Patents

Literature

34results about How to "Safe drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

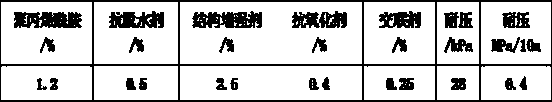

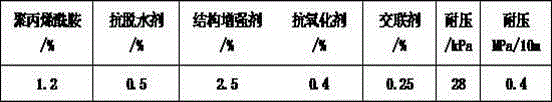

Polyacrylamide strong gel for well control and preparation method thereof

ActiveCN103525385AIncrease elasticityImprove adhesionDrilling compositionAntioxidantUltimate tensile strength

The invention discloses a polyacrylamide strong gel for well control and a preparation method thereof. The polyacrylamide strong gel for well control consists of the following components in percentage by weight: a base solution comprising 1-6% of polyacrylamide, 2-8% of a structure reinforcing agent, 0.4-8% of an anti-dehydrating agent, 0.2-4% of an antioxidant and the balance of water according to the total solution mass of the prepared polyacrylamide strong gel for well control, and 0.2-10% of a crosslinking agent relative to the mass fraction of the base solution. The polyacrylamide strong gel prepared by the preparation method has the characteristics of high strength, good elasticity, good toughness, good adhesion, high compression strength, good gas tightness and the like, can be directly gelatinized and used in an N80 tube special for an oil field, can be adhered to a sleeve, and can effectively prevent gas from escaping out of a pit shaft to achieve good effects of well control and sealing.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

