Prefabricated stair and mounting technology thereof

A stair and installation structure technology, applied in the field of prefabricated stair and its installation technology, can solve the problems of damaged dovetail tenon and dovetail groove clamping and fixing, limited stair fixing effect, influence of prefabricated stair assembly and construction, etc., and achieves easy assembly and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

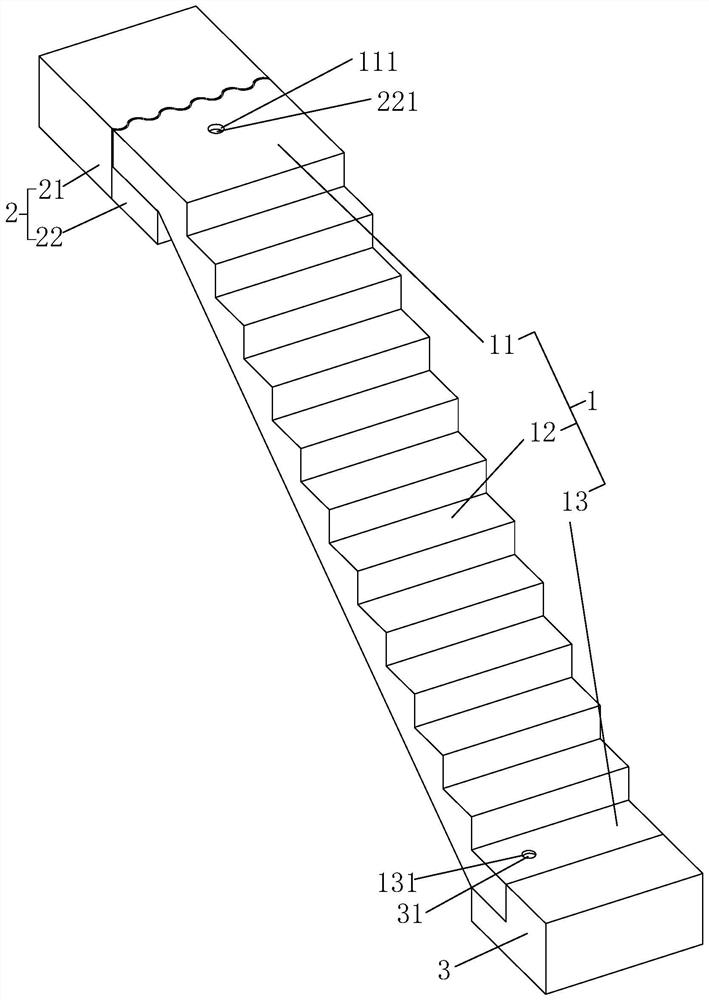

[0048] refer to figure 1 , is a prefabricated staircase disclosed by the present invention, comprising a transfer platform 2, a staircase body 1 and a floor 3, the two ends of the staircase body 1 are respectively assembled on the transfer platform 2 and the floor 3, and the gap between the three is poured with concrete, The assembly and fixing of the staircase body 1 is completed to achieve the effect of rapid assembly of the staircase body 1 .

