A middle tank truck

The technology of a pallet truck and a vehicle frame is applied in the direction of goods transport vehicles, vehicles for freight transportation, motor vehicles, etc., which can solve the problems of low handling efficiency, cumbersome procedures, and hidden safety hazards in the middle tank, so as to facilitate shipment and reduce disassembly and assembly. Number of times, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the drawings:

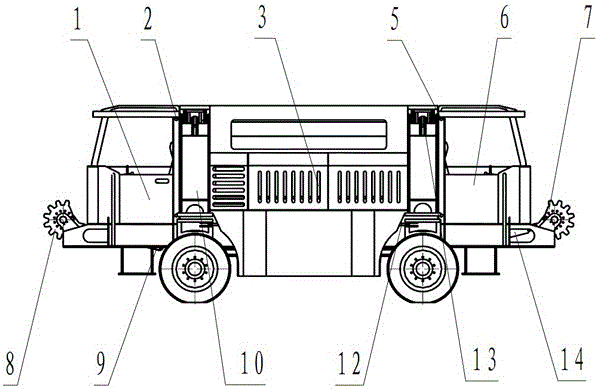

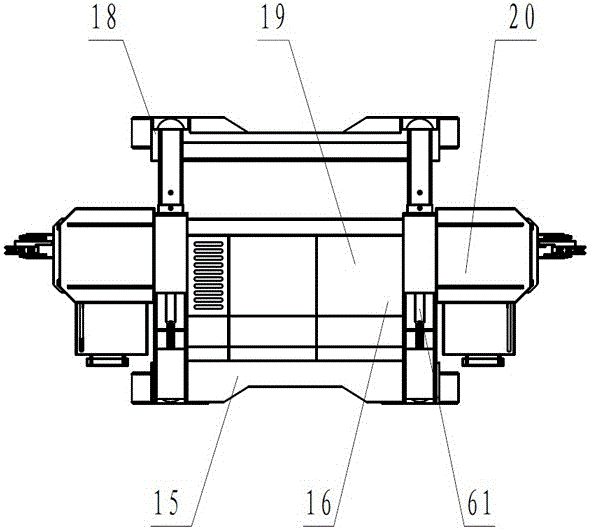

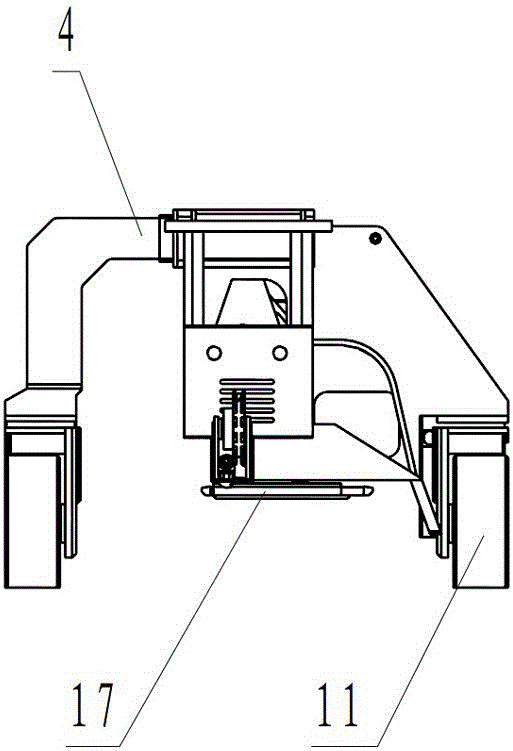

[0025] A middle trough truck includes a gantry frame 4 with a retractable beam, an explosion-proof diesel engine 3 for providing mechanical power, and a hydraulic mechanism 19 for converting mechanical power into liquid pressure. The gantry frame 4 The front side is provided with a front cab 1, the gantry frame 4 is provided with a rear cab 6 on the rear side, and the front and rear ends of the gantry frame 4 are provided with independent walking wheels 11 respectively. Each wheel 11 is provided with a steering mechanism 12 and a brake reduction mechanism 18 respectively. The bottom of the gantry frame 4 is provided with a central slot quick loading and unloading mechanism 17, and the front and rear ends of the gantry frame 4 are respectively provided with sprocket mechanisms 7 , 8, sprocket mechanisms 7, 8 are controlled by sprocket cylinders 9, 14 respectively.

[0026] figure 1 , 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com