Patents

Literature

39results about How to "Improve moving efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

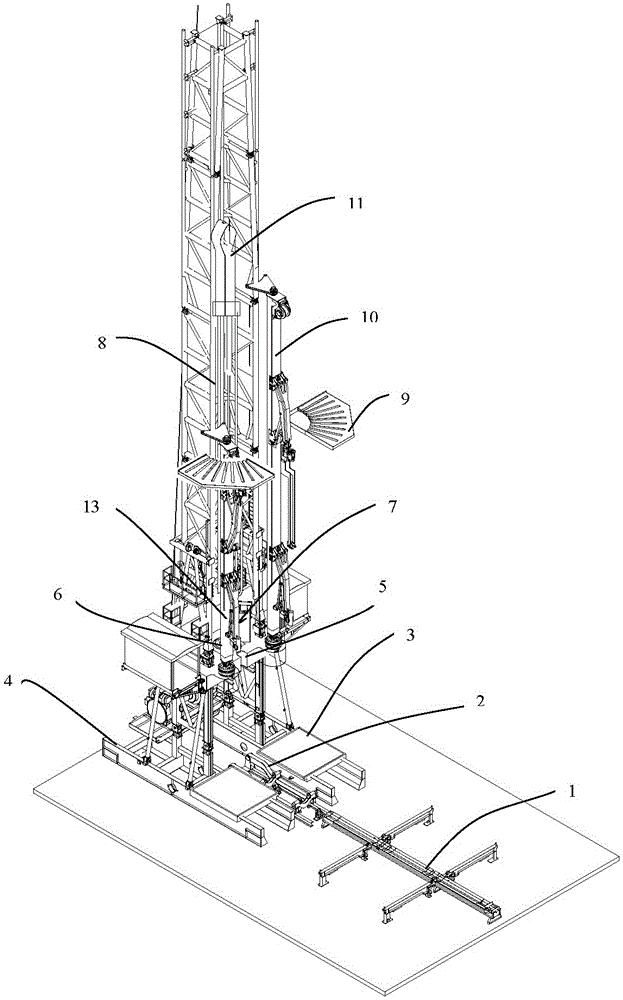

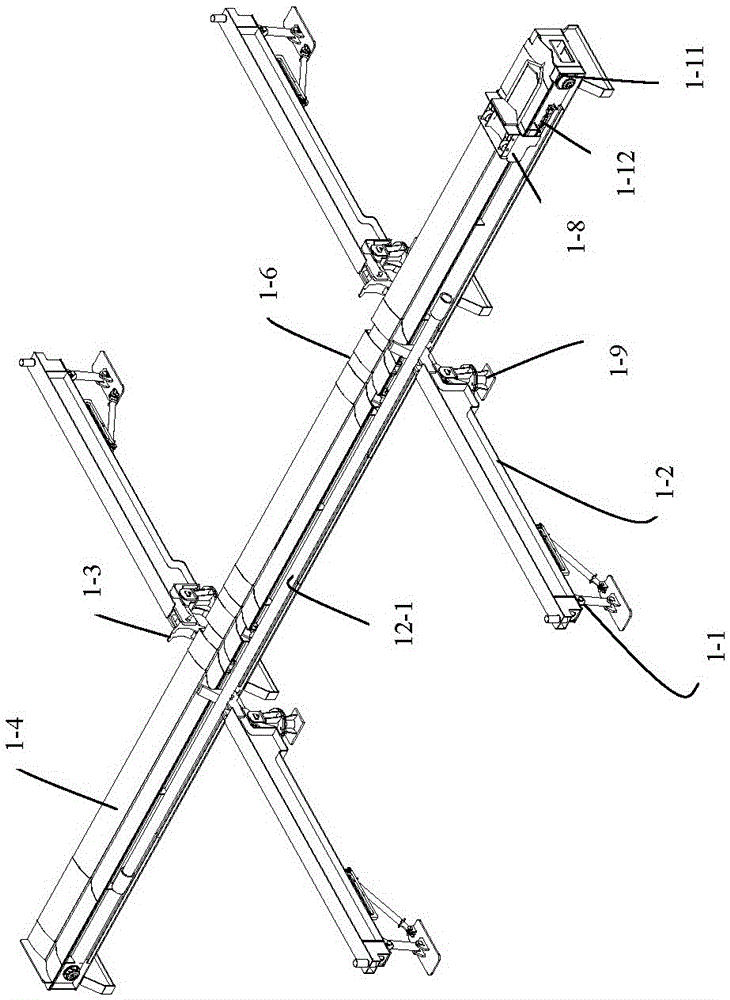

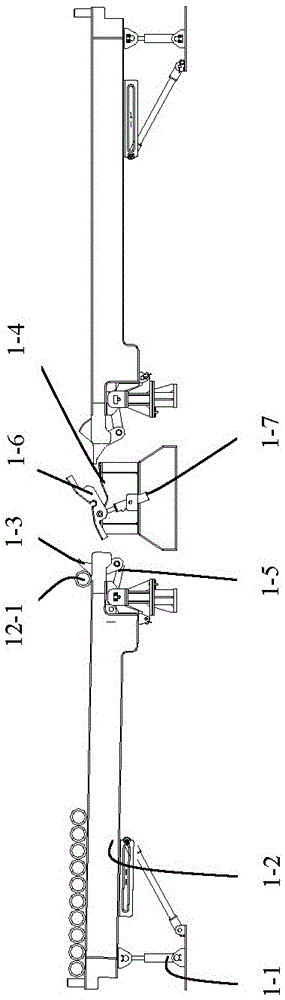

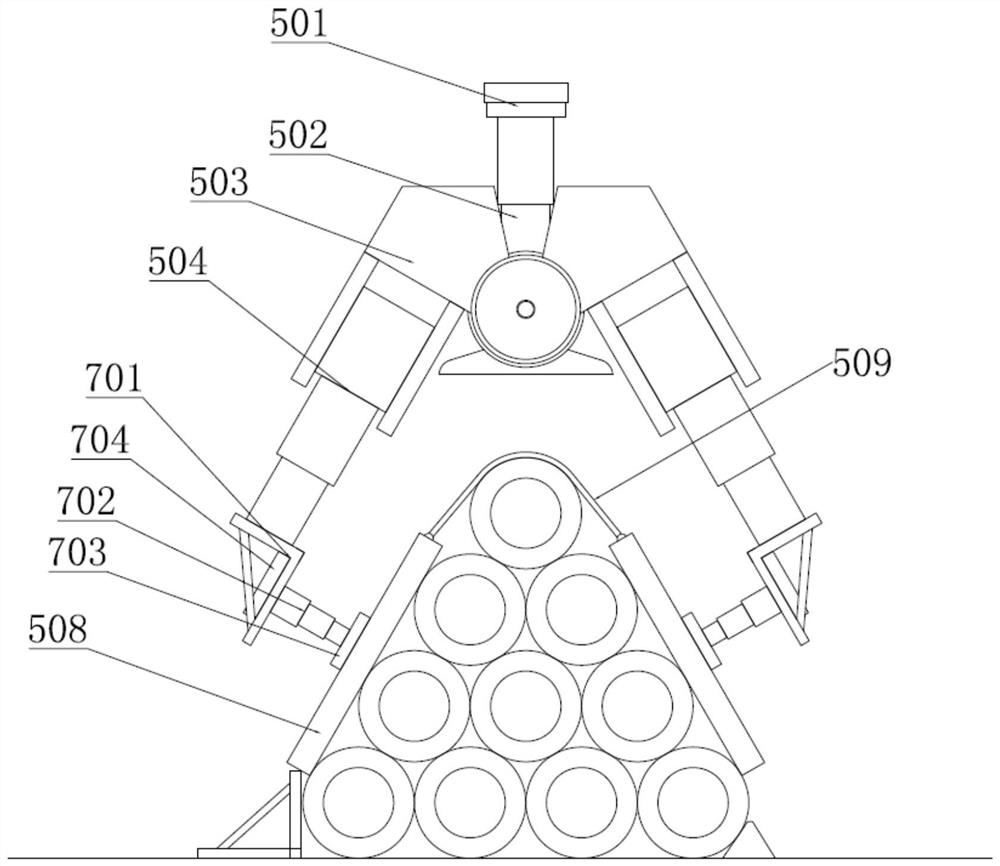

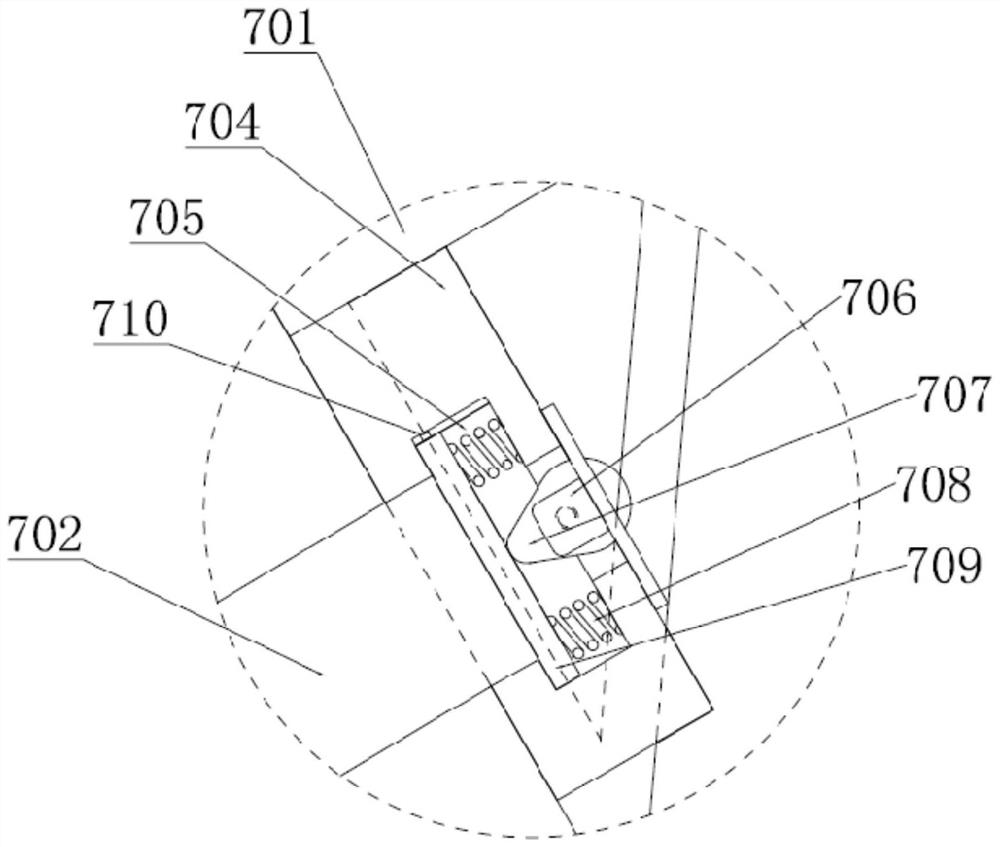

Automated drilling rig

ActiveCN105569566AImprove moving efficiencyReduce manual labor intensityDrilling rodsDrilling casingsManipulatorVideo monitoring

The invention discloses an automated drilling rig. Double fan-shaped fingerboards are arranged on two sides of a headframe, two corresponding sunk type pipe setbacks are arranged on a base; a catwalk automatically turns in, turns out and parallelly moves put-in pipes; a manipulator is turned over to grip the pipes delivered by the catwalk until the manipulator is vertical, lower pipes are clamped to apply reaction torque during screwing on and screwing off; and a double pipe arranging device moves the pipes up and down, makes up the pipes and vertically moves or arranges stands. The drilling rig adopts electrohydraulic combined driving, an omnibearing video monitoring system and integrated control, a driller can achieve operations of drilling of the drilling rig and connecting and detaching stands by operating corresponding procedures in a control cabin, thus realizing truly full automation, off-line operation, safety and reliability, and the operating efficiency can be improved to 3 times of the existing drilling rigs. When a well site is moved, the automated drilling rig can be moved integrally with full stands, thus greatly improving operating efficiency and lowering labor intensity of staff.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

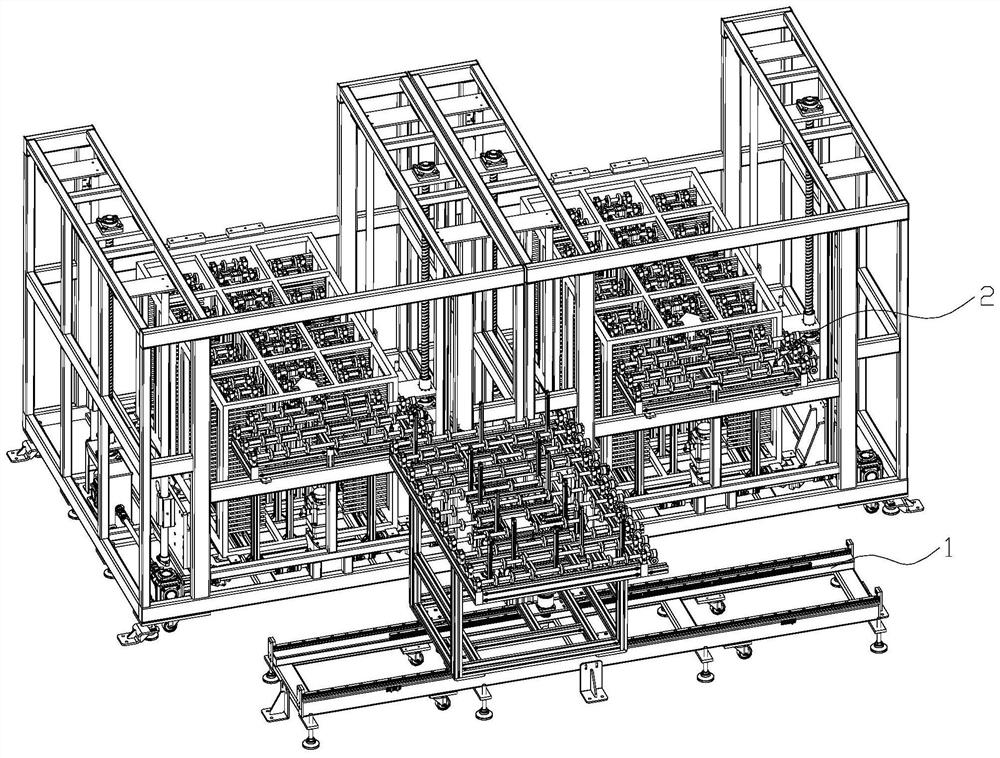

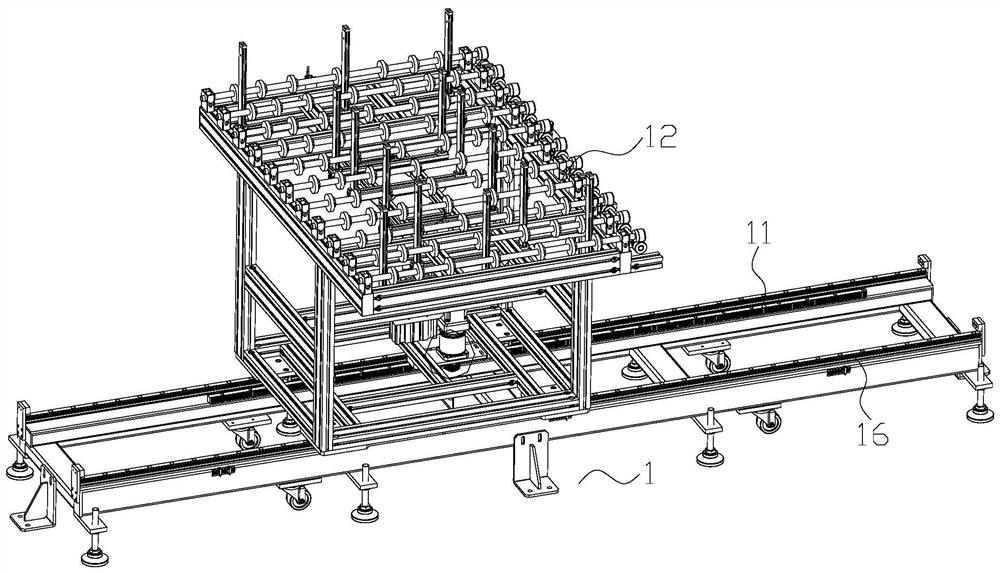

Large cargo translating device

ActiveCN101058372ACompact structureHigh degree of mechanizationStorage devicesConveyor partsEngineeringChassis

Owner:CHINA SHIP DEV & DESIGN CENT

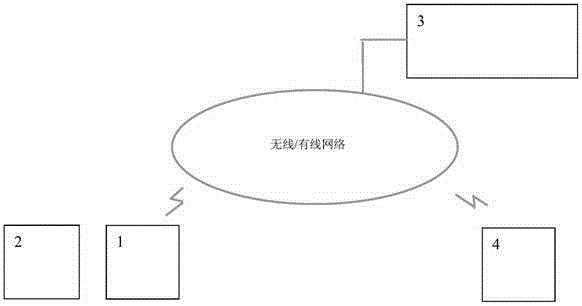

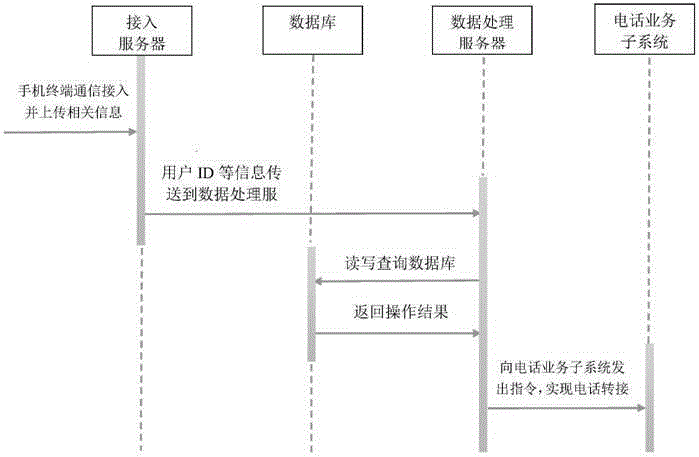

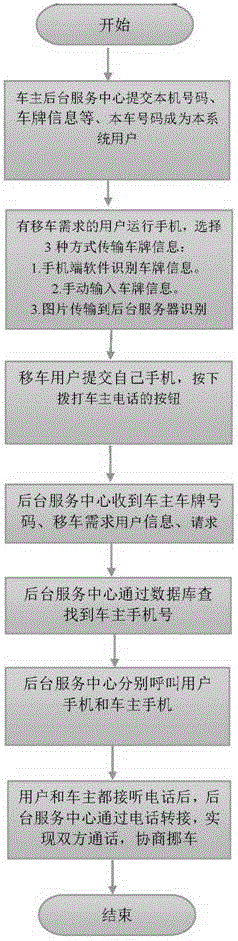

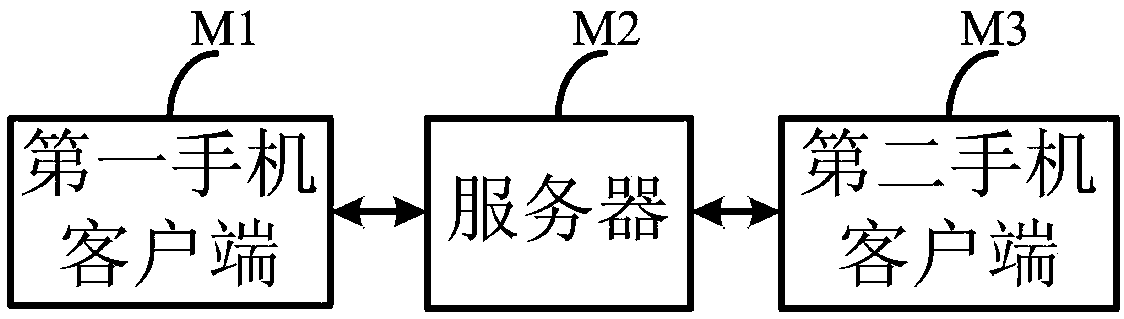

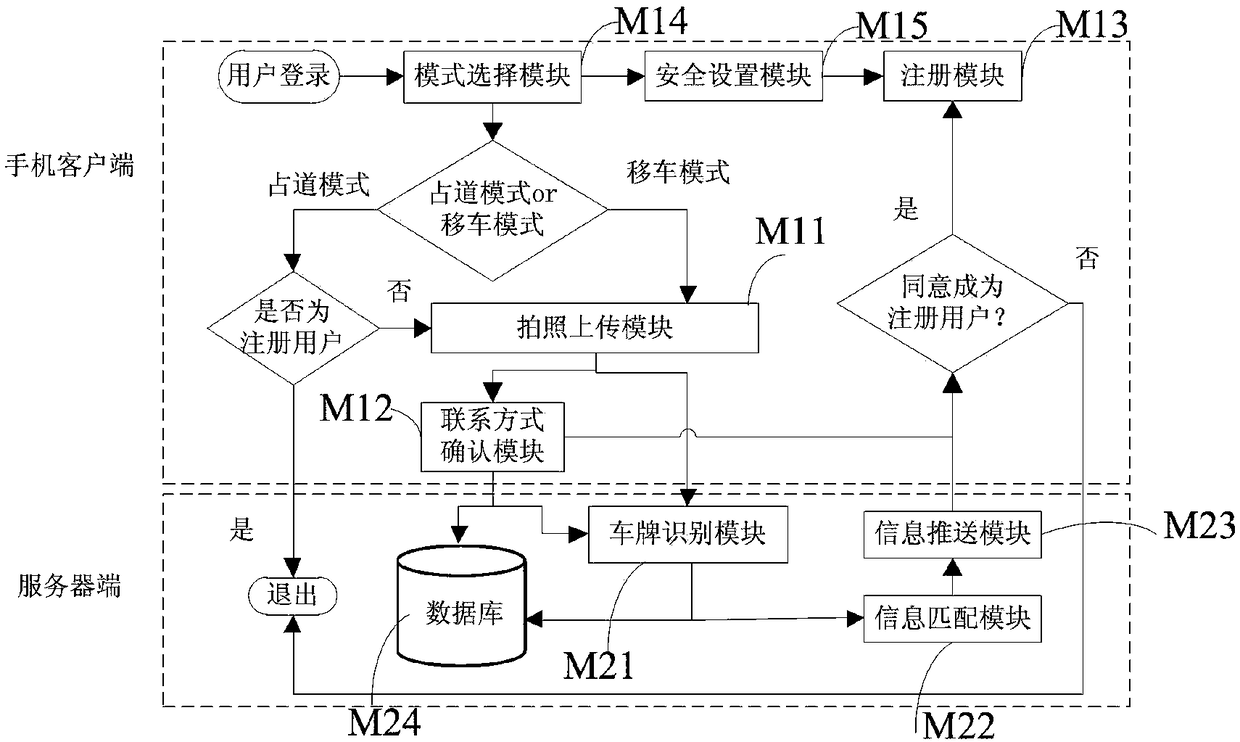

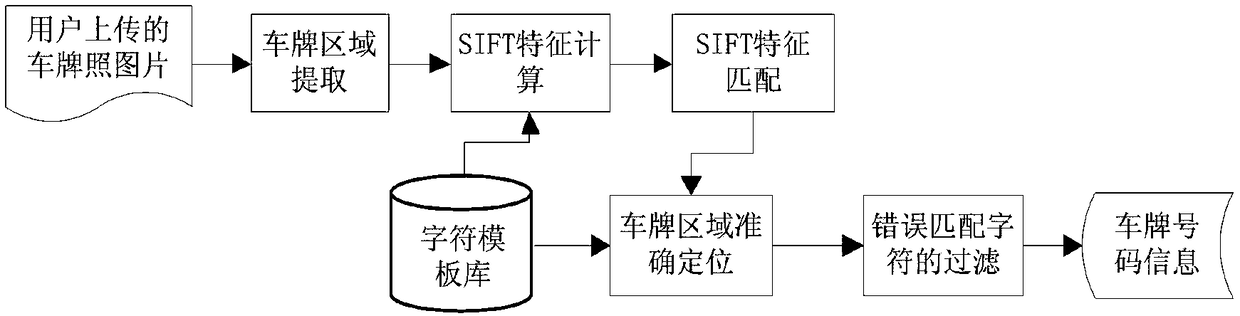

License plate number-based privacy-protecting vehicle moving system and method thereof

InactiveCN105389992APrivacy protectionImprove moving efficiencyRoad vehicles traffic controlIdentification deviceEmbedded system

The invention relates to a license plate number-based privacy-protecting vehicle moving system. The license plate number-based privacy-protecting vehicle moving system includes a license plate recognition device, a data transmission system, a background server and a message service system; the license plate recognition device is installed at the smart phone end of a user or the background server; the background server records vehicle owner information; the data transmission system transmits license plate information to the background server through a network; and the message service system transmits a vehicle moving notice to a vehicle owner.

