Low-density water-based drilling fluid and preparation method thereof

A water-based drilling fluid and low-density technology, which is applied in the field of oil field drilling fluid, can solve the problems of large leakage and pipe sticking risk, and easy pressure leakage in the upper formation, so as to shorten the well construction period, ensure safe drilling, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

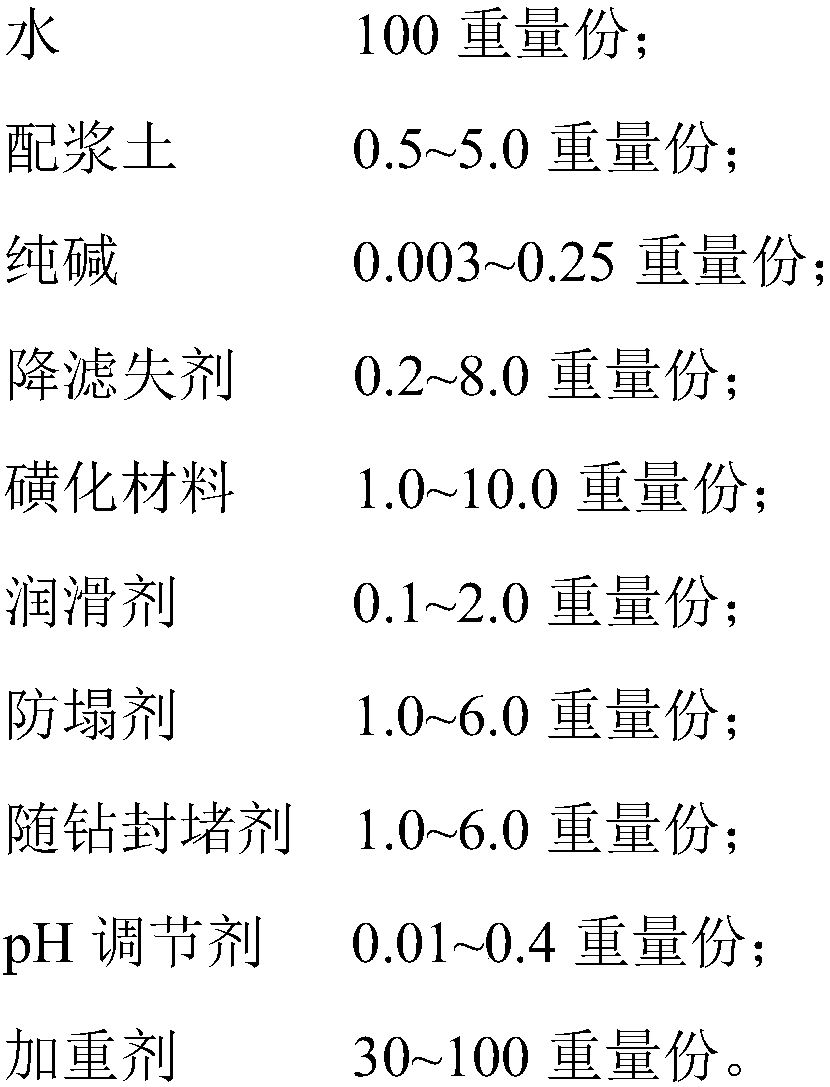

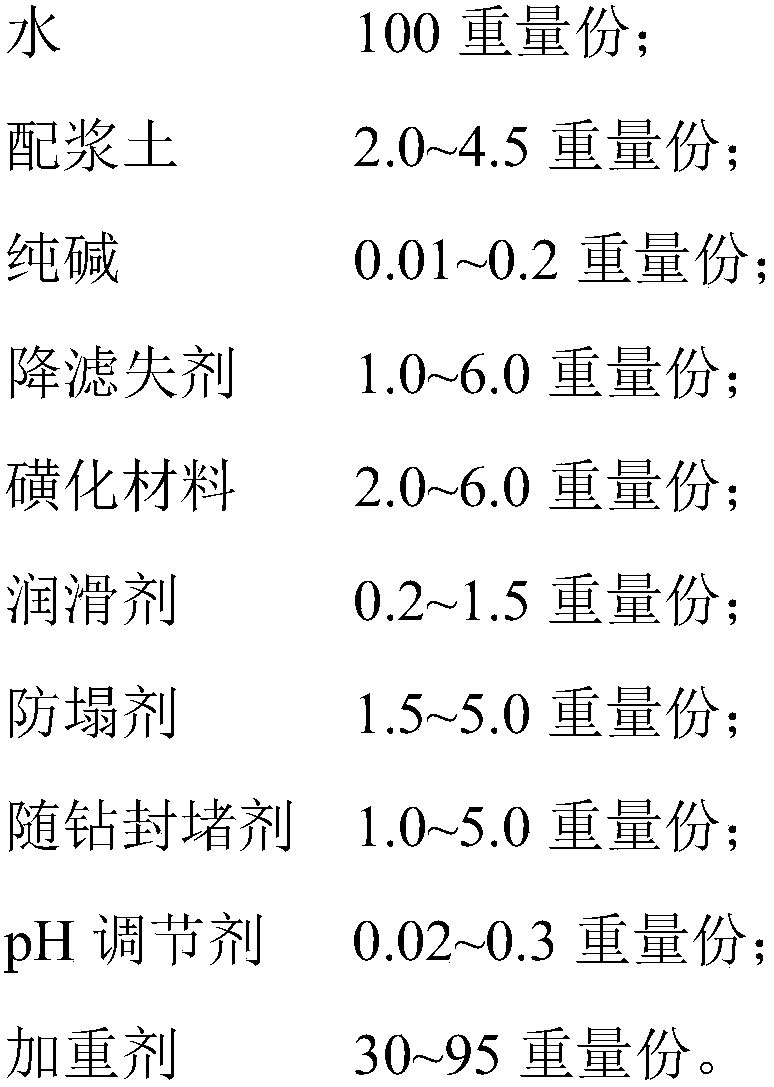

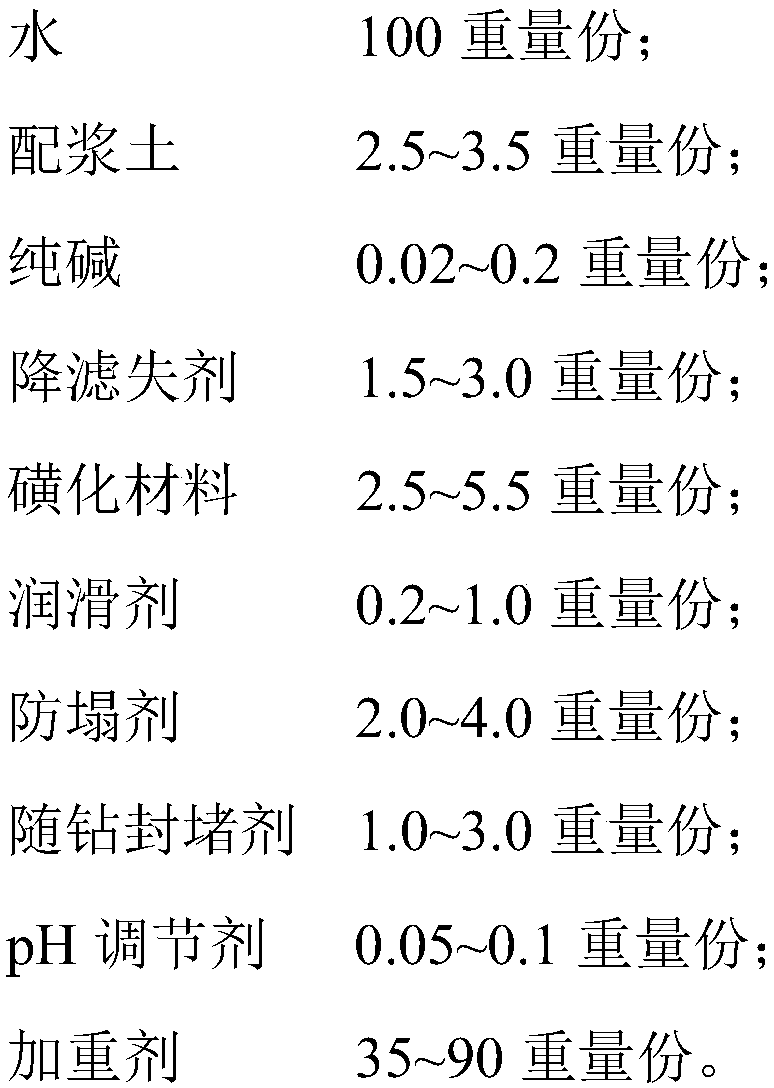

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a low-density drilling fluid suitable for safe drilling in long open-hole diabase well sections. The components are calculated in parts by weight, including 100 parts of water, 3.5 parts of sodium bentonite, and 0.125 parts of Na 2 CO 3 , 2.5 parts of LV-PAC, 2.0 parts of SMC, 3.0 parts of SPNH, 0.8 parts of glass beads, 2.5 parts of emulsified pitch FF-III, 2.5 parts of ultrafine calcium carbonate, 0.1 parts of NaOH, 3.0 parts of NaCl, 38 parts of barite. Ultrafine calcium carbonate particle size 20 ~ 60μm. All components are commercially available products.

