Casting-forging hydropress and method for casting and forging product thereof

A hydraulic press, casting and forging technology, applied in the machine field of the metal forming industry, can solve the problems of low forging pressure and forging deformation, low product quality and yield, low work efficiency, etc., to achieve high forging pressure, high production efficiency, The effect of convenient filling and pressure feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

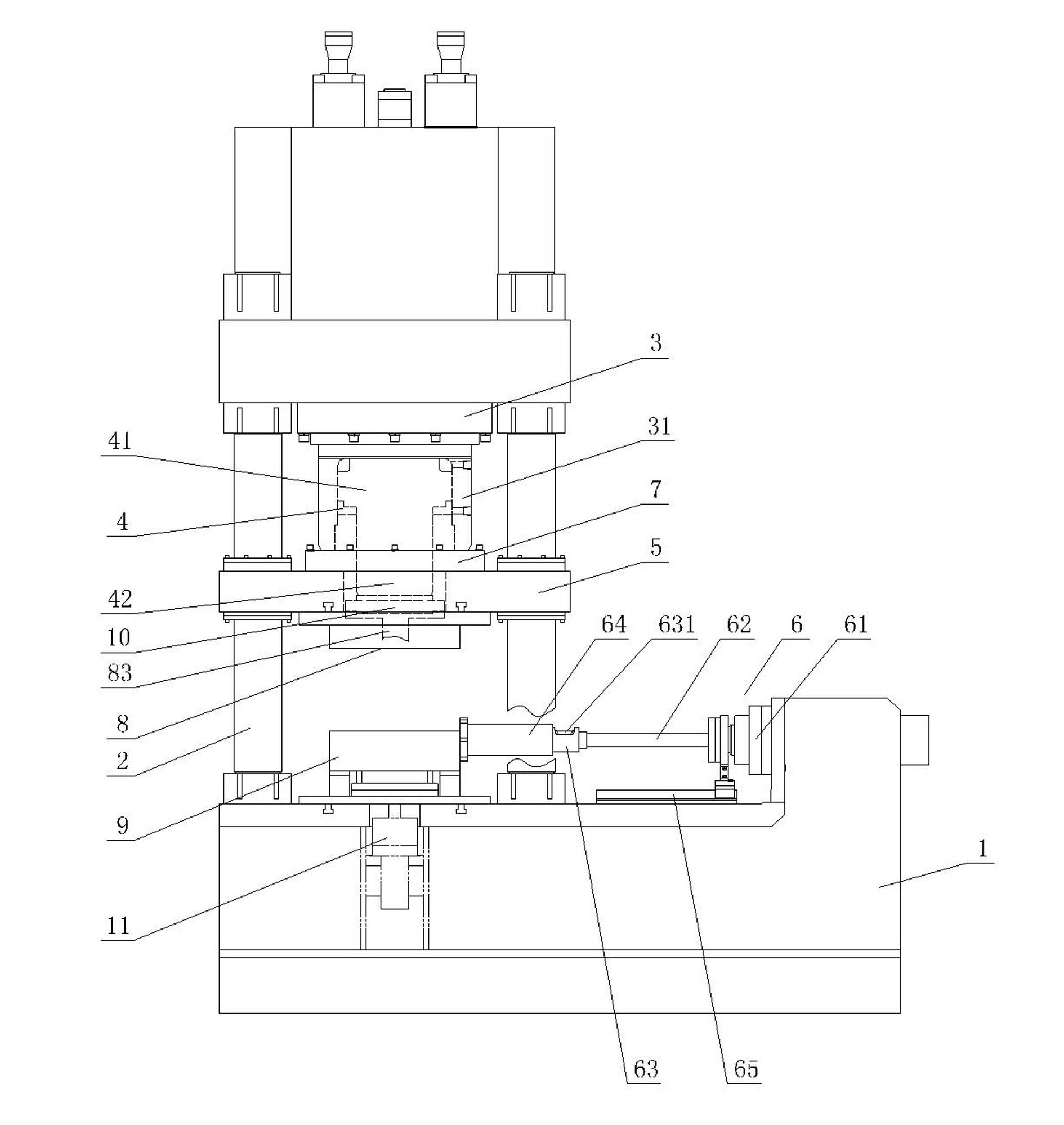

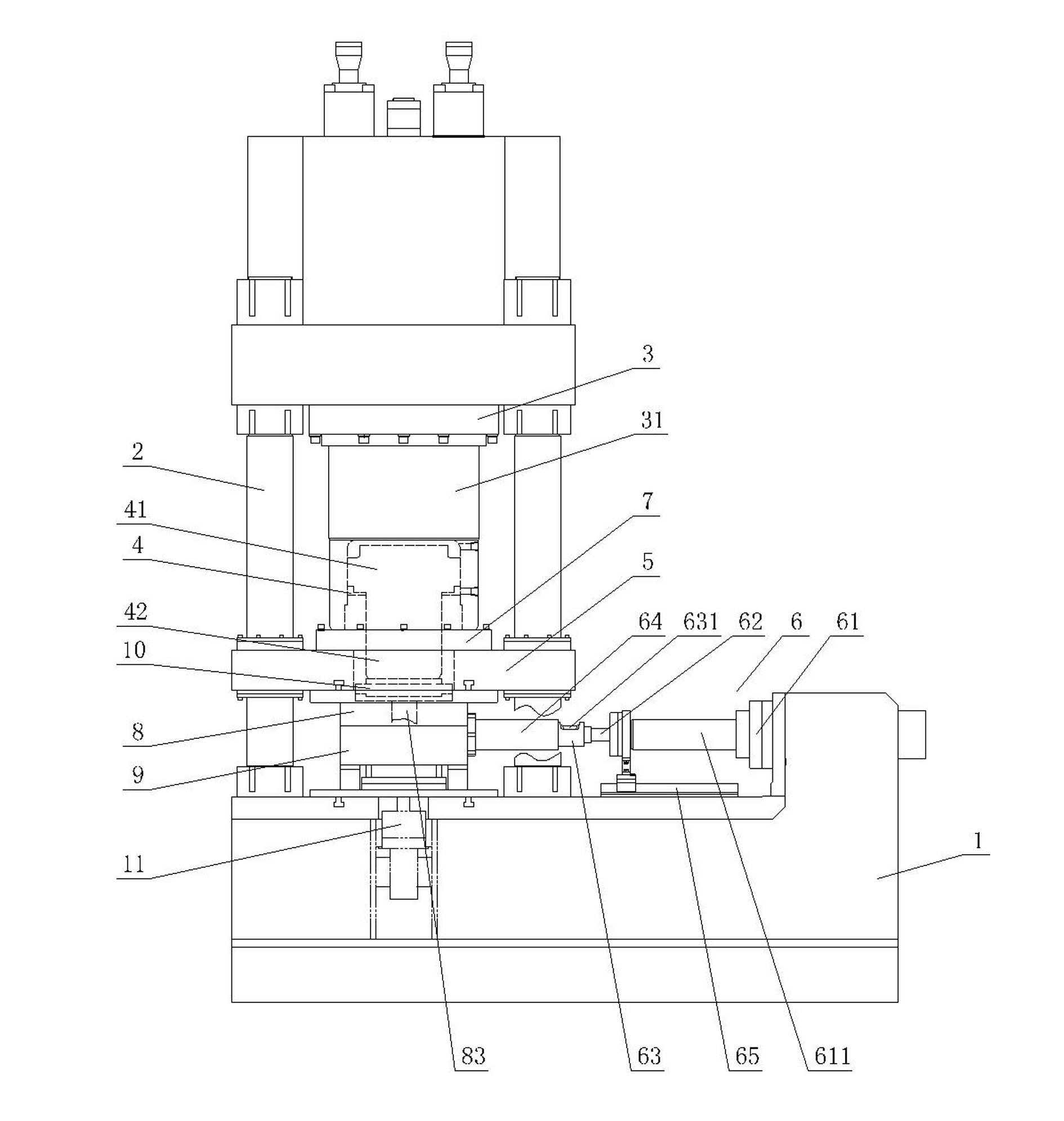

