Patents

Literature

75results about How to "Shorten the well construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

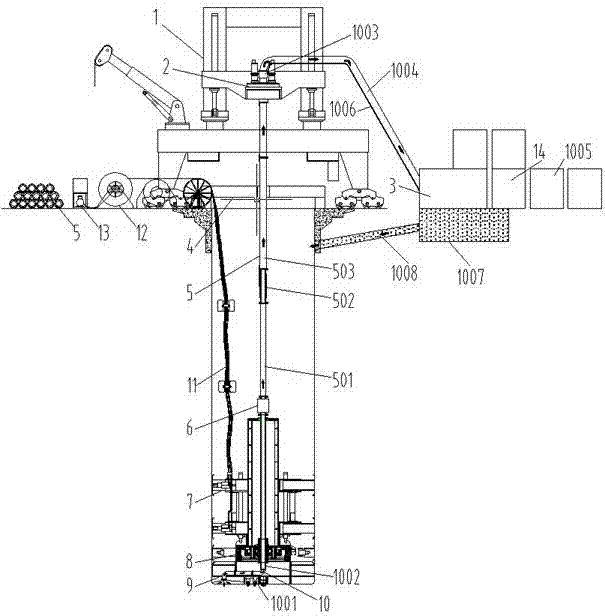

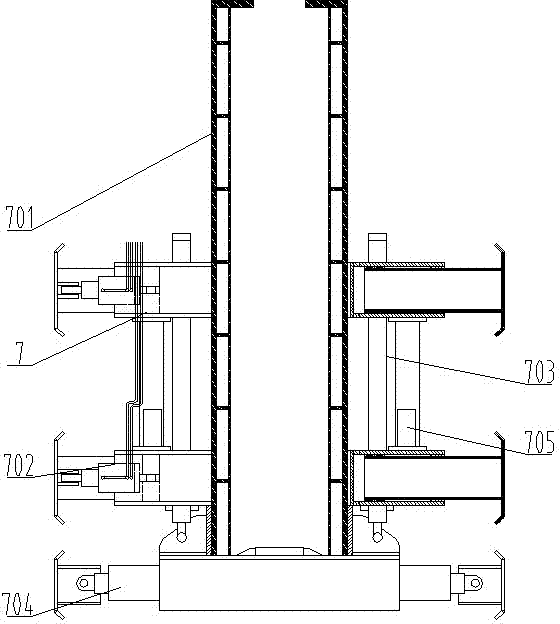

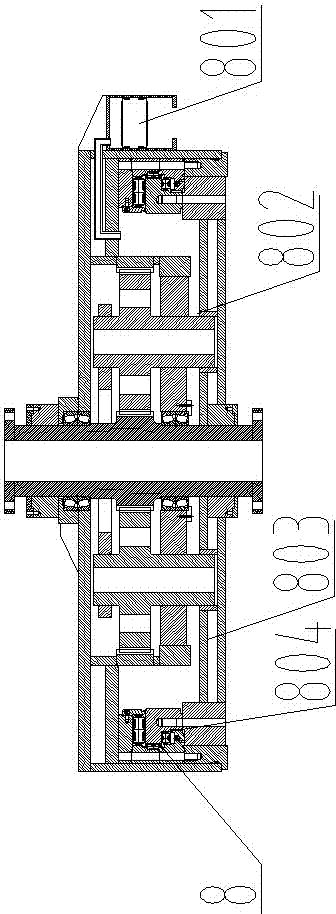

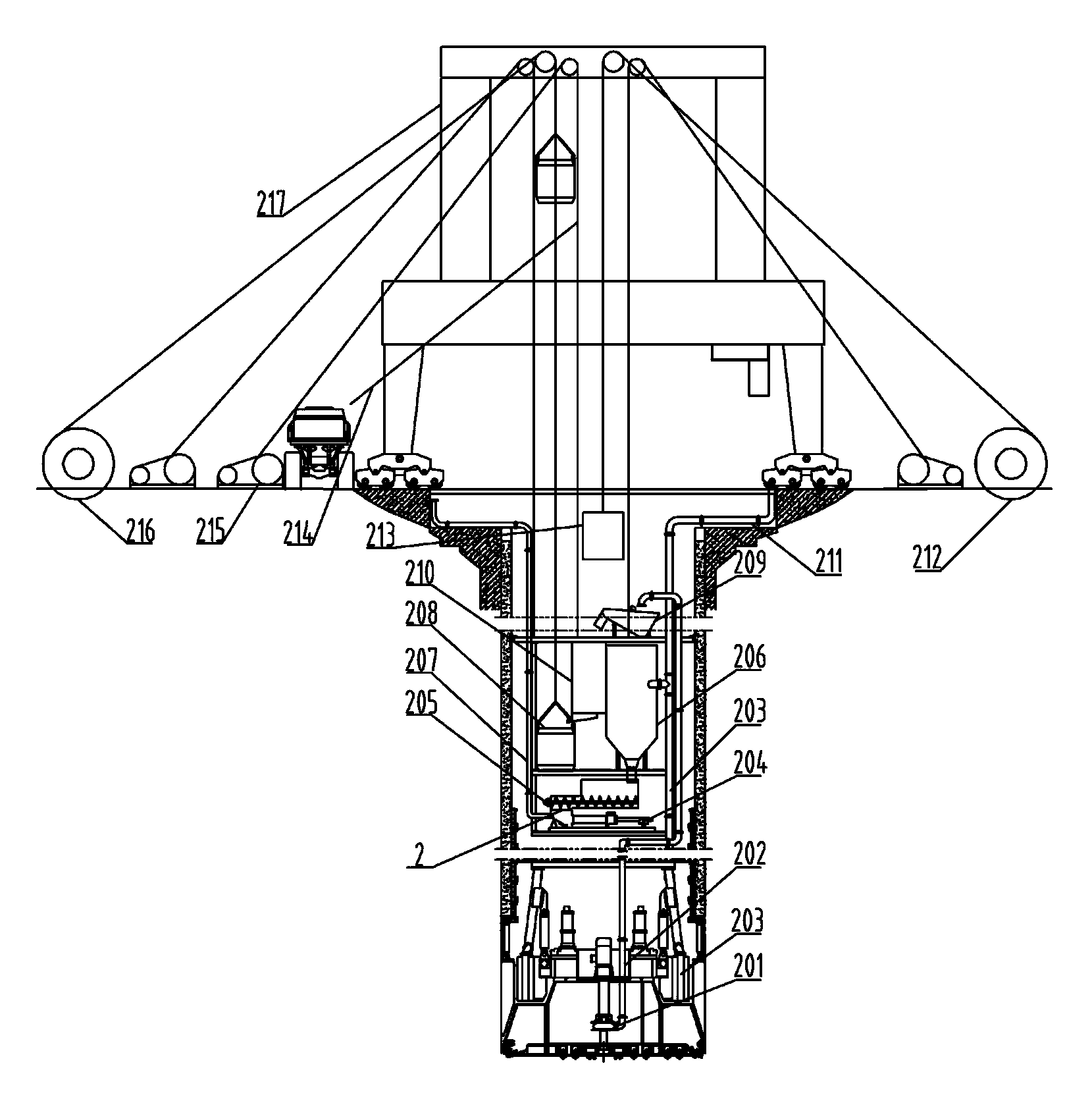

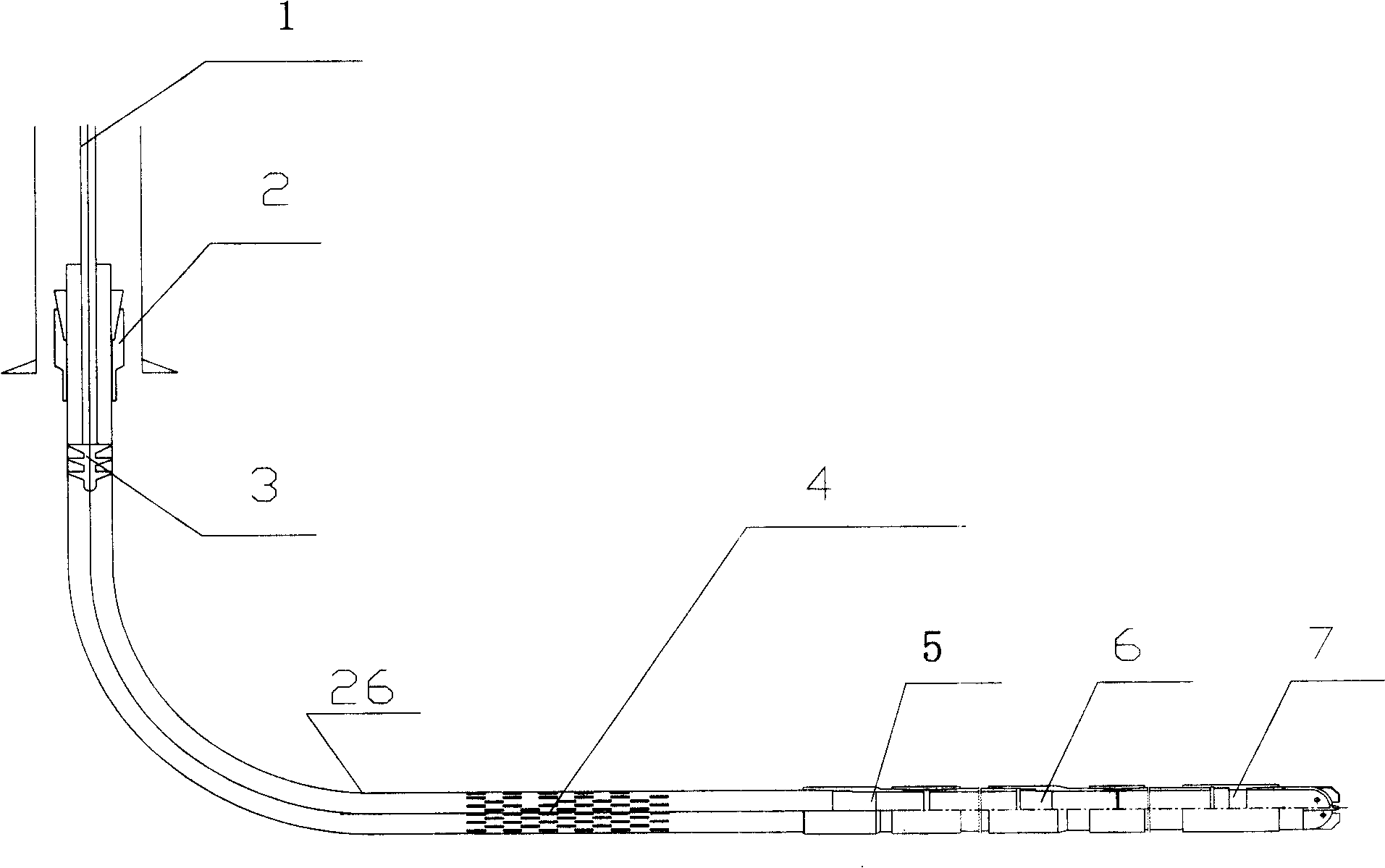

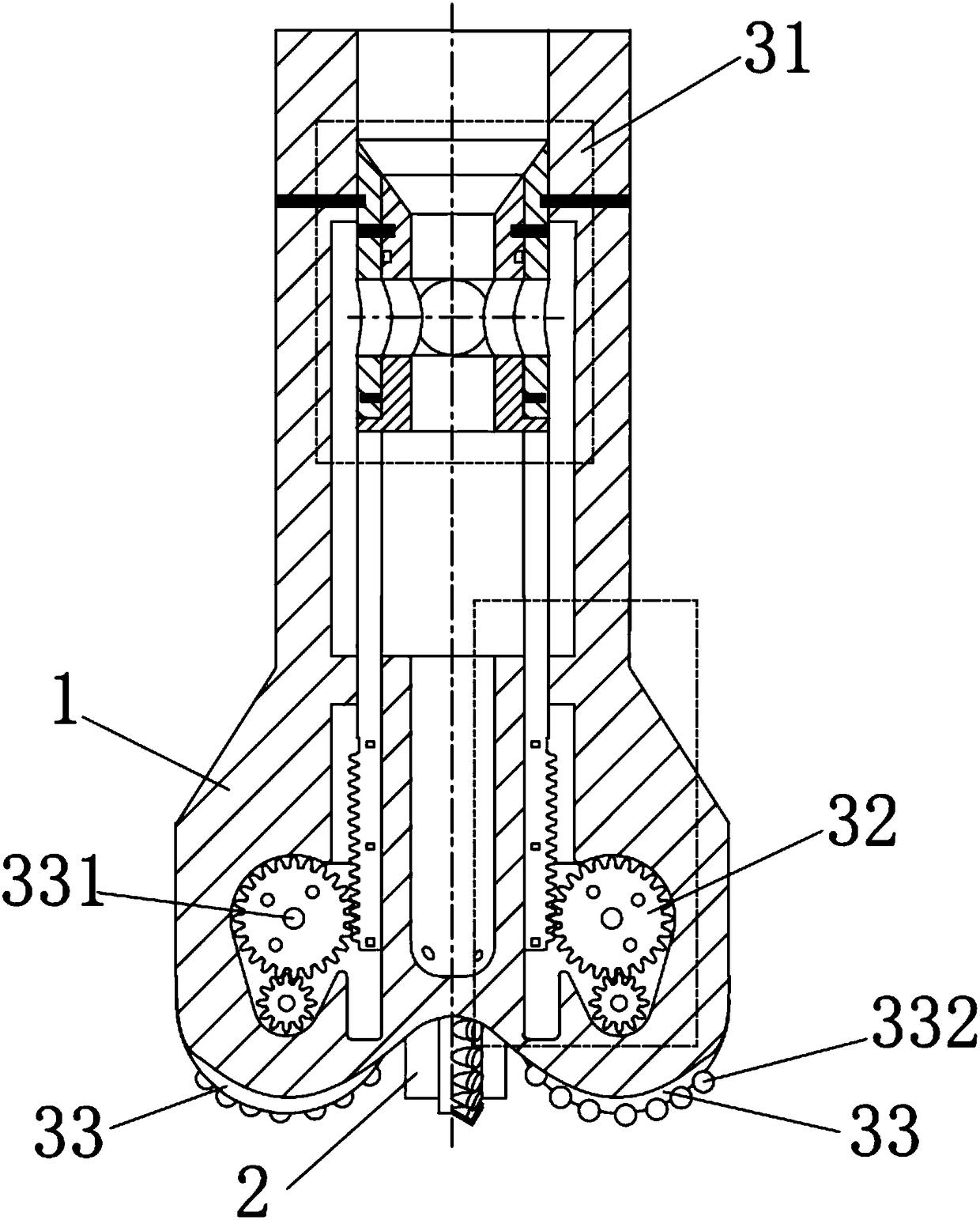

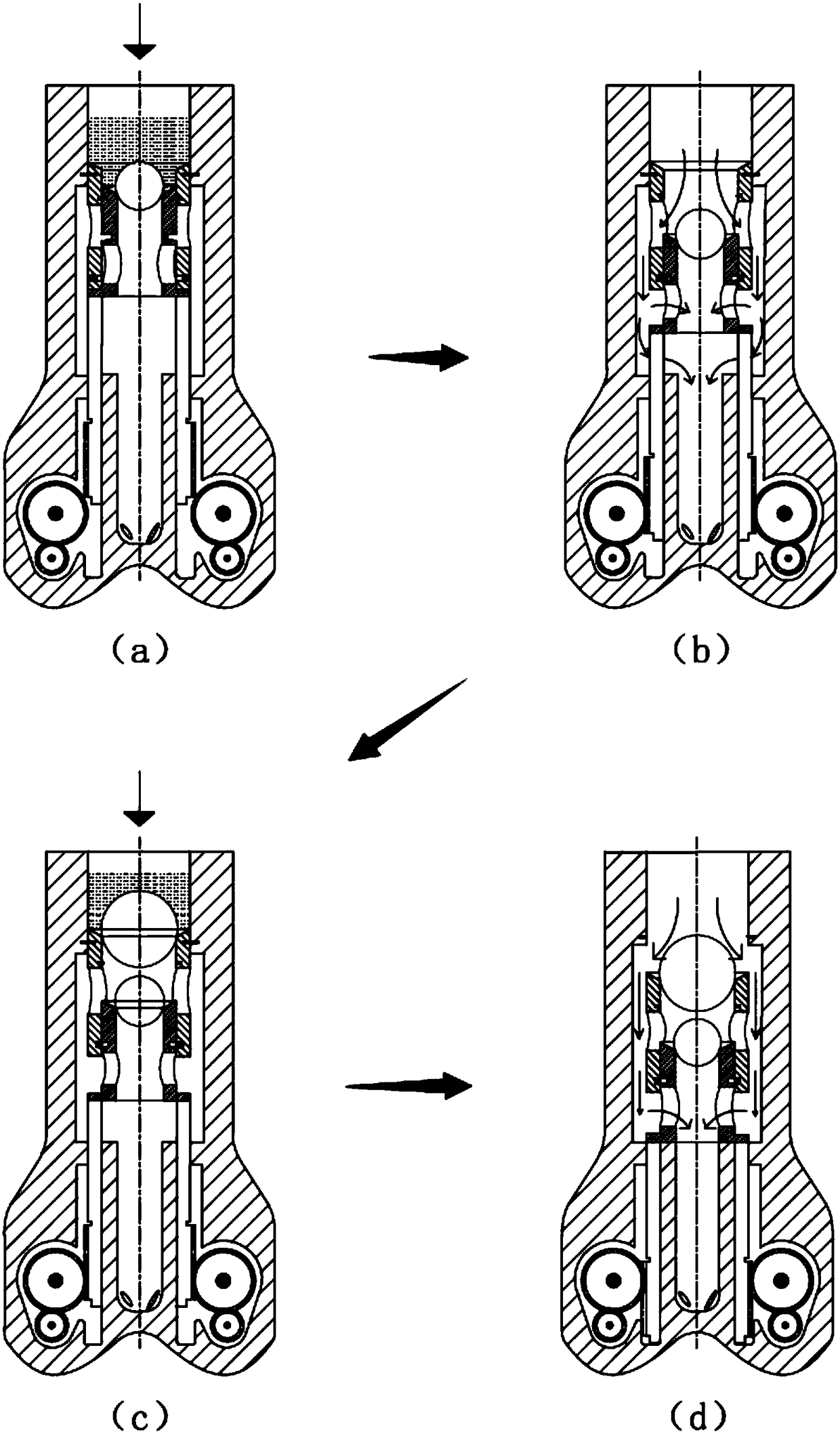

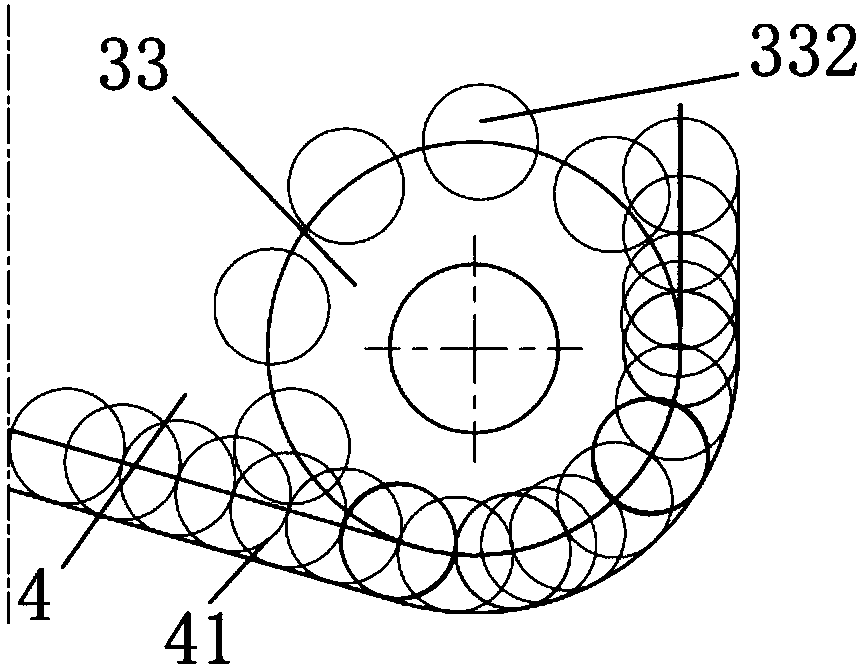

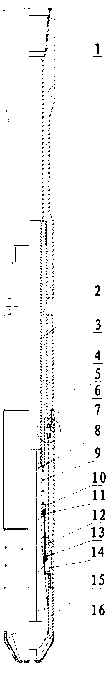

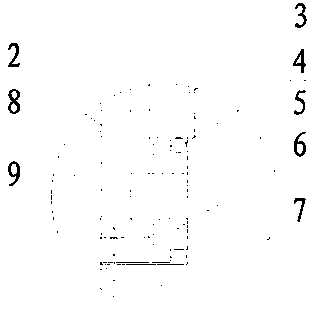

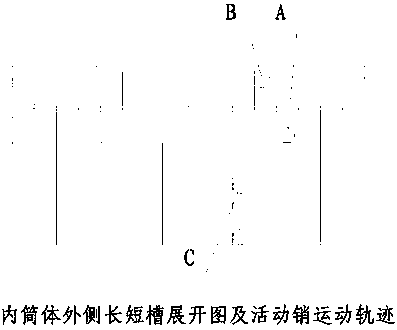

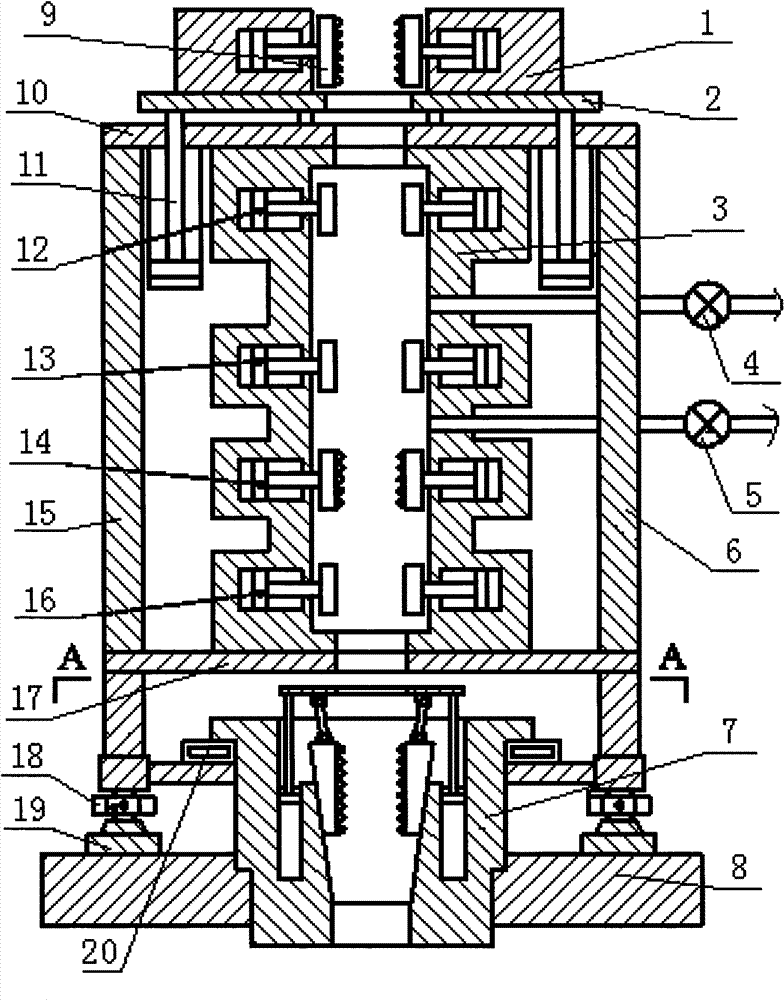

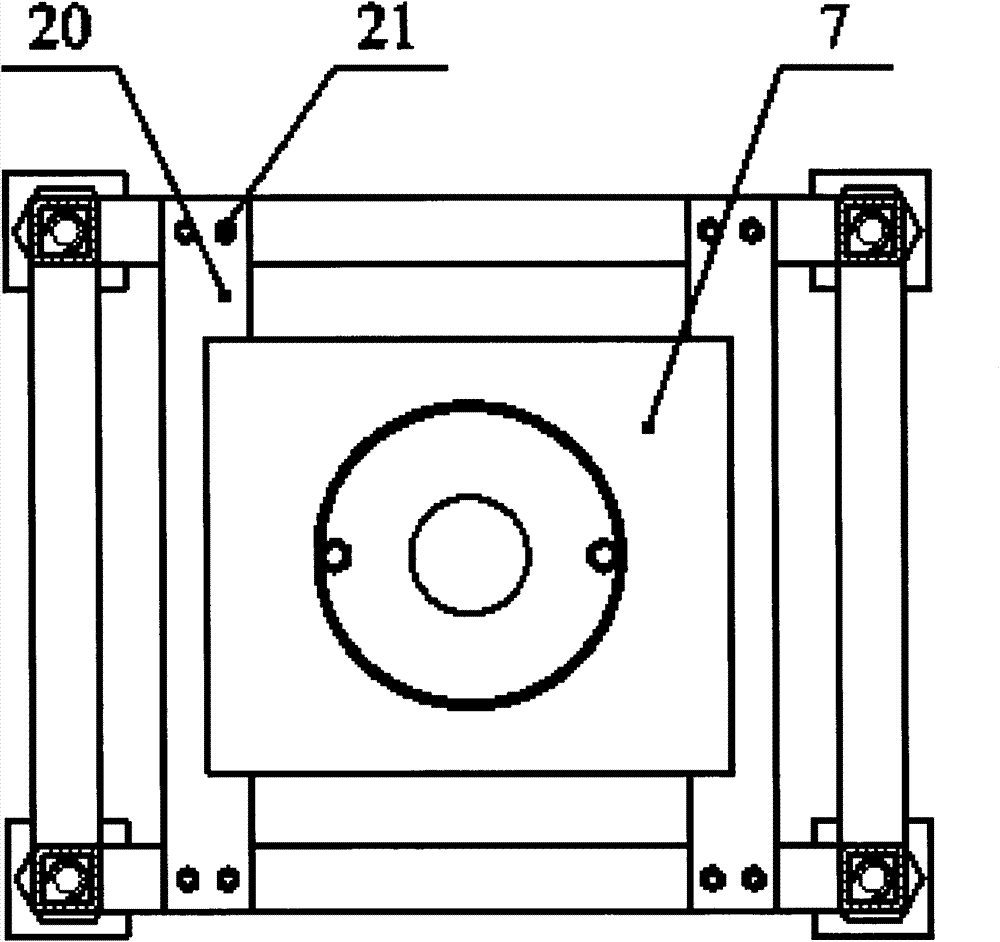

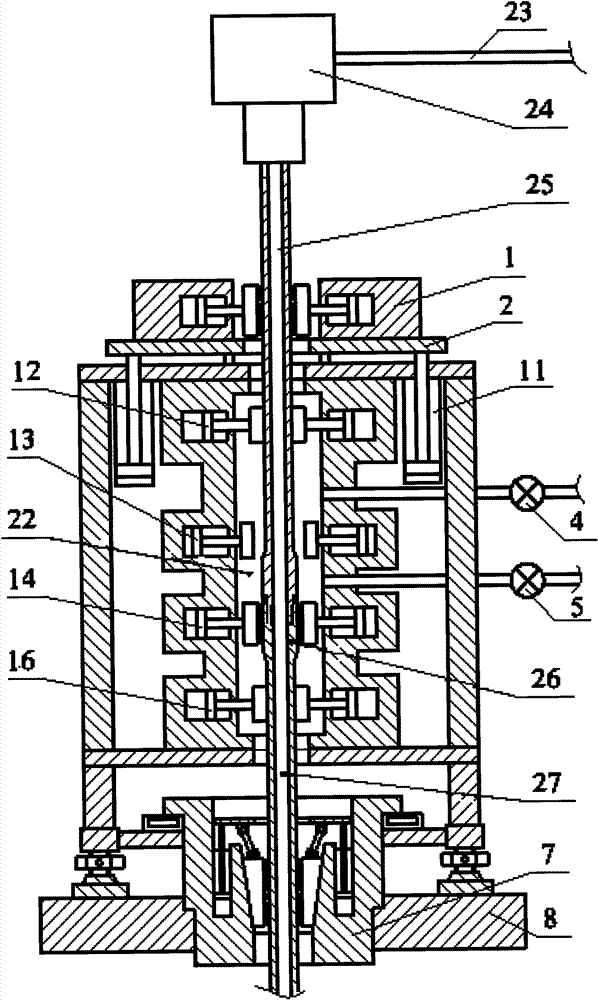

Novel drilling method for shaft drilling machine

ActiveCN103899316AImprove stabilityImprove construction efficiencyDerricks/mastsBorehole drivesSlagWell drilling

