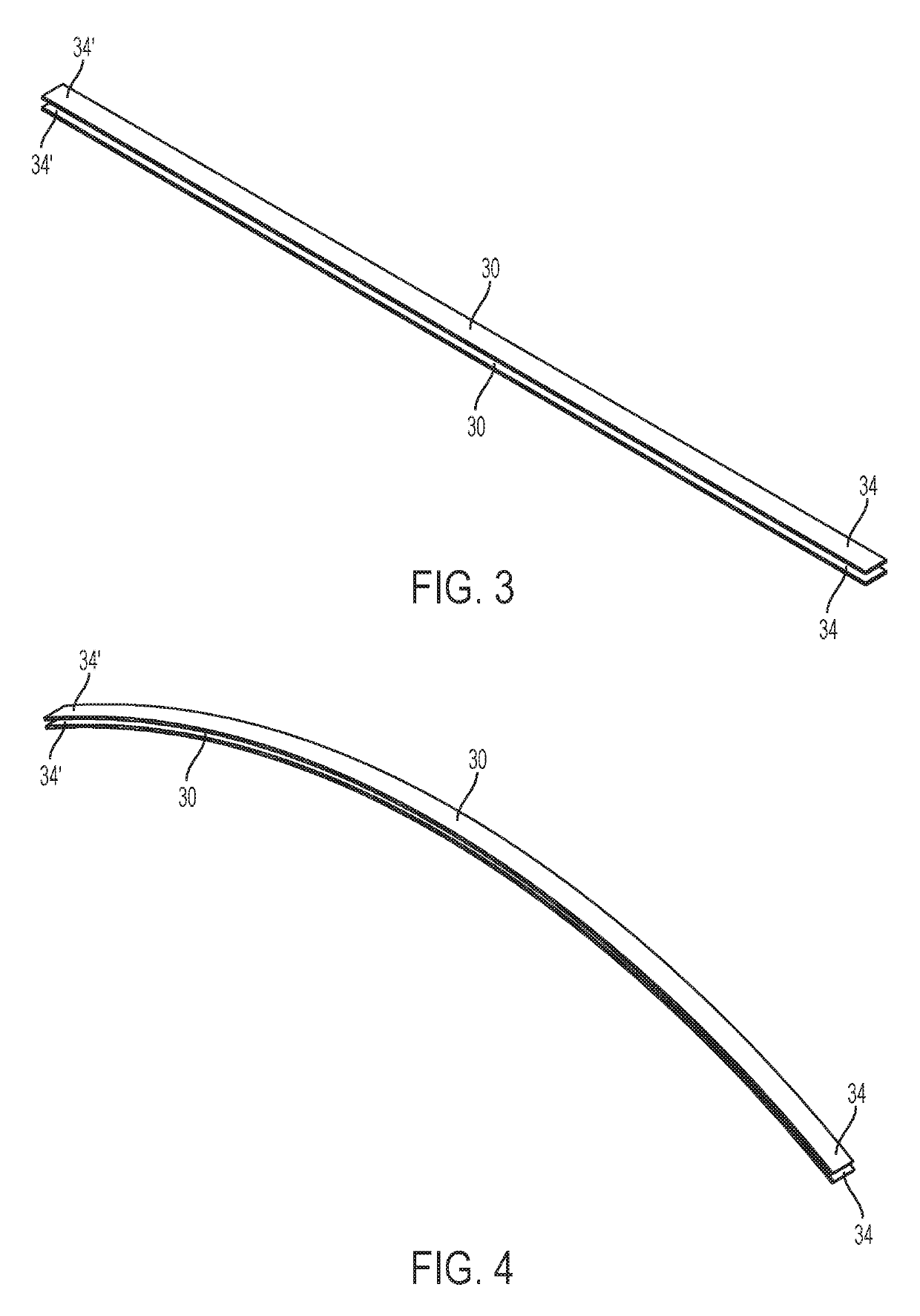

Active grille shutter for curved surface

An active grille shutter system having a frame with a first side facing a vehicle exterior and a second side opposite the first side that generally faces a vehicle engine compartment. The frame also includes at least two opposing cross-sectional curvilinear sides that form part of a curvilinear opening to allow air to selectively pass through the frame from the first side to the second side. Multiple rotatable vanes are placed within the curvilinear opening in order to selectively block airflow through the frame member. During operation of the active grille shutter system the vanes do not extend beyond the perimeter of the curvilinear opening of the frame when in the open and closed position.

Owner:MAGNA EXTERIORS INC

Air inflation device for inflating air support furniture and method of using the same

An air support article of air inflatable furniture comprises an air inflation device. The air inflation device provides an openable and closable opening into the sack that forms the majority of the article. The air inflation device comprises at least one pliable flap attached to the sack. The flap acts as a partial check valve that allows the article to be inflated simply by rapidly opening and closing the opening.

Owner:ZHEJIANG HENGFENG TOP LEISURE CO LTD

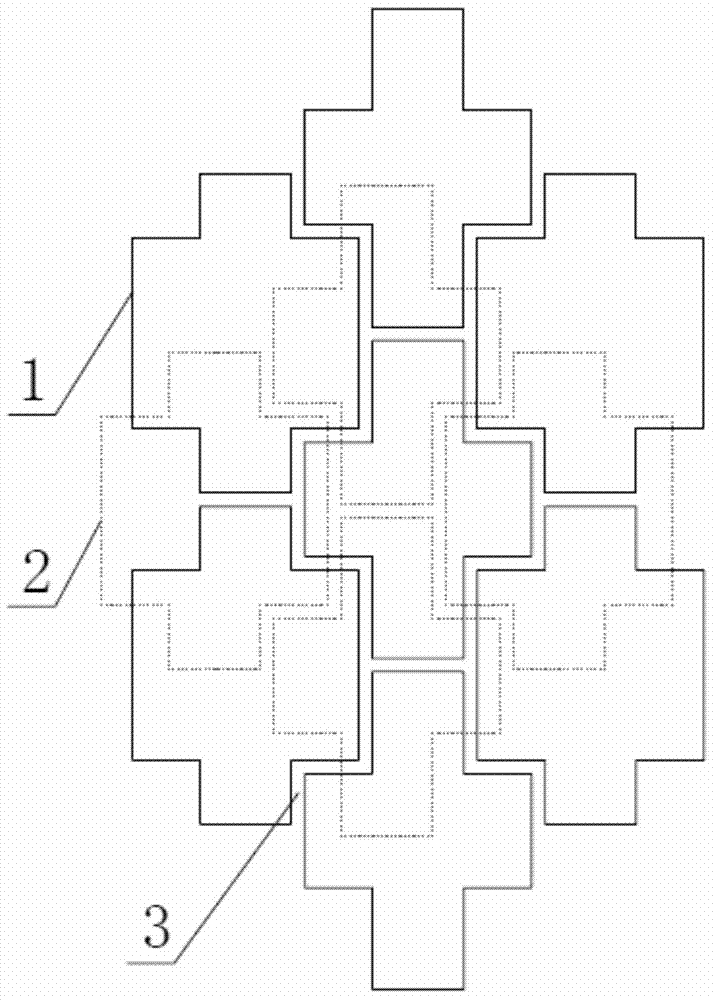

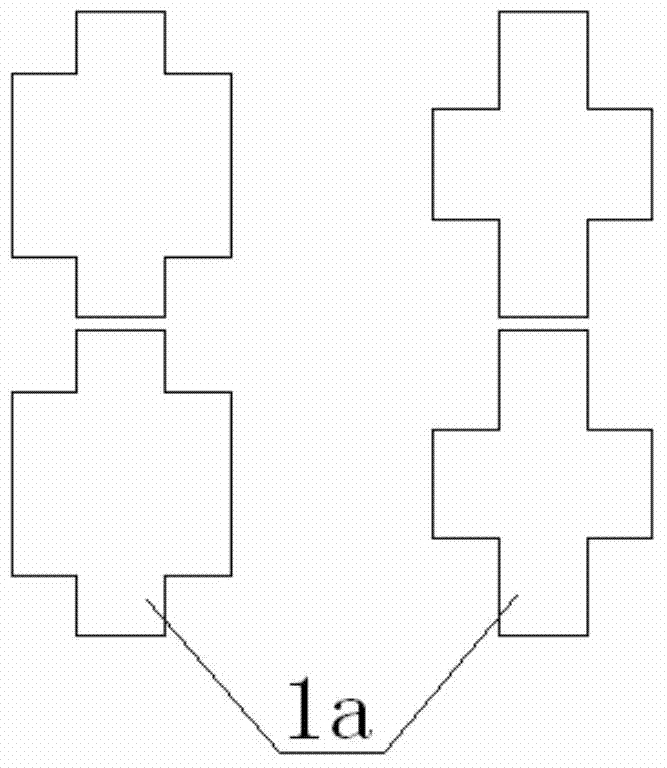

Flow choking strip for printed circuit board

InactiveCN103596361AImprove rigidityReduce board damage defectsElectrical connection printed elementsEngineeringPrinted circuit board

The invention discloses a flow choking strip for a printed circuit board, which is arranged at the edges of the two sides of a printed circuit board core material. The flow choking strip comprises a plurality of flow choking blocks with the cross section being cross-shaped, wherein the plurality of flow choking blocks form a bar-shaped flow choking strip through arrangement and combination, and the flow choking blocks are provided with diversion clearances with the same size therebetween. As adoption of the technical scheme, the flow choking strip provided by the invention for the printed circuit board avoids problems that core materials of traditional bar-shaped flow choking strips, wall-shaped flow choking strips, dot-shaped flow choking strips are low in rigidity, and that the air or resin overflow speed is too high or too low, and enables an empty area of the board side of the printed circuit board core material to be uniformly dispersed without large continuous empty areas, thereby obviously improving the rigidity of the core material, and significantly reducing board damage defects of the core material in the processing and manufacturing process.

