Gear axis position adjustable mechanism

A shaft center and idler shaft technology, applied in the field of transmission, can solve the problem that the position of the idler shaft cannot be changed, and achieve the effects of improving assembly accuracy and transmission accuracy, reducing the number of disassembly and assembly, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

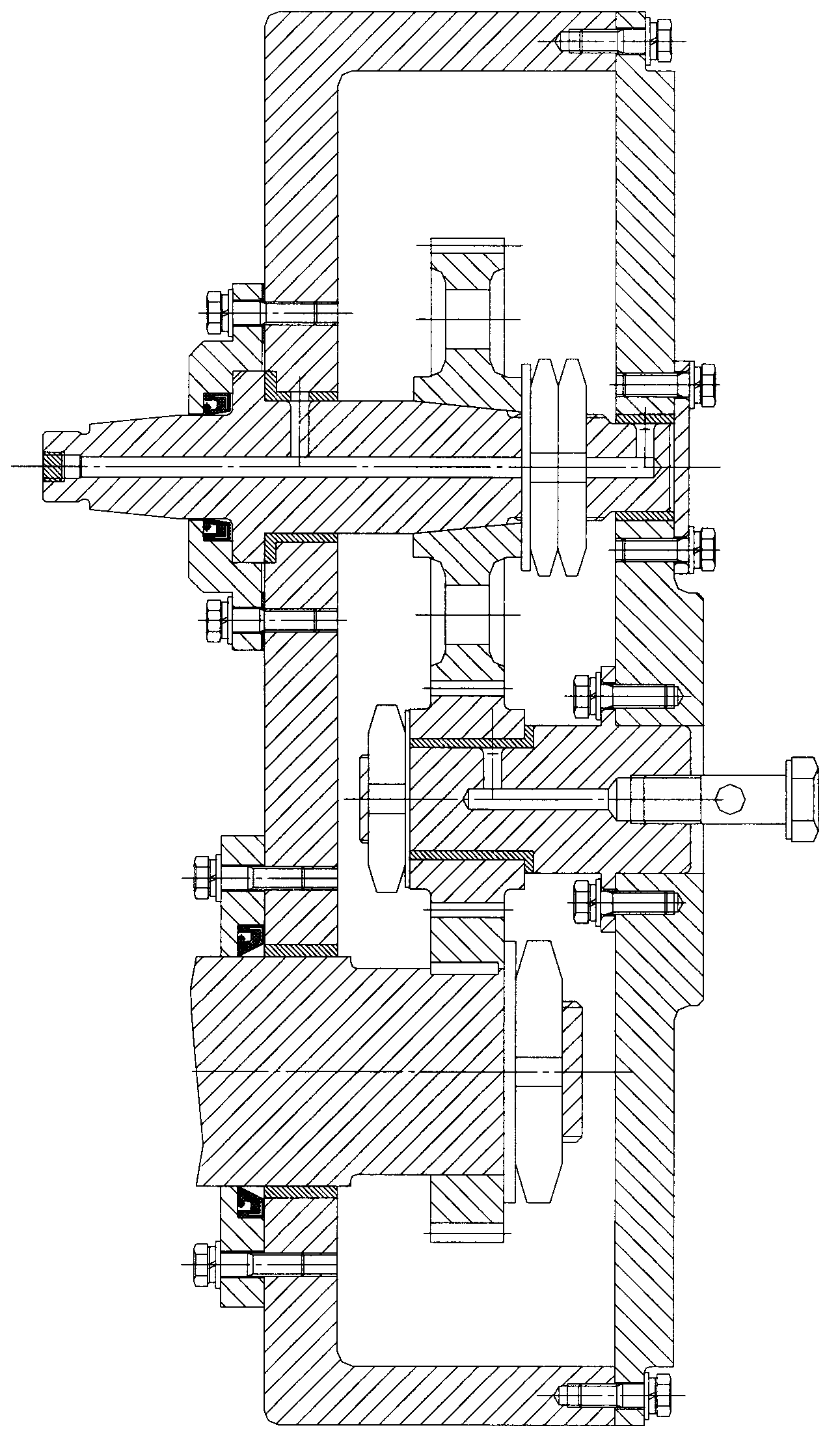

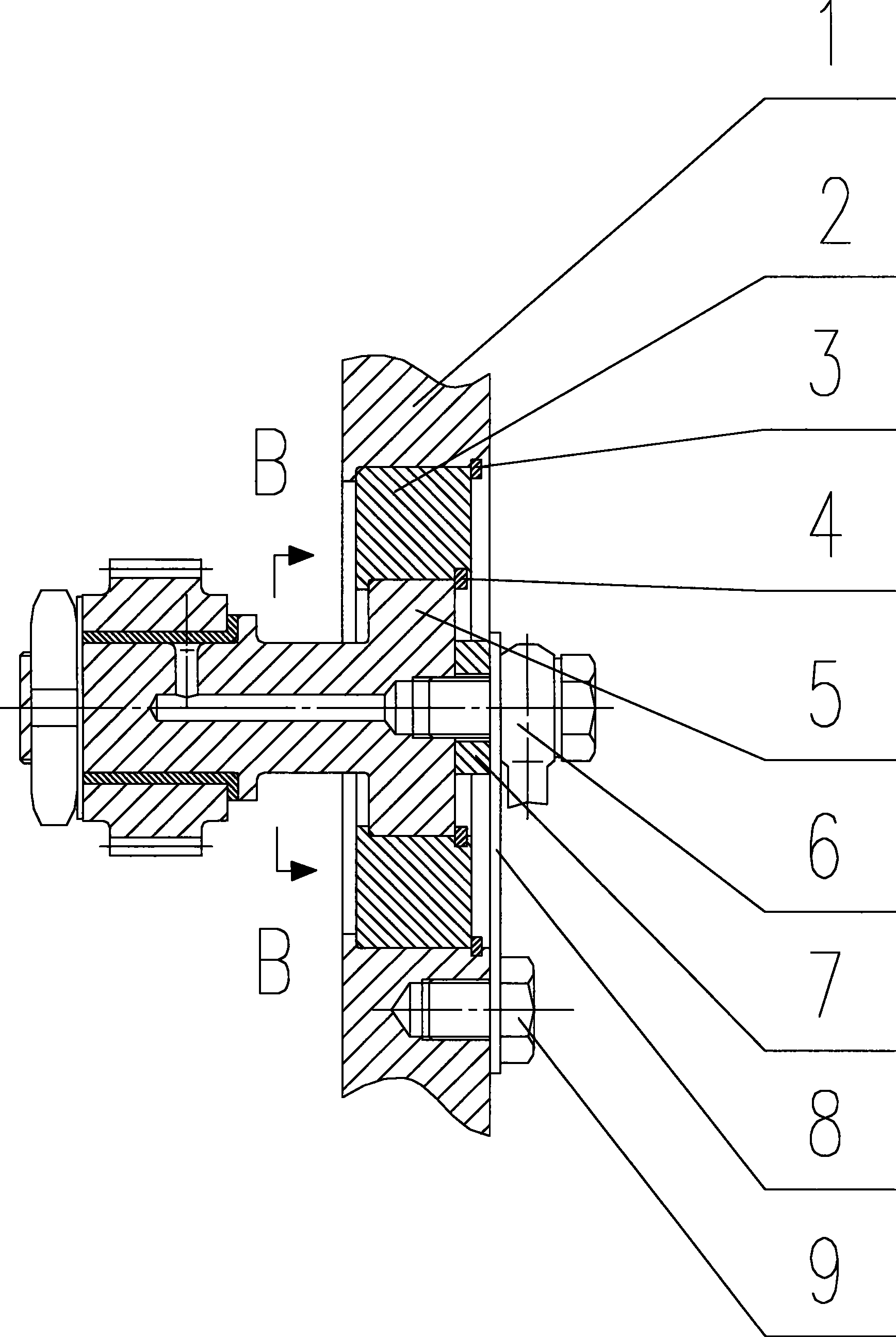

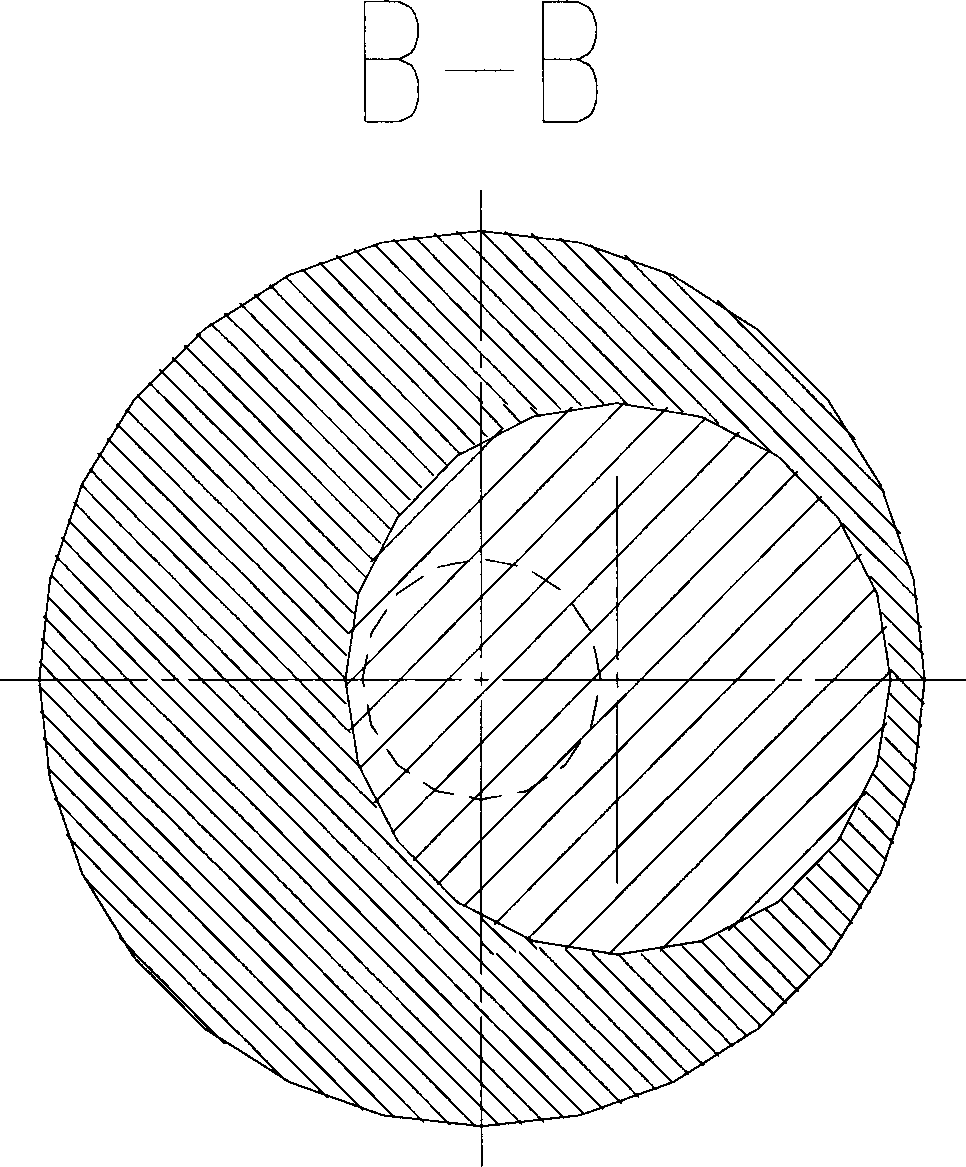

[0026] combined with figure 2 The gear axis position adjustable mechanism is specifically described: a large stepped through hole is processed at the installation part of the idler shaft of the transmission box cover 1. The radius of the large stepped through hole close to the inside of the transmission box is R1, and the radius close to the outside of the transmission box is R2. R2>R1; there is a large retaining ring groove at the large radius of the large stepped through hole, and the distance between the side wall of the large retaining ring groove near the variable diameter of the large stepped through hole and the variable diameter of the large stepped through hole is L1; another radius is processed R2, a large circular plate 2 with a thickness of L1, with an eccentric small stepped through hole on the large circular plate 2, the eccentric distance between the center of the large circular plate 2 and the small stepped through hole is L3, and the radii of the small stepped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com