Needle head separating mechanism for automatic needle head separator

A separation mechanism and automatic separation technology, applied in the direction of needles and instruments introduced into the body, can solve the problems of affecting the clamping degree, wear, and large rigid friction between the guide block and the needle puller, so as to avoid excessive rigidity and shorten the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

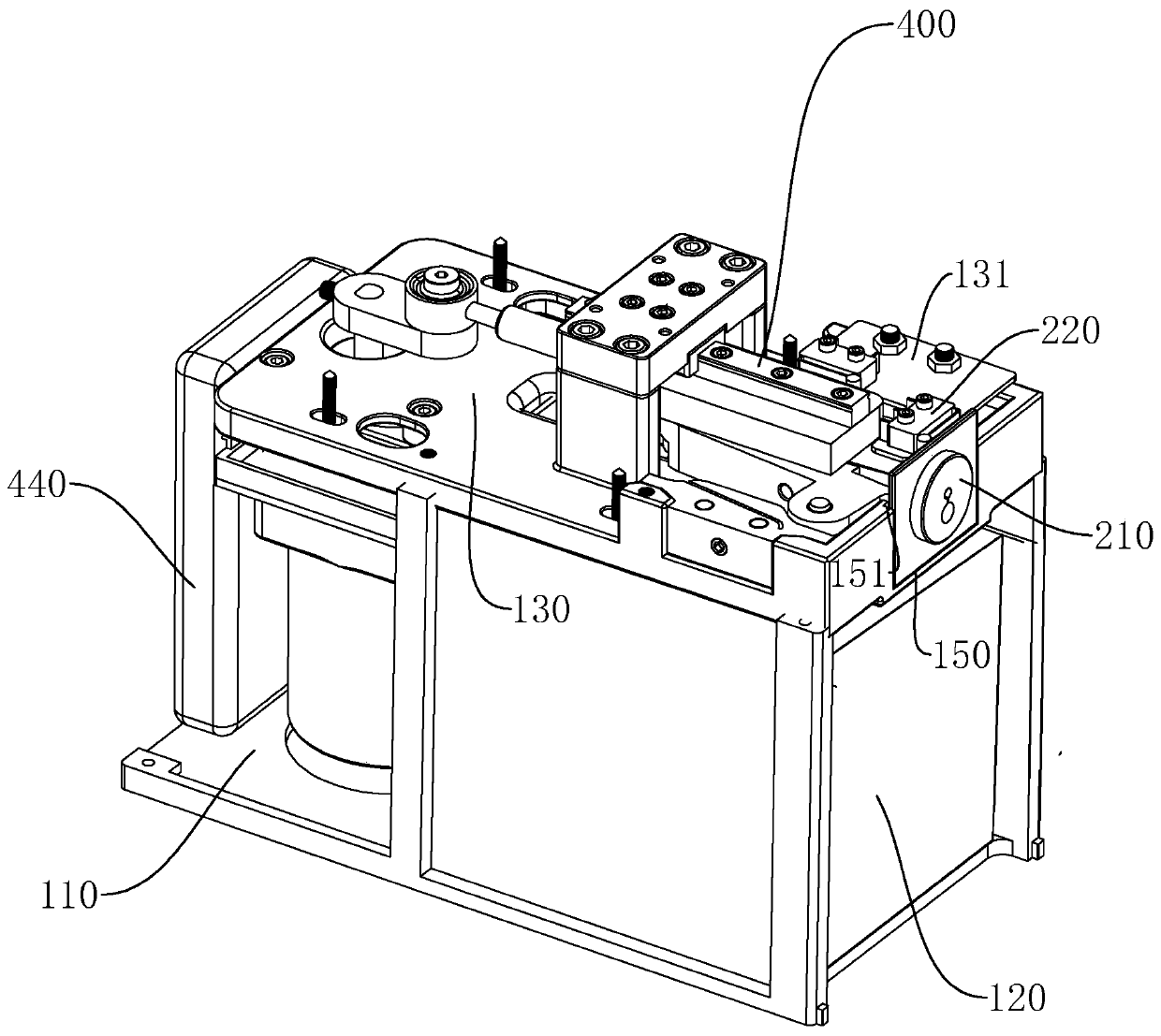

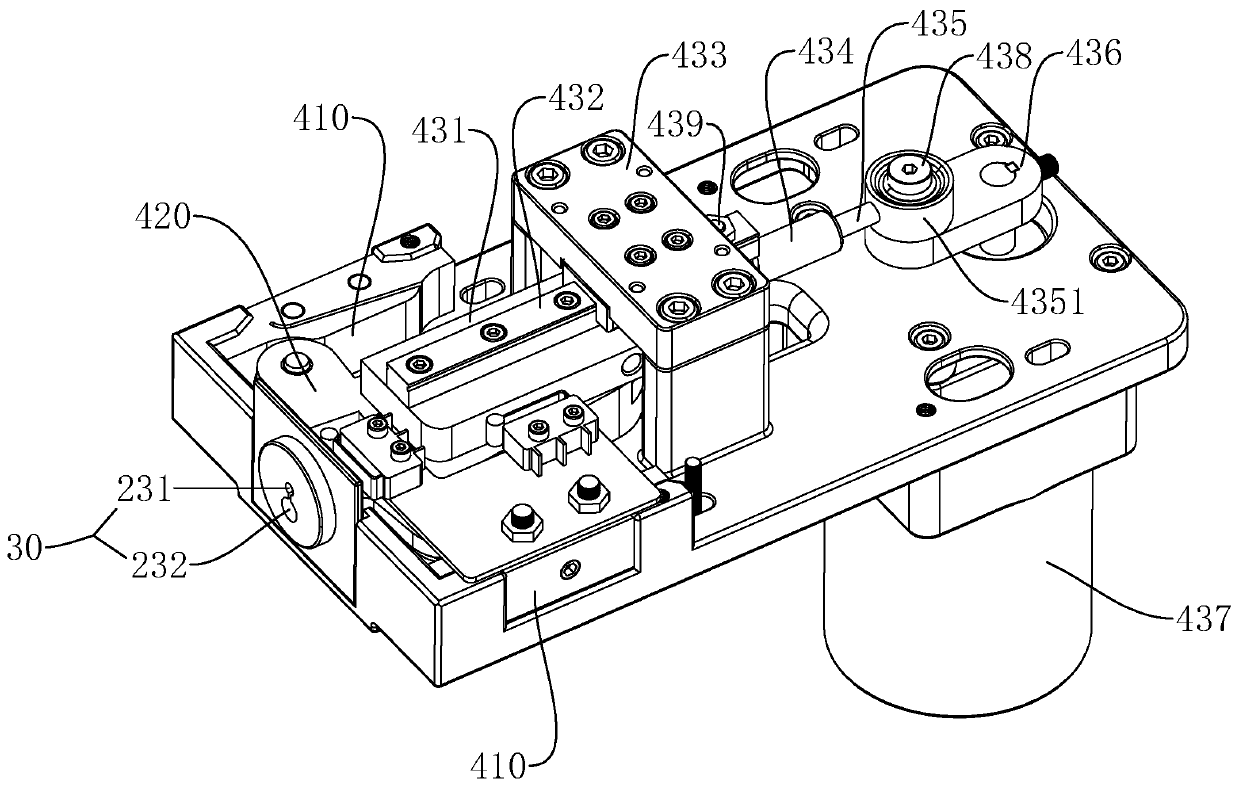

[0035] combine Figure 1 to Figure 7 The needle separation mechanism used in the automatic needle separation device of the present invention will be further described.

