Waterproof organic grouting material for repairing semi-rigid base course cracks and preparing method thereof

A technology of semi-rigid base and grouting materials, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesive additives, etc., can solve the problem of low compressive strength of polymers, slow curing time of single-component polyurethane, Can not be repaired and other problems, to achieve the effect of improving the degree of molecular cross-linking, improving water sensitivity, and good water damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A water-resistant organic grouting material for repairing semi-rigid base cracks and its preparation method

[0033] A water-resistant organic grouting material used for repairing cracks in semi-rigid bases, calculated in parts by mass, includes component A and component B, component A is 64 parts of rigid foam polyol and 23 parts of CASE polyol, 5 parts of lithium chloride, 4 parts of polypropylene glycol, 1 part of A-33L gel catalyst, 2 parts of A-1 starter catalyst, 0.5 parts of DEOA crosslinking agent, DF-853 high carbon alcohol ether emulsion type non-silicon defoaming Agent 0.5 parts; B component is 65 parts of PAPI-2 type isocyanate.

[0034] Its preparation method is as follows:

[0035] S1. Mix and stir the above components A for 1-2 hours to obtain mixture a;

[0036] S2. Add the above component B into the mixture a and mix evenly to obtain a water-resistant organic grouting material for repairing cracks in the semi-rigid base.

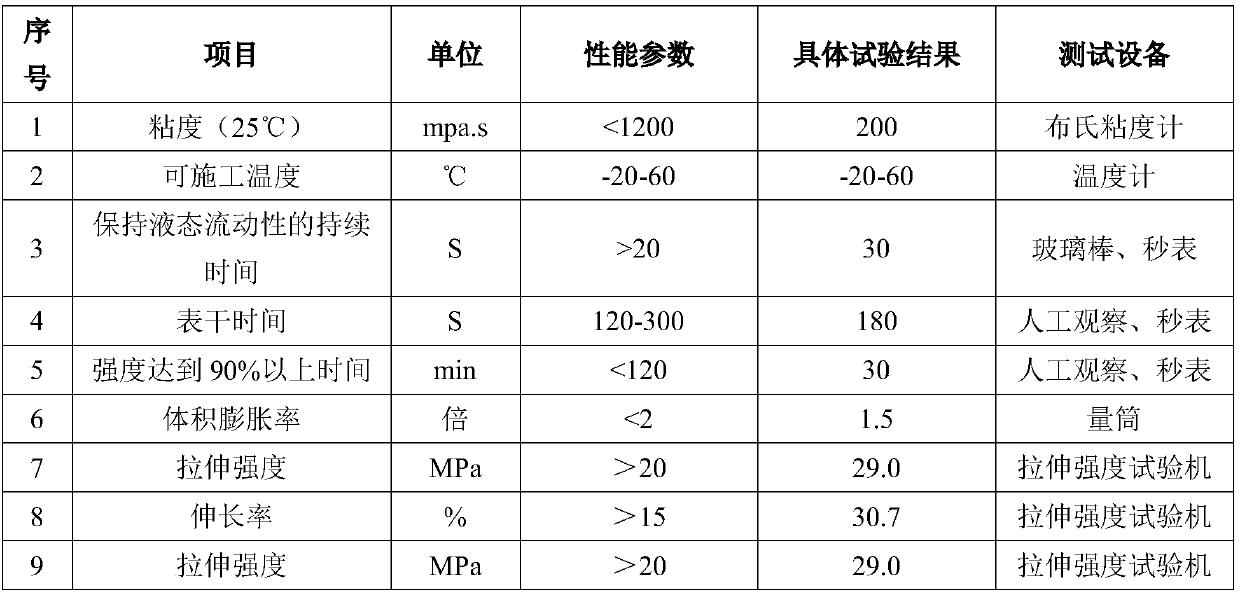

[0037] The basic...

Embodiment 2

[0040] Example 2: A water-resistant organic grouting material for repairing semi-rigid base cracks and its preparation method

[0041] A water-resistant organic grouting material used for repairing cracks in semi-rigid bases, calculated in parts by mass, includes components A and B, and component A is 57 parts of rigid foam polyol and 19 parts of CASE polyol, 10 parts of lithium bromide, 8 parts of polytetramethylene glycol, 2 parts of A-33E gel catalyst, 2 parts of NE-210 initiation catalyst, 1 part of TEOA crosslinking agent, DF-8531 high carbon alcohol ether emulsion type non-silicon defoaming agent 1 part of agent; B component is 100 parts of PAPI-2 type isocyanate.

[0042] Its preparation method is as follows:

[0043] S1. Mix and stir the above components A for 1-2 hours to obtain mixture a;

[0044] S2. Add the above component B into the mixture a and mix evenly to obtain a water-resistant organic grouting material for repairing cracks in the semi-rigid base.

