Ramp drill rod box

A drill pipe box and ramp technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as the inability of drill pipe boxes to be used in rows of drill pipes, the automatic filling of the whole box with drill pipes, and step-by-step filling. , to achieve the effect of improving the moving efficiency, shortening the well construction period and improving the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

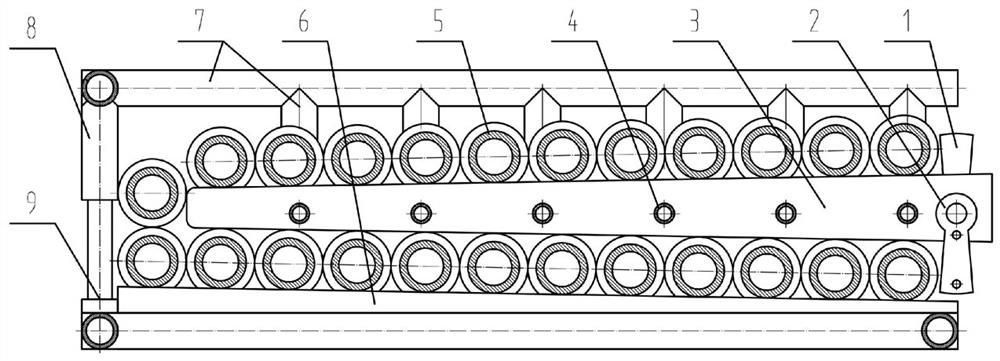

[0023] Embodiment 1, with reference to figure 2 and Figure 4 , the present invention provides a kind of ramp drill rod box, comprising end frame 7 and side frame 8, described end frame 7 and side frame 8 form main frame, one end of two end frames 7 is connected and fixed with side frame 8, two The other end of the end frame 7 is in an open state, and also includes an upper baffle 1, a lower baffle 2, a slant plate 3, a thin steel pipe 4 and a bottom slant plate 6, and a slant plate 3 is installed in the middle of the main frame, and the slant plate 3 Form a ramp with thin steel pipes 4, a plurality of round holes are evenly distributed on the slant plate 3, and a plurality of thin steel pipes 4 pass through it, and the two ends of the thin steel pipes 4 are movably connected with two end frames 7 respectively as cross arms; The lower side of the plate 3 is provided with a bottom inclined plate 6, the upper surface of the bottom inclined plate 6 is a slope structure, the upp...

Embodiment 2

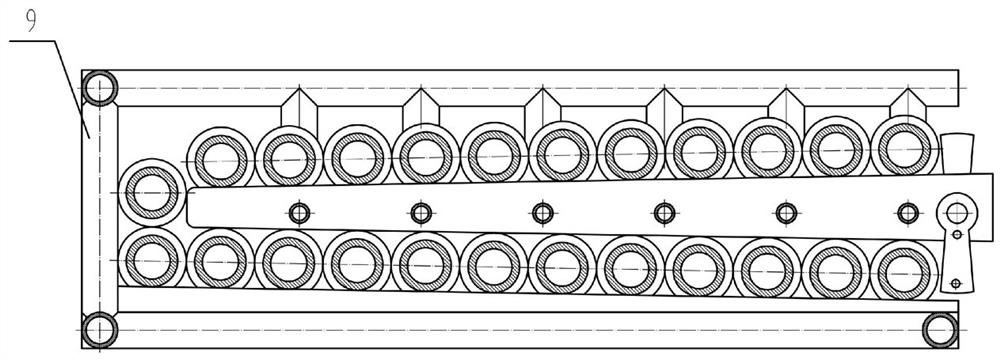

[0025] Embodiment 2, with reference to figure 1 and Figure 4 , the present invention provides the second type of ramp drill pipe box, which is different from Embodiment 1 in that: the side frame 8 and the movable frame 9 are connected by threads, and the position of the movable frame 9 can be adjusted to adapt to drill pipes 5 of various sizes. , also form the rolling channel of drill rod 5, in order to the smooth passage of drill rod 5 in the drill rod box on the left side, and the side frame 8 of embodiment 1 is fixed.

Embodiment 3

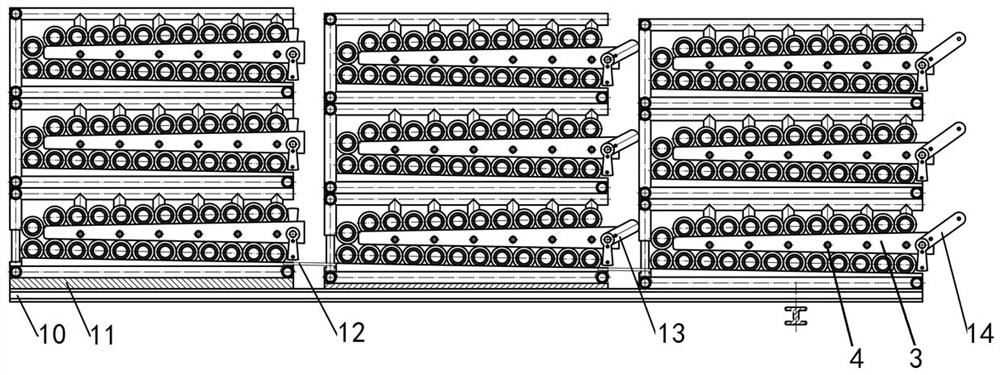

[0026] Embodiment 3, with reference to Figure 5 and Figure 6 , the present invention provides the second kind of ramp drill pipe box, the difference from embodiment 2 is:

[0027] The lower stopper 2 of this embodiment adopts an outlet controller, and the outlet controller is composed of two groups of gear arms 15-1, handle 15-2, rotating rod 15-3, and fixed block 15-4. The two groups of gear arms 15 -1 and the handle 15-2 are welded on the rotating rod 15-3, and the two groups of gear arms 15-1 are arranged at right angles, the handle 15-2 is located at the other end of the two groups of gear arms 15-1, and the rotating rod 15 -3 is inserted in the circular hole of the fixed block 15-4, and the fixed block 15-4 is fixed on the thin steel pipe 4. When the handle 15-2 rotates, the rotating rod 15-3 and the gear arm 15-1 rotate together with it, because there are two gear arms 15-1, and there is an angle and span, the angle is when one of the gear arms 15 When -1 does not r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com