Owner:DALIAN PACIFIC ELECTRONICS

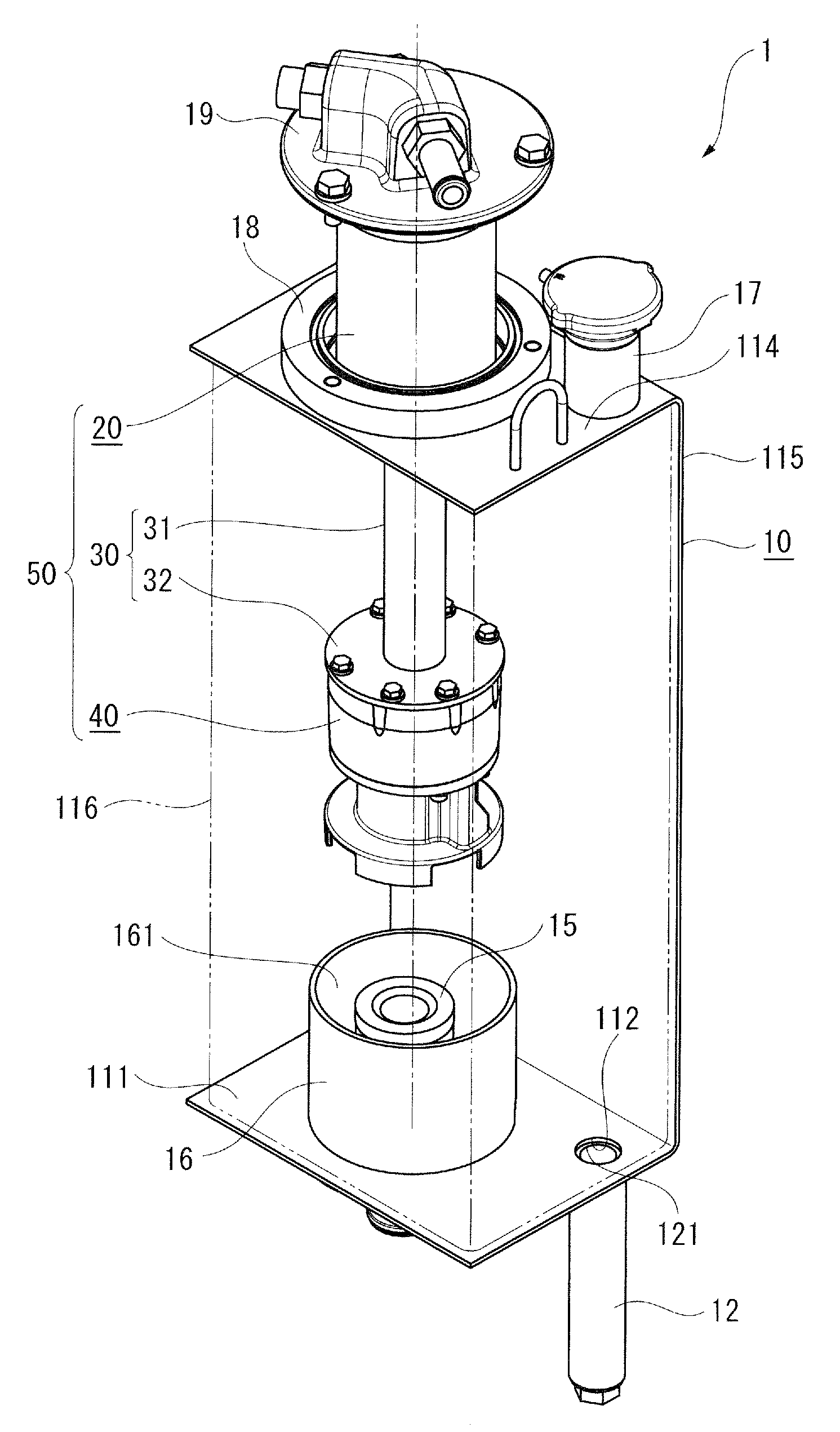

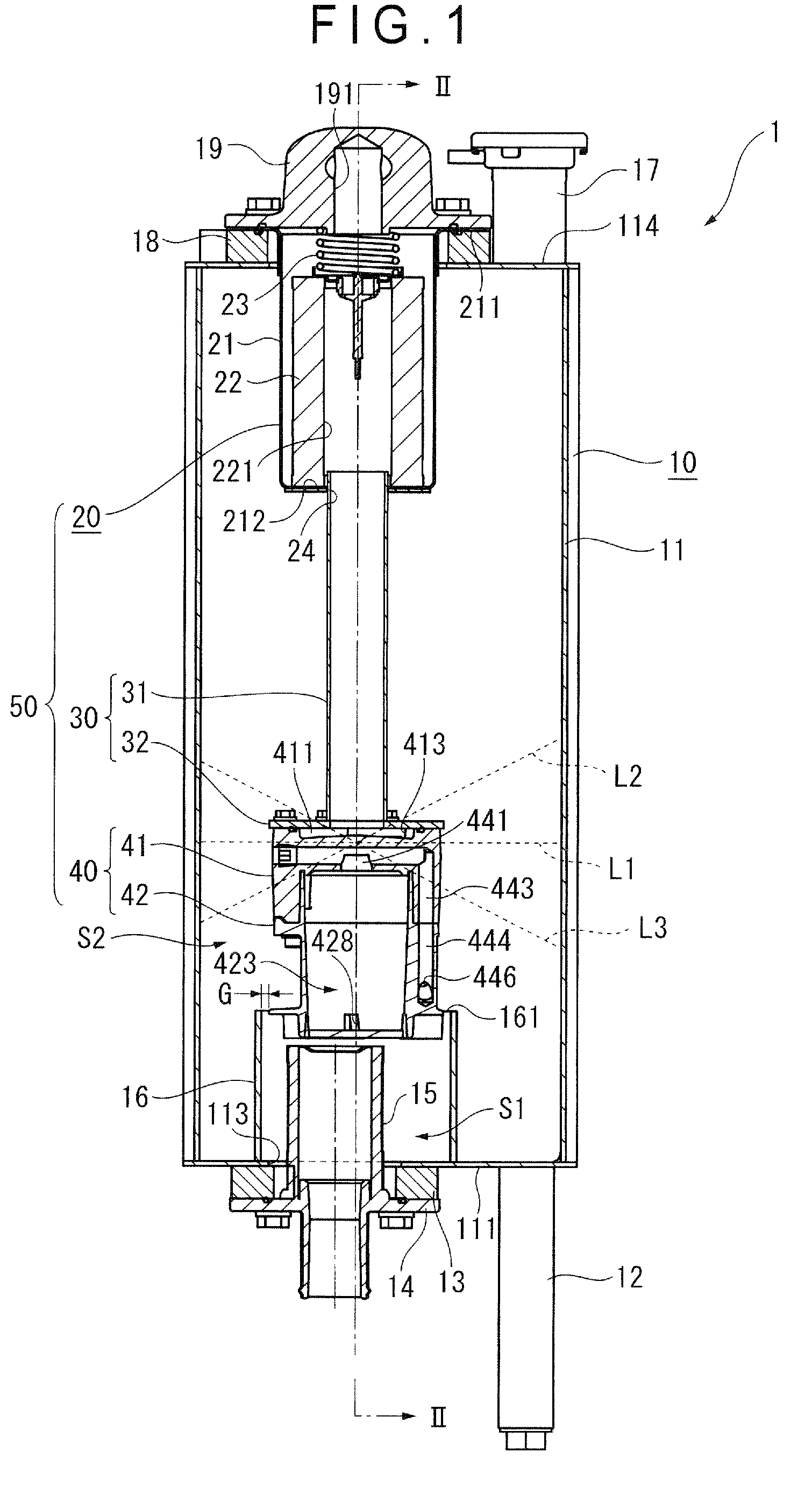

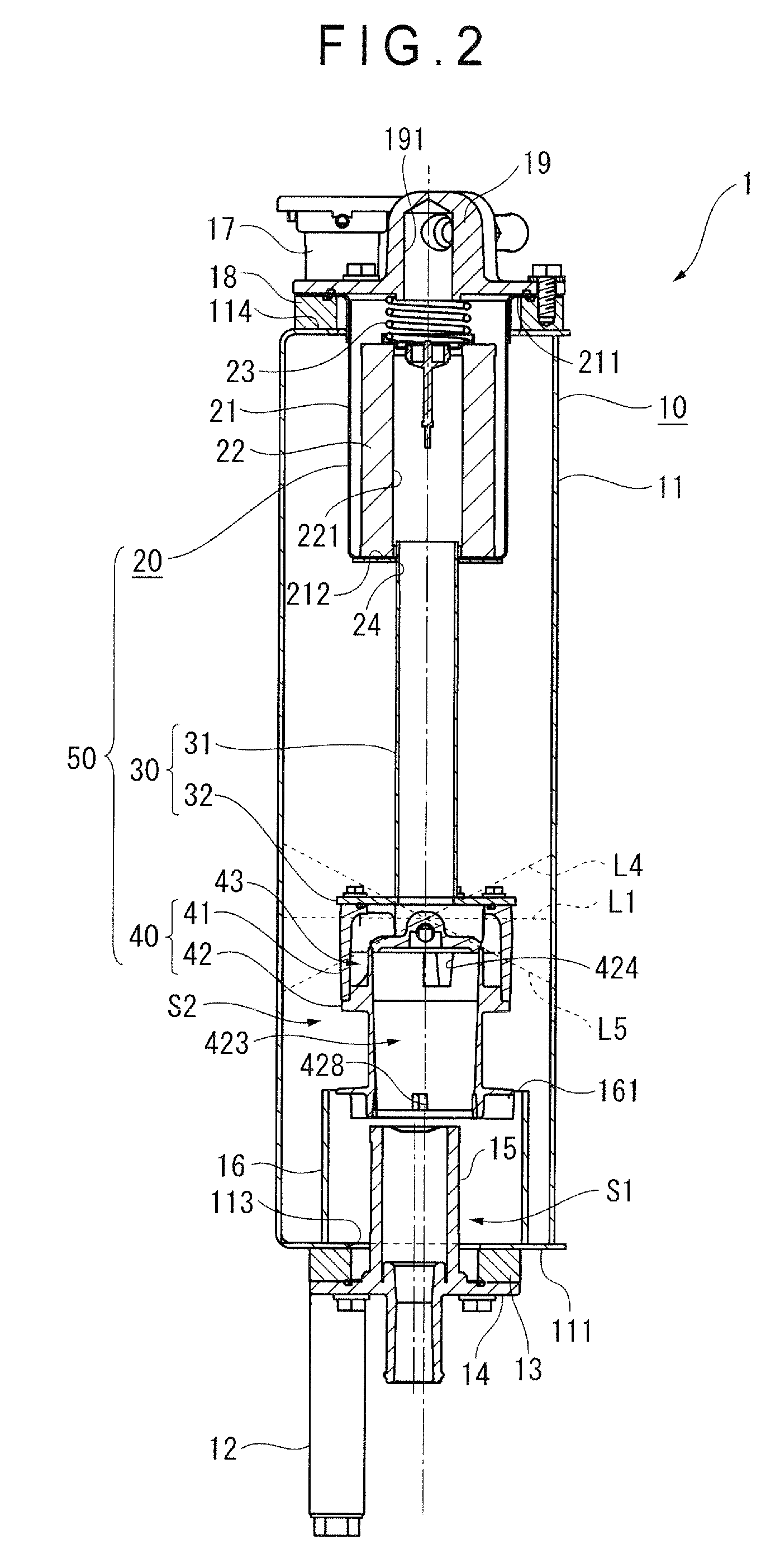

Liquid tank

InactiveUS20090056553A1Reduced installation areaExcessive removalPump assembliesSoil-shifting machines/dredgersLiquid tankAir bubble

Owner:KOMATSU LTD

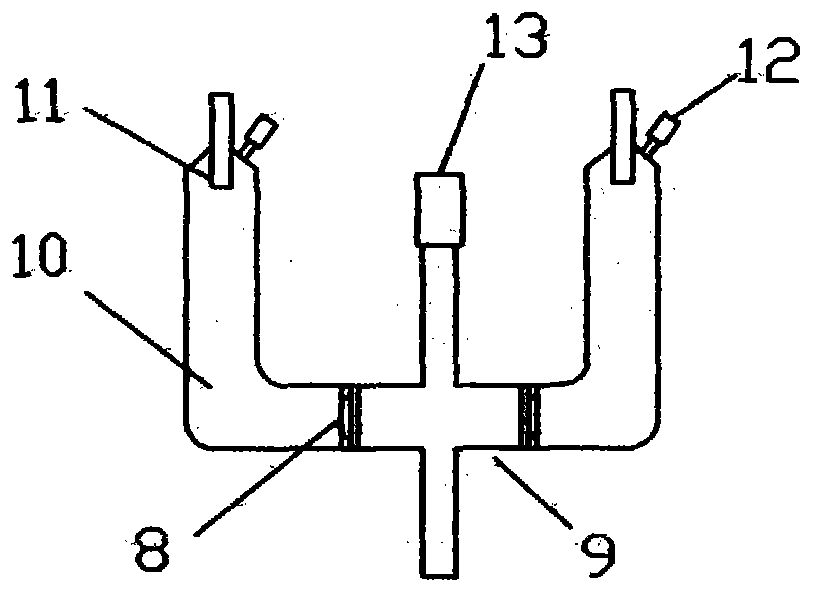

Filter device and liquid injection apparatus having the same

InactiveUS20120022449A1Efficient removalAvoid airLiquid degasificationFiltering accessoriesSolid particleGlass fragment

A filter device of the present invention includes a hydrophilic filter located in a vertical space in a filter housing to filter off solid impurities in an introduced liquid, at least one hydrophobic filter located corresponding to at least one gas discharge hole provided in the filter housing, the hydrophobic filter allowing gas in the introduced liquid to be discharged to the outside before and / or after the liquid passes through the hydrophilic filter, and a blocking member for preventing gas in the liquid passing through the hydrophilic filter from flowing into the outlet tube, the blocking member being installed in the filter housing to block the outlet tube, the blocking member having a longitudinal passage formed in a center portion thereof so that the liquid is introduced into the outlet tube through the passage and discharged therefrom. According to the present invention, there are advantages in that the filter device can effectively remove air and impurities such as solid particles contained in a liquid such as a medicine, prevent the air in the medicine from flowing into an extension tube connected to the filter device, and ensure a maximum surface area of a hydrophilic filter for filtering off solid particles such as glass fragments so that a flow rate of a medicine passing through the filter device does not decrease.

Owner:E WHA FRESENIUS KABI

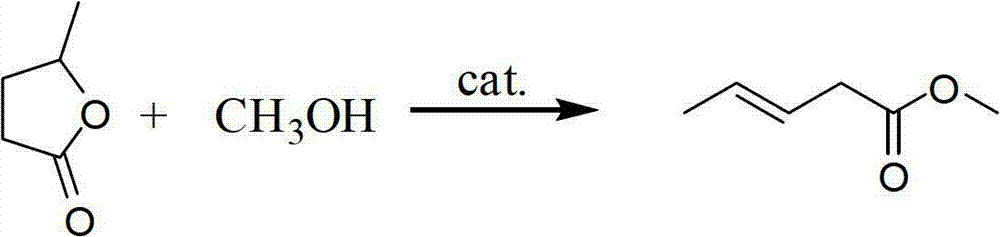

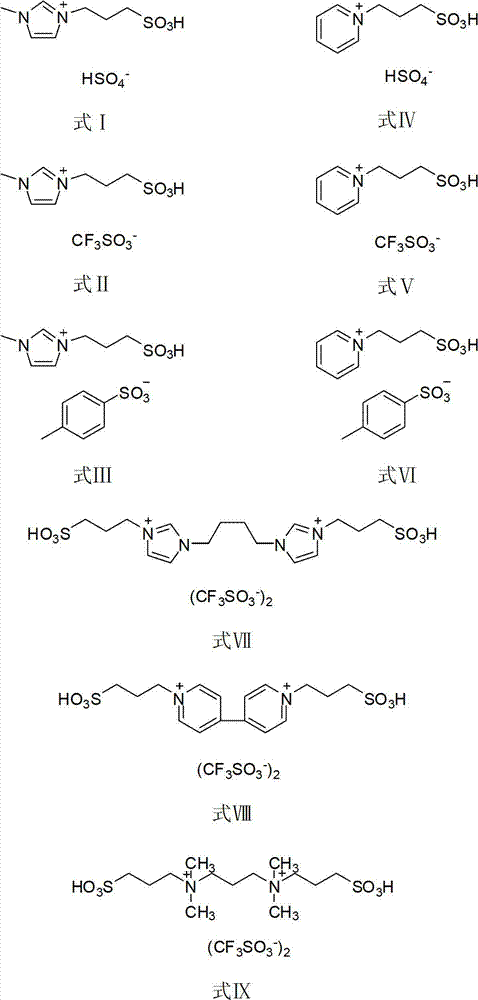

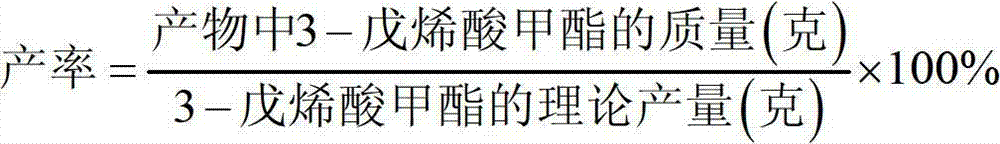

Preparation method of methyl-3-pentenoate

InactiveCN102786416AAvoid generatingReduce generationPreparation by ester-hydroxy reactionDistillationGamma-Valerolactone

The invention discloses a preparation method of methyl-3-pentenoate. According to the invention, gamma-valerolactone and methanol which are adopted as initial raw materials undergo ester change and a dehydration reaction under the action of a catalyst to obtain methyl-3-pentenoate, and simultaneously the obtained methyl-3-pentenoate is separated through distillation. The method provided by the invention has the advantages of high reaction selectivity, simple technology, simple operation, and environmental protection, and the highest yield and the highest selectivity of the methyl-3-pentenoate reach 95% and 98% respectively.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

