Electrical grease filling machine

A butter filling and electric technology, applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of limited effect, poor fluidity, and high butter viscosity, and achieve the effect of high horsepower and avoiding air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

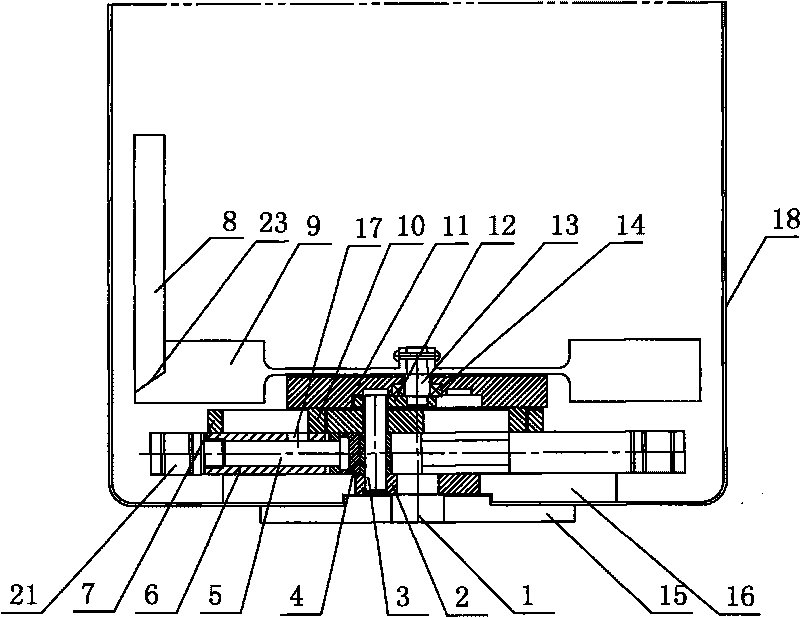

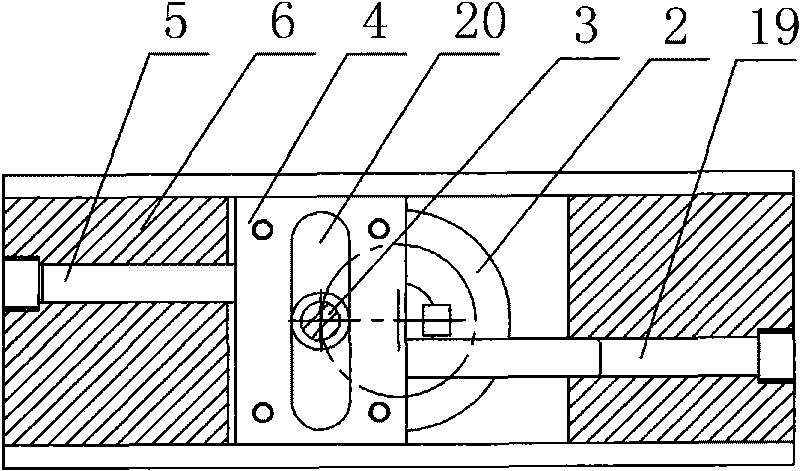

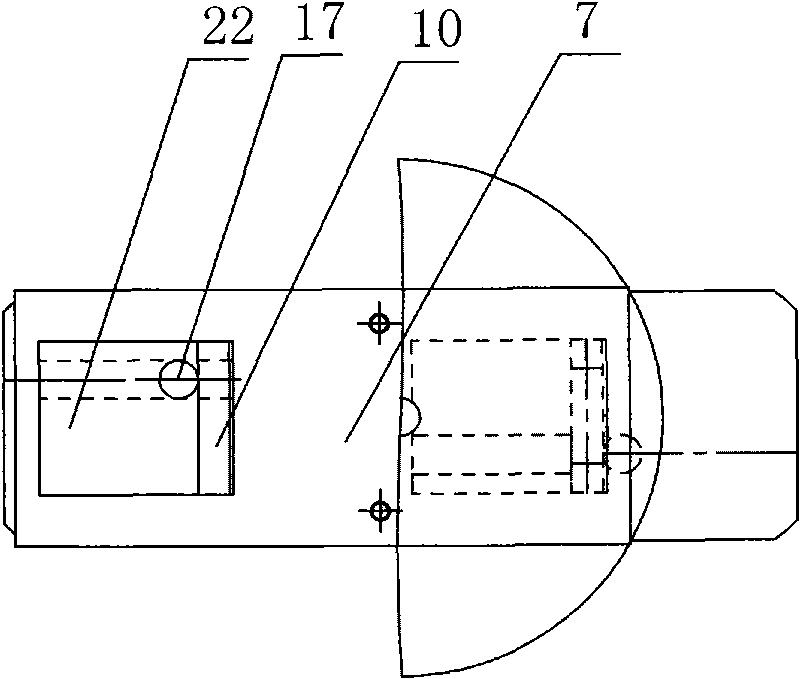

[0012] As shown in the figure, the electric butter filling machine includes an oil barrel 18, the outer and inner sides of the bottom of the oil barrel 18 are respectively fixedly connected to the outer flange 15 and the inner flange 16, and a through hole is set in the center of the outer flange 15, and a through hole is inserted into the through hole. The center of the reducer shaft 1 and the inner flange 16 are provided with a through hole, and the eccentric disc 2 is nested in the through hole, and the center of the eccentric disc 2 is provided with a through hole. The drive shaft 3 perpendicular to the eccentric disc 2 is set at the eccentric position, and the drive shaft 3 is sleeved in the slider 4 with a through groove 20. The two sides of the slider 4 parallel to the through groove 20 are respectively provided with a piston 5 and a piston 5. Perpendicular to the through groove 20, two cylinders 6 are respectively arranged around the two pistons 5, and the lower ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com