Brush-type circular seal

A technology of brush seals and round brushes, applied in the direction of engine seals, passing components, engine components, etc., can solve problems such as large dimensional tolerances, lack of rotation retention, and lack of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

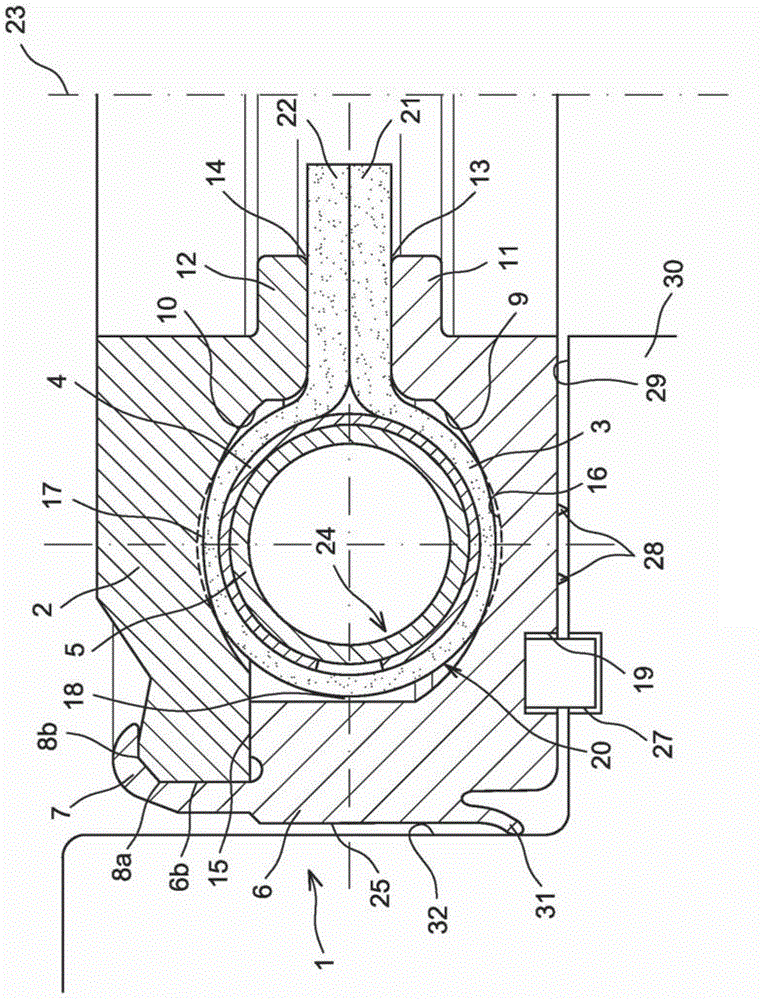

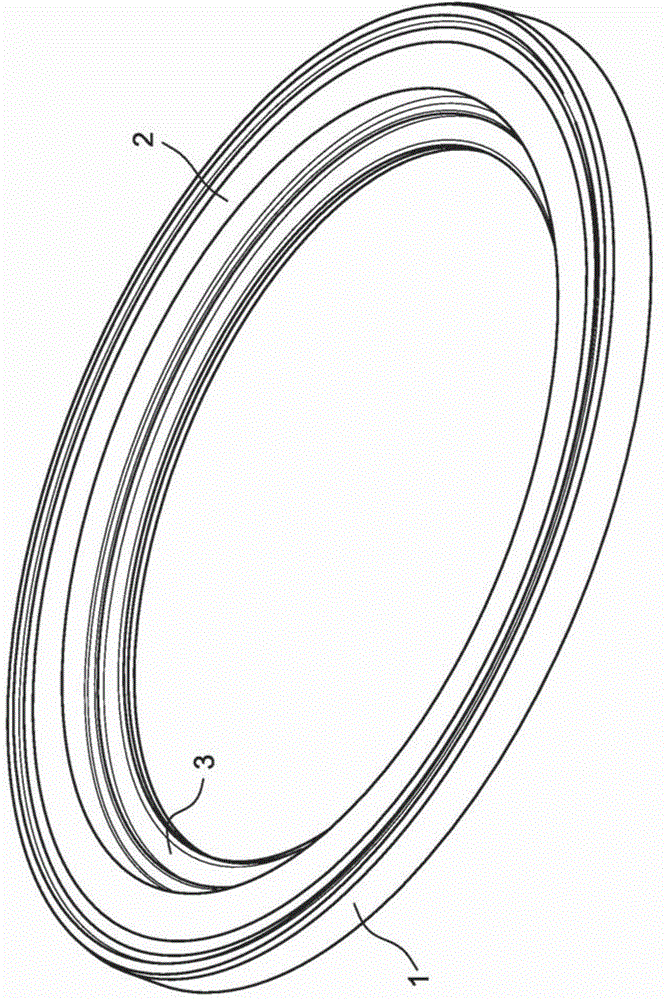

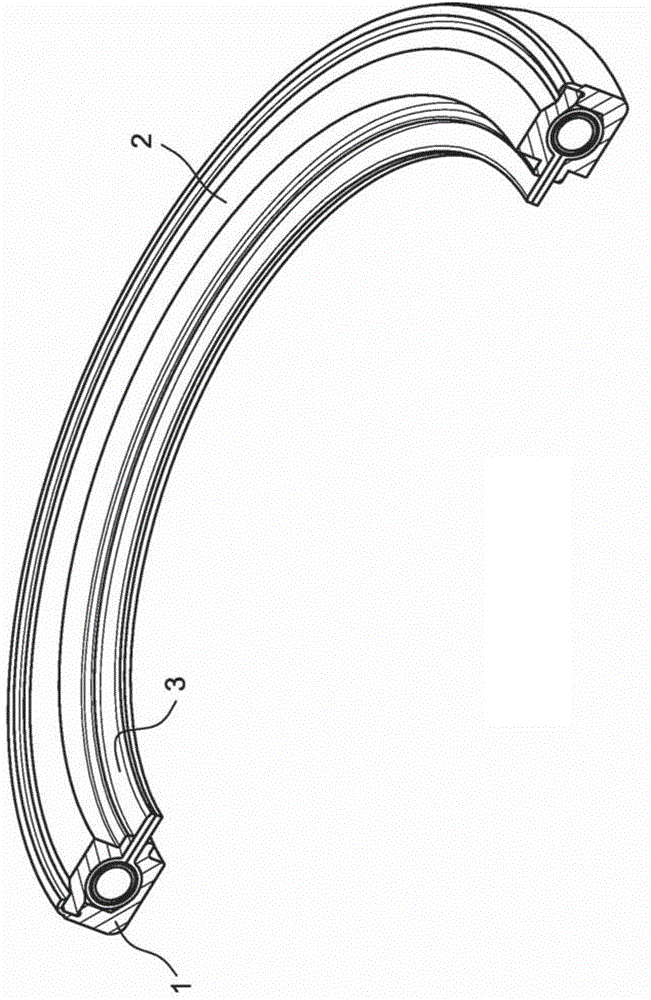

[0023] The illustrated brush seal is circular about a central axis 23 . Firstly, the brush seal comprises a lower housing 1 (according to the selected representation here for the drawing). The brush seal also comprises a composite structure consisting of a layer of bristles 3 and a core 24 . The core here has a hollow section and consists of a helical metal spring 5 which is wound in a ring around the seal and a metal cover 4 which has a C-shaped open section and which surrounds and protects the spring 5 . Such seals are known and in particular under the trademark Make a sale. The invention in its preferred embodiment incorporates a core; however other embodiments of the core are possible, eg comprising only the cover 4, which provides greater flexibility. The bristle layer 3 has a surrounding portion 20 wound around a core 24 and parallel strands 21 and 22 pointing radially inwards and having a sealing effect. The largest diameter of the winding 20 is referred to as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com