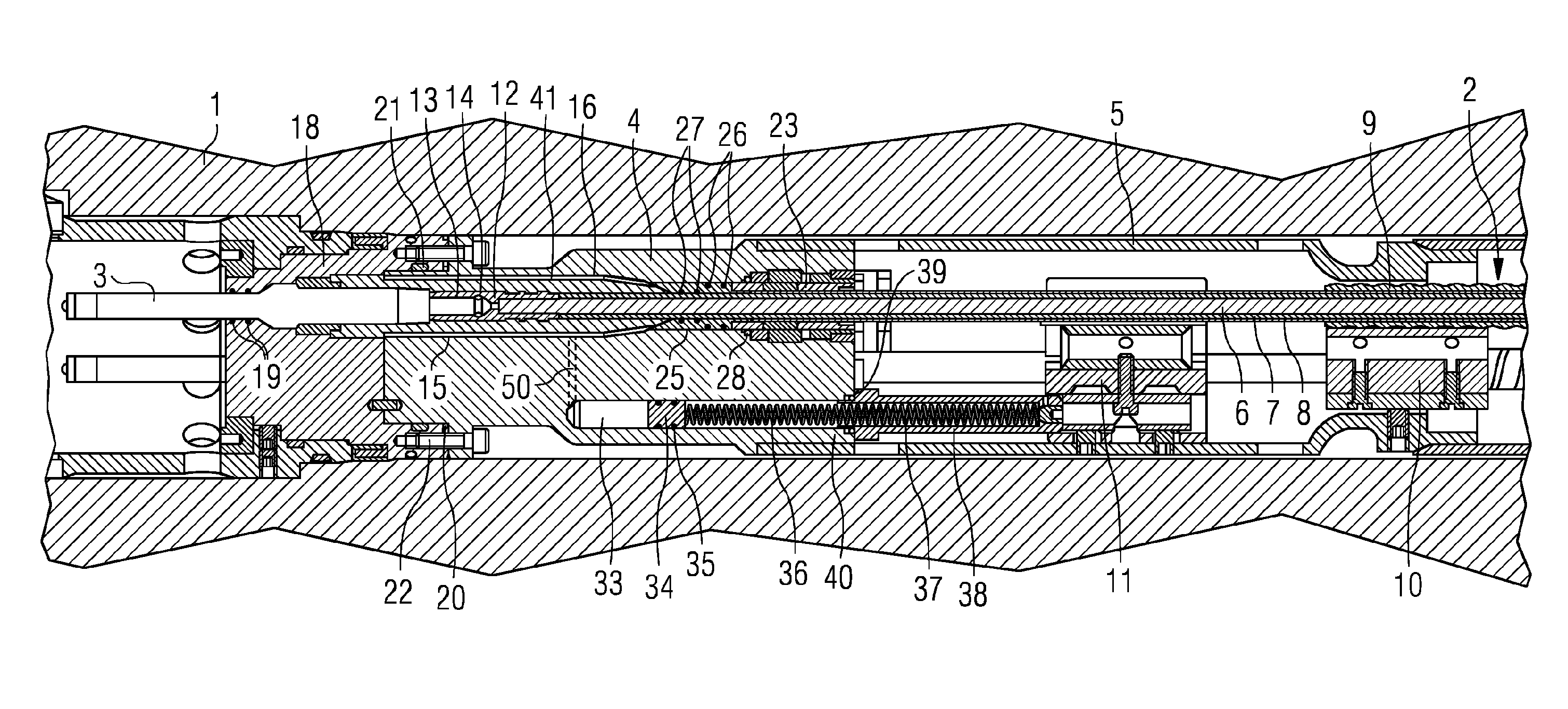

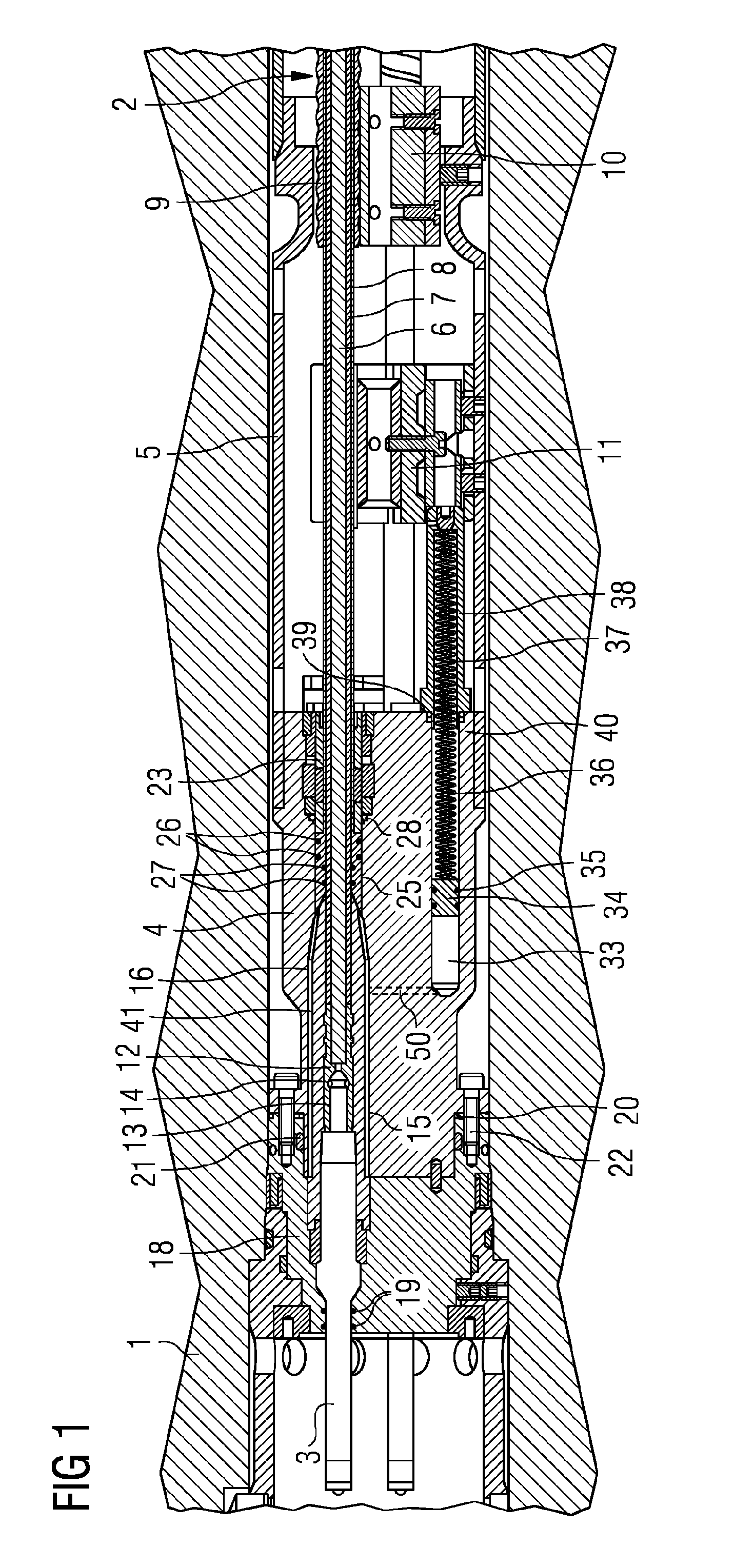

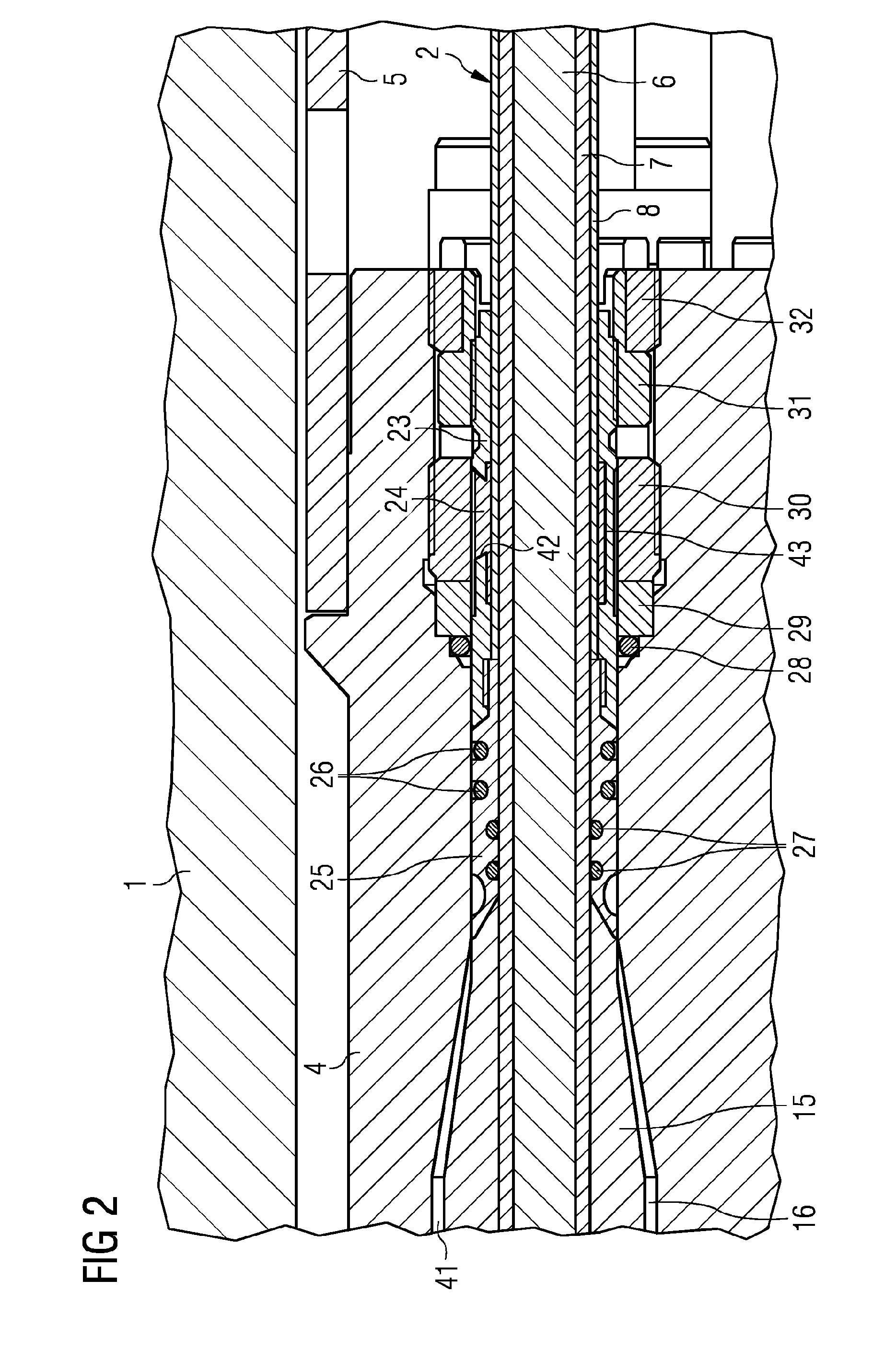

Downhole Cable Termination Systems

InactiveUS20150255974A1Reduce riskEasy to joinLine/current collector detailsDrilling rodsTubing hangerTerminal equipment

A downhole cable termination apparatus is provided for terminating a cable that is to extend downhole from a tubing hanger to electrical equipment. The apparatus includes: a first seal for sealing the apparatus uphole of the first seal from the downhole environment; a second seal for sealing the apparatus uphole of the second seal from the downhole environment; and a sleeve arranged to extend around the cable and to be attached to the cable, the sleeve being for providing a radially outwardly facing engagement portion for the first seal and a radially inwardly facing engagement portion for the second seal, the sleeve having two parts, a first part being arranged to be attached to the cable and providing the radially outwardly facing engagement portion, and a second part providing the radially inwardly facing engagement portion and provided separately from the first part, and the sleeve being arranged such that when the apparatus is assembled on the cable the second part is joined to the first part.

Owner:SIEMENS AG

Light emitting diode combination

InactiveCN101442086AAvoid airEliminate the existence of airCondensersSemiconductor devicesLight beamColloid

Owner:FU ZHUN PRECISION IND SHENZHEN +1

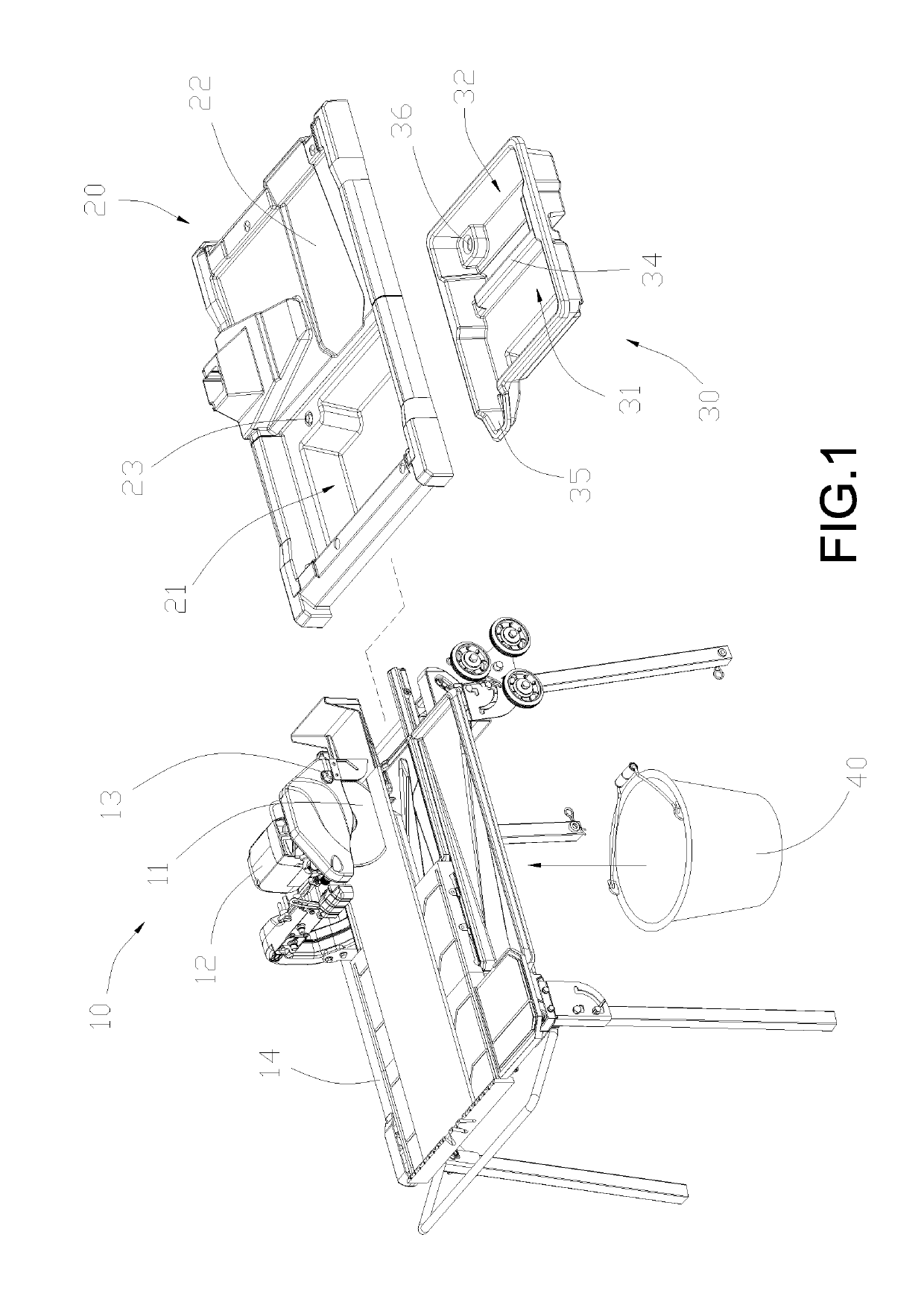

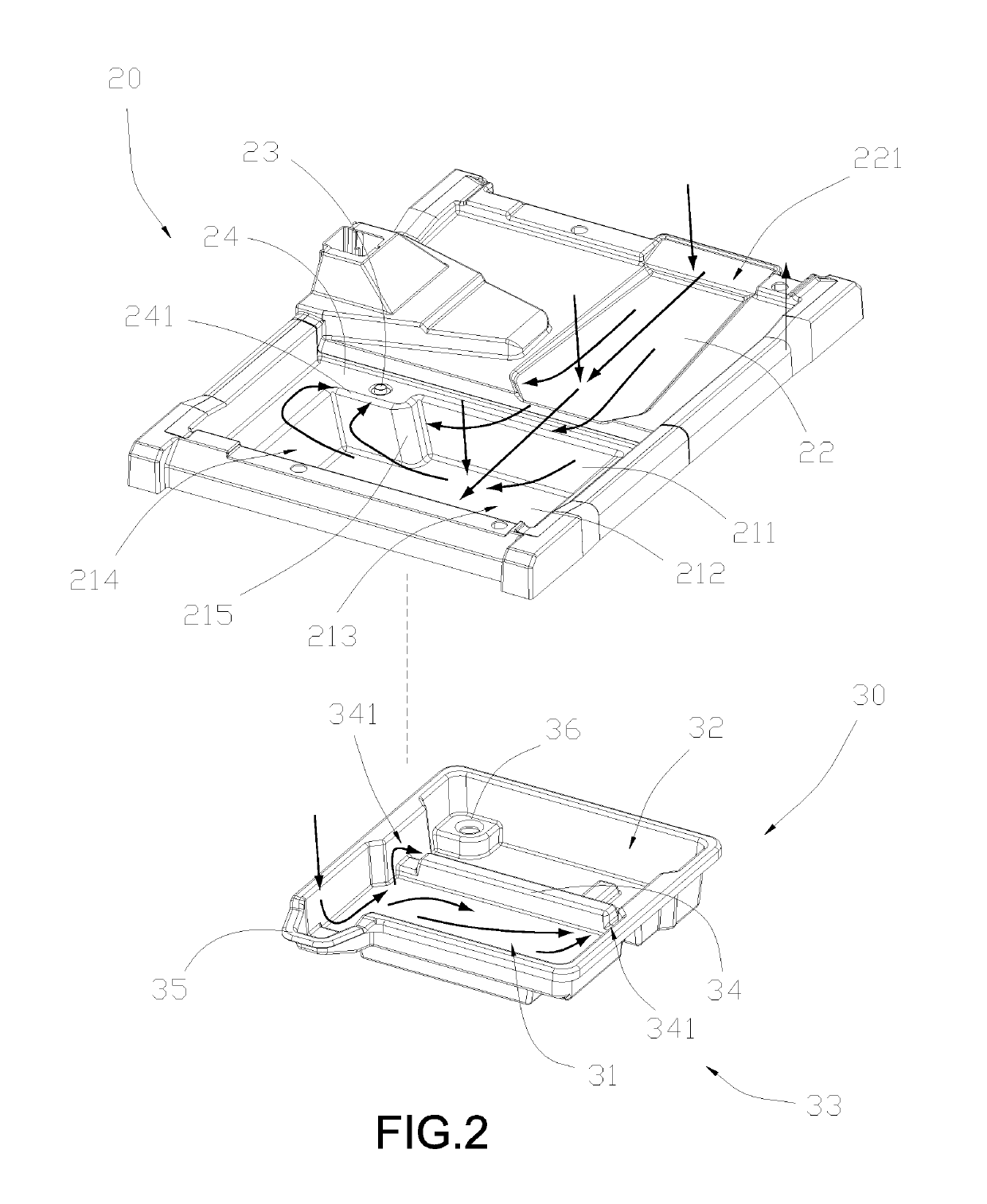

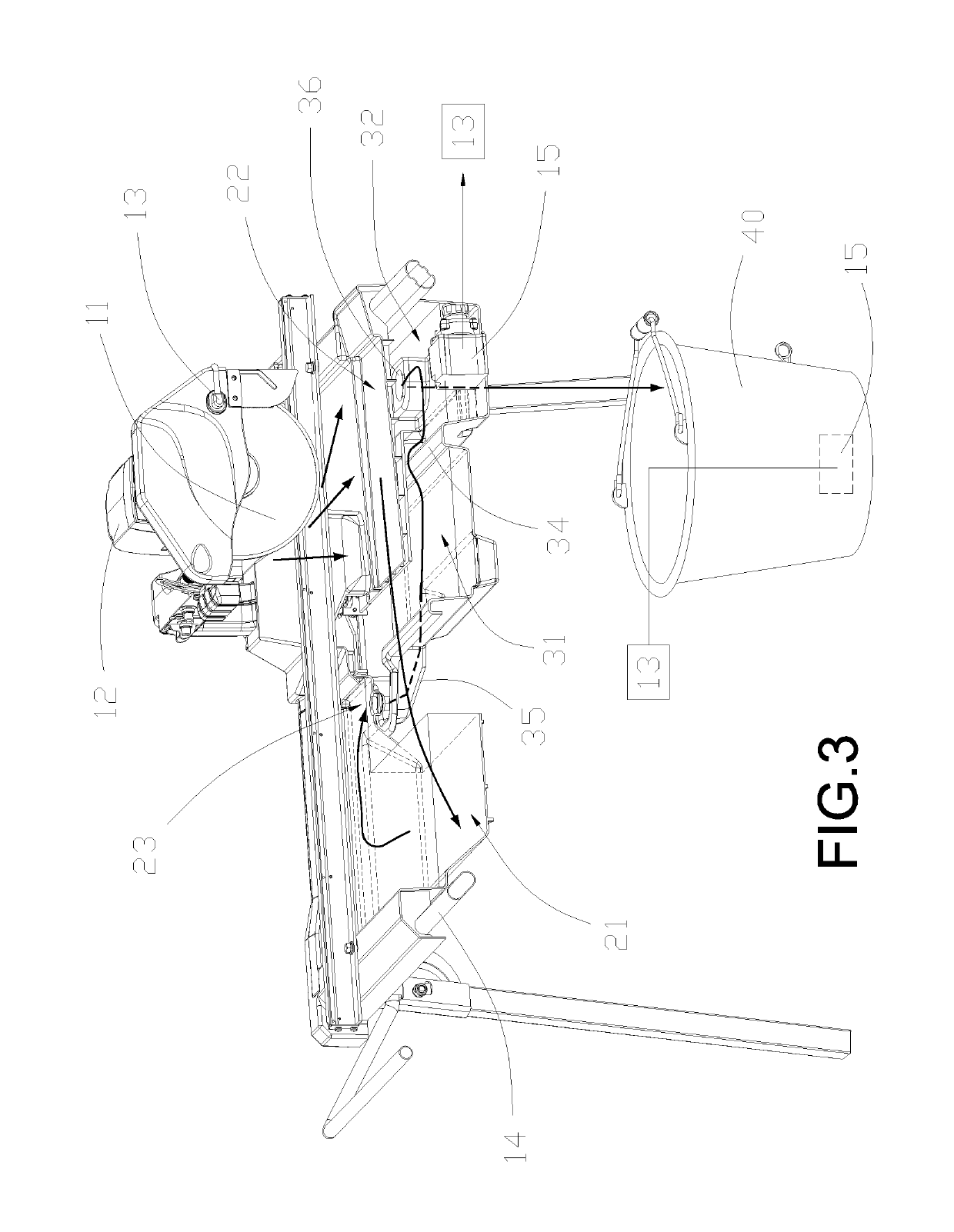

Method and System of Rivering Filtration for Power Saw Machine

ActiveUS20190248037A1Effective filteringEfficient collectionMetal sawing devicesWorking accessoriesFiltrationSlurry

A rivering filtration system for a power saw machine includes a filtration tray having a filtration cavity for collecting operation fluid after the operation fluid is delivered onto the cutting blade, and a fluid collecting tray located underneath the filtration tray, wherein the fluid collecting tray has first and second cavities. The filtration tray provides a first filtration stage for filtrating the visible residual particles out from the operation fluid. The fluid collecting tray provides a second filtration stage that the operation fluid is slowly filled in the first cavity from the filtration cavity to ensure slurry residual particles in the operation fluid being deposited at the first cavity, and a third filtration stage that the operation fluid is slowly filled in the second cavity from the first cavity to ensure the slurry residual particles being filtrated out of the operation fluid.

