Automatic servo driving press machine

An automatic servo and press technology, which is applied in the field of presses, can solve the problems that the slider cannot hover at any position, the speed of the slider movement cannot be controlled, and the slider cannot move, so as to reduce the quality, control it easily and save money. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

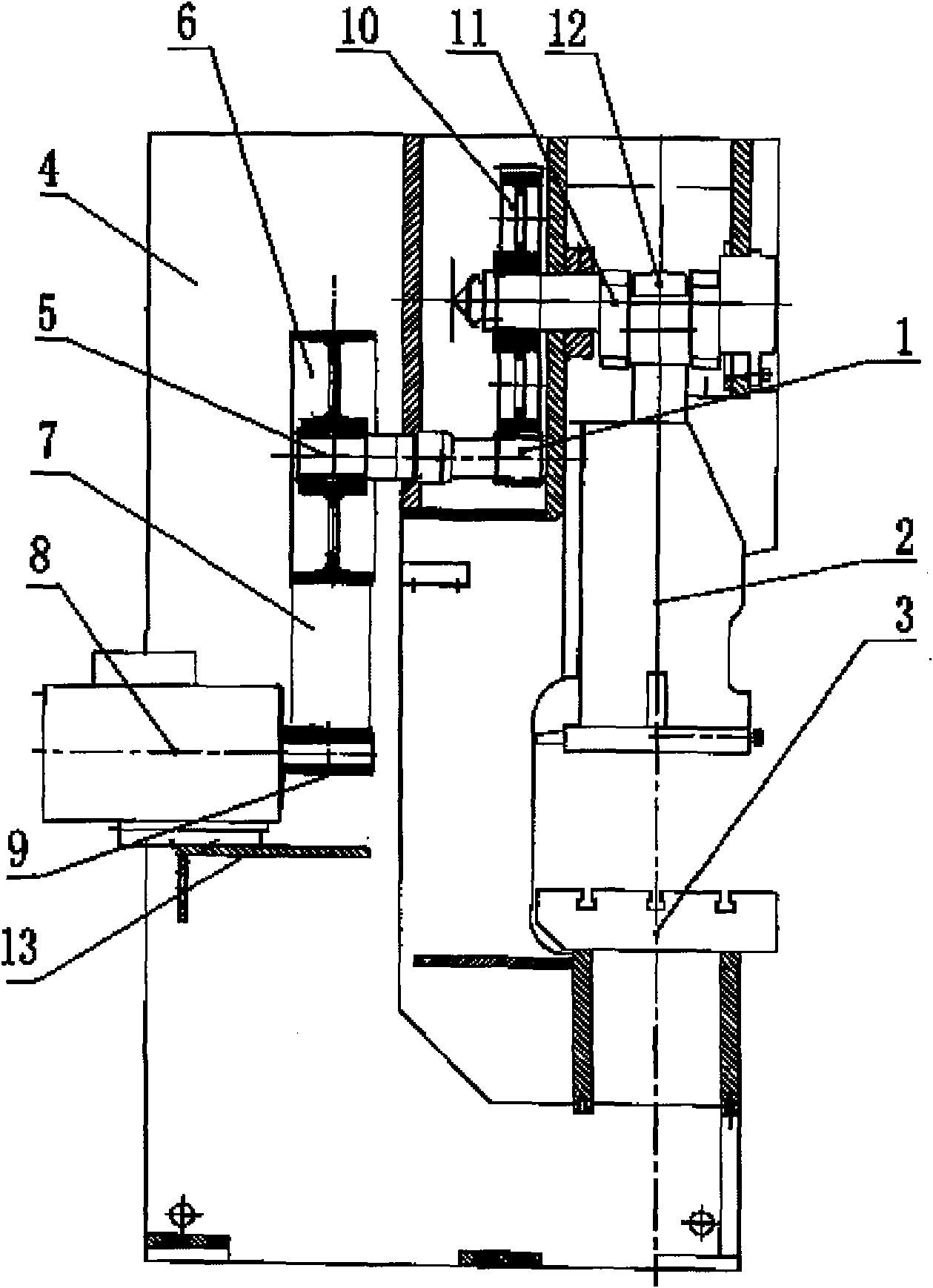

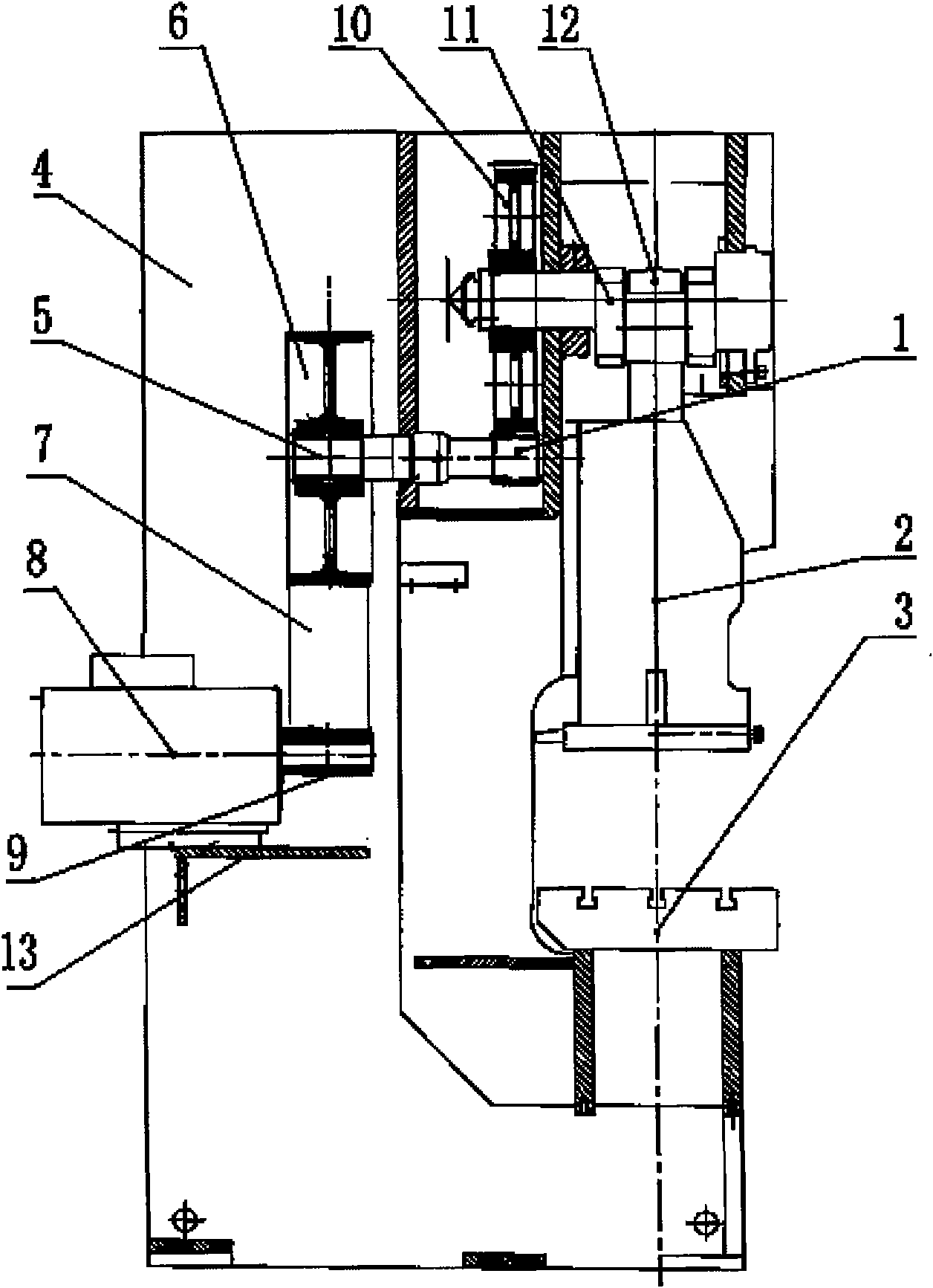

[0009] An automatic servo-driven press, comprising a slider (2) arranged above the workbench (3) of the press and connected to a connecting rod (12) that can slide vertically, and the other end of the connecting rod (12) is hinged on a crankshaft (11), the crankshaft (11) is connected with the driven gear (10) supported on the frame (4), the driven gear (10) is externally meshed with the driving gear (1), and the center of the driving gear (1) is fixed There is a gear shaft (5), the shaft end of the gear shaft (5) is provided with a driven wheel (6), and the rear opening position of the frame (4) is provided with a motor base (13), which is mounted on the motor base (13). There is a servo motor (8), the shaft end of the servo motor (8) is provided with a driving wheel (9), and the driving wheel (9) and the driven wheel (6) are connected through a synchronous belt (7). (8) rotate, and the torque is transmitted to the gear shaft (5) through the transmission of the driving wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com