Light emitting diode combination

A technology of light-emitting diodes and light-emitting chips, which is applied in optics, condenser mirrors, optical components, etc., can solve the problems of low utilization rate of light energy of light-emitting diodes and affect the overall brightness of light-emitting diode lamps, and achieve the goal of avoiding loss of light intensity and high intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

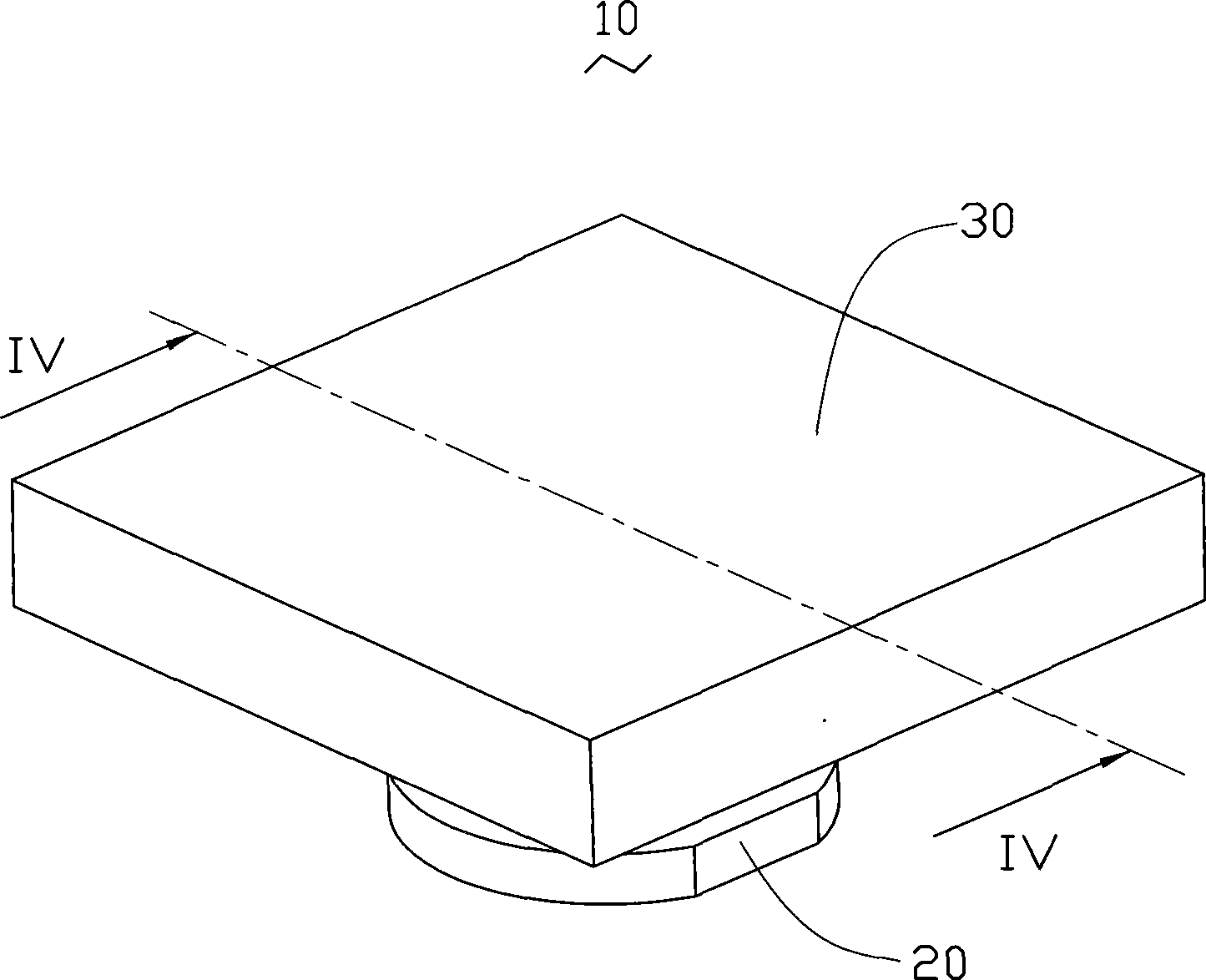

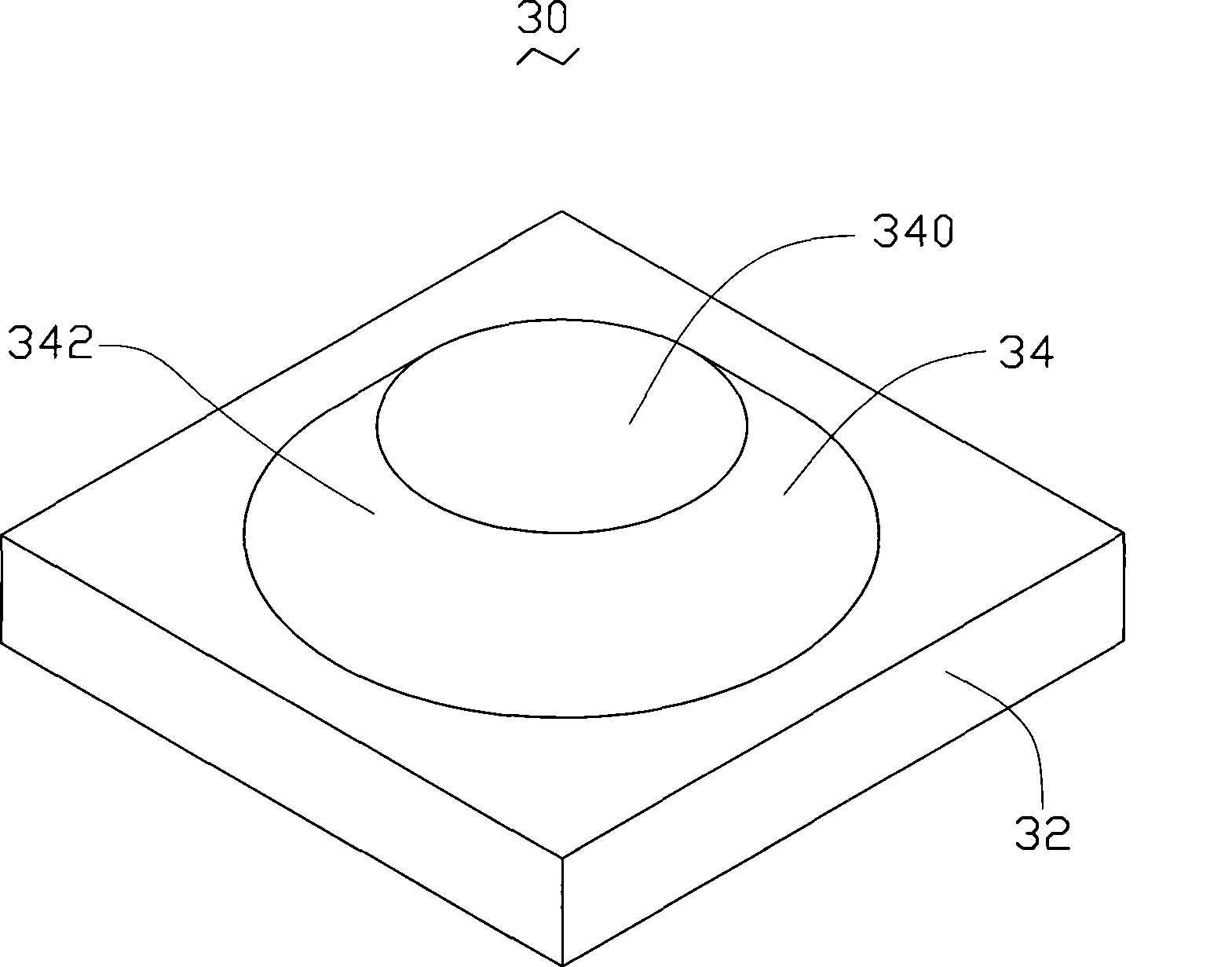

[0017] Such as figure 1 As shown, the LED combination 10 of the present invention includes a LED 20 and a lens 30 fixed on the LED 20 .

