Intermediate branch chain of fully-flexible fine operation platform

An operating platform and a fully flexible technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the difficult to ensure the accuracy and reliability of micro-operations, the destructive effects of operating objects and systems, and the precision limitations of microscopic equipment. and other problems, to achieve the effect of good operation accuracy and reliability, excellent dynamic performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

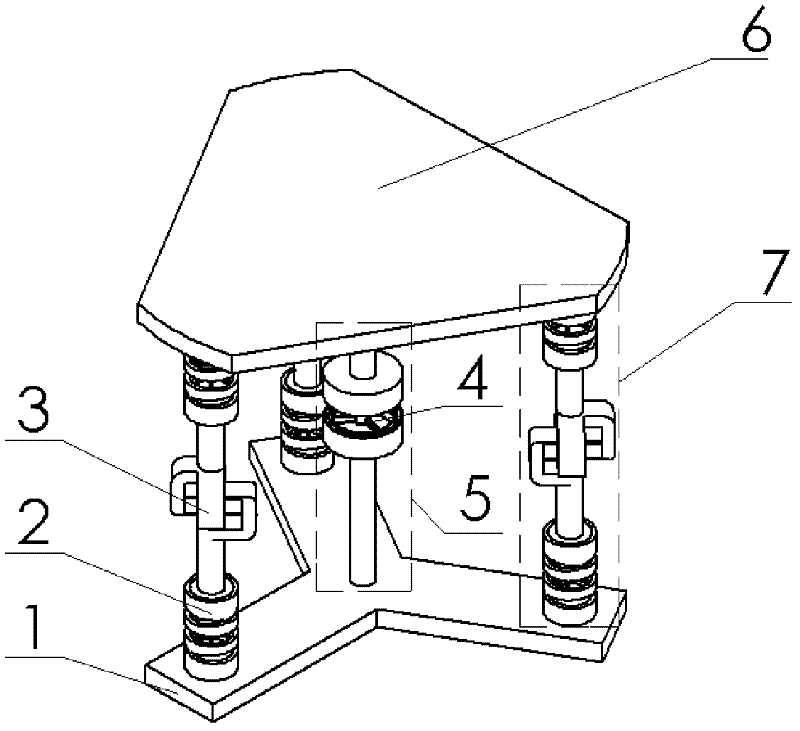

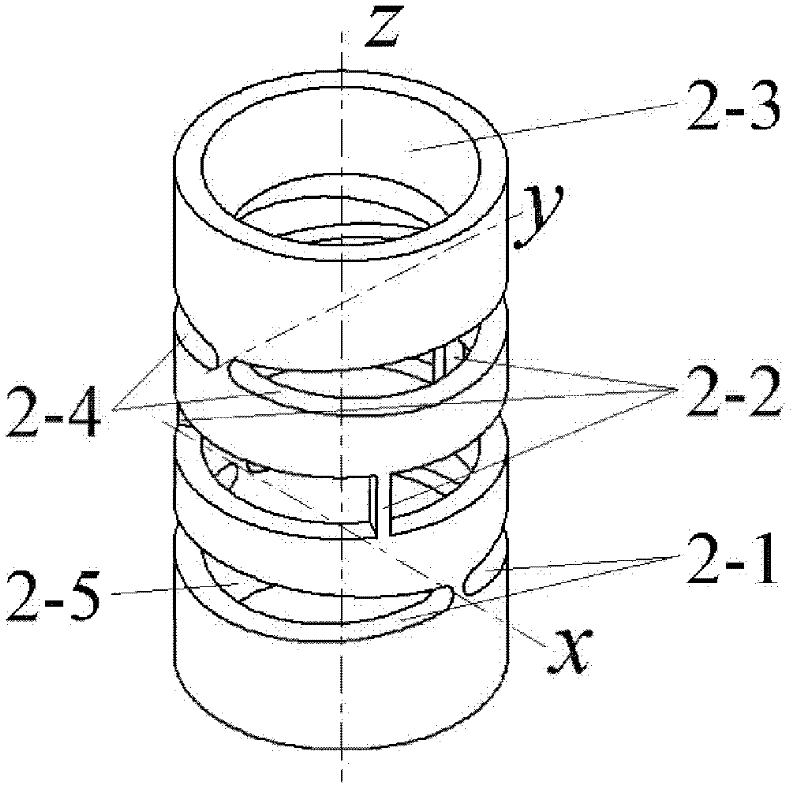

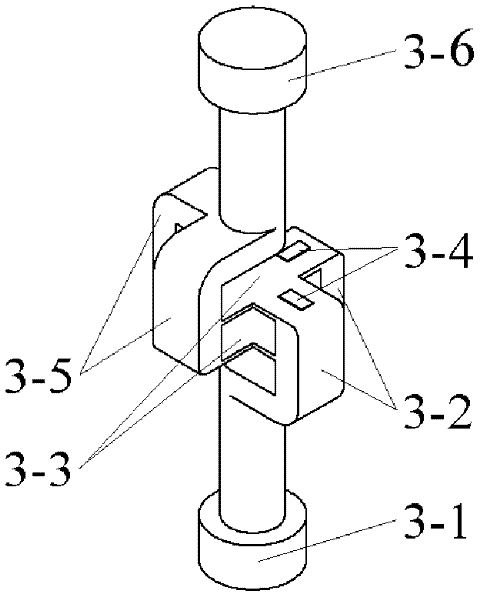

[0029] like figure 1 and Figure 4 , the middle part of the middle branch chain is provided with a four-degree flexible hinge, and the four-degree flexible hinge includes an upper connecting ring, a lower connecting ring and a central column;

[0030] The upper coupling ring is provided with a three-branch Y-shaped coupling piece, and the three branches of the Y-shaped coupling piece are all arranged on the same horizontal plane, the first branch is arranged along the x-axis, the second branch is arranged along the y-axis, and the third branch is arranged along the The axis is arranged in the direction of 135 degrees;

[0031] The lower connecting ring is provided with three radial sheet beams evenly distributed along the circumference; the three radial sheet beams are all installed on the lower end of the central column, and the upper end of the central column is connected to the bottom surface of the Y-shaped coupling piece.

[0032] Both ends of the middle branch chain ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com