Grafted modified chlorinated polyvinyl chloride ultrafiltration membrane, and preparation method thereof

A technology of perchloroethylene and graft modification, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of poor separation membrane hydrophilicity, affecting separation effect and practical application, membrane hole fouling, etc. To achieve the effect of easy control of concentration, reduction of loss and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of preparation method of grafting modified perchlorethylene ultrafiltration membrane comprises the following steps.

[0028] 1.1 Weigh by weight, film substrate: perchlorethylene (CPVC) resin, chemically pure, dosage 16.5%; solvent: N,N-dimethylacetamide (DMAC), chemically pure, dosage 80.0%; porogen Agent: polyvinylpyrrolidone K30 (PVP), chemically pure, dosage 2.5%; additive: nano-scale aluminum oxide (Al2O3), analytically pure, dosage 0.5%; grafting agent: polyethylene polyamine, chemically pure, dosage 0.5%.

[0029] 1.2 Dry the film substrate perchlorethylene resin. The drying method is to spread the perchlorethylene resin on the tray and put it in an electric blast drying oven, and bake it at 60°C for more than 24hrs.

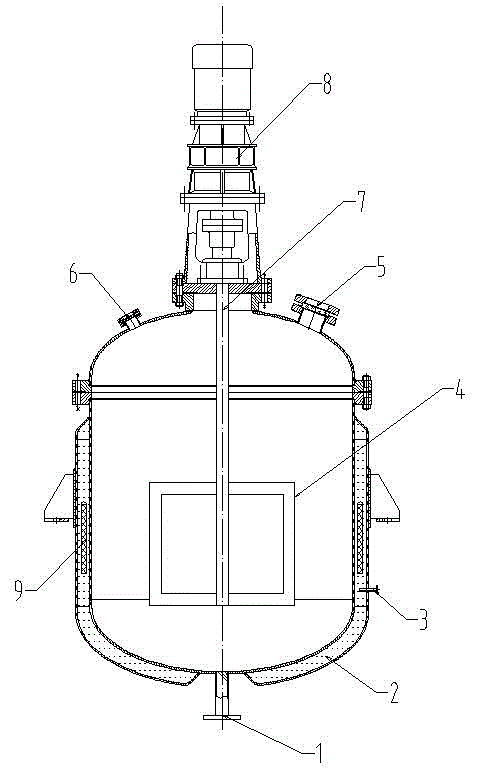

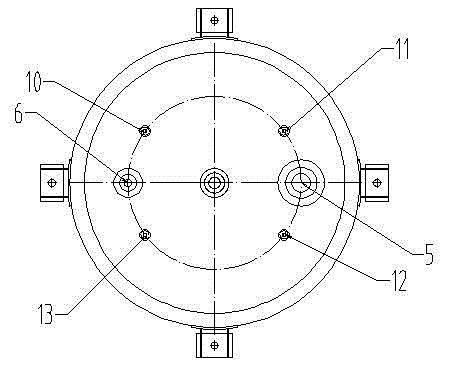

[0030] 1.3 Add the solvent N,N-dimethylacetamide to the casting solution preparation kettle, and raise the temperature to the preparation temperature, set the preparation temperature to 60°C, cool the perchlorethylene resin ob...

Embodiment 2

[0035] Embodiment 2: A kind of preparation method of grafting modified perchlorethylene ultrafiltration membrane comprises the following steps.

[0036]2.1 Weigh by weight, film substrate: perchlorethylene (CPVC) resin, chemically pure, dosage 18.5%; solvent: N,N-dimethylacetamide (DMAC), chemically pure, dosage 77.0%; porogen Agent: polyvinylpyrrolidone K30 (PVP), chemically pure, dosage 2.5%; additive: nano-scale aluminum oxide (Al2O3), analytically pure, dosage 1.0%; grafting agent: polyethylene polyamine, chemically pure, dosage 1.0%.

[0037] 2.2 Dry the film substrate perchlorethylene resin. The drying method is to spread the perchlorethylene resin on the tray and put it in an electric blast drying box, and bake it at 60-65 ° C for more than 24 hours.

[0038] 2.3 Add the solvent N,N-dimethylacetamide to the casting solution preparation kettle, and raise the temperature to the preparation temperature, set the preparation temperature to 60°C, cool the perchlorethylene re...

Embodiment 3

[0043] Embodiment 3: A kind of preparation method of grafting modified perchlorethylene ultrafiltration membrane comprises the following steps.

[0044] 3.1 Weigh by weight, film substrate: perchlorethylene (CPVC) resin, chemically pure, dosage 18.5%; solvent: N,N-dimethylacetamide (DMAC), chemically pure, dosage 73.0%; porogen Agent: polyvinylpyrrolidone K30 (PVP), chemically pure, dosage 5.5%; additive: nano-scale aluminum oxide (Al2O3), analytically pure, dosage 1.5%; grafting agent: polyethylene polyamine, chemically pure, dosage 1.5%.

[0045] 3.2 Dry the film substrate perchlorethylene resin. The drying method is to spread the perchlorethylene resin on the tray and put it in an electric blast drying box, and bake it at 60-65 ° C for more than 24 hours.

[0046] 3.3 Add the solvent N,N-dimethylacetamide to the casting solution preparation kettle, and raise the temperature to the preparation temperature, set the preparation temperature to 60°C, cool the perchlorethylene r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com