Analog simulation test loading device with adjustable model size

A loading device, similar simulation technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of large size difference of similar models, expensive manufacturing cost, complicated operation, etc., to achieve controllability Effects that apply, avoid rigidity, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

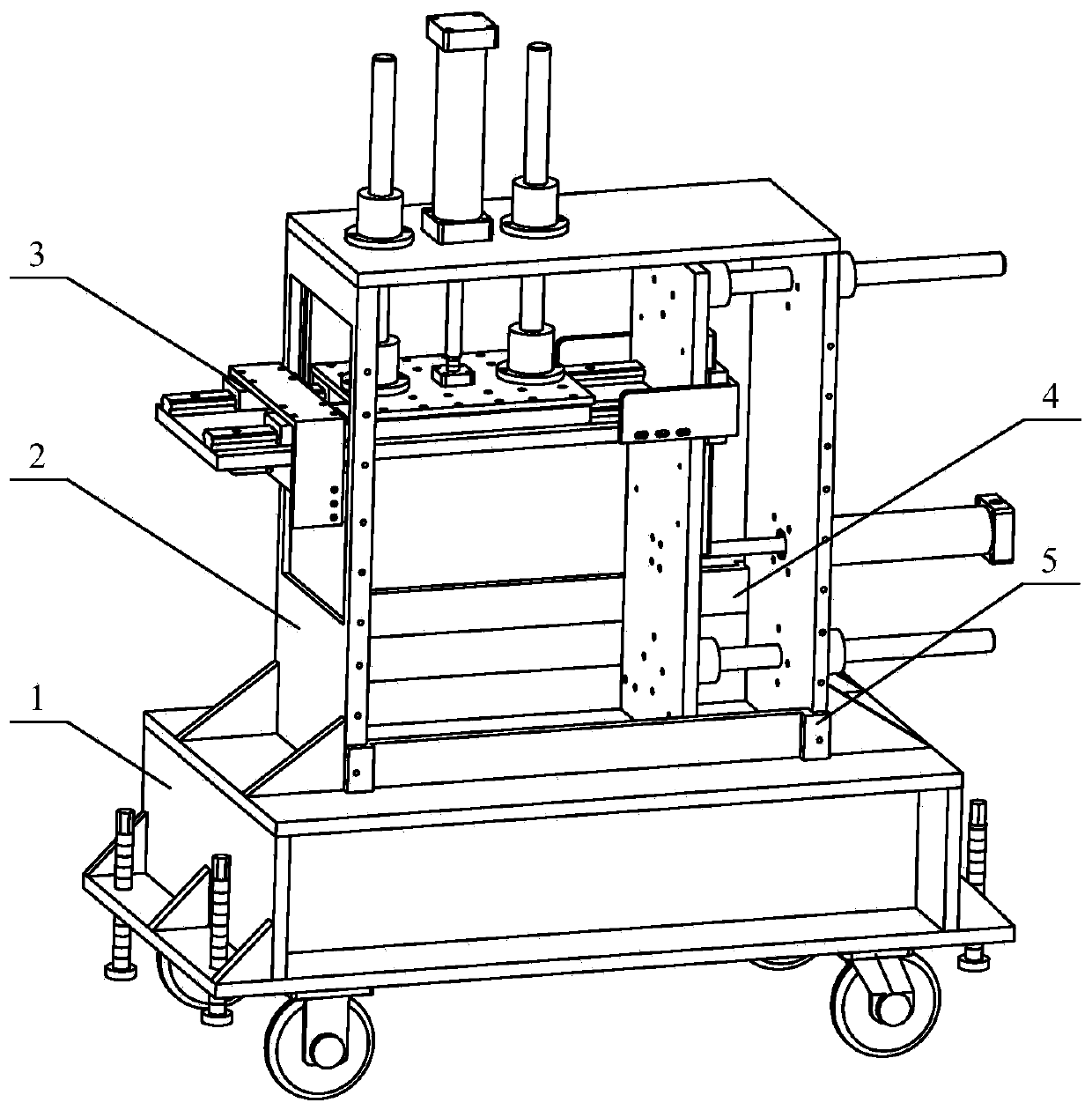

[0052] A similar simulation test loading device with adjustable model size. The similar test loading device as figure 1 As shown, it consists of a base 1, a jack mounting frame 2, a loading system 3, a rear side baffle 4 and a front side baffle 5.

