Compression mechanism and scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of compressors and scroll compressors, can solve the problems of deformation, low strength and rigidity, and cracking of compression parts, and achieve reduced thickness, high strength and rigidity, and increased Effect of Suction Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

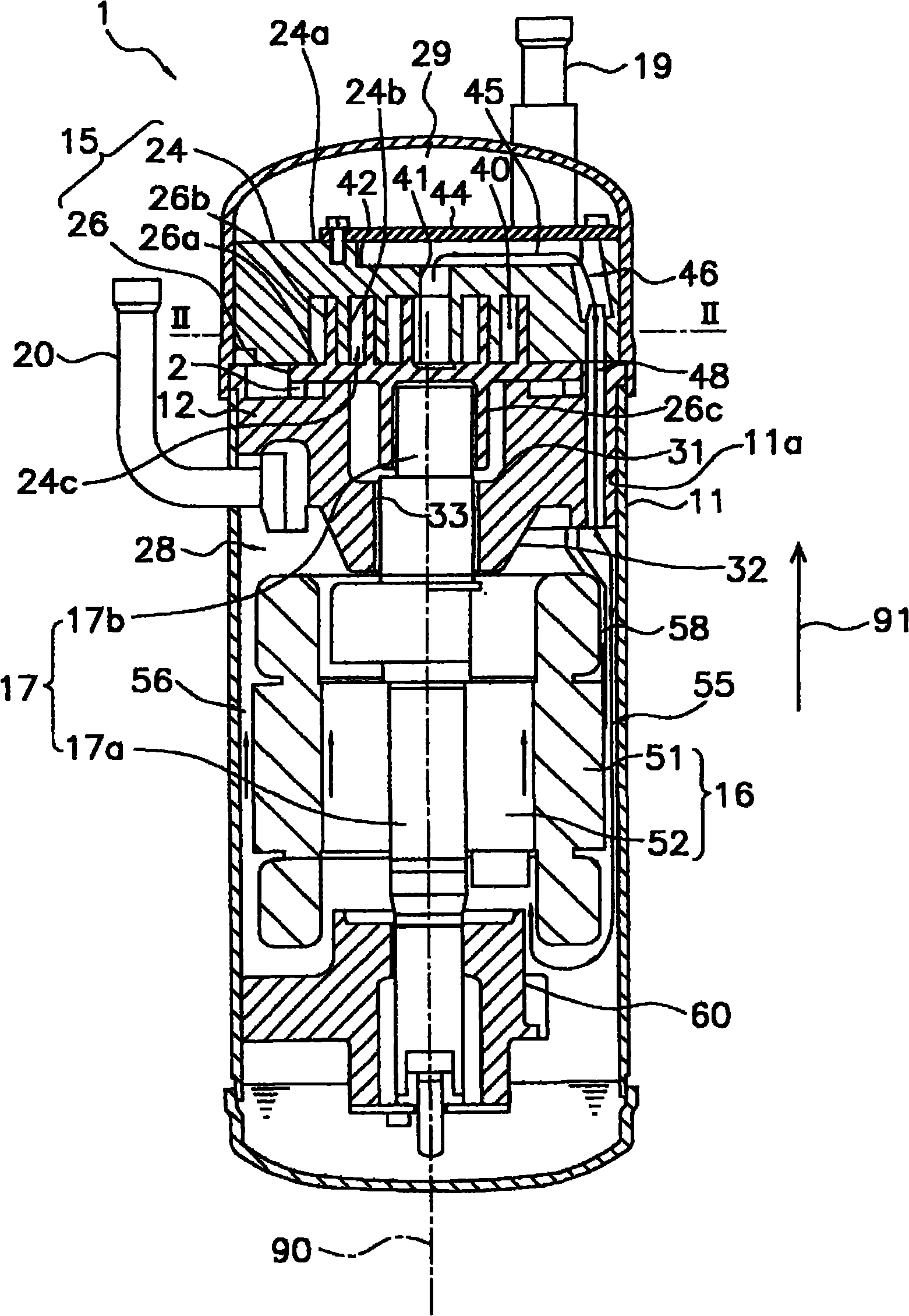

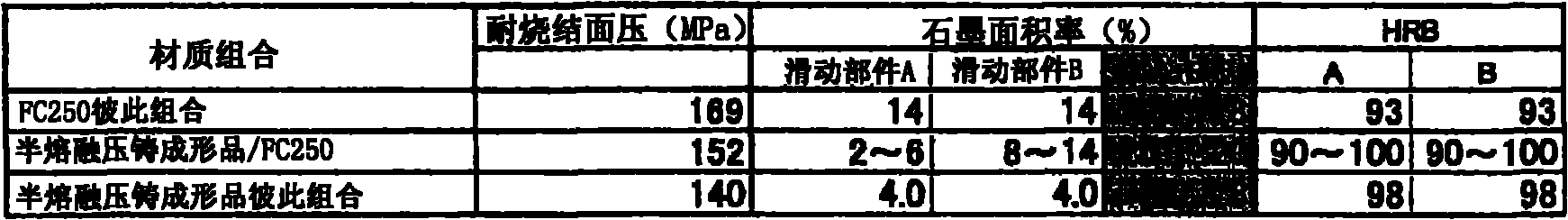

[0082] In the compression mechanism 15 of the present embodiment, the materials used for the fixed scroll 24 and the movable scroll 26 are different from each other.

[0083] Specifically, either one of the fixed scroll 24 and the movable scroll 26 is a molded product formed by molding cast iron by a semi-molten die casting method (hereinafter referred to as "semi-moltendie cast molding"). . Able to adopt a tensile strength of 600N / mm in semi-molten die-casting molded products 2 More than 900N / mm 2 The following components.

[0084] And, the other side is gray cast iron. Gray cast iron products can adopt a tensile strength of 250N / mm 2 More than but less than 300N / mm 2 parts. This is because the strength and rigidity necessary for preventing deformation or cracking can be ensured. In addition, the tensile strength is 250N / mm 2 More than but less than 300N / mm 2 Gray cast iron products are standardized as FC 250 in JIS (Japanese Industrial Standards: Japanese Industrial...

no. 2 approach

[0105] In this embodiment, the shape of the compression mechanism 15 described in the first embodiment will be described.

[0106]

[0107] As described in the first embodiment, the strength and rigidity of the scroll member of the semi-molten die-cast molded product are increased by using the semi-molten die-cast molded product for either the fixed scroll 24 or the movable scroll 26 . Accordingly, the scroll member of the semi-molten die-cast molded product is less likely to be broken and less likely to be bent.