Owner:厦门纬尔科技有限公司

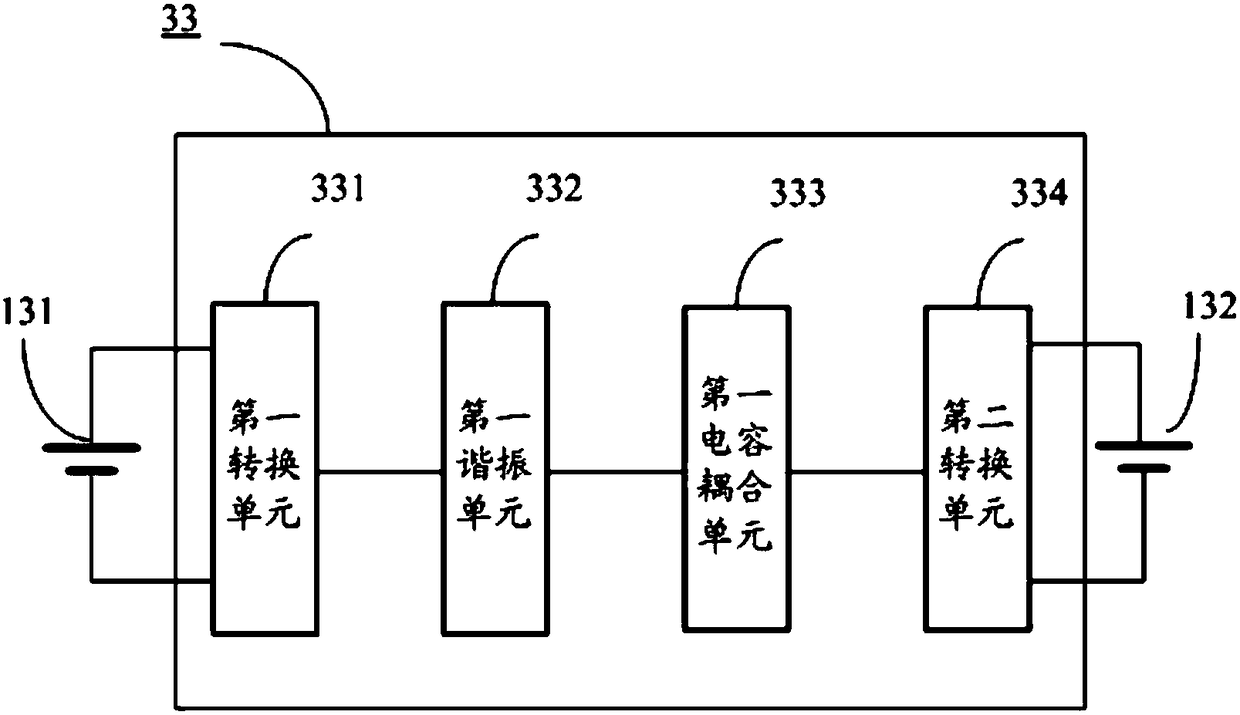

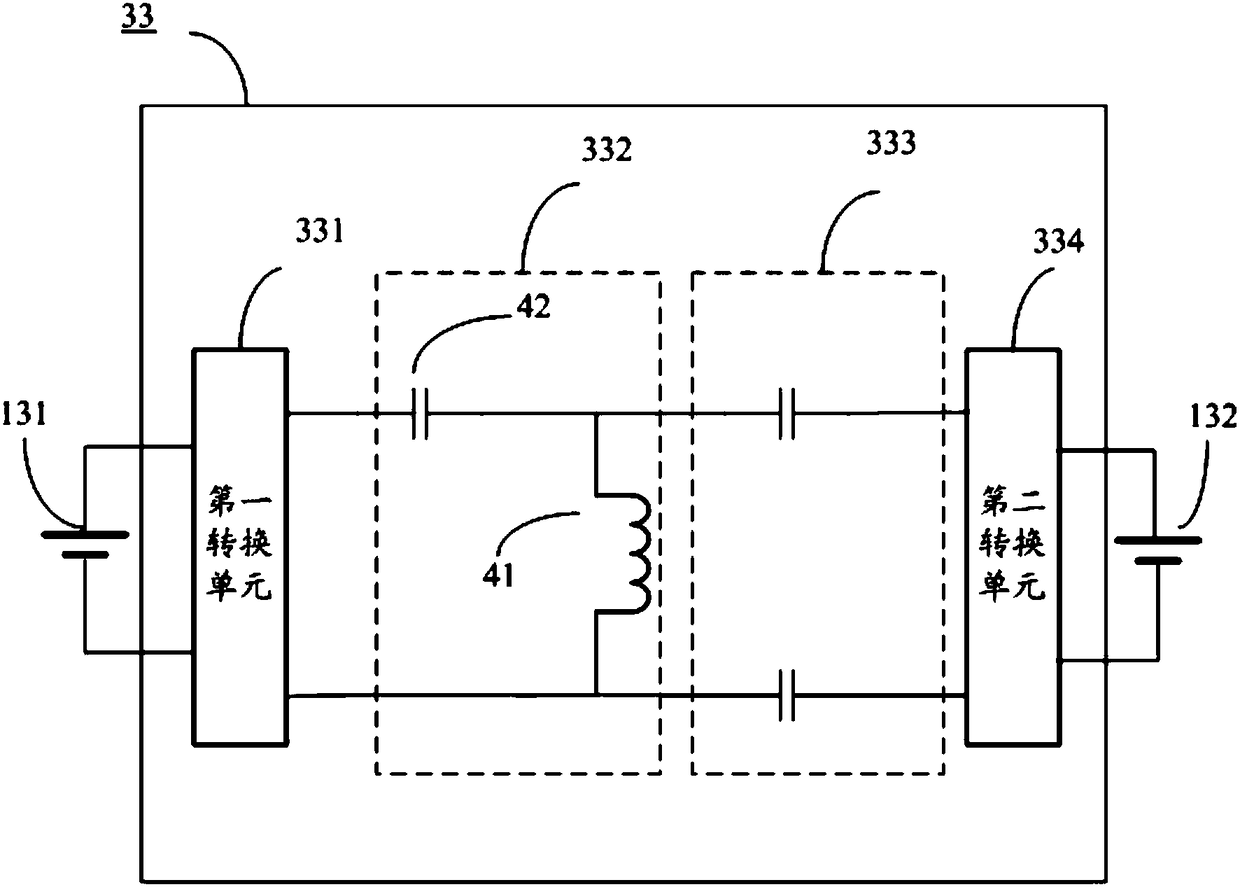

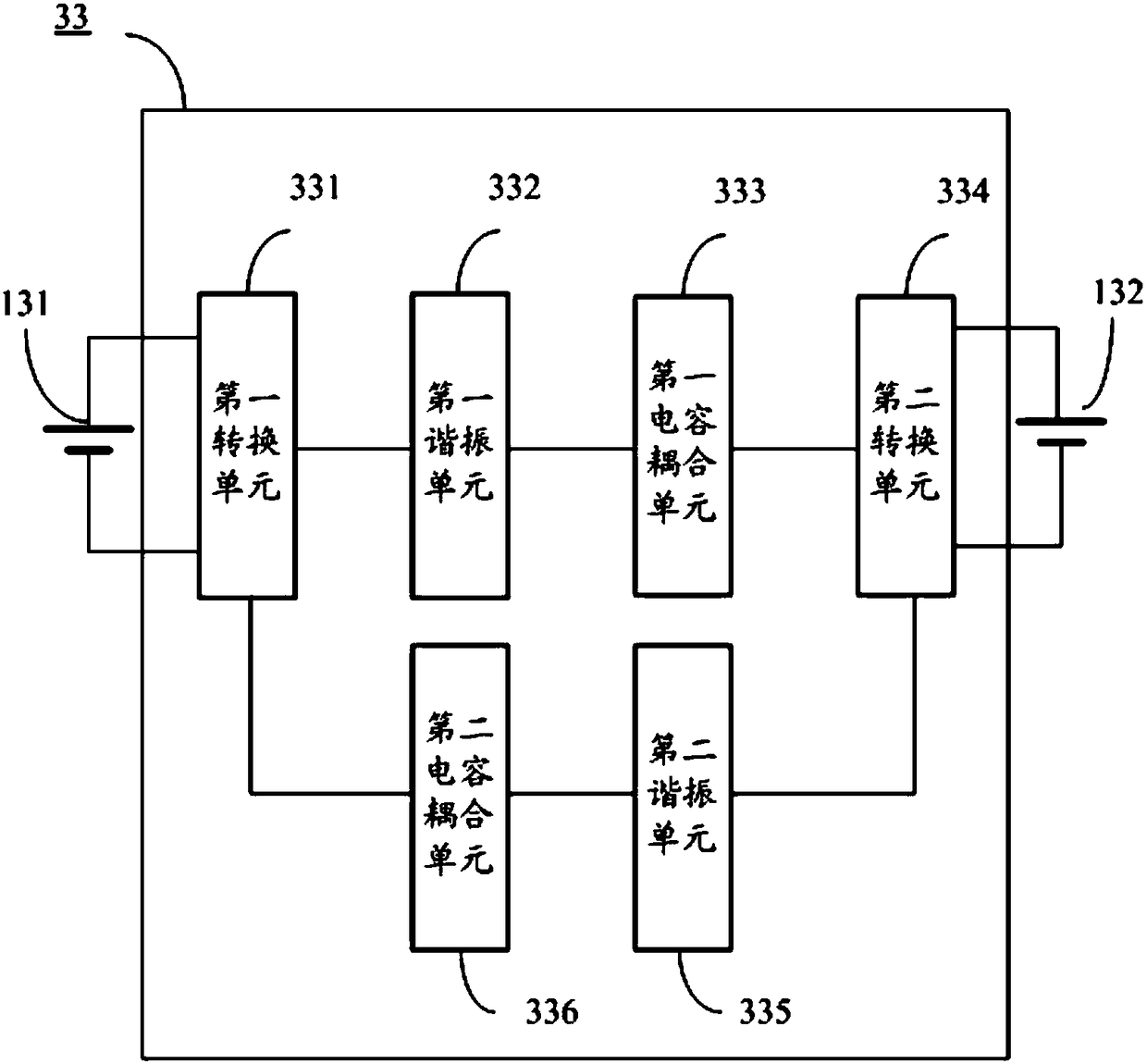

Balancing circuit, to-be-charged device and charge control method

ActiveCN108124498AImprove moving efficiencyCharge equalisation circuitEfficient power electronics conversionCapacitanceResonance

The invention provides a balancing circuit, a to-be-charged device and a charge control method. The balancing circuit (33) includes a first conversion unit (331) used for receiving DC voltage output by a first cell (131) and converting DC voltage output by the first core to a first AC voltage; a first resonance unit (332) used for receiving first AC voltage and converting the first AC voltage to second AC voltage, wherein the amplitude of the second AC voltage is greater than the amplitude of the first AC voltage; a first capacity coupling unit (333) and a second conversion unit (334), whereinthe first capacity coupling unit (333) couples second AC voltage to the second conversion unit in a capacity coupling manner and the second conversion unit converts the second AC voltage to first charging voltage and charges a second cell (132).

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

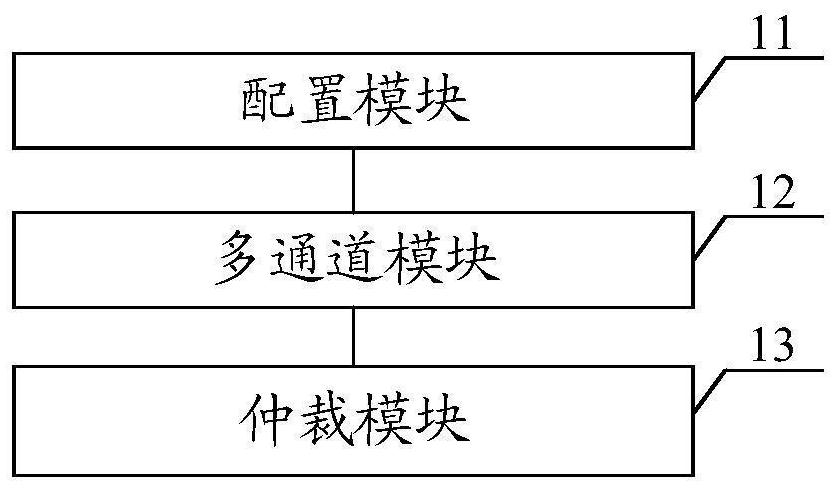

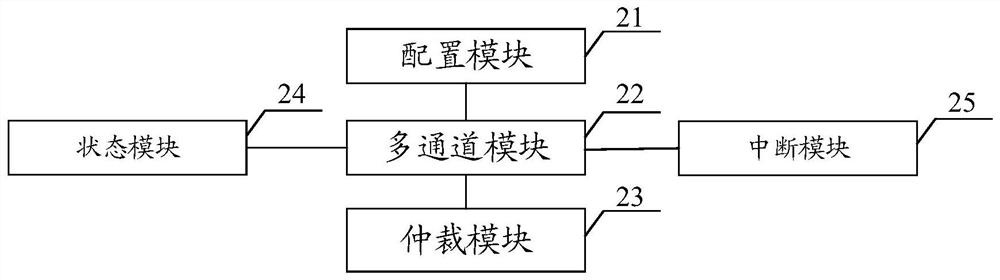

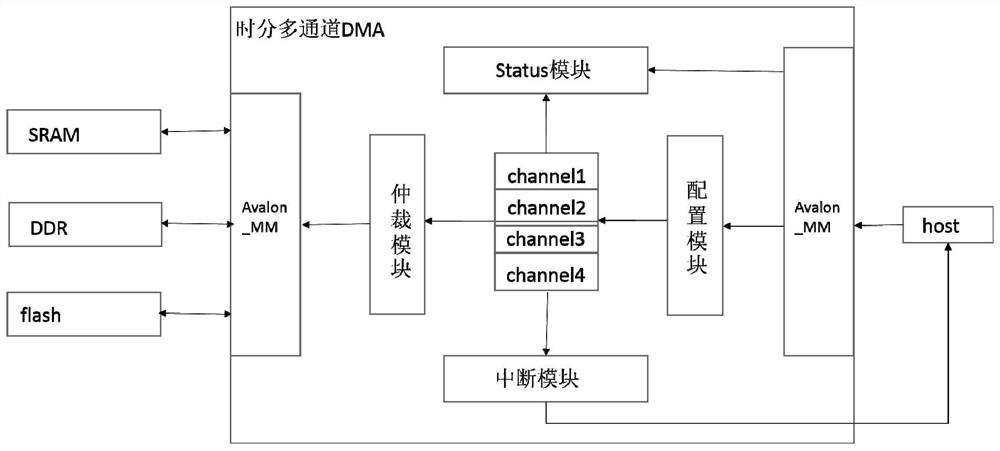

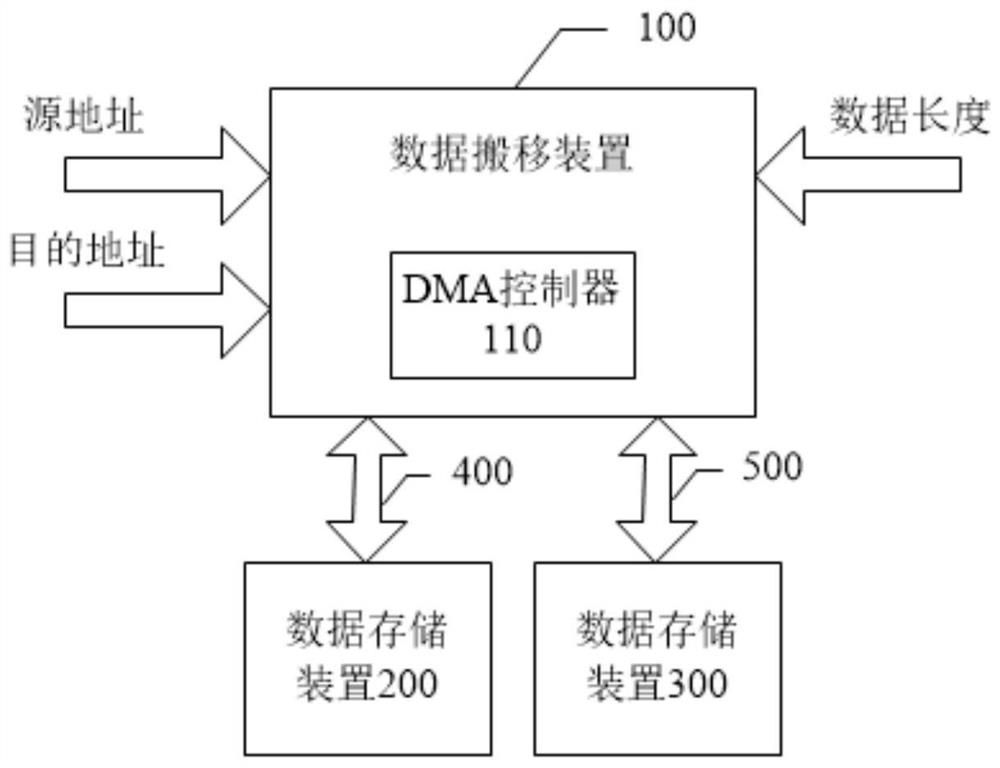

DMA (Direct Memory Access) equipment based on FPGA (Field Programmable Gate Array) and DMA data migration method

InactiveCN112765059ASatisfy data migration needsAvoid waiting timeElectric digital data processingDirect memory accessExternal storage

The invention discloses DMA equipment based on an FPGA and a DMA data migration method. The DMA equipment comprises: a configuration module which is used for obtaining configuration information sent by a host, and transmitting data migration tasks to a plurality of data migration channels in a multi-channel module based on the configuration information, wherein the configuration information comprises a to-be-moved data volume, a source address and a destination address of each channel; a multi-channel module which is used for sending a migration request to a arbitration module through each data migration channel based on a corresponding migration task; and the arbitration module is used for determining a first target request from the plurality of migration requests based on a preset channel priority, and processing the first target request to migrate target data in a first storage device to a second storage device through a corresponding data migration channel, and determining a second target request for processing based on the preset channel priority when the data volume in the first storage device is insufficient. The data migration requirement among multiple external storage devices can be met, and the data migration efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

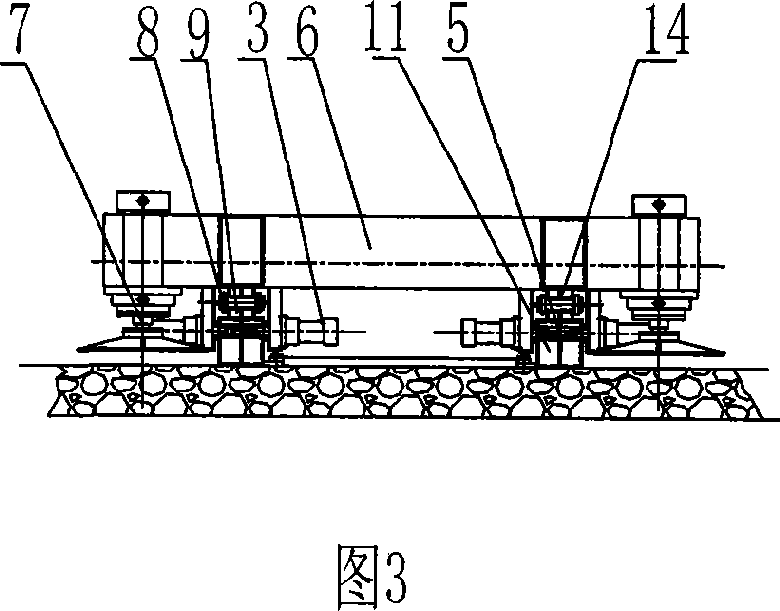

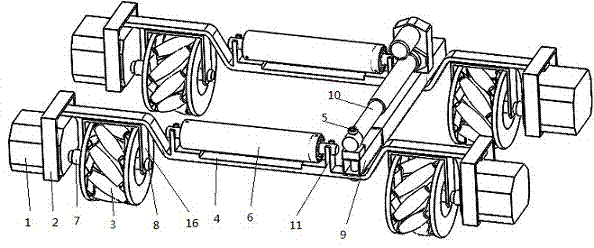

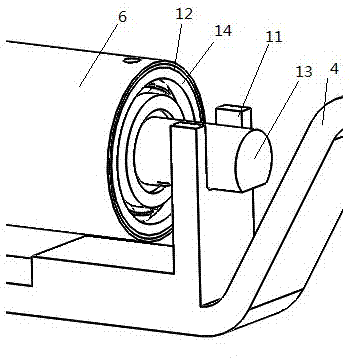

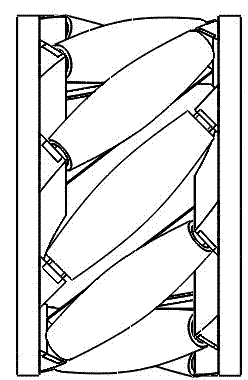

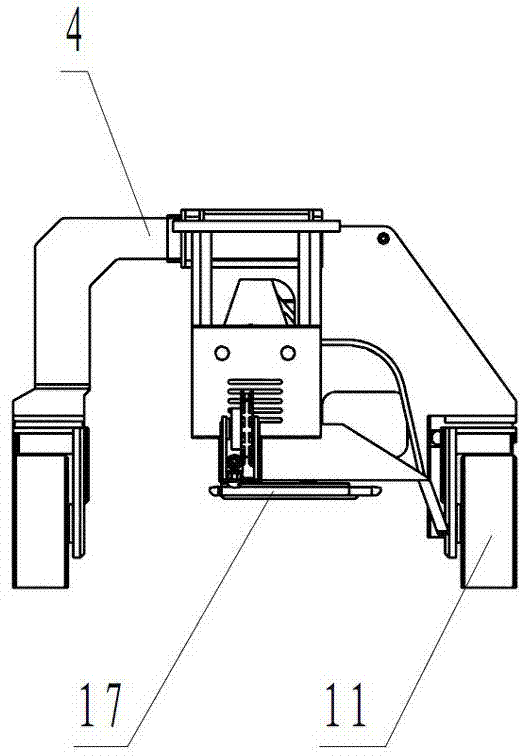

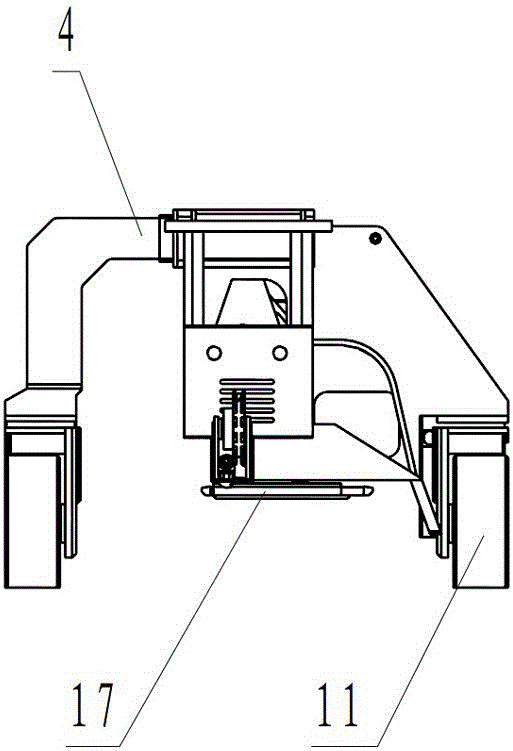

Automatic device capable of quickly moving vehicles

InactiveCN103879390AMove preciselyPrecise positioningVehicle manoeuvring devicesMobile vehicleEngineering

The invention discloses an automatic device capable of quickly moving vehicles. The automatic device comprises a supporting module, a lifting module and a driving module. The supporting module is composed of a roller, an angular contact bearing, a middle shaft, a shaft support, a u-shaped bracket and the like. The roller is covered with a rubber outer shell to increase the friction force between tires and the roller so as to reduce the resistance of the tires of the vehicles in the lifting process. The lifting module comprises an electric-hydraulic pusher, a guide rod and the like. The electric-hydraulic pusher is fixed on the guide rod through a bolt, and the guide rod is welded to the u-shaped bracket. When the electric-hydraulic pusher is shortened, linear movement of the electric-hydraulic pusher in the horizontal direction is converted into displacement of the tires in the vertical direction, so that the lifting movement of the tires is achieved. The driving module is composed of a MCcrum wheel, a wheel shaft, a coupler, a driving motor, a wheel shaft support, a motor support and the like. The MCcrum wheel is used for enabling the vehicles to move flexibly and accurately in all the directions, and through comprehensive analysis, the automatic device capable of quickly moving the vehicles has a broad market prospect.

