Direct-assembling type hollow crank assembly of bicycle and processing method of hollow crank

A direct-mounted, bicycle-based technology, applied in the crank structure, vehicle parts, transportation and packaging, etc., can solve the problems of complex and difficult processing, decreased crankset efficiency, and low degree of freedom, so as to avoid cumbersome disassembly and assembly and reduce weight , the effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

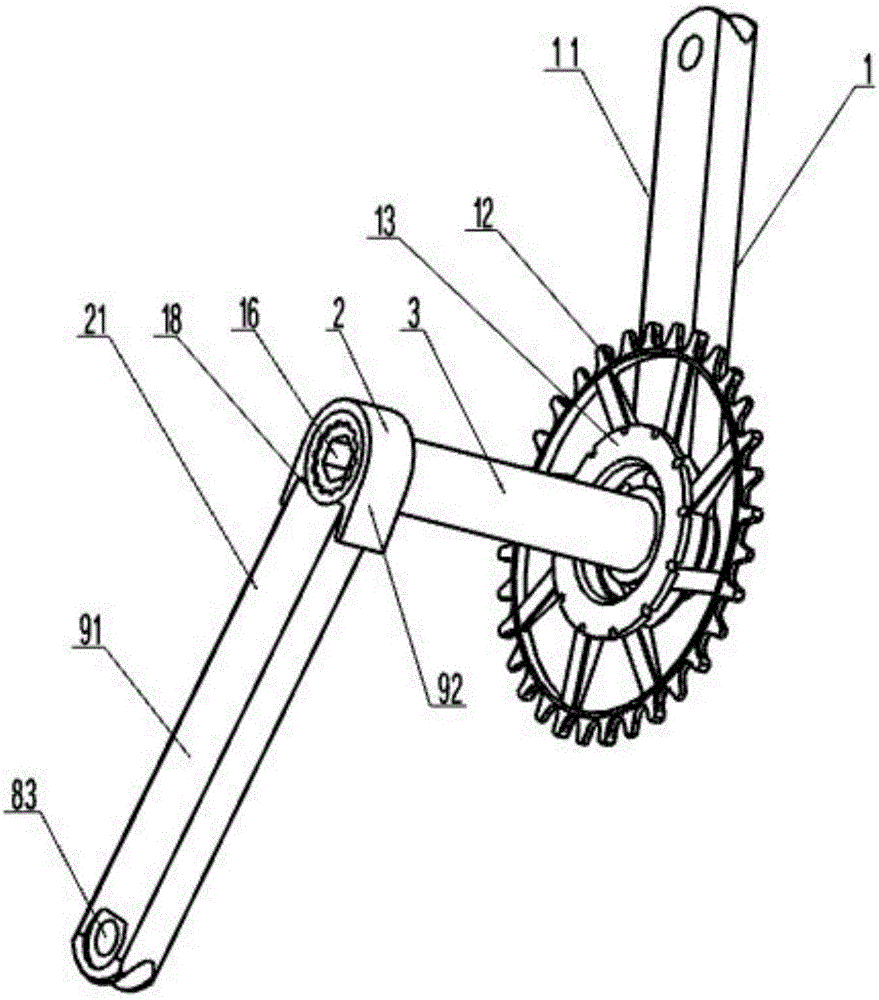

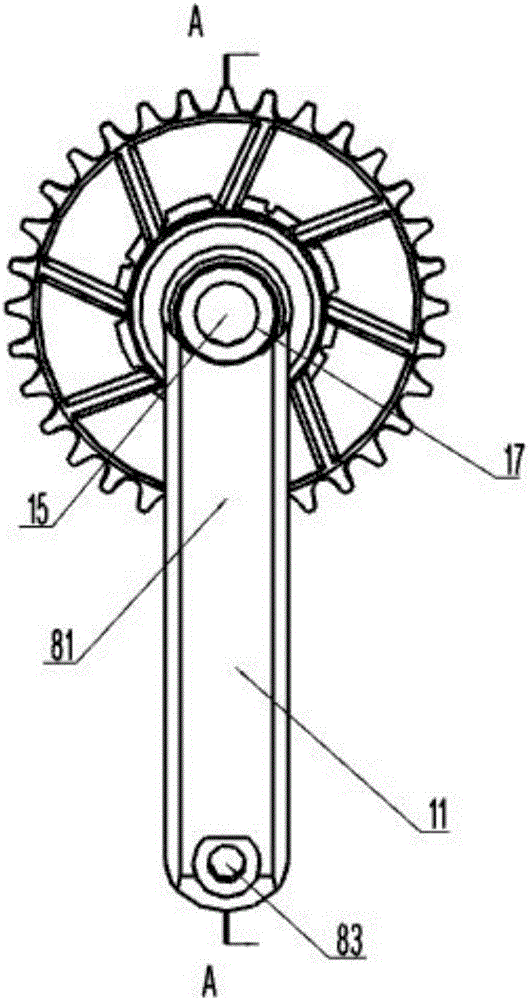

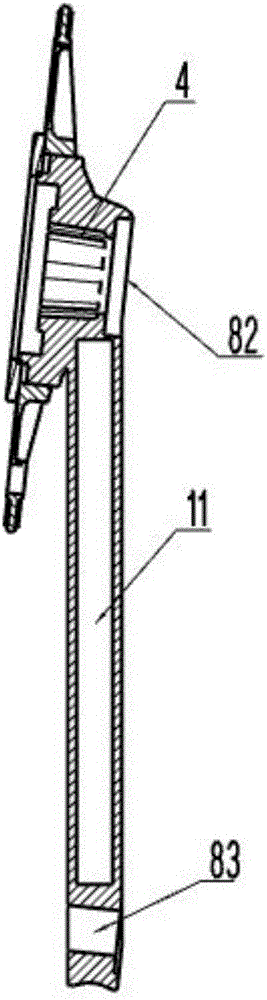

[0032] Such as figure 1 As shown, the present invention provides a direct-mounted hollow crank assembly for bicycles, comprising a right crank device 1, a left crank device 2 and a central axis shaft rod 3, the right crank device 1 includes a right crank 11 with a hollow structure, and the left crank device 2 includes a left crank 21 with a hollow structure, and the central axis rod 3 is arranged between the right crank 11 and the left crank 21. Such as image 3 and Figure 8 As shown, the right crank 11 includes a right crank rod 81 and a right crank head 82, and the right crank head 82 is located at the end of the right crank rod 81, and the left crank 21 includes a left crank rod 91 and a left crank head 92, and the left crank head 92 is located at the end of the right crank rod 81. The end of the left crank rod 91, the inside of the right crank rod 81 and the left crank rod 91 are all provided with the hollow structure, and the cavity extends from one end of the right cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com