Owner:SAWMASTER DIAMOND TOOLS INC

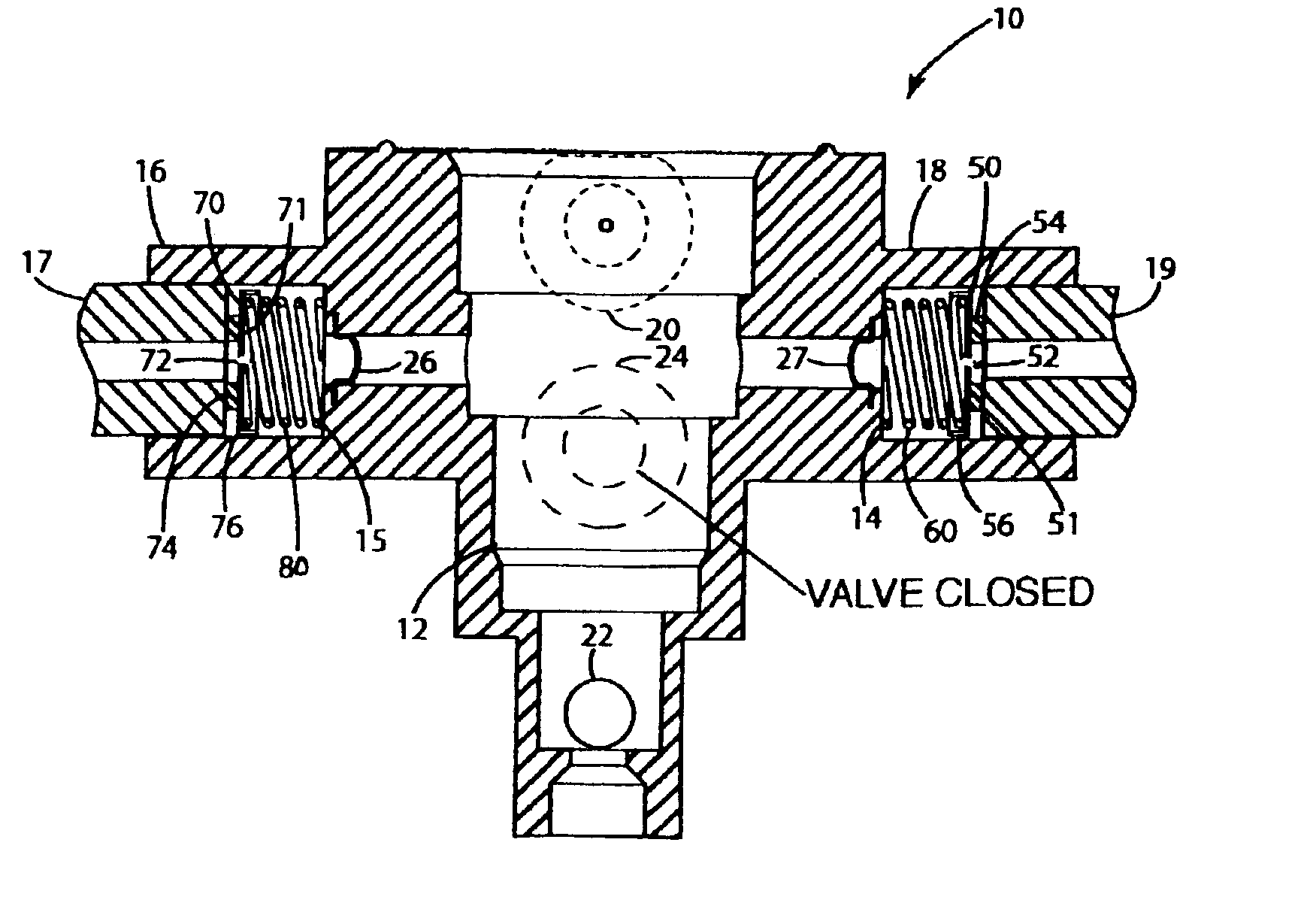

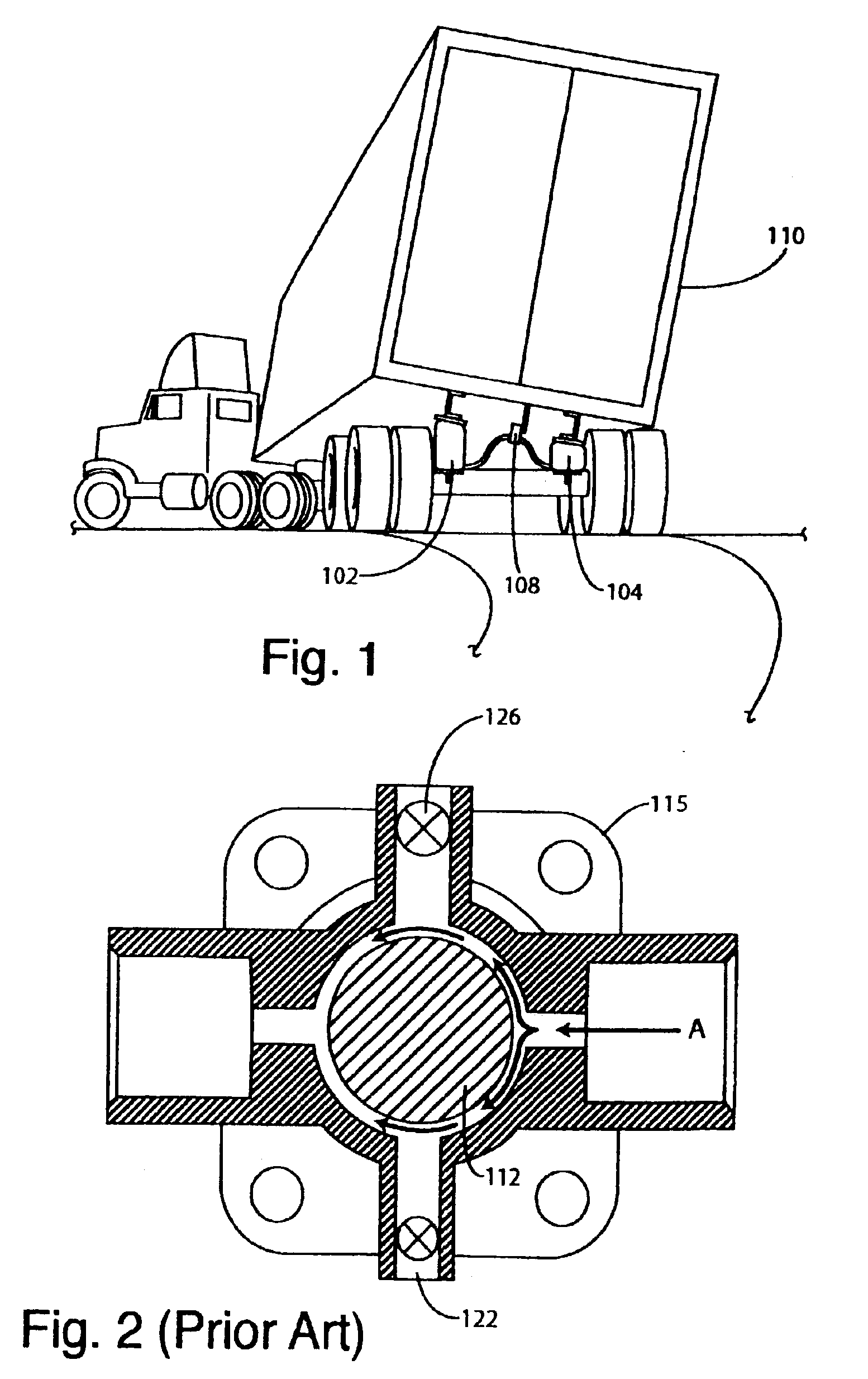

Anti-roll suspension valve body

InactiveUS6857646B2Enhanced sealing engagementRide heightSpringsInterconnection systemsRide heightRestricted Airflow

A suspension system that restricts side-to-side airflow between air springs on opposite sides of a vehicle or trailer. In one embodiment, active airflow discs in suspension ports of a valve operate in two modes; restrictive and non-restrictive. A disc attains a non-restrictive mode when air is exhausted from an air spring. A disc attains a restrictive mode when air is injected into the suspension port from the valve toward an air spring. Airflow discs in opposing suspension ports both attain a non-restrictive state to rapidly dump air from the springs and lower vehicle ride height. In another embodiment, a pneumatic circuit includes one-way check valves, in fluid communication with opposing air springs, aligned to restrict airflow between the opposing springs under uneven loading conditions. A pair of electronic solenoids acts in concert with the check valves to selectively inflate or deflate the air springs.

Owner:LINK MFG

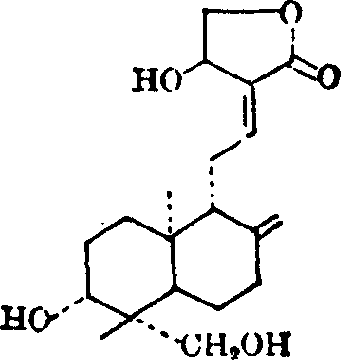

Andrographolide soft capsule and preparing method thereof

ActiveCN1528290AImprove stabilityAvoid airOrganic active ingredientsCapsule deliveryDefoaming AgentsGlycerol

The present invention relates to an andrographolide soft capsule and its production method. Every soft capsule contains 10-300 mg of andrographolide, and contains beeswax and medicinal auxiliary material. Said medicinal auxiliary material includes diluting agent, suspension adjuvant and defoaming agent, and the interior of said capsule shell, contains (by weight ratio) 10 portions of gelatin and 4.0-5.5 portions of glycerine. Its production process includes the following steps: adding water to dissolve gelatin, adding glycerine and proper quantity of preservative, vacuum deaerating, adding suspension adjuvant into vegetable oil, mixing andrographolide, diluting agent and defoaming agent uniformly, die-pressing to obtain said invented soft capsule. Its quality is stable, administration is convenient and its effective components can be quickly resolved out.

Owner:XIAN CHIHO PHARMA

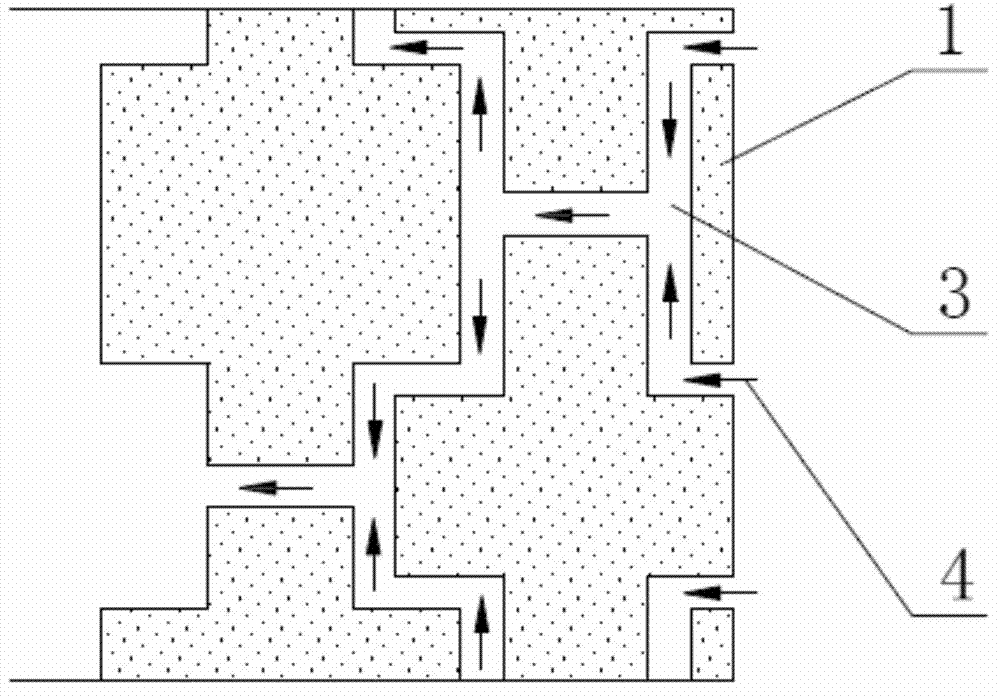

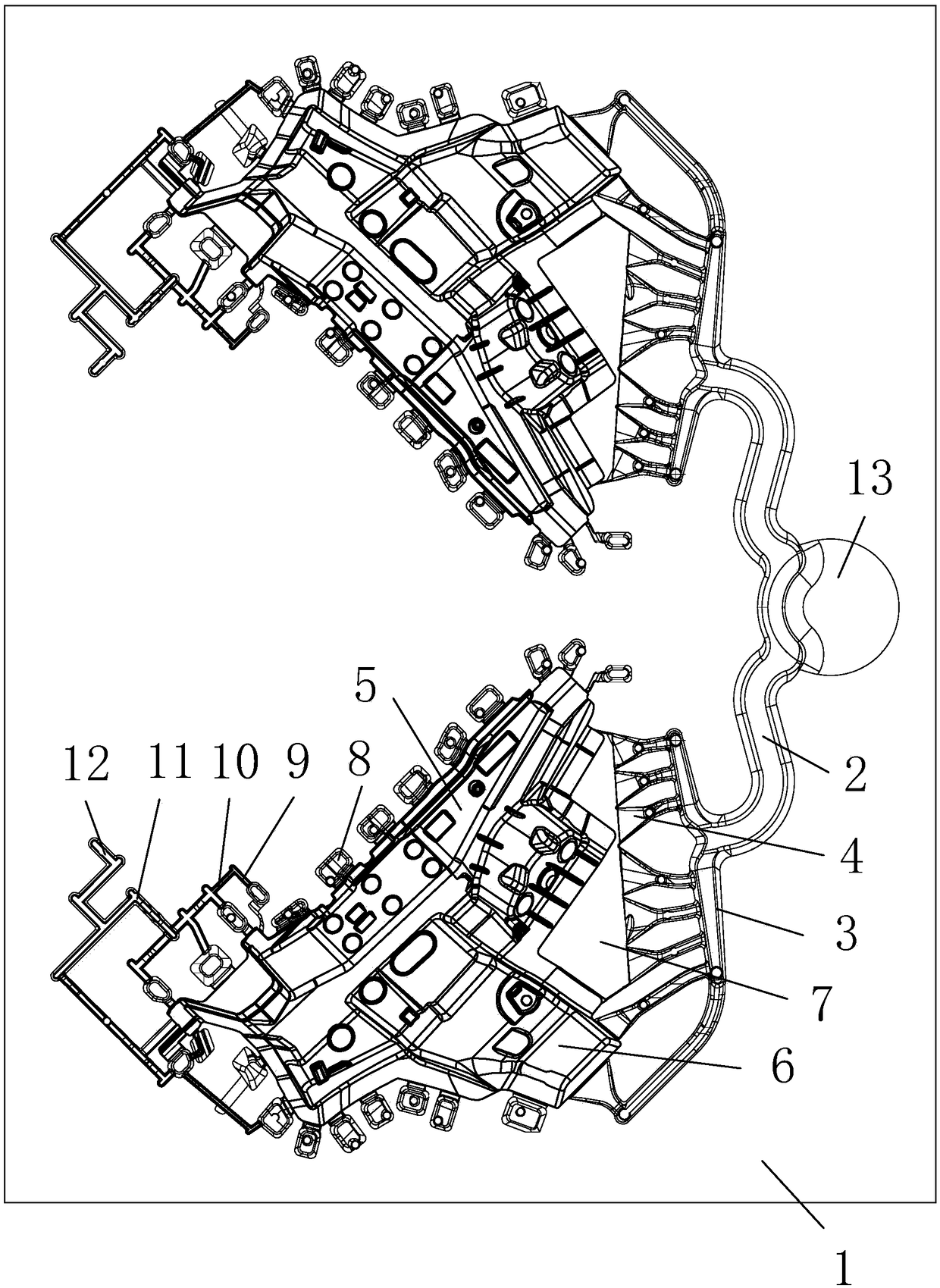

Pouring exhaust system of automobile component die-casting die and arrangement method

The invention relates to a pouring exhaust system of an automobile component die-casting die and an arrangement method. The pouring exhaust system of the automobile component die-casting die comprisesa die-casting die body and cavities, wherein the one or more cavities are formed in the die-casting die body, and each cavity is provided with a sprue, a cross gate and multiple flow gates. Each cavity comprises a main body cavity, a side body cavity, an auxiliary gating cavity and multiple cinder ladle cavities, wherein the inner ends of each auxiliary gating cavity communicate with one end of the corresponding main body cavity, one side of the corresponding main body cavity and one side of the corresponding side body cavity. The inner end of each flow gate communicates with the outer end ofthe corresponding side body cavity or the outer end of the corresponding auxiliary gating cavity. The thickness of each auxiliary gating cavity and the thickness of each flow gate are each 0.7-0.85 times the wall thickness of each die-casting die cavity. The sectional area of each sprue is less than that of the corresponding cross gate. The sectional area of each cross gate is less than the totalsectional area of the multiple flow gates. Each cinder ladle cavity communicates with the periphery of the corresponding main body cavity or the corresponding side body cavity. By means of the pouring exhaust system of the automobile component die-casting die, air holes cannot be generated inside die castings; and the surfaces of the die castings obtained after T6 treatment cannot bulge.