Owner:李超

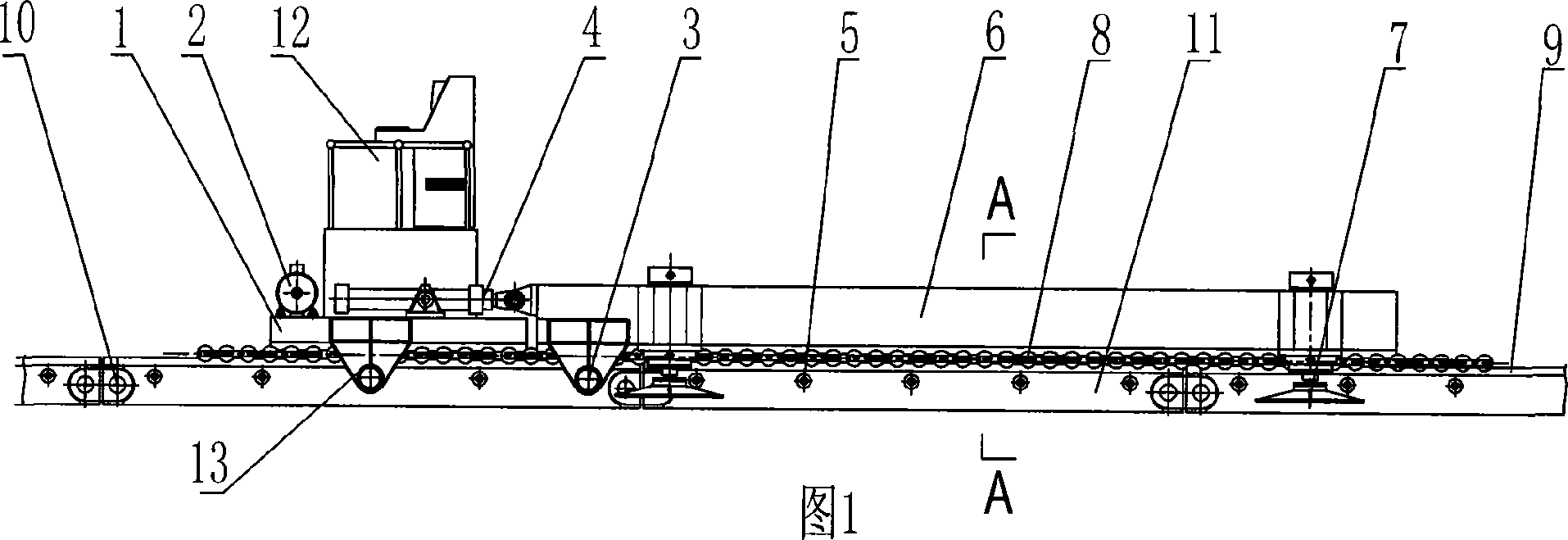

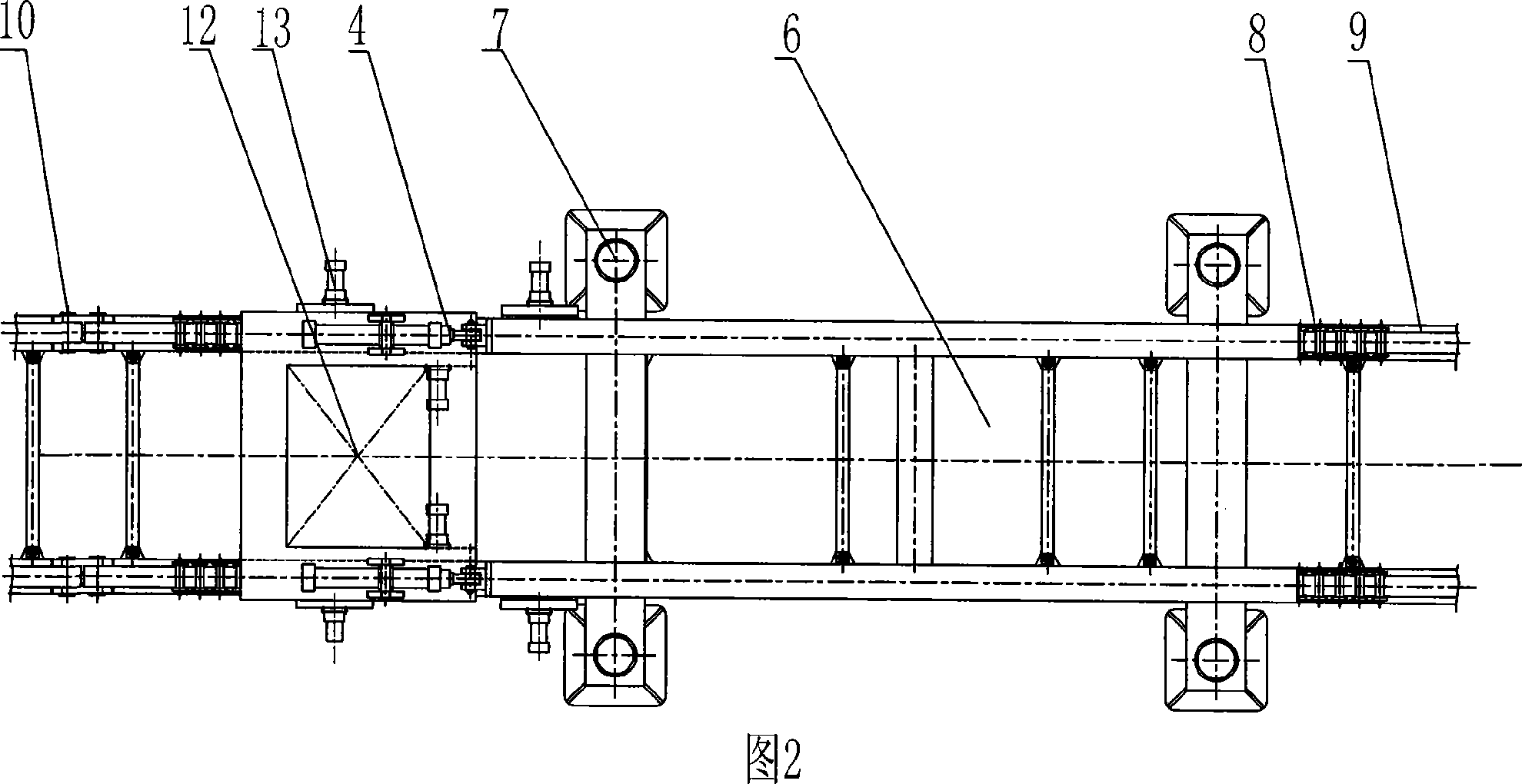

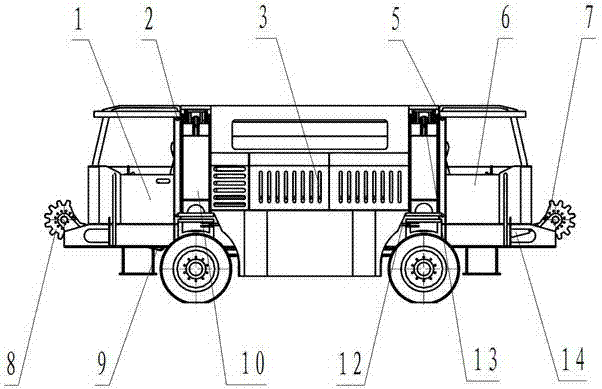

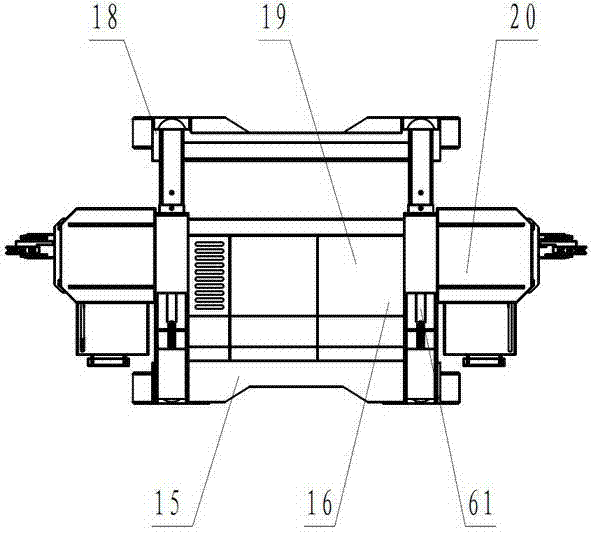

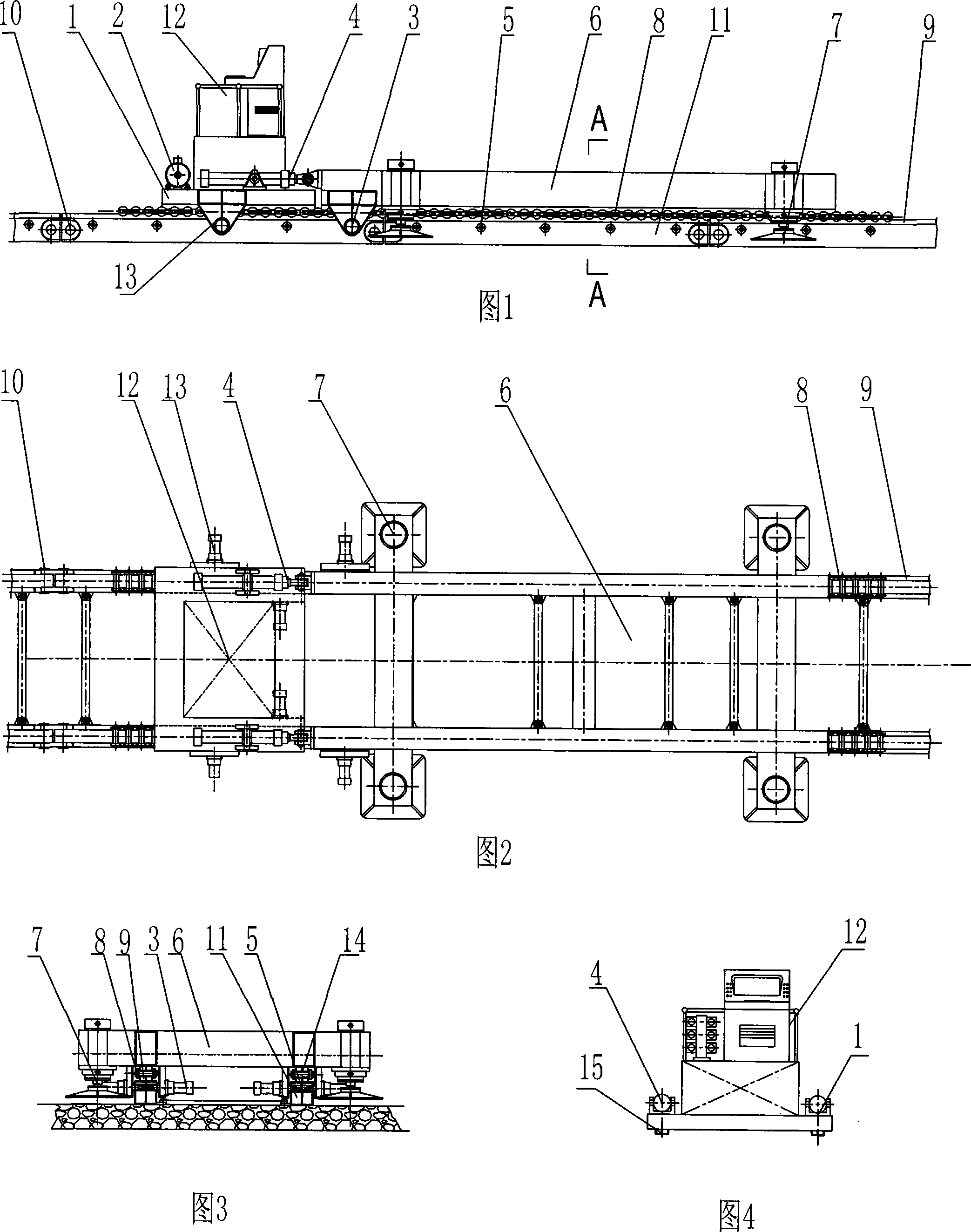

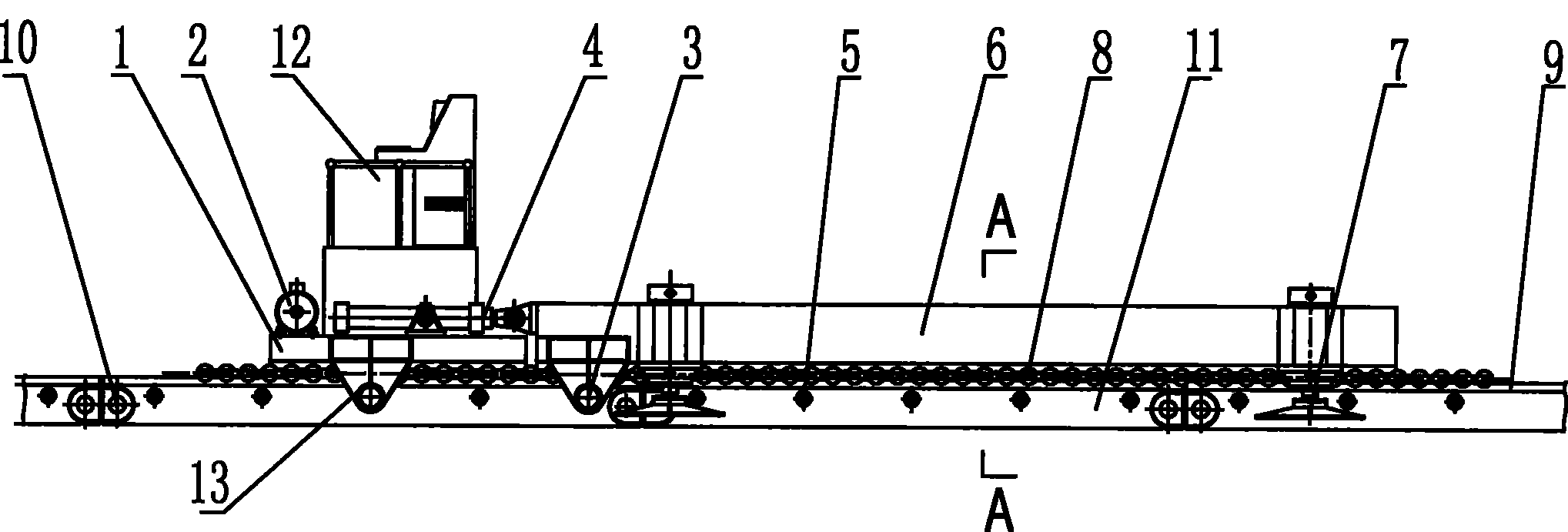

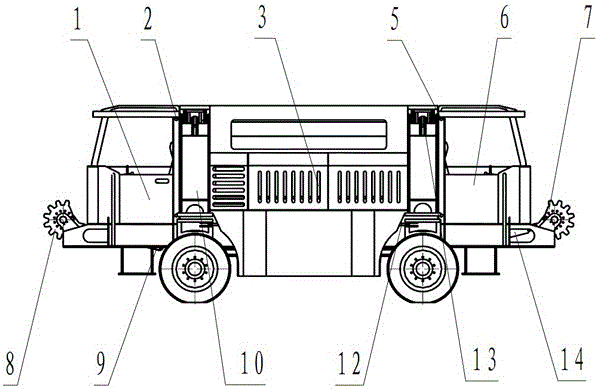

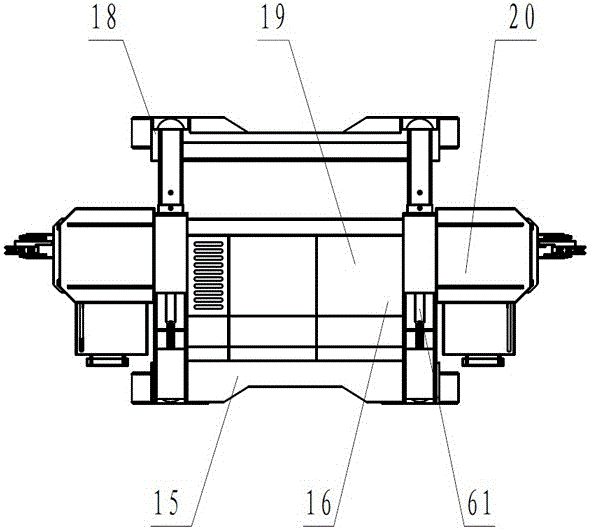

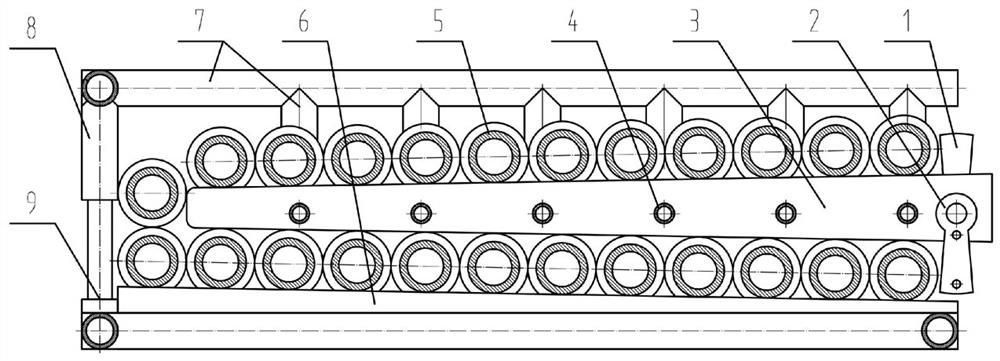

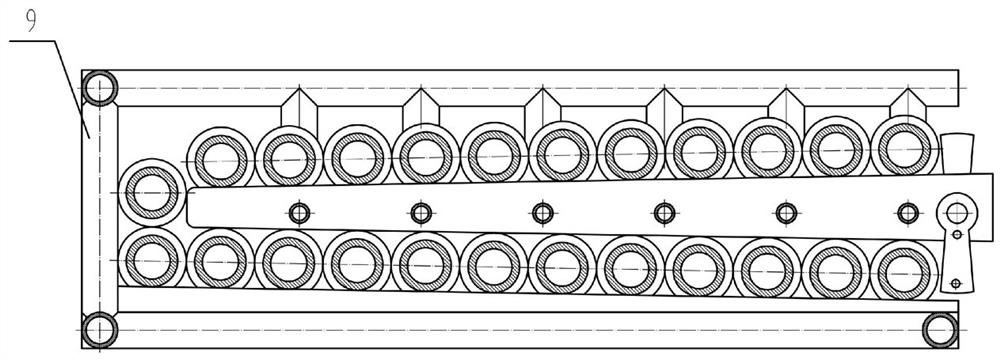

Middle trough moving van

ActiveCN104709152AImprove moving efficiencyIncrease the level of mechanizationItem transportation vehiclesSprocketEngineering

The invention belongs to the technical field of design and manufacturing of coal mine moving equipment, particularly belongs to a middle trough moving van. The problems that the middle trough moving efficiency is low, the process is tedious and certain potential safety hazards exist are solved. The middle trough moving van comprises a gantry type van frame with a telescopic beam, an anti-explosion diesel engine and a hydraulic mechanism, wherein the anti-explosion diesel engine is used for providing mechanical power, the hydraulic mechanism is used for converting the mechanical power into liquid pressure, a front driving cab is arranged at the front side of gantry type van frame, a rear driving cab is arranged at the rear side of the gantry type van frame, wheels capable of independently walking are arranged on the two ends of the front side and the two ends of the rear side of the gantry type van frame respectively, each wheel of the moving van is provided with a steering mechanism and a braking reducing mechanism, a middle trough quick loading and unloading mechanism is arranged on the bottom of the gantry type van frame, chain wheel mechanisms are arranged on the front end and the rear end of the gantry type van frame respectively, and the chain wheel mechanisms are controlled by chain wheel oil cylinders respectively.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

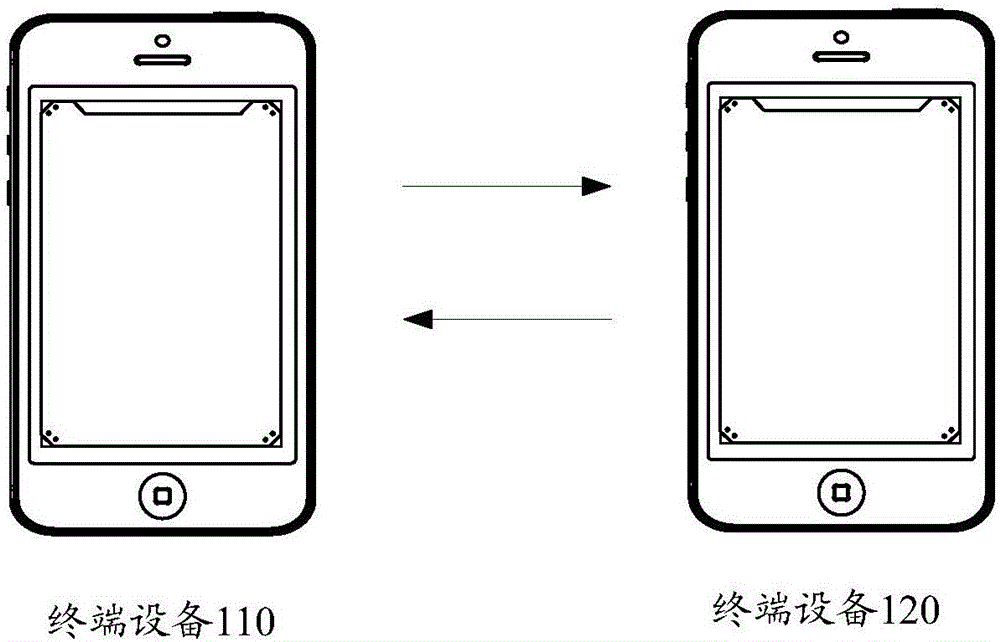

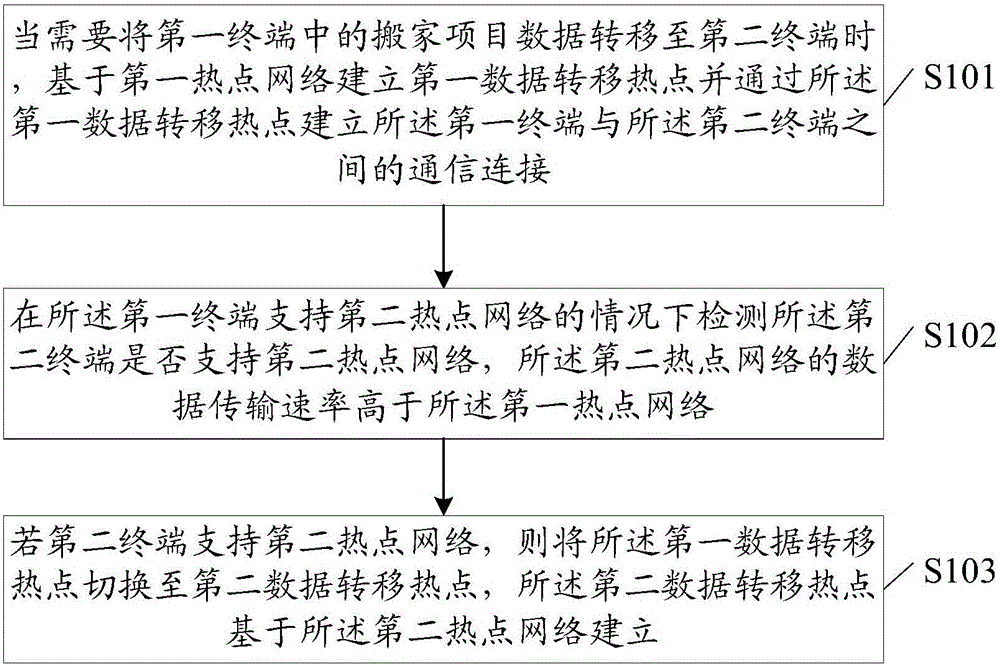

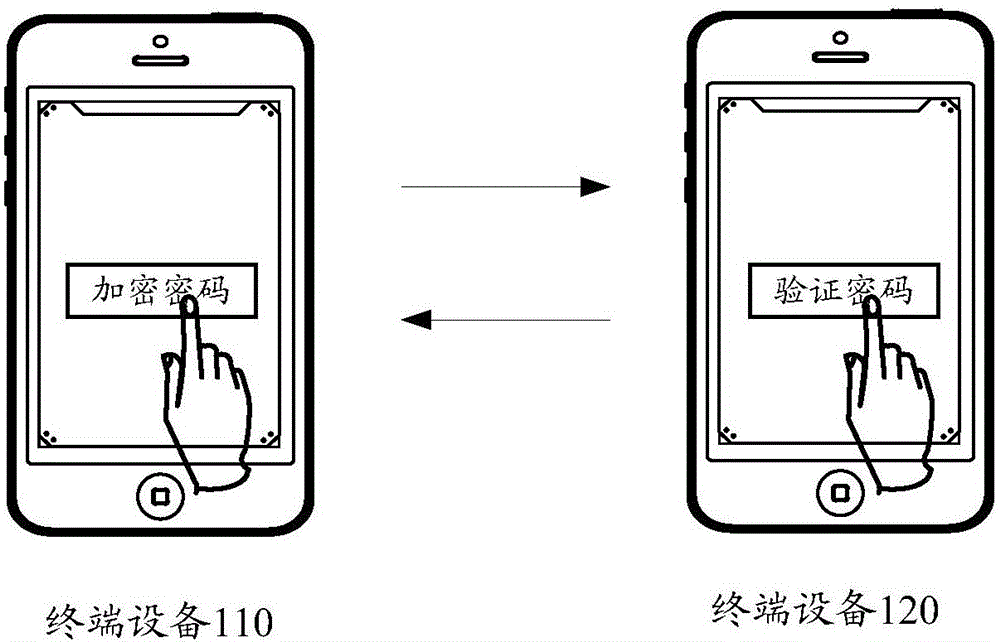

Hotspot network switching method and terminal equipment

InactiveCN106454975AIncrease data transfer rateIncrease transfer rateAssess restrictionConnection managementTerminal equipmentComputer terminal