A novel drilling method for a shaft drilling machine mainly comprises a derrick and an opening-sealing flat wagon which are arranged at a well opening, and further comprises a drill rod, a flexible connector, a stable pressing device, a torque amplification driving device, a cutter head, a slag discharging system, a mud treatment station, an electric appliance cabinet, a hydraulic pressure station and a power pipeline. A main drive is arranged on the derrick, the lower portion of the main drive is connected with the drill rod, the flexible connector is arranged on the drill rod, the lower end of the drill rod is connected with the torque amplification driving device, the lower end of the torque amplification driving device is connected with the cutter head, the stable pressing device is arranged outside the torque amplification driving device; muck dug by the cutter head in a well is delivered to the mud treatment station on the ground through the slag discharging system. According to the novel drilling method for the shaft drilling machine, stability of the whole machine is increased, pressing force of equipment is improved, drilling torque is increased, construction in soft soil layers is available and construction in rock stratums of high hardness is also available, guide is more accurate, so that shaft construction efficiency can be improved, shaft construction cycle is shortened, and finished well quality is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

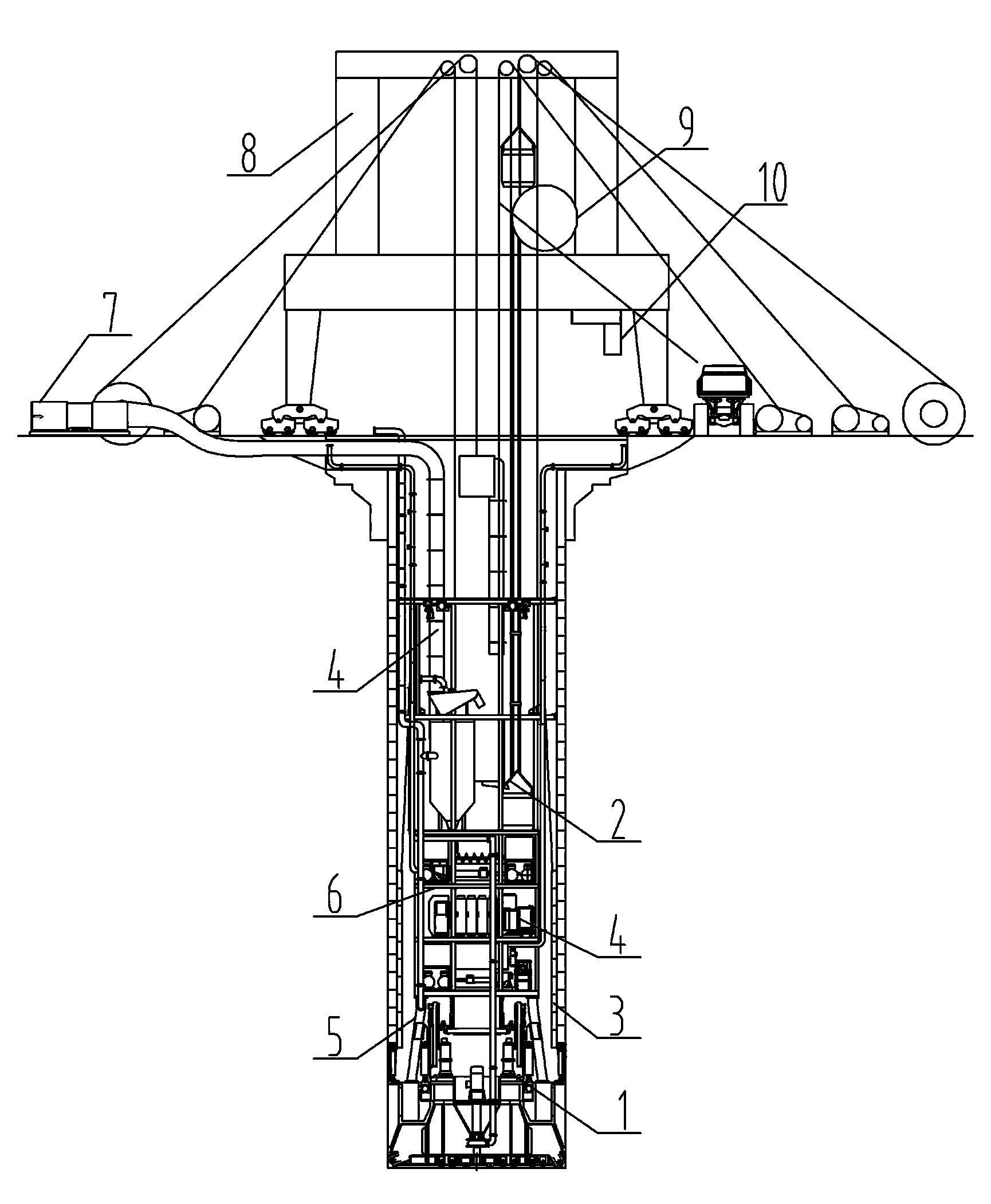

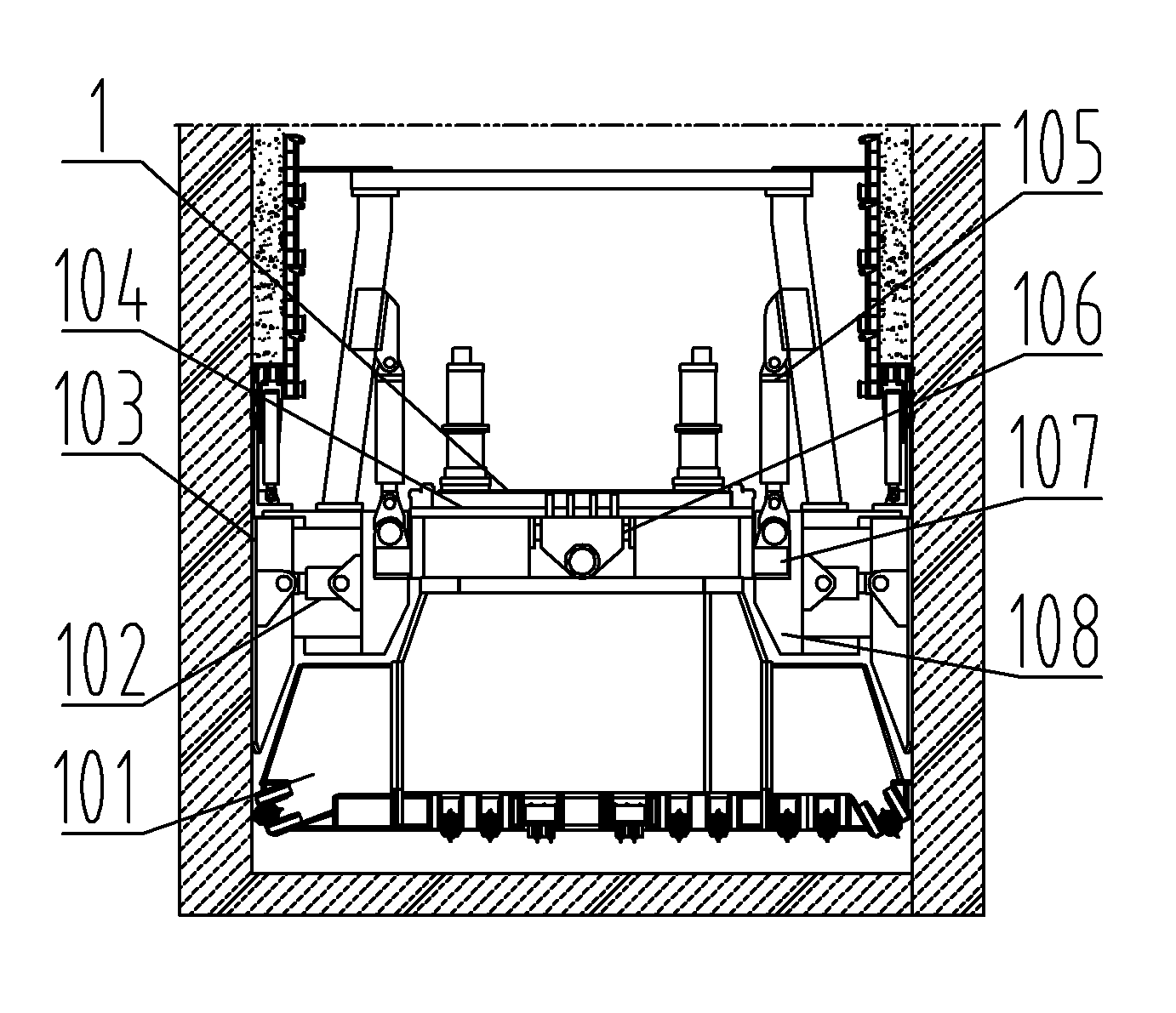

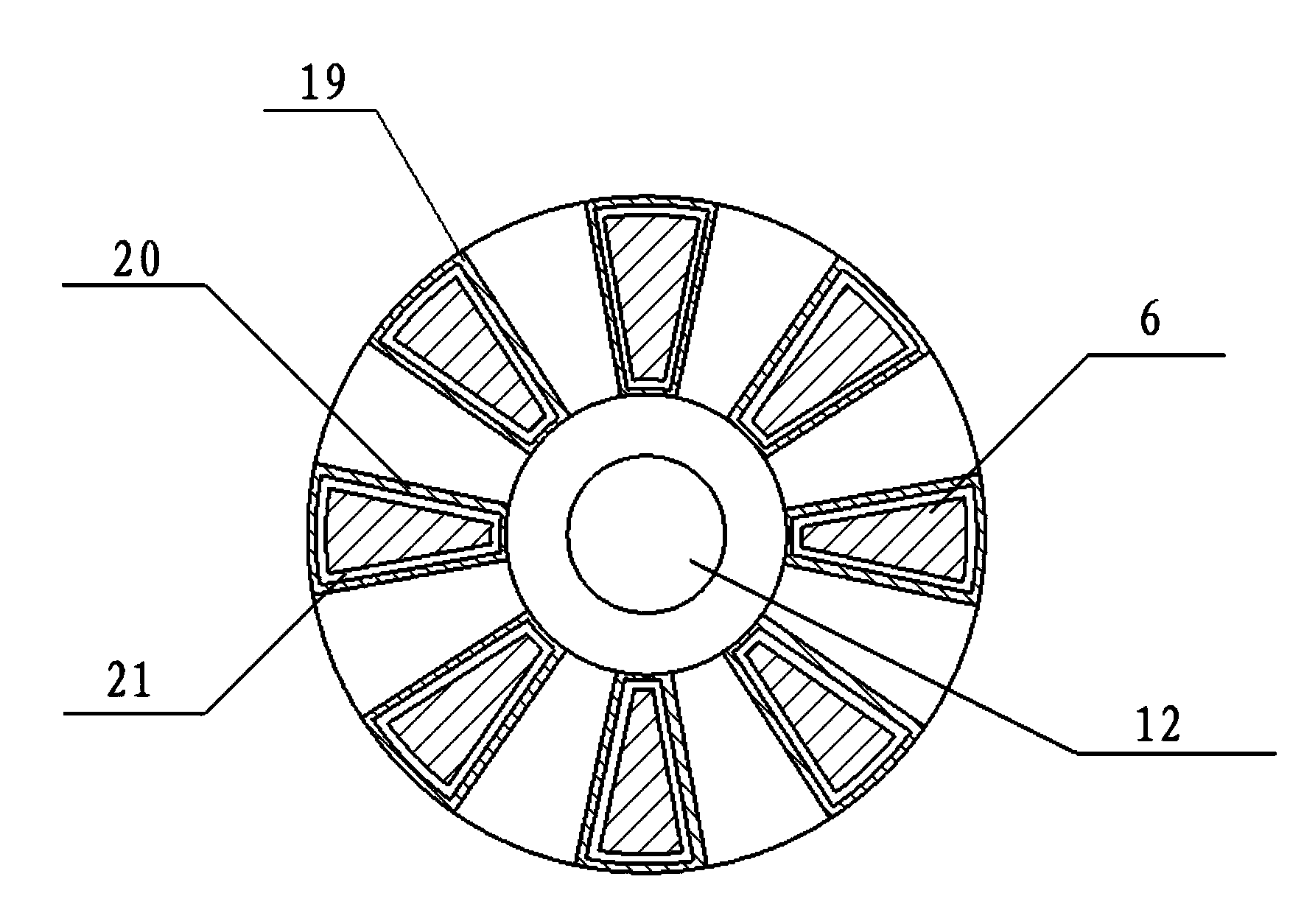

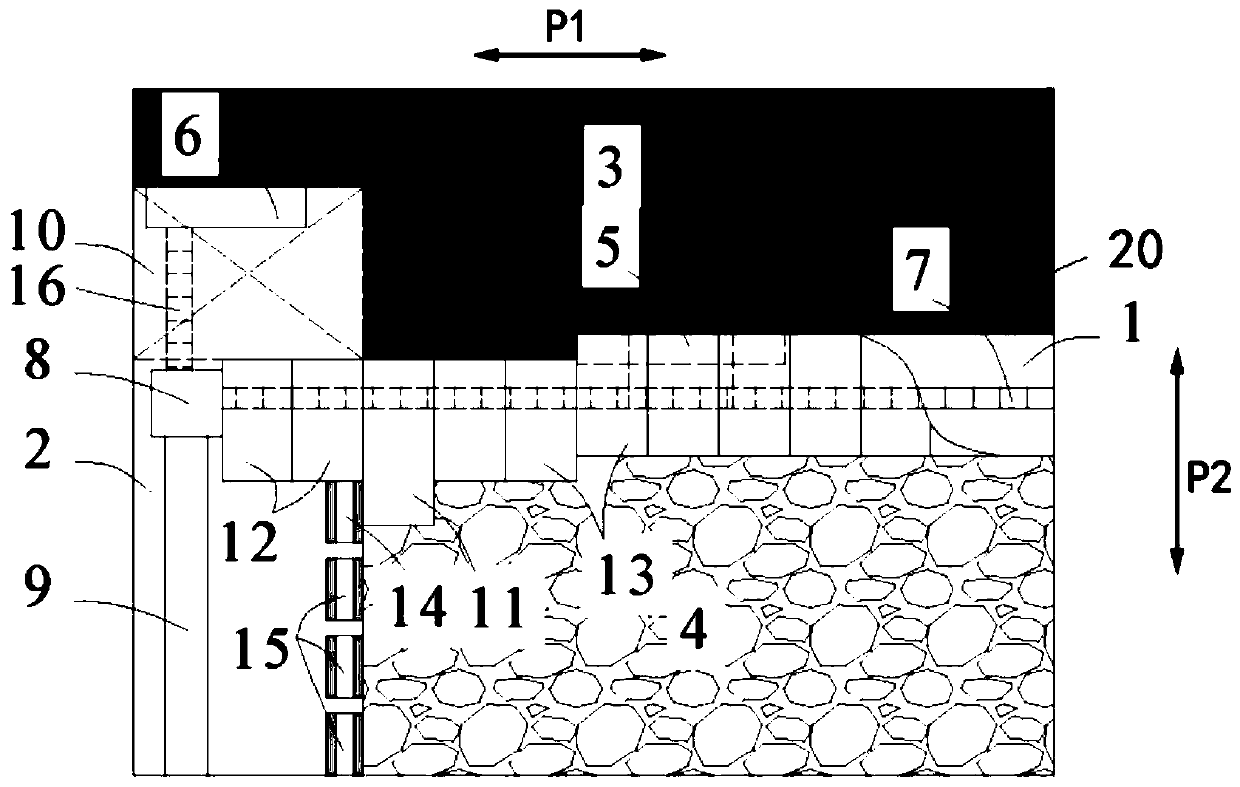

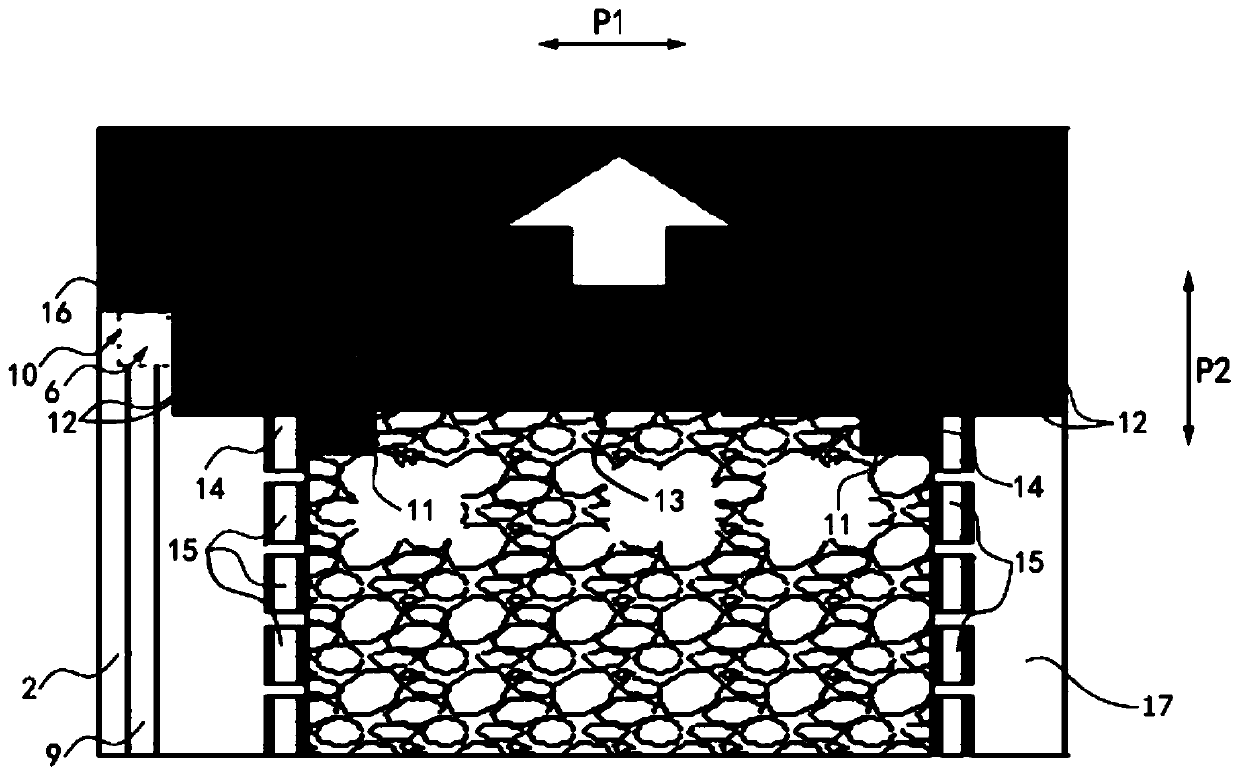

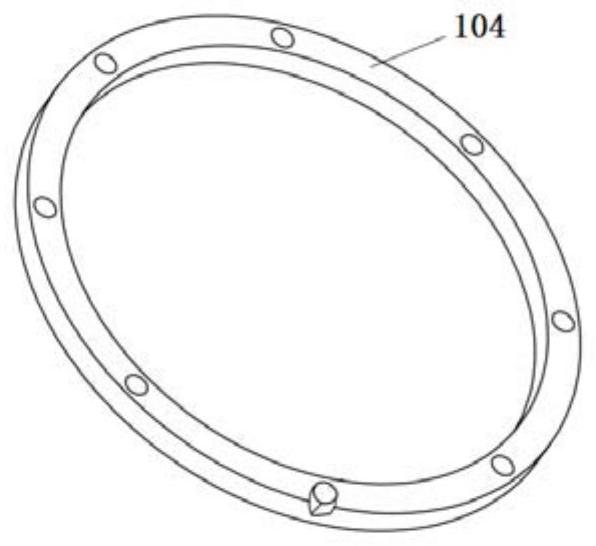

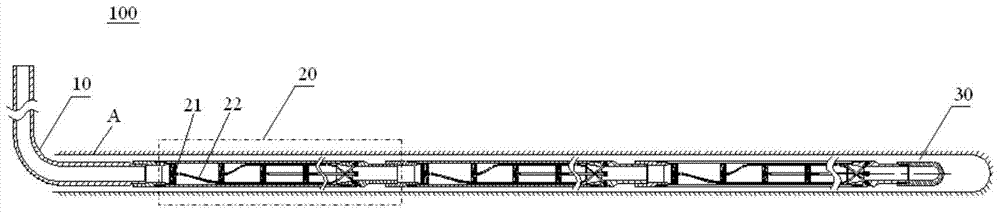

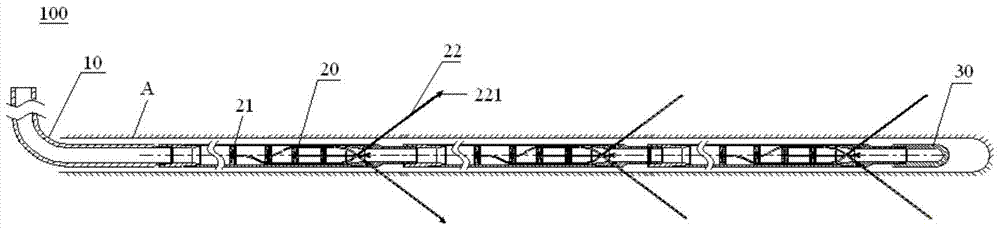

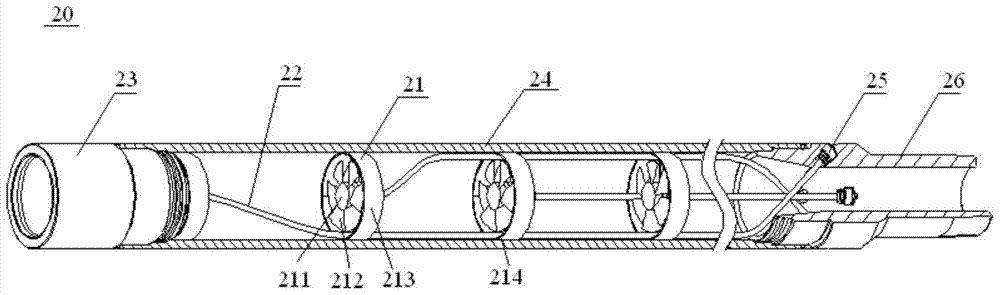

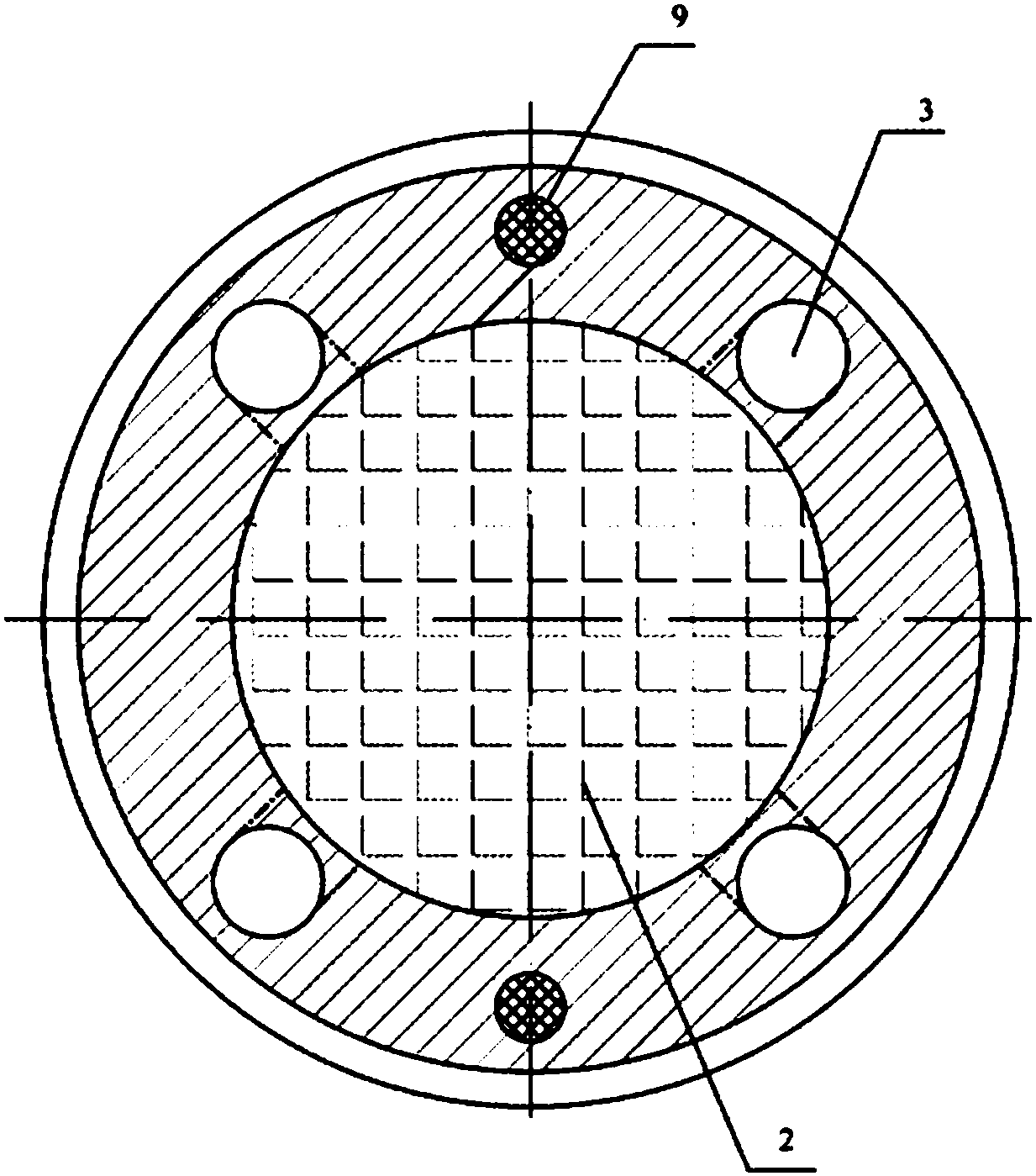

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

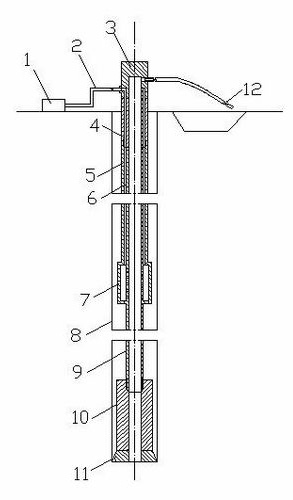

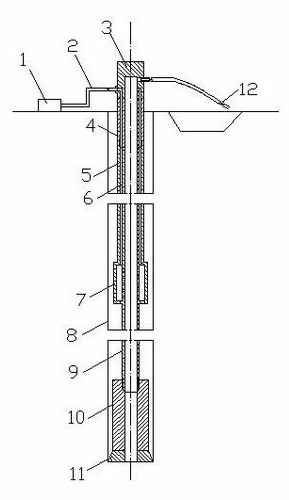

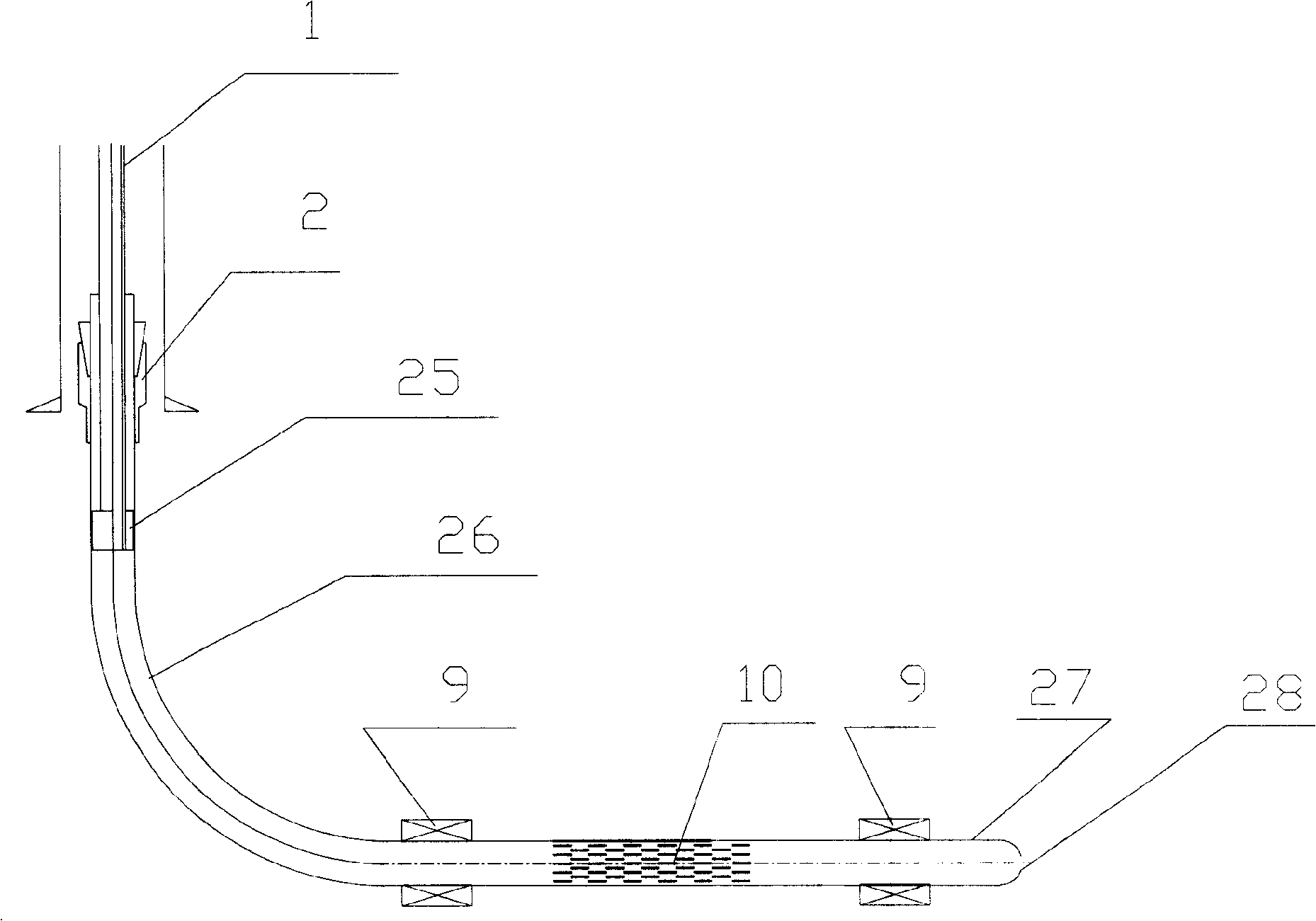

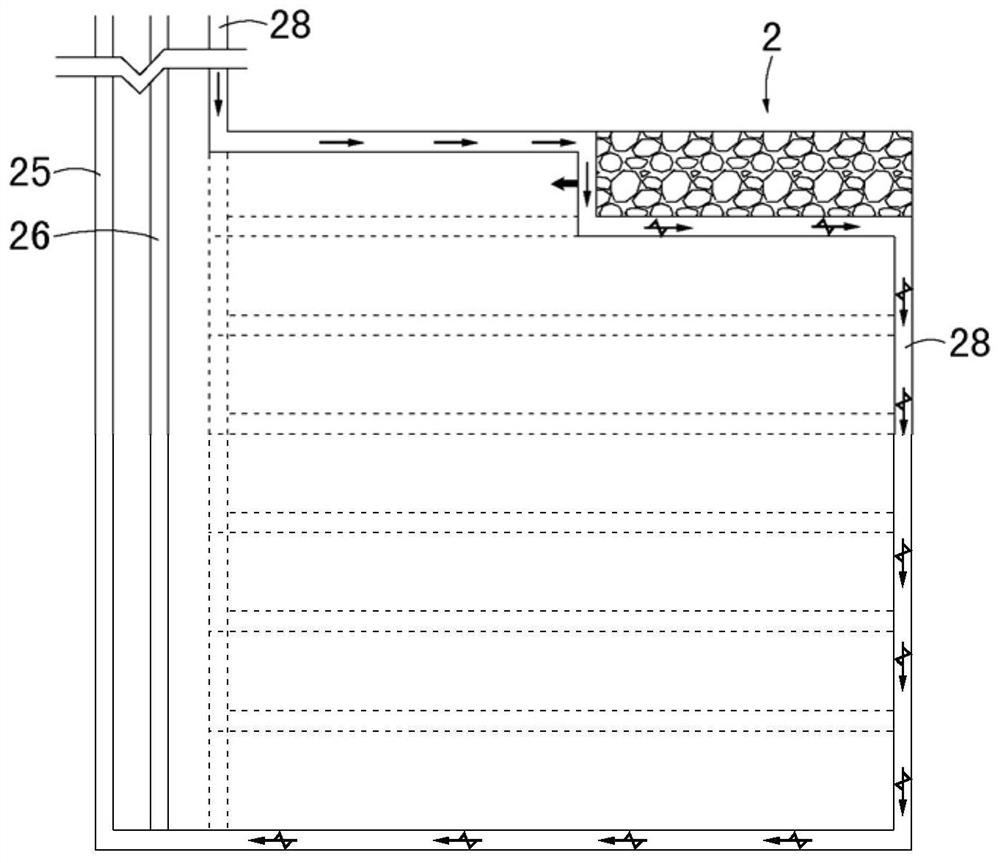

Gas lift reverse circulation drilling process

ActiveCN101929309AImprove drilling efficiencyShorten the well construction periodFlushingDrilling machines and methodsGas compressorGas lift

The invention discloses a gas lift reverse circulation drilling process. The process comprises the following steps of: (1) demounting a double-arm square drill rod, fully filling liquid into a core barrel, and re-arranging the double-arm square drill rod; (2) closing a high-pressure valve at an outlet of a dreg discharging pipe and starting an air compressor to supply air; and (3) when the air pressure is raised to 5.5 to 6MPa, quickly opening the high-pressure valve at the outlet of the dreg discharging pipe. The gas lift reverse circulation drilling process can solve the problem of dill water inlet blockage without needing pulling out all drilling tools.

Owner:河北伟业地热新能源科技有限公司

Low permeable oil deposit virtual horizontal well development method

The invention relates to a low permeable oil deposit virtual horizontal well development method, comprising the following process technologies: deploying a developed well pattern, early flooding under nearly high pressure condition, optimizing a perforation well section and a perforation way, designing and deploying the development technology and producing a long slot by ultra large scale fracturing. When the developed well pattern is deployed, the well pattern is designed and deployed in a region with the thickness of an oil layer being higher than a 4m line, the well pattern is a five-spot square one with the distance between an oil well row and a water well row being 490-520m and the distance between an injection well row and an extraction well row being 170-200m, wherein the directionof the oil well row and the water well row is consistent with the direction of the main geostatic stress; the early flooding is carried out under the nearly high