Owner:宁波埃利特模具制造有限公司

Multi-metal ladder-type compound casting device and method

ActiveCN107812904AThe number of steps increasesGradient adjustableMaterials preparationSurface cooling

The invention belongs to the technical field of metal material preparation, and relates to a multi-metal ladder-type compound casting device and method. The multi-metal ladder-type compound casting device comprises a combined ladder-type crystallizer, a ladder cooling plate, hot tops and dummy ingots, wherein the combined ladder-type crystallizer, the ladder cooling plate, the hot tops and the dummy ingots correspond to one another mutually. The combined ladder-type crystallizer is composed of an initial cooling water tank, a plurality of side surface cooling water tanks and a terminal coolingwater tank from top to bottom in a combined ladder-type mode. The initial cooling water tank, the multiple side surface cooling water tanks and the terminal cooling water tank are connected with thehot tops correspondingly. One end of the ladder cooling plate is correspondingly connected with the initial cooling water tank, the multiple side surface cooling water tanks and the terminal cooling water tank. The other end of the ladder cooling plate is connected with the corresponding hot top. The combined ladder-type crystallizer is divided into a plurality of melt cavities by the ladder cooling plate. Each dummy ingot is mounted under the corresponding melt cavity. Each melt cavity is provided with a shunt plate. The whole melt cavities are distributed in a ladder-type mode in the vertical direction. According to the casting method, casting forming of multi-layer metal can be achieved once, and the problems that a traditional technology is low in production rate and poor in interfacequality are solved.

Owner:CHINA ZHONGWANG

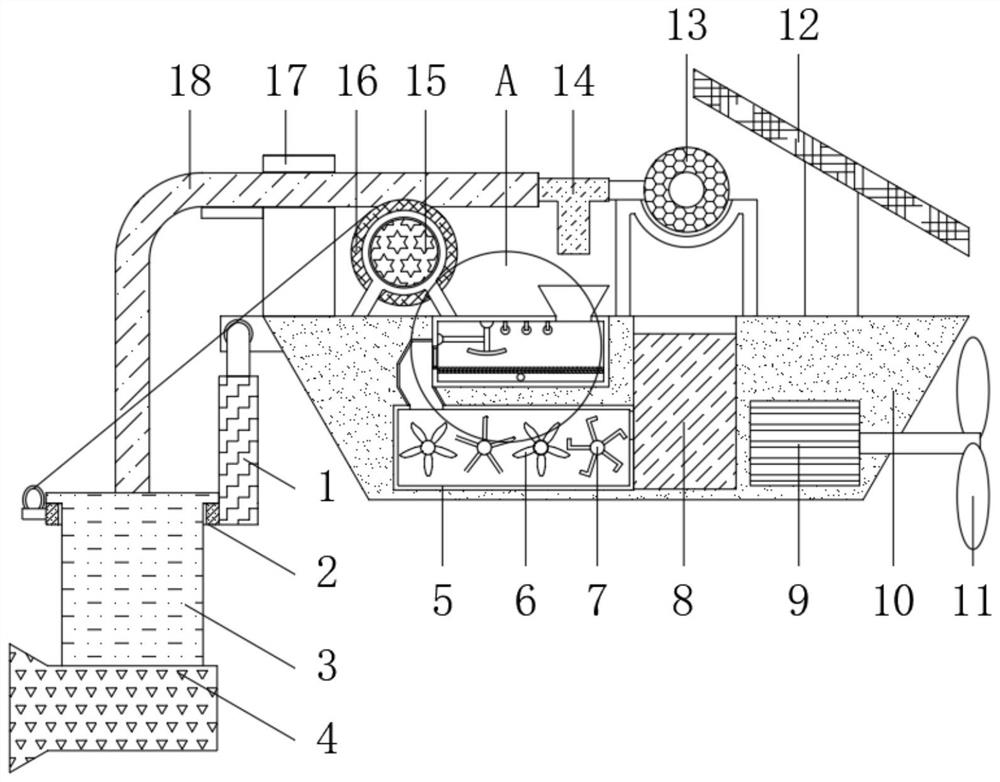

Fish carcass collection device for aquatic product breeding

InactiveCN111851452AAvoid water pollutionAvoid airWater cleaningWaterborne vesselsElectric machineryEngineering

Owner:上犹县赟吉欣科技有限公司

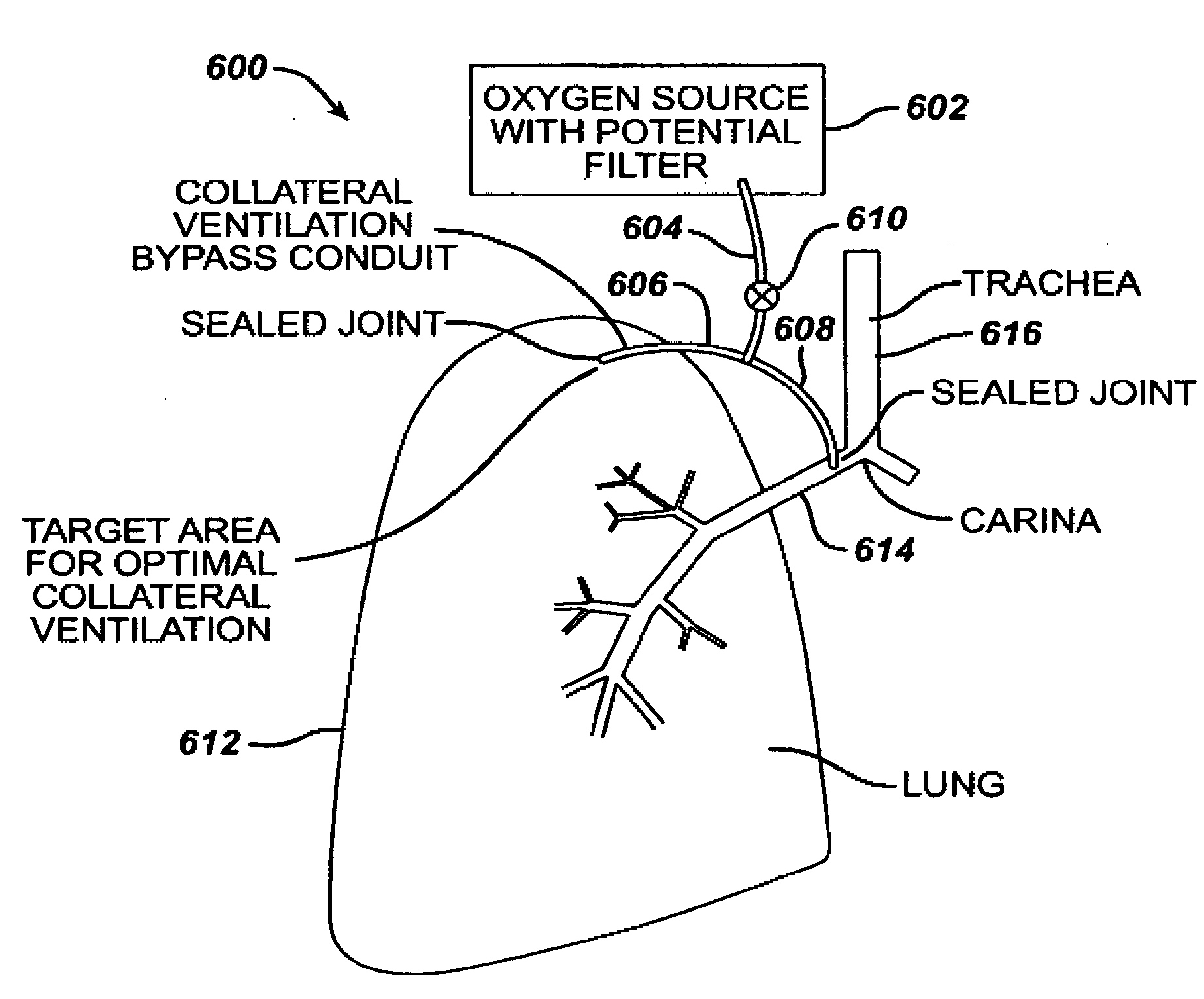

Lung reduction system

InactiveUS20070270776A1Speed up the flowLower the volumeTracheal tubesBronchiObstructive Pulmonary DiseasesObstructive chronic bronchitis

A long term oxygen therapy system having an oxygen supply directly linked with a patient's lung or lungs may be utilized to more efficiently treat hypoxia caused by chronic obstructive pulmonary disease such as emphysema and chronic bronchitis. The system includes an oxygen source, one or more valves and fluid carrying conduits. The fluid carrying conduits link the oxygen source to diseased sites within the patients lungs. A collateral ventilation bypass trap system directly linked with a patient's lung or lungs may be utilized to increase the expiratory flow from the diseased lung or lungs, thereby treating another aspect of chronic obstructive pulmonary disease. The system includes a trap, a filter / one-way valve and an air carrying conduit. In various embodiments, the system may be intrathoracic, extrathoracic or a combination thereof. A pulmonary decompression device may also be utilized to remove trapped air in the lung or lungs, thereby reducing the volume of diseased lung tissue. A lung reduction device may passively decompress the lung or lungs. In order for the system to be effective, an airtight seal between the parietal and visceral pleurae is required. Chemical pleurodesis is utilized for creating the seal.