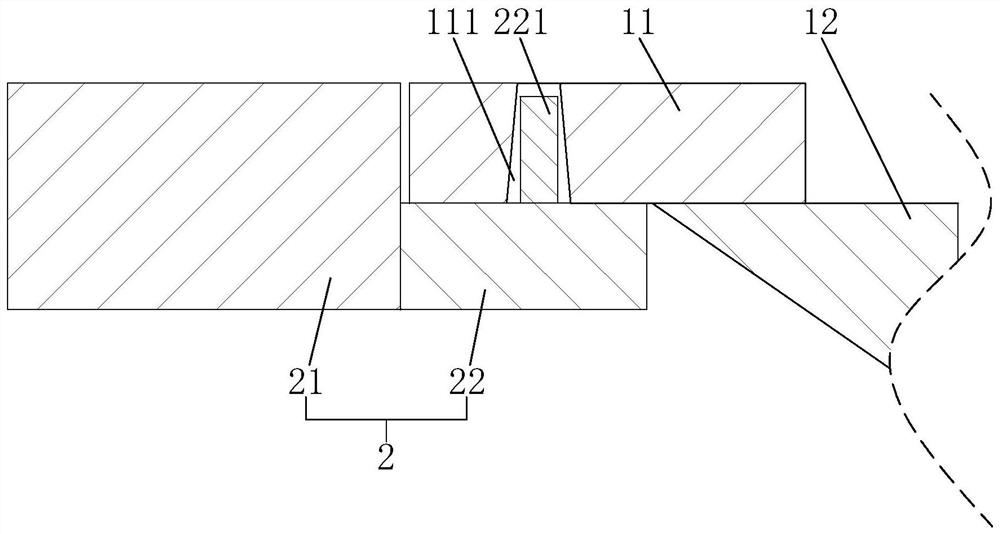

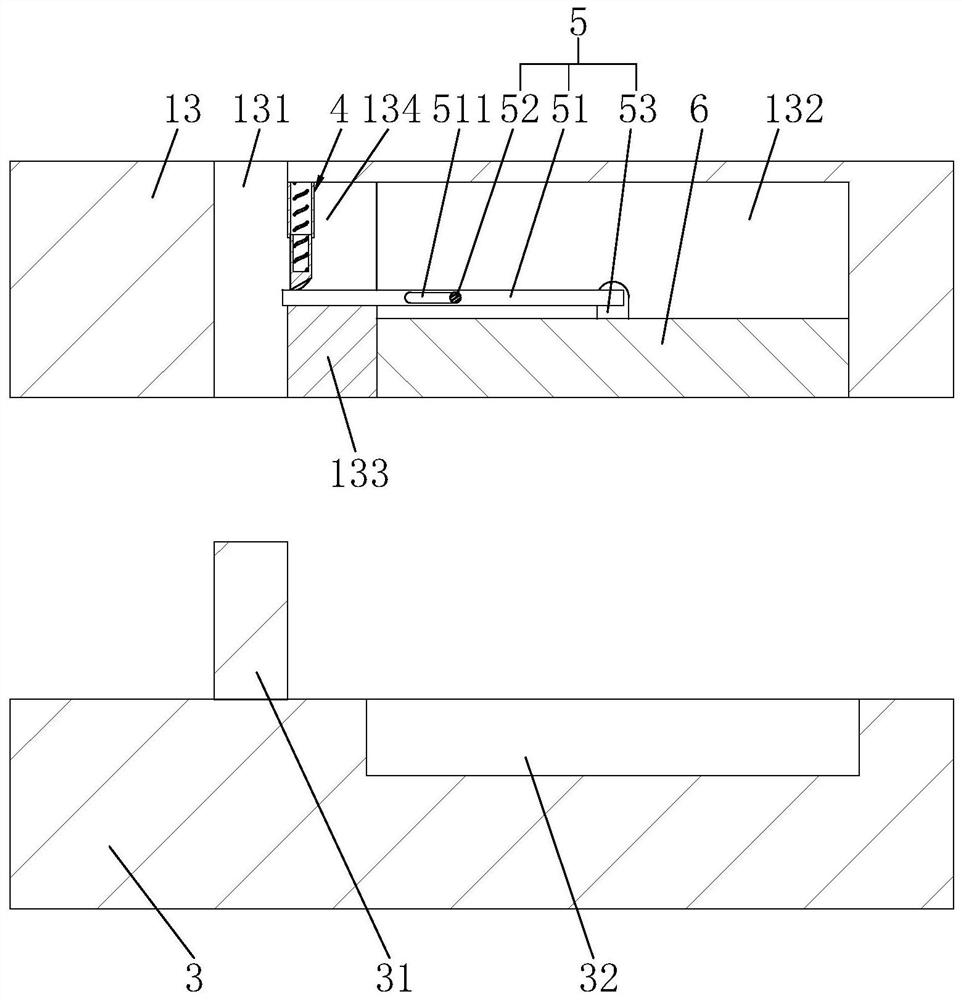

[0049] refer to figure 1 The stair body 1 comprises a top platform 11, an inclined ladder 12 and a bottom platform 13, the top platform 11 and the bottom platform 13 are respectively fixed at both ends of the inclined ladder 12 and arranged horizontally, the top platform 11 is provided with a first positioning hole 111, the first Positioning hole 111 is a circular hole; The second positioning hole 131 is offered on the bottom platform 13, and the second positioning hole 131 is a circular hole. Opening; the transfer platform 2 inclu...

Embodiment 2

[0057] A prefabricated staircase and an installation method thereof, comprising the following steps:

[0058] S1: The prefabricated staircase body 1 is manufactured in a factory, and four-point hoisting is used to suspend the staircase body 1 at the bottom of the chain. The diameter of the first positioning hole 111 gradually increases from top to bottom, and the staircase body 1 is hoisted to the transfer platform 2 and After 300mm-500mm above the floor 3, adjust the position of the prefabricated floor 3 so that the first positioning hole 111 is aligned with the first positioning member 221, and the second positioning hole 131 is aligned with the second positioning member 31;

[0059] S2: Lower the chain so that the first positioning piece 221 is inserted into the first positioning hole 111, and the second positioning piece 31 is inserted into the second positioning hole 131 at the same time. right in place;

[0060] S3: When the second positioning member 31 is inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com