pressure condition that the strata pressure coefficient is kept to be 0.9-1.0; at the middle part of the oil layer is perforated for only 2-4 meters, and the perforating is carried out by adopting a multiphase optimized perforation way; the development technology is designed and oil-water wells and capacities of the oil-water wells are deployed in a block; and the slot is produced by adopting the ultra large scale fracturing while monitoring is carried out, wherein average length of half slot is 190-250m, and high delivery volume construction at the speed of high quality fracturing fluid being 5-6m<3> / min is adopted in the whole course. The invention is applied to a low permeable oil deposit development process.

Owner:胜利油田鲁明油气勘探开发有限公司

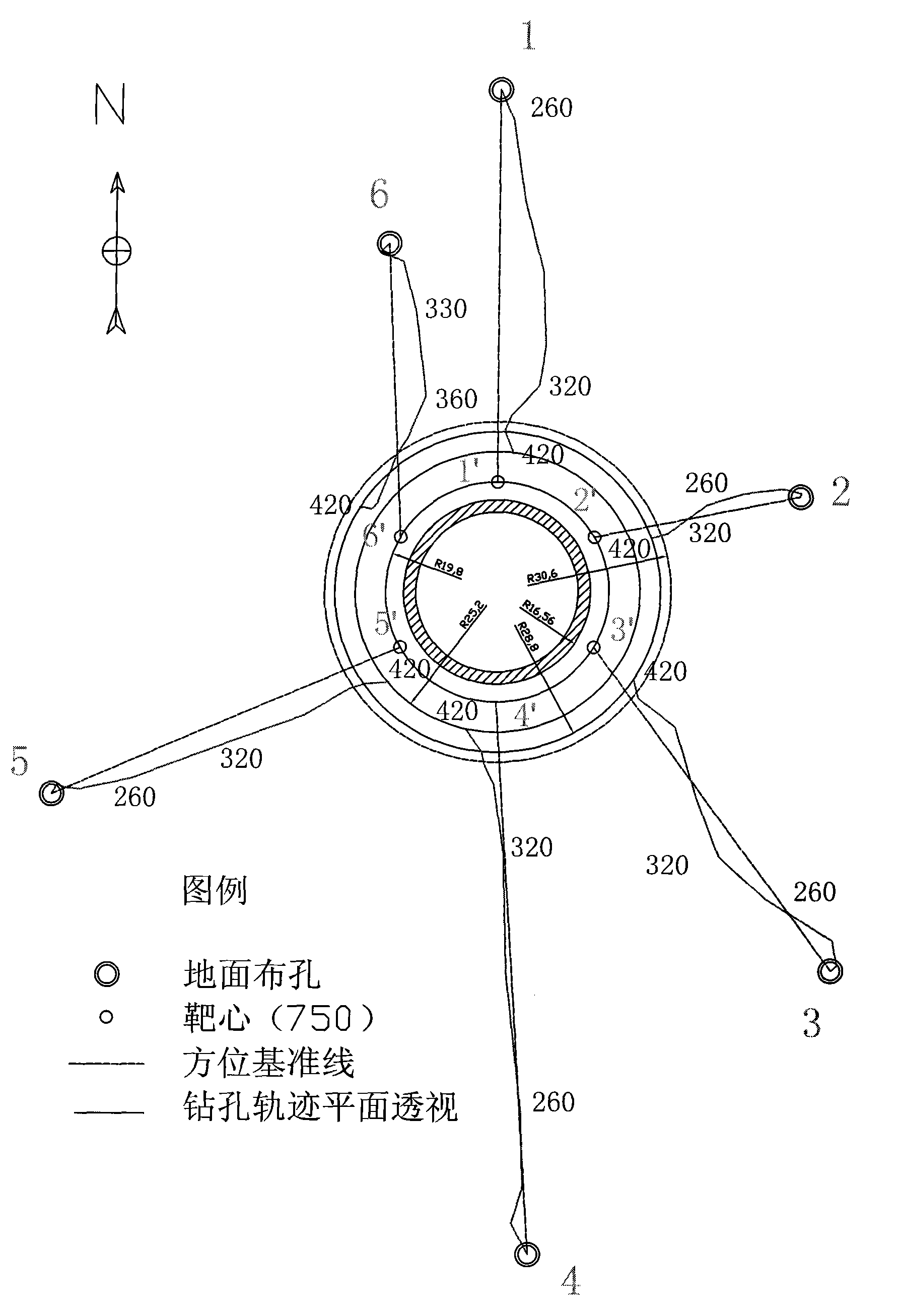

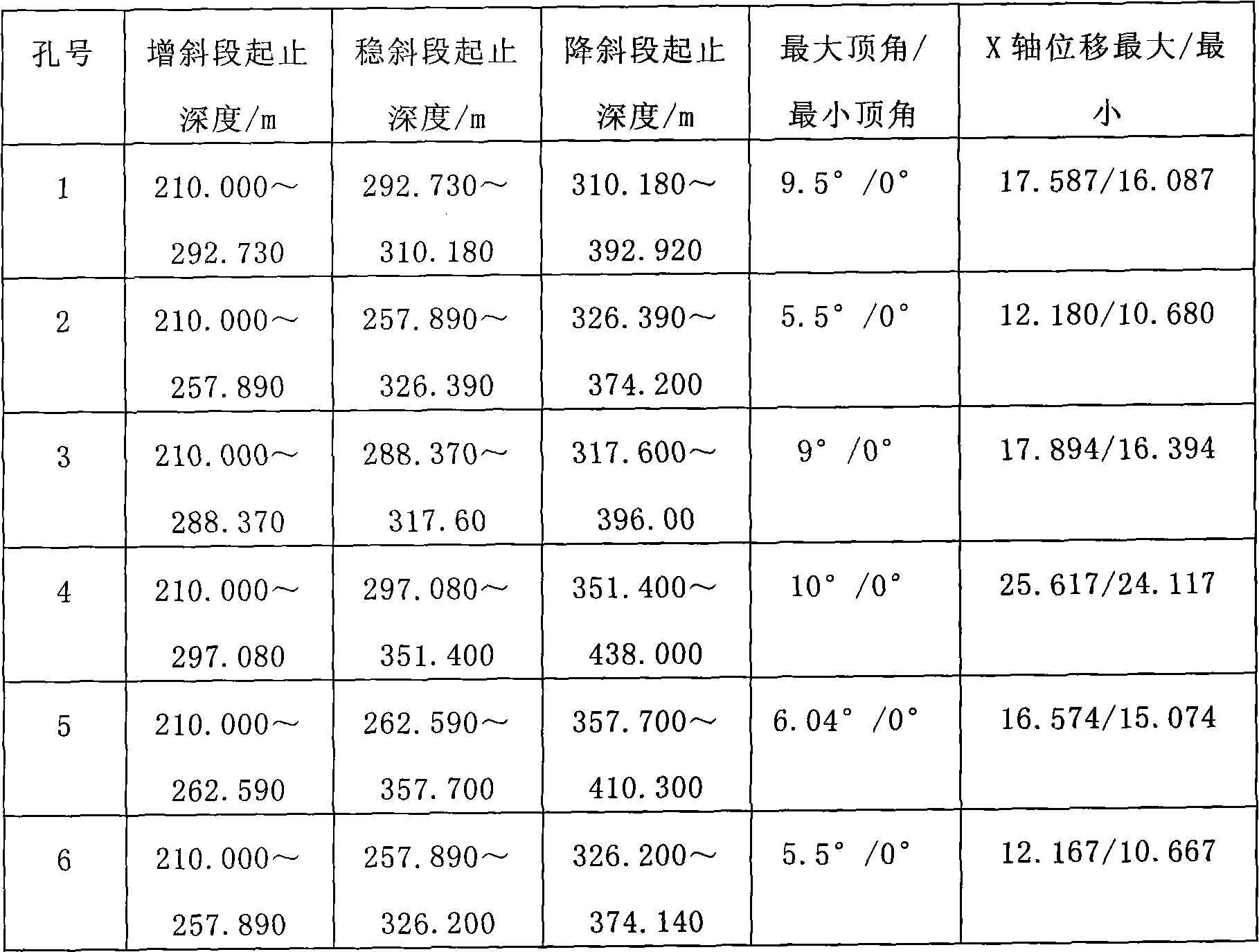

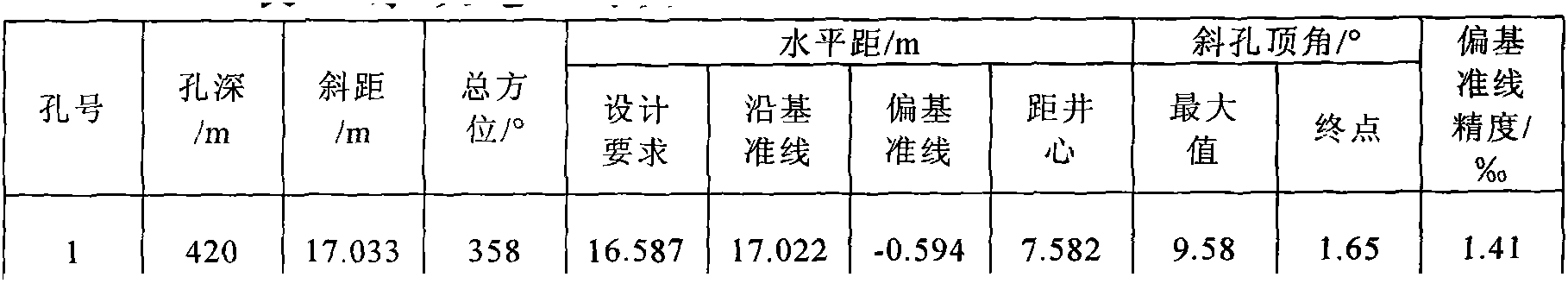

Coal engineering hole directional drilling method

InactiveCN102094580AWon't breakImprove drilling accuracyDirectional drillingCoalDirectional drilling

The invention provides a coal engineering hole directional drilling method, which mainly solves the problems of low drilling precision and complex procedure of the conventional directional drilling method. The directional drilling method is characterized by comprising the following steps of: 1, designing a drilling trace: designing the drilling trace and drilling parameters according to the requirement of engineering drilling; 2, determining special equipment, machines and devices which are required by the engineering, and combining the drilling equipment according to the requirements of all drilling stages; 3, constructing according to the trace and the parameters which are designed in the step 1, measuring the finished drilling trace by using an inclinometer after one stage is finished, analyzing whether data is the same as the designed trace, and expecting the next trace tendency; and 4, performing error correction design if error correction is needed to be performed in the step 3, repeating the content in the step 2, and cycling until the drilling is finished; and if error correction is not needed in the step 3, continuing to drill the next hole section until the drilling is finished. The coal engineering hole directional drilling method has the characteristics of high drilling precision, simple procedure, smooth drilled holes and contribution to the next work of drilling.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

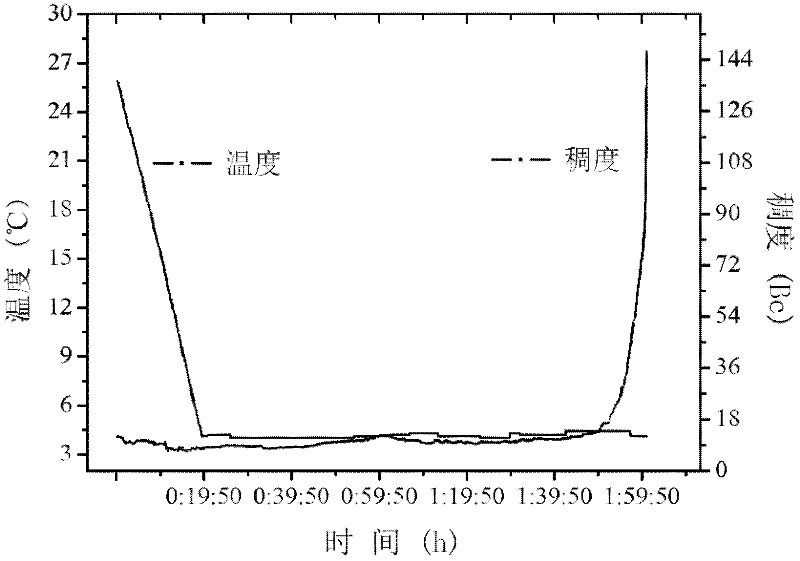

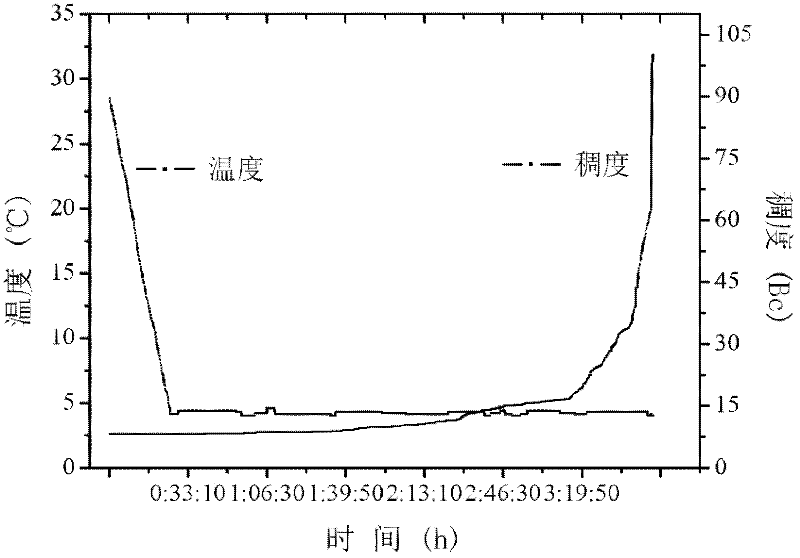

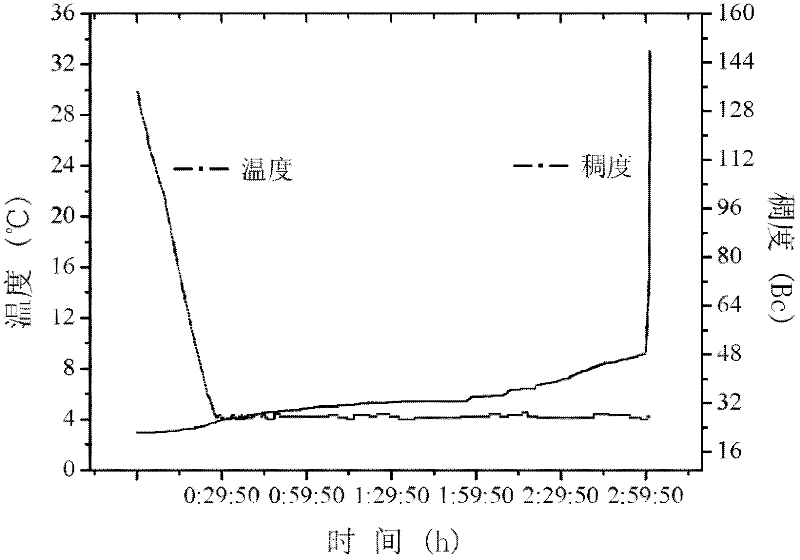

Low-temperature early-strength corrosion-resistant cement paste system for deepwater cementing

ActiveCN102329601AThickening time adjustableImprove liquidityDrilling compositionCement pasteCorrosion resistant

The invention relates to a low-temperature early-strength corrosion-resistant cement paste system for deepwater cementing. The system consists of the following components in part by weight: 100 parts of cement, 20 to 100 parts of density regulator, 0.3 to 0.6 part of retarder, 0.1 to 5 parts of fluid loss agent, 0.1 to 3 parts of early strength agent, 0 to 0.6 part of dispersant, 5 to 30 parts of heat regulator and 60 to 120 parts of water. 100 weight parts of cement contains the following components in part by weight: 20 to 70 parts of CaO, 20 to 60 parts of Al2O3, 5 to 20 parts of SiO2, 10 to 35 parts of P2O5, 0.5 to 5 parts of Fe2O3 and 1 to 4 parts of MgO. The cement paste system has excellent low-temperature early-strength, corrosion-resistant, thickening time-adjustable and 'right angle thickening' properties, and is expected to solve the main problems of low temperature, set cement corrosion, shallow water-gas channeling and the like that the deepwater cementing faces. The system is reliable in technology and low in cost, is convenient to construct on site, and is particularly suitable for low-temperature, corrosion and shallow water-gas channeling cementing operations under deepwater conditions.

