Conveyer belt energy saving property testing device and sample loading and unloading method

A testing device and conveyor belt technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of reducing the accuracy of the entire device, time-consuming loading and unloading samples, and large measurement errors, to simplify the structure, maintain accuracy, and reduce disassembly and assembly. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

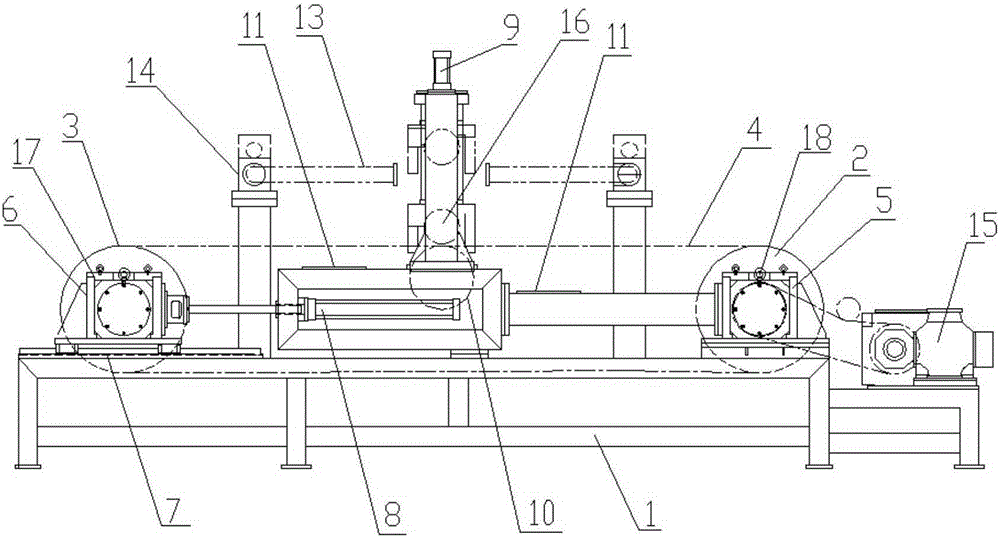

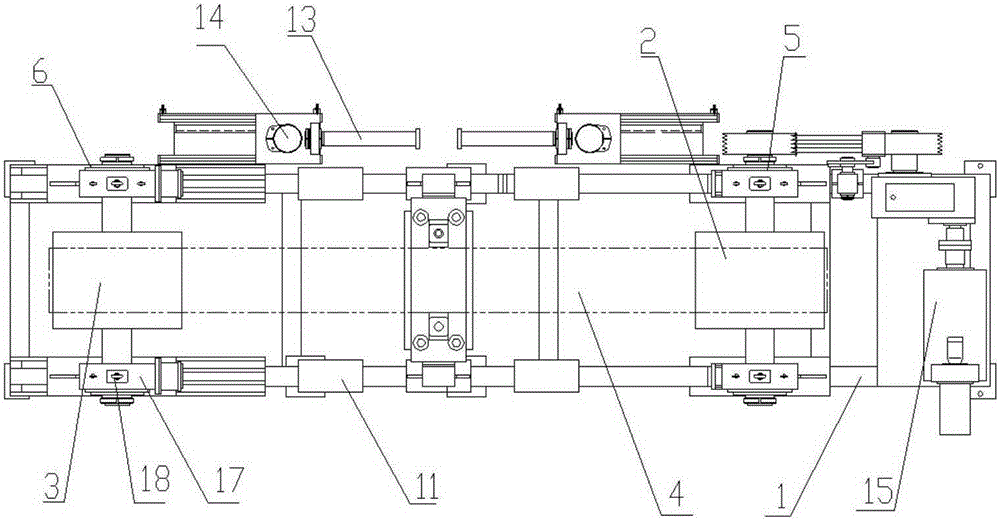

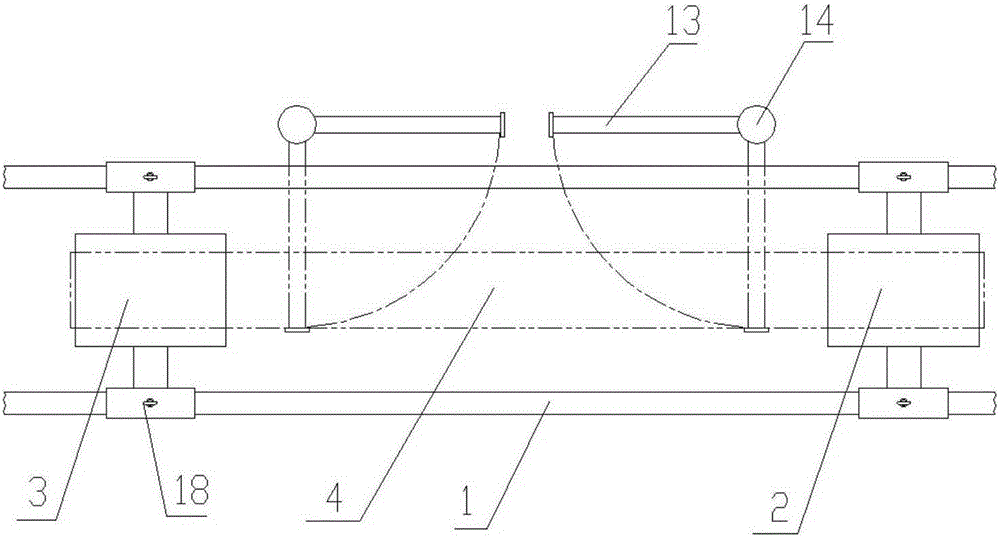

[0048] Such as figure 1 and figure 2As shown, the conveyor belt energy-saving test device of the present invention includes a frame 1, a driving roller 2 and a driven roller 3 installed on the frame 1, a driving roller 2 and a driven roller 3 installed on the The conveyor belt 4, the driving roller 2 and the driven roller 3 are detachably installed on the frame 1, the fixed bearing bracket 5 is installed on the frame 1, the driving roller 2 and the driving roller 2 are installed on the fixed bearing bracket 5 Driven by the driving device 15, it can rotate at a certain speed, and the speed of the driving roller 2 is adjustable; the other side is installed with a movable bearing bracket 6, and the driven roller 3 is installed on the movable bearing bracket 6, and the driven roller 3 , can move along the linear slide rail 7, so that the relative distance between the driving roller 2 and the driven roller 3 can be adjusted. During the test, the oil cylinder 8 pushes the moving b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com