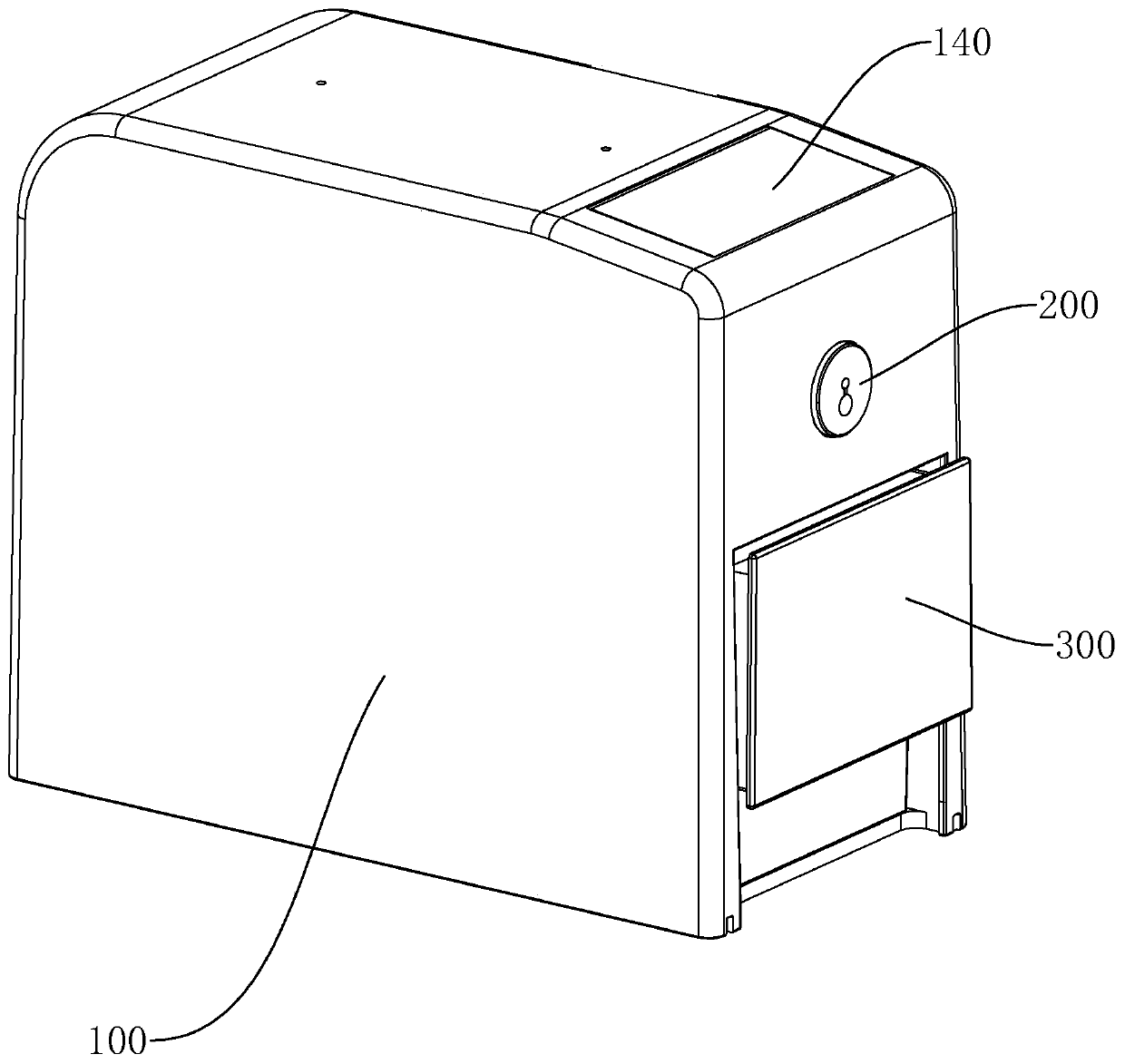

[0036] A needle separation mechanism for an automatic needle separation device, comprising a casing 100, a needle separation mechanism 400, a needle linkage switch 200 and a collection container 300;

[0037] The casing 100 has an installation cavity. In this embodiment, the installation cavity is divided into a front installation cavity 120 , a rear installation cavity 110 and an upper installation cavity 130 , and the installation cavities are separated by partitions.

[0038] The pin linkage switch 200 is installed on the side wall of the casing 100, and is electrically connected with the electrical components in the needle separation mechanism 400 to drive the needle separation mechanism 400 to operate. The pin linkage switch 200 has a pin Mouth 230;

[0039] The needle separation mechanism 400 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com