The embodiment of the invention discloses a hotspot network switching method and terminal equipment. The method comprises the steps of building a first data transfer hotspot based on a first hotspot network when moving project data in the first terminal needs to be transferred to a second terminal; detecting whether the second terminal supports a second hotspot network in the case that the first terminal supports the second hotspot network; and if the second terminal supports the second hotspot network, switching the first data transfer hotspot to a second data transfer hotspot, wherein the second data transfer hotspot is built based on the second hotspot network. According to the embodiment of the invention, after switching from the first hotspot network to the second hotspot network with a higher data transmission rate, the first terminal builds the second data transfer hotspot based on the second hotspot network, and thus the first terminal and the second terminal can achieve the higher transmission rate based on the data transfer hotspot, and handset data transfer efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

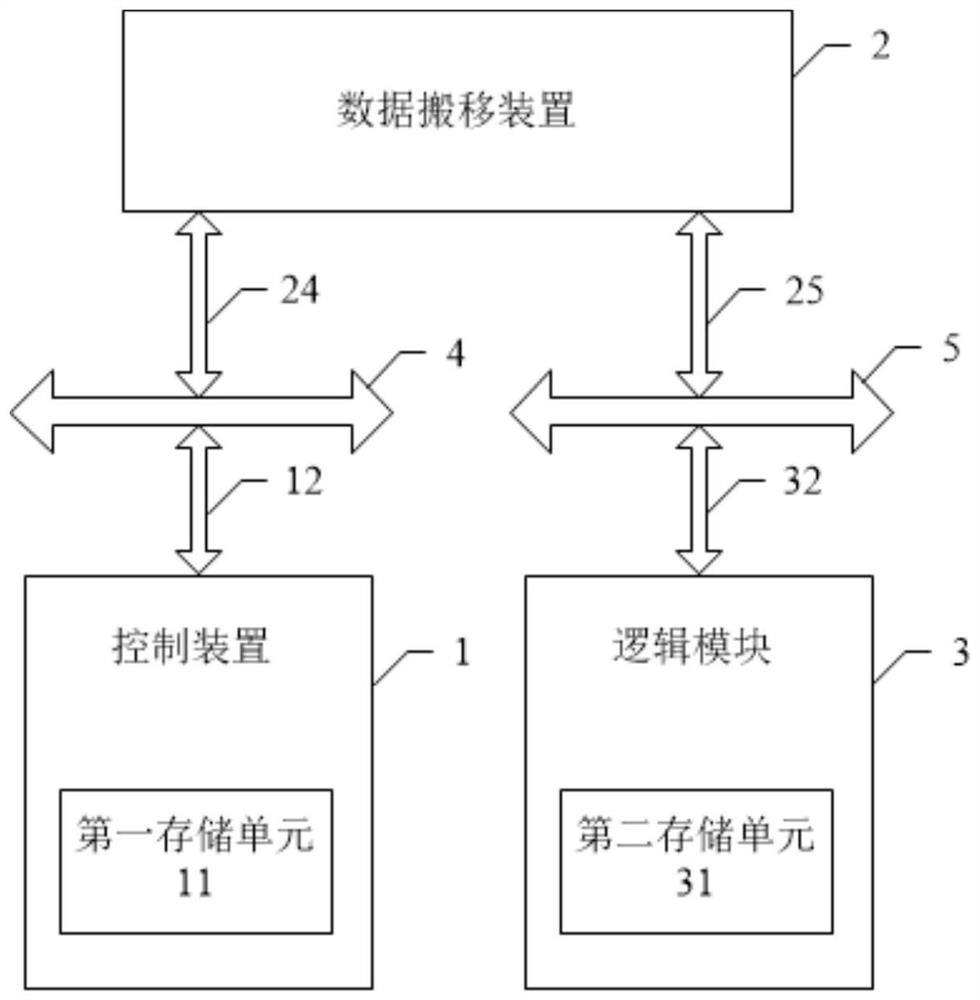

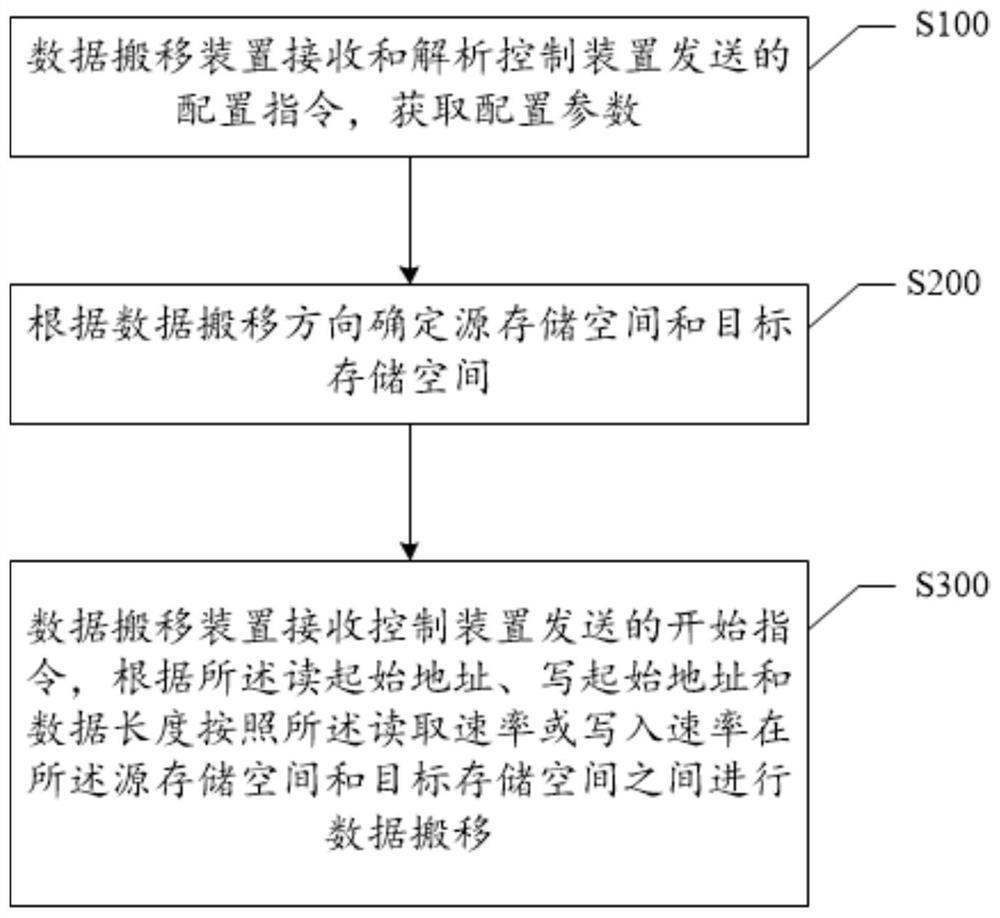

Data migration method, device and system

ActiveCN111782154AReduce power consumptionShorten the durationInput/output to record carriersEnergy efficient computingComputer hardwareEngineering

The invention discloses a data migration method, device and system. The data migration method comprises the following steps: by configuring different data migration directions and a read start address, a write start address, a data length and response time of migrated data, reading moving data in the source storage space according to the configured parameters and writing the moving data into the target storage space to realize data moving between the source storage space and the target storage space. Therefore, the data migration operation is converted into the data read-write operation of thesource storage space and the target storage space, a buffer is not needed, the power consumption and duration required by data migration are reduced, the data migration efficiency is high, the universality is high, and the method can be suitable for various scenes with determined response time.

Owner:BEIJING SIGBEAN INFORMATION TECH CO LTD

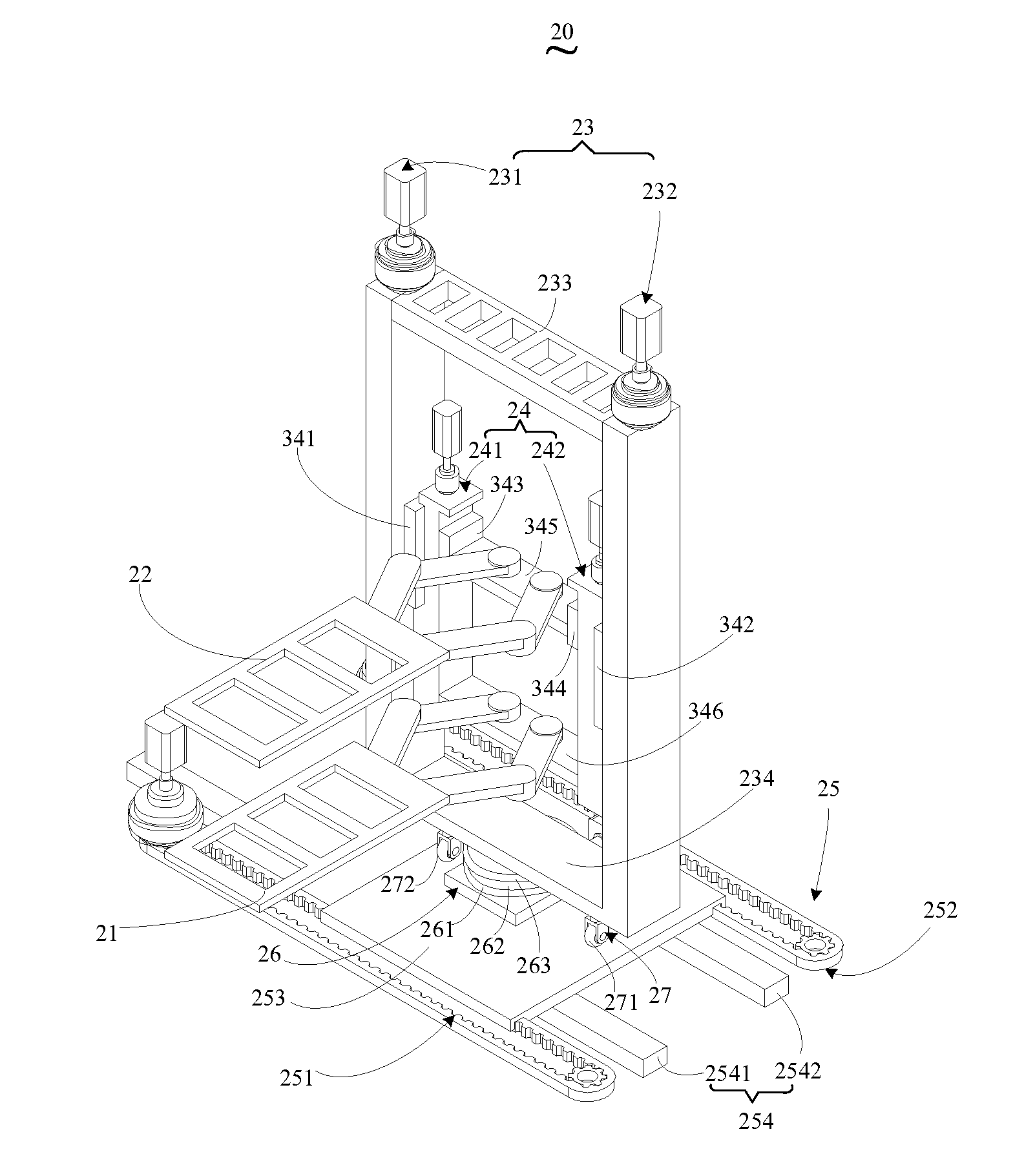

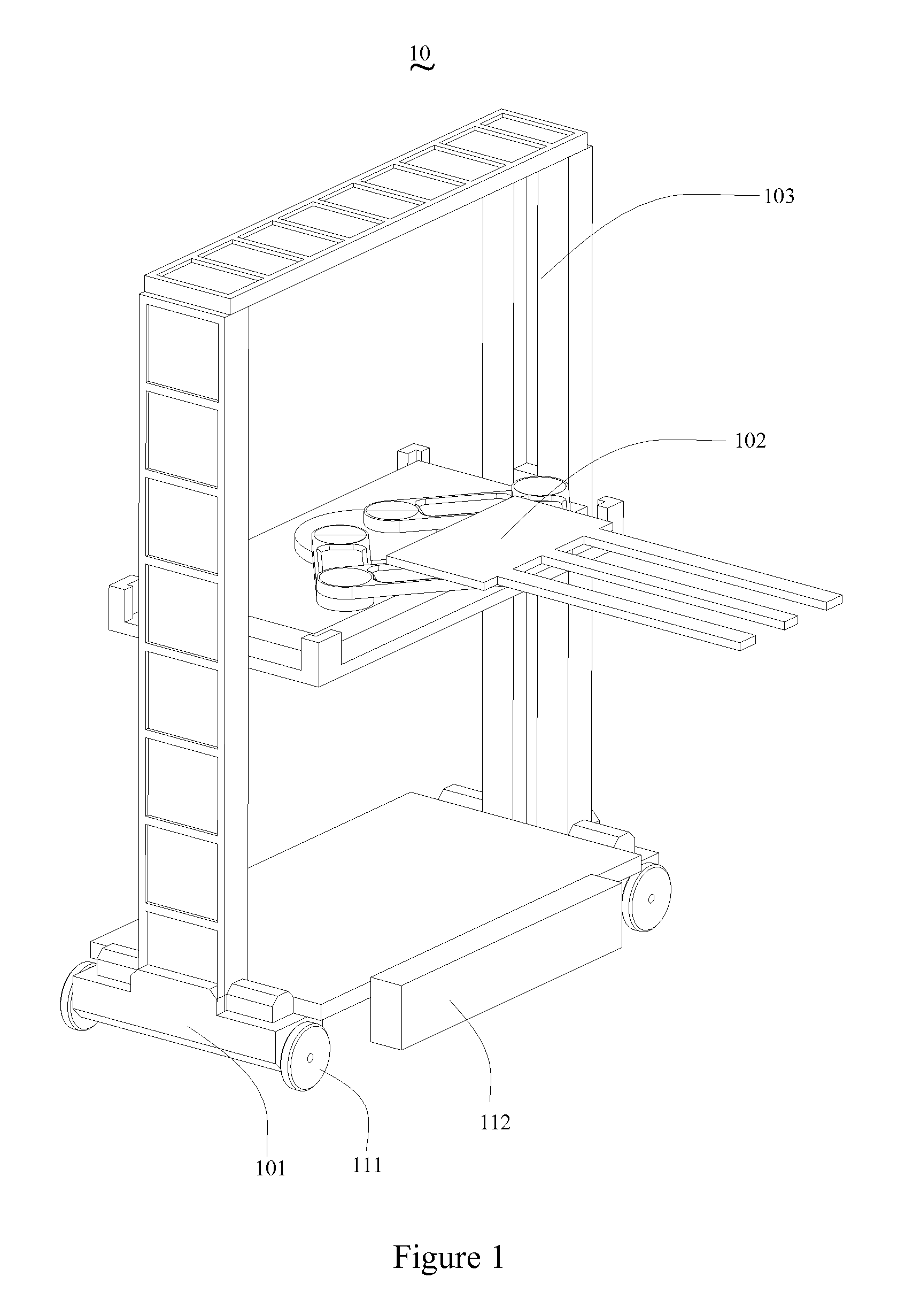

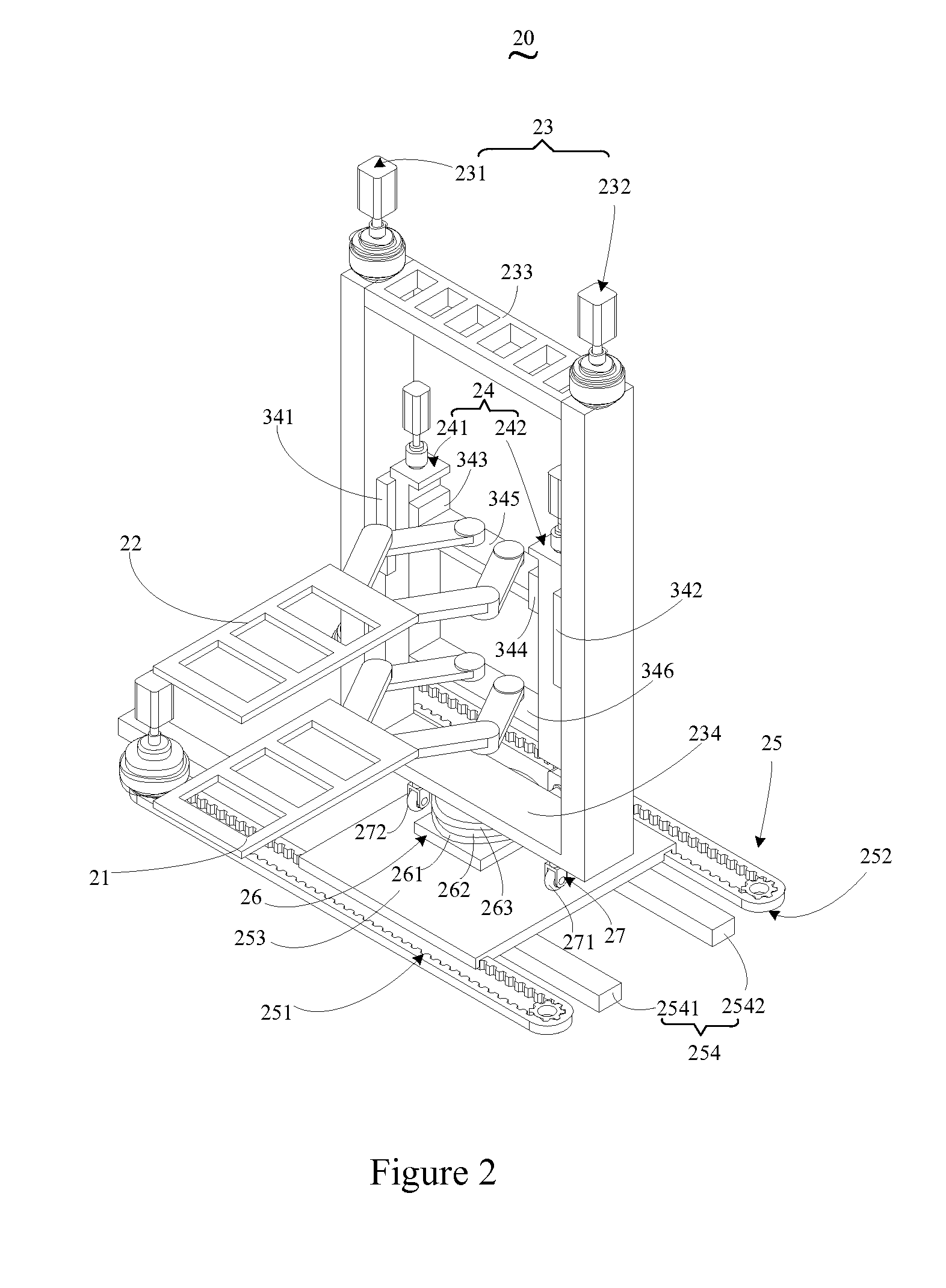

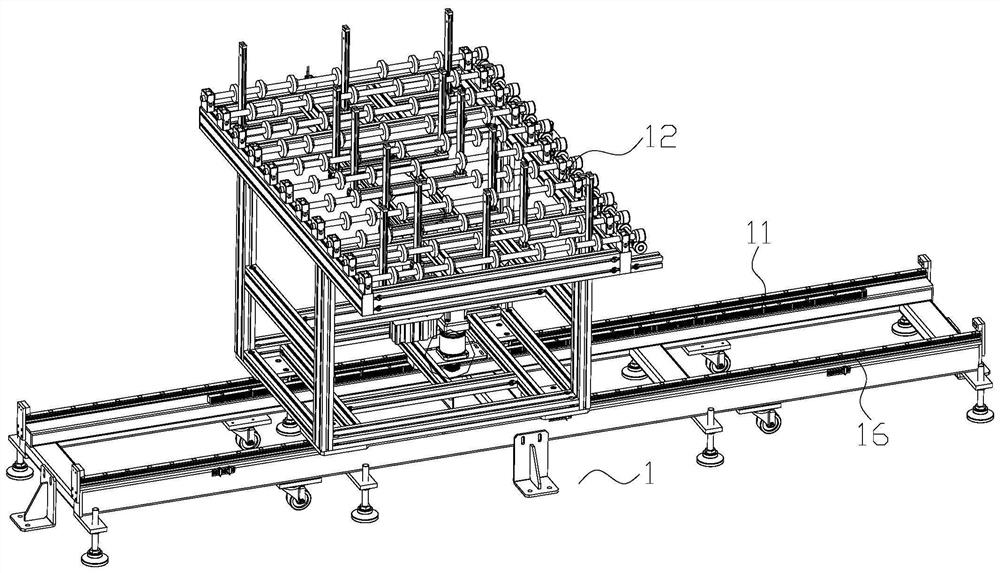

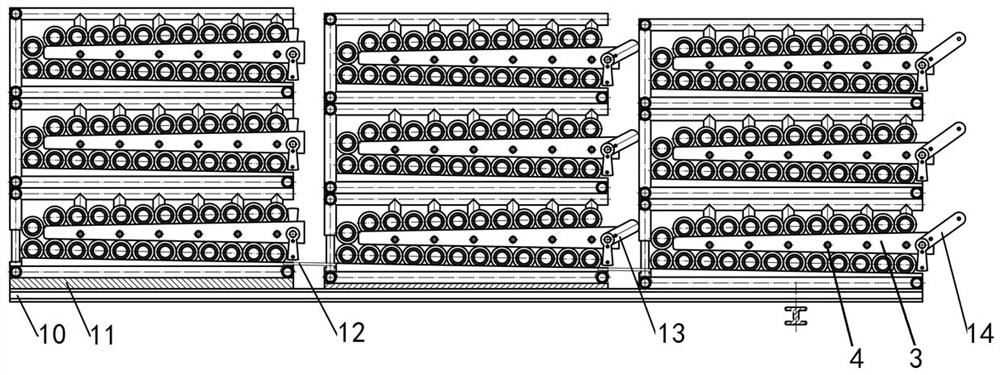

Crane and Automated Storage and Retrieval System

ActiveUS20140112742A1Increase volumeImprove moving efficiencyProgramme-controlled manipulatorLifting devicesEngineeringVertical motion

The present invention discloses a crane and an automated storage and retrieval system. The crane includes a first arm, a second arm, a first vertical transmission mechanism and a second vertical transmission mechanism. The first vertical transmission mechanism transmits the first arm and the second arm to move vertically in a synchronous manner, and the second vertical transmission mechanism transmits the second arm to move vertically with respect to the first arm. As such, the present invention can increase the moving volume of a single turn of movement as well as improve the moving efficiency and production efficiency.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