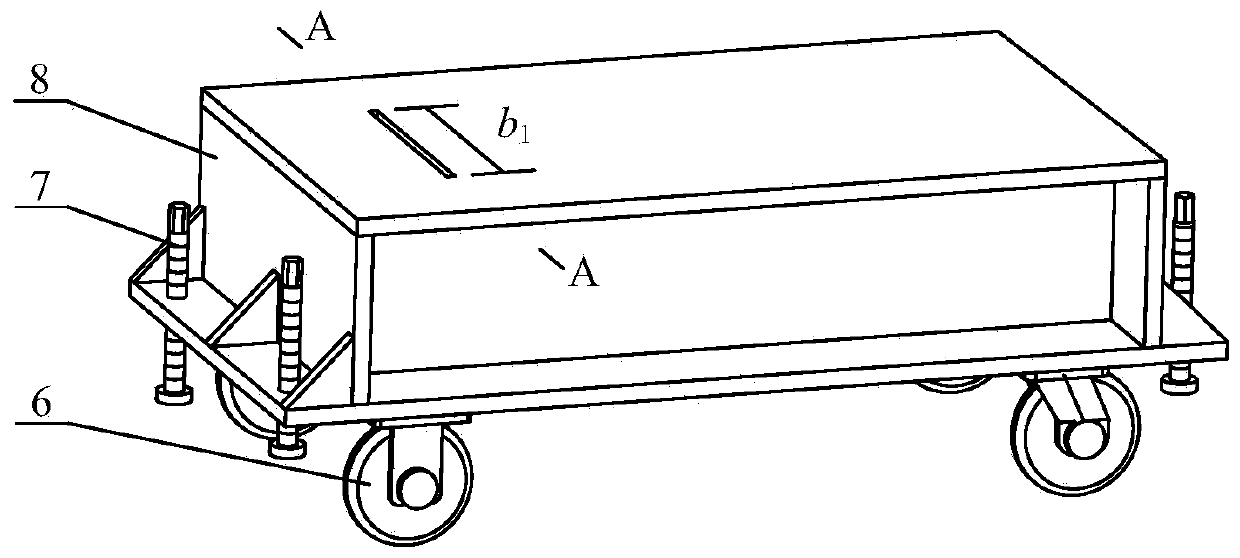

[0053] Such as figure 2 As shown, the base 1 is composed of a universal wheel 6 , an adjusting bolt 7 and a base box 8 . The base box 8 is a box structure formed by connecting a lower plate, a left side plate, a right side plate, a front side plate, a rear side plate and an upper plate. There is a strip hole near the left side of the upper plate, and the strip hole is set along the front and rear directions; the front side plate and the rear side plate are symmetrically fixed on the lower plate, and the front side plate and the rear side plate are located at the front end and the rear end corresponding to the strip hole . The two ends of the front side plate and the rear side plate are respectively fixed with the left side pla...

Embodiment 2

[0072] A similar simulation test loading device with adjustable model size. Except following technical parameter, all the other are identical with embodiment 1:

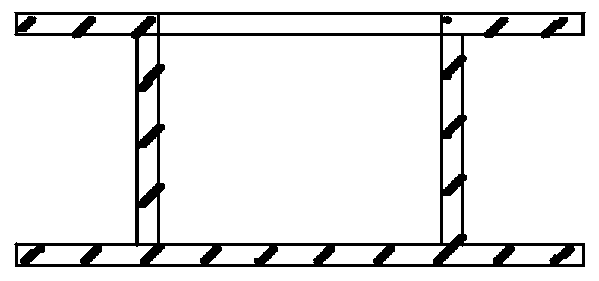

[0073] Such as figure 2 and image 3 As shown, the width of the lower plate, the width of the upper plate, the width of the left plate and the width of the right plate are equal, the length of the lower plate is equal to the sum of the length of the upper plate and 180-200mm, and the length b1 of the strip hole is the lower plate 0.5 to 0.62 times the width of the

[0074] Such as Figure 6 As shown, the width b2 of the right rectangular loading plate 34 is 0.32-0.35 times the length of the right rectangular loading plate 34, and the difference between the width b2 of the upper rectangular loading plate 26 and the right rectangular loading plate 34 is 6-8 mm.

[0075] The method of using this device is:

[0076] Step 1. Adjust the pouring space of similar models

[0077] Make the distance between the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com