Owner:SOUTHWEST PETROLEUM UNIV

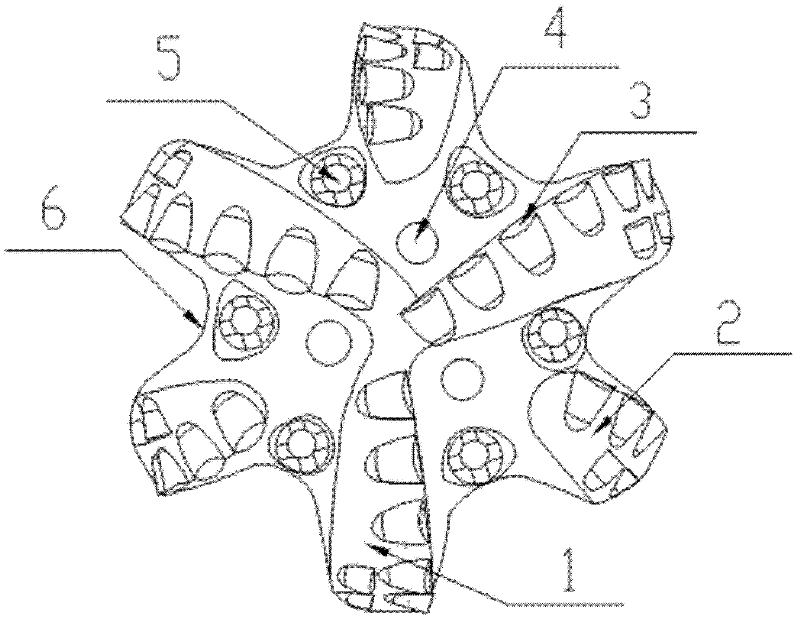

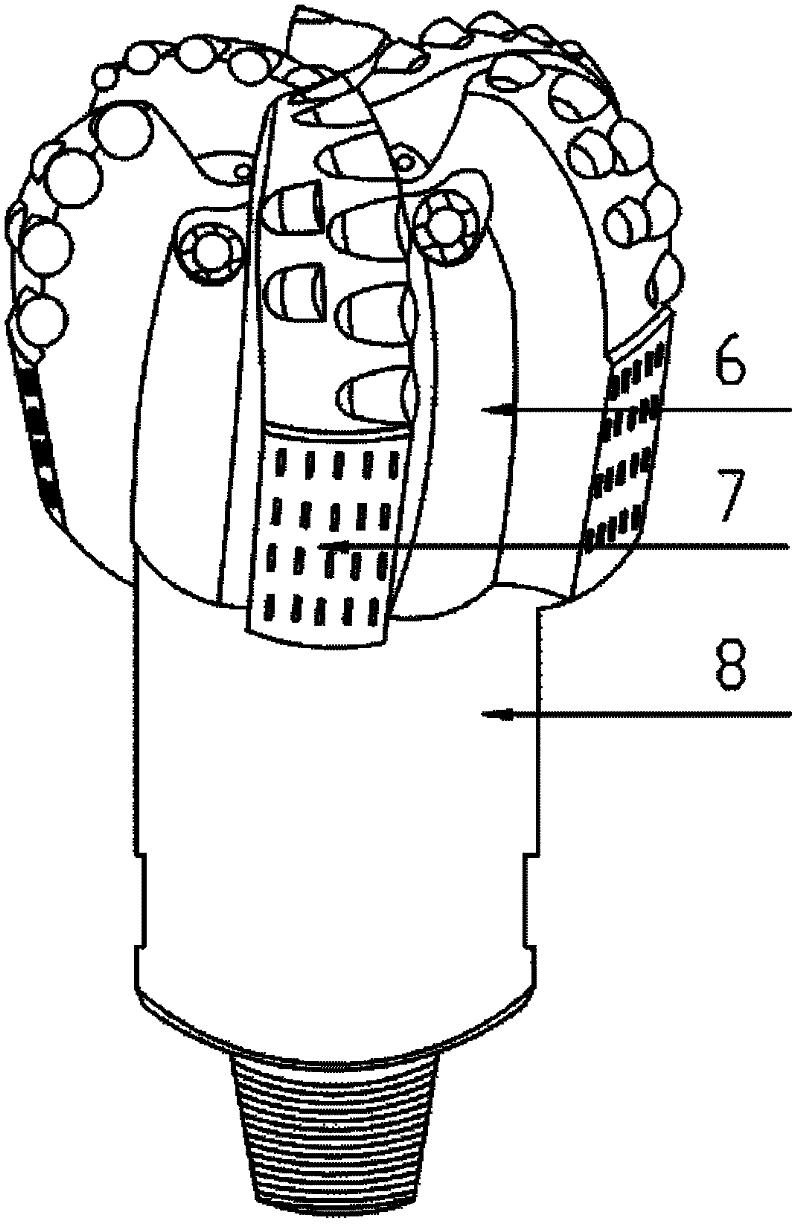

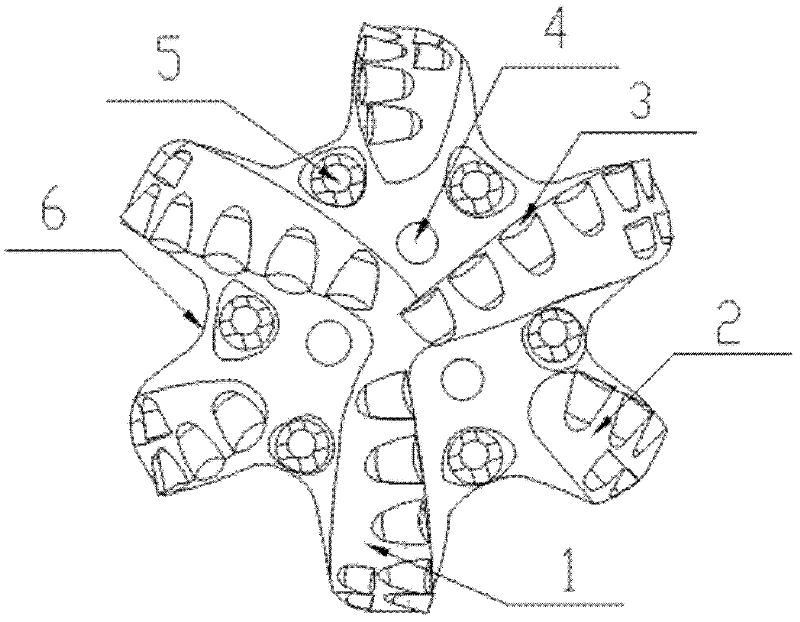

Blade type PDC (Polycrystalline Diamond Compact) drill bit

InactiveCN102409980APrevent crappy drillingExtended service lifeConstructionsPolycrystalline diamondOil and natural gas

The invention discloses a blade type PDC (Polycrystalline Diamond Compact) drill bit, comprising blades, PDC cutting teeth, nozzles, chip grooves, a drill bit diameter-maintaining part and a drill bit body, wherein the blades are fixed on the crown head of the drill bit body; the blades includes main blades and short blades, which are uniformly distributed at intervals; the tail ends of the three main blades extend to be connected with one another and supported mutually; the distances of the short blades of a 8.5'' drill bit from the drill bit center respectively are 45 mm, 55 mm and 65 mm; the back of each blade forms an inclination of 8-12 degrees with the central line of the crown head of the drill bit body; the thickness of each blade is gradually increased along with the distance between the blades and the cutting edge; the tail part of each blade is of the shape of a parabola; PDC cutting teeth are arranged on the blades; the chip grooves are arranged between adjacent blades; and the fixed nozzles and the adjustable nozzles are inlaid on the drill bit body. According to the drill bit, the shape of the main blades and the distribution of the nozzles and water holes are adjusted based on the traditional drill bit structure, therefore, the diameter of the drill bit can be better prevented from being worn, the forming of drill bit bouncing and drill bit balling can be avoided, the service life of the drill bit can be prolonged so that the well building period can be shortened. The blade type PDC drill bit is also applicable to drilling ultra deep wells and wells in complex conditions for oil and natural gas.