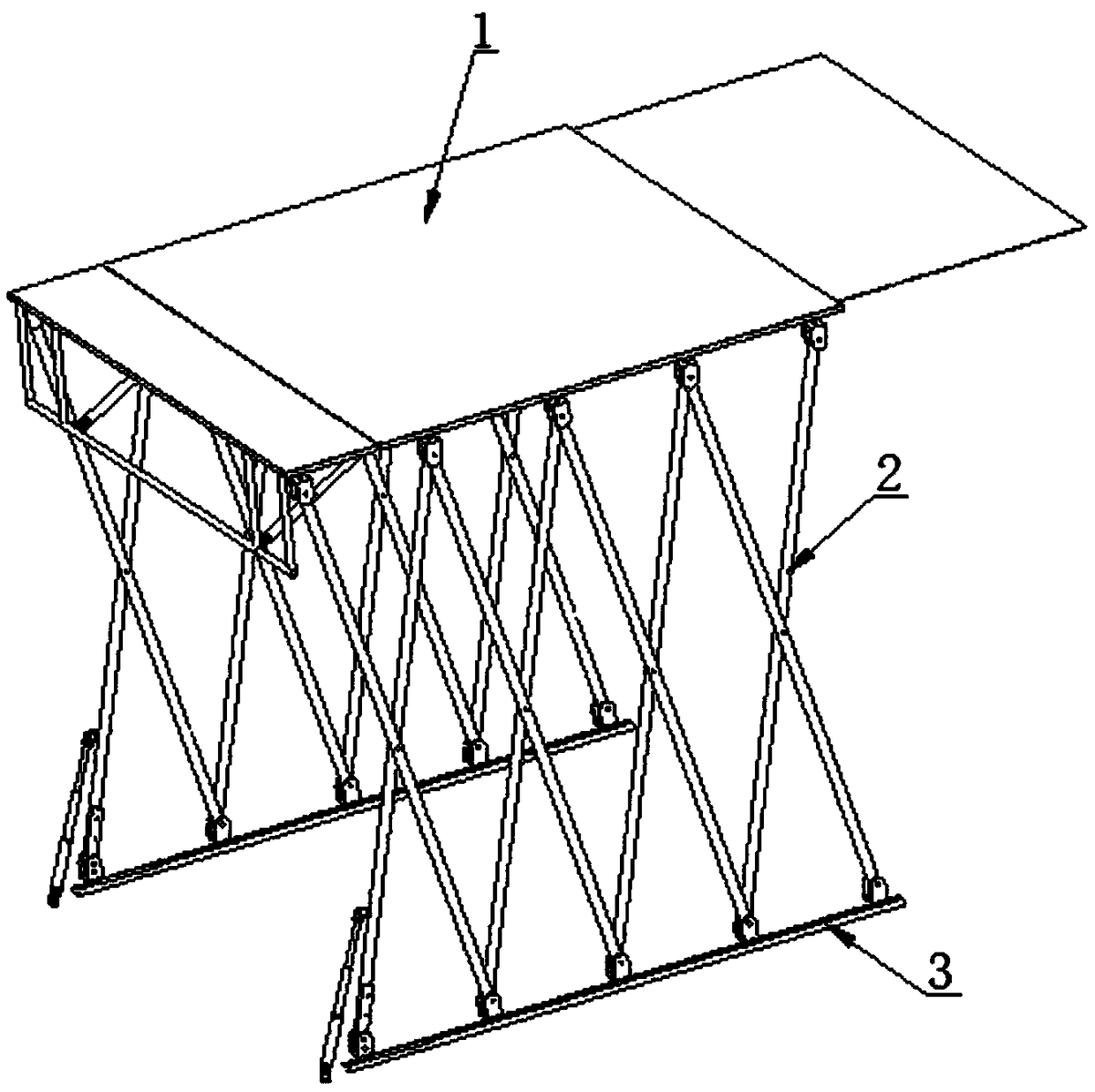

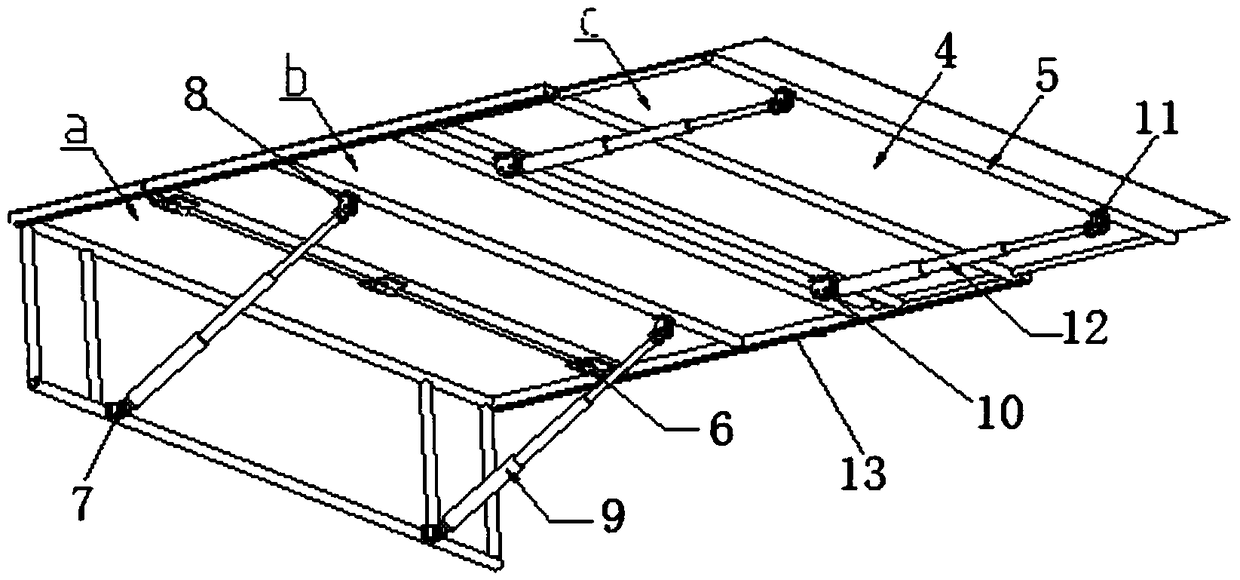

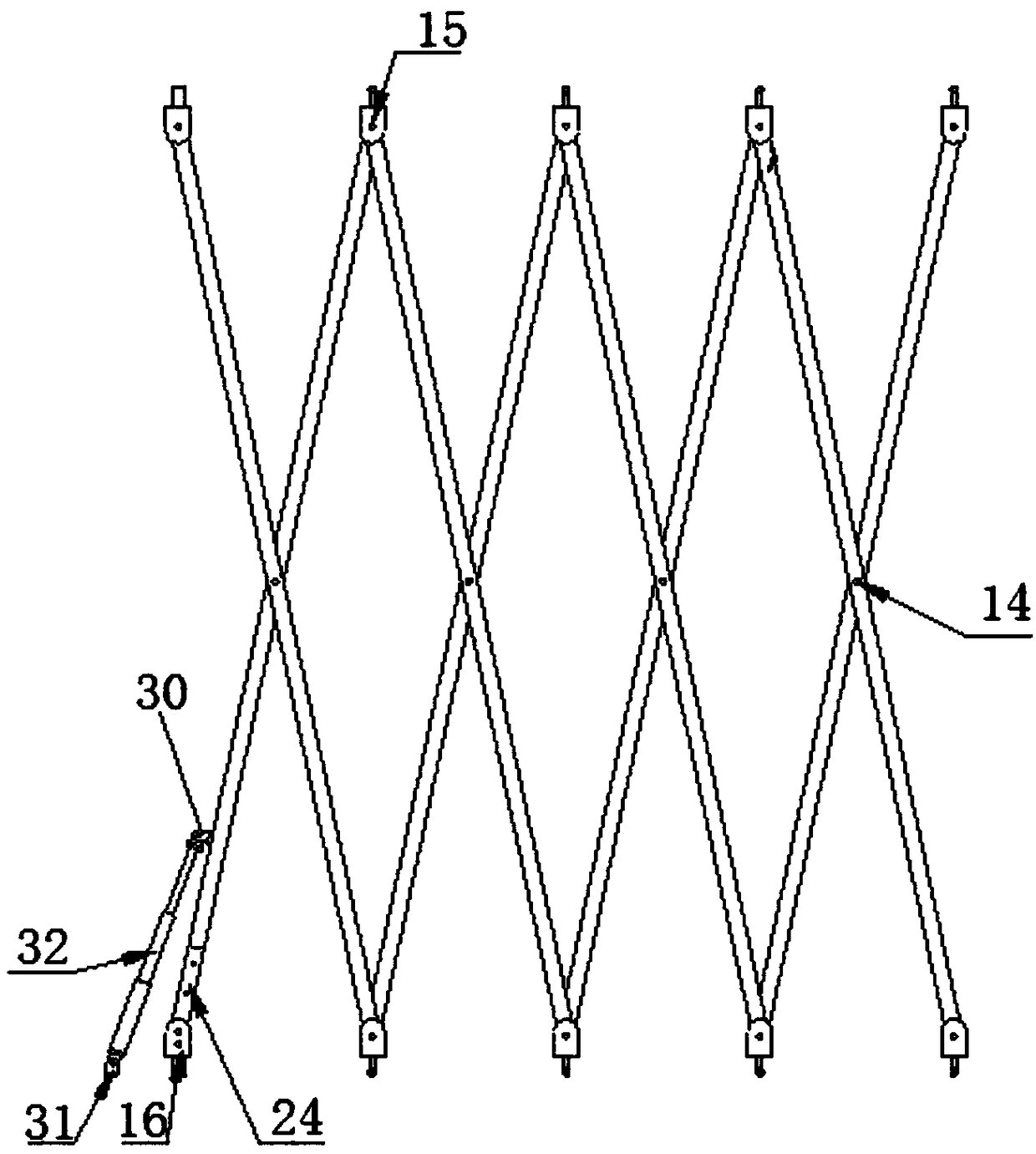

Sliding folding telescopic rain-proof canopy for well drilling slurry tank

PendingCN109296081AReduce manufacturing costLarge coverage areaBuilding constructionsWell drillingSlurry

The invention relates to the technical field of oil equipment auxiliary protection devices, in particular to a sliding folding telescopic rain-proof canopy for a well drilling slurry tank. The slidingfolding telescopic rain-proof canopy for the well drilling slurry tank comprises a top canopy, sliding folding uprights symmetrically arranged on the lower parts of the front and back sides of the top canopy and bottom sliding rails arranged at the bottom ends of sliding folding uprights. The sliding folding telescopic rain-proof canopy for the well drilling slurry tank has a simple structure andconvenient utilization, rapid installation and disassembly can be realized, a sliding structure and a hydraulic transmission mode are used for replacing manual labor, participation of excessive humanis not needed, and the manual labor and time are saved; when a well site is moved, the sliding folding telescopic rain-proof canopy for the well drilling slurry tank only needs to be folded and put down on the slurry tank, and the moving efficiency is greatly improved; the sliding folding uprights can replace guard barriersto lower the manufacturing cost of the rain-proof canopy; during working of the telescopic top canopy, the covering area of the rain-proof canopy can be greatly enlarged; and when a tank surface equipment needs to be hoisted, hoisting of the tank surface equipment can be realized only by retracting a C top canopy or / and folding a top canopy B.

Owner:SHANDONG KERUI PUMP

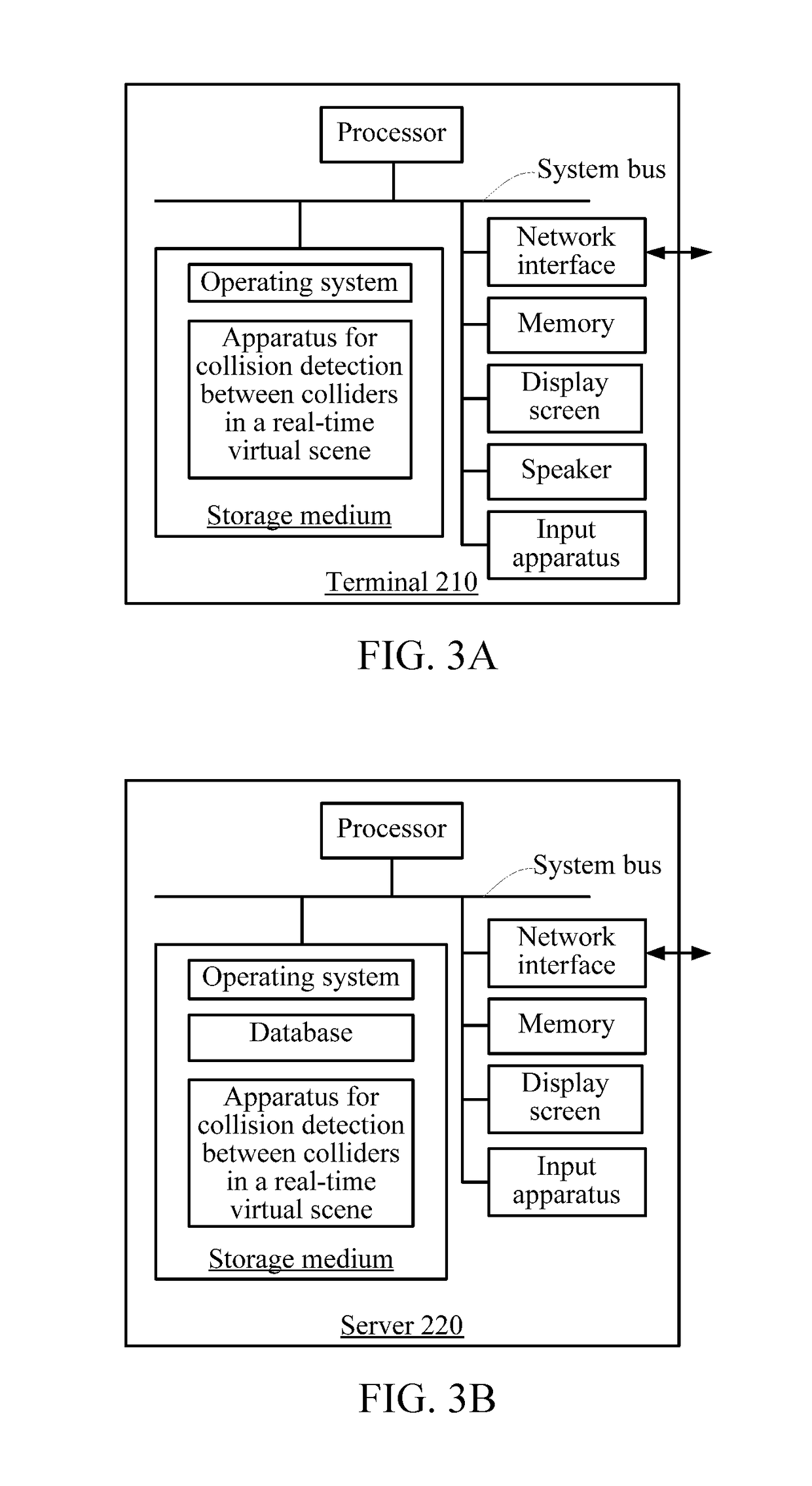

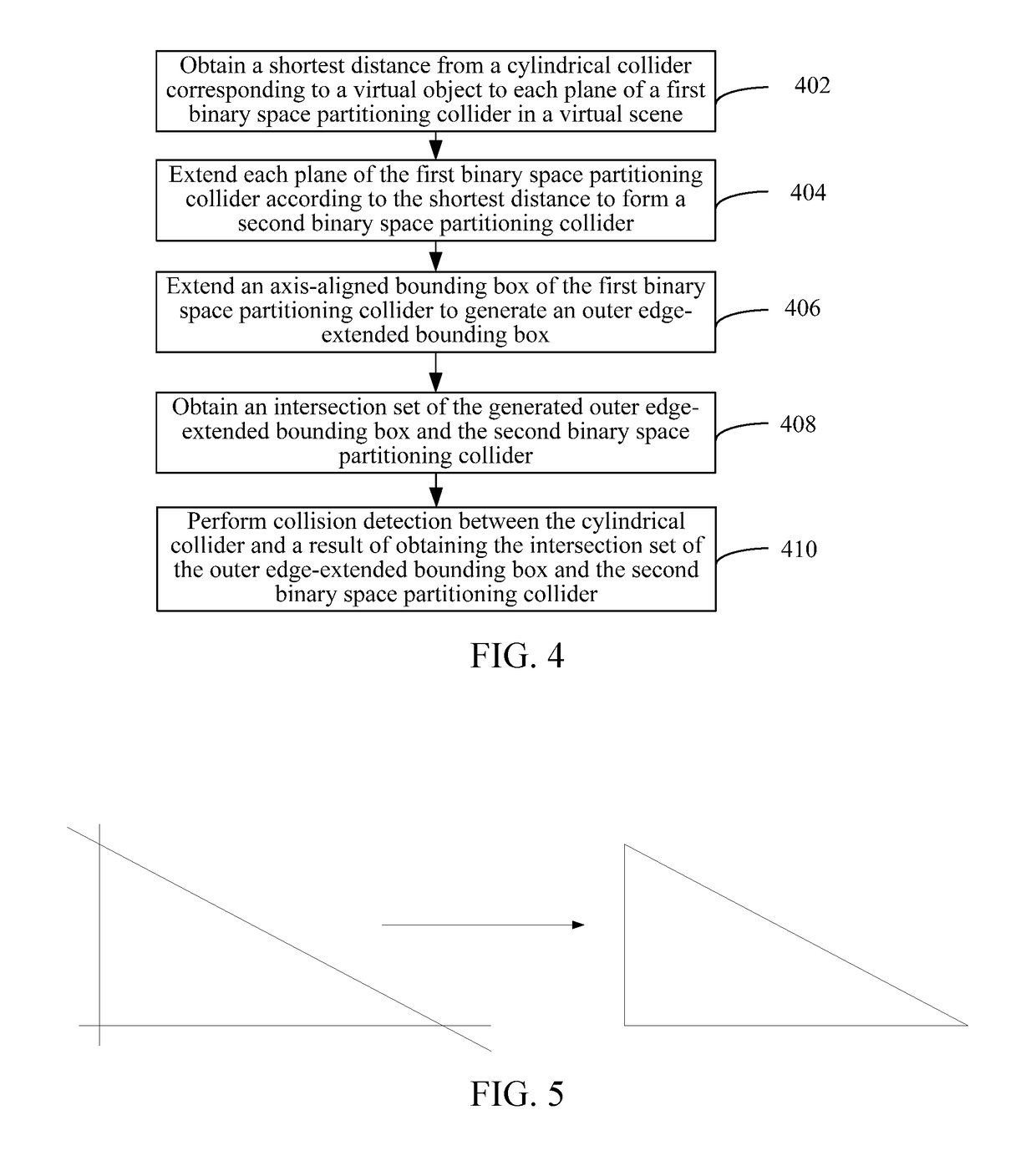

Method, terminal, and storage medium for detecting collision between colliders in real-time virtual scene

ActiveUS10235764B2Easy to operateImprove handling efficiencyImage analysisGeometric image transformationBinary space partitioningCollision detection

A method for collision detection between colliders in a real-time virtual scene includes: obtaining a shortest distance from a cylindrical collider corresponding to a virtual object to each plane of a first binary space partitioning collider in a virtual scene; extending each plane of the first binary space partitioning collider according to the shortest distance to form a second binary space partitioning collider; extending an axis-aligned bounding box of the first binary space partitioning collider to generate an outer edge-extended bounding box; obtaining an intersection set of the generated outer edge-extended bounding box and the second binary space partitioning collider; and performing collision detection between the cylindrical collider and a result of obtaining the intersection set of the outer edge-extended bounding box and the second binary space partitioning collider.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Large cargo translating device

ActiveCN101058372BCompact structureHigh degree of mechanizationStorage devicesConveyor partsEngineeringChassis

