Well drilling device for double-wellhead operation

A technology for drilling and moving devices, which is applied to drilling equipment, support devices, drill pipes, etc., and can solve problems such as high labor intensity, long preparation time, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

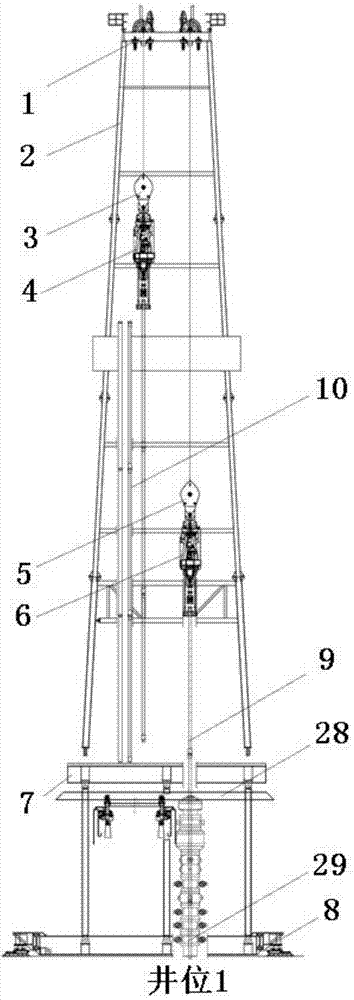

[0019] refer to figure 1 , Figure 5 , the structure of the double wellhead drilling operation device of the present invention is to include the base 7 of the drilling rig, the supporting leg at the lower end of the base 7 is provided with a drilling rig moving device 8, and a blowout preventer lifting system 28 is installed on the lower surface of the base 7 table top, and the blowout preventer The hoisting system 28 is used to hoist the blowout preventer 29; the derrick 2 is fixedly connected to the platform of the base 7, the top of the derrick 2 is provided with a crown block 1, and two groups of traveling cars are hoisted on the crown block 1, and the traveling block 3 is downward Connect with top drive 4, traveling block 2 5 connects downward with top drive 2 6, top drive 4 or top drive 2 6 connects downward with drill string stand 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com