Owner:HENAN SHENLONG GASOLINEEUM DRILLING TOOLS

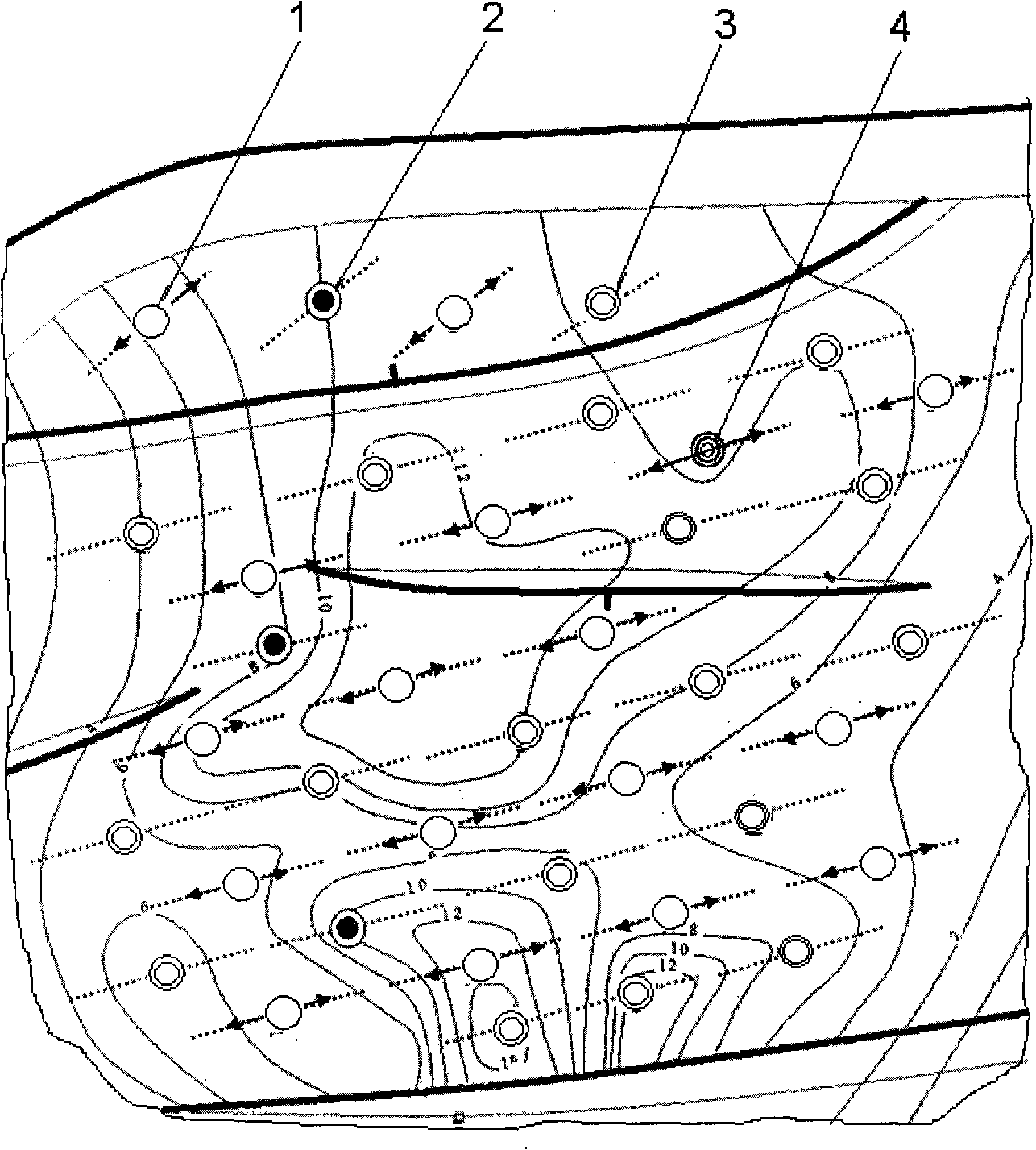

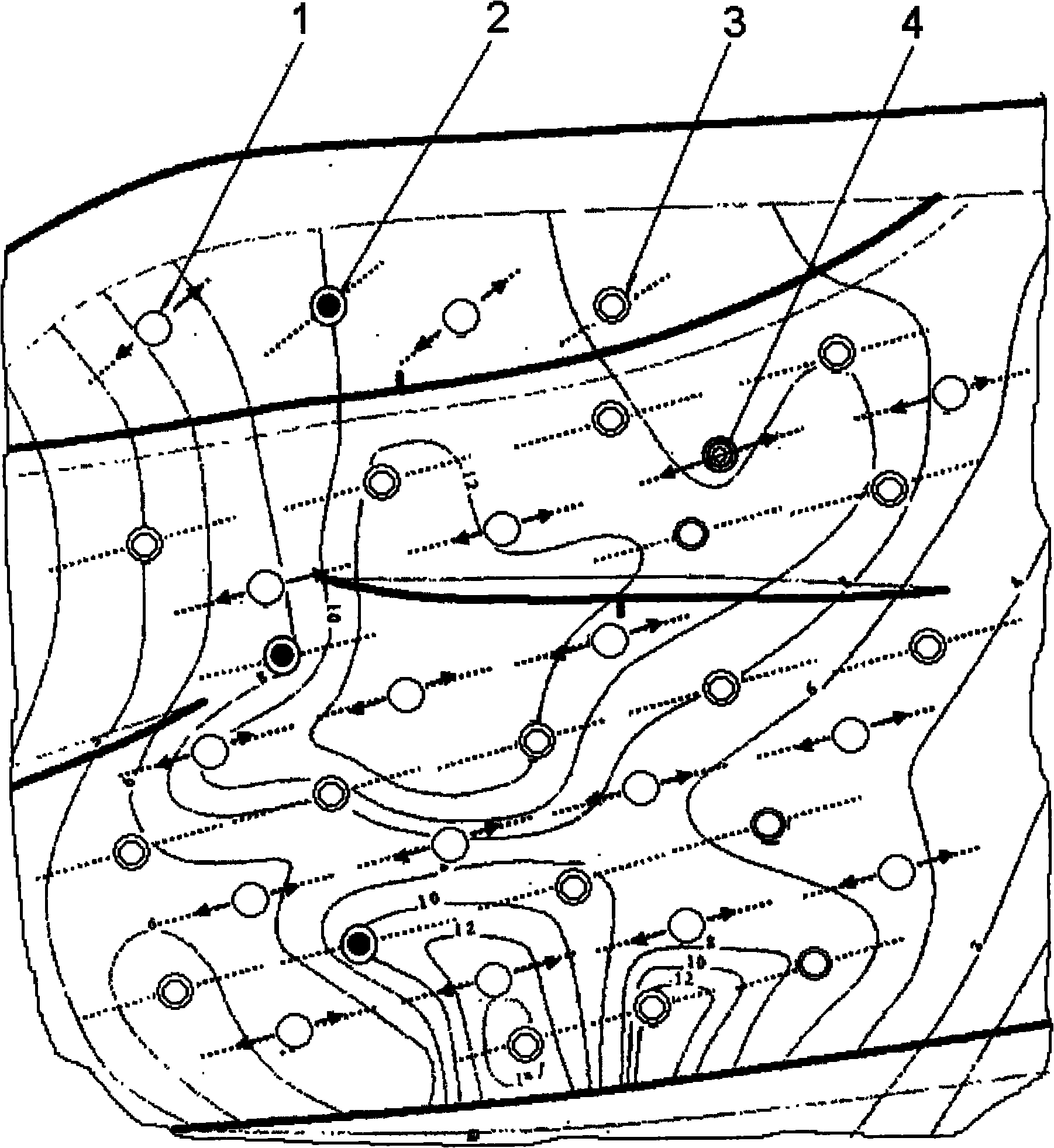

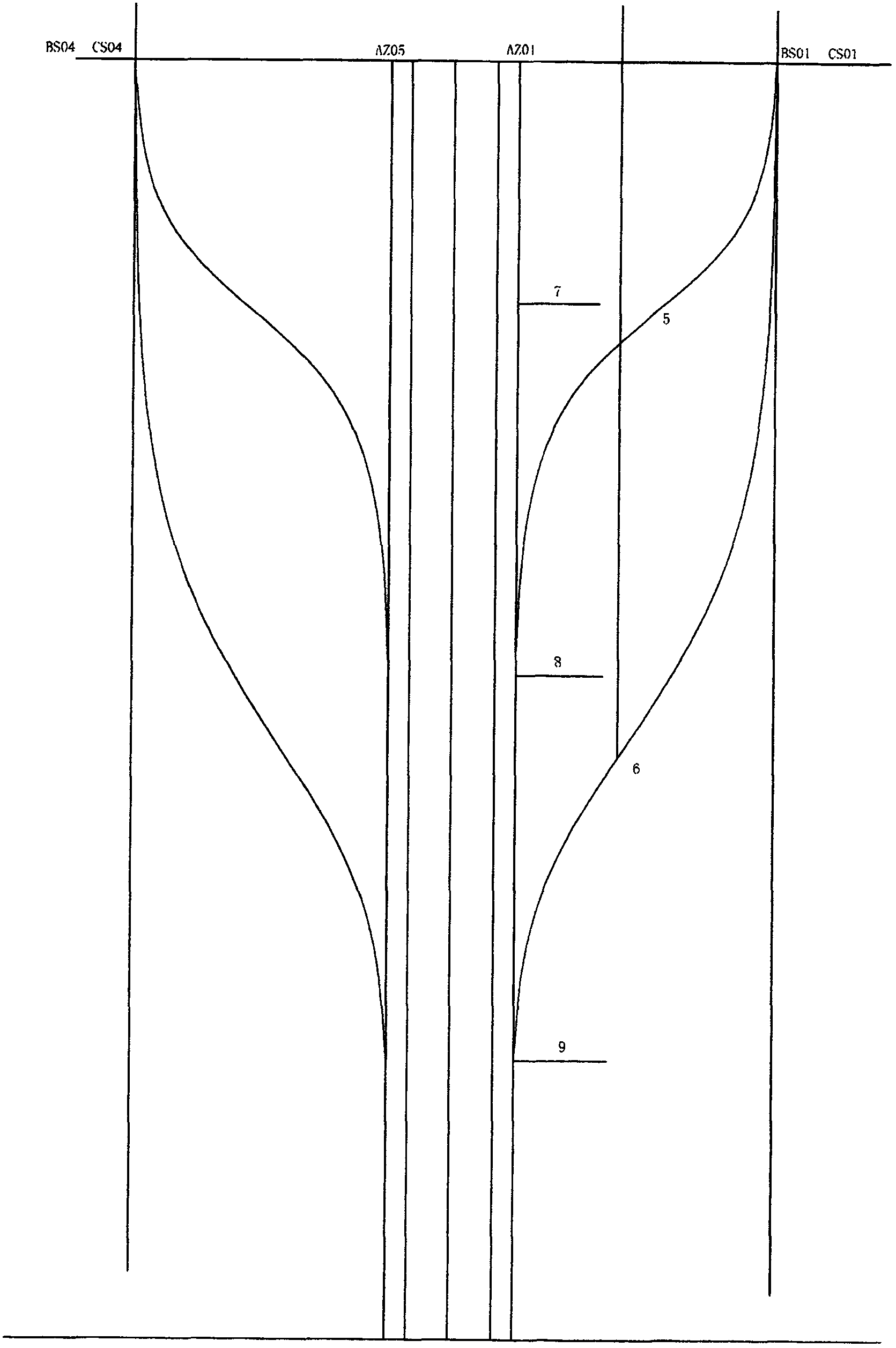

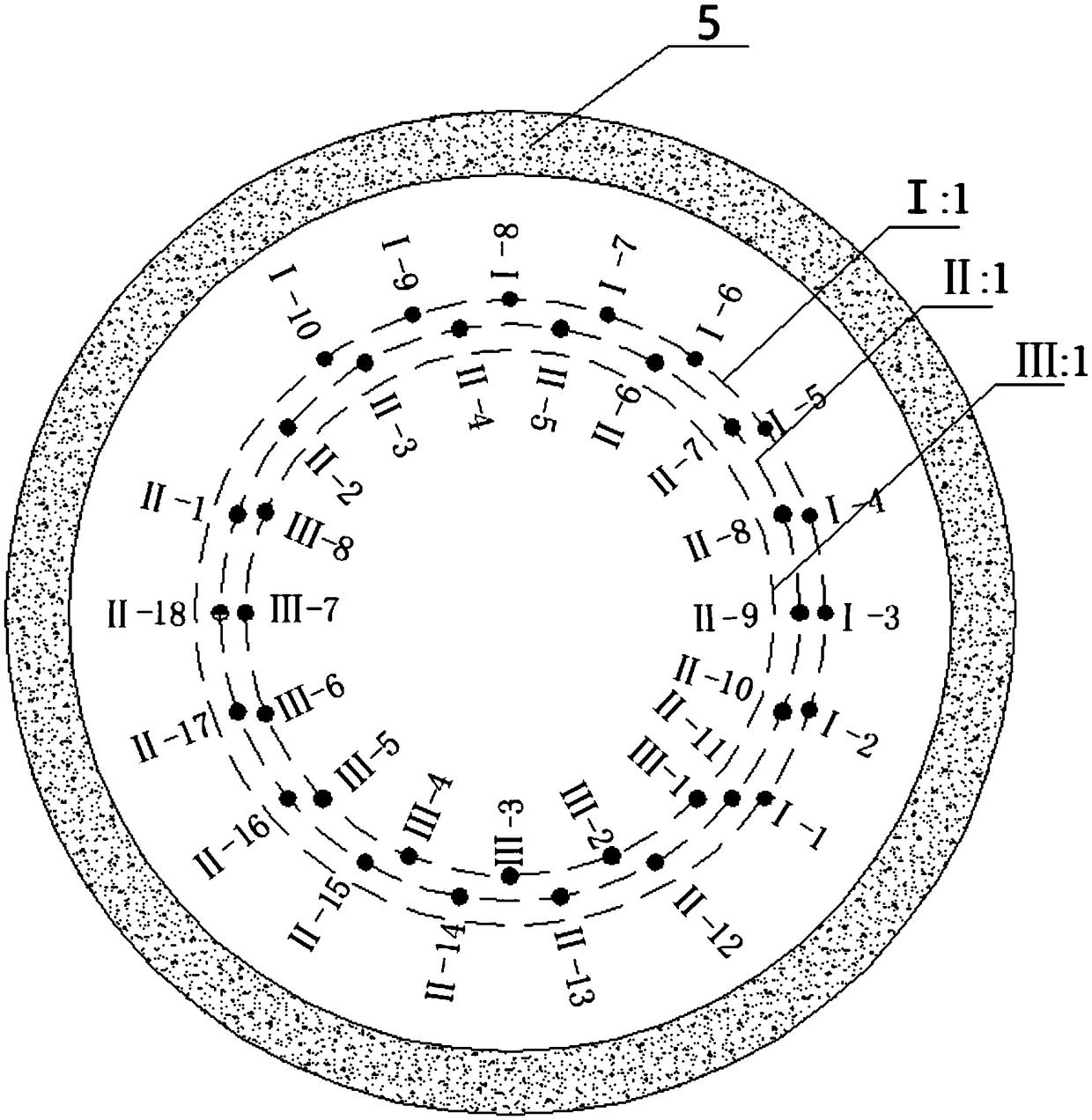

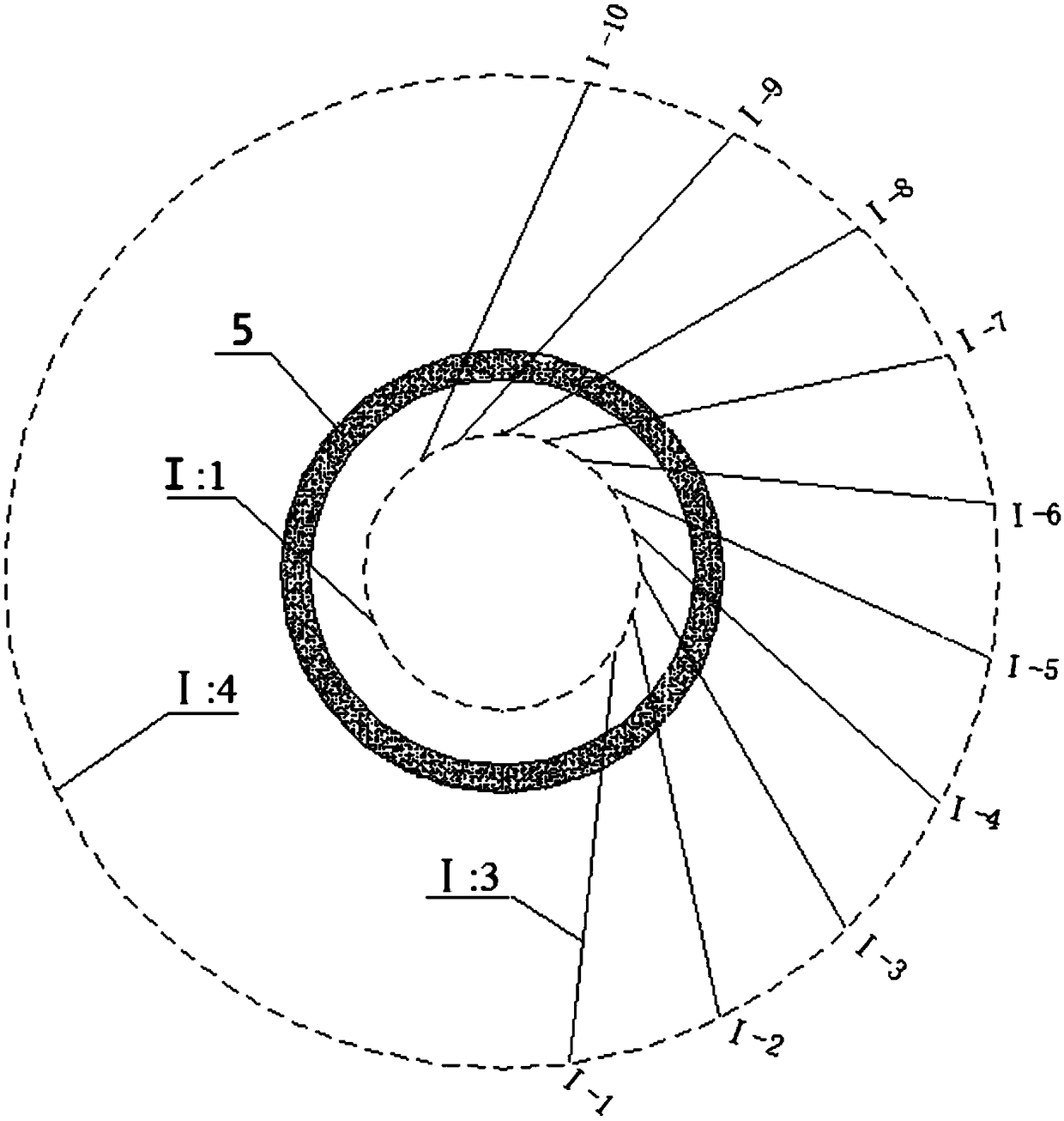

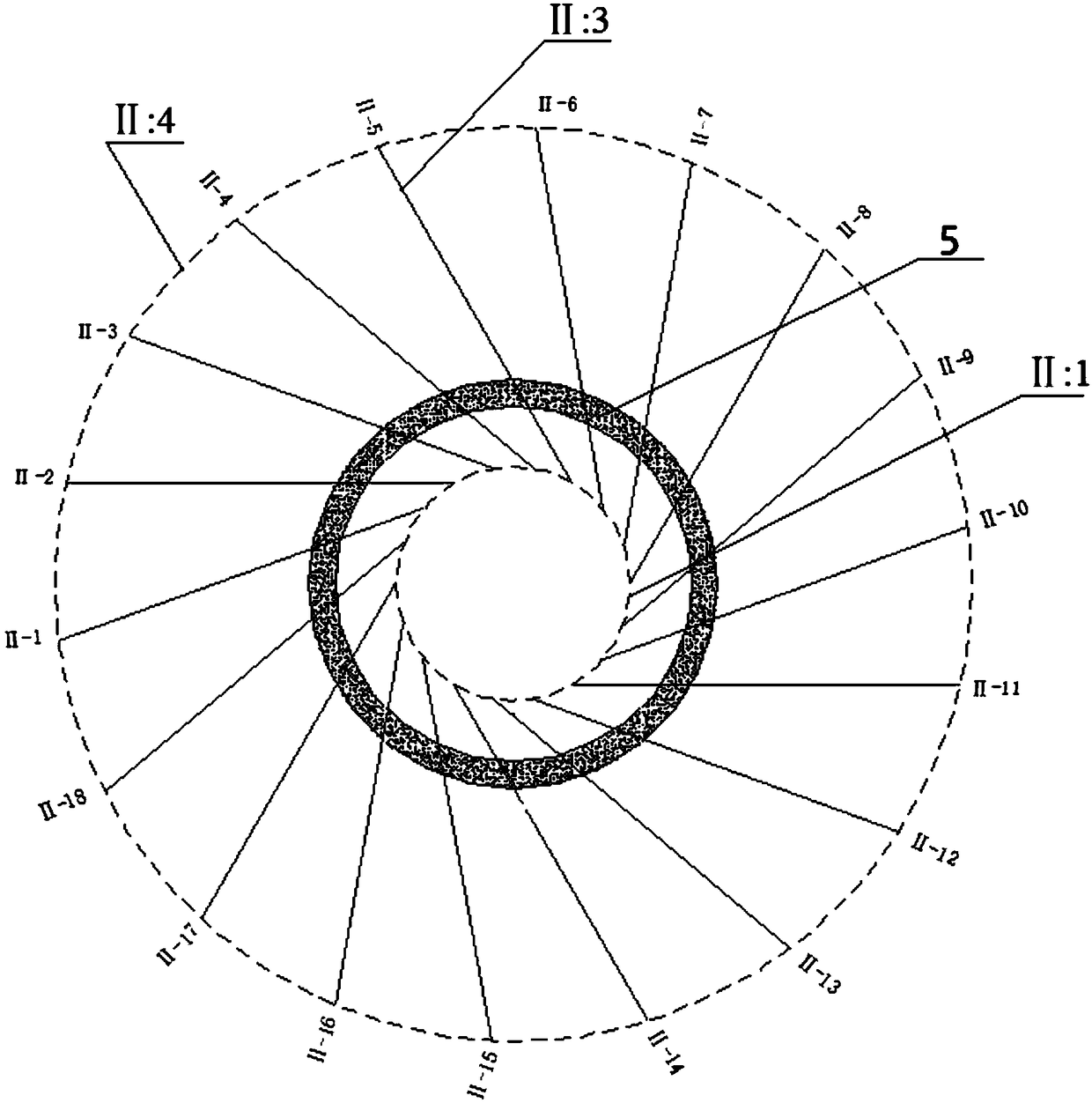

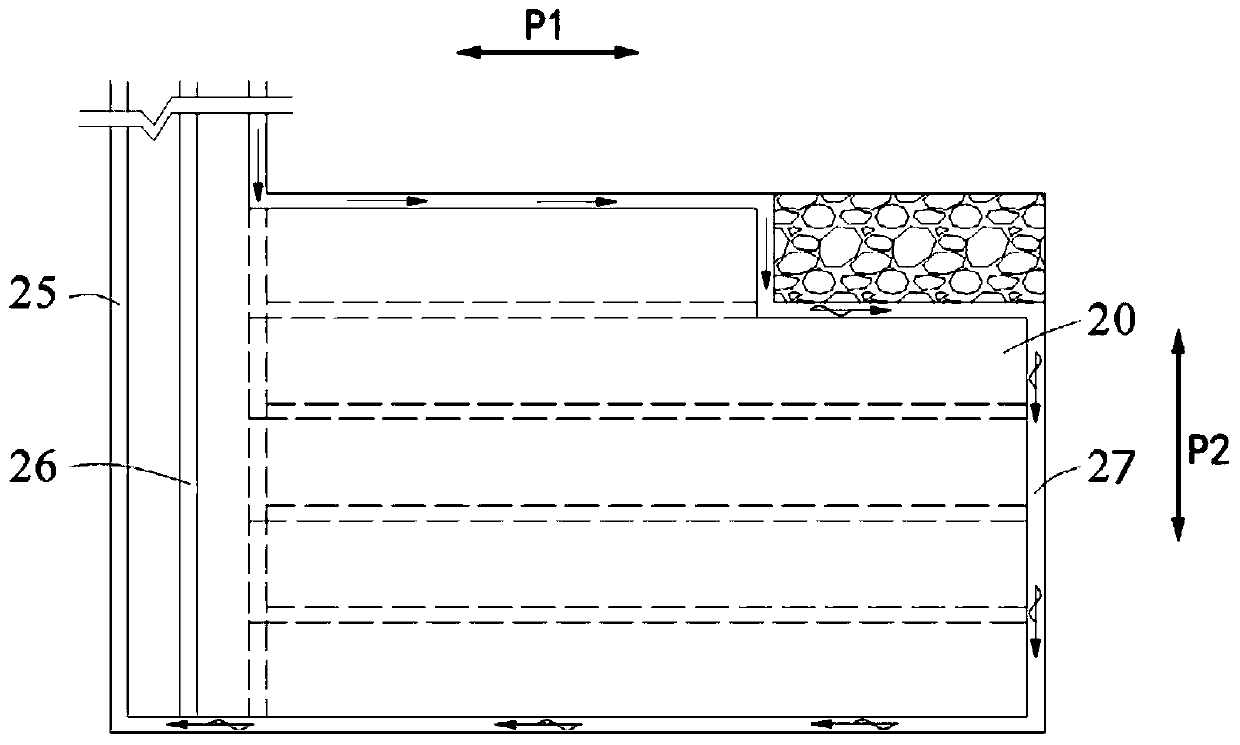

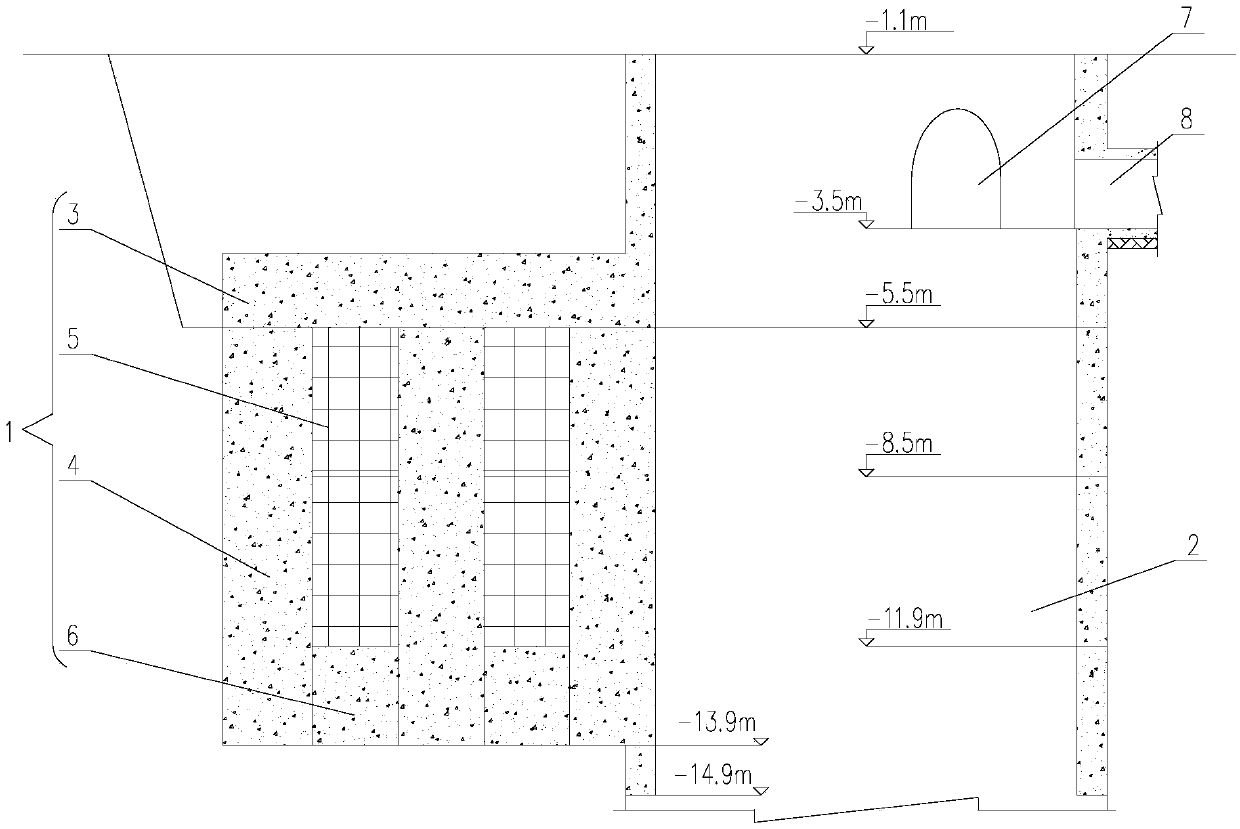

Multiple-working-face parallel working process for shaft ground pre-grouting

InactiveCN103233699AQuality assuranceFast constructionSealing/packingField conditionsIndustrial engineering

The invention provides a multiple-working-face parallel working process for shaft ground pre-grouting. The process is accurate in positioning and high in working efficiency. The technical scheme includes that the process comprises the steps of implementing an innovative process route which is different from traditional grouting for ground pre-grouting, dividing a shaft into a plurality of working faces, conducting multi-section grouting, during 800-1000m ultra-deep shaft operation, according to field conditions, enabling the 200-300m section to serve as a main grouting section, and dividing the main grouting section into three layers, wherein the first layer is the straight-hole grouting section, the second layer is the S-hole grouting section, and the third layer is the S-hole grouting section. According to the process, the technology of a straight hole and multiple-working-face S holes is adopted, the parallel working process that the vertical shaft ground pre-grouting is divided into a plurality of portions for simultaneous construction is initiated, specific positions in traditional processes are not required to be adopted, parallel operation of construction such as freezing and shaft sinking is possible, while the quality is guaranteed, the construction speed is accelerated, and the shaft building cycle is shortened for construction units.