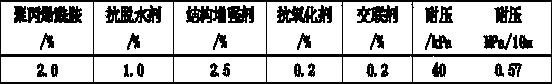

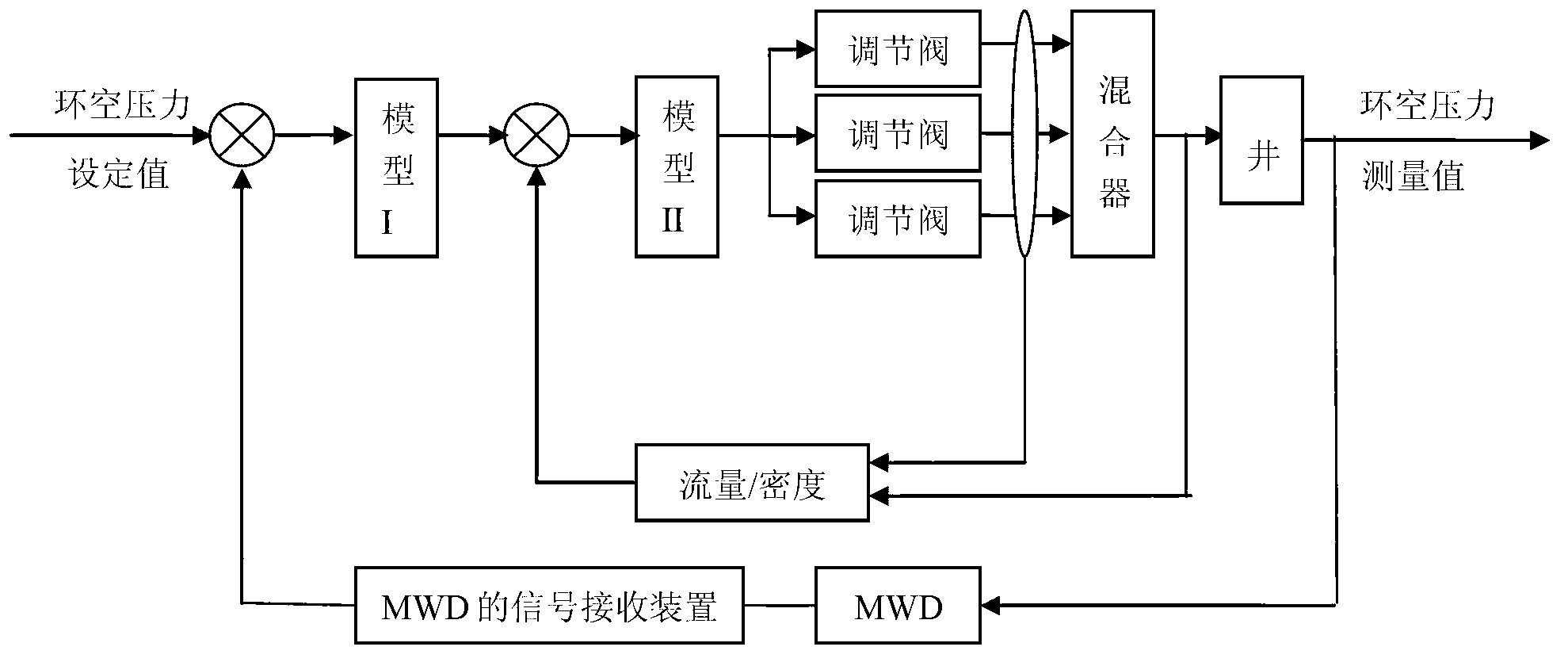

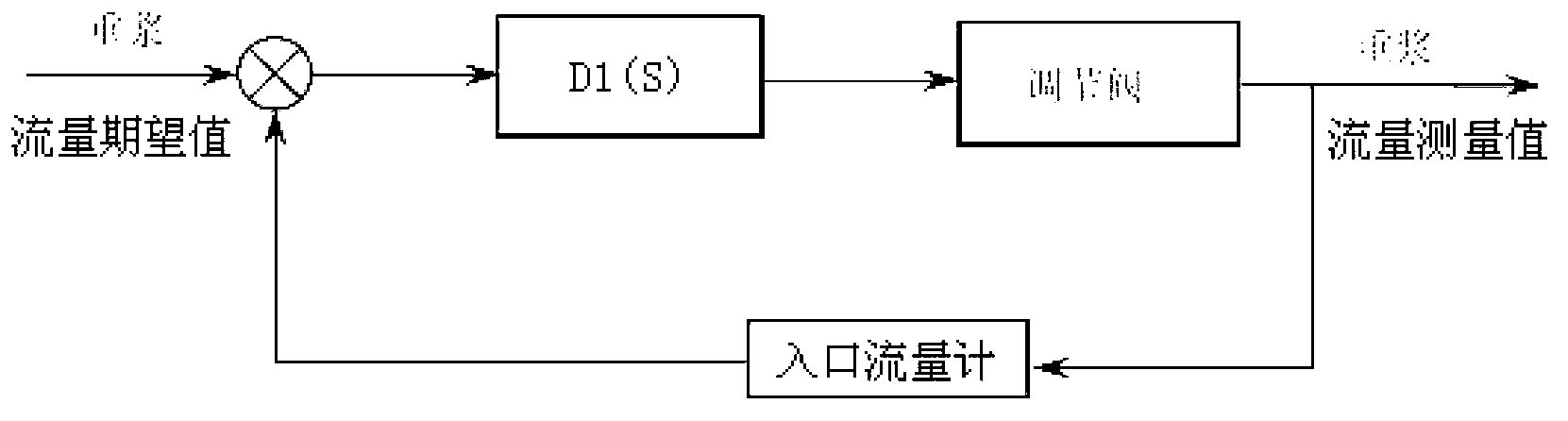

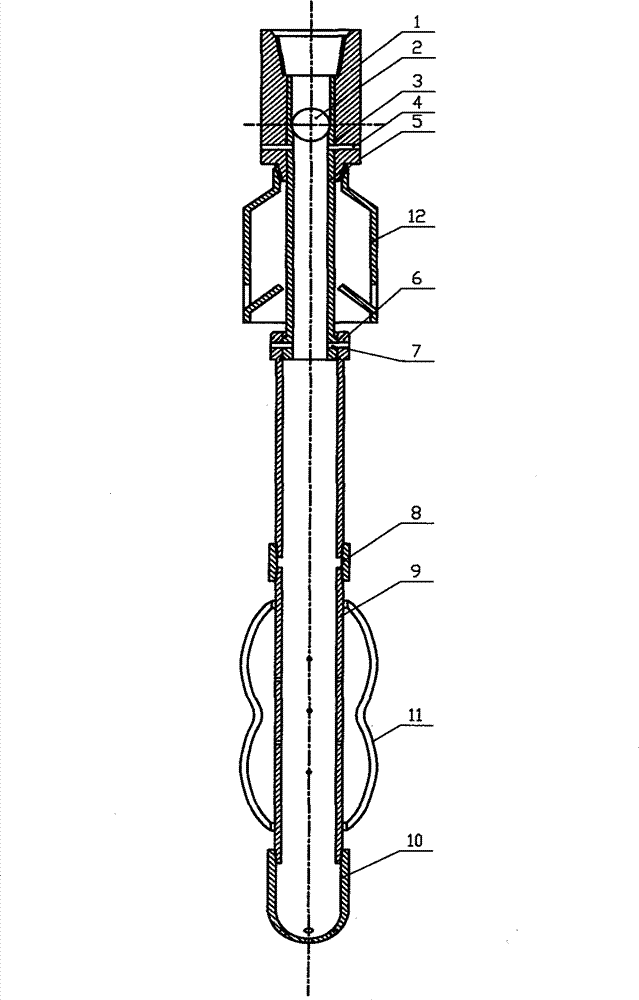

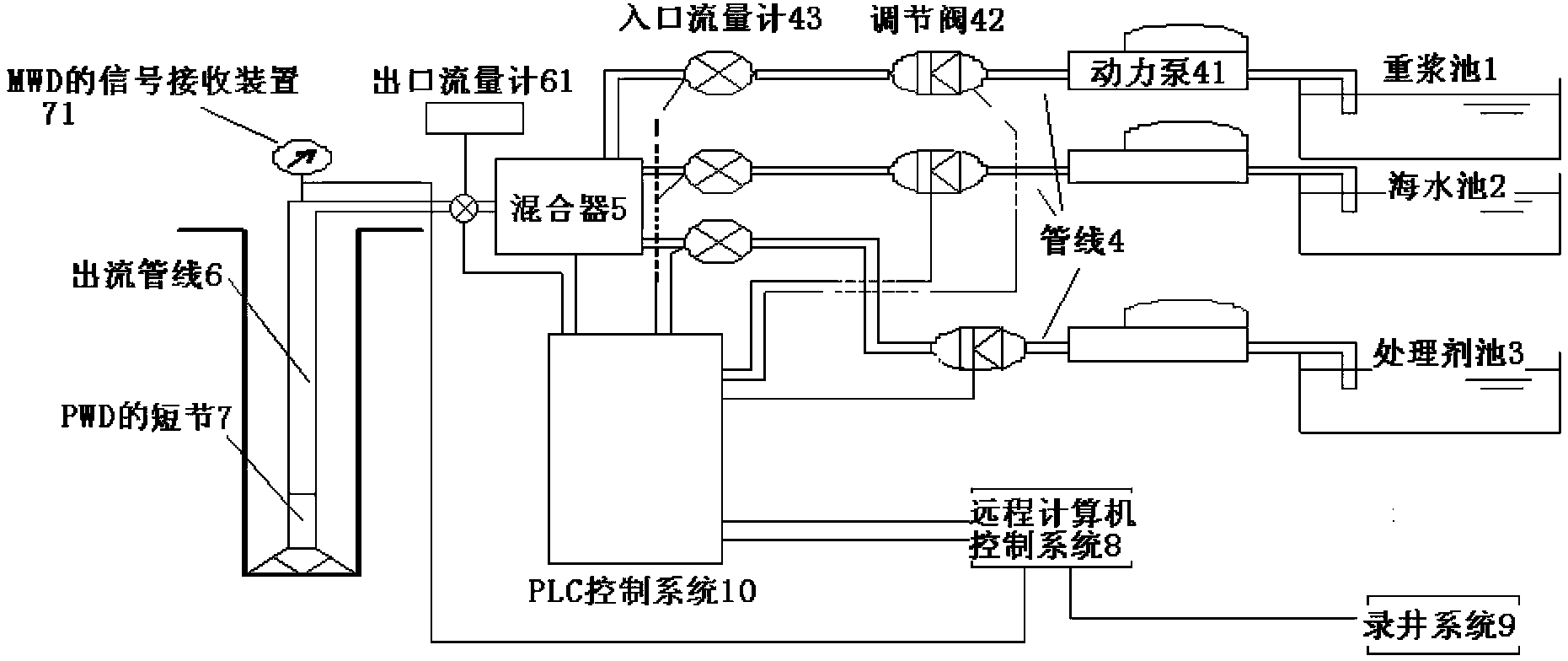

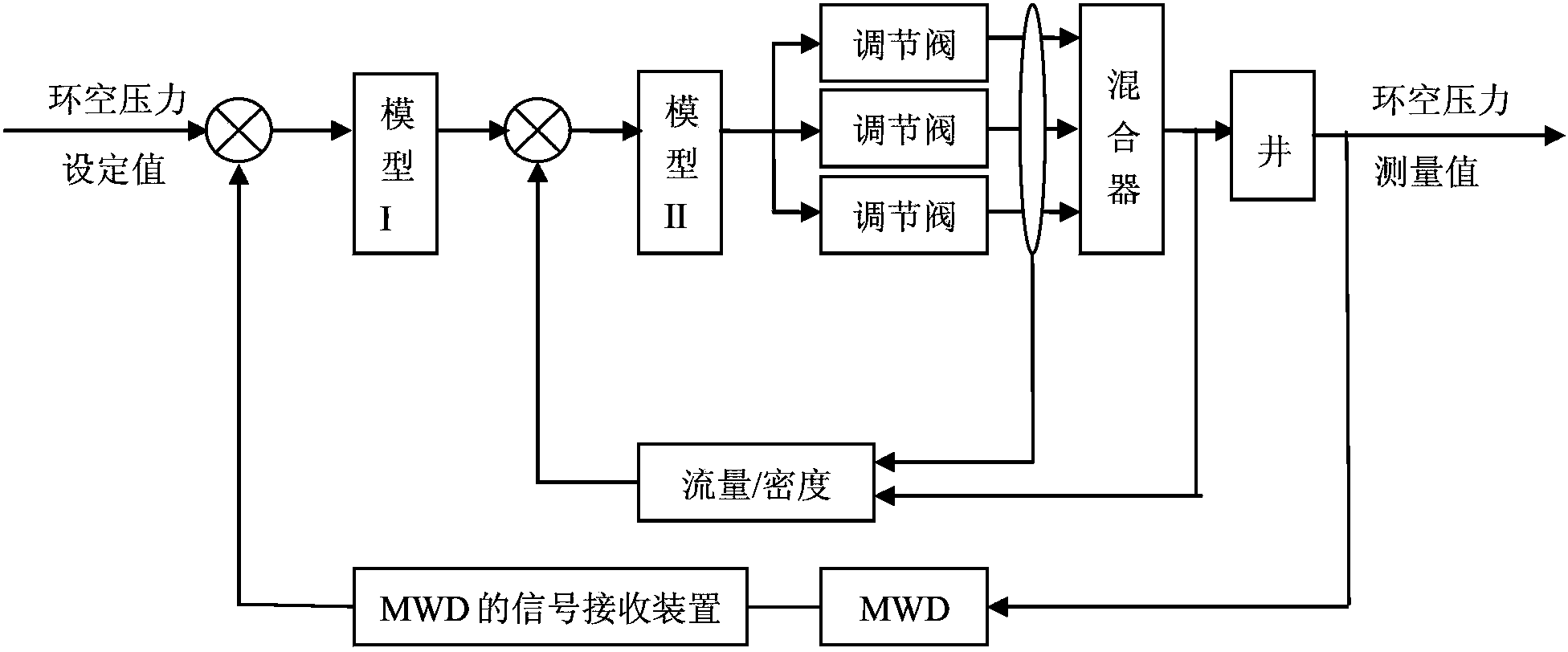

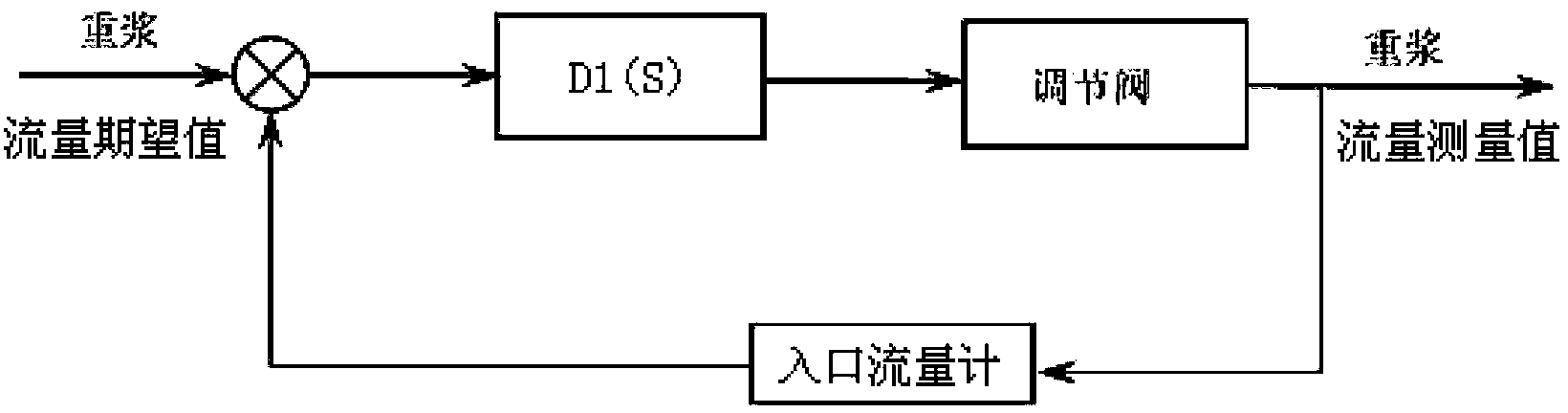

Automatic control system and method for underground annulus pressure of deep water surface layer drilling

ActiveCN102797451ARealize automatic adjustmentReduce biasAutomatic control for drillingOcean bottomAutomatic control

The invention relates to an automatic control system and method for underground annulus pressure of deep water surface layer drilling. The system comprises three pipelines which are respectively arranged in a heavy slurry pond, a seawater pond and a treating agent pond, wherein each pipeline is connected with the input end of a mixer, the output end of the mixer is connected with an outflow pipeline, and the outflow pipeline is connected with a pup joint of a seabed underground PWD. Each pipeline is internally provided with a power pump, a regulating valve and an inlet flow meter, and the outflow pipeline is internally provided with an outlet flow meter. The underground PWD is connected with an MWD, a signal receiving device of the MWD is in communication connection with a remote computer control system, the remote computer control system is connected with a logging system and a PLC (Programmable Logic Controller) control system through a data bus, and the PLC control system is connected with the regulating valve, the inlet flow meter, the mixer and the outlet flow meter through data. According to the invention, a secondary microcomputer control system is created through the remote computer control system and the PLC control system, so that the mixing proportion of heavy slurry and seawater is automatically regulated, and drilling slurry with required density and flow is input to the underground to carry out underground pressure balance regulation to further realize safe drilling.