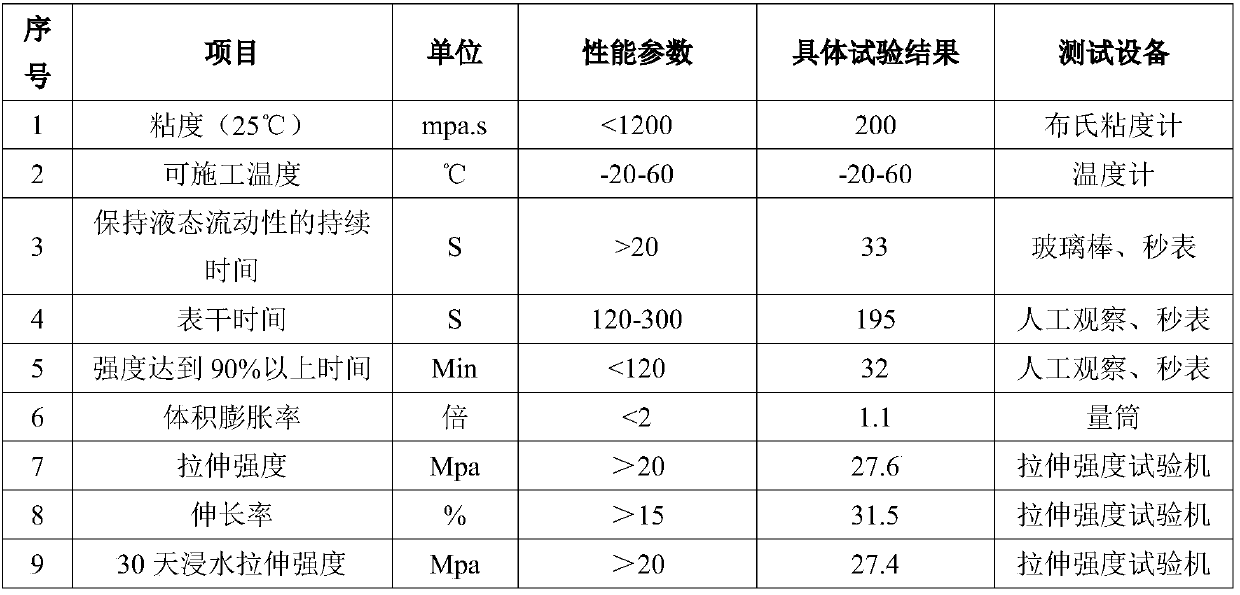

[004...

Embodiment 3

[0048] Example 3. A water-resistant organic grouting material for repairing semi-rigid base cracks and its preparation method

[0049] A water-resistant organic grouting material used for repairing cracks in semi-rigid bases, calculated in parts by mass, includes components A and B, component A is 61 parts of rigid foam polyol and 21 parts of CASE polyol, 3 parts of calcium chloride, 3 parts of lithium bromide, 6 parts of polytetramethylene glycol, 2 parts of NE-1070 gel catalyst, 2 parts of BL-11 starting catalyst, 0.5 parts of NGK crosslinking agent, 0.5 parts of 1,4-BG Cross-linking agent, 1 part of DF-8531 high carbon alcohol ether emulsion type non-silicon defoamer; B component is 80 parts of PAPI-2 type isocyanate.

[0050] Its preparation method is as follows:

[0051] S1. Mix and stir the above components A for 1-2 hours to obtain mixture a;

[0052] S2. Add the above component B into the mixture a and mix evenly to obtain a water-resistant organic grouting material ...

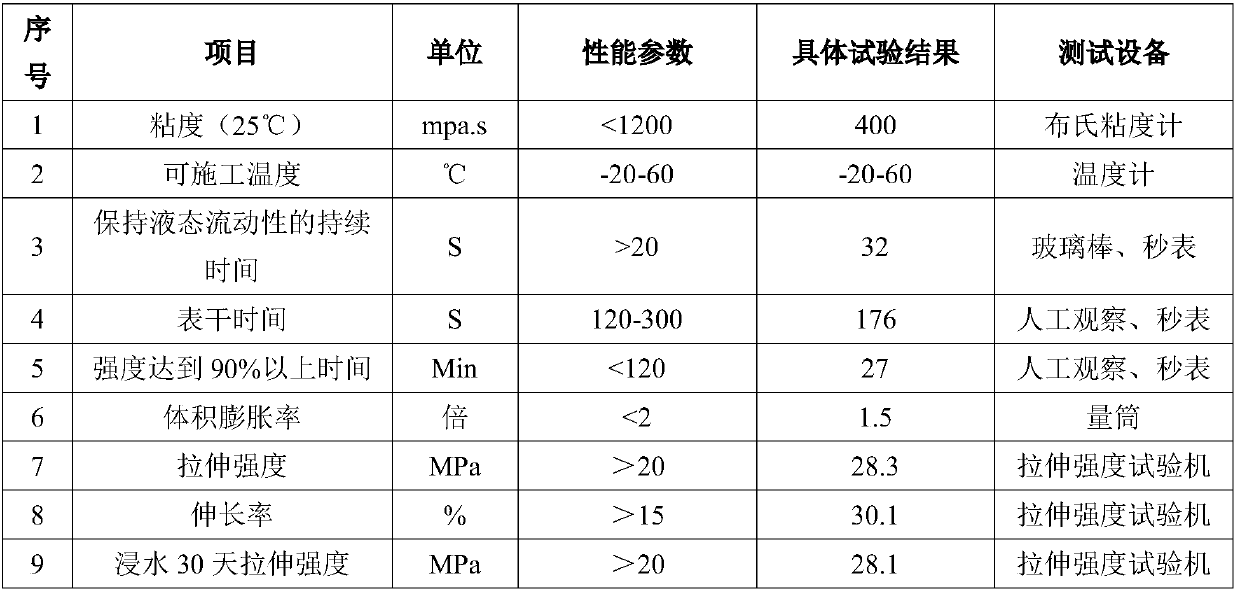

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com