Owner:张新立

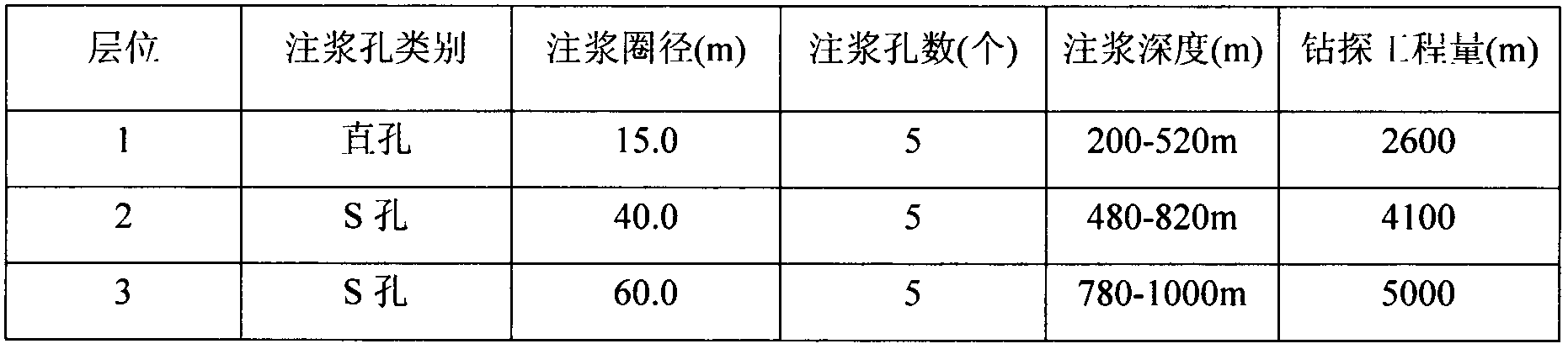

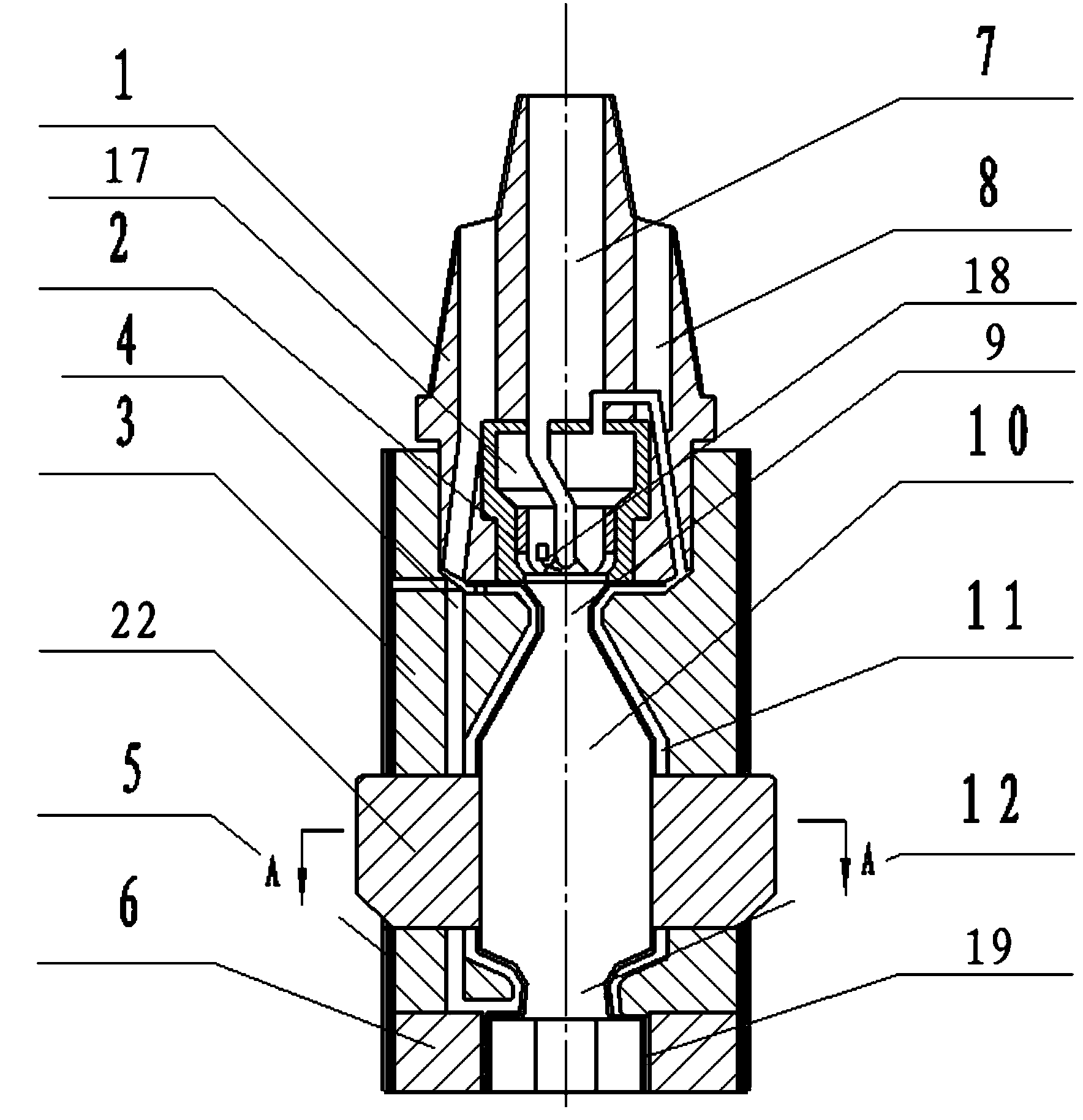

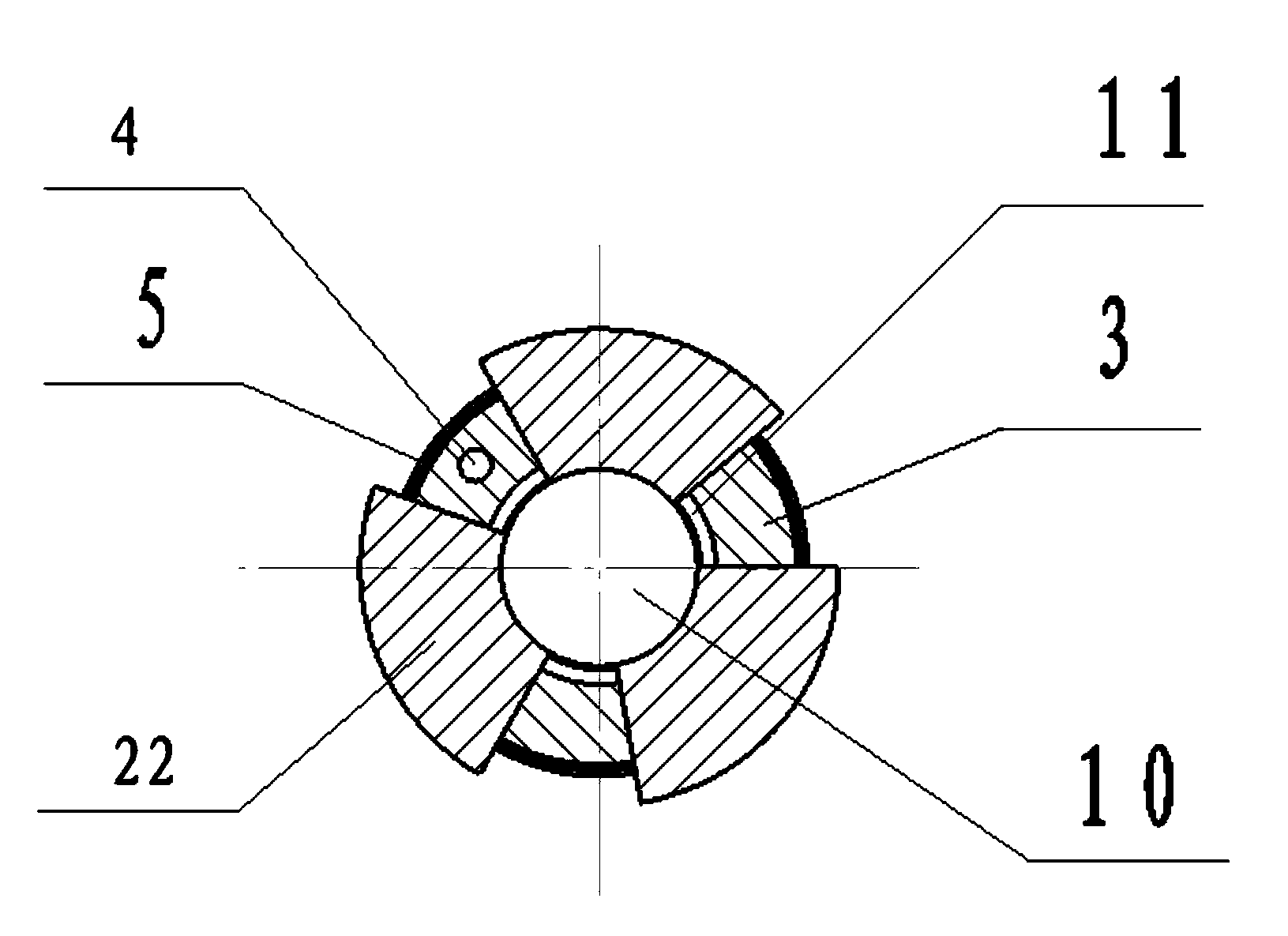

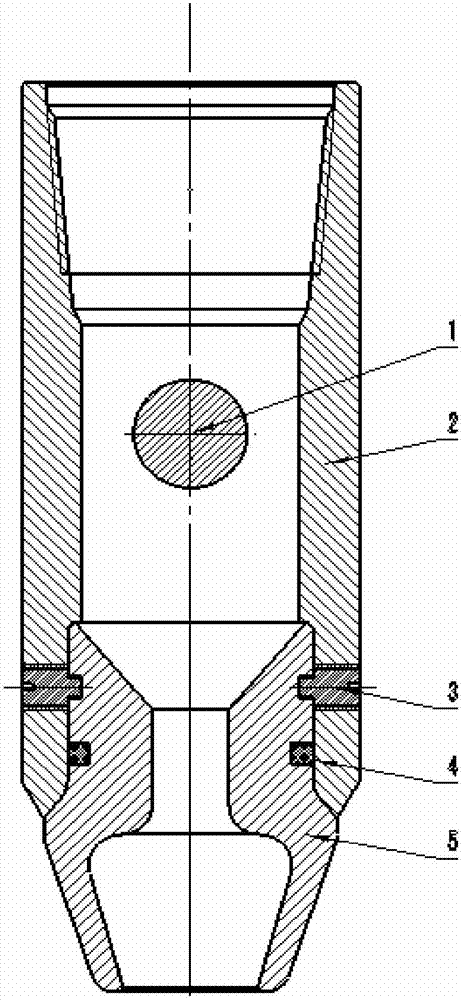

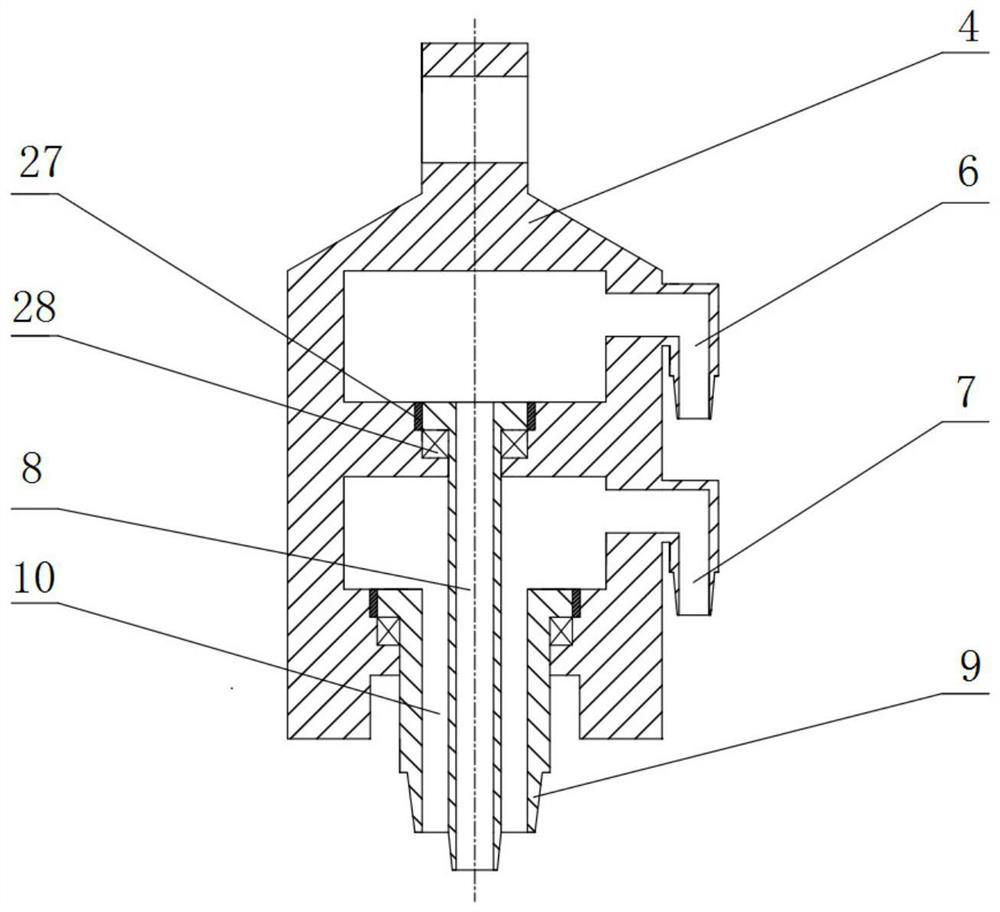

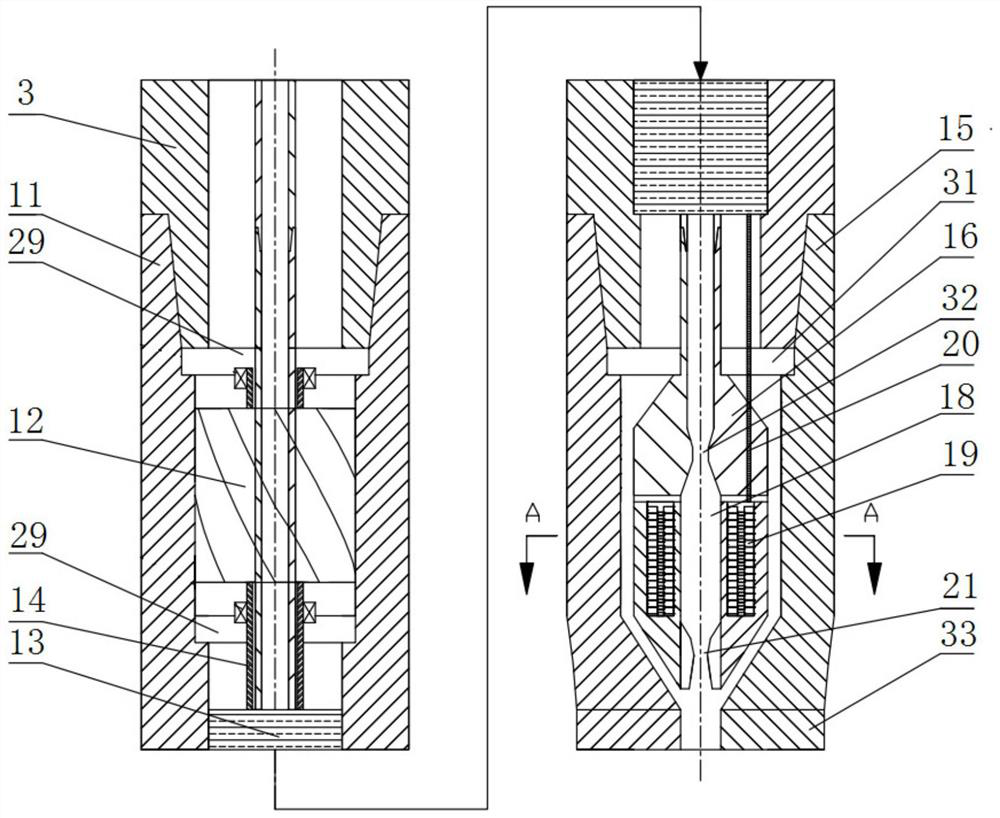

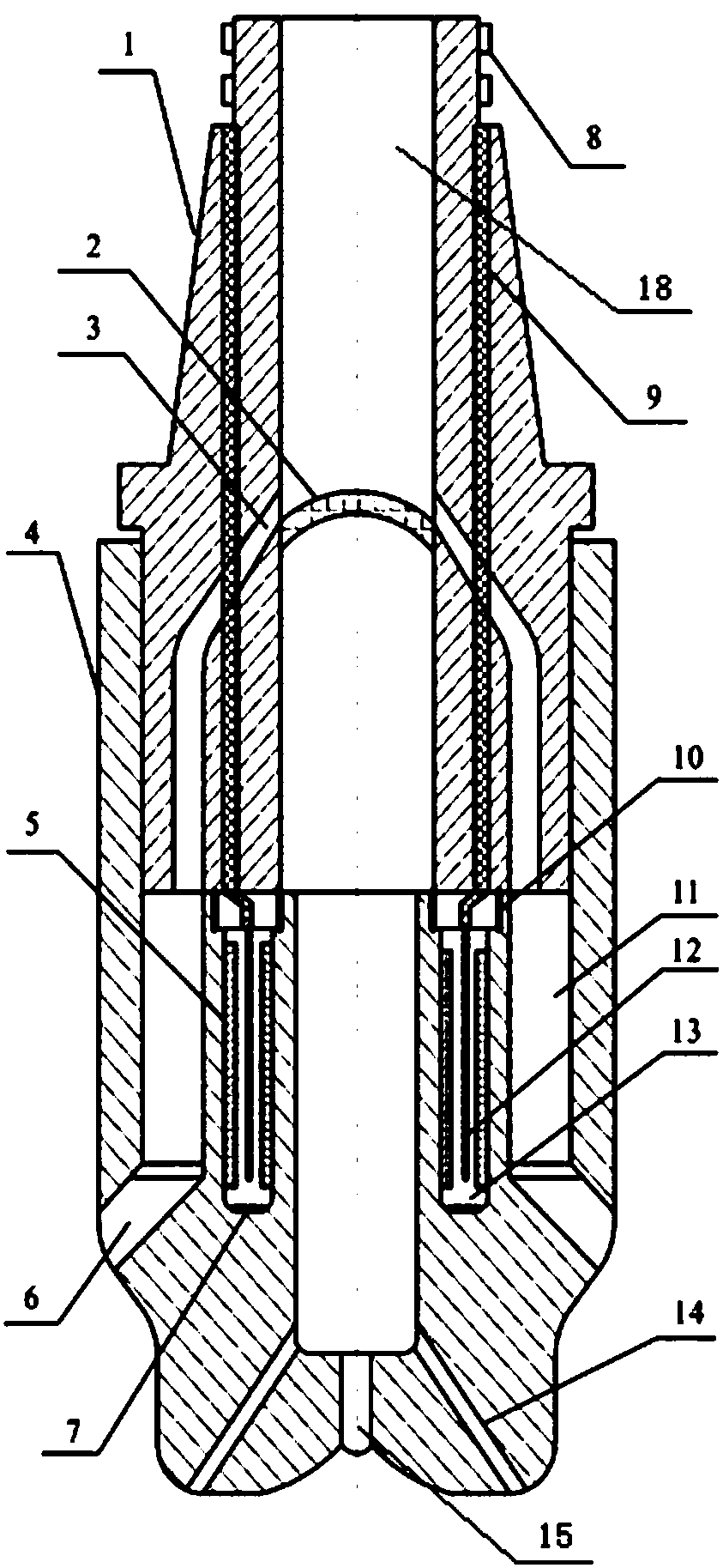

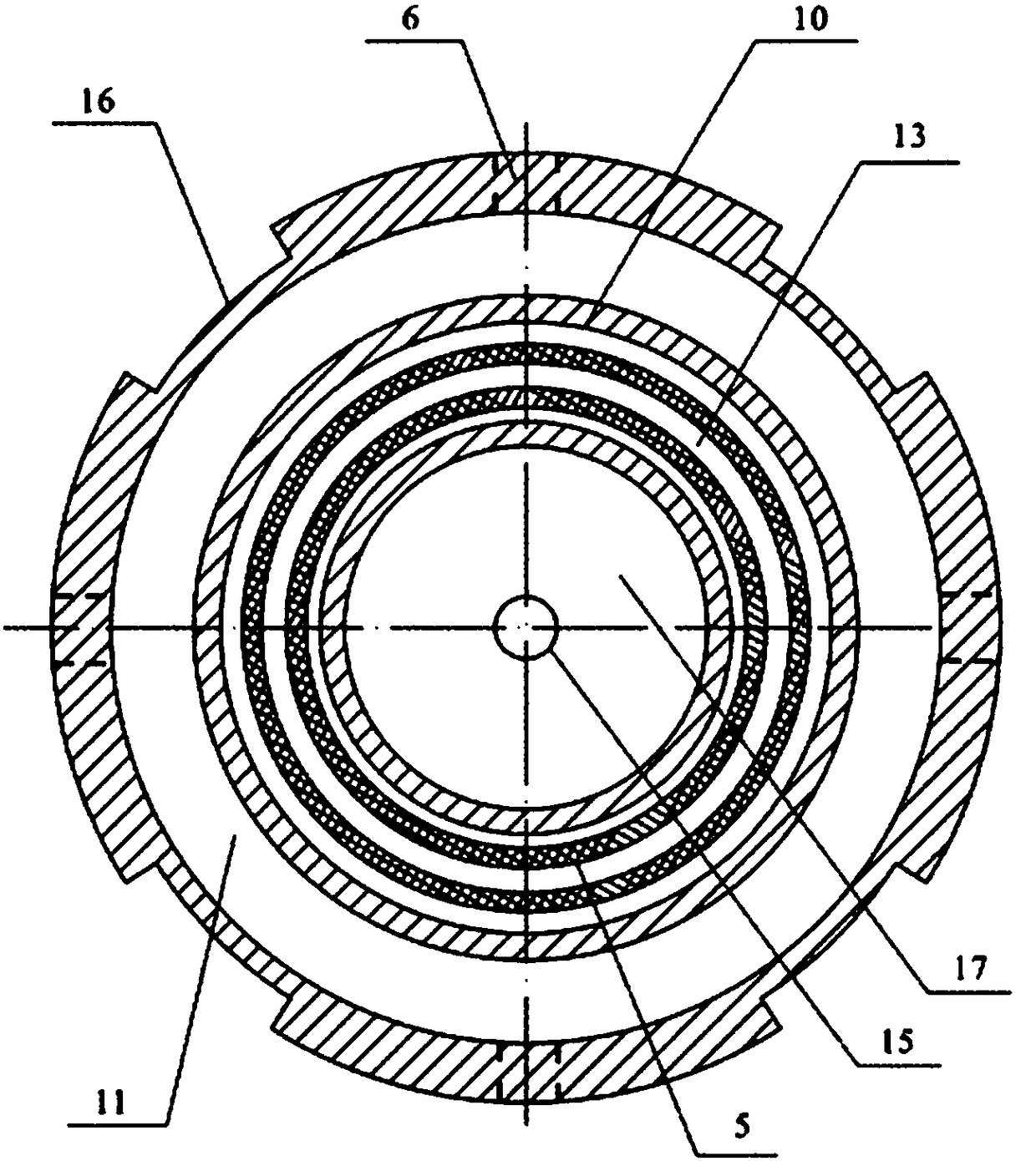

Combined drill for drilling with casing

The invention relates to a casing drilling combined drill which comprises a casing column, a casing shoe, a drill bit plug and a changeable tool assembly. The casing drilling combined drill is characterized in that the casing shoe is connected with the casing column through screw threads, the drill bit plug is connected with the changeable drilling tool assembly through screw threads, and the casing shoe and the drill bit plug form the casing drilling combined drill through the positioning of positioning steps of the casing shoe and the drill bit plug. When the drill bit plug needs changing or other measuring tools are needed to be put into a well during the casing drilling construction, the drill column is not needed to be pulled out just like a conventional drilling process; instead, the changeable drilling tool assembly and the drill bit plug are pulled out of the well top through a cable winch system, and the drilling can be continued after the good changeable assembly and the good drill bit plug are sent in through the cable winch system.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