Owner:CHINA NAT OFFSHORE OIL CORP +1

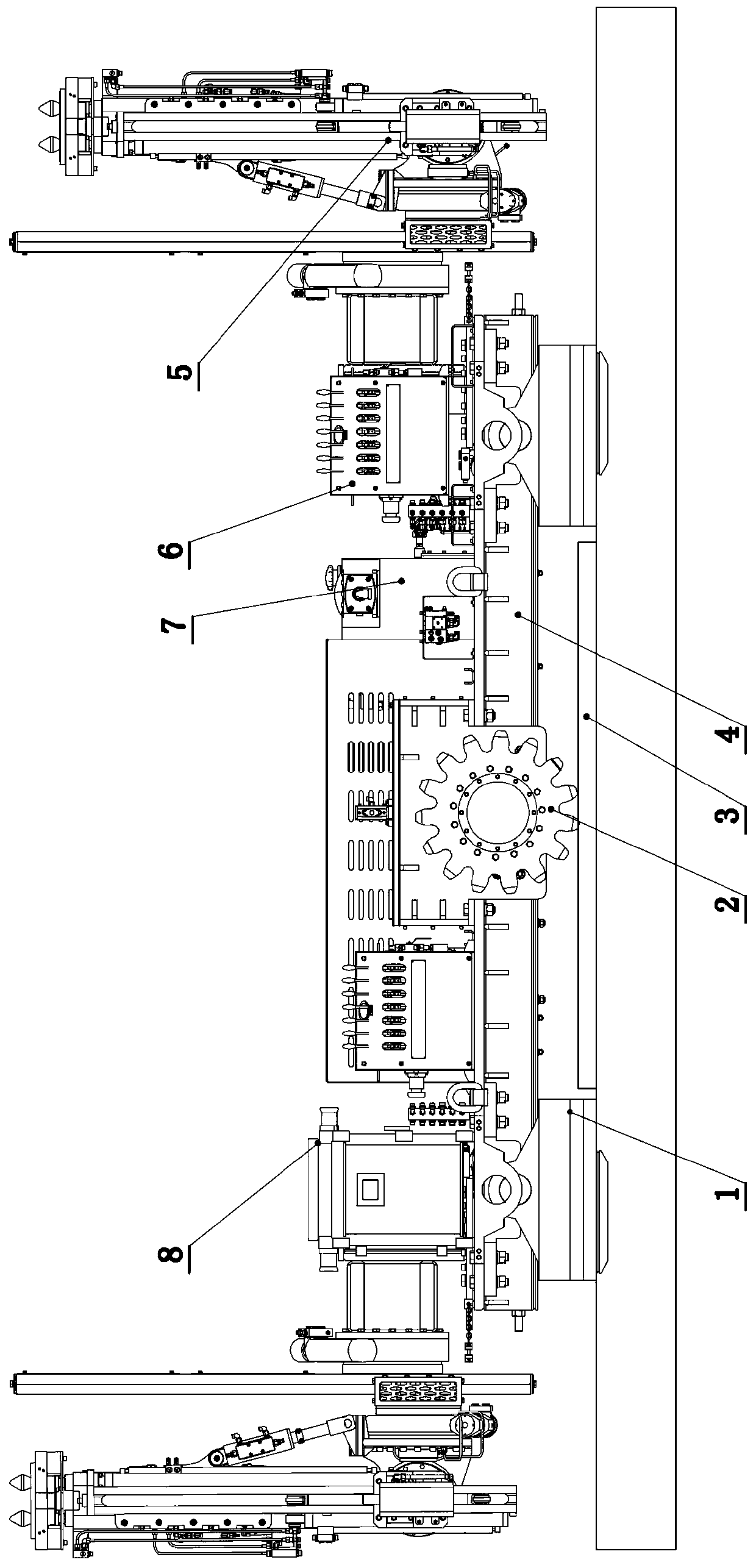

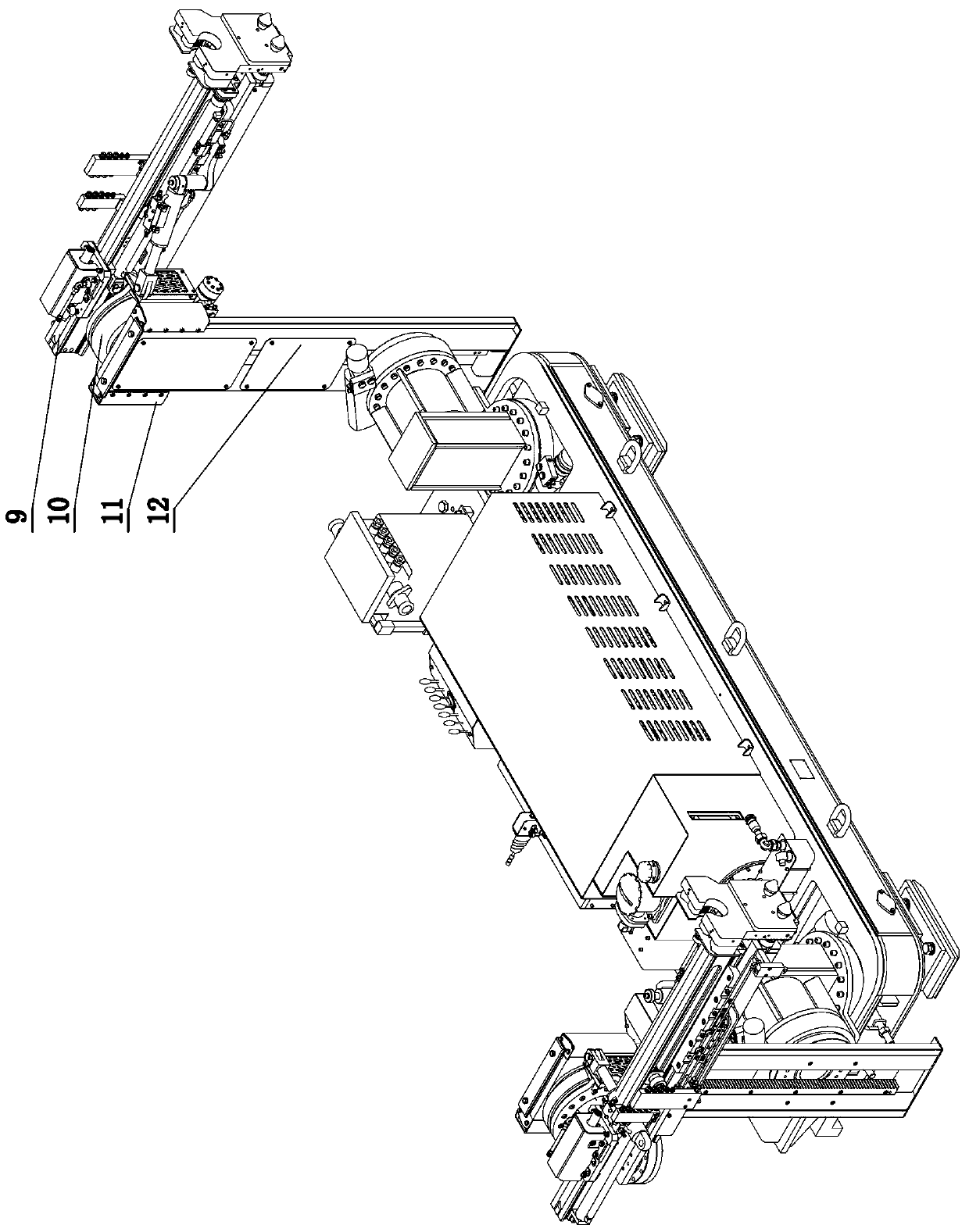

Moving hydraulic anchoring drill rig for coalface

PendingCN109611026ASolve the disadvantages of being heavy and difficult to movePrevent slippingDirectional drillingUnderground transportHydraulic motorDrive wheel

The invention discloses a moving hydraulic anchoring drill rig for a coalface. The moving hydraulic anchoring drill rig comprises a chassis assembly, an operating table, a pump station system and a drill rig assembly, the operating table, the pump station system and the drill rig assembly are all installed on the chassis assembly, a travelling assembly is further installed in the middle of the chassis assembly, and drill rig bodies are installed on the two sides of the chassis assembly through guiding rails correspondingly; the travelling assembly comprises a gear rail driving wheel, a transmission mechanism, and a hydraulic motor, the hydraulic motor is installed in the middle of the chassis assembly, an output shaft of the hydraulic motor is connected with the gear rail driving wheel, the gear rail driving wheel is connected with a scraper gear rail on a scraper in an engaged mode, travelling supporting slipping boots are installed on the two sides of the chassis assembly, and installed on a groove ledge of the scraper; and the drill rig assembly comprises a drill rig body, a sliding seat, a guiding rail and a rotary assembly, a rotary reducer is installed between the guiding rail and a rotary base, the rotary base is connected with the chassis assembly through the rotary reducer, and the drill rig body is connected with the guiding rail through a rotary assembly.

