PDC (polycrystalline diamond compact) drilling bit with transposition cutter wings and long service life

A long-life, knife-wing technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of weakening the ability of drill bits to penetrate rocks, easy failure of bearing systems, impact on the working life of PDC composite sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

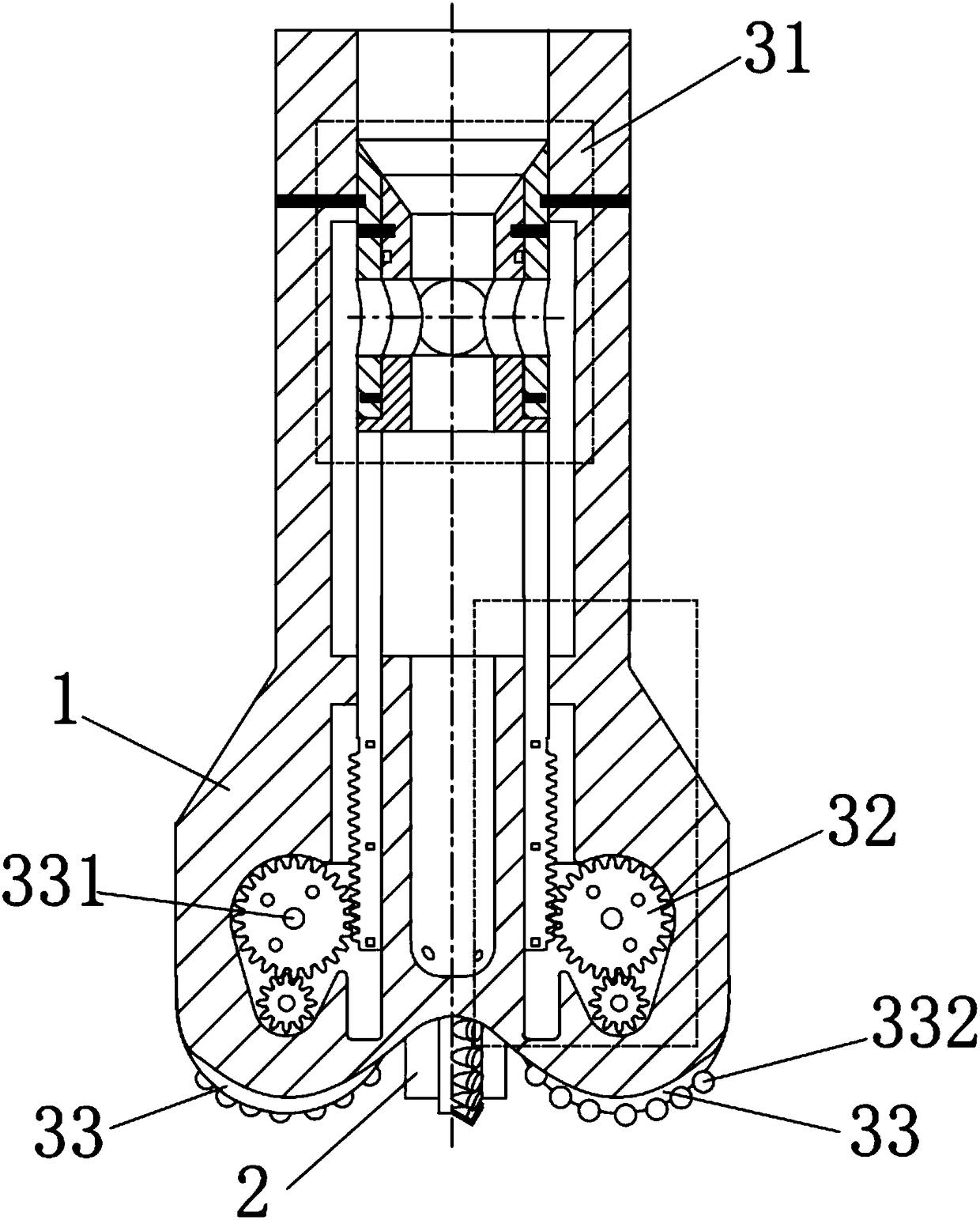

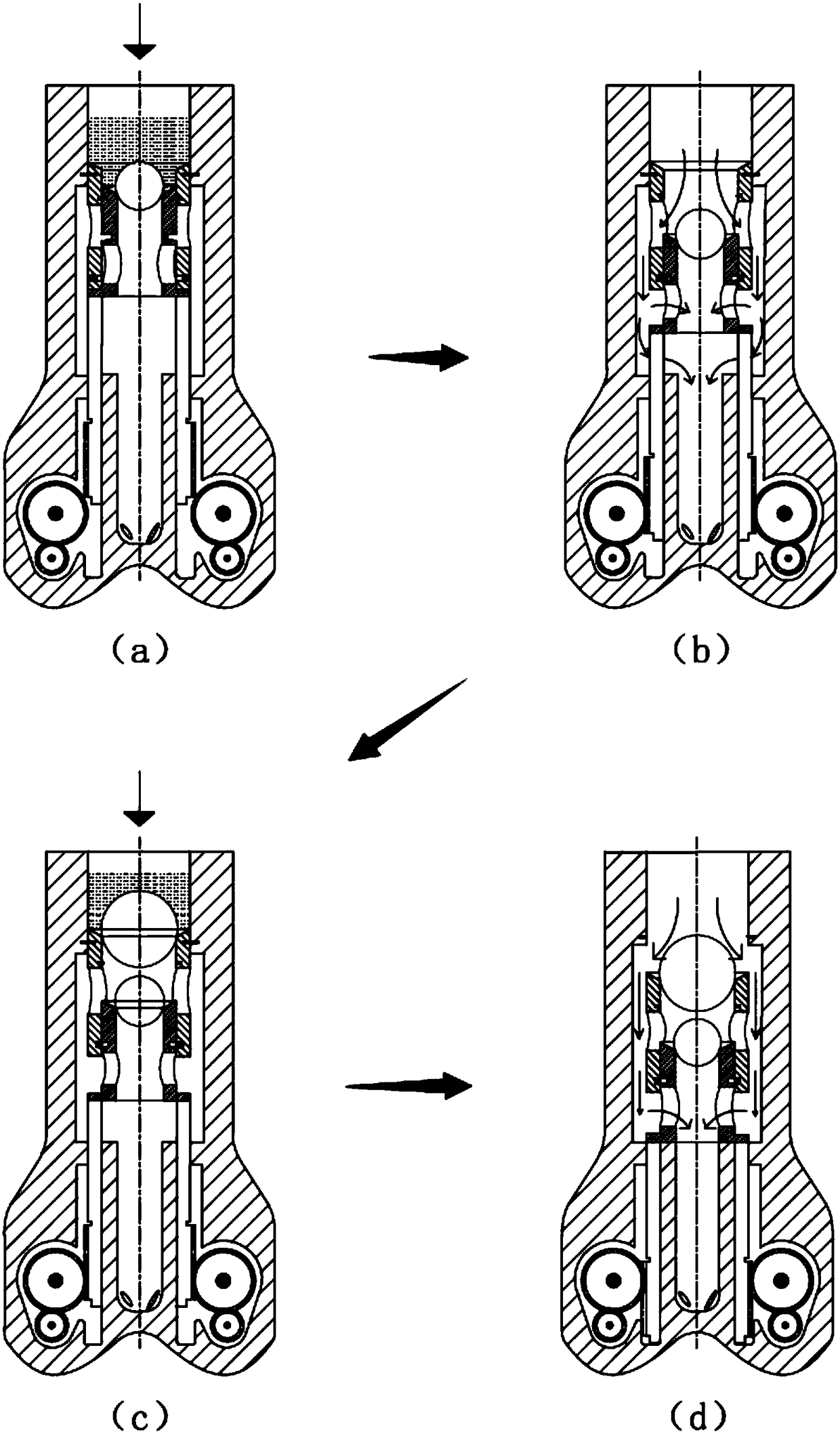

[0066] Such as figure 1 As shown, a long-life PDC drill bit with an indexing blade includes a drill body 1, an indexing blade 33 and an indexing blade support 2, and the indexing blade support 2 extends from the drill body 1 or Fixed on the bit body 1, the indexing blade 33 is provided with a cutting element 332 to form an indexing cutting structure. Only the indexing blade 33 and the indexing blade supporting body 2 can be set on the drill body 1, and the fixed blade 4 can be further included. When the fixed blade 4 is set, the fixed blade 4 extends from the drill body 1 or Fixed on the drill bit body 1, the fixed blade 4 is provided with a fixed blade cutting