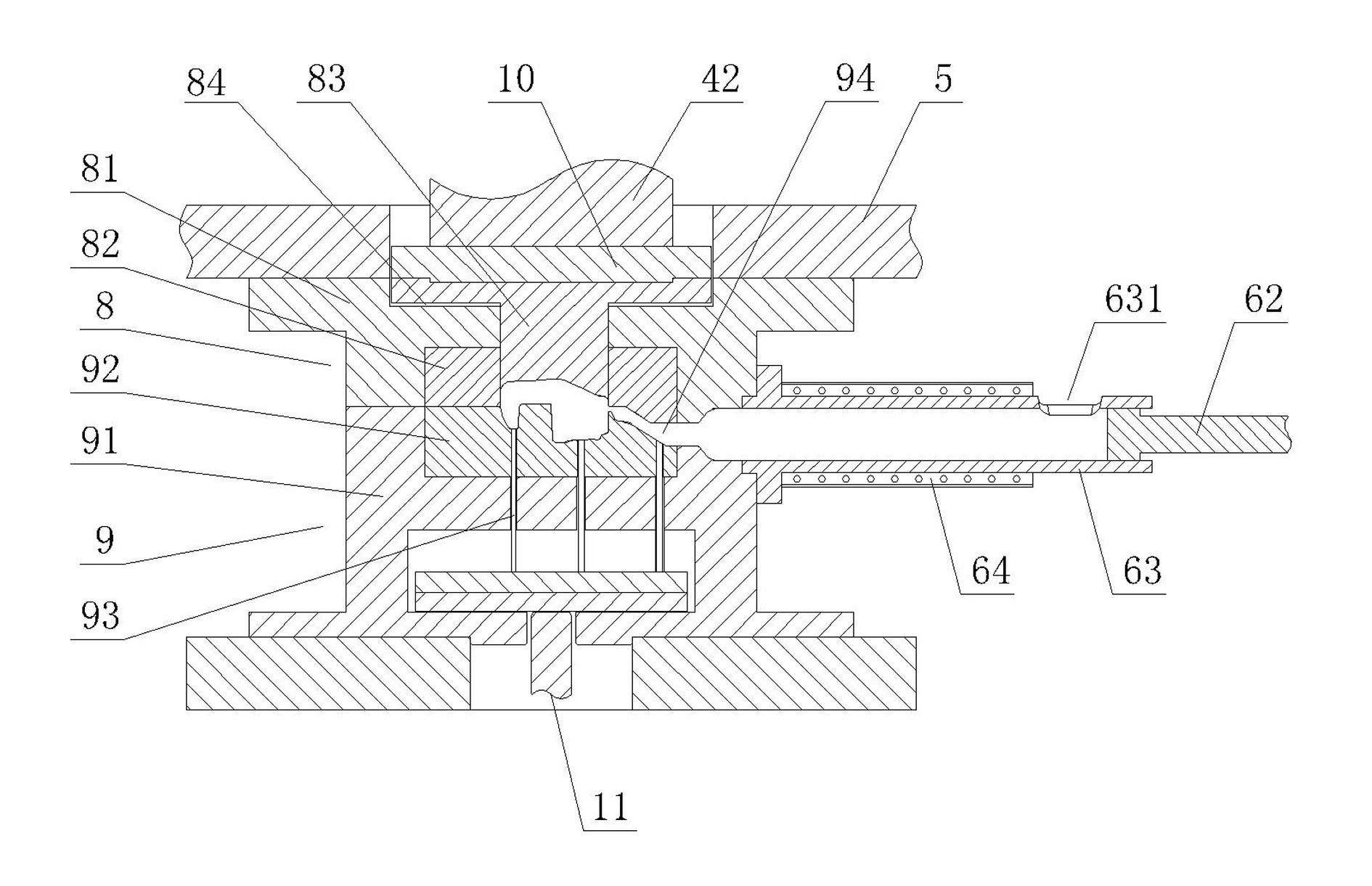

[0026] Such as Figure 1-Figure 3 As shown, the casting and forging hydraulic press and the method for casting and forging products thereof of the present invention include a workbench 1, a column 2, a mold clamping cylinder 3, a forging cylinder 4, a movable beam 5 and a pressure casting device 6, wherein the column 2 is arranged on On the workbench 1, the clamping cylinder 3 is set on the column 2, the movable beam 5 is movably installed on the column 2 and connected with the piston rod 31 of the clamping cylinder 3, the forging cylinder 4 is set on the clamping cylinder 3, In order to facilitate the filling of molten metal and effectively improve the working efficiency of the present invention, the die casting device 6 is arranged on the table top of the workbench 1 . And this pressure casting device 6 comprises pressure casting cylinder 61, injection punch 62 and injection barrel 63, wherein pressure casting cylinder 61 is fixed on the table top of workbench 1, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com