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

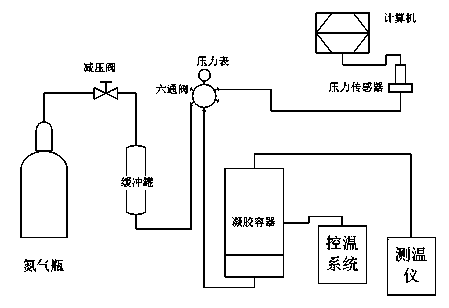

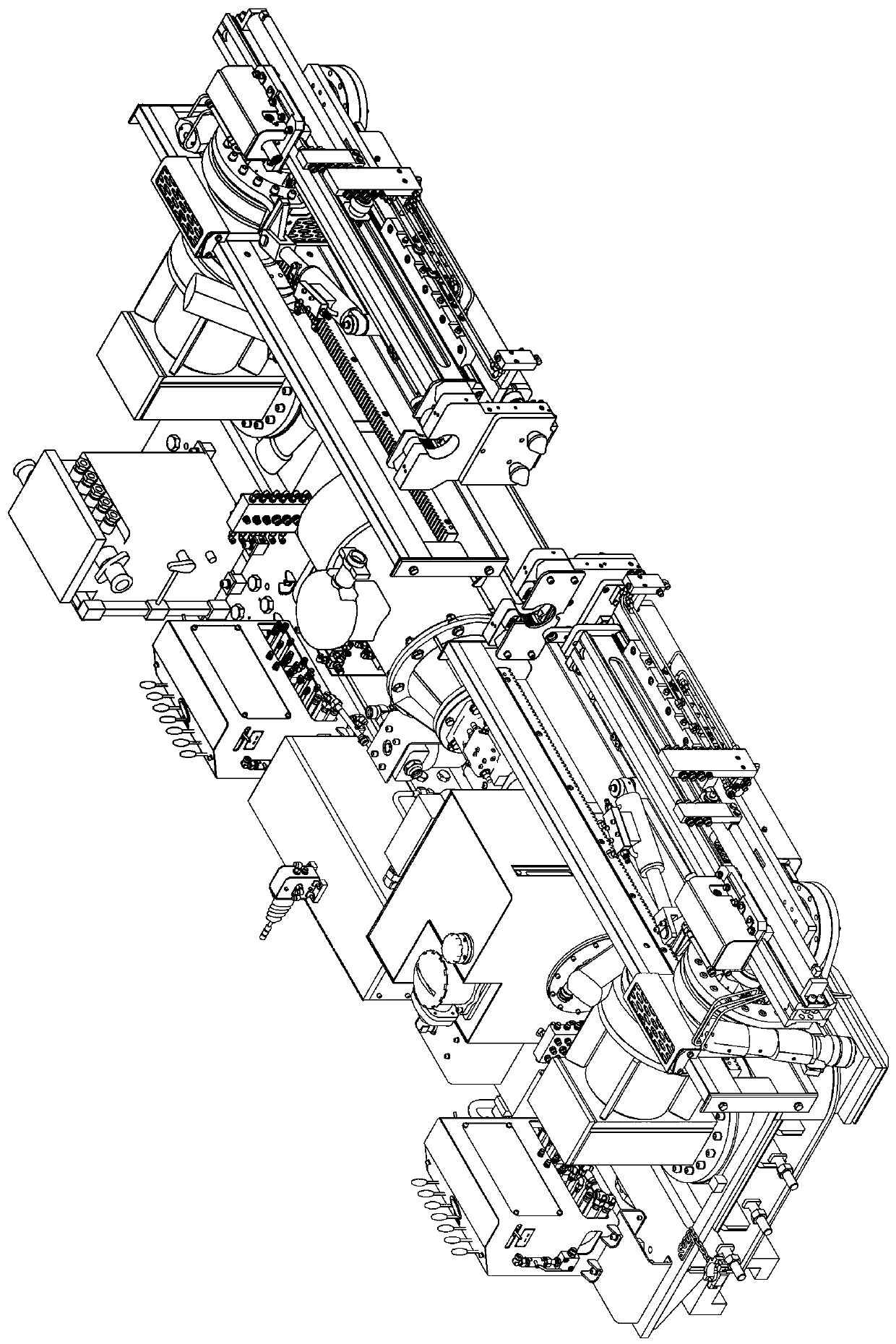

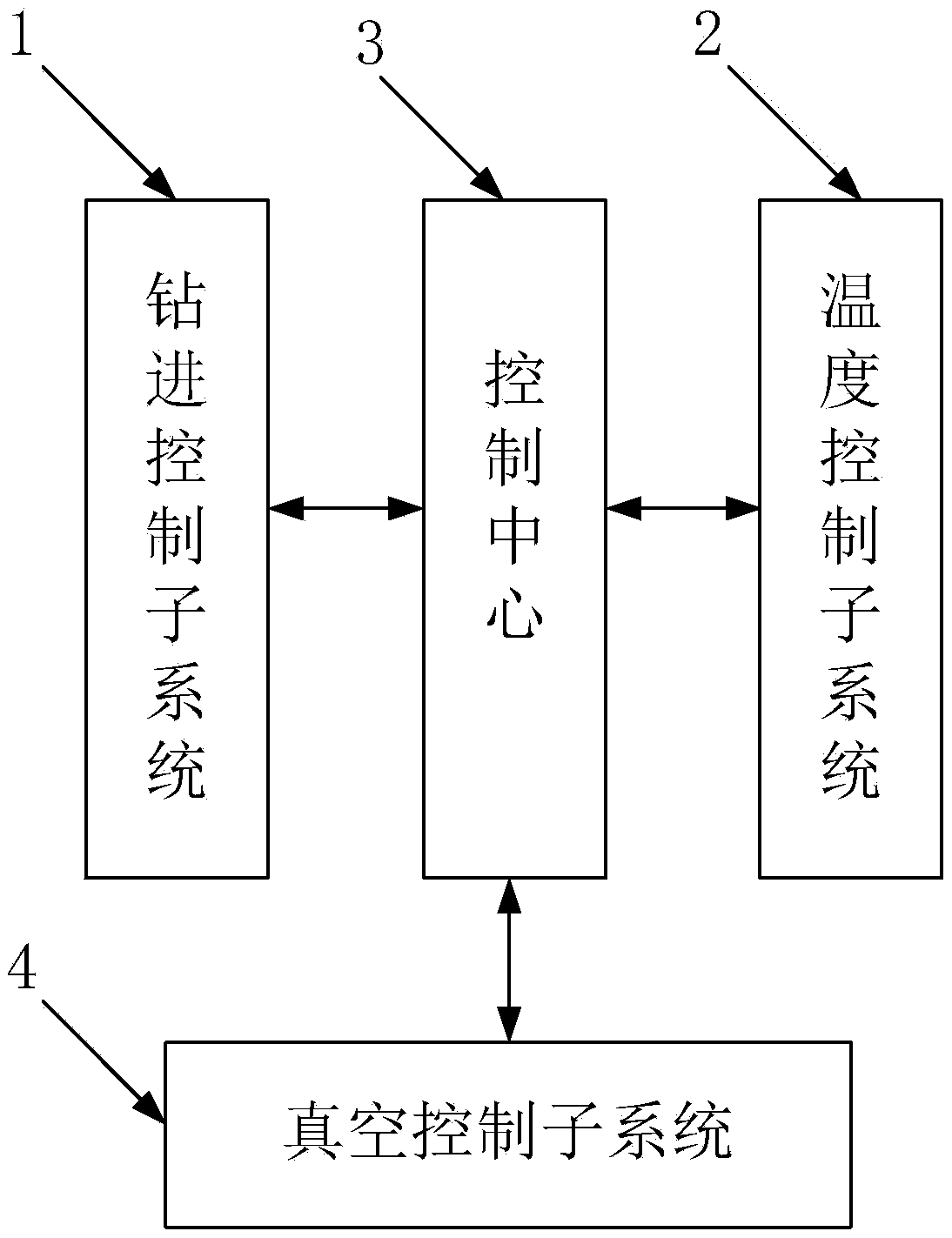

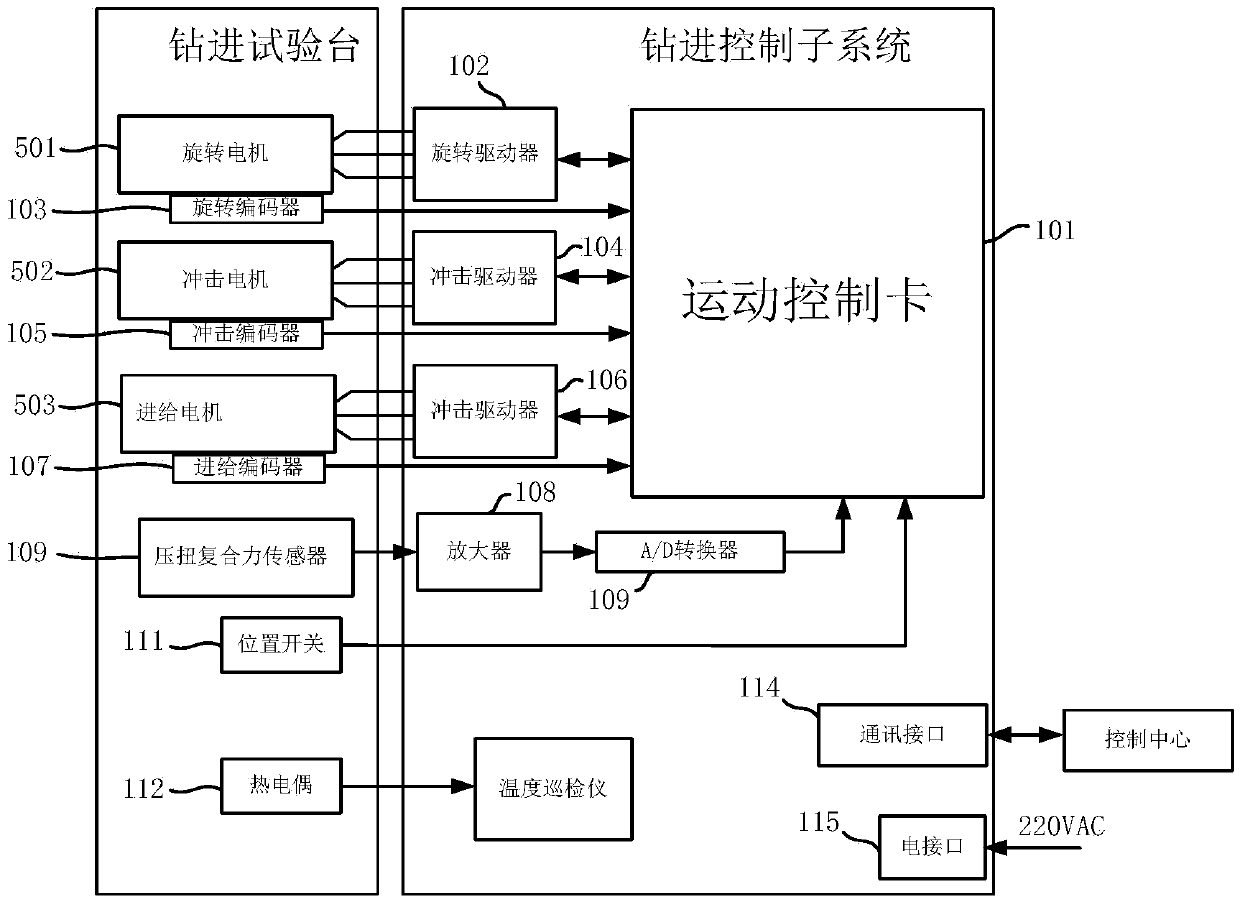

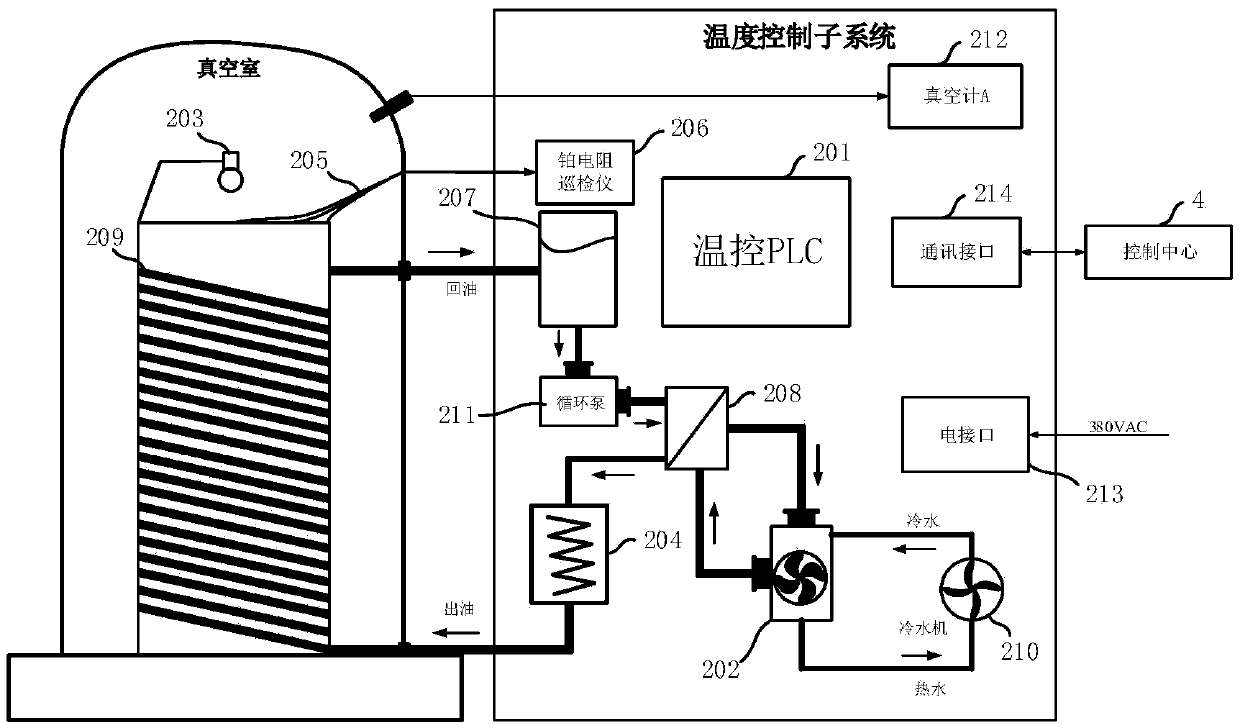

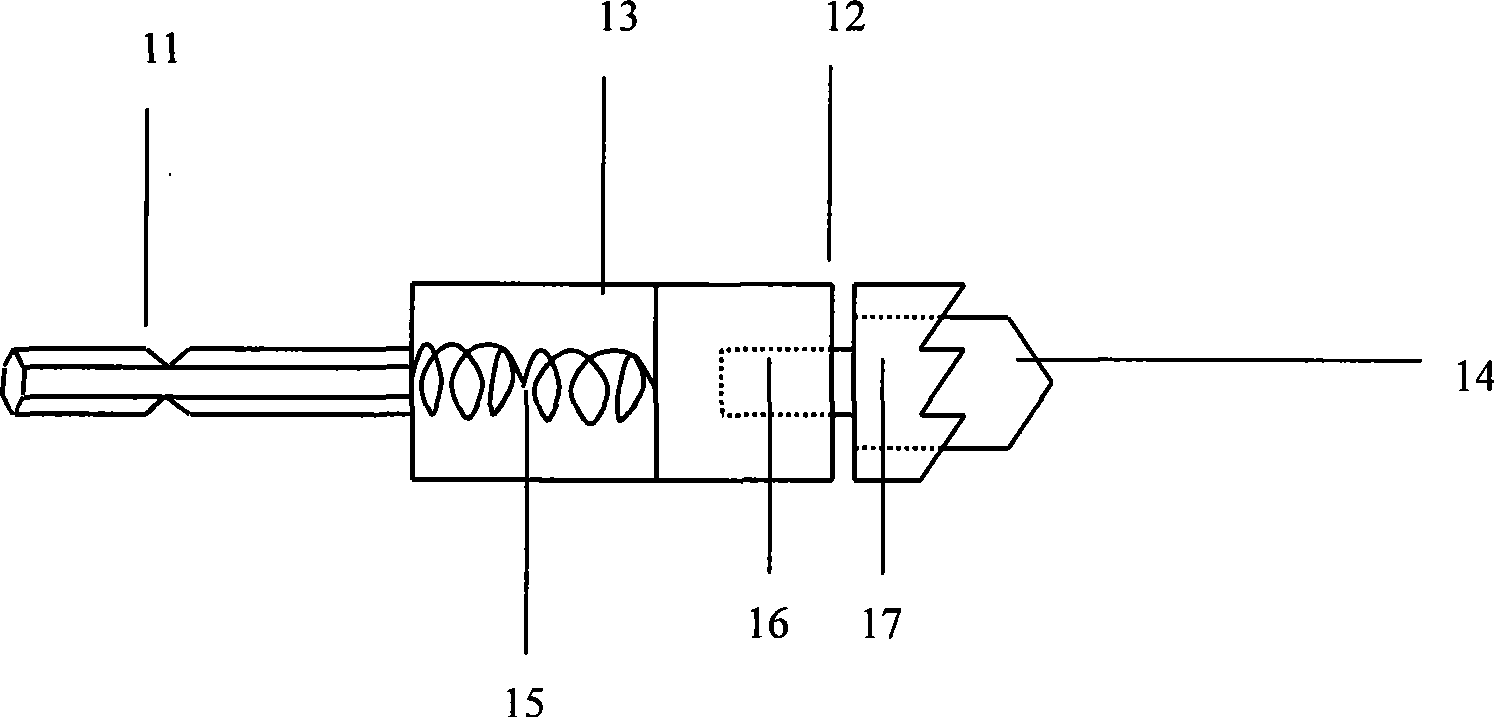

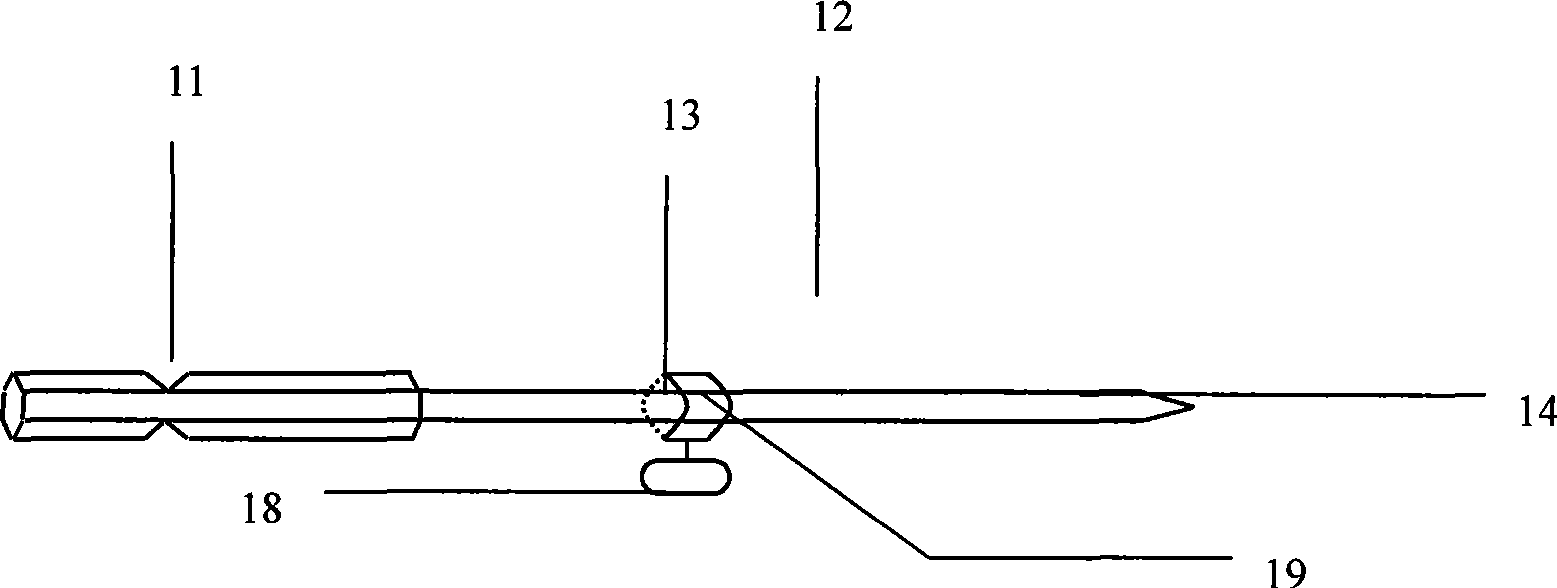

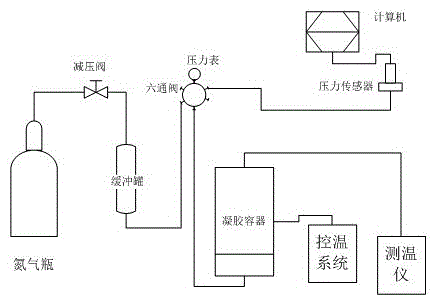

Drilling tool technology procedure parameter adjustment test device controller and control method

ActiveCN105373099AEasy to debugShorten the development cycleTotal factory controlProgramme total factory controlCommunication interfaceLow speed

The invention discloses a drilling tool technology procedure parameter adjustment test device controller and a control method. The drilling process of a drilling tool, temperature of a drilling environment and the vacuum degree of the drilling environment can be controlled by the controller. Besides, communication with a control center is realized by respective communication interfaces, and the control center can control independent operation of each subsystem. The control method of the controller comprises the steps that firstly a feed motor performs low-speed feeding, and whether the drilling tool is contacted with a drilling object is judged according to force feedback; then the drilling tool is contacted with the drilling object, the feed motor maintains low-speed feeding, and a rotation motor starts low-speed rotation; the drilling speed level is adjusted anytime in the drilling process, and the speed of the feed motor gradually transforms to low speed from high speed according to the force feedback speed level; and an impact motor is started when encountering severe working conditions, and rotation-impact drilling is applied. Advantages of the controller and the control method are that different combinations of tests can be performed through control so that test device debugging is greatly facilitated and the great drilling effect of the drilling tool can be guaranteed.

