Novel noise-reducing scroll compressor

A scroll compressor, noise-reducing technology, applied in the field of compressors, to solve noise problems, avoid rigidity and weak strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

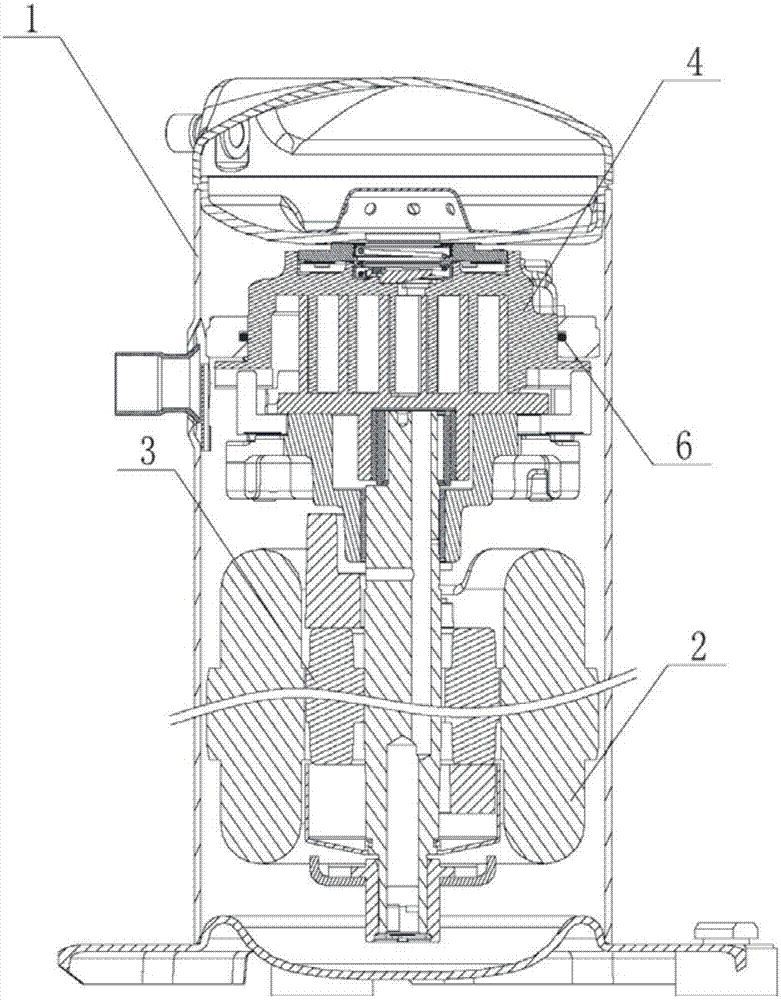

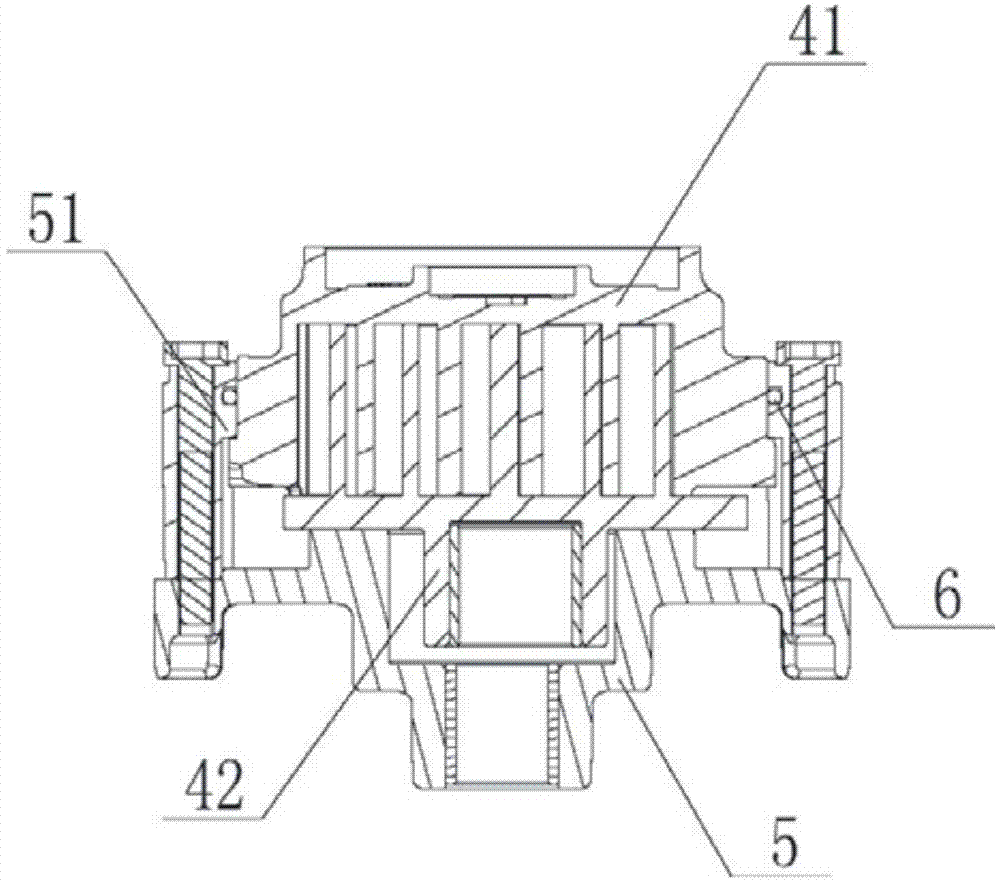

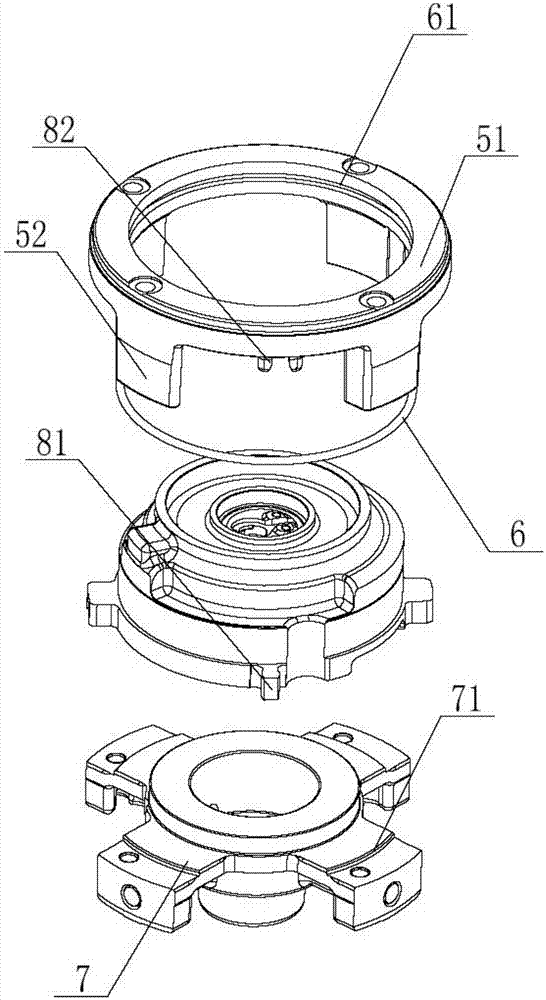

[0023] In order to achieve the purpose of the present invention, in the first embodiment of the present invention, such as Figure 1-3 As shown, the new noise-reducing scroll compressor includes: a scroll assembly 4, which includes a movable scroll 41 and a fixed scroll 42 engaged with each other; The member 51 is sleeved on the lower end of the scroll assembly 4, and the inner wall of the annular member 51 is fitted with the side wall of the fixed scroll 42 along the axial clearance, and an elastic element 6 is arranged on the inner wall of the annular member 51, and the elastic element 6 can be made of materials with elastic properties such as rubber known in the prior art, and will not be listed in detail here. Such as figure 1 As shown, the scroll compressor also includes a casing 1, a stator assembly 2 and a rotor assembly 3, etc., wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com