Full-automatic drill grinder

A fully automatic, grinding machine technology, applied in the field of grinding machines, can solve the problems of manual grinding, such as large amount of grinding, high frequency of work, and low efficiency, and achieve the effect of fast grinding speed, correct grinding angle and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

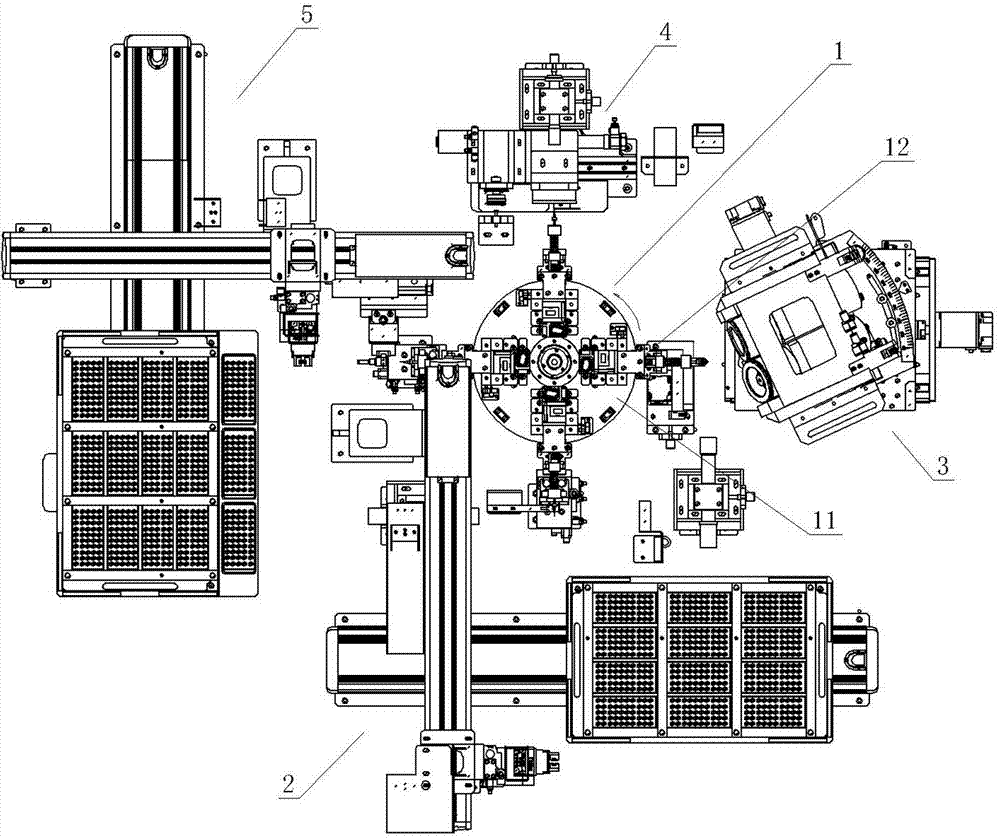

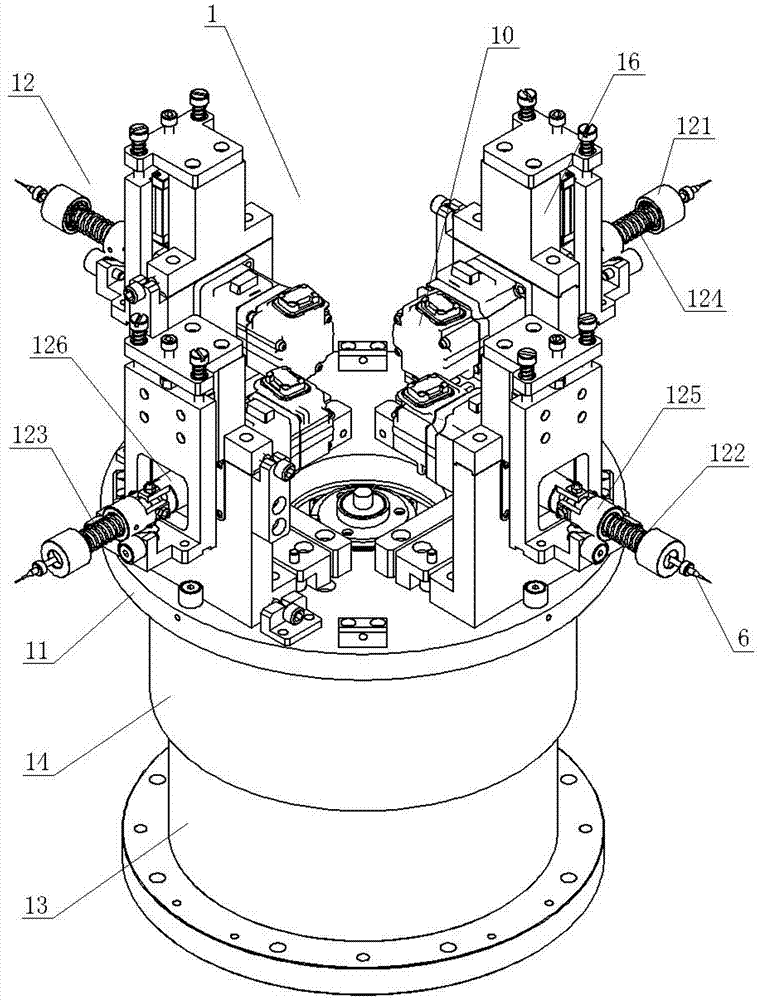

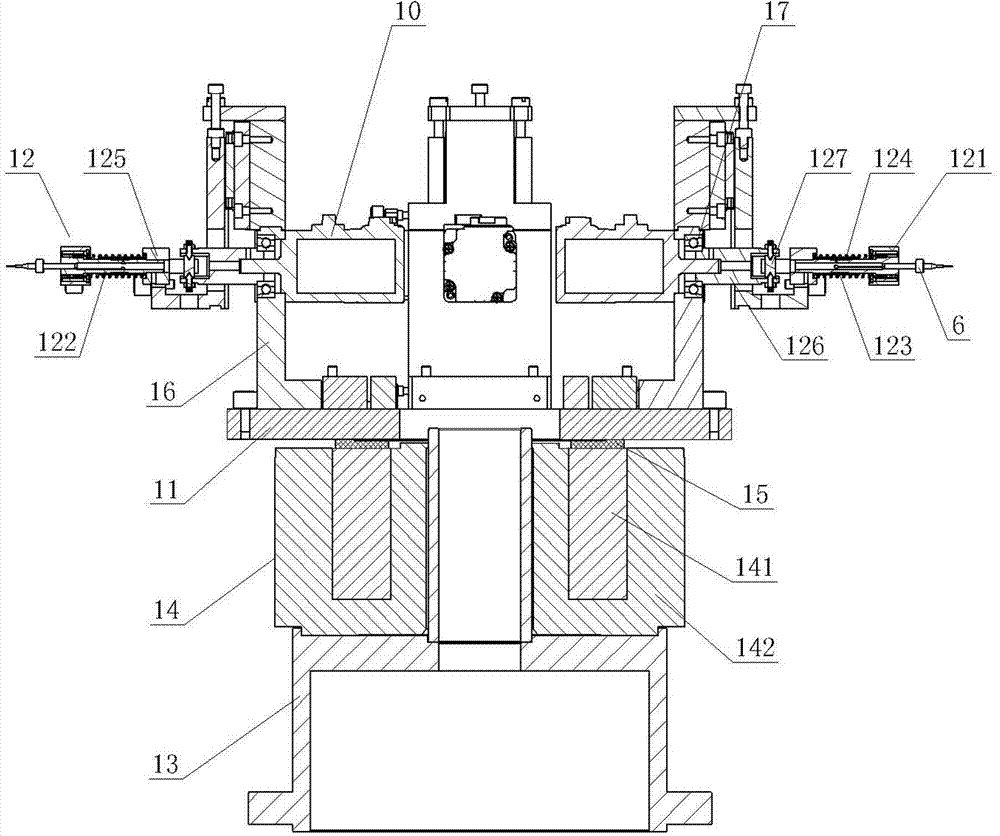

[0026] Such as Figure 1 to Figure 11 As shown, a kind of automatic drill grinding machine described in this embodiment includes an indexing device 1, a feeding device 2 positioned around the indexing device 1, a grinding device 3, a detection device 4 and a discharge device 5, wherein The indexing device 1 includes an indexing disc 11 and a clamping head 12 installed on the indexing disc 11. The drill bit 6 is installed on the clamping head 12 of the indexing device 1 through the feeding device 2, and then the indexing disc is rotated. 11 Make the drill bit 6 sequentially pass through the grinding device 3, the detection device 4 and the unloading device 5 for corresponding processing, so that the entire grinding process can be completed after one clamping, which can reduce the number of disassembly and assembly of the drill bit 6 and reduce errors. The auxiliary time is shortened and the work efficiency is improved. In addition, a servo motor 10 is installed at the rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com