Owner:BEIHANG UNIV

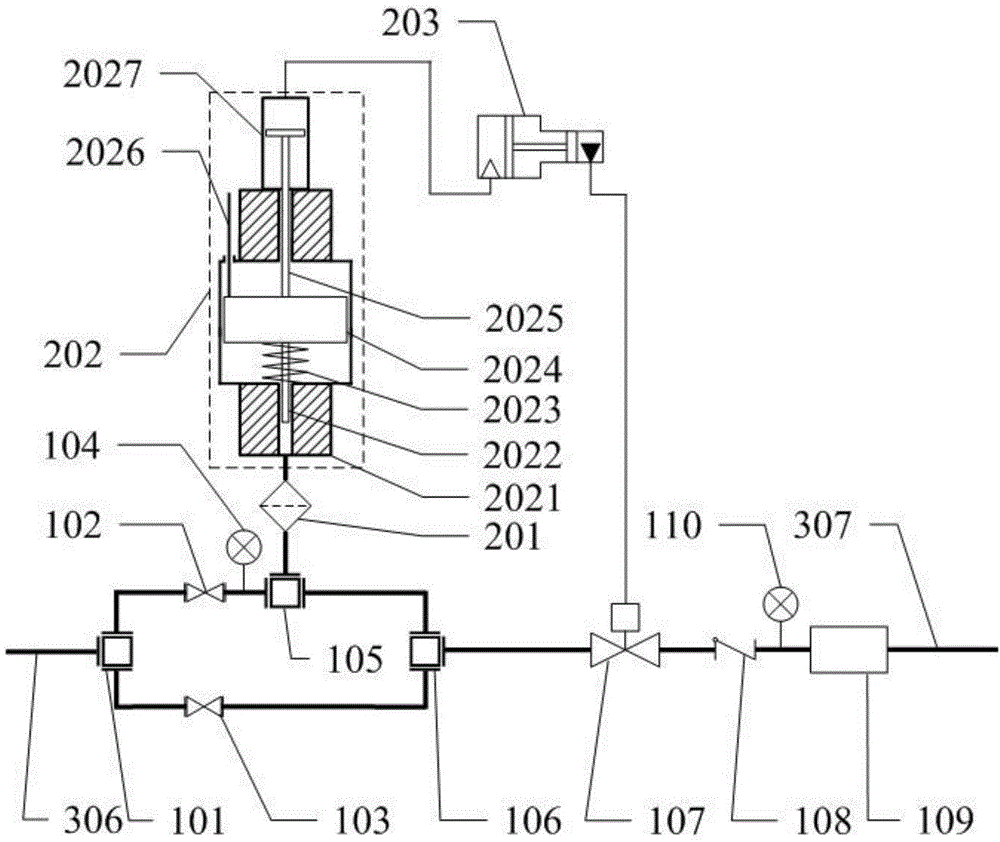

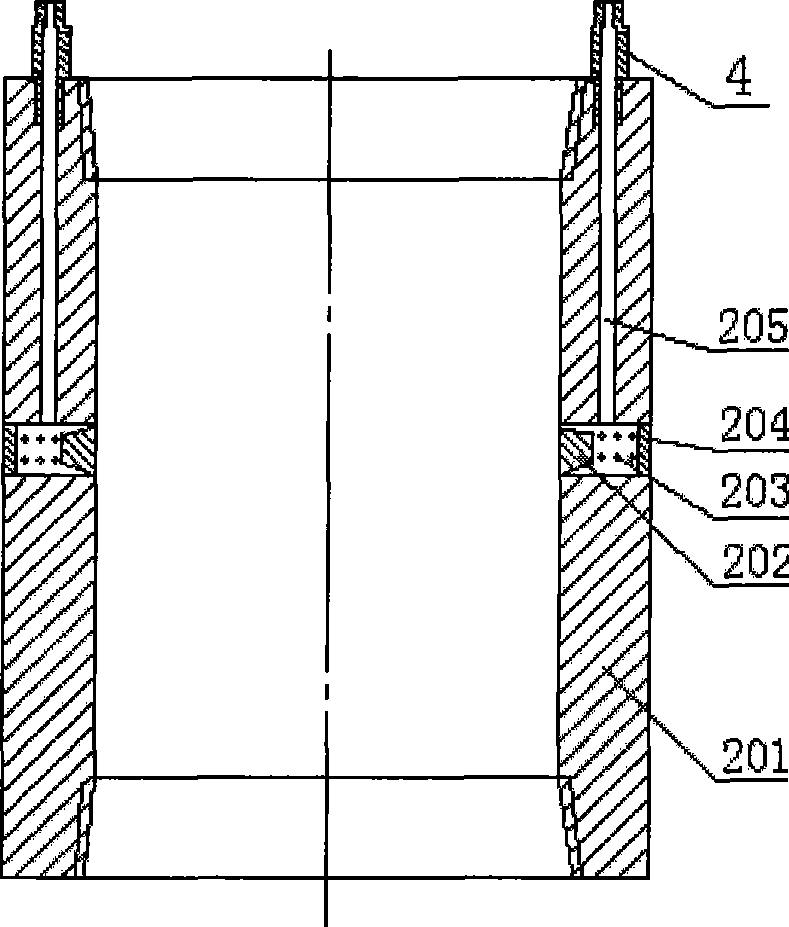

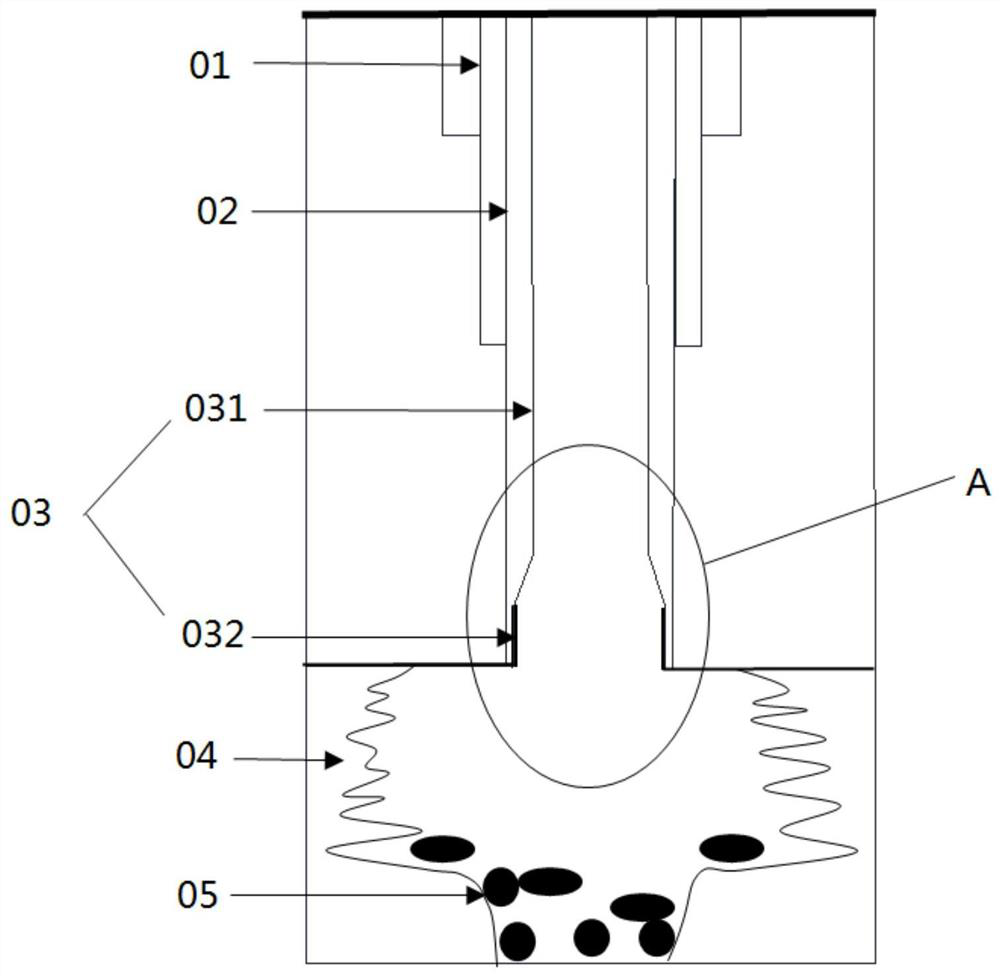

Seabed wellhead pressure indicating and automatic adjusting device for deepwater dual-gradient well drilling

ActiveCN104895548ASimple structureEasy to implementFluid removalAutomatic control for drillingWell drillingHydrostatic pressure

The invention belongs to the field of deepwater well drilling of petroleum engineering, and particularly relates to a seabed wellhead pressure indicating and automatic adjusting device for deepwater dual-gradient well drilling. The seabed wellhead pressure indicating and automatic adjusting device for the deepwater dual-gradient well drilling comprises a seabed drilling fluid manifold system and a seabed wellhead pressure indicating and automatic adjusting device, wherein the seabed drilling fluid manifold system provides a flowing channel to shaft returning and drilling fluid so that the drilling fluid can successfully return to a drilling platform and provide a foundation to the seabed wellhead pressure indicating and automatic adjusting device; the seabed wellhead pressure indicating and automatic adjusting device can display and adjust seabed wellhead pressure in real time, and keep seabed wellhead pressure to be constantly equal to seawater hydrostatic pressure at the seabed. According to the seabed wellhead pressure indicating and automatic adjusting device for the deepwater dual-gradient well drilling provided by the invention, the seabed wellhead pressure can be automatically kept to be constantly equal to the hydrostatic pressure of seawater deepwater dual-gradient well drilling process at the seabed so that the dual-gradient well drilling can be ensured to be successfully implemented.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

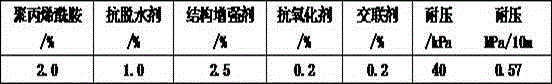

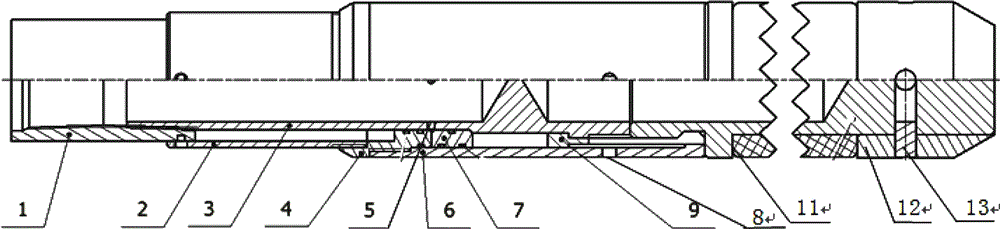

Well drilling gas injection joint and use method thereof

The invention relates to a well drilling gas injection joint applied to the technical filed of petroleum drilling. The upper end of a main body is drilled with a longitudinal hole communicated with a horizontal hole; the inner end of the horizontal hole is a round hole and a valve core is arranged in the horizontal hole; one end of the valve core matches with the round hole at the inner end of the horizontal hole, which plays a sealing role, the other end of the valve core is fixed with a positioning disk and a spring is positioned between the positioning disk and a plug; high pressure air is transmitted to the horizontal hole through the longitudinal hole, the positioning disk is provided with a through hole, the spring is an helical extension spring and the thread of the longitudinal hole is fixed with a pipeline joint. The application process comprises the following steps of: A. putting down a bushing: the well drilling gas injection joint is connected on the pipe column of the bushing; B. well cementation; C. connection with a ground gas injection system; D. drilling construction; E. the injection of high pressure gas into the bushing; and F. stopping gas injection. The well drilling gas injection joint can effectively reduce annular hohlraum inner fluid column pressure and fulfill the purpose of safety, quick and high efficient drilling.

Owner:PETROCHINA CO LTD

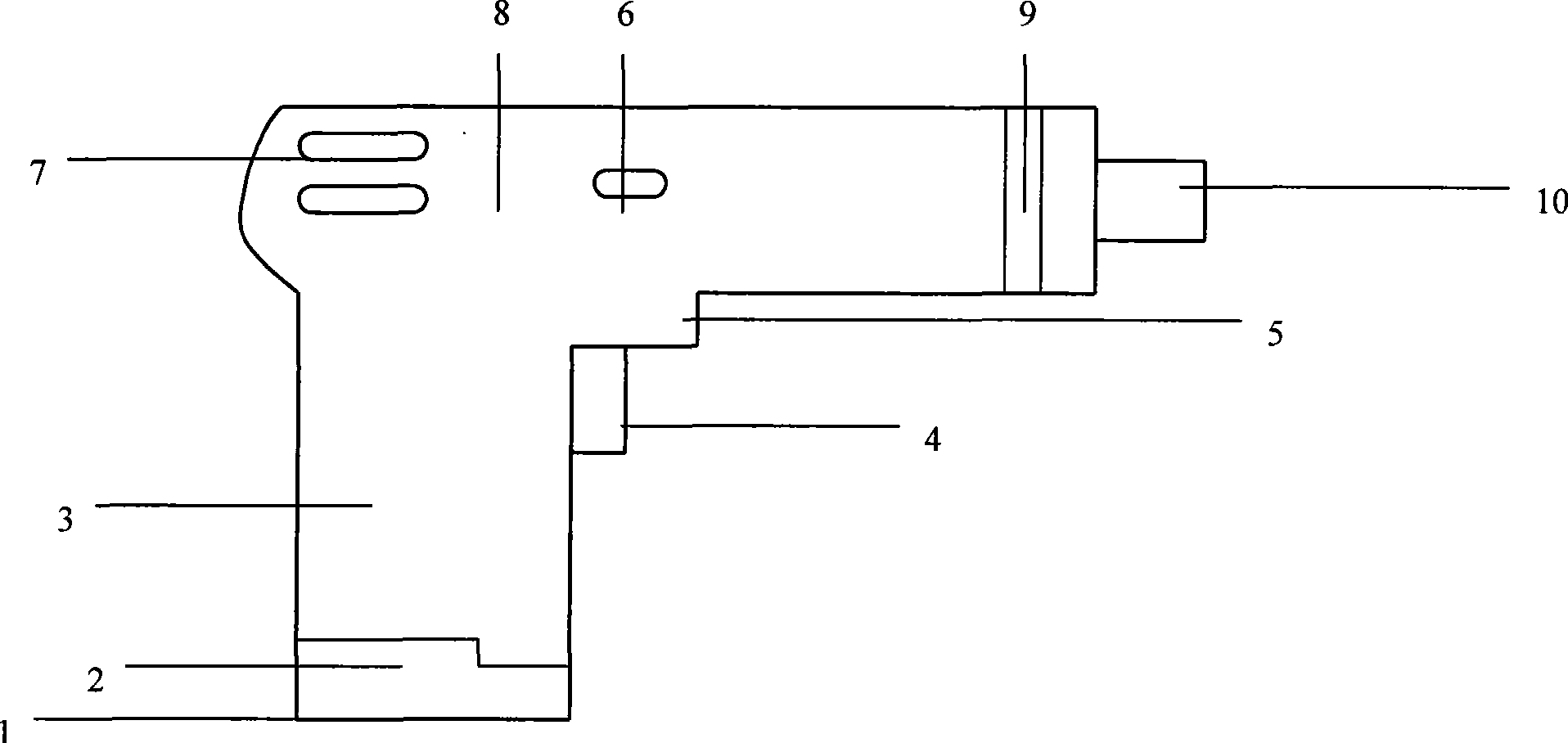

Portable chargeable multifunctional skull brad awl

InactiveCN101507647AIncrease drilling speedDynamic stabilitySurgeryClosed head injuryNeurosurgical Procedure

The invention relates to a portable rechargeable multifunctional skull drill and application thereof. The skull drill is a novel multifunctional neurosurgical electric tool, can be used for checking, diagnosing, preventing, treating and researching severe closed craniocerebral injury patients, particularly extremely severe craniocerebral injury patients, has simple structure, easy operation, low use cost, small volume, symmetrical force application, stable drilling, and improved utilization safety, and is more suitable for emergent treatment of pre hospitals, 120 ambulances, low level hospitals and emergency rooms in large size hospitals to provide possibility of early and super-early neurosurgical operation interference so as to greatly facilitate protraction of emergency medical treatment, achieve the aim of reducing the pre-hospital death rate of battling craniocerebral injury, and improve the effects and quality of the emergent medical treatment. The portable rechargeable multifunctional skull drill can be effectively combined into a complete set as a portable craniocerebral injury first-aid equipment kit which can be applied to field fight first aid for various battling craniocerebral injuries.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Low-density water-based drilling fluid and preparation method thereof

