Method for judging machinability of aircraft component compensation layer

A technology for aircraft parts and compensation layers, applied in sustainable transportation, instruments, geometric CAD, etc., can solve problems such as insufficient machinability judgment methods, low efficiency, and slingshots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

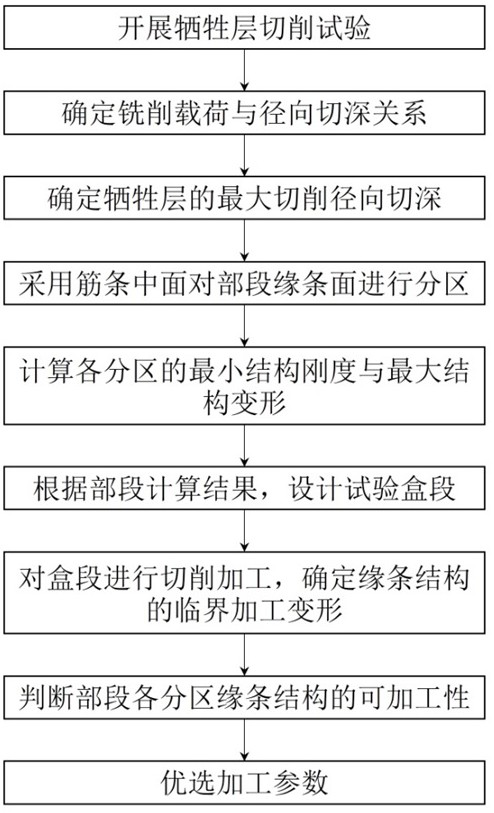

[0069] This embodiment discloses a method for judging the machinability of an aircraft component compensation layer, as a basic implementation of the present invention, such as figure 1 shown, including the following steps:

[0070] S1, design the cutting test, obtain the law between the cutting load and the cutting parameters through the cutting test, and determine the limit cutting parameters;

