Combined construction method of air return vertical shaft permanent fore shaft and fan drift piling wall

A construction method and wind shaft technology, which is applied in sinking, shaft equipment, earthwork drilling and mining, etc., can solve the problems of prolonging the operation time of the permanent ventilation system of the mine, heavy maintenance workload of deep foundation pits, and difficulties in safety control, etc. Achieve the effects of reducing the scope of enclosure and enclosure material expenses, reducing labor costs and mechanical equipment usage costs, and working environment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further description will be made below in conjunction with the accompanying drawings and specific embodiments.

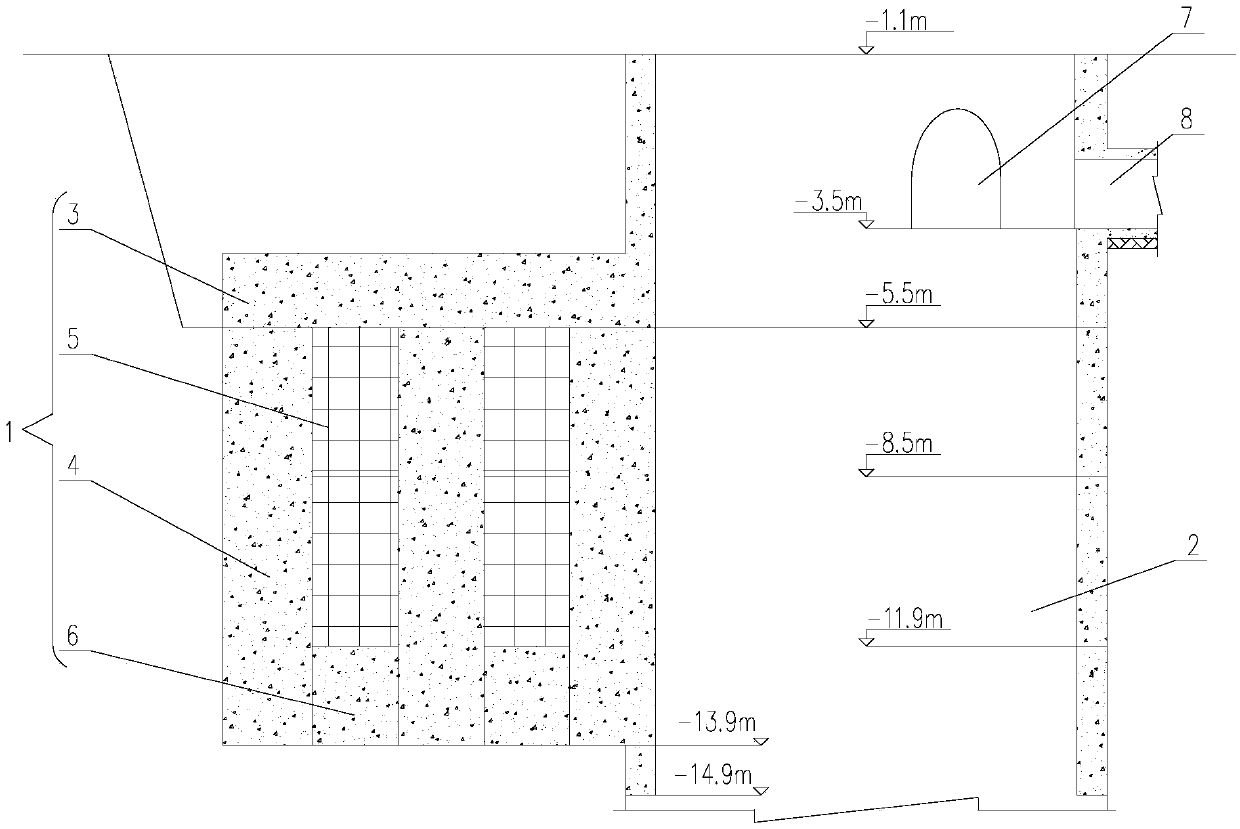

[0034] In the specific embodiment, taking the Libi mine of Shanxi China Coal Huajin Energy Co., Ltd. (the Libi mine is a coal and gas outburst mine) as an example, four wells are used to develop, and the main inclined shaft and the auxiliary shaft are arranged in the main industrial square. The wind shaft and the return air shaft are arranged in Mayigou Industrial Plaza. The shaft is drilled by the common method. The chambers above the permanent lock section of the return air shaft -4.0m (relative elevation, the relative elevation of the wellhead is ±0.000m) include safety exits , Gas pipeline access, -13.900m~-5.000m designed with wind tunnel, wind tunnel clear width × clear height = 6.4m × 6.4m, barren width × barren height = 9.4m × 9.4m, the length of the air duct is 8.792 m. The wind tunnel is characterized by large width, high height, and deep buried de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com