InactiveCN109868123AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

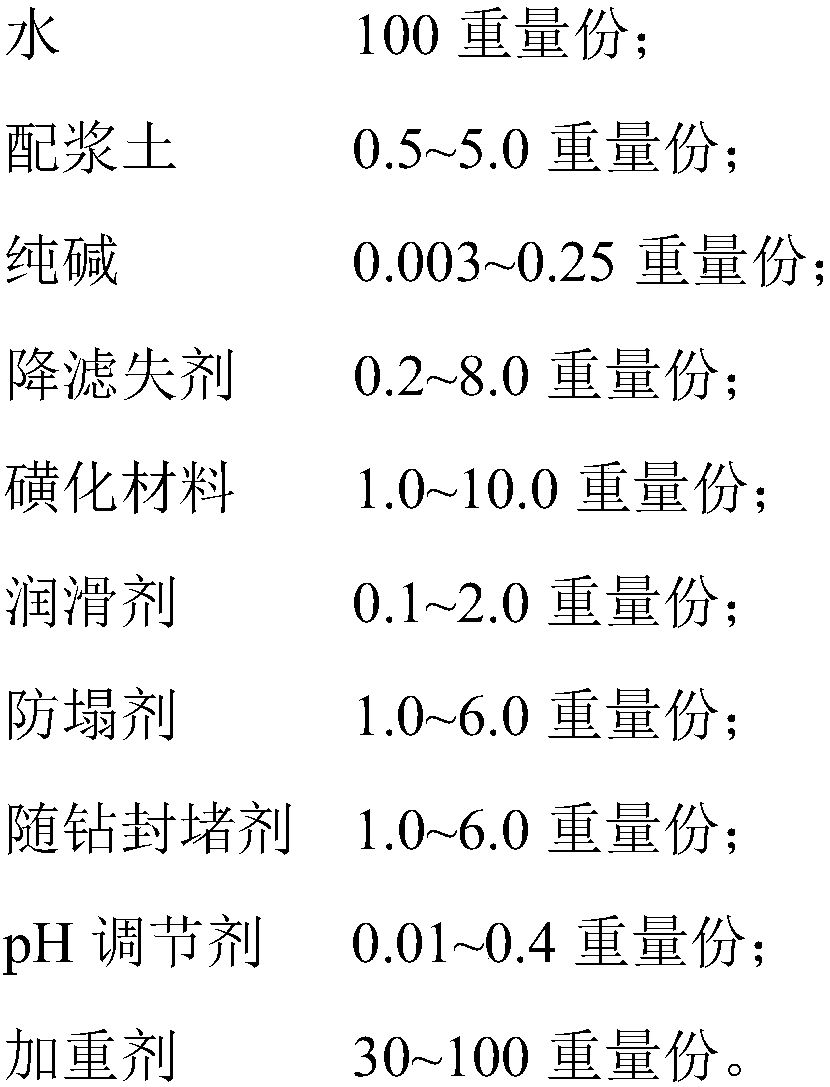

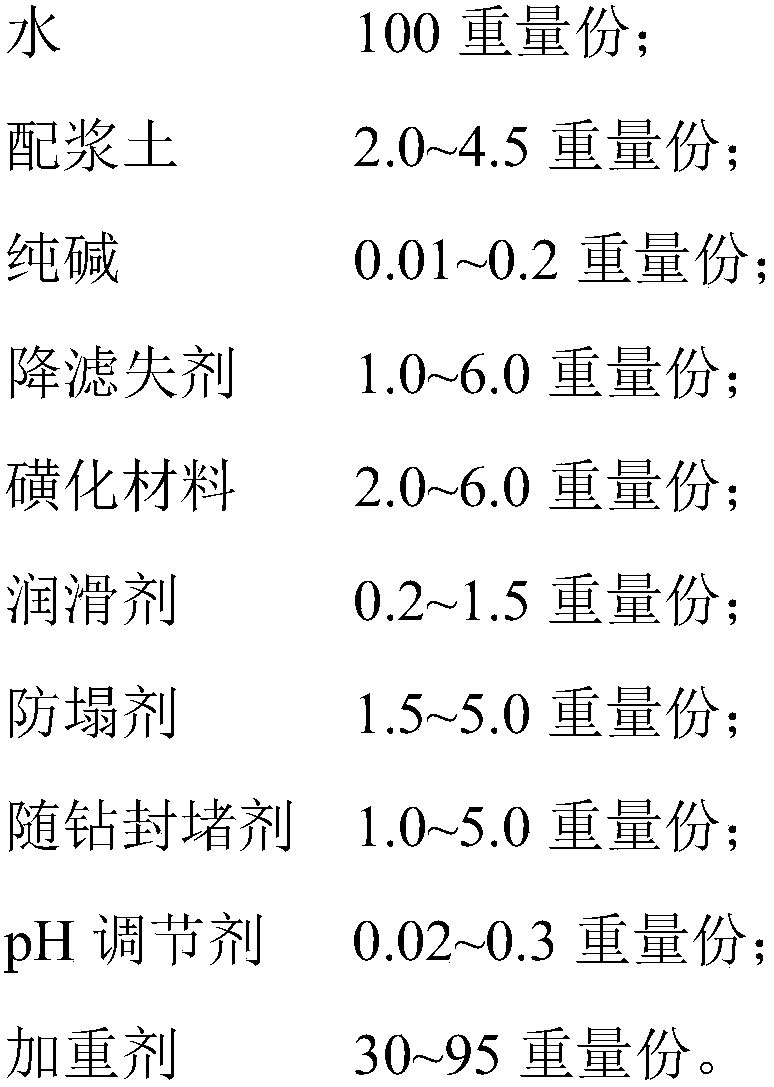

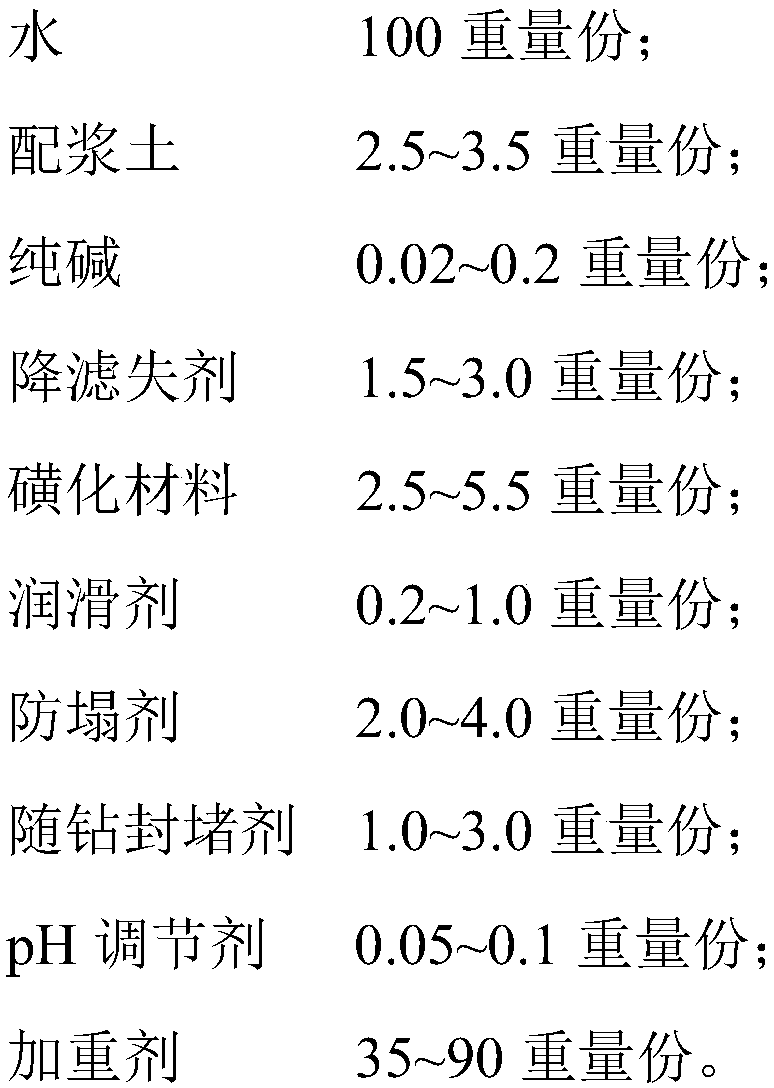

The invention provides a low-density water-based drilling fluid system for safely drilling through a long open-hole diabase formation. The drilling fluid system comprises the following components, inparts by weight: 100 parts by weight of water, 0.5-5.0 parts by weight of slurry mixing soil, 0.003-0.25 part by weight of sodium carbonate, 0.2-8.0 parts by weight of a fluid loss agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of a plugging agent while drilling, 0.01-0.4 part by weight of a pH adjusting agent and 40-80 parts by weight of a weighting agent; and the drilling fluid system further comprises 0.1-10.0 parts by weight of an inorganic salt. The drilling fluidprovided by the invention has good rheological performance and rock-carrying capacity; the drilling fluid can not only safely drill through the diabase formation, but also can meet the purpose that fallen diabase returns to the ground in time, effectively avoid stuck drilling, ensure safe drilling and shorten a well construction period through improvement of plugging while drilling and collapse resistance of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Well bore structure for out-of-round oversized hole

PendingCN111946303AInner Bore Safety and Stability RulesImprove performanceFluid removalEngineeringStructural engineering

The invention discloses a well bore structure for an out-of-round oversized hole. The well bore structure comprises N well opening layer sections, wherein a first well opening casing pipe to an Nth well opening casing pipe are arranged in the first well opening layer section to the Nth well opening layer section in a lowered mode respectively, the Mth well opening layer section is provided with anout-of-round oversized complex layer section, N is a positive integer larger than or equal to two, and M is a positive integer larger than or equal to two and smaller than or equal to the N; a section of first hole reaming well wall is arranged below the out-of-round oversized complex layer section, one expansion pipe is arranged at the position of the out-of-round oversized complex layer sectionin a sleeved mode, and the inner drift diameter of the expanded expansion pipe is larger than the hole diameter of the Mth well opening layer section and smaller than the inner diameter of the M-1thwell opening casing pipe; and the upper end of the expansion pipe is located above the out-of-round oversized complex layer section, and the lower end of the expansion pipe is located below the out-of-round oversized complex layer section. According to the well bore structure, under the condition that the well bore structure on the upper portion is fixed, the out-of-round oversized complex layer section can be effectively packed under the principle that the hole size is not lost, and therefore continuous safe drilling is achieved.