Owner:PORTAERO

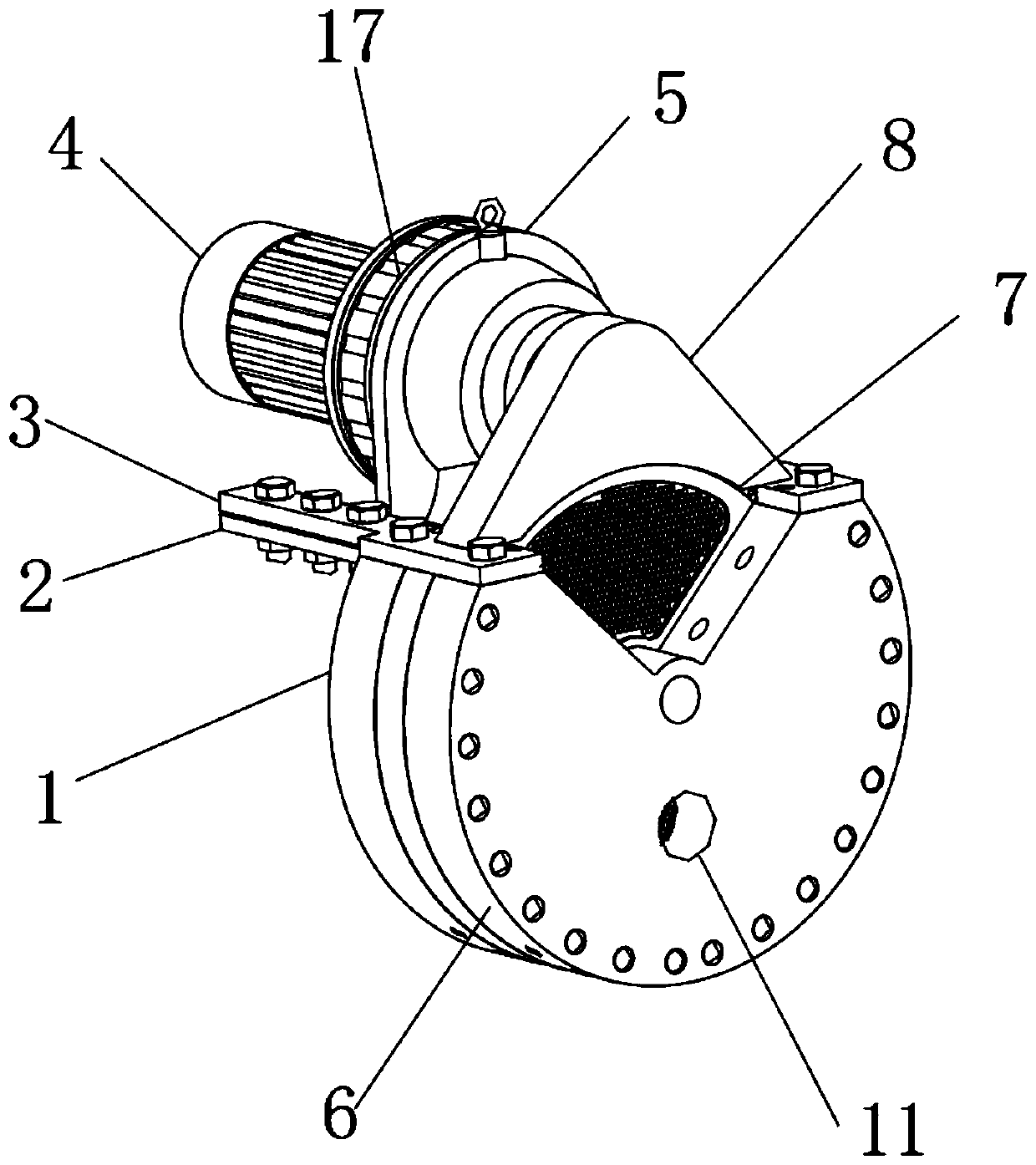

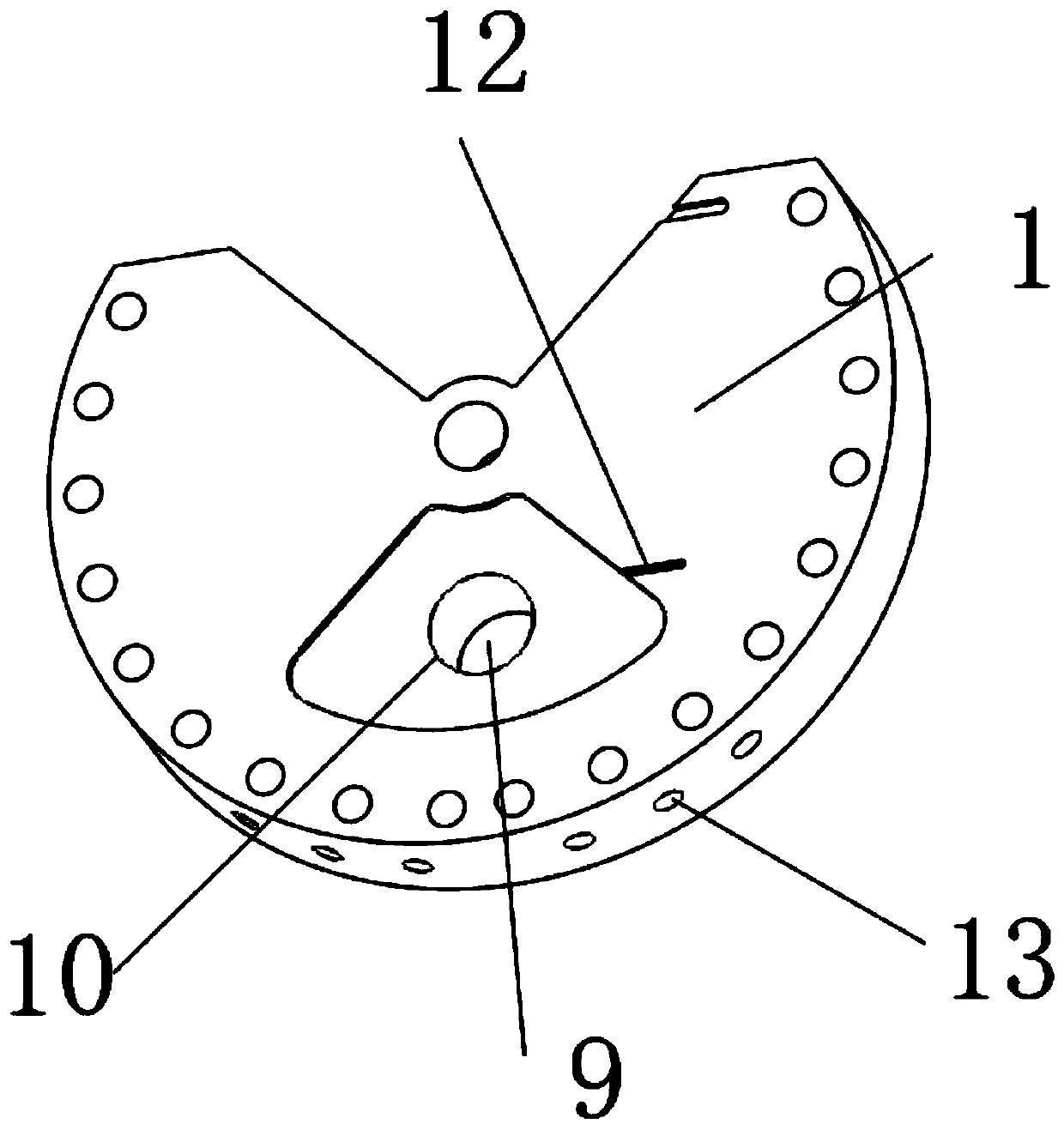

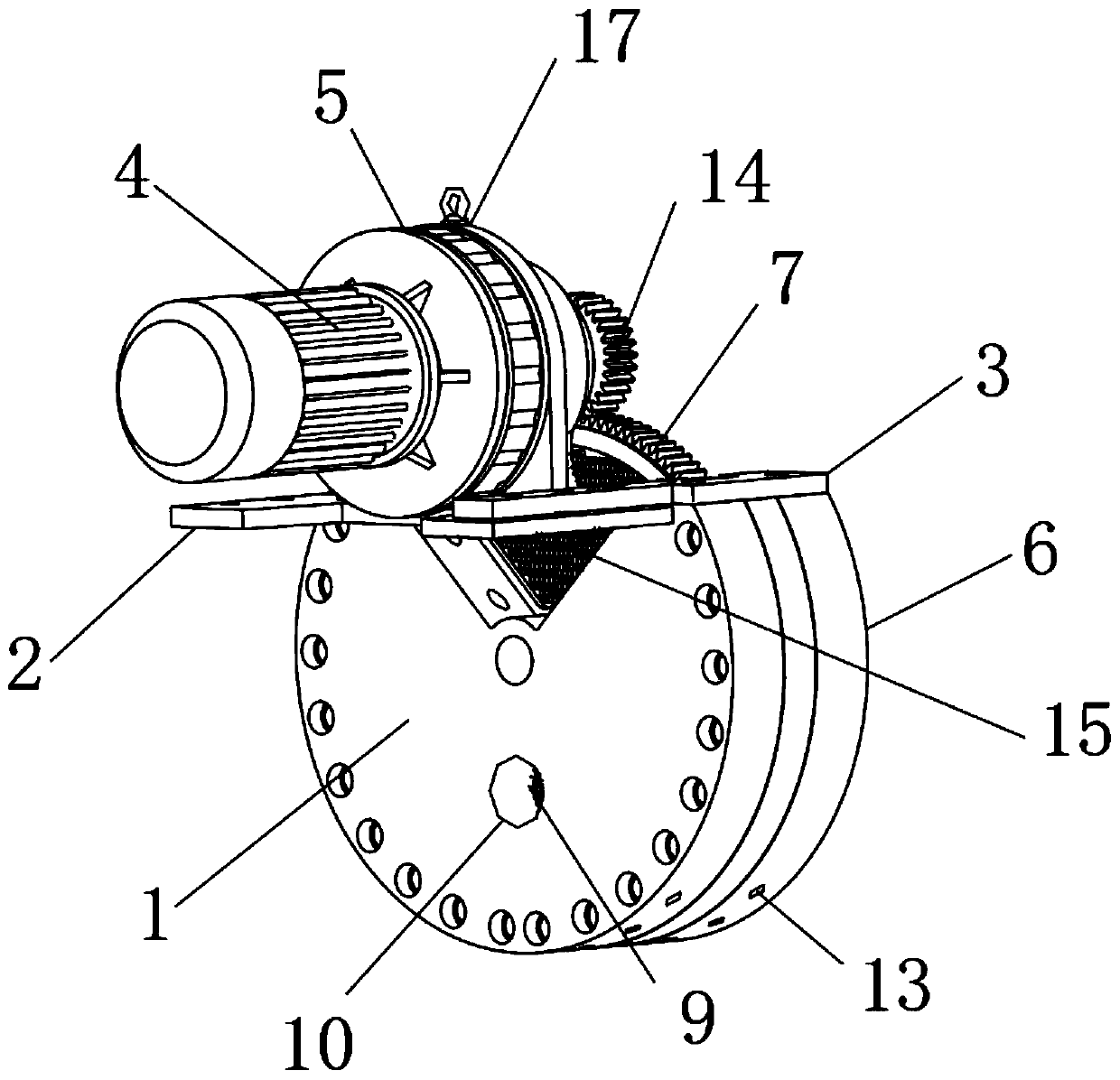

Non-stop automatic screen changer

The invention discloses a non-stop automatic screen changer comprising a front shell, a support plate, a motor bracket, a rotating motor, a speed reducer, a rear shell, a gear disk, a gear housing, adriving gear, a filter plate and filter screen clamping slots. Fixing plates are fixedly welded on the top of one side of the front shell symmetrically, and the top of each fixing plate is fixedly connected with the motor bracket by bolts; one side of the motor bracket is fixedly provided with the rotating motor, and an output shaft of the rotating motor is fixedly provided with the speed reducer;an output shaft of the speed reducer is fixedly provided with the driving gear, and the side, far away from the fixing plates, of the front shell is provided with the rear shell; and the top end of the rear shell is fixedly connected with the motor bracket by bolts, and the gear disk is arranged between the front shell and the rear shell. According to the non-stop automatic screen changer, filterscreens can be replaced under the non-stop condition of a plastic extruding machine, not only is the machining speed of the plastic extruding machine increased, but also the efficiency of the plasticextruding machine is improved.

Owner:李增现 +1

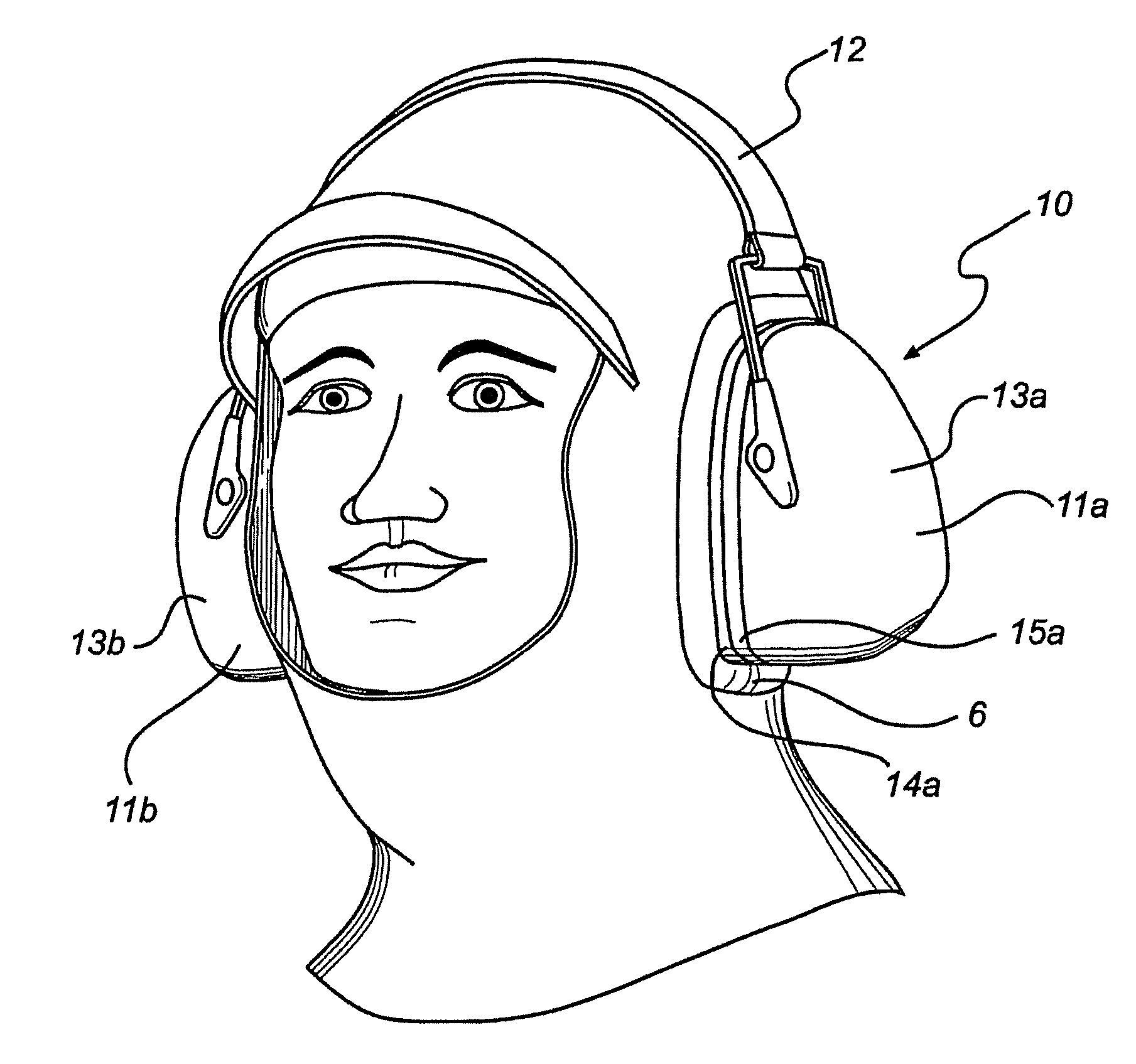

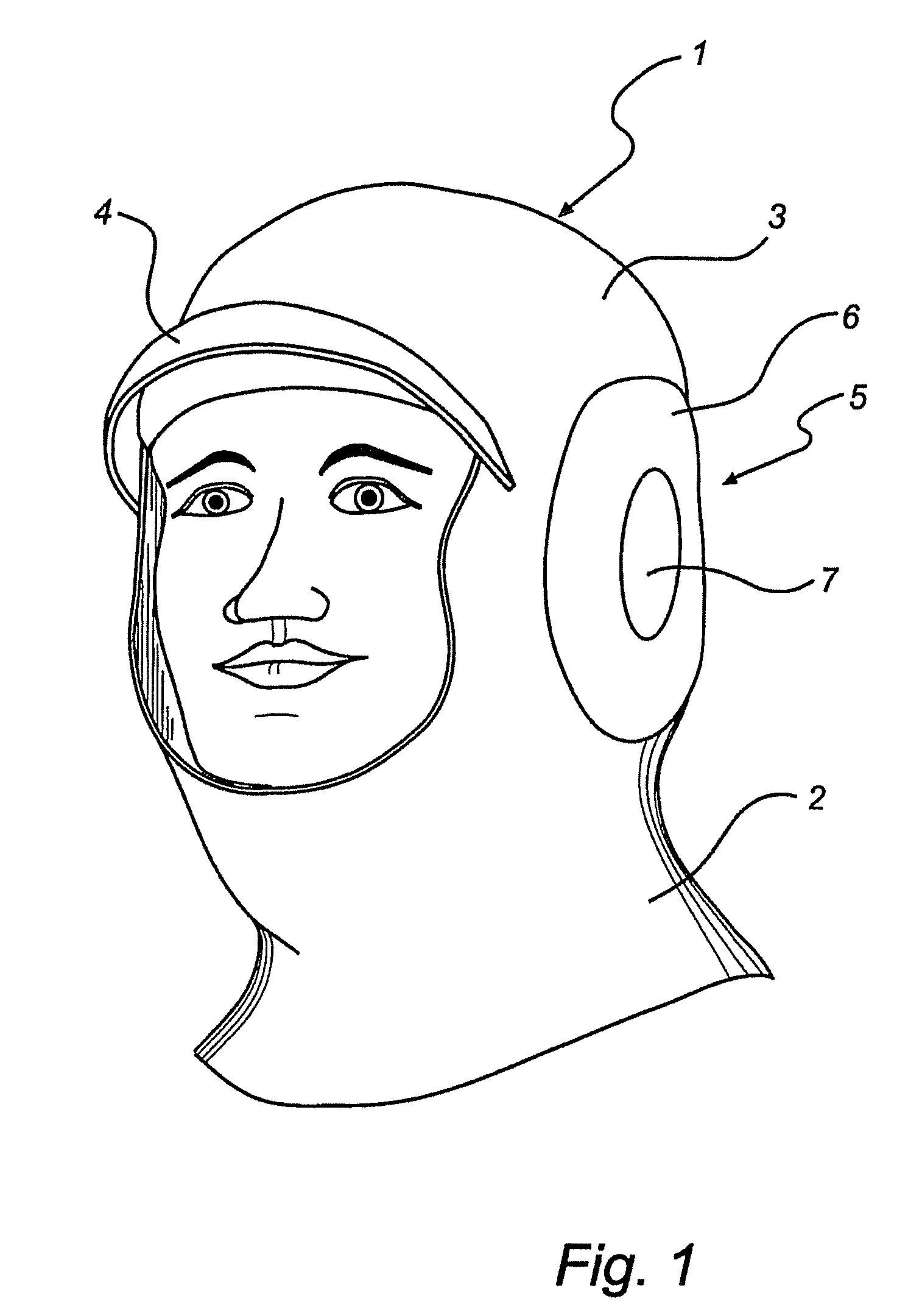

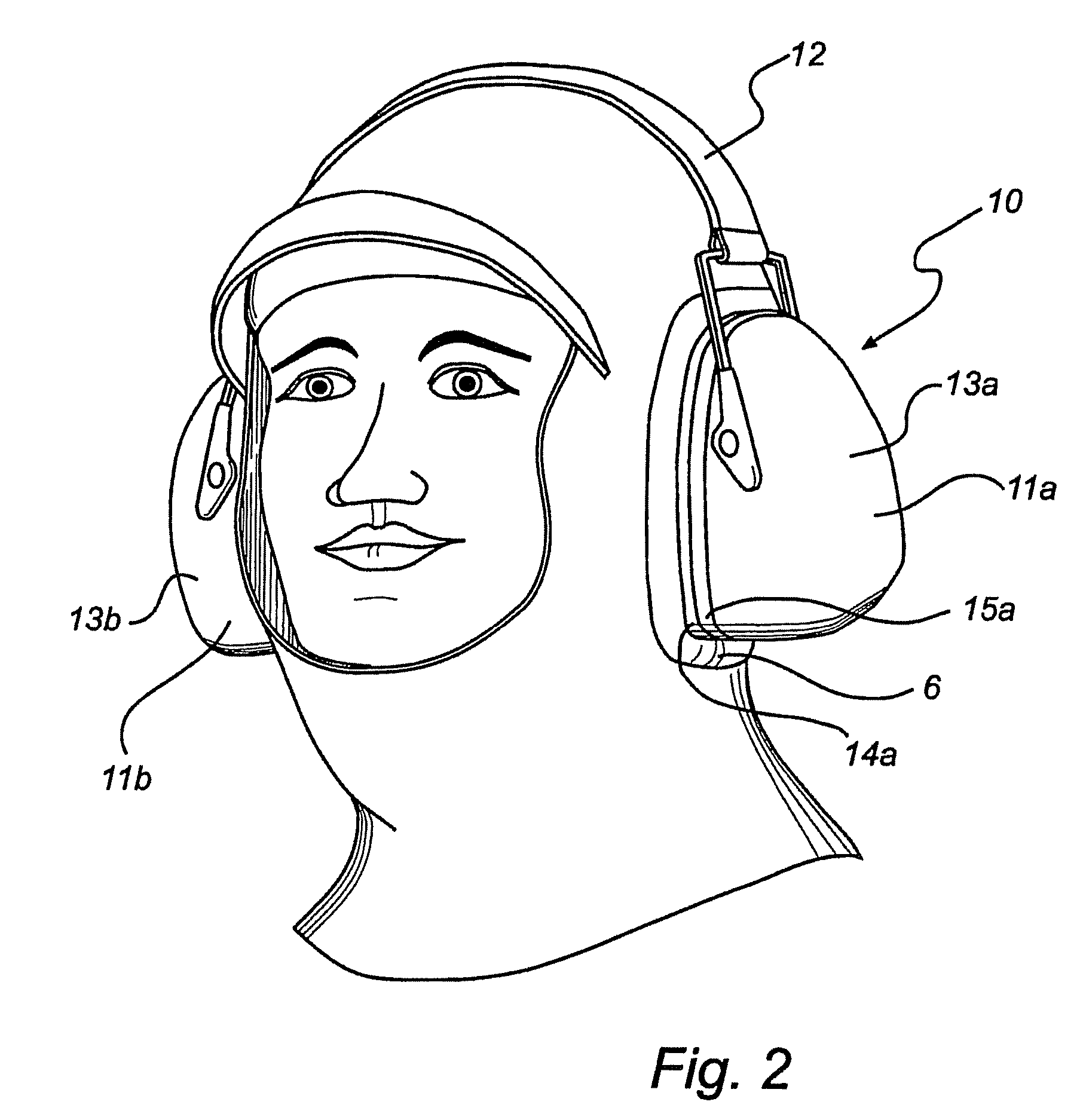

Headpiece for use in association with a hearing cap

InactiveUS20090314298A1Avoid airSatisfactory sound attenuationHatsHeadwear capsCombined useEngineering