Owner:CHINA SHIP DEV & DESIGN CENT

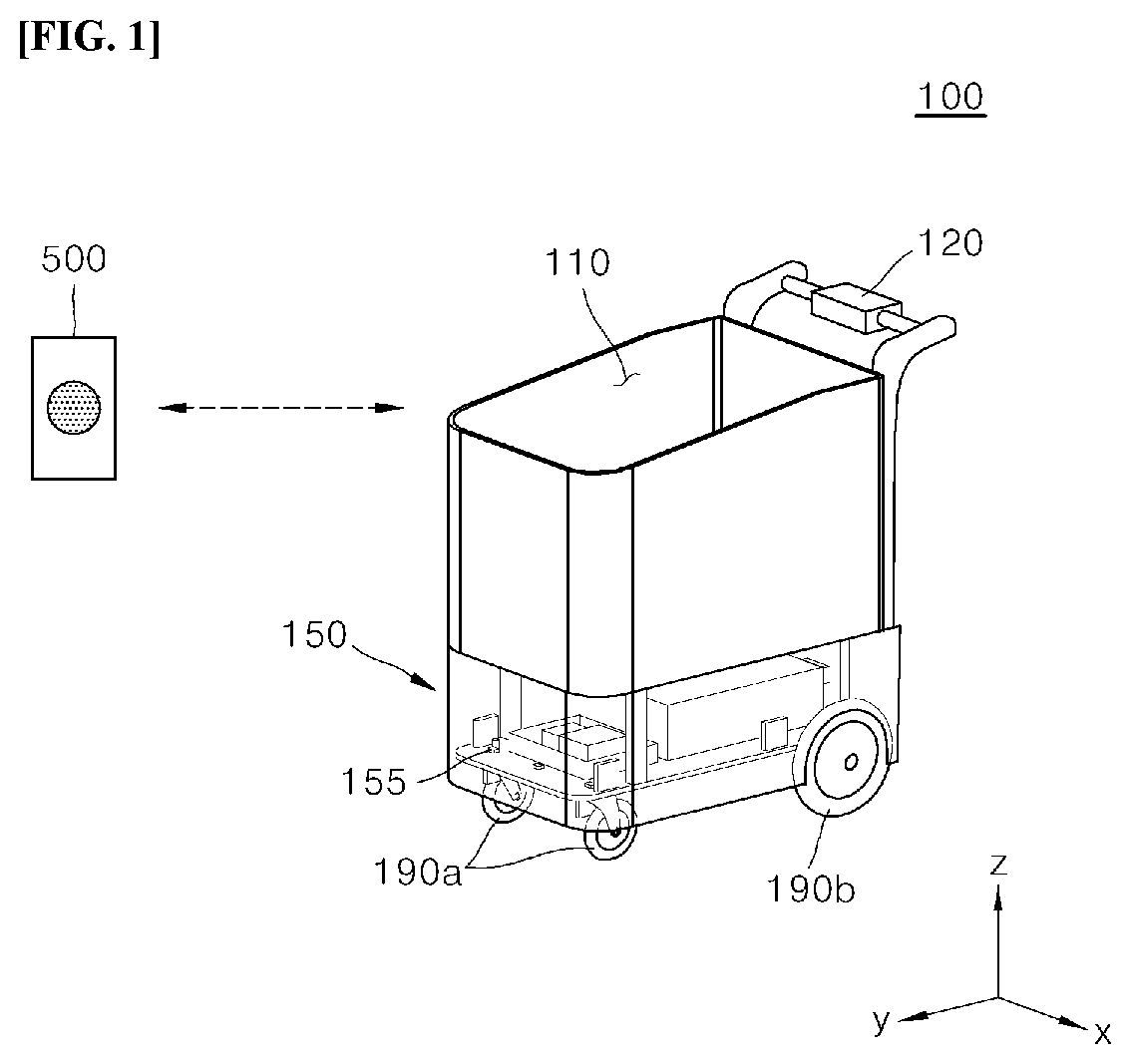

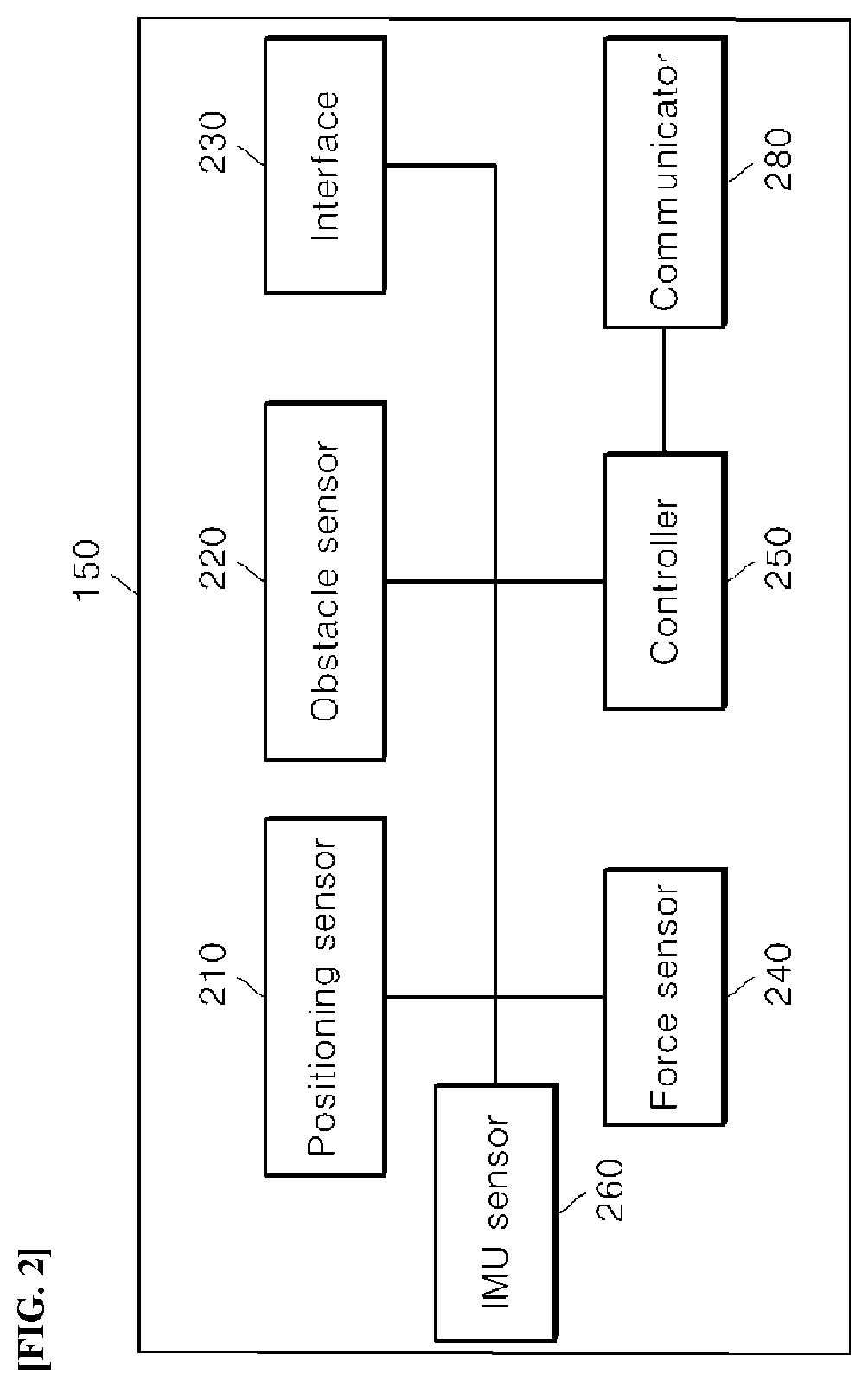

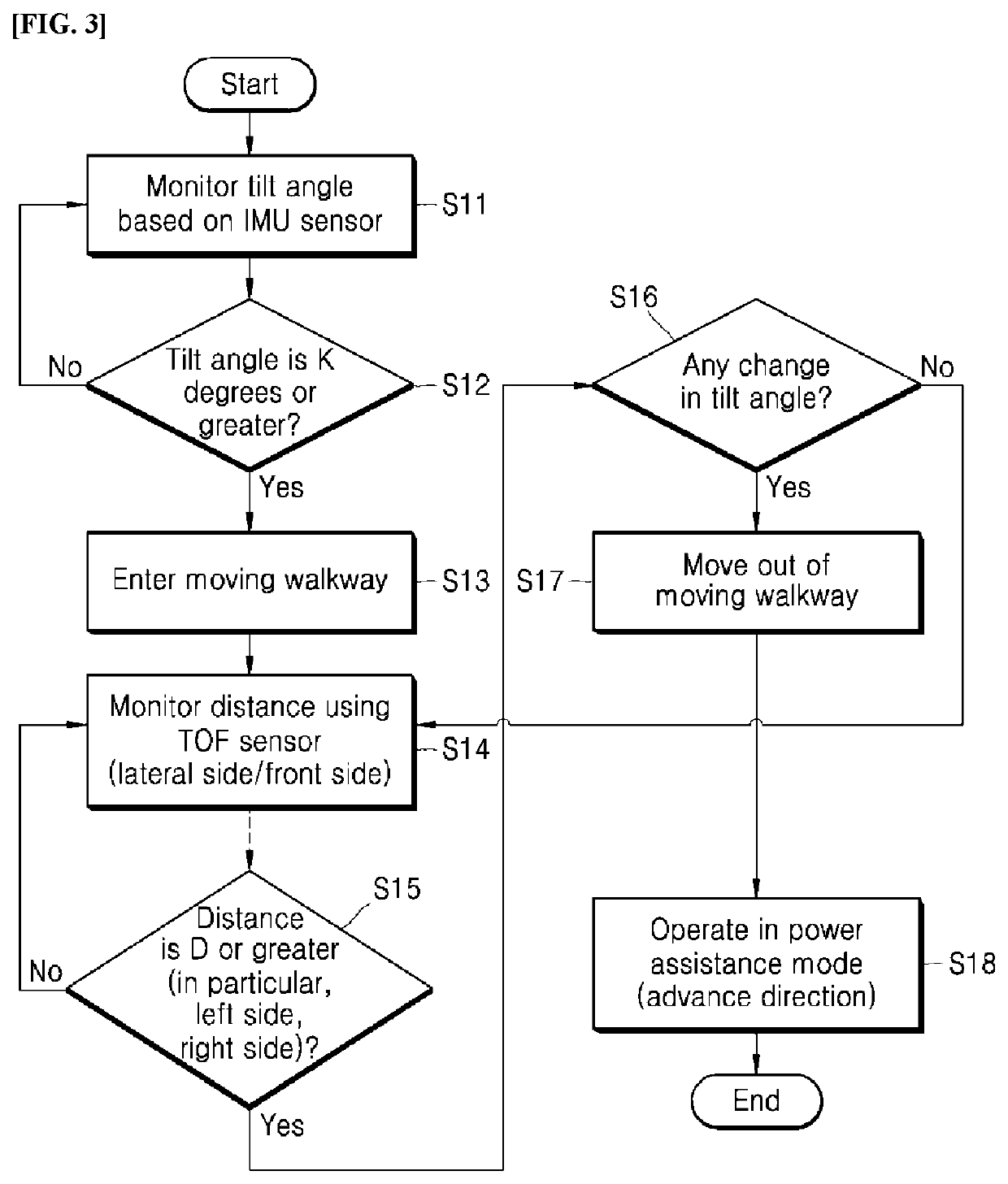

Method of controlling movement of cart robot in response to change in travel surface using artificial intelligence and cart robot implementing the same

PendingUS20220118613A1Prevent slippingReduce the likelihood of a collisionProgramme-controlled manipulatorVehicle position/course/altitude controlSimulationControl theory

The present disclosure relates to a method of controlling movement of a cart in response to a change in a travel surface using artificial intelligence and a cart implementing the same, and in a cart robot of one embodiment, an IMU sensor senses a change in a travel surface, and an obstacle sensor senses a distance from an installed object placed in a direction of an advance of the cart robot, to control a moving part of the cart robot.

Owner:LG ELECTRONICS INC

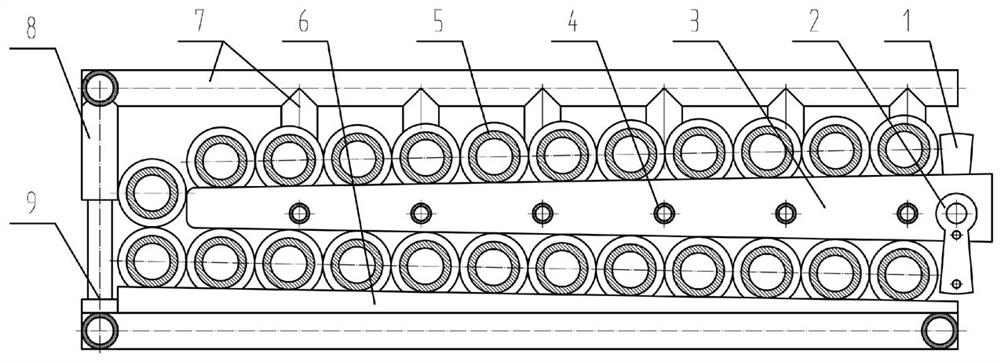

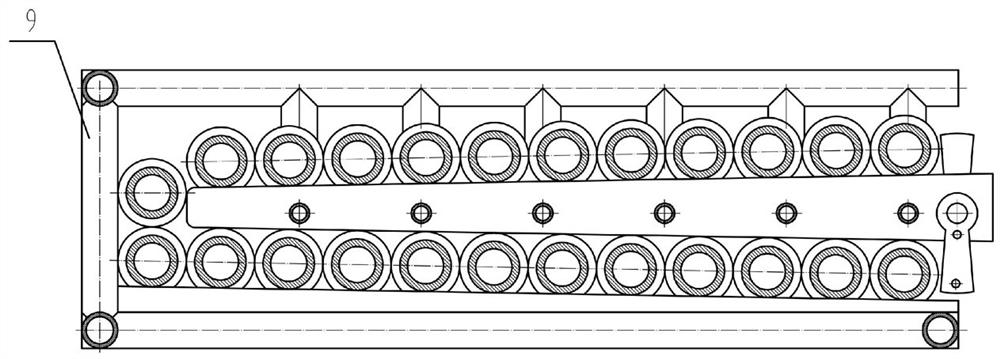

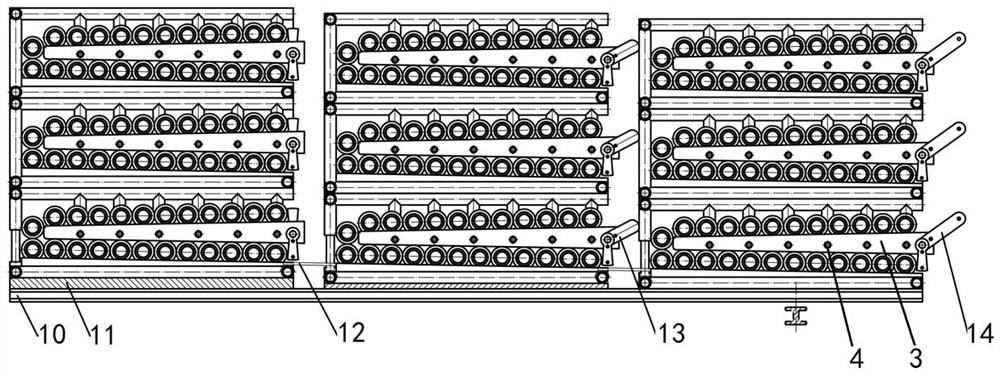

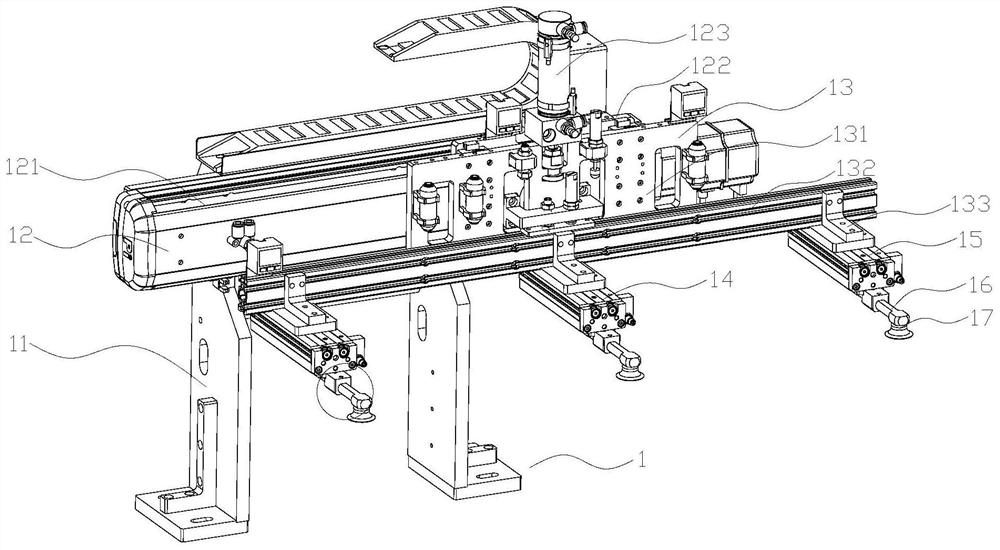

Glass panel pushing mechanism, glass panel conveying device and glass panel feeding and discharging equipment

InactiveCN113184539AImprove moving efficiencyReduce labor intensityCharge manipulationConveyor partsElectric machineryEngineering

Owner:郑少华

Ramp rod box

ActiveCN114075932BRealize root-by-root sequential entry and exitReduce labor intensityDrilling rodsDrilling casingsWell drillingOil field

Owner:山东胜油石油工程有限公司 +1

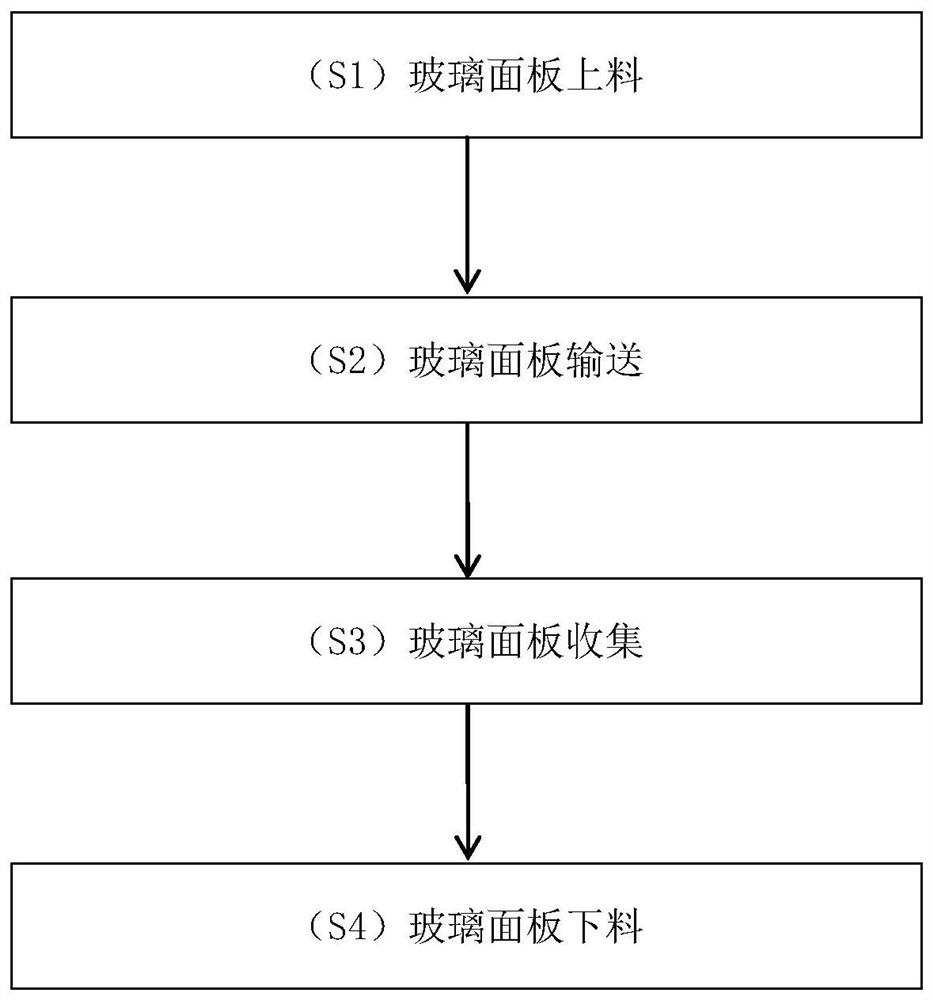

Glass panel feeding and discharging method

InactiveCN113071926AImprove moving efficiencyReduce labor intensityCharge manipulationConveyor partsMechanical engineeringIndustrial engineering

The invention relates to the field of glass panels, in particular to a glass panel feeding and discharging method. Equipment adopted by the method comprises a rack, a conveying device, a collecting device and a discharging and moving device, wherein the conveying device, the collecting device and the discharging and moving device are fixed to the rack; the conveying device comprises a conveying driving mechanism and a pushing mechanism; the collecting device comprises a collecting rack, a lifting mechanism and a collecting box body; and the method comprises the steps of glass panel feeding, glass panel conveying, glass panel collecting and glass panel discharging. According to the method, automatic feeding and discharging of the glass panels are achieved by arranging the conveying device, the collecting device and the discharging and moving device, and the automation degree of the whole equipment is improved.

Owner:郑少华

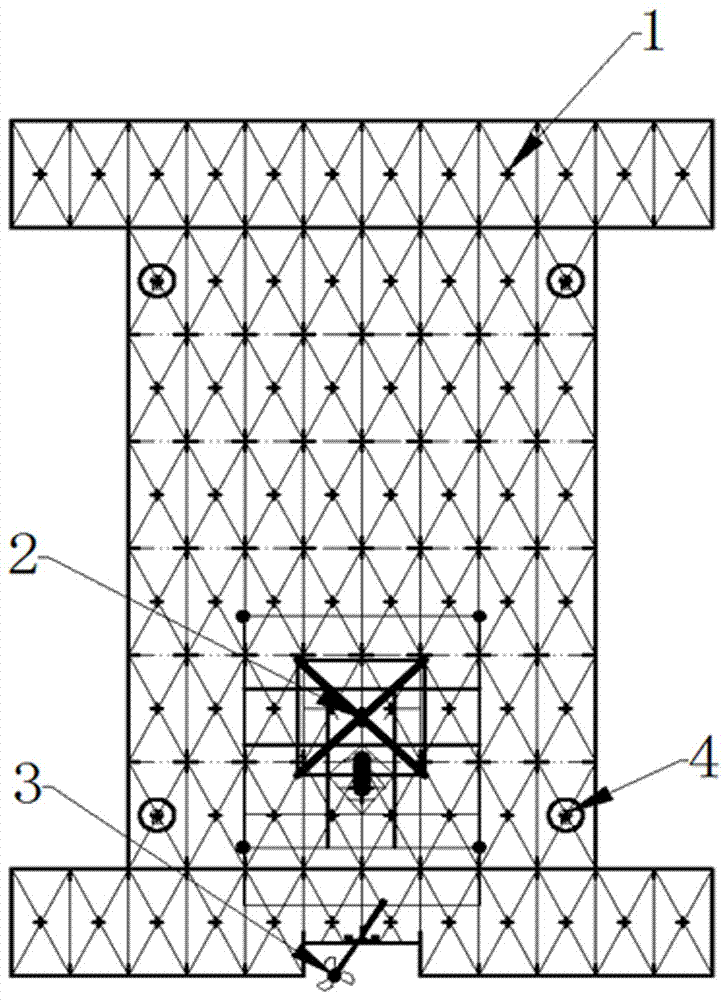

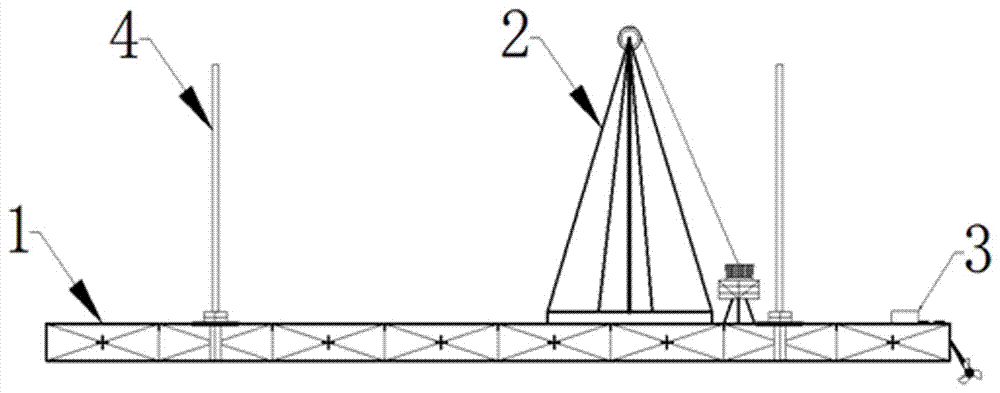

Water exploration platform with power device

PendingCN106985980AMove accurately and quicklyImprove moving efficiencyFloating buildingsAnchoring arrangementsMarine propulsionThe Internet

The invention discloses a water exploration platform with a power device. The water exploration platform is characterized by comprising a platform body which is formed by splicing a plurality of float bowls, drilling equipment installed on the platform body, an anchor rod fixed to the platform body through an anchor rod locking device, and a plug-in type ship propeller hung on one side of the platform body and capable of providing power for advancing of the platform body and achieving the guide function. The water exploration platform with the power device replaces a conventional water operation platform capable of moving through manual boating, through cooperation of the ship propeller and the anchor rod locking device, the platform body can accurately and rapidly move to the point location, and the carrying efficiency of the platform body and accuracy for moving to the hole location can be greatly improved. Certain manpower is liberated, and operation difficulty of operators is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