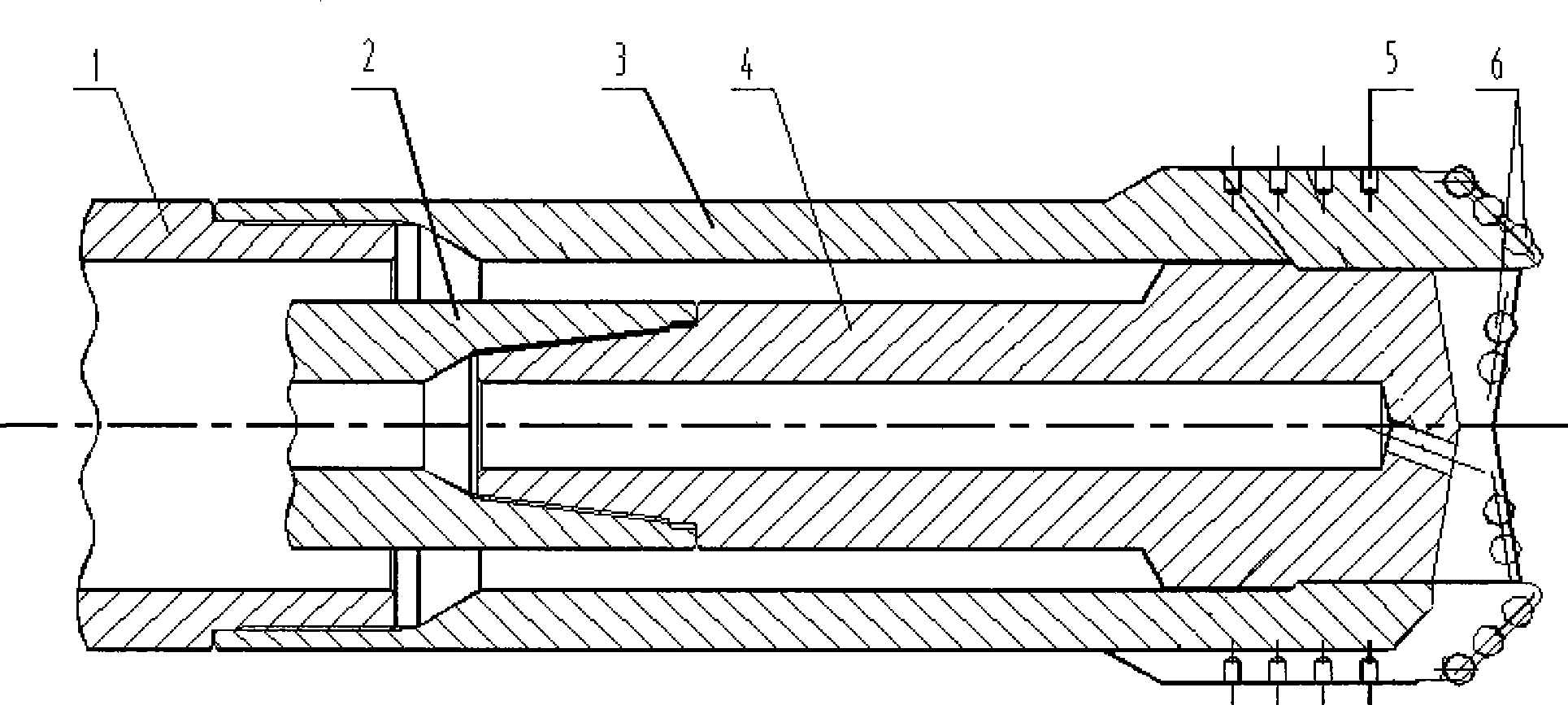

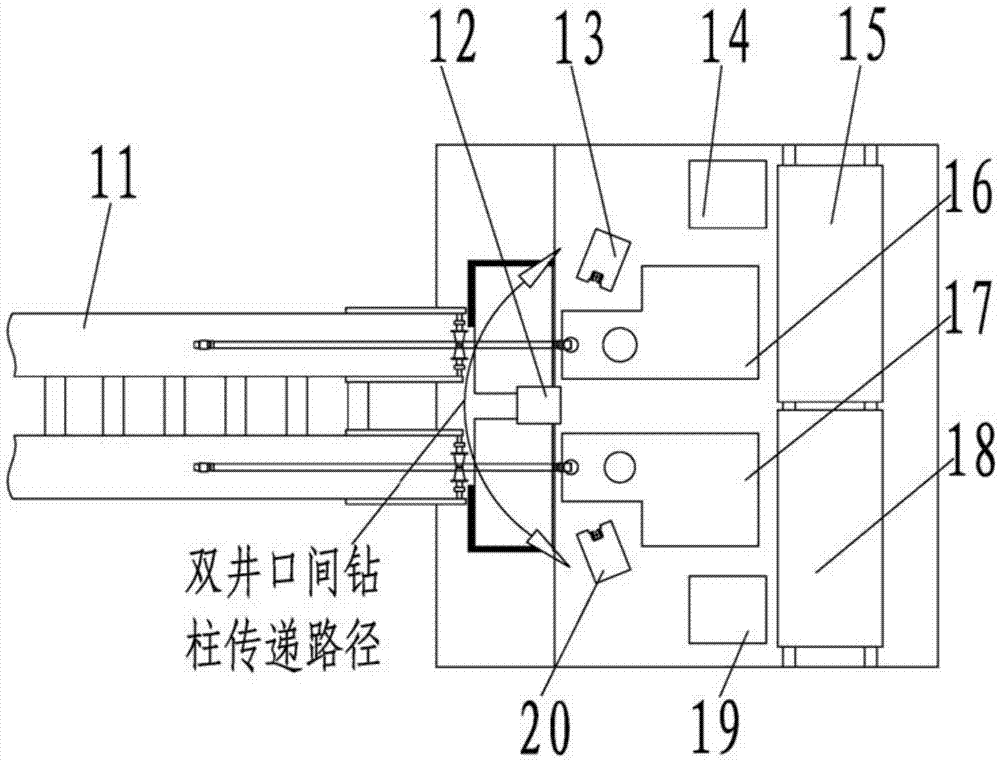

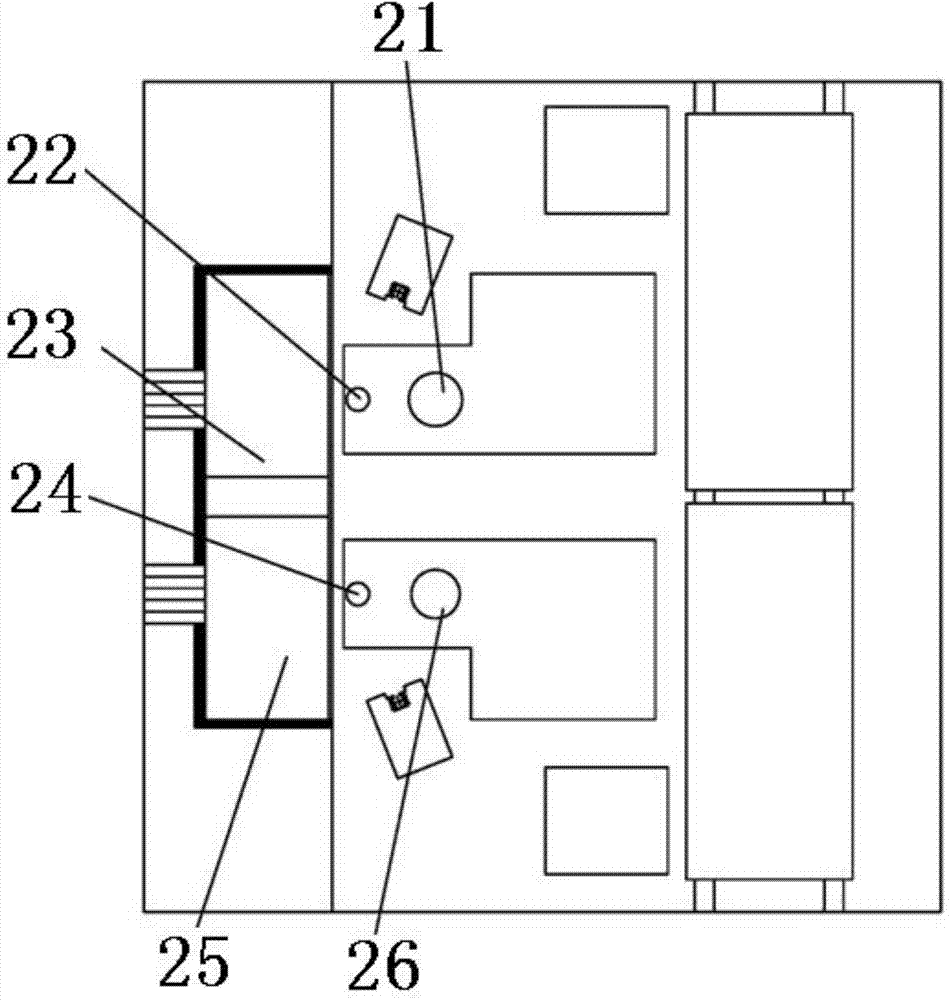

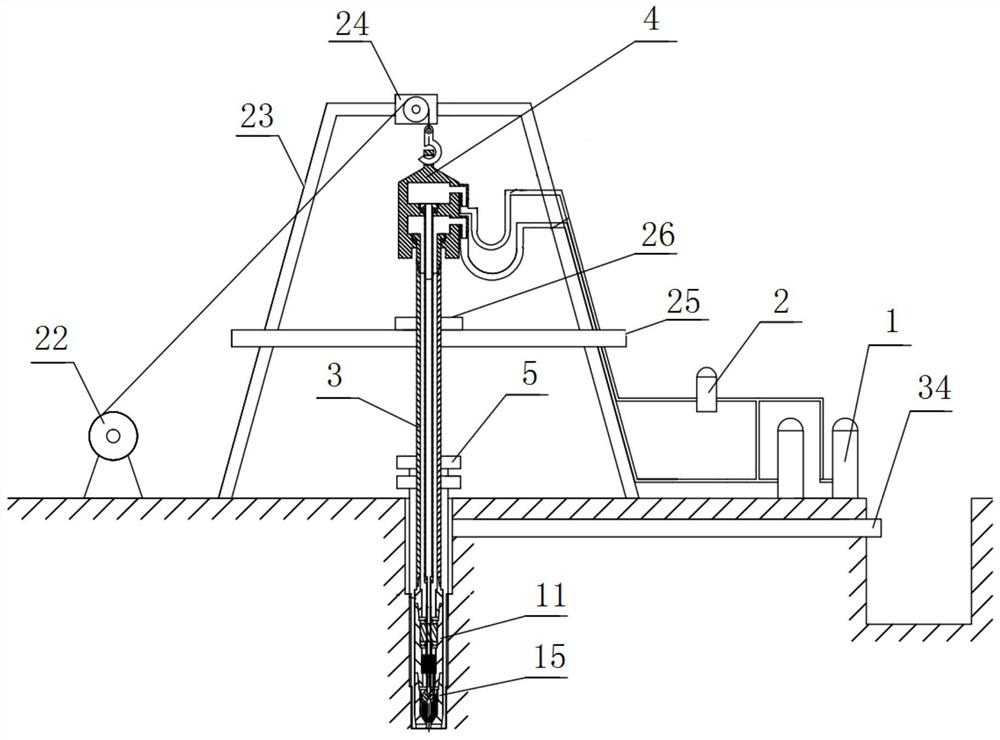

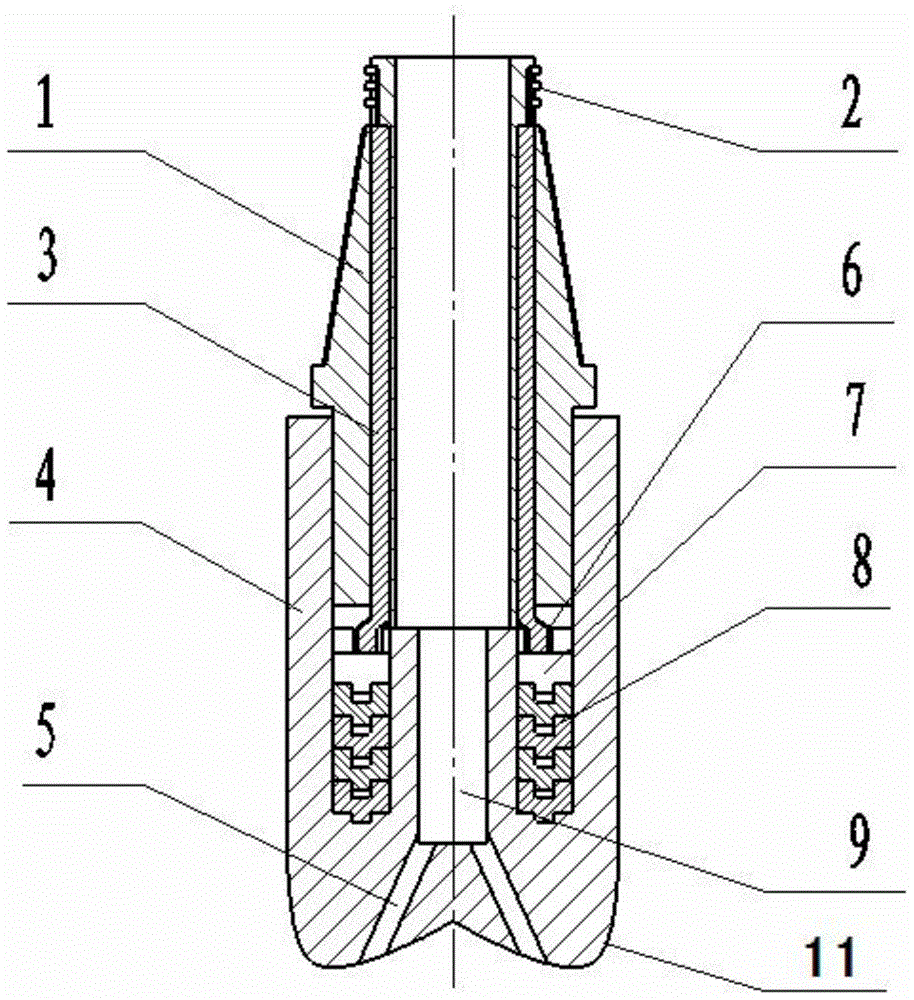

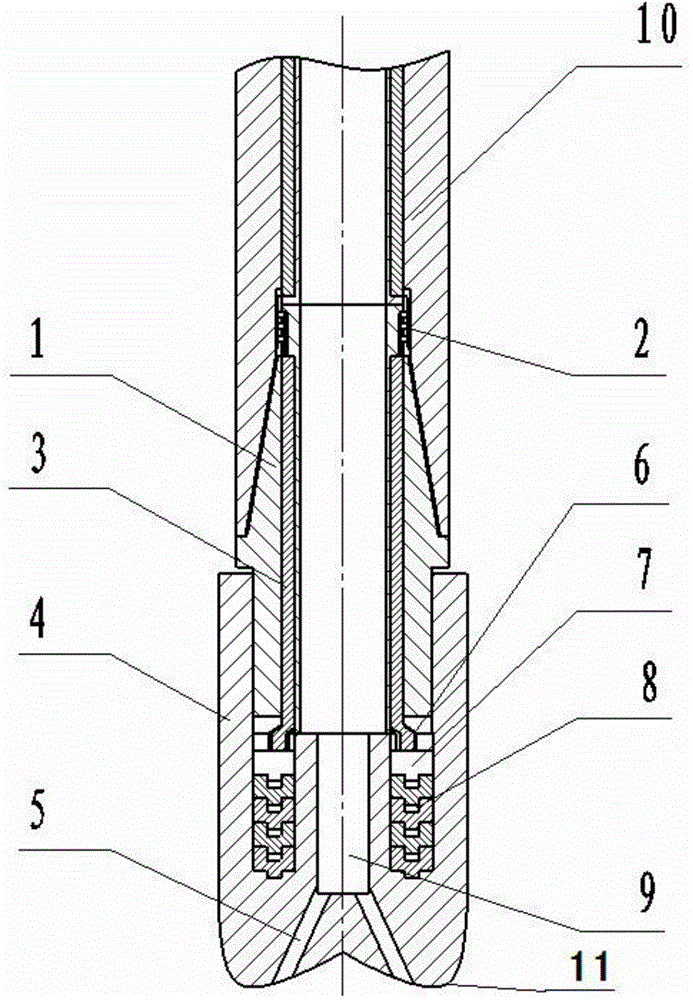

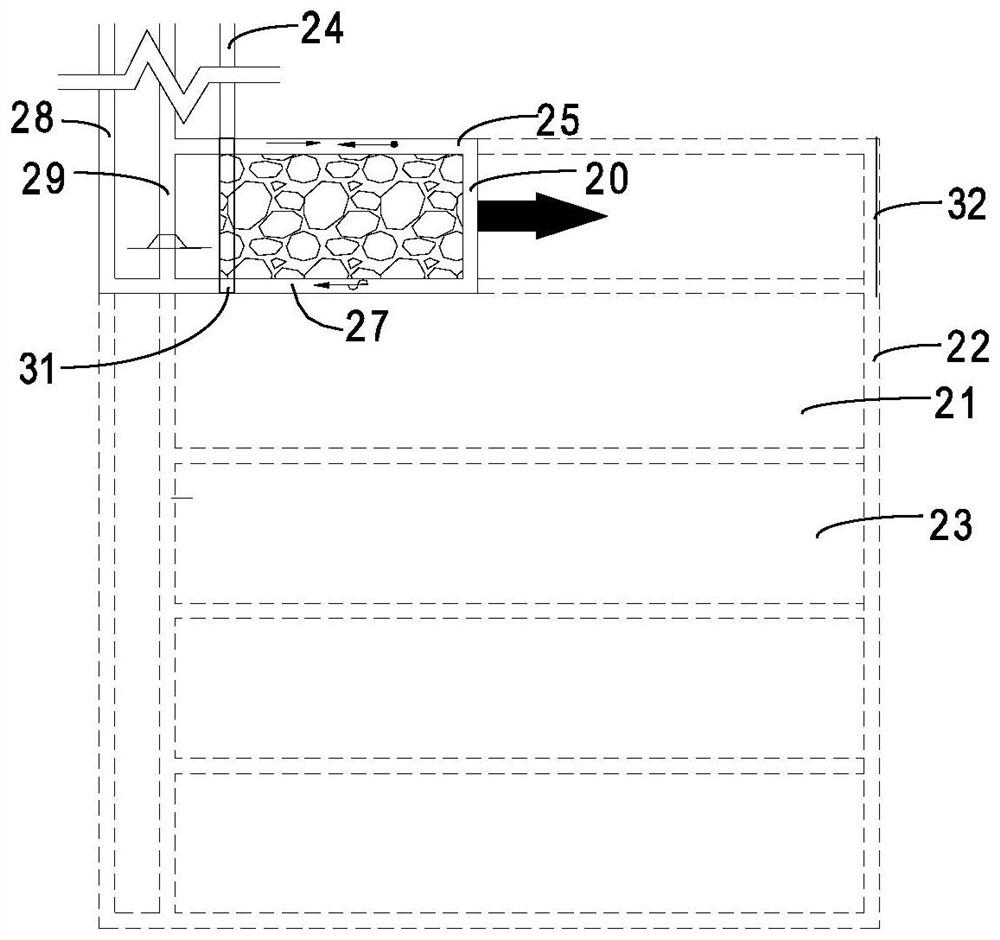

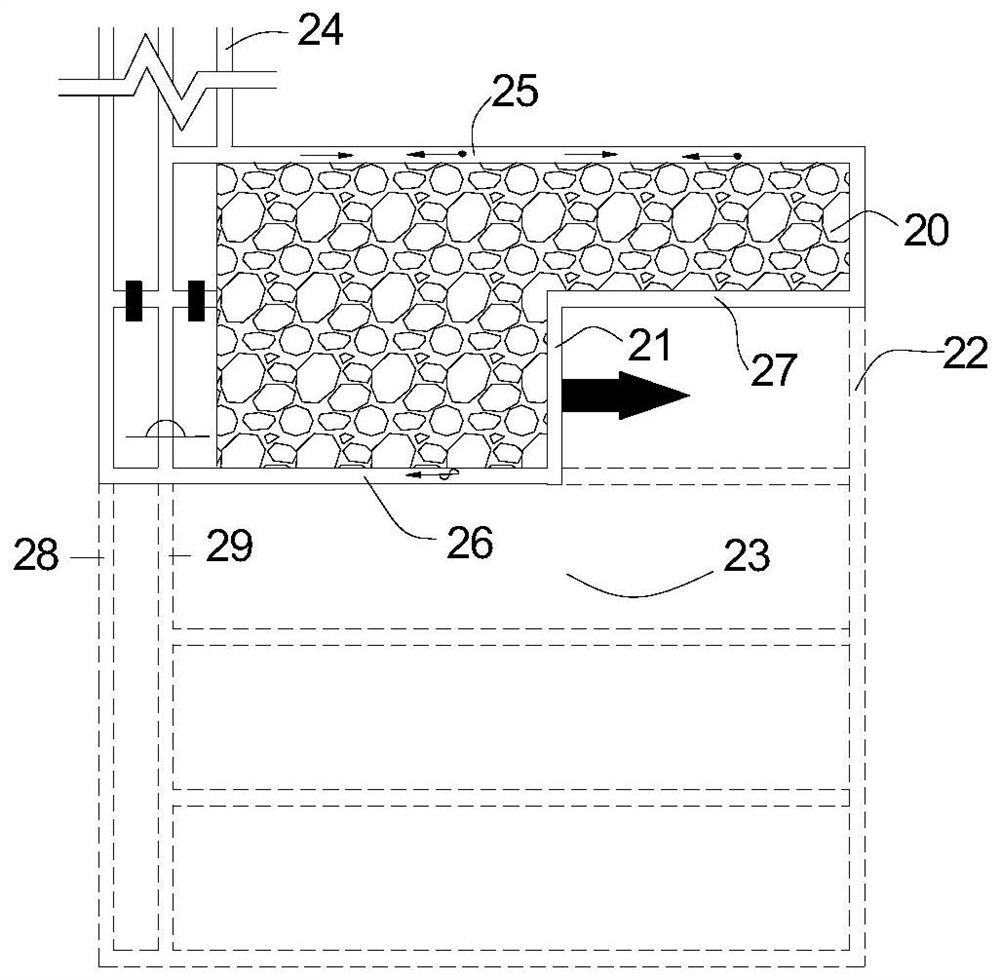

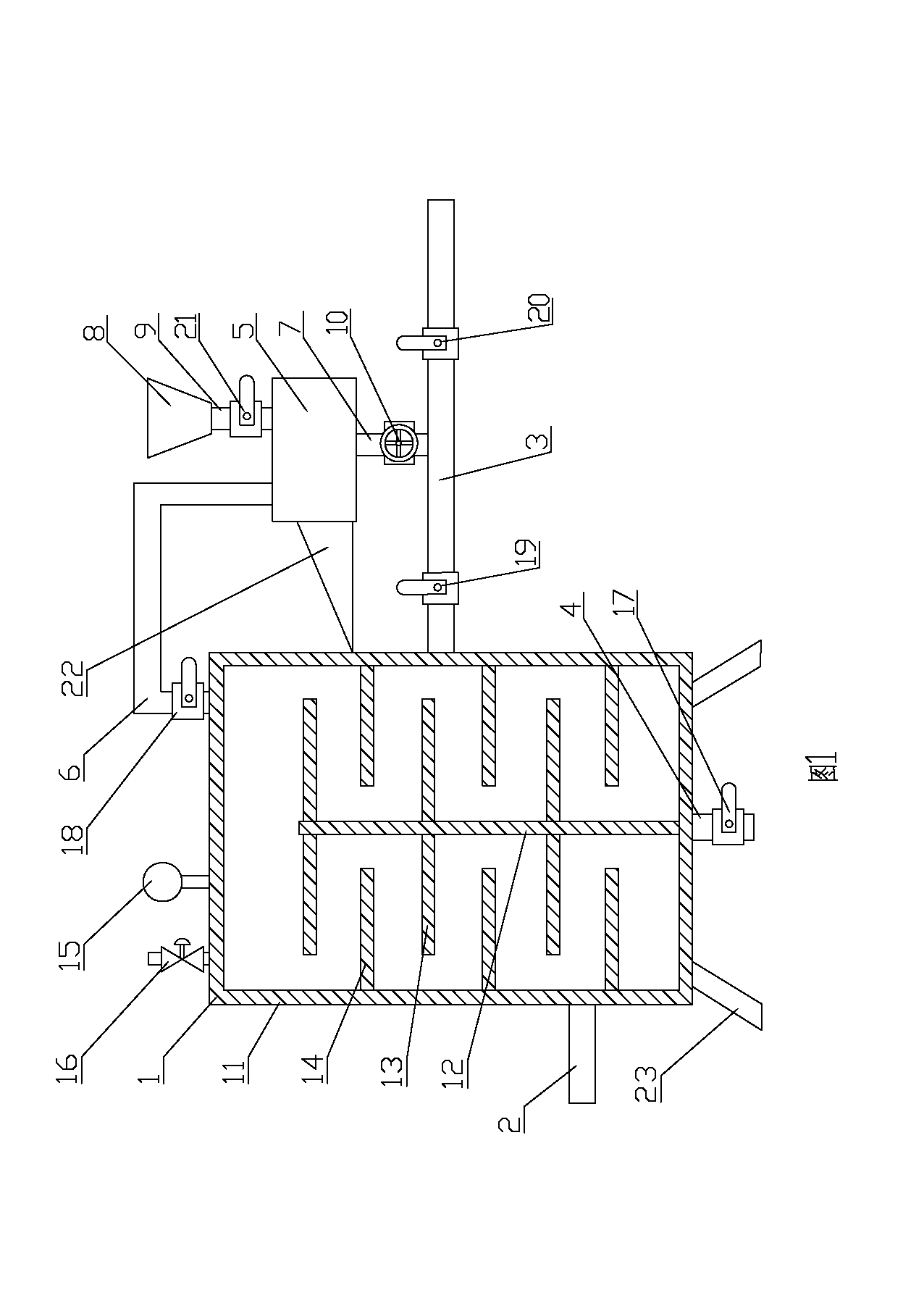

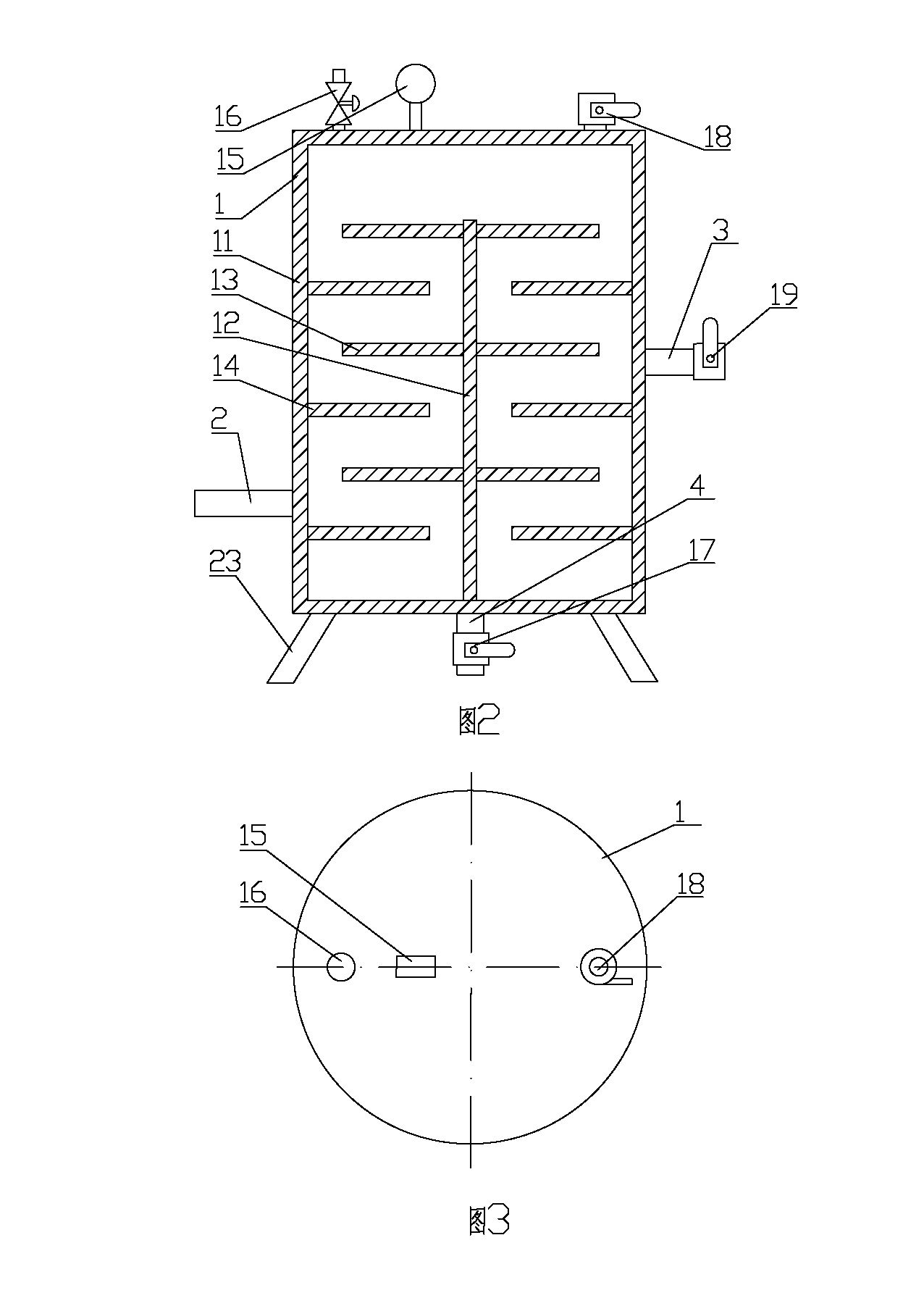

Well drilling device for double-wellhead operation

InactiveCN103696700AShorten the well construction periodIncrease productivityDrilling rodsDerricks/mastsWellheadWell cementing

The invention discloses a well drilling device for double-wellhead operation. The well drilling device comprises a base of a drilling machine, wherein a drilling machine moving device is arranged on each support leg at the lower end of the base; a blowout preventer hoisting and moving system is arranged on the lower surface of the table-board of the base; the blowout preventer hoisting and moving system is used for hoisting a blowout preventer; a derrick is fixedly connected to the table-board of the base; a crown block is arranged on the top end of the derrick; two groups of travelling blocks are arranged on the crown block in a hoisting manner. The well drilling device disclosed by the invention realizes synchronous well drilling, sleeve setting, well cementation, waiting on cement setting, blowout preventer installation and pressure test operation on a plurality of well sites; various operations of well drilling production operation and assisted operations are organized together to be carried out on the well sites by adopting an offline operation manner, so that the well construction period is shortened, the production efficiency is improved and the well drilling cost is reduced.

Owner:BAOJI PETROLEUM MASCH CO LTD +1

Drill bit capable of enabling well wall to be ceramic

ActiveCN103397846AReduce intensityImprove rock breaking efficiencyDrill bitsCombustion chamberCombustor

The invention discloses a drill bit capable of enabling a well wall to be ceramic. The drill bit comprises a connector, a drill bit body, a wall construction device, drill bit cutting teeth and a combustor, wherein the lower end of the connector is connected with the drill bit body, the wall construction device is installed on the drill bit body, the drill bit cutting teeth are arranged at the lower end of the drill bit body, a central pipeline and a combustion gun are arranged in the connector, the combustion gun is arranged at the lower end of the central pipeline, a flame nozzle is arranged at the lower end of the combustion gun, the combustor is arranged inside the drill bit body, a high temperature gas nozzle is arranged at the lower end of the drill bit body, the two ends of the combustor are communicated with the flame nozzle and the high temperature gas nozzle respectively, and an outer annular pipeline is arranged in the connector and is communicated with an air inlet of the combustion gun. The drill bit can achieve rock breaking through combination of combustion heat energy and mechanical energy, and improve the rock breaking efficiency remarkably. In addition, the well wall is made to be ceramic by the utilization of the combustion heat energy, the smooth and hard well wall is formed, even a lower casing pipe is not needed for well cementation, and the drilling cost is remarkably saved.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Raising-out type ball seat

ActiveCN101260791AIncrease drilling speedLow costWell/borehole valve arrangementsSealing/packingWell drillingWell cementing

The invention relates to a drilling device, in particular to a ball seat for drilling, comprising a pipe nipple, a pressed cap, a ball, a ball seat body, a sealing ring and a housing, wherein, the short barrel wall is provided with a pressure transmitting hole, the pressed cap is supported by the horizontal circular surface on the pipe nipple, the inner part of the lower section of the ball seat body is provided with a taper hole, the outside surface is provided with the sealing ring; and a taken-out ball seat can be directly connected to the lower part of a hanger to make the pitch easier and make the implementation of building the pressure of the hanger easier. The drilling device solves the problems of the on-site horizontal well sieve tube well cementation and the absorption well cementation, thereby shortening the well completion cycle, lowering the operation cost, raising the drilling efficiency and having great popularization and application potential. The drilling device is used in the petroleum drilling field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Segmented curtain grouting method for fault working face with too large inclination angle of shaft

ActiveCN109209287AReduce in quantityImprove drilling efficiencySealing/packingWater blockCement slurry

The invention discloses a segmented curtain grouting method for a fault working face with a too large inclination angle of a shaft. The driving working face of the shaft is casted with a concrete grouting stop cushion, an initial drilling stage of construction is started in the grouting stop cushion along the concentric circumference of the shaft, an orifice pipe is mounted in a boring orifice position, construction drilling is continued via the orifice pipe till a grouting depth position, a flange is installed in the orifice pipe, and connected with a high-pressure grouting hose and a grouting device, the orifice pipe is sealed and fixed in a gravity grouting manner, and space between the orifice pipe and a boring is filled tightly by a cement slurry. A segmented boring grouting manner isused to avoid construction of multiple grouting holes in a narrow space of the shaft, the number of grouting holes is reduced much, the drilling efficiency is improved, and shaft construction periodis shortened; and grouting is carried out in a cyclic manner by alternation among penetration, soil compaction and cleavage, the water blocking performance of grouting is improved, fragmented surrounding rocks are more reliable, and it is ensured that the shaft penetrates the fault efficiently and safely.

Owner:CHINA UNIV OF MINING & TECH

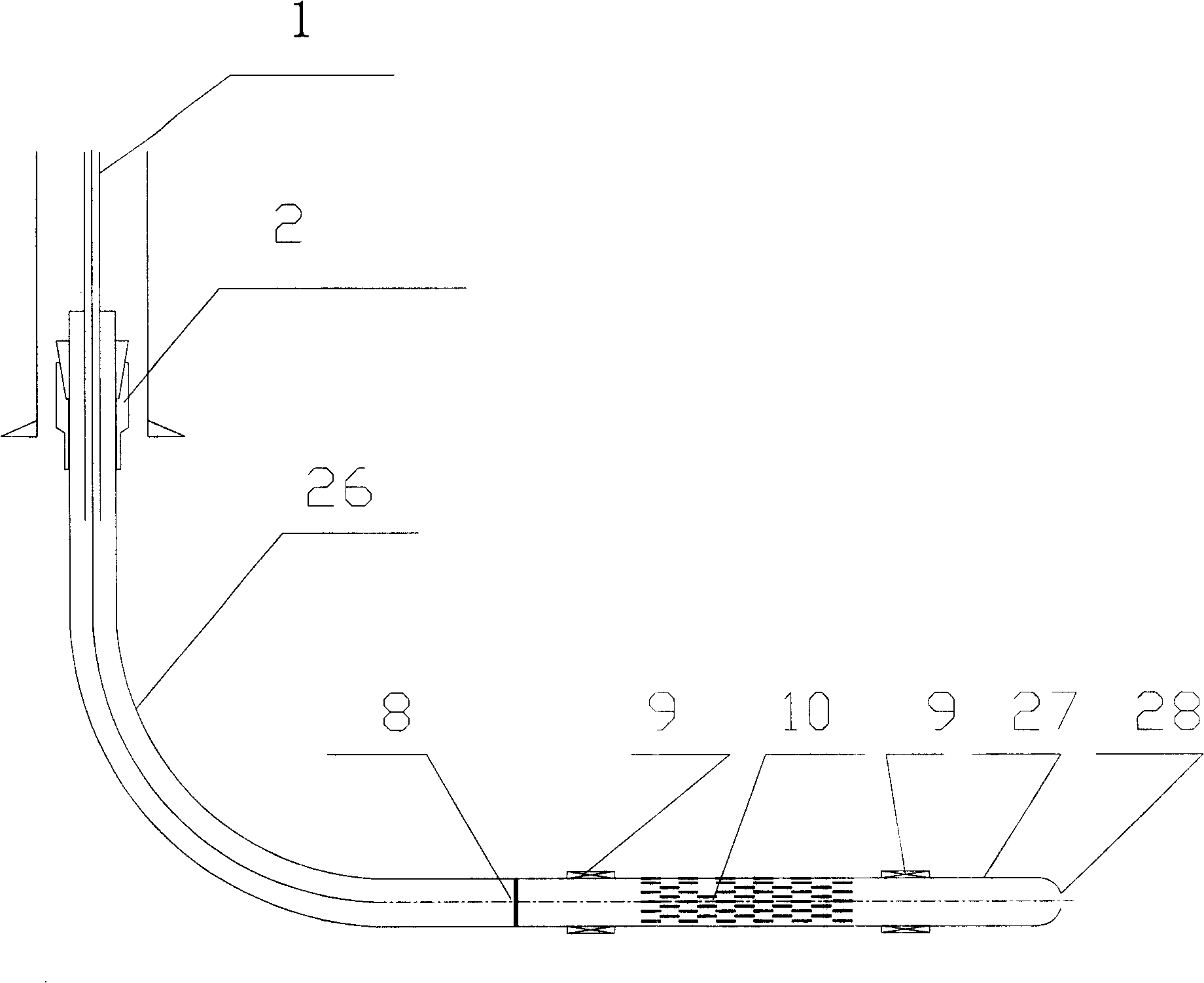

Basement rock fractured formation mixed drilling well completion process

ActiveCN102268963AShorten the well construction periodLess investmentConstructionsFluid removalBedrockGas lift

The invention discloses a basement rock fractured formation mixed drilling well completion process. The process comprises the following process steps of: (1) drilling at a certain depth from an upper part loose layer to a basement rock layer by a mud positive circulation process, inserting a surface casing after the drilling, and fixedly sealing by using cement; (2) drilling the basement rock layer by an air downhole hammer reverse circulation process; (3) after a water-bearing layer is drilled, drilling convertibly by a gas lift reverse circulation process until a target layer is reached when drilling efficiency is influenced by back pressure, which is generated by a water column in a hole, on the downhole hammer; (4) washing a well by acidification; (5) washing the well by using a piston; (6) washing the well by using air; and (7) pumping water by using a water pump to complete the well, namely putting a submersible pump down to pump the water after the process that the well is washed by the air is finished until a water pumping test is finished. The invention has the advantages that: 1, dry holes are avoided or reduced, and construction risks are reduced; 2, a well constructioncycle is shortened, unnecessary investment is reduced, and production cost is reduced; 3, mud is not used, fresh water resources are saved, and environment pollution caused by mud construction or emission is prevented; and 4, all fractures are changed into water catchment channels to the maximum extent to realize the maximum water yield of a single hole.

Owner:河北伟业地热新能源科技有限公司

Coal mining system and no-pillar self-forming lane mining method based on coal mining system

ActiveCN111379561ASolve the problem of excavation without roadwaySolve the alley problemUnderground miningSlitting machinesMining engineeringCoal pillar

The invention discloses a coal mining system and a no-pillar self-forming lane mining method. The coal mining system comprises a coal mining mechanism, the coal mining mechanism comprises a first scraping plate conveyor and a first coal mining machine, the coal mining system further comprises a machine head lane forming mechanism, a reversed loader and a conveyor, the machine head lane forming mechanism comprises a second scraping plate conveyor and a second coal mining machine, the second scraping plate conveyor is mounted on one side of a machine head of the first scraping plate conveyor inthe second direction and extends forwards, the second direction is perpendicular to the first direction, the second coal mining machine is movably mounted on the second scraping plate conveyor, the reversed loader is mounted on one side of the machine head of the first scraping plate conveyor, the first scraping plate conveyor and the second scraping plate conveyor are connected to the reversed loader, the conveyor is mounted in the second direction and is connected to the reversed loader, the coal mining system carries out propelling towards a work face in the second direction, the second coal mining machine carries out mining on the part, located on one side of the machine head, of the work face when the coal mining system carries out propelling, and in combination with top cutting pressure relief, a machine head reserved lane crossheading is formed.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

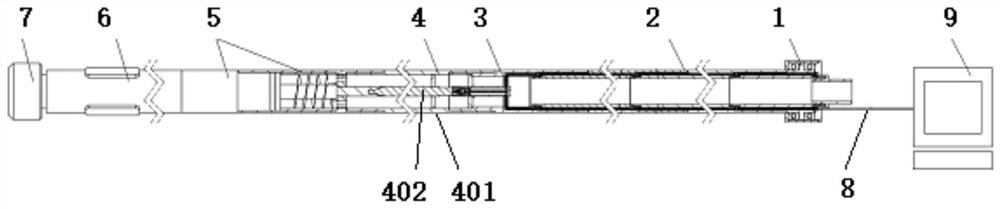

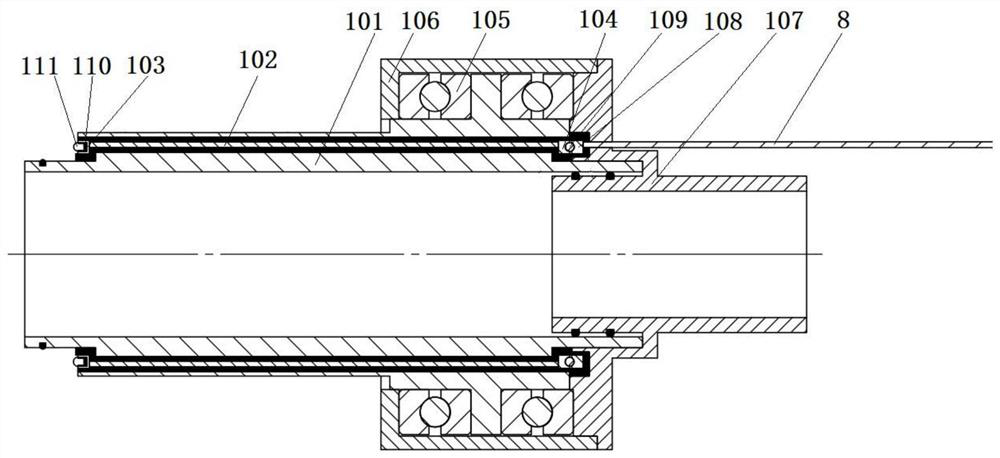

Underground coal mine wire-buried rotary guide drilling tool combination and industrial control method

ActiveCN112878913AHigh strengthExtended service lifeSurveyDirectional drillingMining engineeringControl cell

The invention discloses an underground coal mine wire-buried rotary guide drilling tool combination and an industrial control method. The underground coal mine wire-buried rotary guide drilling tool combination comprises a wire-buried water feeder, a wire-buried drill rod, an adapter, a measurement short circuit, a launch control short circuit, a rotary guide drilling tool and a drill bit which are coaxially connected in sequence; a control center communicates with insulated wires buried in the wire-buried water feeder and the wire-buried drill rod; the insulated wires are gathered into a bundle in the adapter and then connected with a measurement probe in the measurement short circuit; the measurement probe is connected with the launch control short circuit; the launch control short circuit communicates with a control unit in the rotary guide drilling tool through the insulated wires; and the control center sends an instruction, the measurement short circuit transmits back attitude information of the drilling tool in a hole, a pushing palm on the rotary guide drilling tool pushes the well wall with different pushing forces according to the instruction, and continuous three-dimensional guiding is achieved. According to the underground coal mine wire-buried rotary guide drilling tool combination and the industrial control method, hole bottom power supply and signal transmission can be achieved, the data size and stability of signal transmission are improved, the overall strength of the drill rod is enhanced, the pressure on-way loss in long drilling construction is reduced, the stratum adaptability and directional drilling efficiency are improved, and the smoothness of the directional drilling track is ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

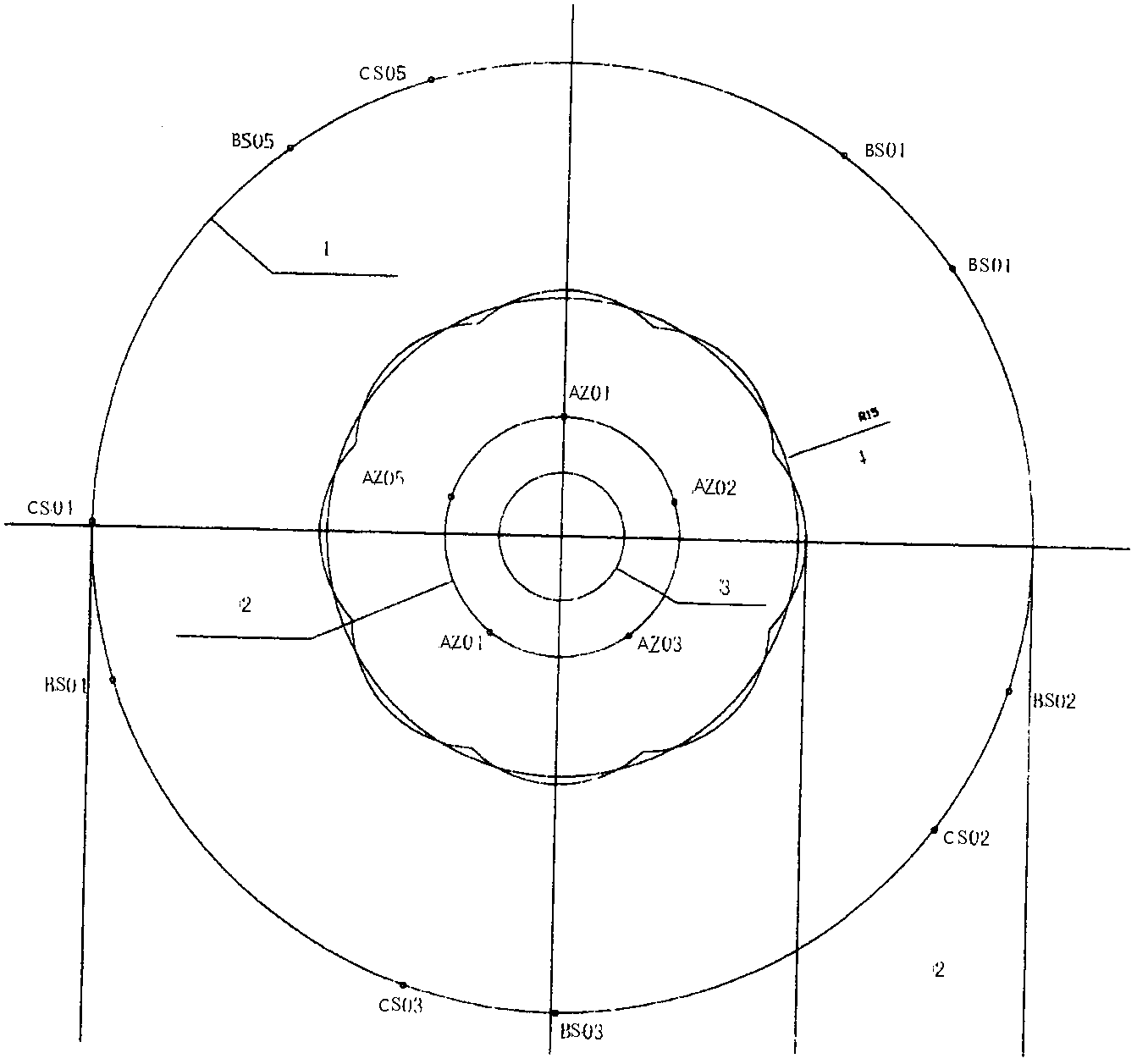

PDC (polycrystalline diamond compact) drilling bit with transposition cutter wings and long service life

PendingCN108086916AExtend your lifeShorten the well construction periodDrill bitsRemote controlWell drilling

The invention discloses a PDC (polycrystalline diamond compact) drilling bit with transposition cutter wings and a long service life, and relates to a drilling bit for well drilling or underground boring. The drilling bit comprises drilling bit bodies, the transposition cutter wings and transposition cutter wing supporting bodies, the transposition cutter wing supporting bodies extend from the drilling bit bodies or are fixed onto the drilling bit bodies, cutting elements are arranged on the transposition cutter wings to form transposition cutting structures, and the transposition cutter wingscan rotate to a certain preset working position and are locked from an initial working position through at least one rotation relative to the transposition cutter wing supporting bodies through remote control or can rotate to other preset working position and are locked from some preset working position through at least one rotation. According to the drilling bit, a new cutting gear can replace an abraded cutting gear to continue to drill through remote control on the ground after an initial cutting gear is abraded, so that a cutting structure of the drilling bit can be singly updated underground even can be repeatedly updated underground, and 'the drilling bit is renewed without lifting the drilling bit'.

