Numerical control winding apparatus and method for square glass fiber reinforced plastic air pipe

A fiberglass and square technology, applied in the field of CNC winding equipment for square fiberglass air ducts, can solve problems such as poor quality stability, hidden dangers to workers' health and safety, and environmental pollution, and achieve improved processing quality and efficiency, and a wide range of processing sizes. Avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

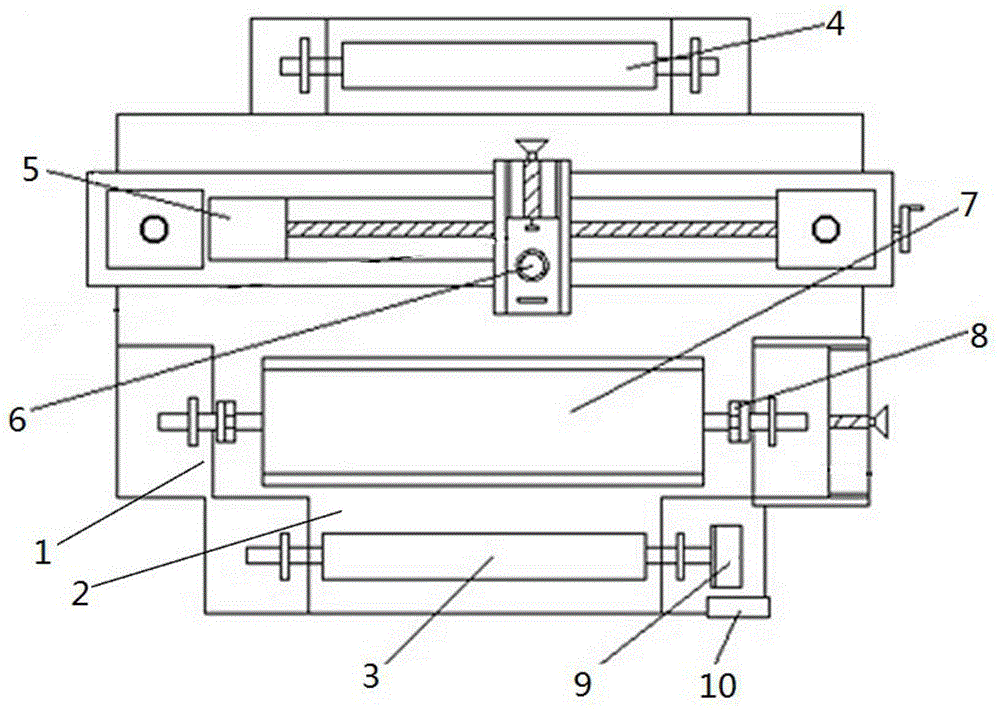

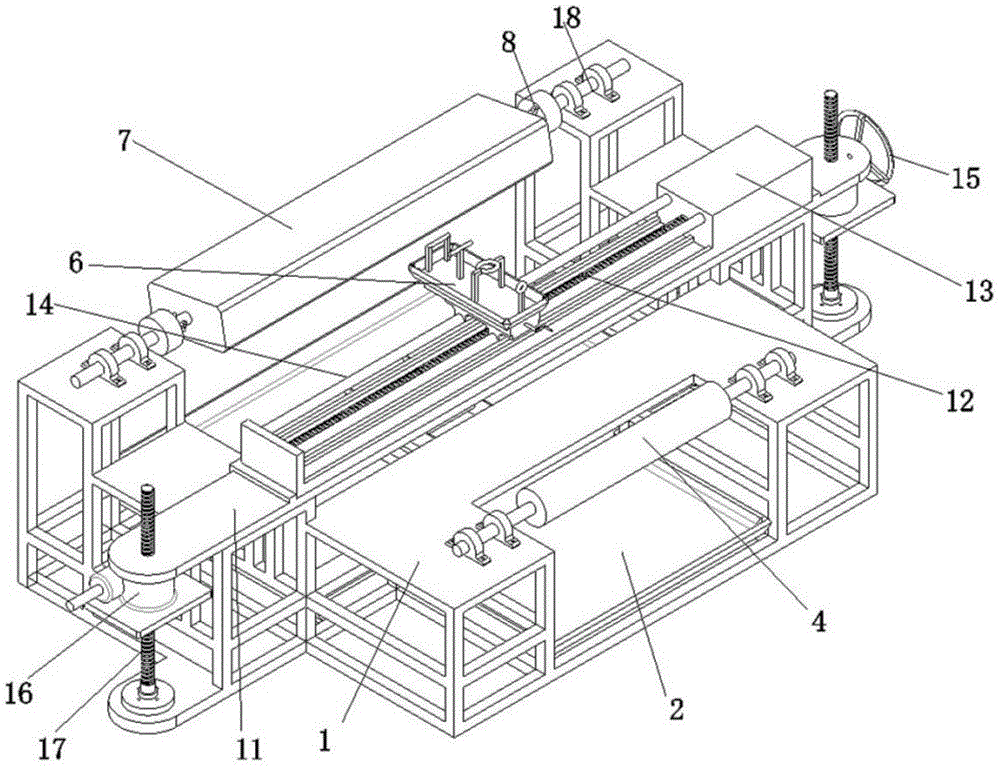

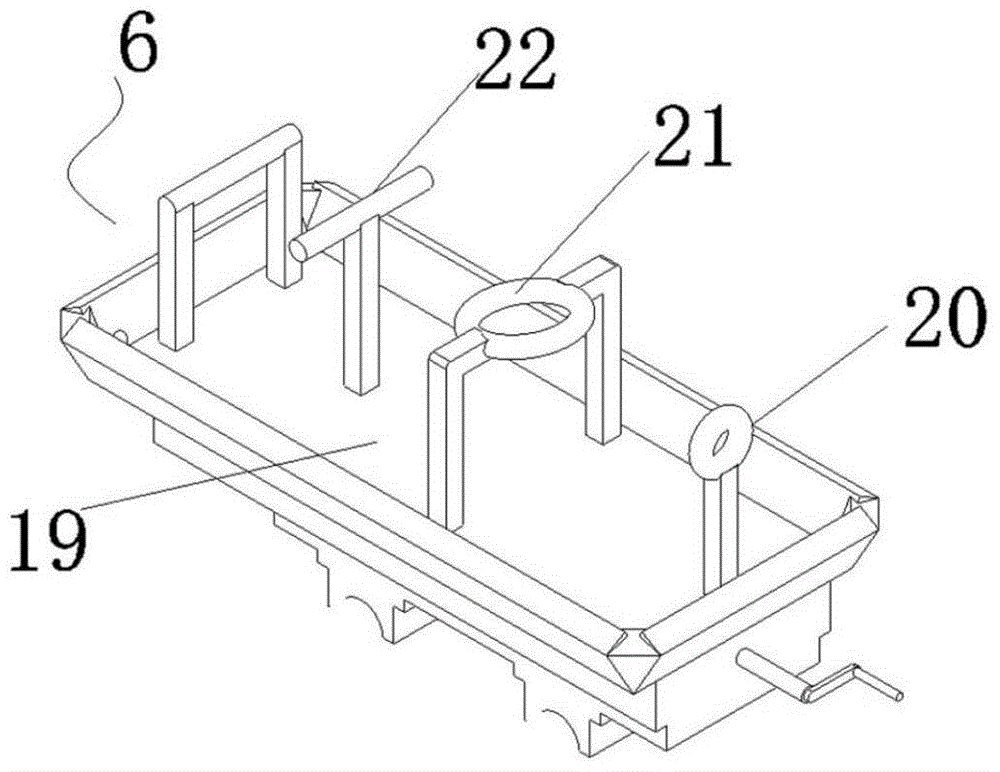

[0037] Such as figure 1 Shown is the top view of the numerical control winding equipment of square FRP air duct of the present invention; figure 2 Shown is the structural schematic diagram of the numerical control winding equipment of square glass fiber reinforced plastic air duct of the present invention; The numerical control winding equipment of a kind of square glass fiber reinforced plastic air duct of the present invention comprises frame 1, is arranged on frame 1 and connects successively by glass fiber yarn Pay-off roller 3, guiding device 4, cable arrangement 5, square mandrel winding device 7 and numerical control system, described cable arrangement 5 comprises the base 11 that is arranged on the frame, and described base 11 is provided with servo Motor 13, the screw mandrel 12 that is connected with servomotor 13, guide rail 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com