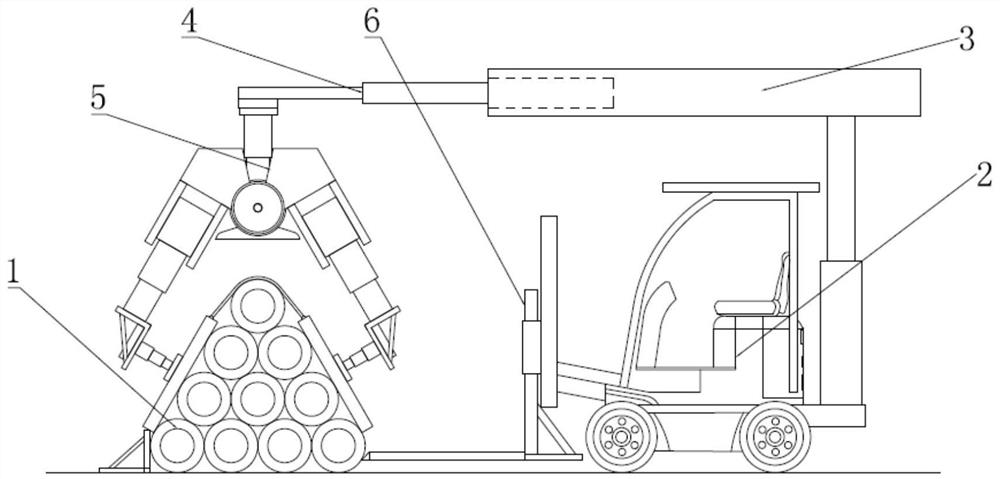

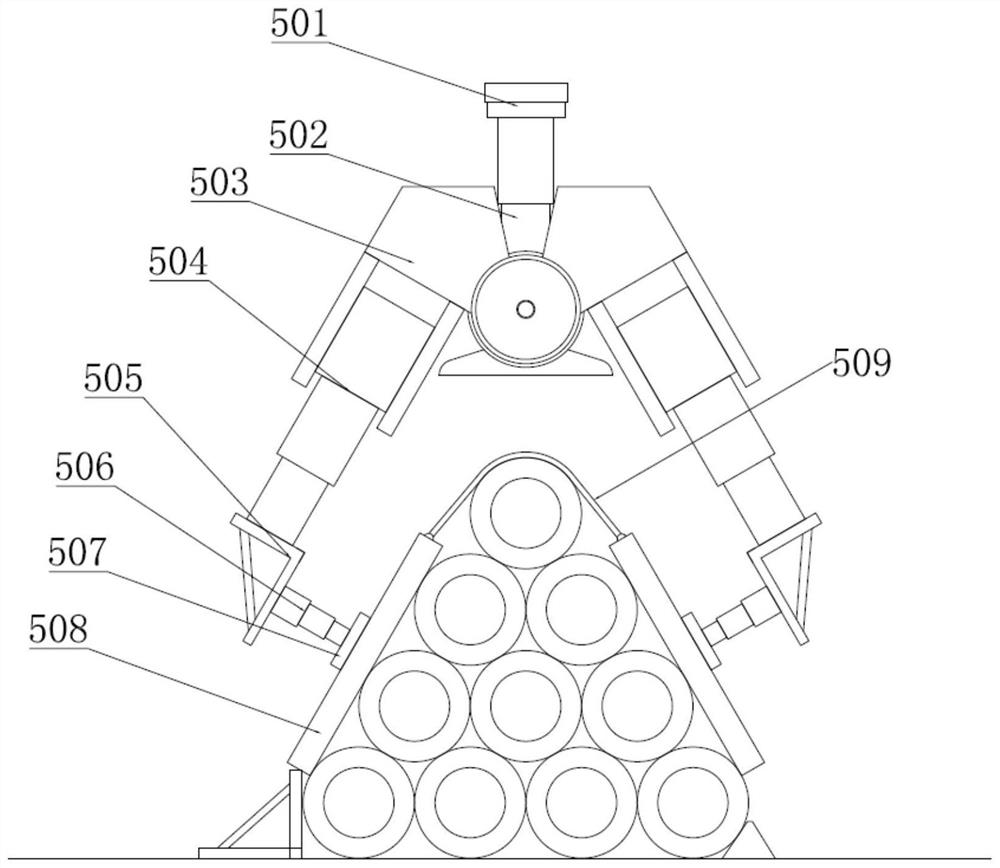

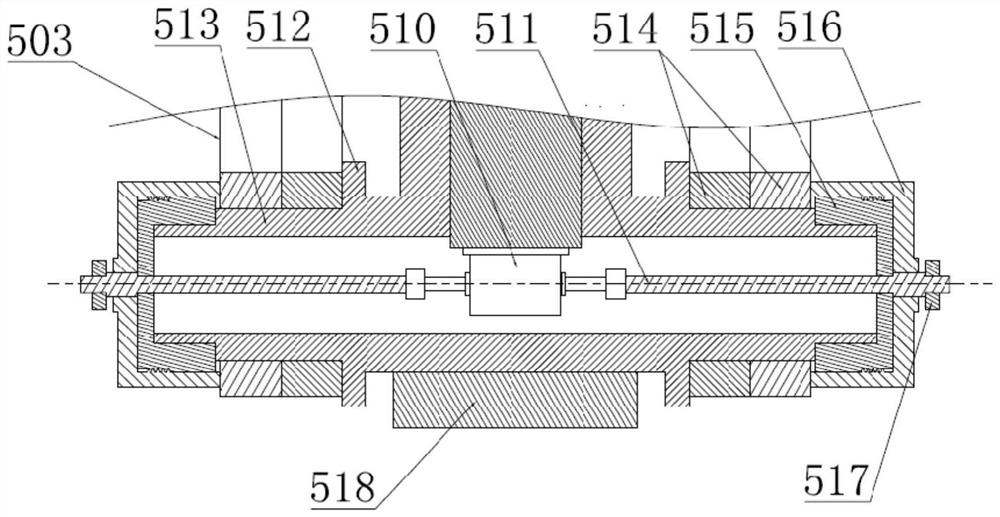

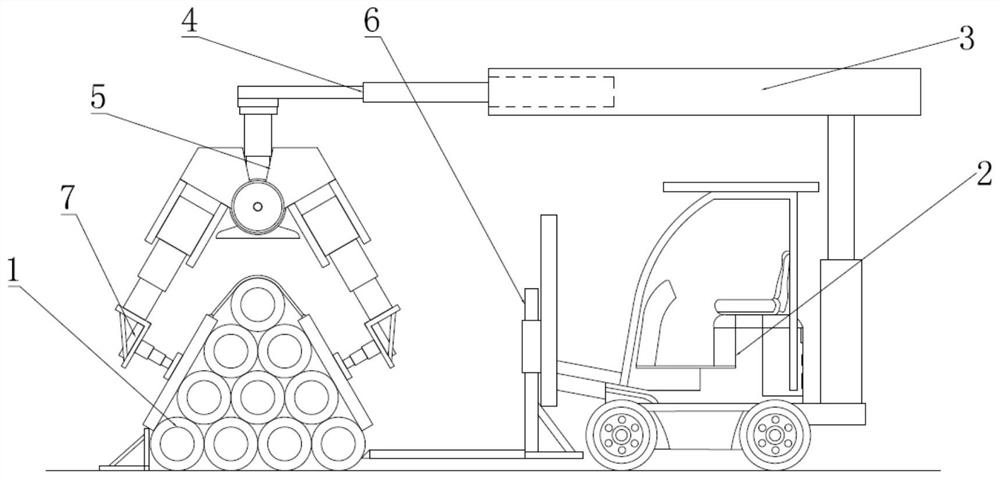

A forklift suitable for cylindrical materials

ActiveCN112794246BAvoid the phenomenon of rollingGuarantee job securityLifting devicesStructural engineeringControl theory

Owner:ANHUI BUSINESS COLLEGE

Vehicle moving system and method based on image recognition

ActiveCN106776814BContact validImprove moving efficiencyData processing applicationsSpecial data processing applicationsContact methodContact mode

The invention relates to a system and a method for shifting vehicles on the basis of image identification. A first mobile phone client in the system for shifting the vehicles is used for acquiring first license plate photos of the road occupying vehicles and at least one contact mode of each road occupying vehicle owner and transmitting the first license plate photos and the contact modes to a server; the server is communicated and connected with the first mobile phone client, license plate numbers can be identified by the server according to the first license plate photos of the road occupying vehicles, and the contact modes of the road occupying vehicle owners can be stored by the server; a second mobile phone client is used for acquiring second license plate photos of the road occupying vehicles and transmitting the second license plate photos to the server; the server is communicated and connected with the second mobile phone client, the license plate numbers of the road occupying vehicles can be identified by the server according to the second license plate photos and can be matched with existing vehicle owner information in a database by the server, the contact modes of the road occupying vehicle owners can be acquired by the server according to matching results, and the road occupying vehicle owners can be in contact. The method is implemented on the basis of the system. The system and the method have the advantages that the system and the method are free of public resource and police force occupation, the road occupying vehicle owners can effectively be in contact, and the vehicle shifting efficiency can be improved.

Owner:HEFEI UNIV OF TECH

Underground support dismantling and mounting method

InactiveCN103899339AReduce frictionReduce loadProps/chocksArchitectural engineeringStructural engineering

The invention relates to an underground support dismantling and mounting method, in particular to an underground fully-mechanized mining support dismantling method applied to dismantling and mounting of supports in roadways and cut holes with high unevenness level, high gradient t and soft floor rock. The method has the advantages that effectiveness of dismantling time is guaranteed by decreasing friction between the supports and the roadway floor, shifting efficiency is improved, load of carriers is lowered, equipment loss and maintenance are decreased, and time is gained for extraction.

Owner:折俊杰

A middle tank truck

ActiveCN104709152BImprove moving efficiencyIncrease the level of mechanizationItem transportation vehiclesSprocketTruck

The invention belongs to the technical field of design and manufacturing of coal mine moving equipment, particularly belongs to a middle trough moving van. The problems that the middle trough moving efficiency is low, the process is tedious and certain potential safety hazards exist are solved. The middle trough moving van comprises a gantry type van frame with a telescopic beam, an anti-explosion diesel engine and a hydraulic mechanism, wherein the anti-explosion diesel engine is used for providing mechanical power, the hydraulic mechanism is used for converting the mechanical power into liquid pressure, a front driving cab is arranged at the front side of gantry type van frame, a rear driving cab is arranged at the rear side of the gantry type van frame, wheels capable of independently walking are arranged on the two ends of the front side and the two ends of the rear side of the gantry type van frame respectively, each wheel of the moving van is provided with a steering mechanism and a braking reducing mechanism, a middle trough quick loading and unloading mechanism is arranged on the bottom of the gantry type van frame, chain wheel mechanisms are arranged on the front end and the rear end of the gantry type van frame respectively, and the chain wheel mechanisms are controlled by chain wheel oil cylinders respectively.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

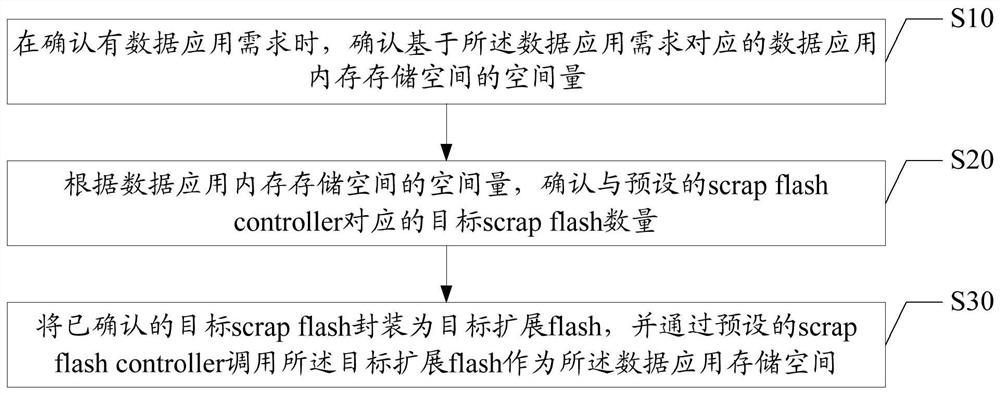

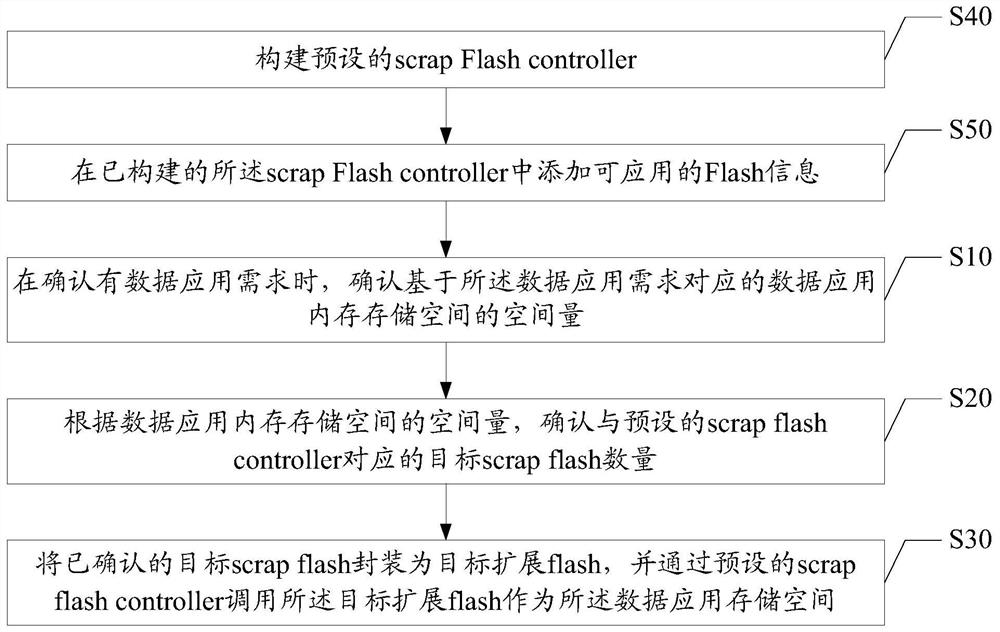

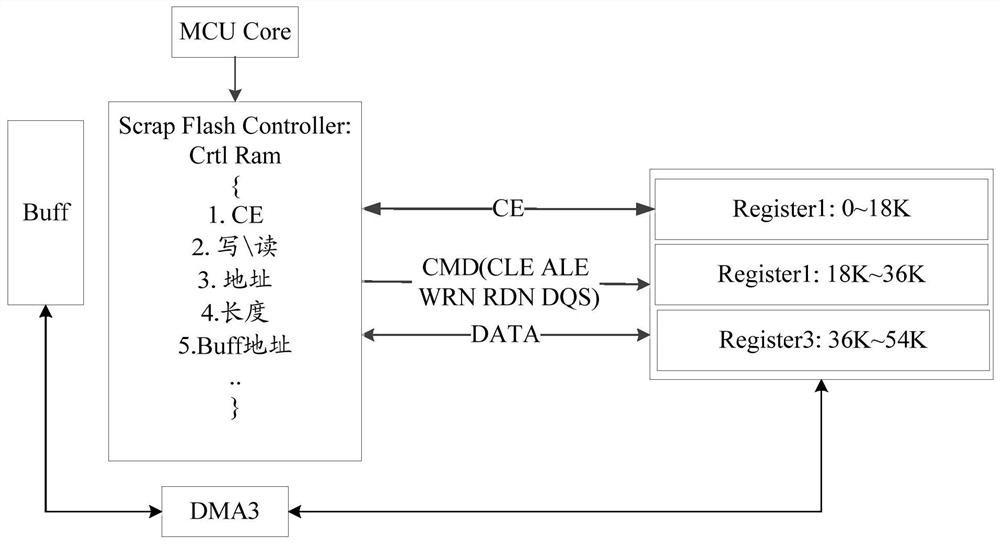

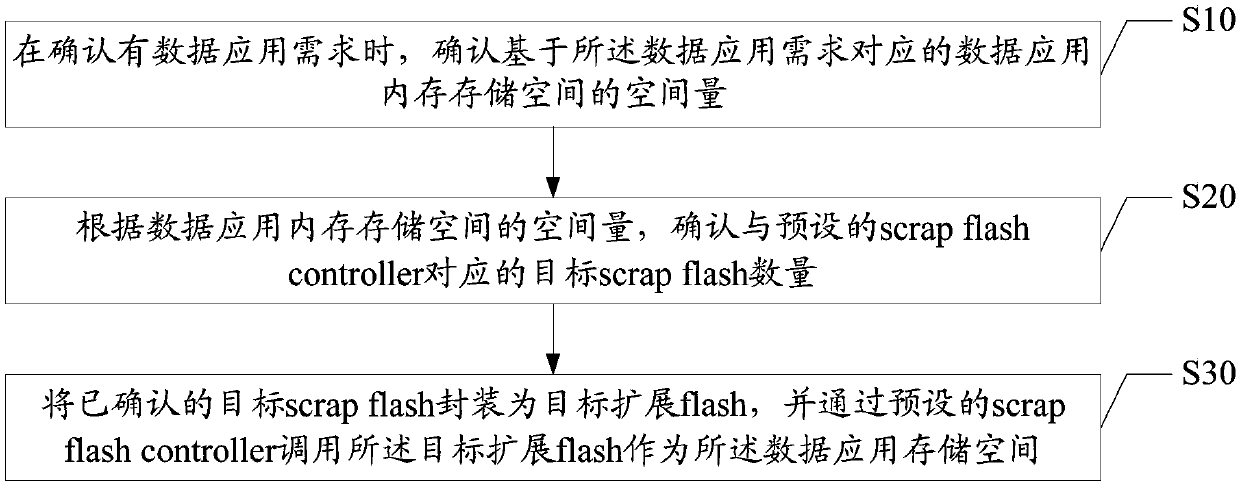

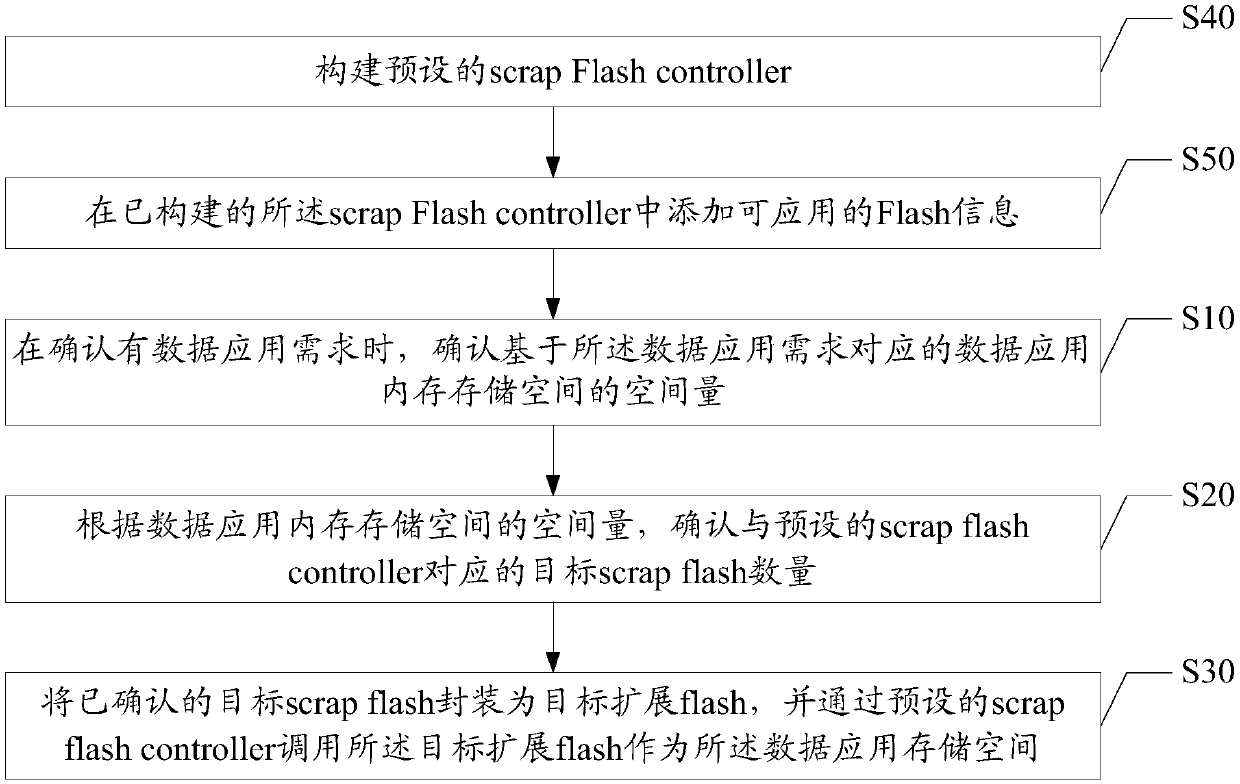

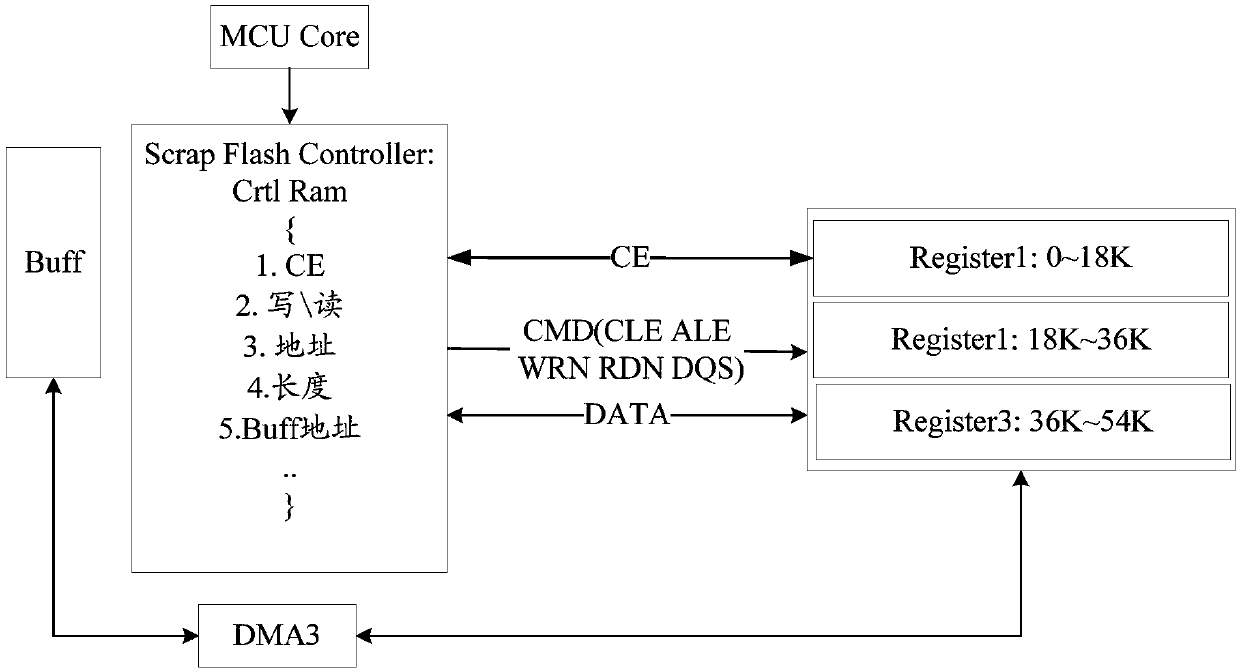

Storage expansion method, device, readable storage medium and system of main control memory

ActiveCN109582243BImprove moving efficiencyMeet memory expansion requirementsInput/output to record carriersProcess engineeringTerm memory

The invention discloses a storage expansion method of a main control memory, which includes: according to the data application requirements, confirming the amount of memory storage space corresponding to the data application requirements; according to the space amount of the data application memory storage space, confirming Set the number of target scrap flashes of the scrap flash controller, wherein the target scrap flashes include one or more; finally package the confirmed target scrap flashes as target extension flash, and call the target extension flash through the preset scrap flash controller Memory storage space is used as the data. The invention also discloses a storage expansion device of the main control memory, a readable storage medium and a system. The present invention encapsulates scrap Flash and Flash according to the current data storage requirements, and stores data and expands memory through the encapsulated Flash, thereby realizing the beneficial effect of improving application performance at the lowest cost.