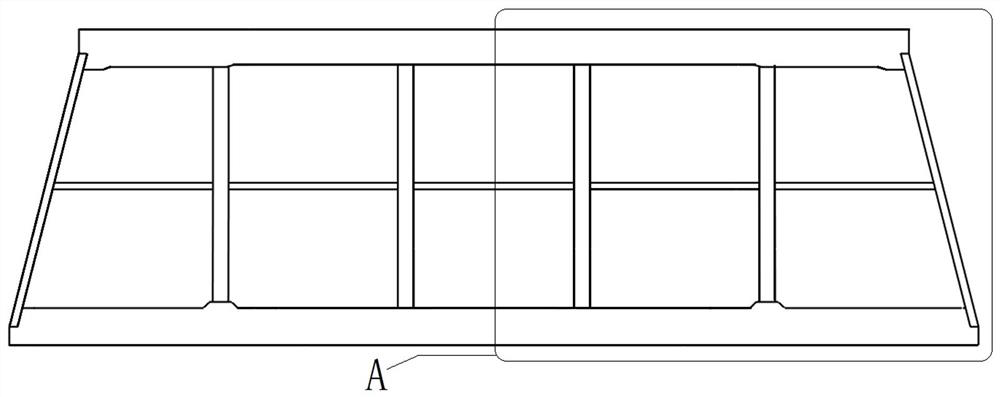

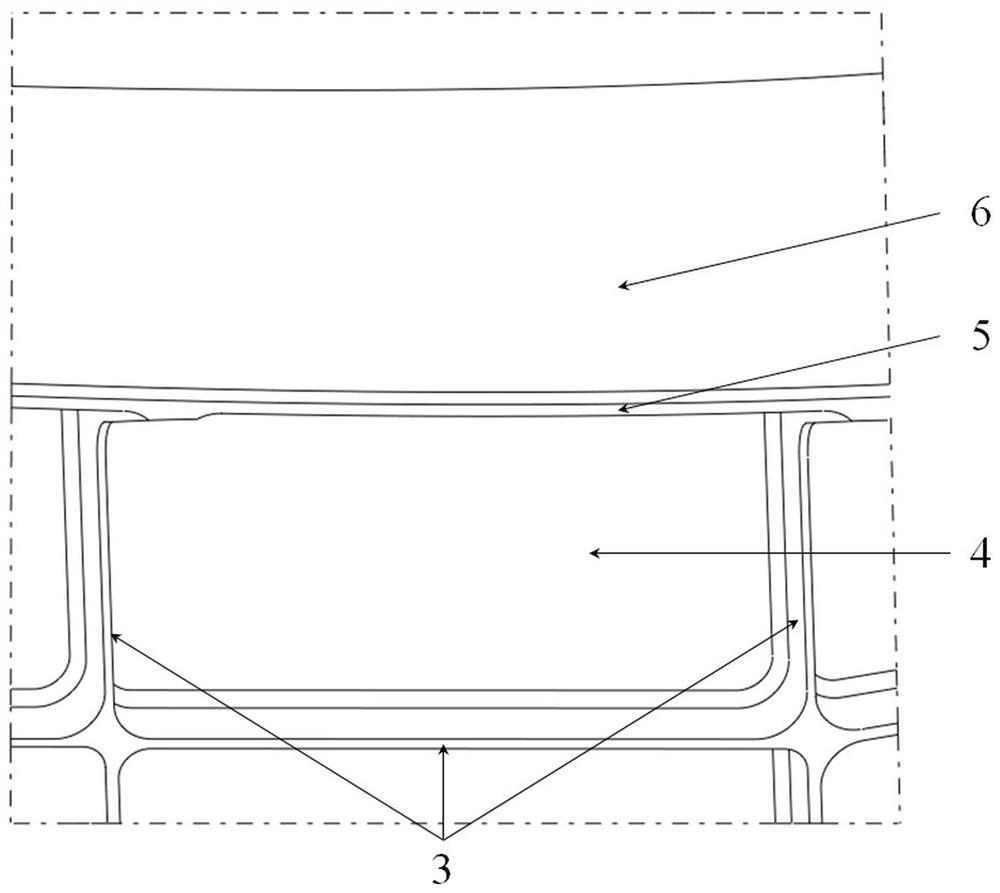

[0071] S2, combined with the structural characteristics of the section (the section structure is left-right symmetrical, bounded by the mid-plane of the web of the rib, frame and beam, and the edge of the edge), the processing surface of the compensation layer liner is divided to form Section processing area, such as Figure 6 and Figure 7 As shown, it is divided into 83 section processing areas, Figure 7 (1-1)~(1-83) in each represent a section processing area, and each section processing area has a relative stiffness minimum point ( Figure 8 As shown, the edge of the compe...

Embodiment 2

[0086] This example discloses a method for judging the machinability of an aircraft component compensation layer. As a preferred embodiment of the present invention, that is, in Example 1, the cutting test in step S1 is to select EW100 fiberglass composite material as the compensation layer lining Pad, carry out mechanical performance test, and calibrate the cutting mechanical performance of compensation layer pad, including the following steps:

[0087] S1-1, bonding a 2mm thick compensation layer liner on the aluminum alloy plate;

[0088] S1-2, the bottom of the aluminum alloy plate is connected to the dynamometer, and the dynamometer is directly below the pad of the compensation layer, such as Figure 5 shown;

[0089] S1-3, based on the numerical control system of the machine tool, set the processing parameters for the compensation layer liner. Among the processing parameters, the radial depth of cut ; Preferably, the cutting tool used by the machine tool for processin...

Embodiment 3

[0096] This example discloses a method for judging the machinability of an aircraft component compensation layer. As a preferred embodiment of the present invention, that is, in Example 2, the limit cutting parameter in step S1 is the maximum machinable value of the compensation layer liner. radial depth of cut , and the maximum radial depth of cut is based on the bond-peel strength of the compensation liner To determine the bond-peel strength of the compensation layer liner Including the tear-off strength between the FRP composite material and the glue and the tear-off strength between the aluminum alloy plate and the glue is , then the maximum radial depth of cut The determination includes the following steps:

[0097] S1-6, based on , combined with of axis, axis and range of axis orientations, obtain the formula and , then during the cutting process, the tangential cutting load borne by the compensation layer liner ;

[0098] S1-7, order and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com