Method for reducing pentadiene petroleum resin color number

A technology for petroleum resin and piperylene, applied in the field of preparing piperylene petroleum resin, can solve the problems of difficult control of polymerization reaction, deepening color number of petroleum resin, unstable product quality, etc., and achieves easy control and stable product quality. , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

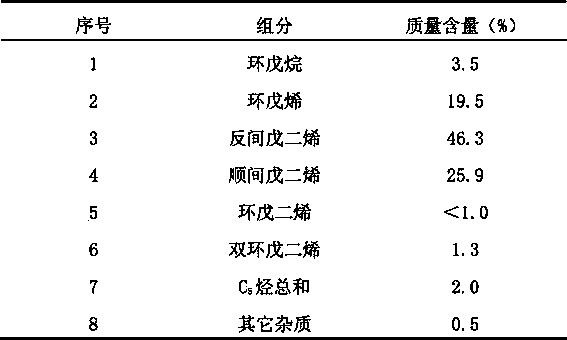

Image

Examples

Embodiment 1

[0023] Add 30 grams of toluene (containing 0.3 grams of silicon tetrachloride) and 0.5 grams of aluminum trichloride catalyst, and add 100 grams of piperylene concentrate dried with silicon tetrachloride into the reactor. (Containing 1.0 g of silicon tetrachloride). Control the dropping rate, the dropping temperature is less than 20°C, the reaction temperature is 50°C, and the reaction time is 8h. Carry out one time of excessive alkaline washing, three times of water washing, and layering. After removing the catalyst from the upper layer, vacuumize at 210°C to obtain piperylene petroleum resin. The resin yield is 82%, the hue (Fe-Co) is ﹦3, and the softening point is 80°C. Treatment of the three wastes of alkaline water in the lower layer, and water use for primary, secondary and tertiary.

Embodiment 2

[0025] Add 30 grams of silicon tetrachloride dry solvent toluene (containing 0.6 grams of silicon tetrachloride) and 1.0 grams of aluminum trichloride catalyst into the reaction kettle. Add 100 grams of piperylene concentrate (containing 1.0 grams of silicon tetrachloride). G). Control the dropping rate, the dropping temperature is less than 20°C, the reaction temperature is 50°C, and the reaction time is 8h. Carry out one time of excessive alkali washing, three times of water washing, layering of excessive alkaline washing, and layering; the upper layer is vacuumed to remove the toluene solvent, and the piperylene petroleum resin is obtained. The resin yield reaches 86%, and the hue (Fe-Co)<4 , The softening point is 92℃. Treatment of the three wastes of alkaline water in the lower layer, using water in the first, second and third time.

Embodiment 3

[0027] Add 30 grams of toluene (containing 1.5 grams of silicon tetrachloride), 1.5 grams of aluminum trichloride catalyst, and 100 grams of piperylene concentrate (containing 1.0 of silicon tetrachloride) into the reaction kettle. G). Control the dropping speed, and the dropping temperature is less than 20°C. The reaction temperature is 50°C, and the reaction time is 8h. Carry out one time of excessive alkali washing, three times of water washing, and layering; the upper layer is vacuumed to remove the toluene solvent, and the piperylene petroleum resin is obtained. The resin yield reaches 89%, the hue (Fe-Co)≤4, and the softening point is 97°C. . Treatment of the three wastes of alkaline water in the lower layer, with primary, secondary and tertiary water reuse

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com