Owner:YEESTOR MICROELECTRONICS CO LTD

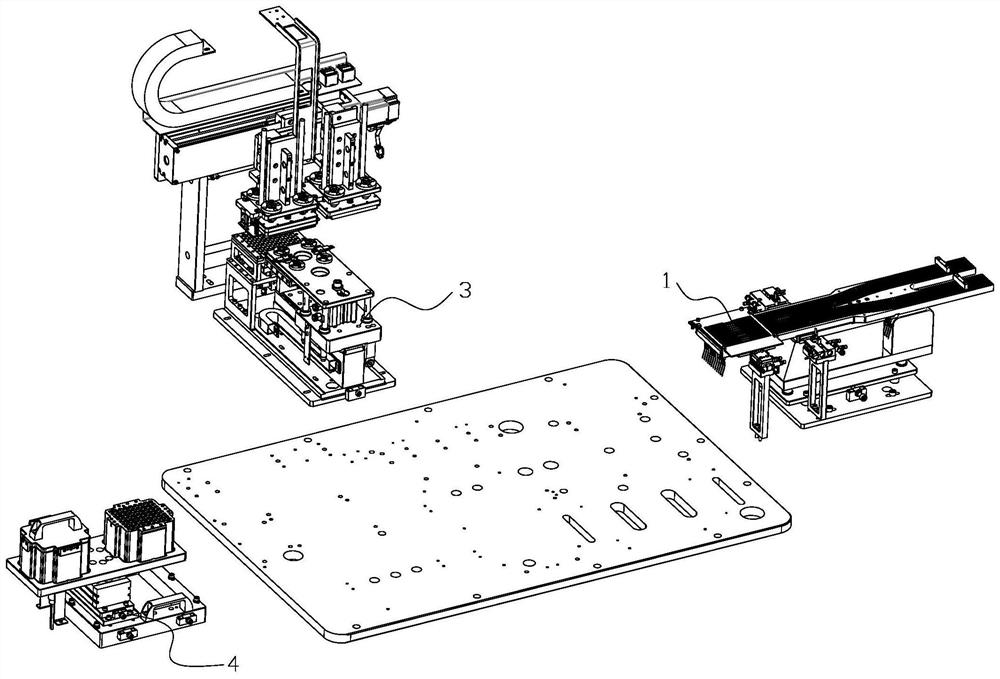

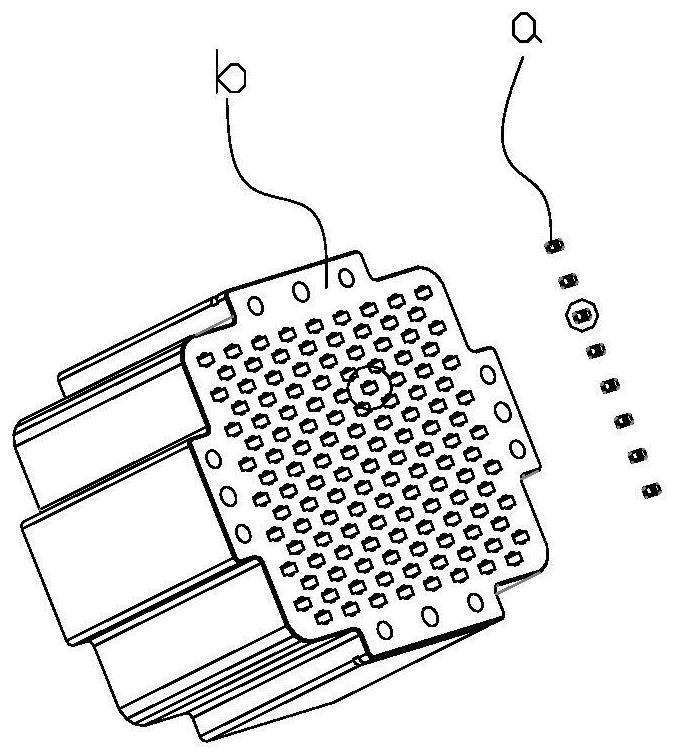

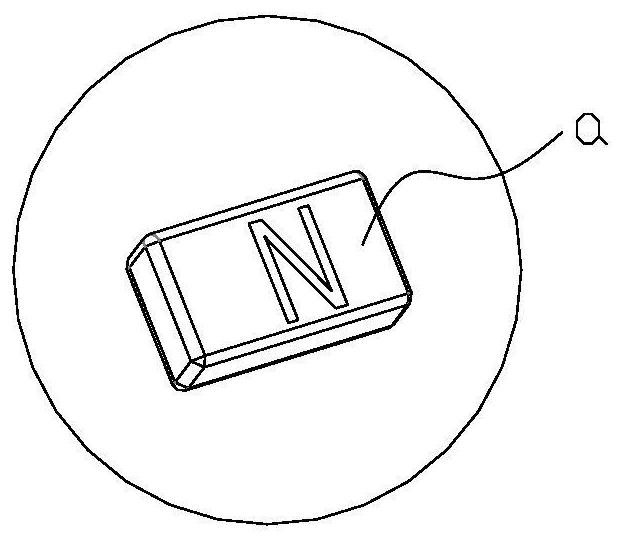

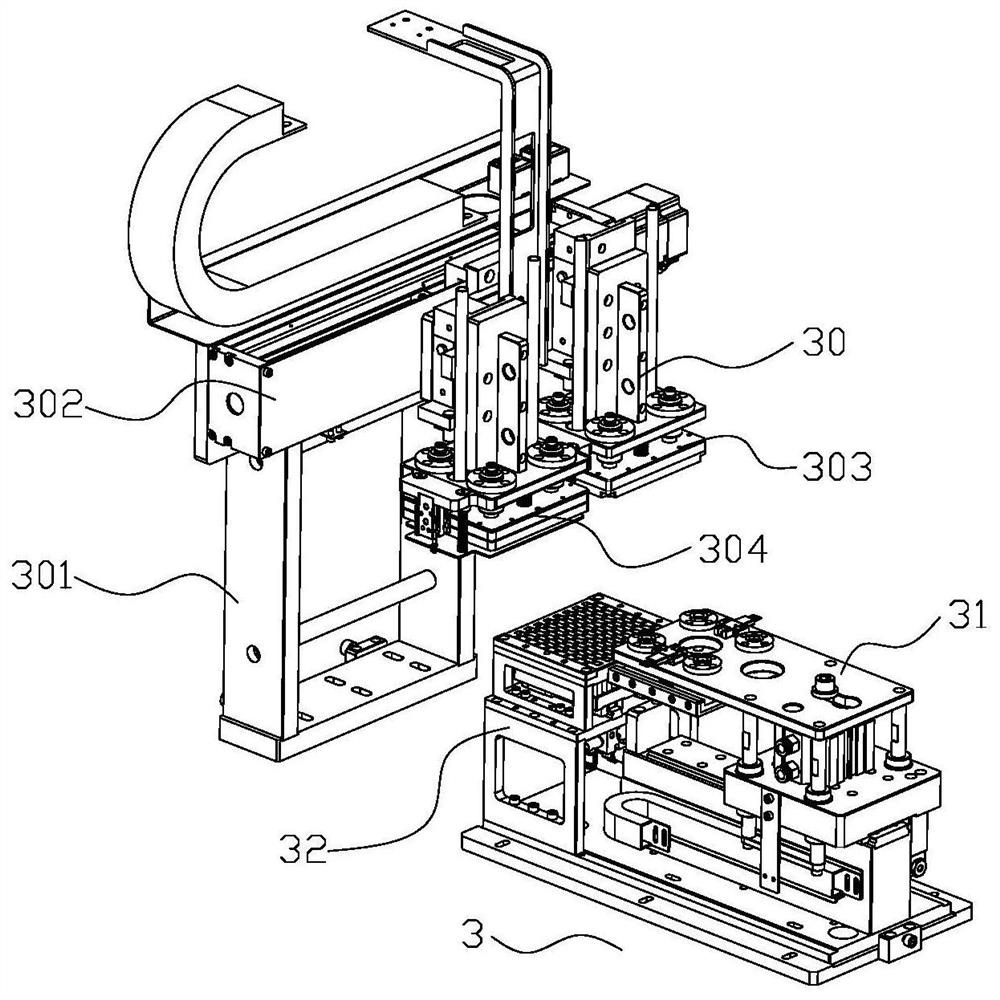

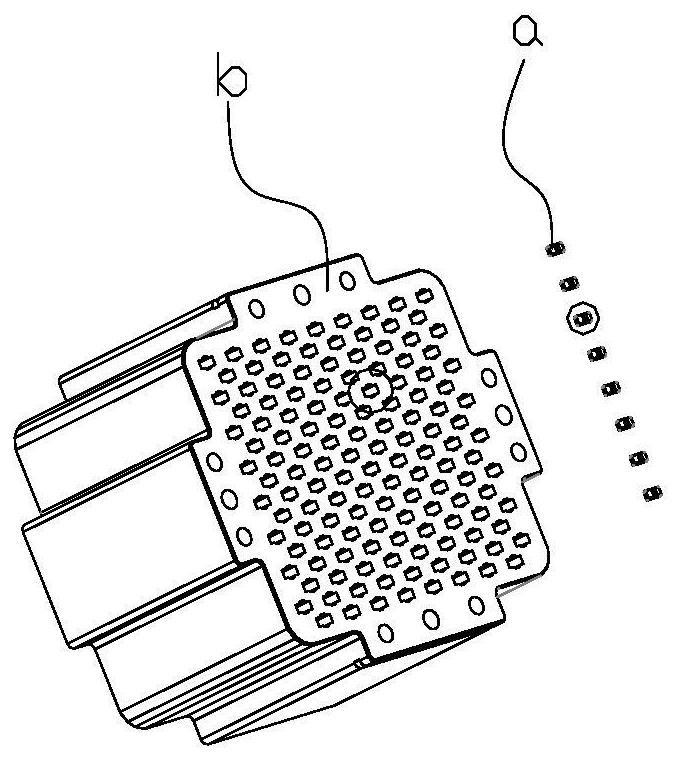

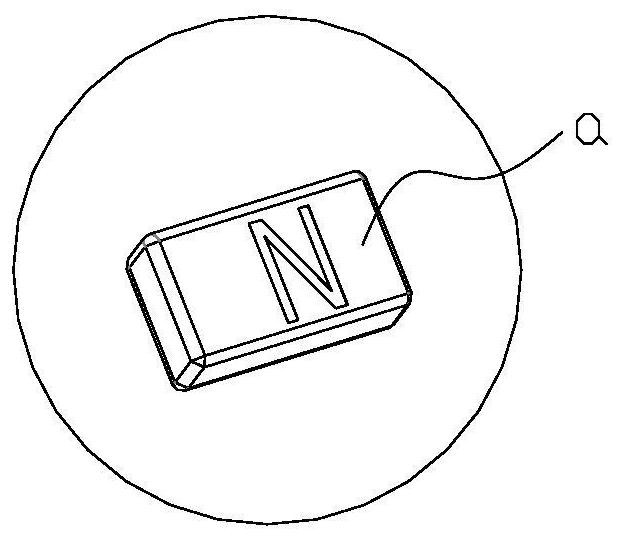

Neodymium-iron-boron permanent magnet feeding device and feeding method

InactiveCN111994629AAvoid automatic suction of NdFeB permanent magnetsGuaranteed accuracyJigging conveyorsConveyor partsEngineeringWorkbench

The invention relates to the field of neodymium-iron-boron permanent magnet production, in particular to a neodymium-iron-boron permanent magnet feeding device, feeding method and magnetizing collection equipment. The device comprises a vibration disc feeding mechanism and a feeding staggering mechanism, wherein the vibration disc feeding mechanism and the feeding staggering mechanism are fixed toa workbench; a material outlet opening of the vibrating disc feeding mechanism is connected with a material inlet end of the feeding staggering mechanism, and the material outlet end of the feeding staggering mechanism is connected with the output end of a material distributing and carrying and moving device; and the vibration disc feeding mechanism is used for feeding neodymium-iron-boron permanent magnets into the feeding staggering mechanism in a vibration mode, and the feeding staggering mechanism is used for controlling the carrying and moving time of the neodymium-iron-boron permanent magnets. According to the neodymium-iron-boron permanent magnet feeding device, feeding method and magnetizing collection equipment, by arranging the feeding staggering mechanism, a carrying and movingair cylinder is prevented from automatically moving downwards, so that the feeding action accuracy of the feeding device is guaranteed.

Owner:温州源利智能科技有限公司

Neodymium-iron-boron permanent magnet distribution device and distribution method

InactiveCN111977351AGuaranteed accuracyAvoid the situation of shifting the distribution groove where the NdFeB permanent magnet is locatedMagnetic bodiesConveyor partsCondensed matter physicsWorkbench

The invention relates to the field of neodymium-iron-boron permanent magnet production, in particular to a neodymium-iron-boron permanent magnet distribution device, a distribution method and a distribution carrying device. The distribution device comprises a surface attaching mechanism and a distribution staggering mechanism, wherein the surface attaching mechanism and the distribution staggeringmechanism are both fixed to a workbench; the output end of the surface attaching mechanism is engaged with the upper surface of the distribution staggering mechanism; the distribution staggering mechanism is matched with neodymium-iron-boron permanent magnets; the surface attaching mechanism is used for attaching to and compressing the upper surface of the distribution staggering mechanism; and the distribution staggering mechanism is used for arranging the neodymium-iron-boron permanent magnets in a staggered mode according to a set shape. According to the device, by arranging the surface attaching mechanism, deflection of the neodymium-iron-boron permanent magnets relative to located grooves is avoided, and the distribution accuracy of the neodymium-iron-boron permanent magnets is guaranteed.

Owner:温州源利智能科技有限公司

Storage expansion method and device of main control memory, readable storage medium and system

ActiveCN109582243AImprove moving efficiencyMeet memory expansion requirementsInput/output to record carriersOperating system

The invention discloses a storage expansion method for a main control memory, which comprises the following steps: confirming the space quantity of a memory storage space corresponding to a data application demand according to the data application demand; Confirming the number of target sctrap flash based on a preset sctrap flash controller according to the space quantity of the memory storage space of the data application, the number of the target sctrap flash being one or more; And finally, packaging the confirmed target sctrap flash into a target expansion flash, and calling the target expansion flash as the data application memory storage space through a preset sctrap flash controller. The invention further discloses a storage expansion device of the main control memory, a readable storage medium and a system. According to the method, the sctrap Flash and the Flash are packaged according to the current data storage requirement, and the data are stored and the memory is expanded through the packaged Flash, so that the beneficial effect of improving the application performance at the lowest cost is achieved.

Owner:YEESTOR MICROELECTRONICS CO LTD

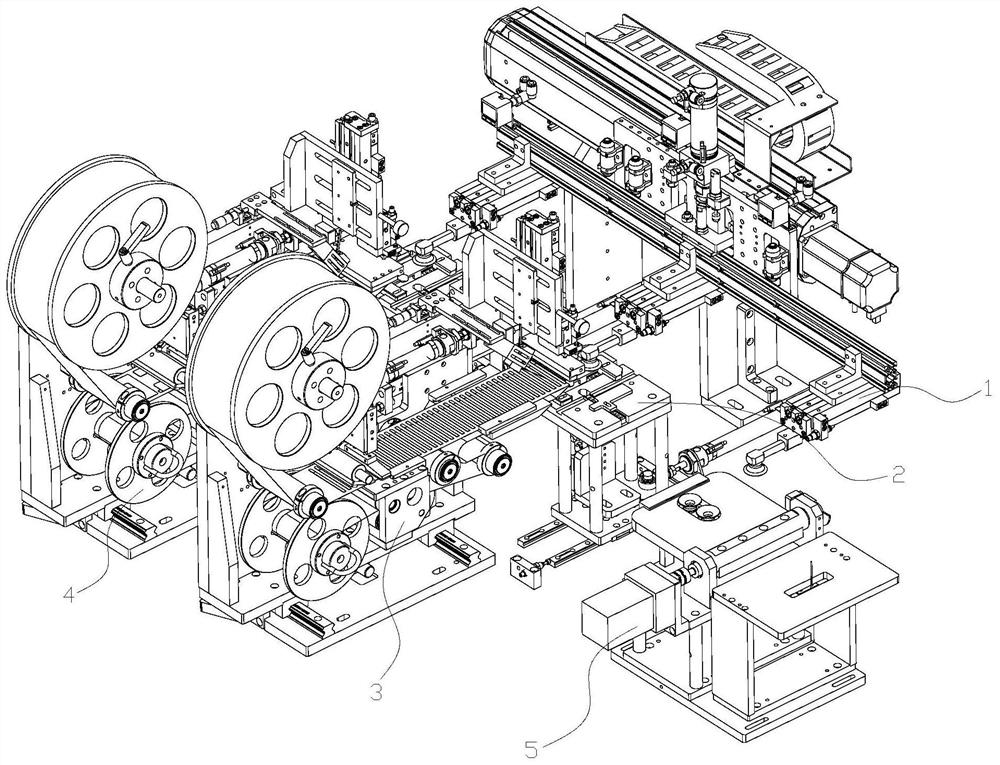

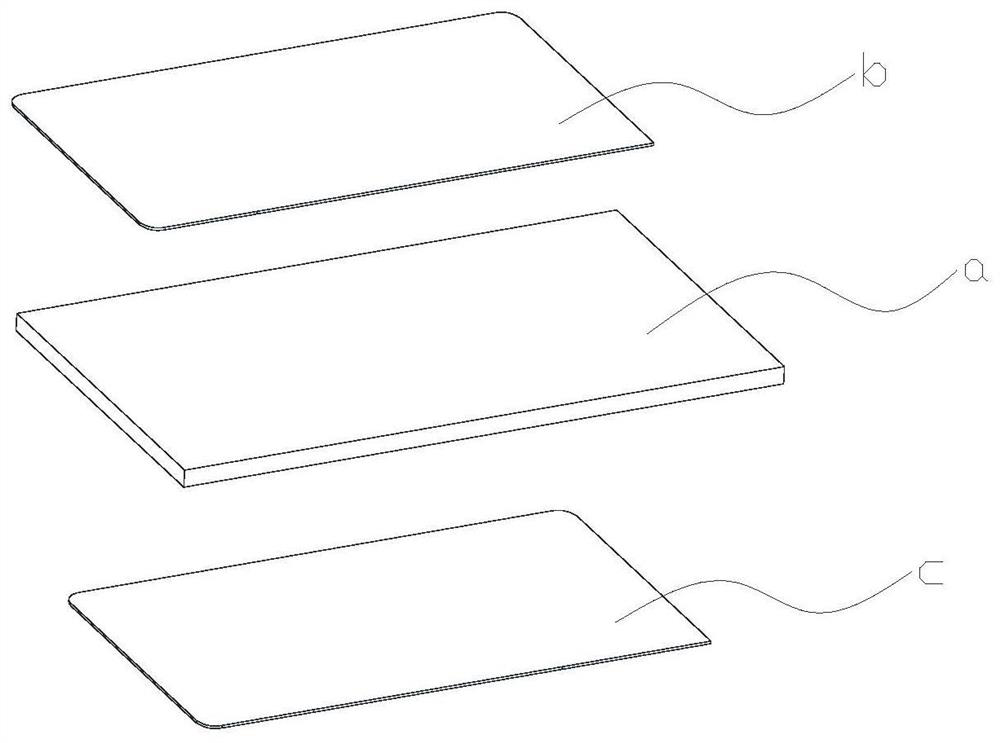

Screen glass film pasting moving device and method and film pasting equipment

InactiveCN113247350AReduce distanceImprove moving efficiencyCharge manipulationPackagingEngineeringManipulator

The invention relates to the technical field of pasting of electronic screen glass protective films, in particular to a screen glass pasting film moving device and method and film pasting equipment. The device comprises a moving rack, a moving driving mechanism, a moving bottom plate and moving manipulators; the driving end of the moving driving mechanism is connected with the moving bottom plate, and the plurality of moving manipulators are fixed on the moving bottom plate; each moving manipulator comprises a moving extension cylinder, a moving ventilation rod and a moving suction cup; the output ends of the moving extension air cylinders are connected with the moving ventilation rods, and ventilation holes are formed in the moving ventilation rods; and the two ends of the ventilation holes are connected with vacuum suction devices and the moving suction cups correspondingly, and the suction ends of the moving suction cups make contact with the surface of screen glass. According to the device, the moving manipulators are arranged to drive the screen glass to move in the left-right direction to bypass a blocking device, the moving distance is shortened, and the moving efficiency is improved.

Owner:郑少华

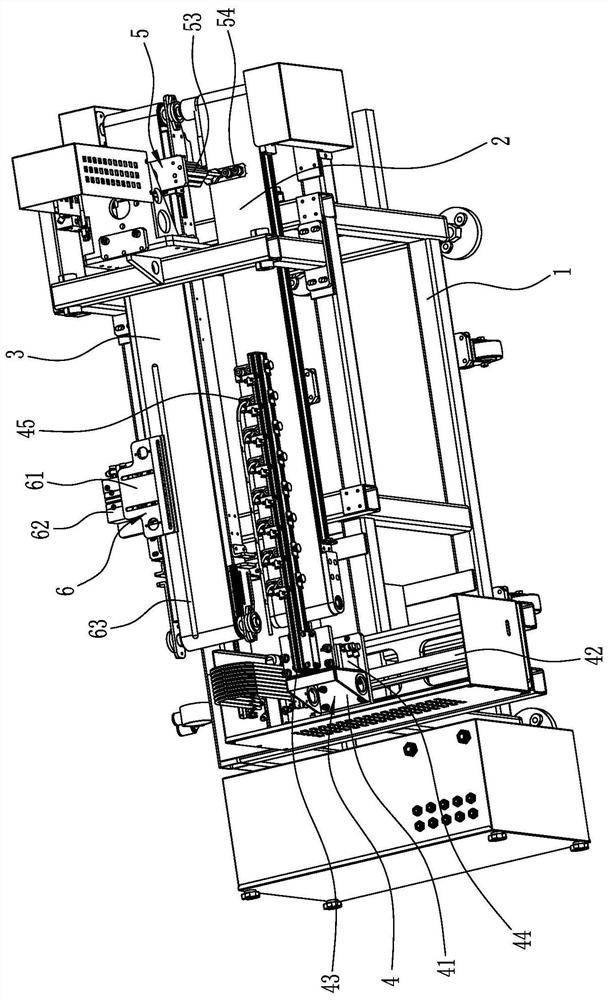

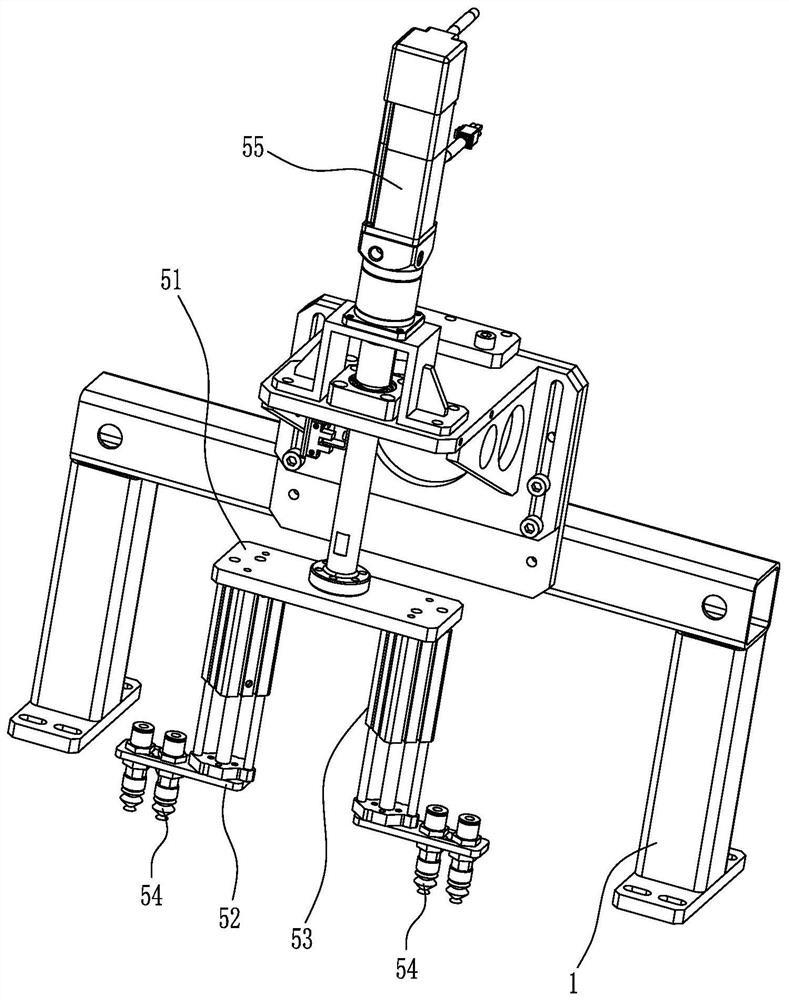

Rapid transplanting and moving device for magnetic shoes

PendingCN112249697AImprove moving efficiencyImprove securityConveyorsAuxillary shaping apparatusLeather beltStructural engineering

The invention discloses a rapid transplanting and moving device for magnetic shoes. The rapid transplanting and moving device comprises a rack, wherein a moving buffer conveying belt of which the feeding end is positioned on the side of a forming output belt is arranged on the rack; a buffer belt feeding device is arranged on the rack; a moving arrangement conveying belt is arranged on the rack; atransplanting arrangement device is arranged between the discharging end of the moving buffer conveying belt and the feeding end of the moving arrangement conveying belt on the rack; and an arrangement shaping device is arranged at the discharging end of the moving arrangement conveying belt on the rack. According to the rapid transplanting and moving device disclosed by the invention, after feeding buffer, single transplanting and unified arrangement, the magnetic shoes can be easily moved to a sintering tray by a stacking device so as to be orderly placed. According to the rapid transplanting and moving device disclosed by the invention, the moving efficiency is improved, the manual labor intensity is reduced, and the safety is improved.

Owner:上海奇宝智能科技有限公司

Forklift for round tube material piles on flat ground

ActiveCN112794247AAvoid the phenomenon of rollingGuarantee job securityLifting devicesEngineeringStructural engineering

The invention discloses a forklift for round tube material piles on flat ground. The forklift comprises a forklift body, a liftable pallet fork bracket is arranged at the front part of the forklift body, a bracket pallet fork is fixed at the front part of the pallet fork bracket, the forklift further comprises an anti-rolling device and a liftable mechanical arm, the mechanical arm is mounted on the forklift body, the front end of the mechanical arm is connected with the anti-rolling mechanism through a horizontal telescopic mechanism, the anti-rolling mechanism extends downwards and clamps the two sides of the inclined face of the round tube material pile from the front side and the rear side, the anti-rolling mechanism comprises a clamping plate pressing mechanism with the pressing function, when the round tube material pile is forked or unloaded, the clamping plate pressing mechanism is switched into an elastic pressing mode to elastically press a round pipe, and rigid pressing is carried out in the carrying process. The phenomenon that when the pallet fork is inserted into the material pile and the material pile is unloaded from the pallet fork, the stability of the stacking structure is damaged, and consequently materials at the upper portion roll down is effectively avoided, the working safety is guaranteed, and meanwhile the moving efficiency can be greatly improved.

Owner:ANHUI BUSINESS COLLEGE

Ramp drill rod box

ActiveCN114075932ARealize root-by-root sequential entry and exitReduce labor intensityDrilling rodsDrilling casingsWell drillingClassical mechanics

The invention relates to the technical field of oil field drilling tools and particularly relates to the ramp drill rod box. According to the ramp drill rod box, a main frame is composed of a bottom inclined plate, an end frame and a side frame, an inclined plate is installed in the middle of the main frame, a ramp is composed of the inclined plate and a thin steel pipe, the bottom inclined plate is arranged on the lower side of the inclined plate, an upper surface of the bottom inclined plate is of an inclined face structure, an upper baffle is installed at an outer end of the inclined plate, and a lower blocking piece is installed at an outer end of the bottom inclined plate; a cavity of a U-shaped structure is formed between the inclined plate and an inner wall of the main frame, drill rods are sequentially installed in the cavity, and the drill rods are blocked through an upper baffle and a lower blocking piece. The ramp drill rod box is advantaged in that drill rods in the drill rod box rolls along a ramp under the action of self gravity, and the function of sequential arrangement is achieved; the multiple drill rod boxes are used in cooperation, the function that the multiple drill rods enter and exit from the ramp drill rod box one by one in sequence can be achieved, and therefore the drill rod boxes can be directly used as drill rod row bases, working efficiency can be improved, and labor intensity of workers can be effectively reduced.

Owner:山东胜油石油工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com