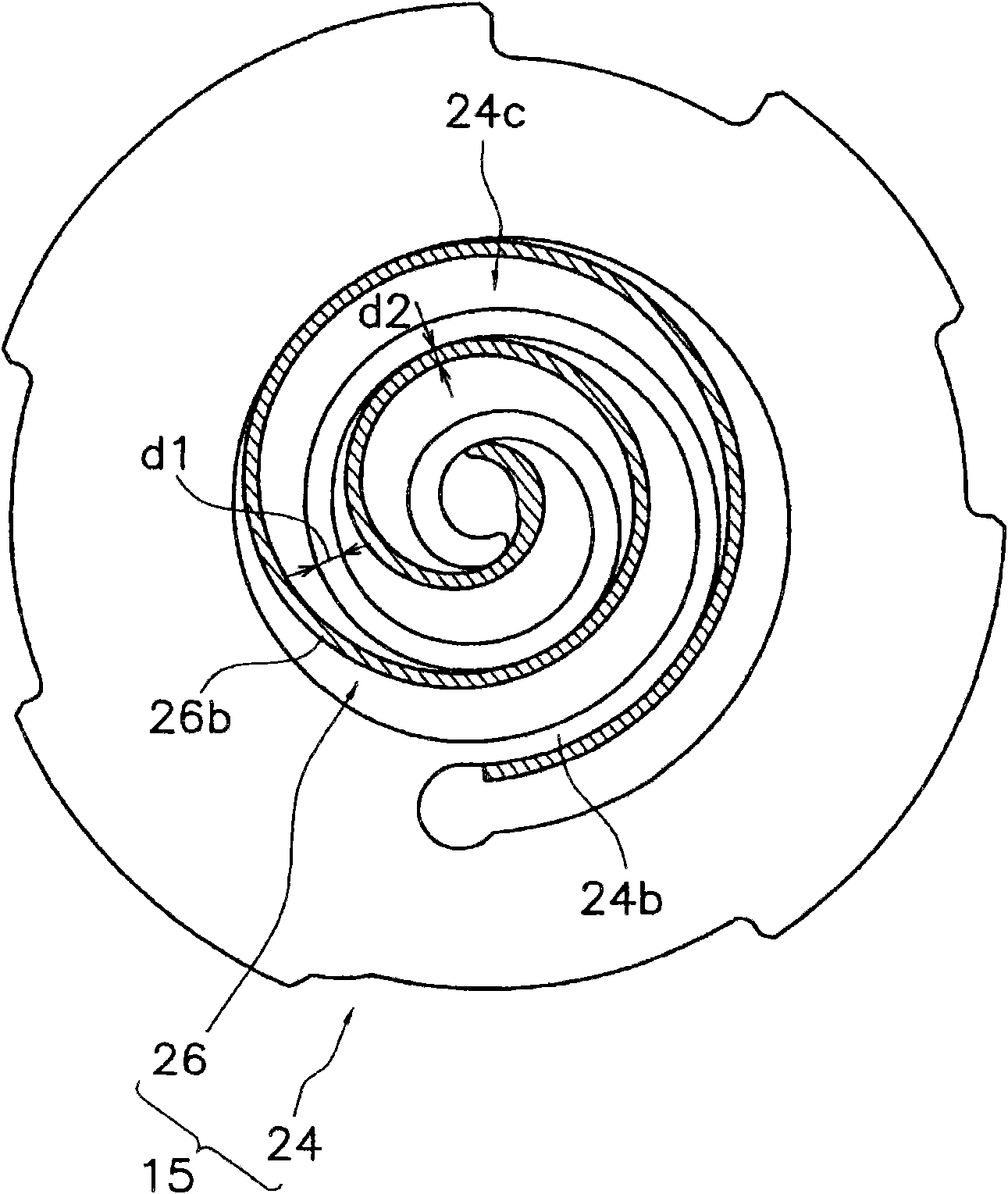

[0108] On the other hand, when the strength and rigidity of the scroll member increase, the thickness d2 (d1) of the compression member 26b (24b) of the semi-molten die-cast molded product can be reduced. However, for semi-molten die-cast molded products, its strength is about 2.4 to 3.6 times (600 to 900 MPa / 250 MPa) that of FC250, while its rigidity is only 1.6 to 1.7 times (175 to 190 GPa / 110 GPa) that of FC250. )degree. Therefore, if the thickness d2 (d1) at...

no. 3 approach

[0144] In this embodiment, the fixed scroll 24 is made of gray cast iron (FC250) and the movable scroll 26 is made of semi-molten die-cast compression mechanism 15, and the discharge hole (discharge hole) provided on the fixed scroll is described ).

[0145] First, regarding the release hole, use Figure 13 A conventional example will be described. The release hole 242 is disposed on the fixed scroll 24 . Specifically, it is disposed on the mirror plate 24a at a position between the swirl-shaped compression parts 24b. The release hole 242 communicates with the compression chamber (space 40 ) and the space 45 ( figure 1 ). In addition, the space 45 is located on the opposite side of the movable scroll 26 with respect to the mirror plate 24a of the fixed scroll 24 ( figure 1 ).

[0146] Conventionally, gray cast iron (FC250), for example, is used for either the fixed scroll 24 or the movable scroll 26, and the thickness d1 of the compression member 24b is substantially the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com