element 41 to form a fixed cutting structure, and the fixed blade 4 can be independent of the indexable blade support body 2, or both can be combined. Two for one. The blade supporting body or the indexing blade is provided with an indexing shaft 331, and the indexing blade 33 is installed on the drill bit body 1 and / ...

Embodiment 2

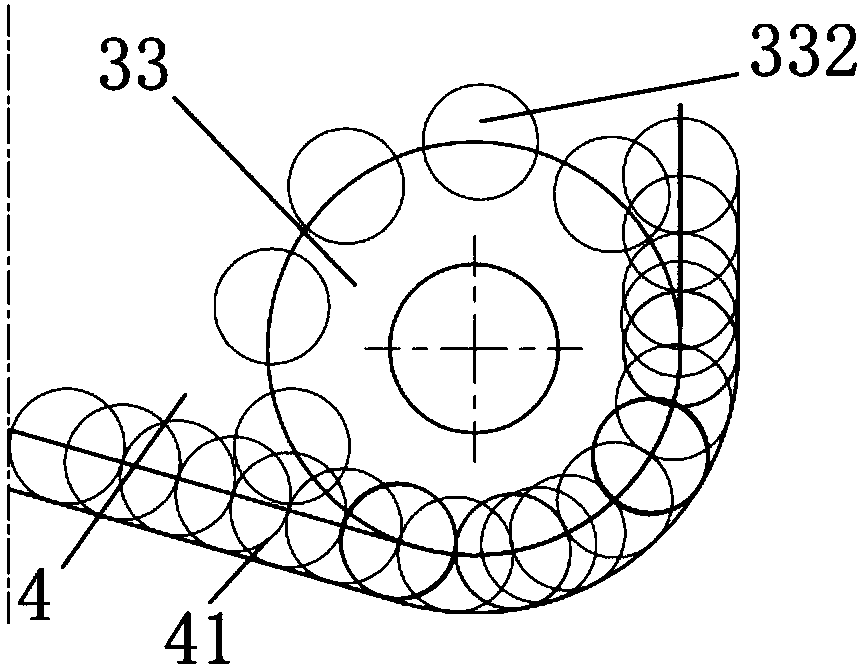

[0070] This embodiment is basically consistent with Embodiment 1, and its characteristics are: as image 3 As shown, the drill bit has a conventional fixed blade 4 and an indexable blade 33 at the same time, and the indexed blade 33 is circular, and three working positions are provided on the indexed blade. The cutting outline of the common working area of the indexing blade 33 matches the cutting contour of the circular indexing blade 33 . Shown in the figure is the well bottom coverage diagram of the drill bit of this embodiment. The number 4 is the conventional fixed blade, and 41 is the cutting tooth of the fixed blade. It can be seen from the figure that the profile of the indexable blade is composed of three sections of 120° arc A circle formed by line segments, each 120° arc segment corresponds to a working position.

Embodiment 3

[0072] This embodiment is basically consistent with Embodiment 1, and its characteristics are: as Figure 4 As shown, the drill bit has a conventional fixed blade 4 and an indexable blade 33 at the same time, and the indexed blade 33 is provided with three working positions, and the cutting profile on each working position is the same as that of the conventional fixed blade inner cone. Area cutting profile matching, such as Figure 4 As shown in (a); or the cutting profile on each working position matches the cutting profile of the outer cone and shoulder area of the conventional fixed blade, such as Figure 4 (b) shown. Shown in the figure is the well bottom coverage diagram of the drill bit of this embodiment. The number 4 in the figure is the conventional fixed blade, and 41 is the cutting tooth of the fixed blade. It can be seen from the figure that the profile of the indexing blade 33 is a nearly triangle formed by three-segment line segments and the arcs of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com