Owner:SPERIAN HEARING PROTECTION

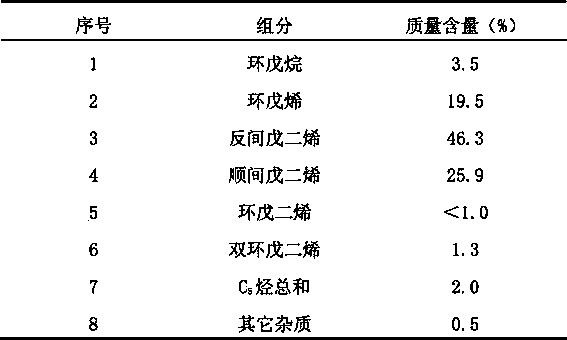

Method for reducing pentadiene petroleum resin color number

ActiveCN103665266AConcentration controllableThe generation is easy to controlPetroleum resinDesiccant

The invention relates to a method for reducing pentadiene petroleum resin color number. The method is characterized in that C5 olefin fraction obtained by a C5 separation device is used as a raw material, the weight of pentadiene concentrate is 60-75 percent; silicon tetrachloride is used as a drying agent, solvents and aluminum chloride anhydrous serving as a catalyst are added to control the dropwise adding speed, and the dropwise adding temperature is less than 30 DEG C, the reaction temperature is 0-80 DEG C and the reaction time is 0.5-10h, so that pentadiene petroleum is prepared. According to the method, the using amount of the synthetic pentadiene petroleum resin catalyst and the resin color number are successfully reduced, and the problem that the color needs to be deepened when high-grade pentadiene petroleum resin is produced is solved, so that the quality of the pentadiene petroleum resin is stable, the process is controlled, and multi-grade requirement of clients is met, and the economic benefit is improved.

Owner:PETROCHINA CO LTD

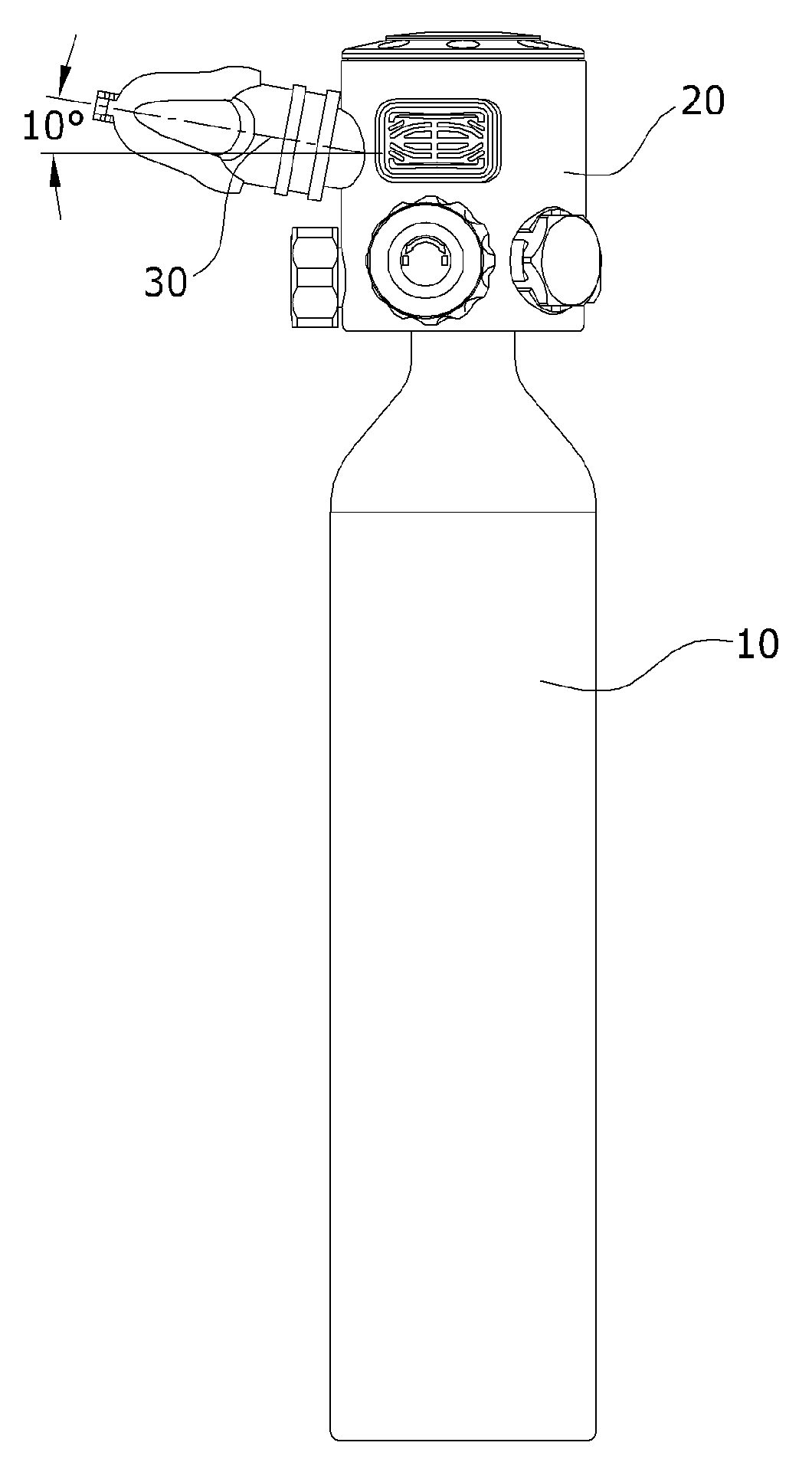

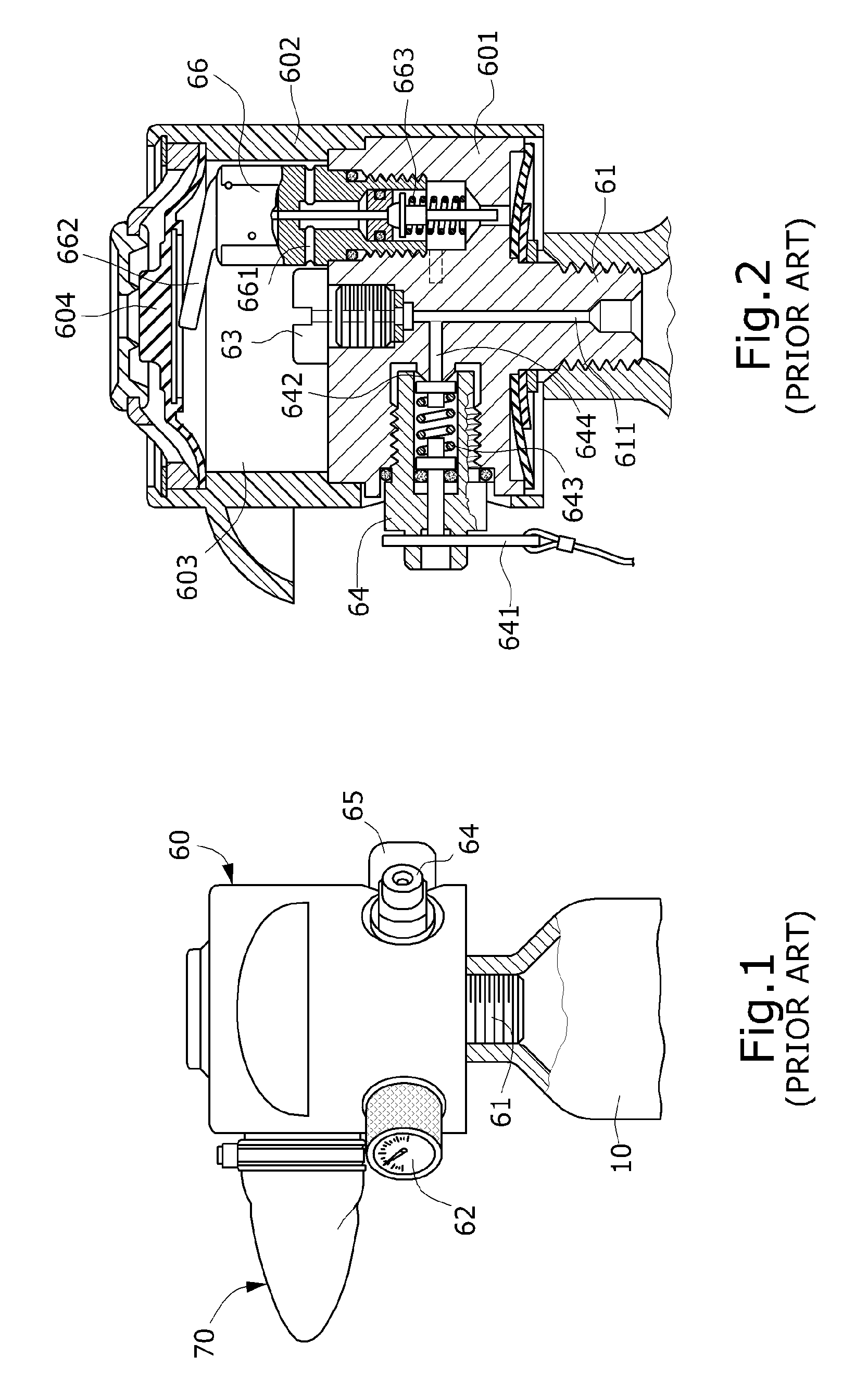

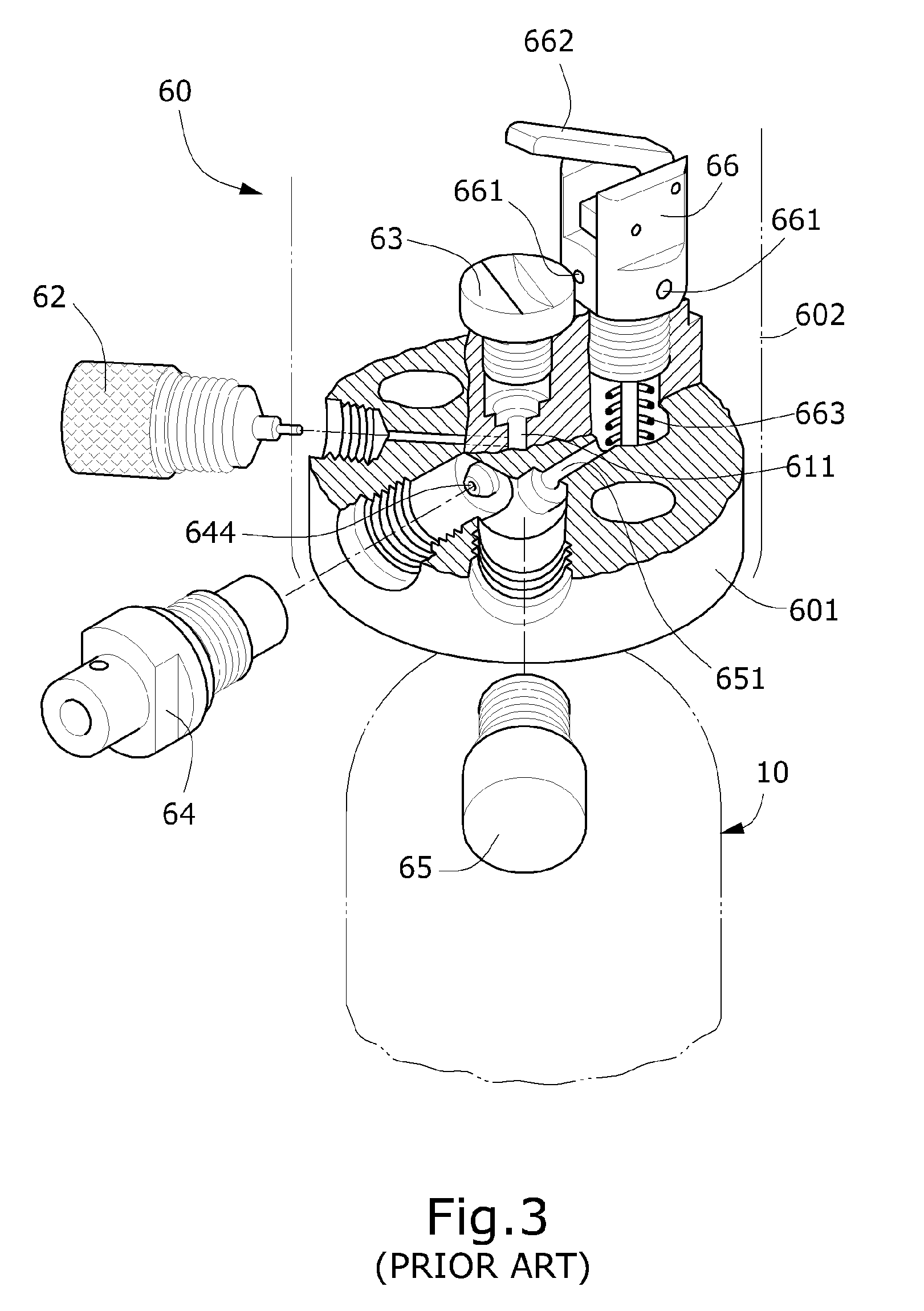

Breathing apparatus structure with two-stage reduced-pressure spare air bottle head

A breathing apparatus structure with a two-stage reduced-pressure spare air bottle head is provided, which includes an air bottle head mounted at an outlet end of a spare air bottle and an inhalation mouthpiece, so as to provide an air at a suitable pressure to a diver or drowning person for emergency use. The air bottle head is sequentially provided with an air bottle head switch, a high pressure reducing valve, and a low-pressure valve connected in series on an air passage thereof. Thus, an air leakage of a high-pressure air in the air bottle can be avoided when the high-pressure air is not used, and the service life of elastic elements of the low-pressure valve can also be prolonge

