Blade type PDC (Polycrystalline Diamond Compact) drill bit

A blade and bit technology, applied in construction and other directions, can solve the problems of complex formation, easy wear of the bit, hard rock, etc., and achieve the effect of prolonging the service life, preventing the bit from drilling badly, and shortening the construction period of the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

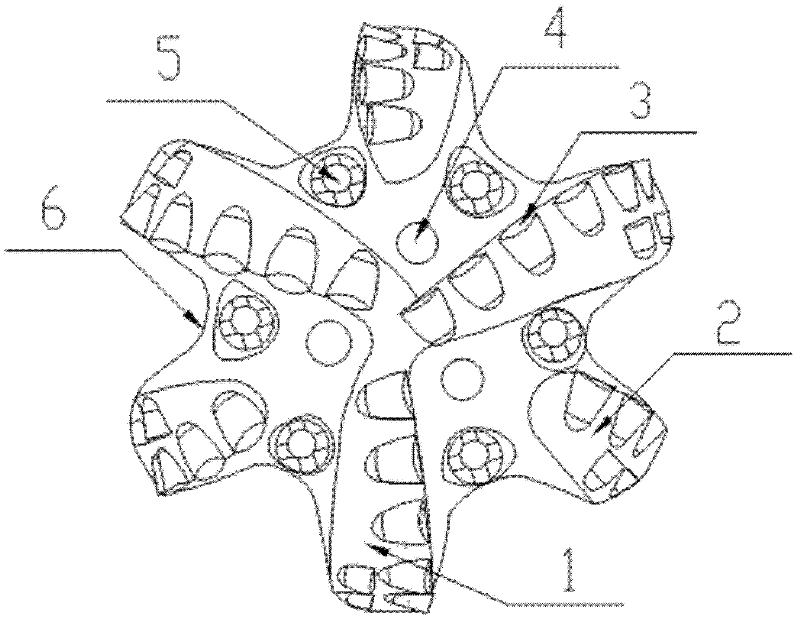

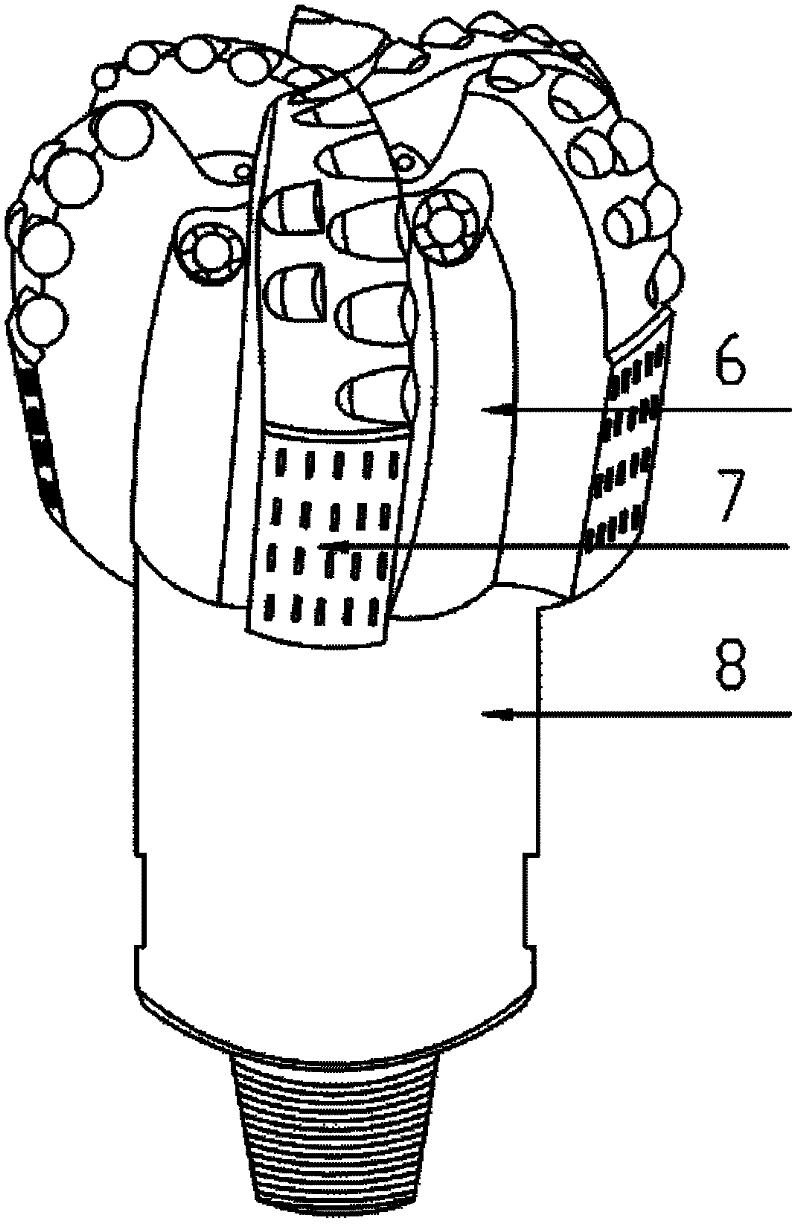

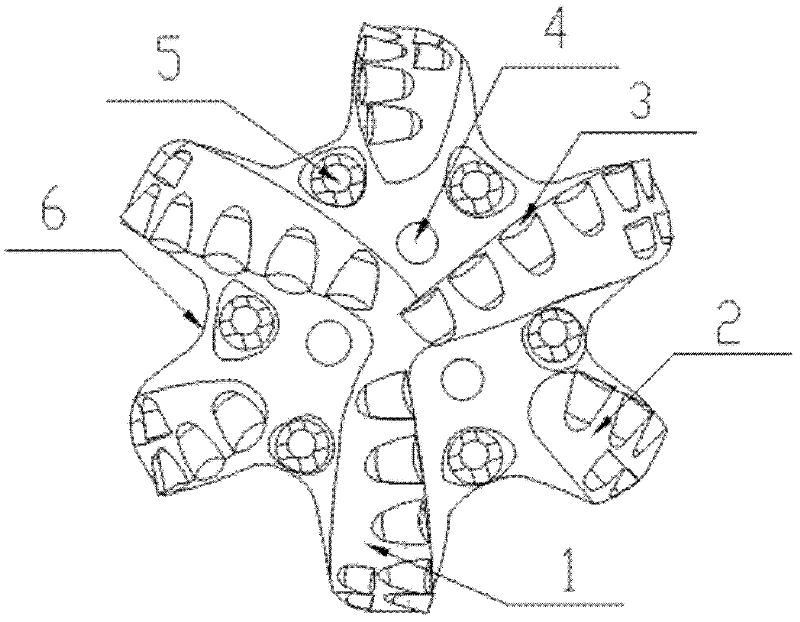

[0015] like figure 1 and figure 2 As shown, the blade-type PDC drill includes a blade, a PDC cutting tooth 3, a nozzle, a flute 6, a gauge part 7 and a drill body 8.

[0016] The blade part includes three main blades 1 and three short blades 2, each blade is inlaid with φ16 polycrystalline diamond PDC cutting teeth in the front row, and φ13 polycrystalline diamond PDC cutting teeth inlaid in the rear row; between adjacent blades The chip removal groove 6 is set; the nozzle has a fixed nozzle 4 and an adjustable nozzle 5, and the adjustable nozzle 5 can replace nozzles with different inner diameters according to geological conditions and drilling needs to adjust the water volume; the diameter gauge part 7 of the drill bit is the outer diameter of the drill bit, A sheet-like polycrystalline diamond composite sheet is inlaid; the drill bit joint part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com