Special fixture for welding multi-weld blade ring parts and welding deformation control method

A technology of ring-type parts and special fixtures, applied in the field of aero-engines, can solve the problems affecting the normal delivery of products, deformation of the blades and the inner flow channel of the outer ring, etc., to improve dimensional accuracy and performance, avoid scrap parts, and improve dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

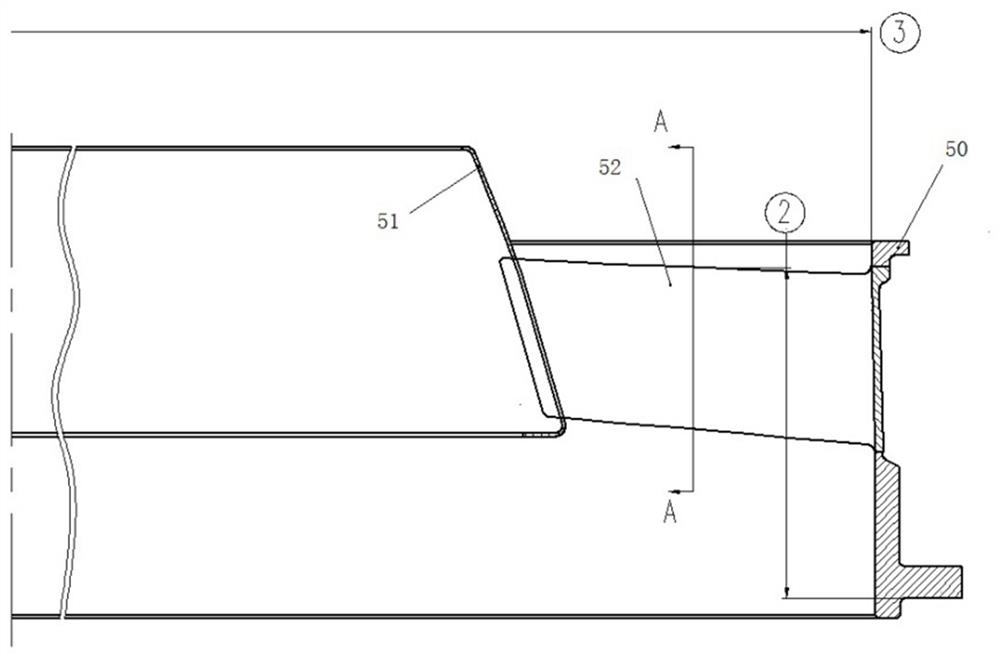

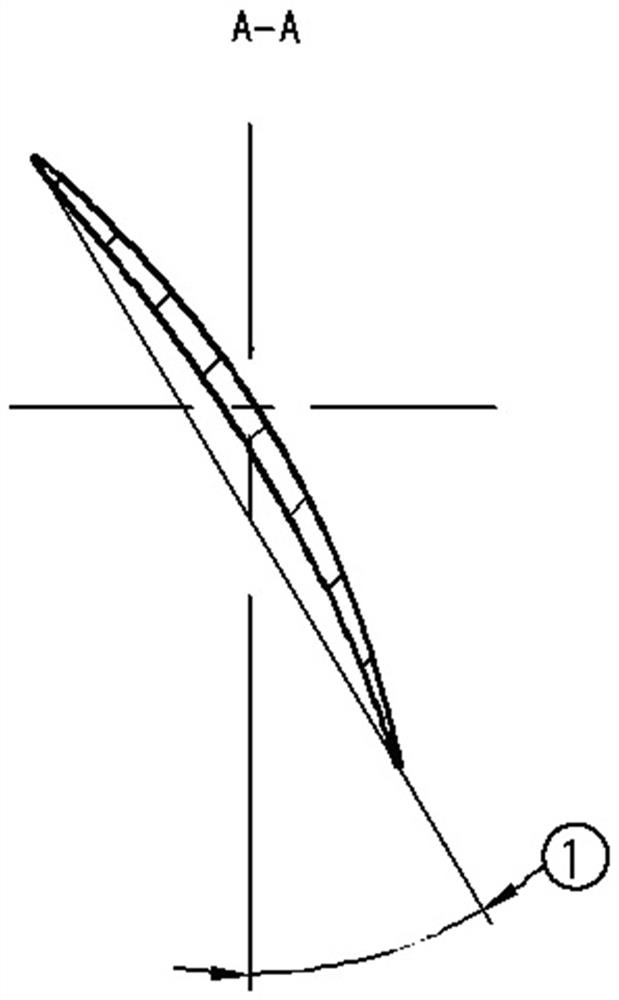

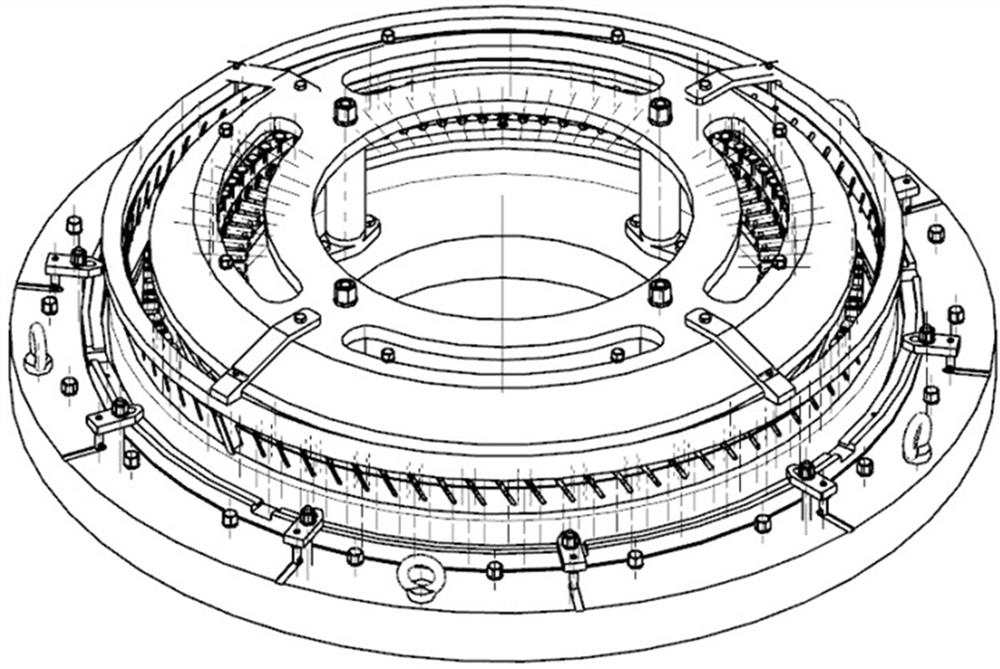

[0054] Such as Figure 3-7 Shown is a special fixture for welding leaf ring parts with multiple welds, including a chassis 1, a positioning ring 2, a support ring 3, an inner positioning ring 4, an inner support ring 5, a bushing 6, a bolt 7, a large pillar 8, an upper positioning Ring 9, baffle plate 10, lever 11, top plate 12, upper support ring 13, ejector rod 14, nylon pad 15, pressure ring 17, lifting ring screw 16, adjustment support 20, moving pressure plate 21, upper protection ring 22 and lower protection ring twenty three;

[0055] The large pillars 8 are uniformly arranged on the upper surface of the inner ring of the chassis 1 through hexagon head bolts;

[0056] The inner support ring 5 is arranged on the upper end surface of the inner ring of the chassis 1 by hexagon socket head screws, and the inner positioning ring 4 is arranged on the upper end surface of the inner ring of the chassis 1 outside the inner support ring 5, and fixed by hexagon socket head screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com