Owner:PAN CHIEH CHENG

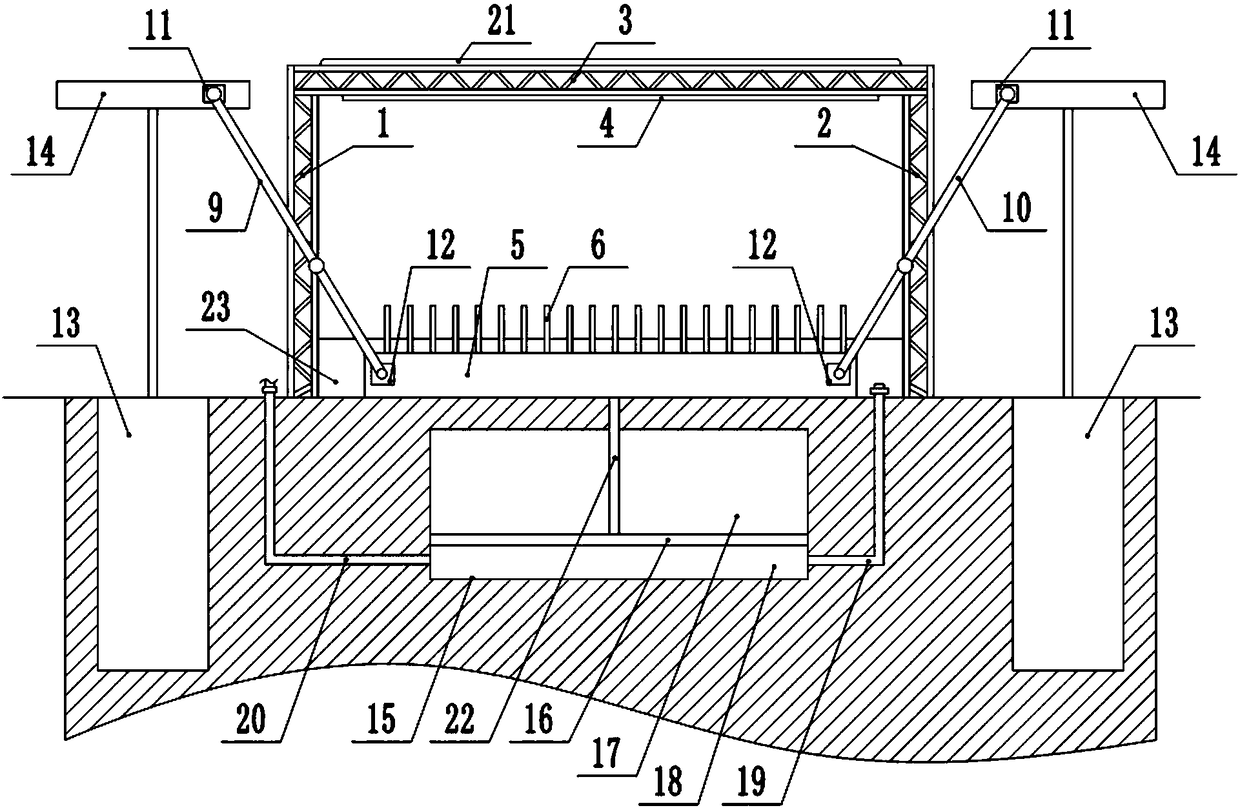

Activity square stage truss

The invention relates to the technical field of stage lifting devices, and particularly discloses an activity square stage truss. The activity square stage truss comprises a first truss body, a secondtruss body and a third truss body; the third truss body is connected with the first truss body and the second truss body, rockers are hinged to the first truss body and the second truss body correspondingly, a transverse plate is arranged on the lower portion of the third truss body, a first sliding block is hinged to one end of each rocker, a second sliding block is hinged to the other end of each rocker, and the first sliding blocks are horizontally and slidably connected to the side wall of the transverse plate; hydraulic cylinders are mounted on the two sides of the transverse plate correspondingly, a horizontal plate is connected to the output ends of the hydraulic cylinders, and the second sliding blocks are horizontally and slidably connected to the side wall of the horizontal plate; and a cylinder body is arranged on the lower portion of the transverse plate, a piston is slidably connected into the cylinder body, a telescopic rod is fixedly connected to the piston and connected to the transverse plate, the cylinder body communicates with an air inlet pipe and an air outlet pipe, the air outlet pipe is connected with an elastic airbag, and the elastic airbag is mounted on the third truss body. According to the activity square stage truss, the safety during mounting stage apparatus in mid-air by workers can be ensured, and fall damage of personnel is avoided.

Owner:重庆如虹文化传播有限责任公司

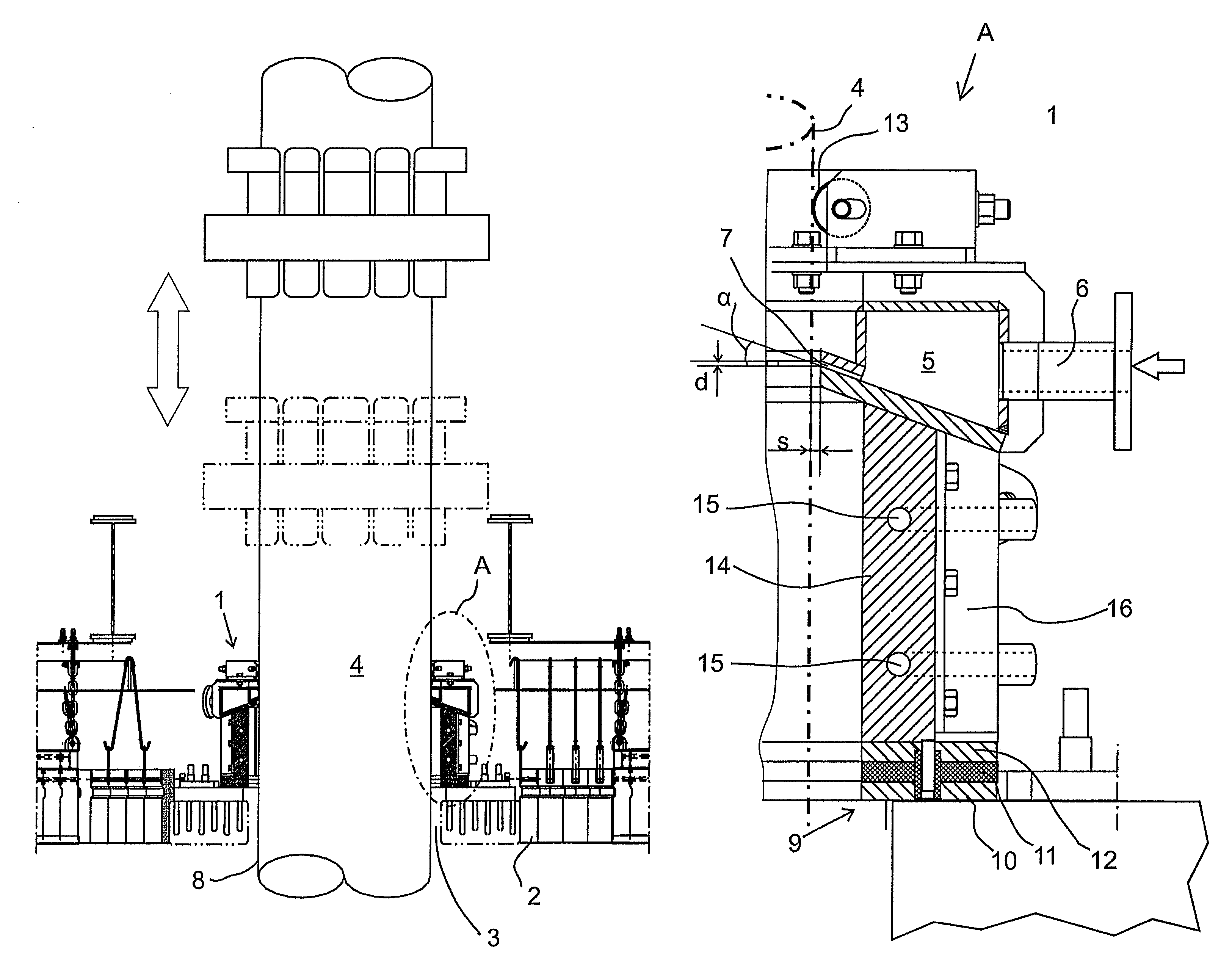

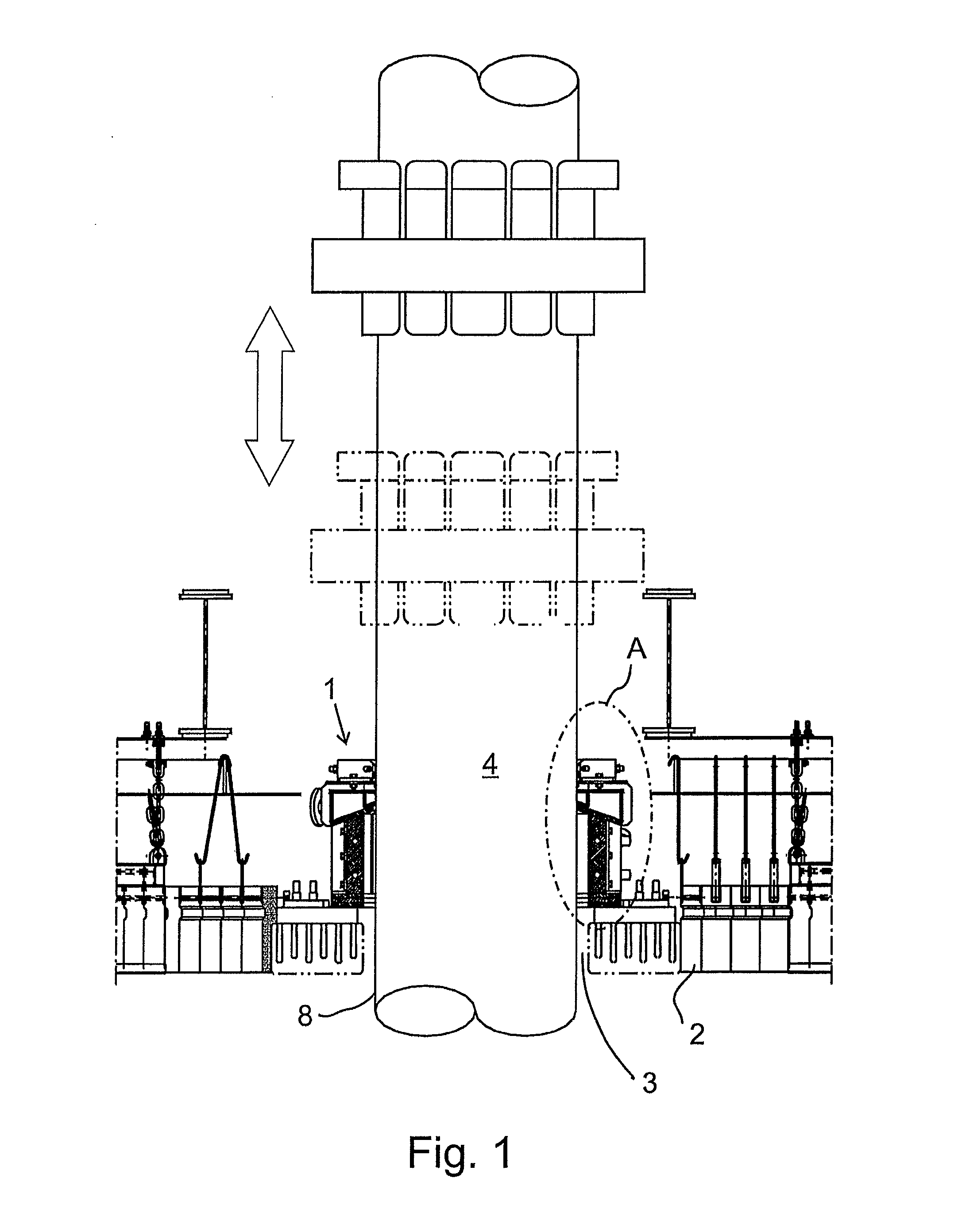

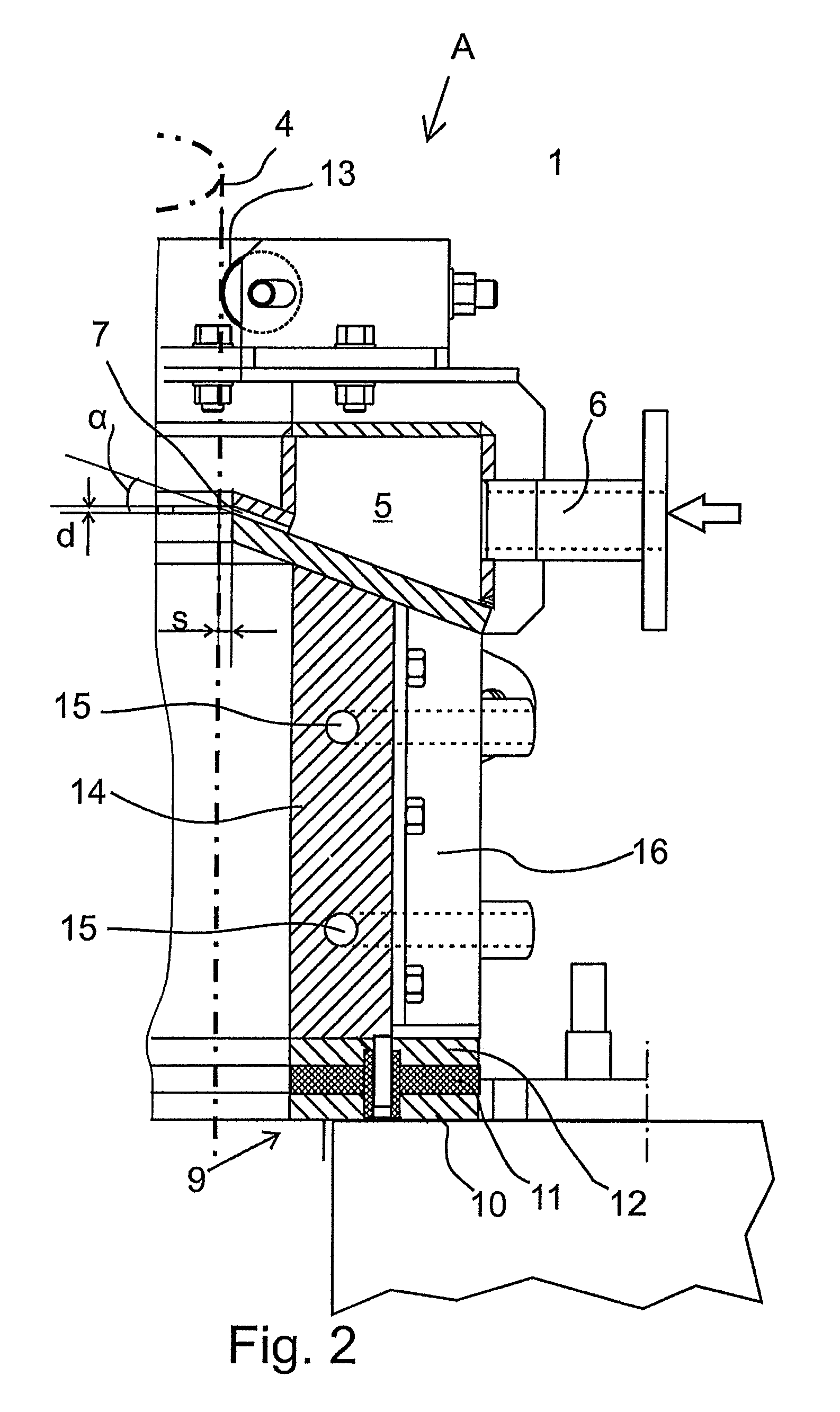

Sealing device

InactiveUS8837552B2Improve sealingGas leakages out of the furnace can be preventedEngine sealsFurnace componentsInlet channelElectric arc furnace

A sealing device is arranged around a rod electrode extending vertically through an aperture made in the ceiling of an arc furnace and being vertically movable inside the furnace to prevent the access of gases from the furnace through the aperture to the atmosphere, and on the other hand to prevent air from flowing from the atmosphere into the furnace. The sealing device comprises a gas distribution chamber provided with an inlet channel for feeding essentially passive gas, such as nitrogen or air, into the gas distribution chamber. The sealing device also includes a slit nozzle encasing the electrode, through which nozzle a gas jet is arranged to be discharged from the gas distribution chamber towards the electrode in a direction that is at an angle with respect to the horizontal plane and has a slightly upwards inclined orientation, and that is, with respect to the furnace interior, pointed outwardly, so that the sealing is carried out owing to the effect of the created stagnation pressure.

Owner:OUTOTEC OYJ

Apparatus and method of making a nonwoven ceiling tile and wall panel

A nonwoven ceiling tile or wall panel with noise absorption properties utilizes unique acoustical absorbing fibers. During manufacturing, binder fibers melt between interstitial spaces to fill spaces and create impedance to air flow and sound flow through the fibers. Various shapes and / or sizes of fibers may also be utilized to further impedance of air and sound through the ceiling tile or panel. The ceiling tiles and panels are made from 100% organic fibers that are either virgin or recycled material. The material is structurally self-supporting eliminating need for structural additives or structural design features. Fire and smoke retardants are incorporated into the fibers. Antimicrobial and anti-stain additives may also be used in the fibers. The material is 100% polyester fibers (PET and PETG). The material is printable using sublistatic printing or transfer printing process. The ceiling tiles and panels are light weight and moldable in a wide range of designs.

Owner:NONWOVEN NETWORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com