Large cargo translating device

A translation device and cargo technology, applied in storage devices, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, and many safety hazards, and achieve a high degree of mechanization, simple implementation, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

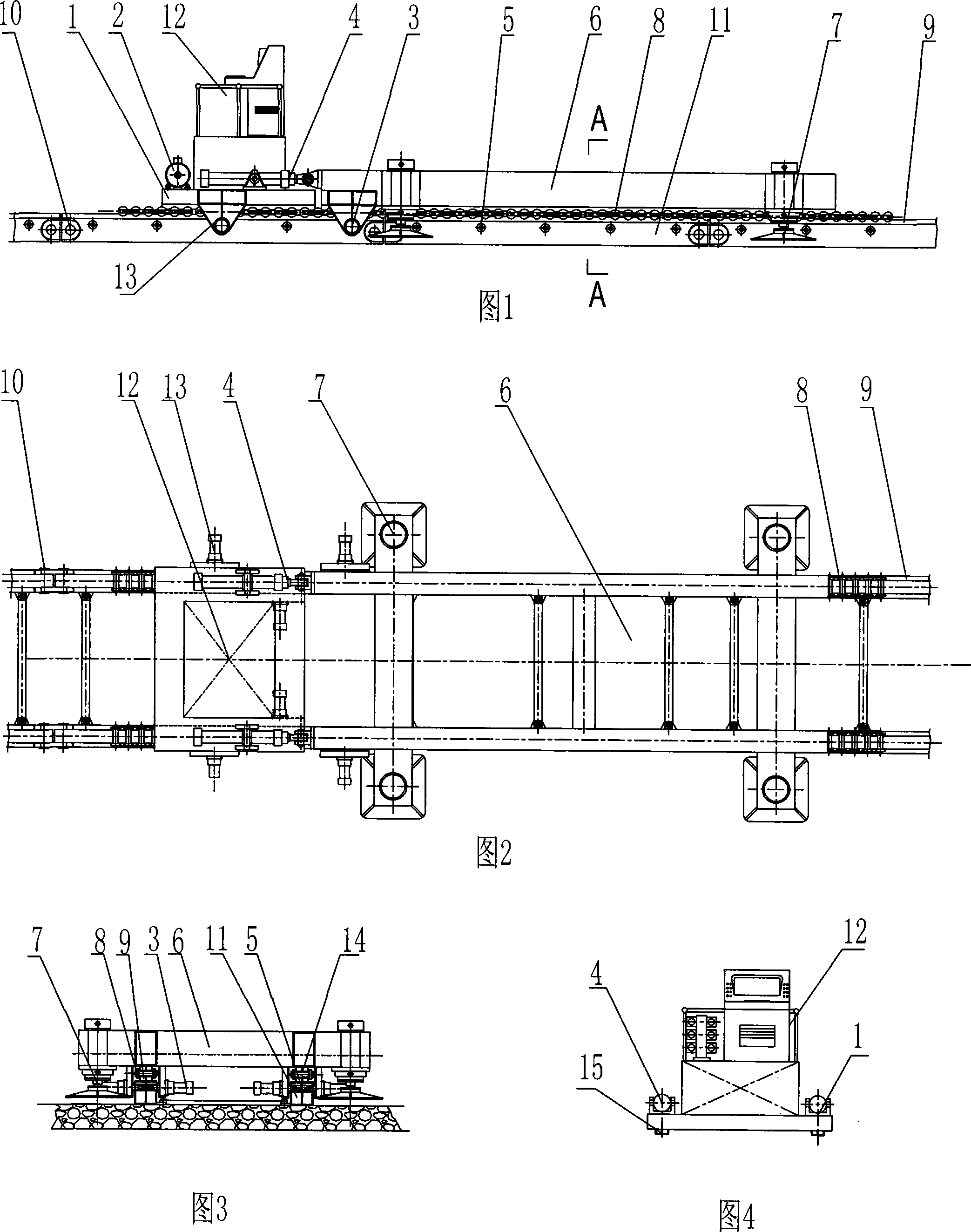

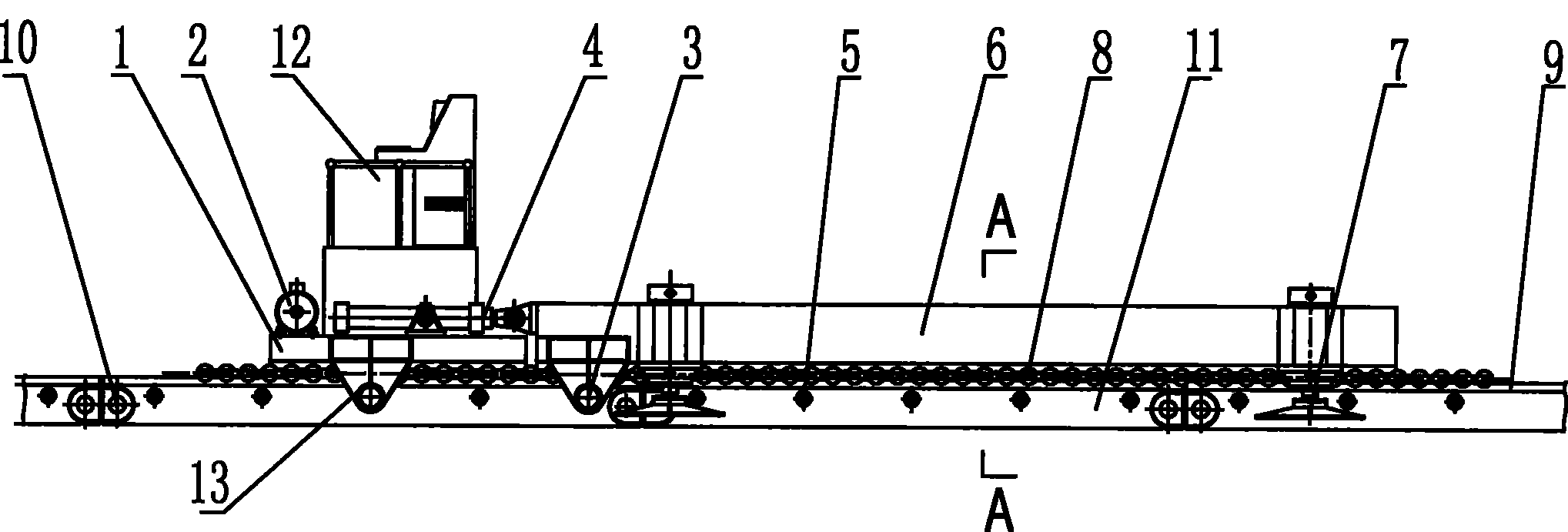

[0013] The embodiment of the present invention will be further described below in conjunction with the accompanying drawings, including a track chassis 11. The track chassis is composed of two parallel longitudinal box girders and transverse connecting braces. The longitudinal boxes on both sides above the track chassis The guide rails 9 extending in parallel are installed on the beam, and the track chassis is formed by 3 to 6 single track chassis connected before and after. The two ends of the track chassis 11 are provided with movable joints 10, and the movable joints are composed of connecting plates and The lock piece is formed to facilitate the connection and disengagement of the front and rear of the two track chassis; the stepping lock holes 5 are arranged on both sides of the track chassis; the guide rail 9 is laid with a roller group 8, and the roller group consists of a plurality of rollers. It is formed by linking; the carrier frame 6 is placed above the roller group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com