[0029] The concrete preparation method of this embodiment is: at first 0.125 parts of Na 2 CO 3 Dissolve in 100 parts of water, add 3.5 parts of sodium bentonite, after hydration, add 2.5 parts of LV-PAC, 2.0 parts of SMC, 3.0 parts of SPNH, 0.8 parts of glass microspheres, 2.5 parts of emulsified asphalt FF-III, 2.5 parts of superfine Calcium carbonate, 0.1 part of NaOH and 3.0 par...

Embodiment 2

[0034] This embodiment relates to a low-density drilling fluid suitable for safe drilling in long open-hole diabase formations. The components include 100 parts by weight of water, 3.0 parts of calcium-based sodium bentonite, and 0.175 parts of Na 2 CO 3 , 2.0 parts of LV-CMC, 1.5 parts of SMC, 2.0 parts of SPNH, 0.5 parts of graphite, 2.0 parts of paraffin nanoemulsion, 1.5 parts of ultrafine calcium carbonate, 0.08 parts of NaOH, 7.5 parts of KCl, 46 parts of barite. Ultrafine calcium carbonate particle size 40 ~ 60μm. All components are commercially available products.

[0035] The concrete preparation method of this embodiment is: at first 0.175 parts of Na 2 CO 3Dissolve in 100 parts of water, add 3.0 parts of calcium-based sodium bentonite, after hydration, add 2.0 parts of LV-CMC, 1.5 parts of SMC, 2.0 parts of SPNH, 0.5 parts of graphite, 2.0 parts of paraffin nanoemulsion, 1.5 parts of ultrafine carbonic acid Calcium, 0.08 parts of NaOH and 7.5 parts of KCl are ad...

Embodiment 3

[0040] This embodiment relates to a low-density drilling fluid suitable for safe drilling in diabase formations. The components include 100 parts of water, 3.0 parts of sodium bentonite, and 0.125 parts of Na 2 CO 3 , 1.5 parts of LV-CMC, 1.5 parts of SMC, 1.5 parts of SMP-II, 1.5 parts of SPNH, 0.5 parts of vegetable oil-based lubricant SMJH-1, 2.5 parts of emulsified asphalt FF-III, 2.5 parts of asbestos fiber, 0.06 parts of KOH, 80 parts Micromanganese ore powder. The length of asbestos fiber is 20-60 μm, and the diameter is 15-30 μm. All components are commercially available products.

[0041] The concrete preparation method of this embodiment is: at first 0.125 parts of Na 2 CO 3 Dissolve in 100 parts of water, add 3.0 parts of sodium bentonite, after hydration, add 1.5 parts of LV-CMC, 1.5 parts of SMC, 1.5 parts of SMP-II, 1.5 parts of SPNH, 0.5 parts of vegetable oil-based lubricant SMJH-1, 2.5 parts Add emulsified asphalt FF-III, 2.5 parts of asbestos fiber, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com