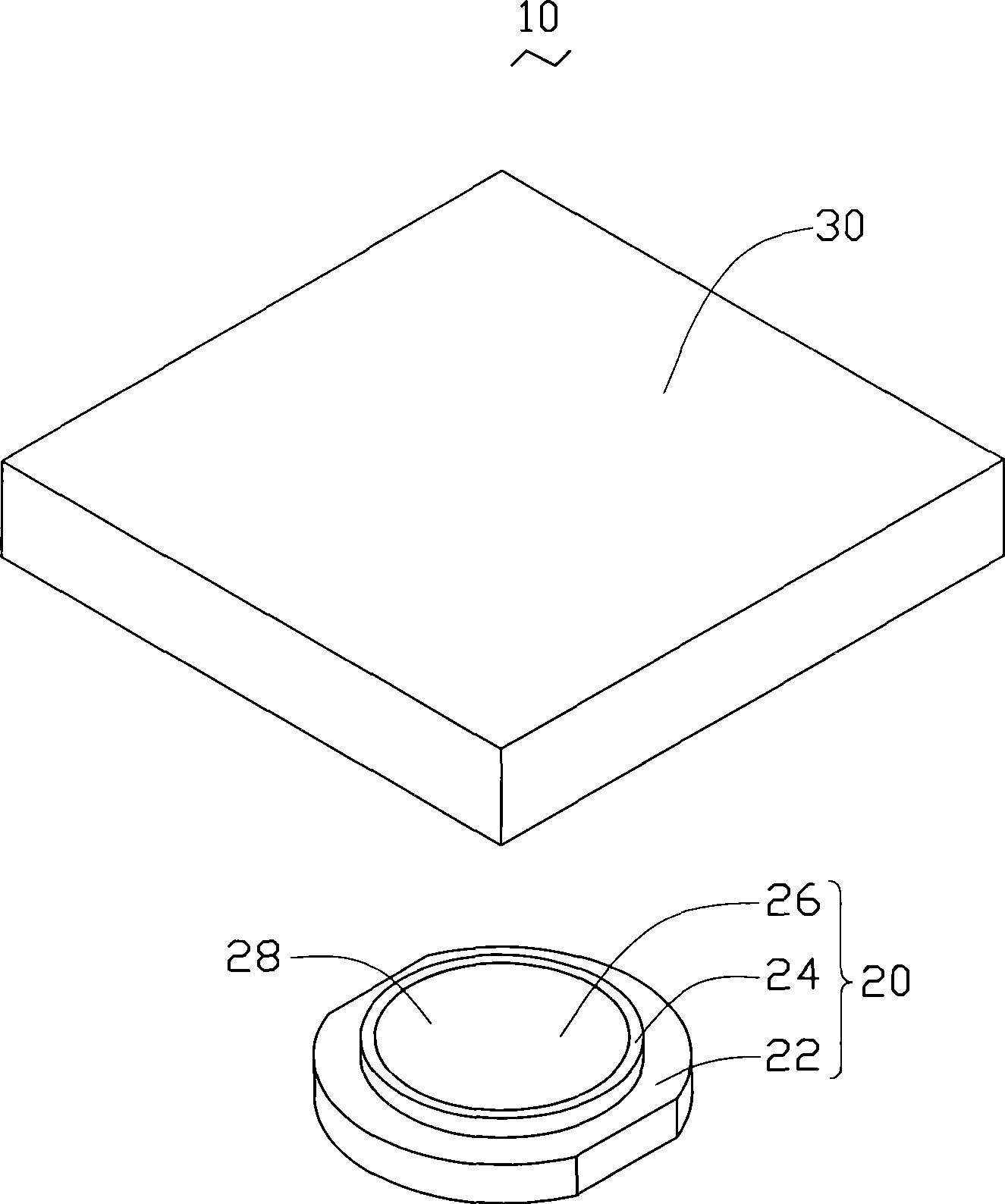

[0018] see figure 2 with Figure 4 The light-emitting diode 20 includes a base 22, a light-emitting chip 220 bonded on the base 22, a side wall 24 extending vertically upward from the base 22, and a package accommodated in the side wall 24 and covering the chip 220. Cladding 26. The base 22 is roughly circular, and two opposite sides of the base 22 are respectively cut off to form two parallel sides. The chip 220 is bonded to the central area of the upper surface of the substrate 22 by a die-bonding glue (not shown). According to different structures of the chip 220 , the die-bonding adhesive can be an insulating die-bonding adhesive, such as relatively pure epoxy resin, or a conductive die-bonding adhesive, such as epoxy resin doped with silver paste. The sidewall 24 is ring-shaped, and is formed on the upper surface of the base 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com