Owner:SOUTHWEST PETROLEUM UNIV +1

High solid content cement slurry and preparation method thereof

InactiveCN102127405ARapid development of strengthShorten the well construction periodDrilling compositionDistilled waterReducer

The invention provides high solid content cement slurry and a preparation method thereof and relates to cement slurry used in the cementing project. The invention aims to effectively increase the density of cement slurry, increase the solid content of the cement slurry for cementing and save the weighting agent material. The technical scheme of the invention is that the cement slurry contains the following components according to proportions: oil-well cement, high solid content filtrate reducer for cementing, high solid content dispersant for cementing, expanding agent, defoaming agent, retarder, weighting agent and distilled water. The preparation method of the high solid content cement slurry comprises the following steps: adding retarder in distilled water to form stable and uniform solution which is set to be a component A; mixing oil-well cement, high solid content filtrate reducer for cementing, high solid content dispersant for cementing, expanding agent, defoaming agent, retarder and weighting agent according to the proportions to prepare uniform powder which is set to a component B; and mixing the component A with the component B according to a ratio, preparing slurry according to the air pollution index (API) method to obtain the high solid content cement slurry. The invention is mainly used in the cementing project.

Owner:邓天安

Acid soluble leak stopping agent

The leak stopping agent consists of acid soluble material15-45 wt%, bentone powder 5-25 wt%, lime powder 5-30 wt%, calcium carbonate powder 5-25 wt%, cement 0-40 wt% and fibrous material 0-20 wt%. When it is used in stopping leak, the above said materials are mixed homogeneously before further mixing with 2-7 times of water or 3-10 times of well drilling liquid. It is superior in stopping leak during well drilling owing to the high adhesion force and shearing resistance between the stopping matter and the leak layer. It is especially suitable for treatment of indefinite and complicated leak layer.

Owner:四川石油管理局有限公司川东钻探公司

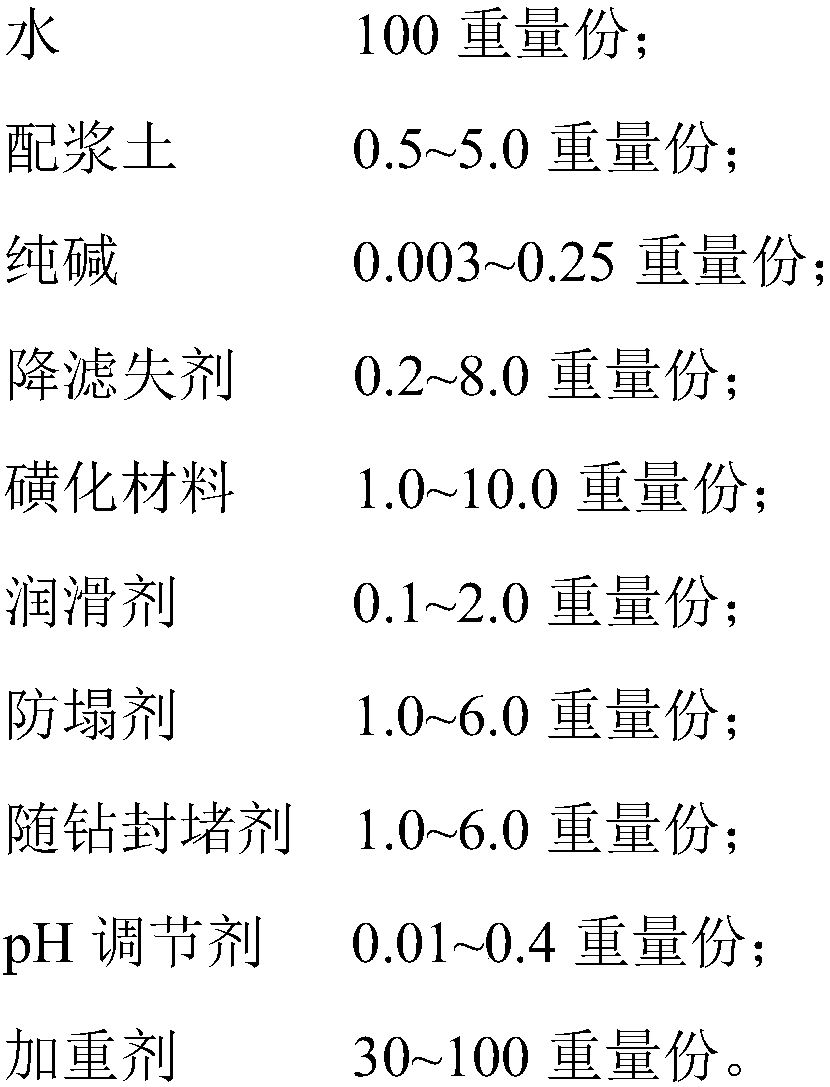

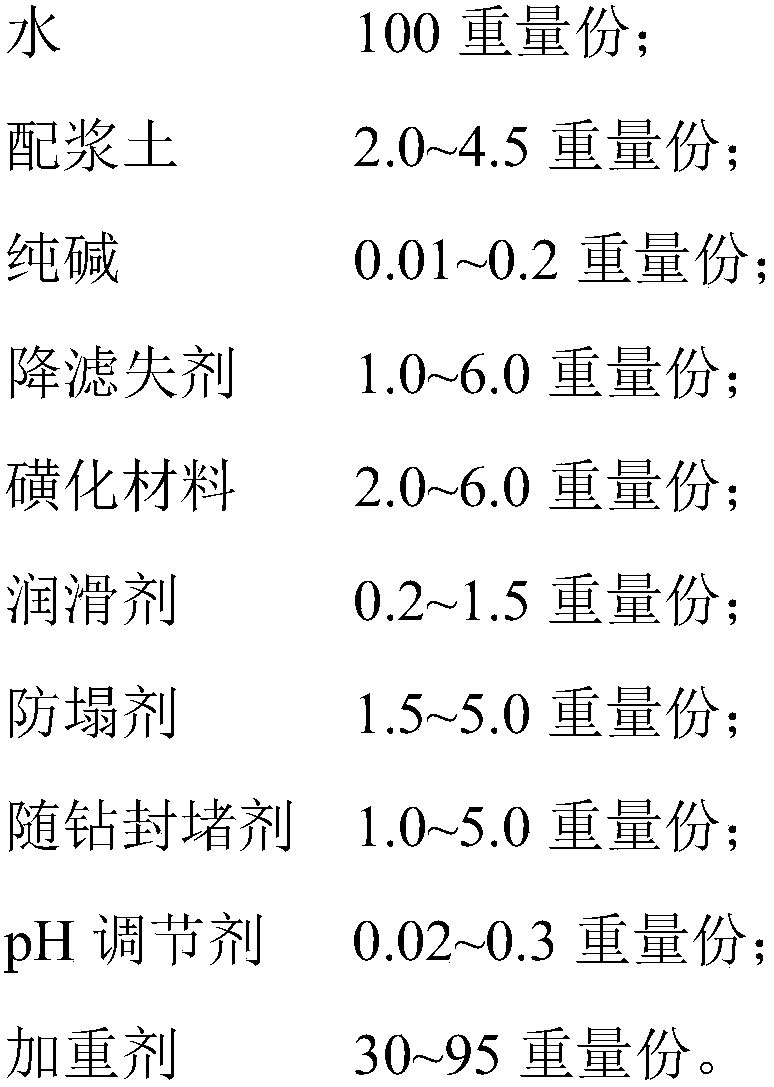

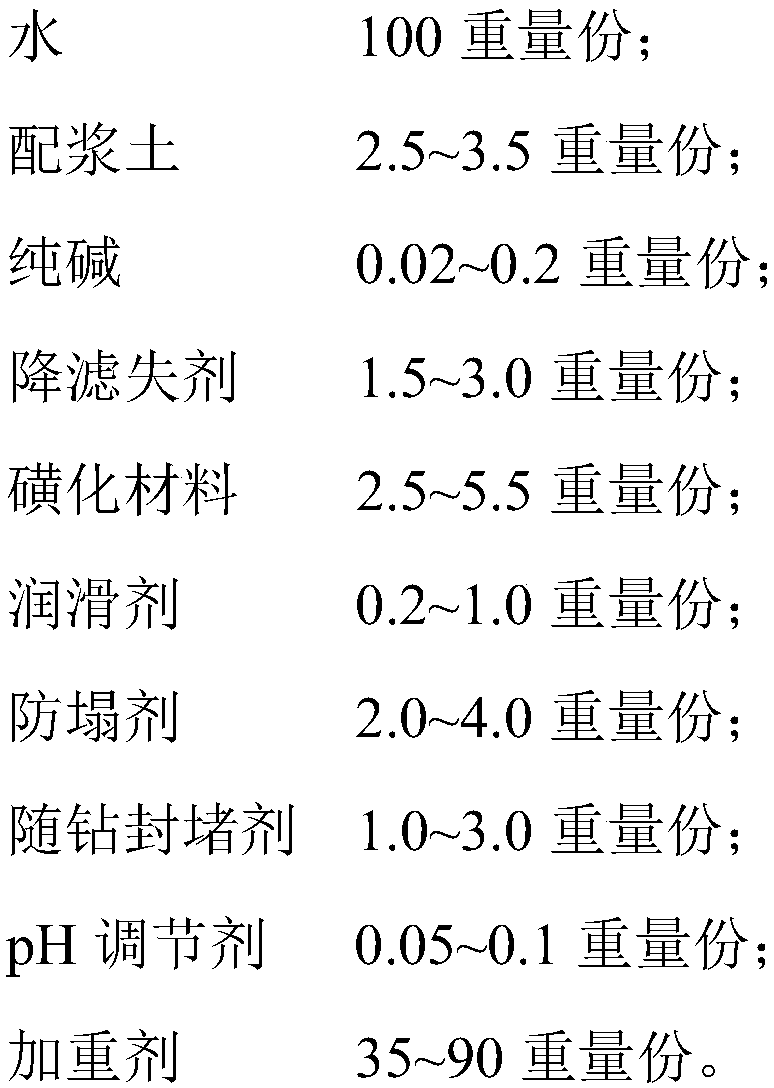

Low-density water-based drilling fluid and preparation method thereof

InactiveCN109868123AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

The invention provides a low-density water-based drilling fluid system for safely drilling through a long open-hole diabase formation. The drilling fluid system comprises the following components, inparts by weight: 100 parts by weight of water, 0.5-5.0 parts by weight of slurry mixing soil, 0.003-0.25 part by weight of sodium carbonate, 0.2-8.0 parts by weight of a fluid loss agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of a plugging agent while drilling, 0.01-0.4 part by weight of a pH adjusting agent and 40-80 parts by weight of a weighting agent; and the drilling fluid system further comprises 0.1-10.0 parts by weight of an inorganic salt. The drilling fluidprovided by the invention has good rheological performance and rock-carrying capacity; the drilling fluid can not only safely drill through the diabase formation, but also can meet the purpose that fallen diabase returns to the ground in time, effectively avoid stuck drilling, ensure safe drilling and shorten a well construction period through improvement of plugging while drilling and collapse resistance of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated drilling-free ball seat guiding shoe

InactiveCN107201879ASave processReduce construction riskDrilling rodsConstructionsBarrel ShapedEngineering

The invention discloses an integrated drilling-free ball seat guiding shoe which comprises a seat sealing ball and a body, wherein a sleeve internal thread is machined at the upper end of the barrel-shaped body; multiple shear pin holes are uniformly formed in a position, close to an end surface, on the lower half part; a ball seat inner core and a guiding shoe guide mechanism are designed into an integrated inner core; the upper half part of the integrated inner core is a ball seat part, and the lower half part of the integrated inner core is a hollow guiding shoe cap part; shear pin slots and sealing slots are respectively formed in the outer side of the ball seat part; the outer side of the ball seat part of the integrated inner core is matched with the inner side surface of the body; the hollow guiding shoe cap part is exposed out of the lower end of the body; the shear pin slots are aligned to the shear pin holes of the body; pressure shear pins are mounted in the shear pin holes and the shear pin slots; sealing assemblies mounted in the sealing slots realize sealing on the inner side surface of the body. According to the integrated drilling-free ball seat guiding shoe, due to the integrated inner core connected to the body in a pressure holding detachable manner, a special procedure of drilling off the inner core through a drill is eliminated, so that the construction risk is lowered, the construction time is shortened, the well building period is shortened, and the single well cost is reduced.

Owner:CNPC BOHAI DRILLING ENG

Cementing device salvage device

PendingCN108019176ASmooth and convenient salvageProtect cementing qualityBorehole/well accessoriesEngineeringSteel ball

A cementing device salvage device is composed of a lifting short section, an inner tube body, an upper tube body, a steel ball, a movable ring, a movable pin, a lower tube body, a conical body, a spring, a sliding sleeve, screws, a push rod, a slip and a guiding tapered mill which are arranged from top to bottom. The lifting short section is in threaded connection with the inner tube body, and thelower end of the lifting short section is provided with a U-shaped clamping groove which is clamped into a T-shaped clamping groove of the upper tube body in a matched mode. The upper tube body is inthreaded connection with the lower tube body, and a bearing set is pressed into the threaded connecting position. The movable pin in the bearing seat moves in a long-short groove in the outer side ofthe inner tube body, thus the conical body is in threaded connection with the inner tube body. The spring, the sliding sleeve, the push rod and the slip are arranged on the outer side of the conicalbody from top to bottom, the push rod is connected with the sliding sleeve and the slip through the screws, and the guiding tapered mill is in threaded connection with the lower tube body. After cementing well completion, all assemblies in an inner cavity can be subjected to salvage to get out from a wellhead by using the cementing device salvage device, the well building period is shortened, thewell cementing quality is improved, and the situation that subsequent tool lowering for measure work is not influenced by the dimension of the drift diameter in a sleeve is guaranteed.

Owner:德州隆科石油装备有限公司

Combined construction method of air return vertical shaft permanent fore shaft and fan drift piling wall

ActiveCN109630179AFast constructionSmall footprintTunnel/mines ventillationShaft sinkingWellboreSafety risk

The invention relates to a combined construction method of an air return vertical shaft permanent fore shaft and a fan drift piling wall, and belongs to the technical field of mine ventilation. According to the construction method, the mode of combining open excavation and underground excavation is mainly adopted, foundation pits of a fan drift and a shaft are subjected to open excavation, after aroof of the fan drift and part of the shaft are cast, the foundation pits can be subjected to open excavation, and a hoisting system in the shaft is installed; afterwards, the fan drift and the shaftare subjected to underground excavation. According to the construction method, the occupied area is small, which is beneficial for early work starting of other permanent civil engineering facilitieswithin the air return vertical shaft wide range, and the overall construction speed of engineering projects is increased; the safety risks that deep foundation pit slopes are unstable and personnel are in the high-position working state for a long term are avoided to a certain degree, the cost expenditure for earth excavation of the deep foundation pits under open excavation, intensive supports and high and large scaffolds is effectively reduced, and the cost is lowered.

Owner:CHINA COAL FIRST CONSTR

Tubular column

InactiveCN106988686AReduce well construction costsShorten the well construction periodDrilling rodsBorehole drivesImpellerWell drilling

The invention discloses a tubular column which comprises an oil tube and a branch well short section connected with the oil tube, and the branch well short section is internally provided with a drive impeller and a branch well drill pipe connected with the drive impeller. The drive impeller moves and rotates at the same time under driving of fluid, so that the branch well drill pipe is driven to extend out of the tail end of the branch well short section. The tubular column greatly shortens the well building period of branch holes and reduces the well building cost of the branch holes in the drilling completion of the branch holes.

Owner:CHINA PETROLEUM & CHEM CORP +1

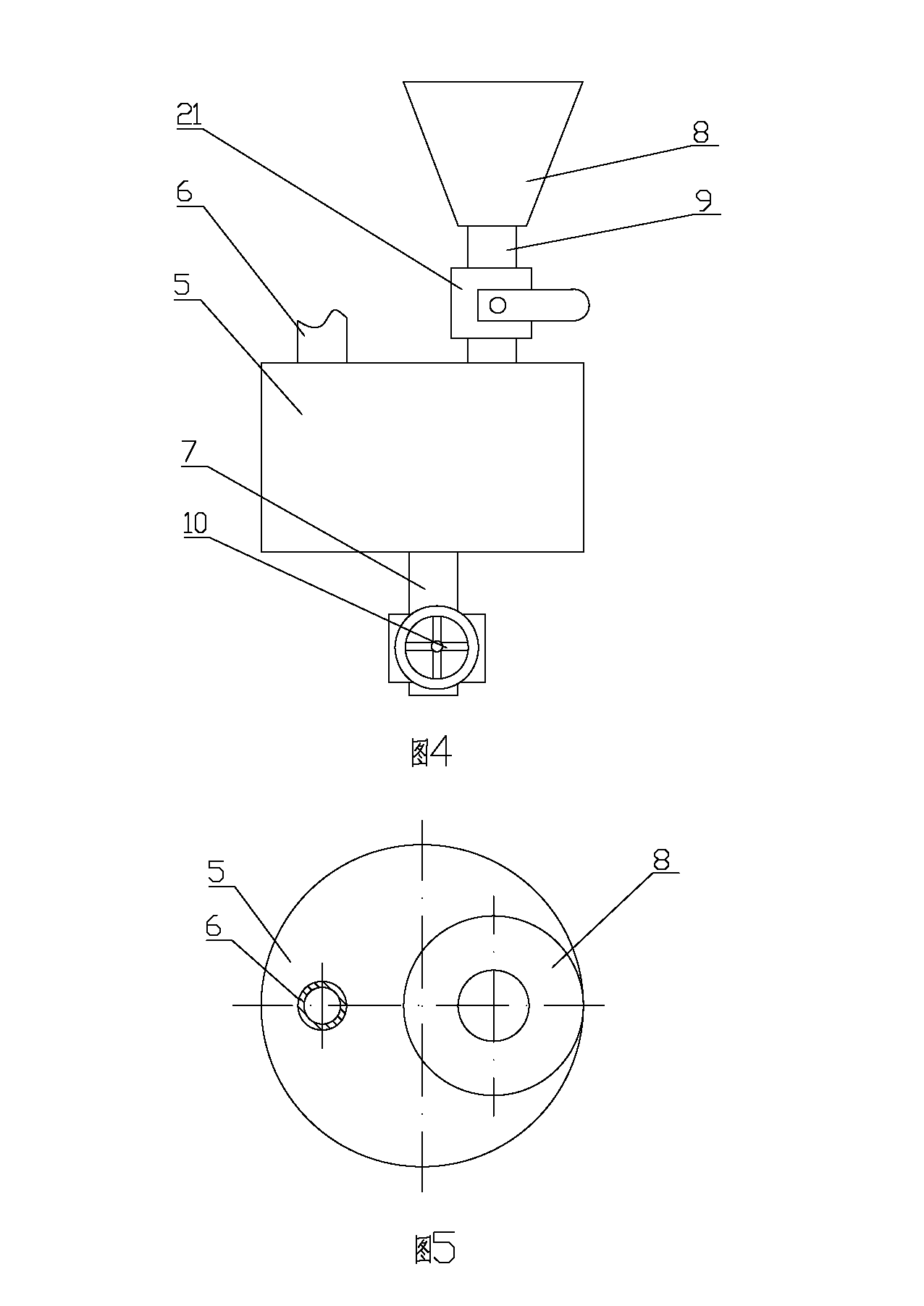

Gas drilling wall building device

ActiveCN113006685AEnsure stabilityAvoid waterDrill bitsConstructionsWell drillingStructural engineering

The invention provides a gas drilling wall building device. The gas drilling wall building device comprises a compressor, a fusible material tank and a drill rod; a double-channel connector is arranged at the top of the drill rod, and the bottom of the drill rod is located in a wellhead device; the double-channel connector is provided with a fusible material channel and a gas channel; a center pipeline is arranged in the fusible material channel; a lower connector is arranged in the gas channel, and a power generation device and a drill bit are sequentially arranged at the bottom of the drill rod; and the drill bit comprises a drill bit body, a drill bit inner body is arranged in the drill bit body, a heating cavity, an inlet nozzle and an outlet nozzle are arranged in the drill bit inner body, and an annular heater is arranged in the heating cavity. In the gas drilling process, a layer of fusible material hard shell can be formed on the well wall of the wellhead device, the fusible material hard shell has certain strength, the purposes of preventing stratum water outflow and keeping the well wall stable are achieved, the safety of the drilling process is improved, stratum water can be blocked while drilling is conducted, drill pulling and drill stopping are avoided, and the well building period is shortened.

Owner:SOUTHWEST PETROLEUM UNIV

Electrical heat energy-mechanical energy comprehensive rock breaking drill

ActiveCN104790875AReduce intensityImprove securityDrill bitsThermal drillingWell drillingMechanical energy

The invention relates to an electrical heat energy-mechanical energy comprehensive rock breaking drill. The electrical heat energy-mechanical energy comprehensive rock breaking drill comprises a threaded connector, a cable, an outer shell, a heat exchange pipe, an electric heating device and a heat conduction element; the lower end of the threaded connector is connected with the outer shell, a center hole is formed inside the threaded connector, the interior of the outer shell is provided with an annular groove, the heat exchange pipe and a spraying nozzle, the center hole, the heat exchange pipe and the spraying nozzle are sequentially communicated, an outlet of the spraying nozzle is formed in the bottom face of the outer shell, the electric heating device and the heat conduction element are arranged in the annular groove, the heat conduction element is in contact with the electric heating device and the outer shell, the cable is connected with the electric heating device, and cutting teeth are arranged at the lower end of the outer shell. According to the electrical heat energy-mechanical energy comprehensive rock breaking drill, air flow is heated through electric heating energy so as to be blown to rock, the mechanical energy is used in a matched mode to achieve rock breaking, so that the energy consumption is small, the cost is low, the safety factors are high, the working efficiency is high, and the well drilling depth is large.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

Continuous cyclic drilling device

The invention discloses a continuous cyclic drilling device used in the technical field of petroleum drilling. A drill pipe power tong is fixed on a power tong baseplate on the top of a balance compensation hydraulic cylinder, the balance compensation hydraulic cylinder is vertically fixed below the upper connection board of a support assembly, the piston rod of the balance compensation hydrauliccylinder passes through the upper connection board, and the top of the piston rod of the balance compensation hydraulic cylinder is fixedly provided with the power tong baseplate. A cavity assembly is fixed between the upper connection board and the lower connection board of the support assembly, the lower end of a drilling power slip is fixed in the bushing of a drilling turntable, the upper endof the drilling power slip is connected with the support assembly through a bearing beam, and the centers of the drill pipe power tong, the cavity assembly and the drilling power slip are coincident.The device has the effects of keeping the continuous cycling of the drilling fluid to discharge the drilling cuttings during the period of making a connection, avoiding the damage to the drill pipe caused by the up tong when screwing on and screwing off, eliminating the adverse effect of the slip holding capacity caused by the upset force of the drilling fluid, and improving the stress state between the slip and the drill string.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Working face mining method

ActiveCN111828005AReduce huge workloadReduce workloadUnderground miningSurface miningMining engineeringProcess engineering

The invention relates to an underground mineral mining method and discloses a working face mining method. The mining process comprises the following steps of before mining, performing constructing onworking faces to form a cut hole so as to form a starting point of mining on the working faces; and performing gob-side entry retaining while mining at the two ends of each working face to respectively form a first gate way and a second gate way, wherein the first gate way and the second gate way form ventilation and transportation channels of the working faces. The mining method for bilateral entry retaining has the advantages and positive effects that compared with the prior art, the underground mineral mining method can ensure the ventilation of a whole coal mining area without the need ofperforming tunneling around the mining area to prepare a roadway; the gate ways do not need to be tunneled in advance when each working face in the mining area is mined, but the gate ways are formed after coal mining, thereby greatly reducing the huge workload caused by tunneling the gate ways in advance and greatly shortening the well construction period; and simultaneously, no coal pillars needto be reserved, thereby saving resources.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

Gas drilling device and drilling method for dealing with formation water and stabilizing well wall

The invention discloses a gas drilling device and method capable of treating formation water production and stabilizing a well wall and relates to the technical field of drilling devices using liquid with or without projectiles and gas spraying. The device comprises an adapter and a drill bit body, wherein a distributing channel and a metal filter film are arranged in the adapter, a central flow channel, a heating cavity, a melting cavity, a lateral nozzle and the like are arranged in the drill bit body, the distributing channel, the melting cavity and the lateral nozzle are sequentially communicated, and the outlet of the lateral nozzle is located in the lateral wall of the drill bit body. The heating cavity transmits heat to the melting cavity, fusible material micro-granules are heated and melted in the melting cavity and sprayed out from the lateral nozzle so as to form a layer of hard fusible-material shell on the well wall. The drilling device has the advantages that formation water blocking can be performed along with drilling, the pumping of fusible materials can be stopped after the water-producing formation is drilled through, well construction period can be shortened effectively, cost can be saved, and the device is widely applicable to gas drilling operations.

Owner:SOUTHWEST PETROLEUM UNIV

Alcohol-spraying type steam path anti-freezing device for oil drilling

InactiveCN102705306APrevent freezingReduce labor intensityFluid-pressure actuator componentsPetroleumFreezing point

The invention relates to the technical field of steam path control devices for drilling engineering in oil fields, in particular to an alcohol-spraying type steam path anti-freezing device for oil drilling. The steam path anti-freezing device comprises a water-steam separator, an alcohol tank and an alcohol funnel, wherein a steam intake pipe communicated with an inner cavity of the water-steam separator is fixedly installed on the left side wall of the water-steam separator; a steam escaping pipe communicated with the inner cavity of the water-steam separator is fixedly installed on the right side wall of the water-steam separator; a sewage draining pipeline communicated with the inside of the water-steam separator is fixedly installed at the bottom of the water-steam separator; and a sewage draining valve is fixedly installed on the sewage draining pipeline. The steam path anti-freezing device provided by the invention has a reasonable and compact structure and is convenient to use, and also has the advantages that the steam path of a steam controlling system is effectively prevented from being frozen in winter by separating the residual water content from the compressed air and lowering the freezing point of the residual water content, so that the working intensity of the workers is reduced, and the safety of equipment and personnel in a drilling well is ensured, the cost is saved, the unnecessary time consumption is reduced, the drilling speed is improved, and the well constructing period is shortened.

Owner:CNPC XIBU DRILLING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com