Owner:PETROCHINA CO LTD +2

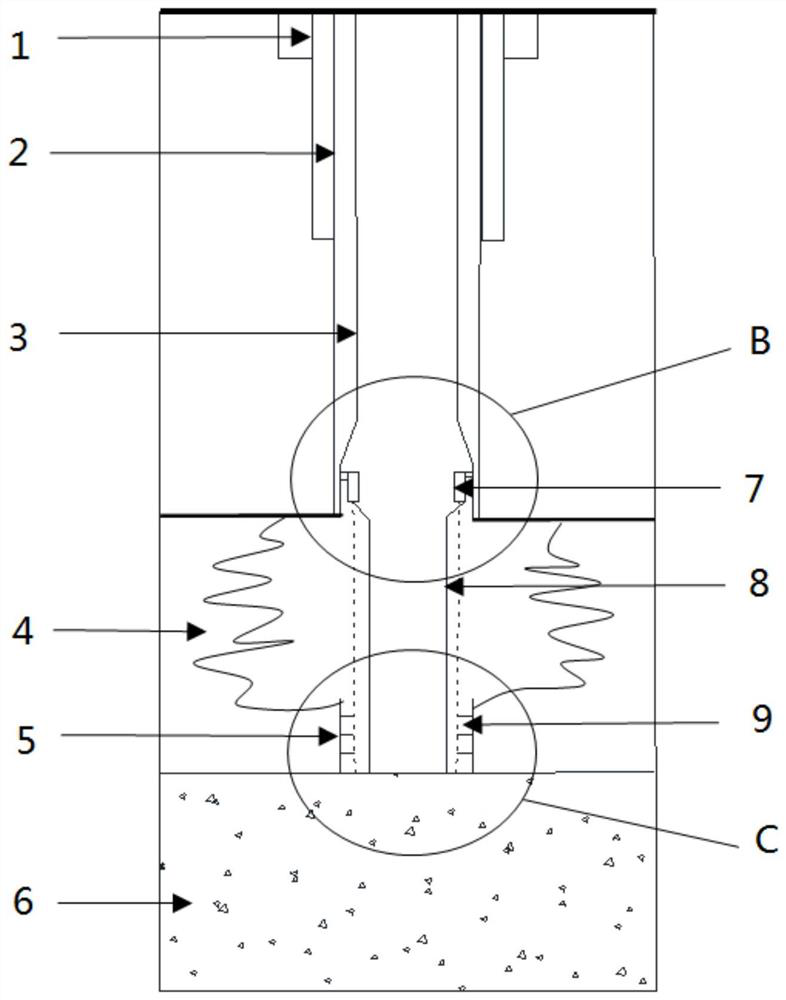

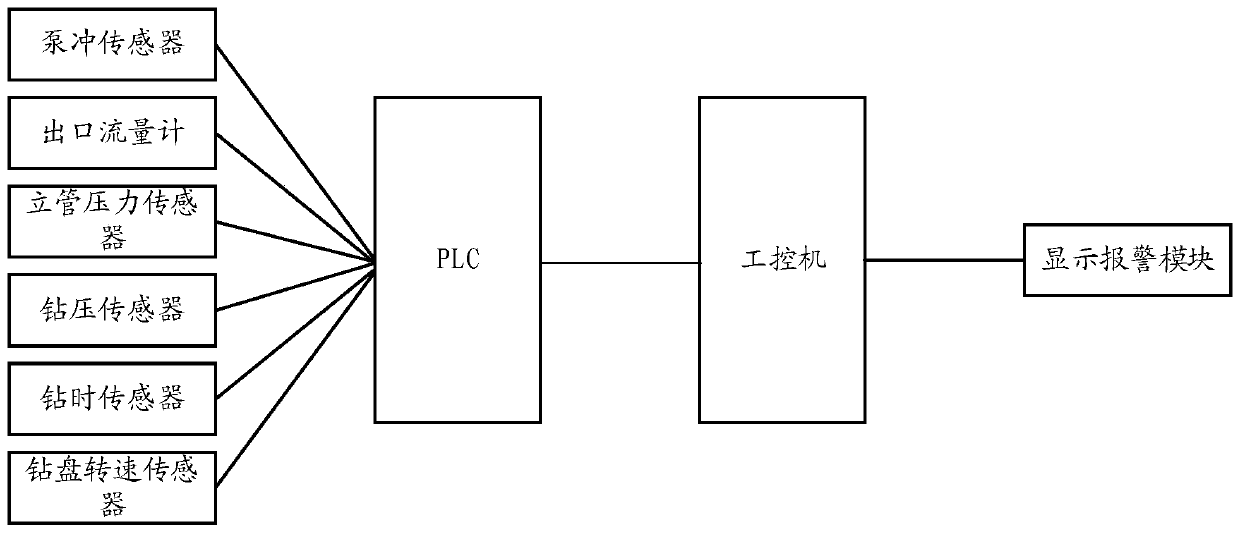

Overflow leakage monitoring and alarm system

PendingCN110529097ASafe drillingDrill quicklySurveyMeasurement devices for drillingPersonal computerPressure sensor

The invention discloses an overflow leakage monitoring and alarm system. The overflow leakage monitoring and alarm system comprises a pump impulse sensor, an outlet flowmeter, a vertical pipe pressuresensor, a drilling time sensor, a drilling pressure sensor, a drilling disc speed sensor, a PLC, an industrial personal computer and a display alarm module; and the pump impulse sensor, the outlet flowmeter, the vertical pipe pressure sensor, the drilling time sensor, the drilling pressure sensor and the drilling disc speed sensor are correspondingly connected with the PLC, the PLC is connected with the industrial personal computer, and the industrial personal computer is connected with the display alarm module. The provided overflow leakage monitoring and alarm system can accurately discoveroverflow and leakage, and provides technical guarantee for safe and rapid drilling well-completion operation.

Owner:XINJIANG GRAND OILFIELD TECH

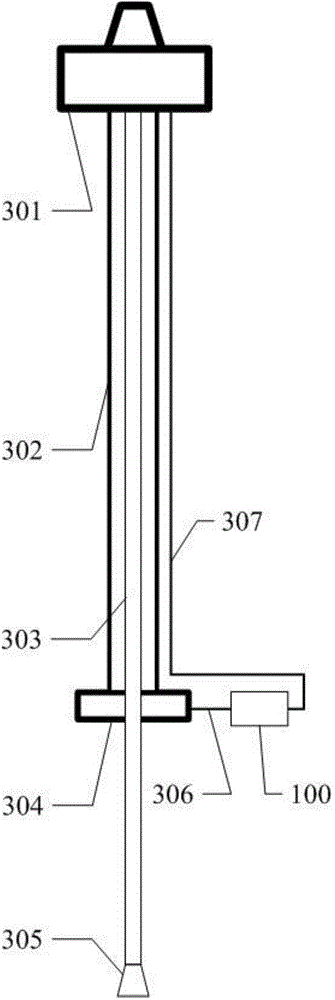

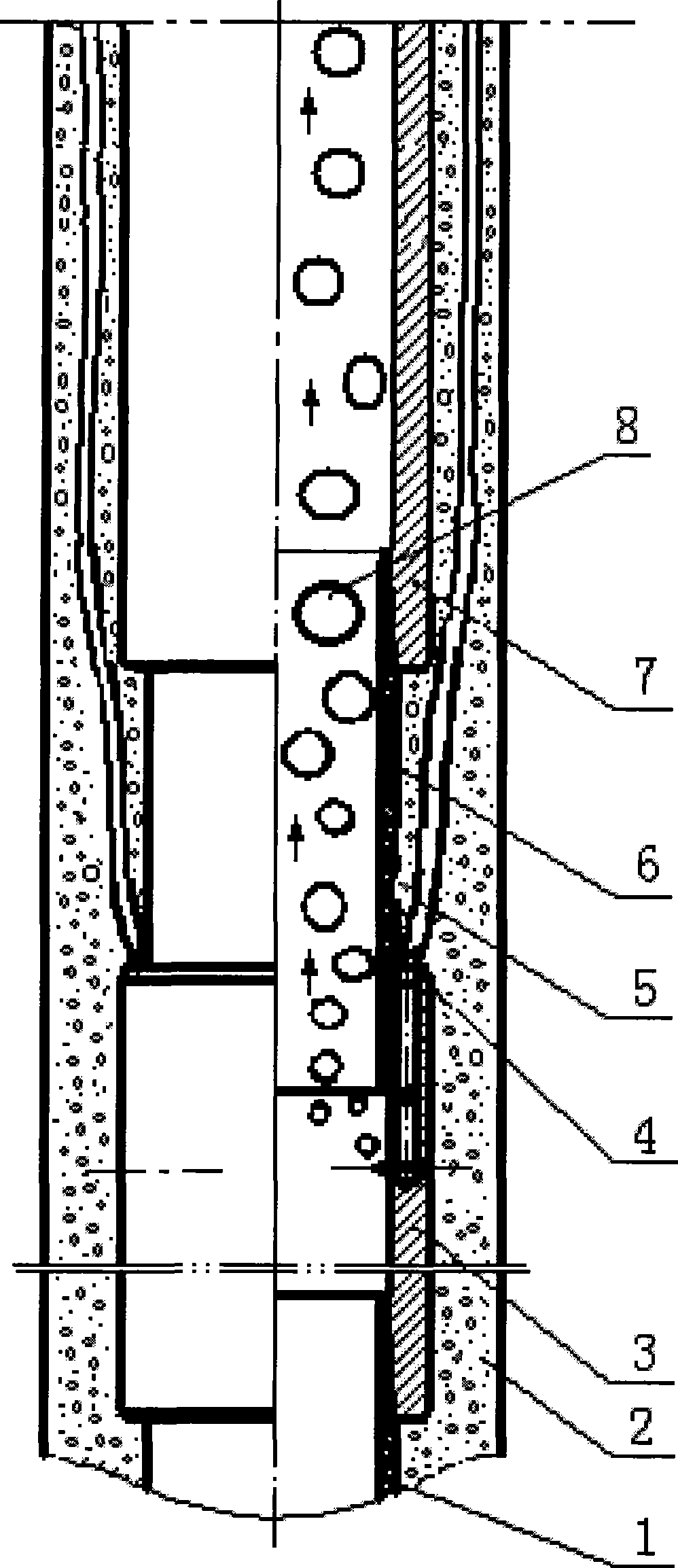

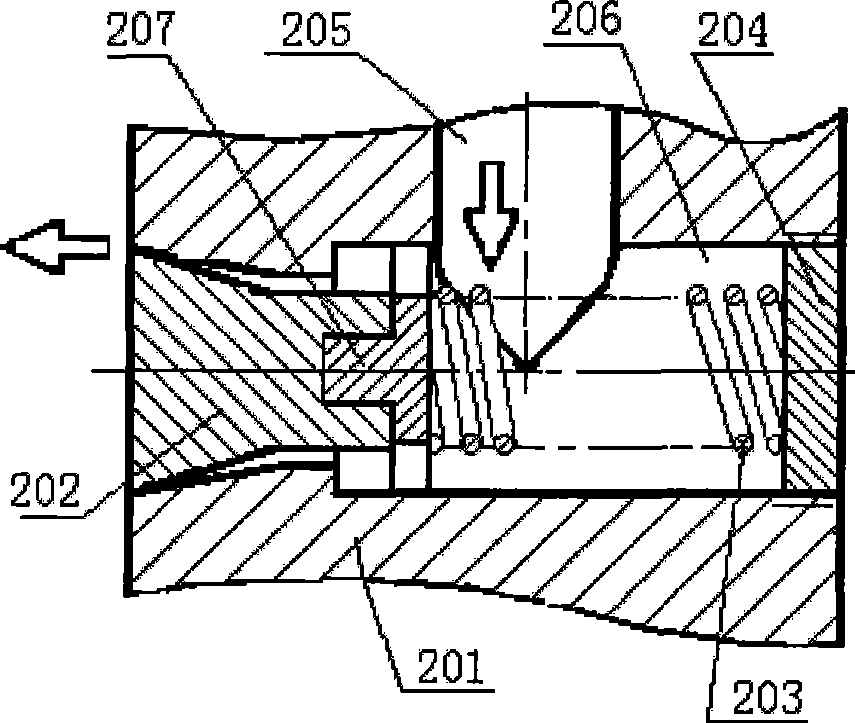

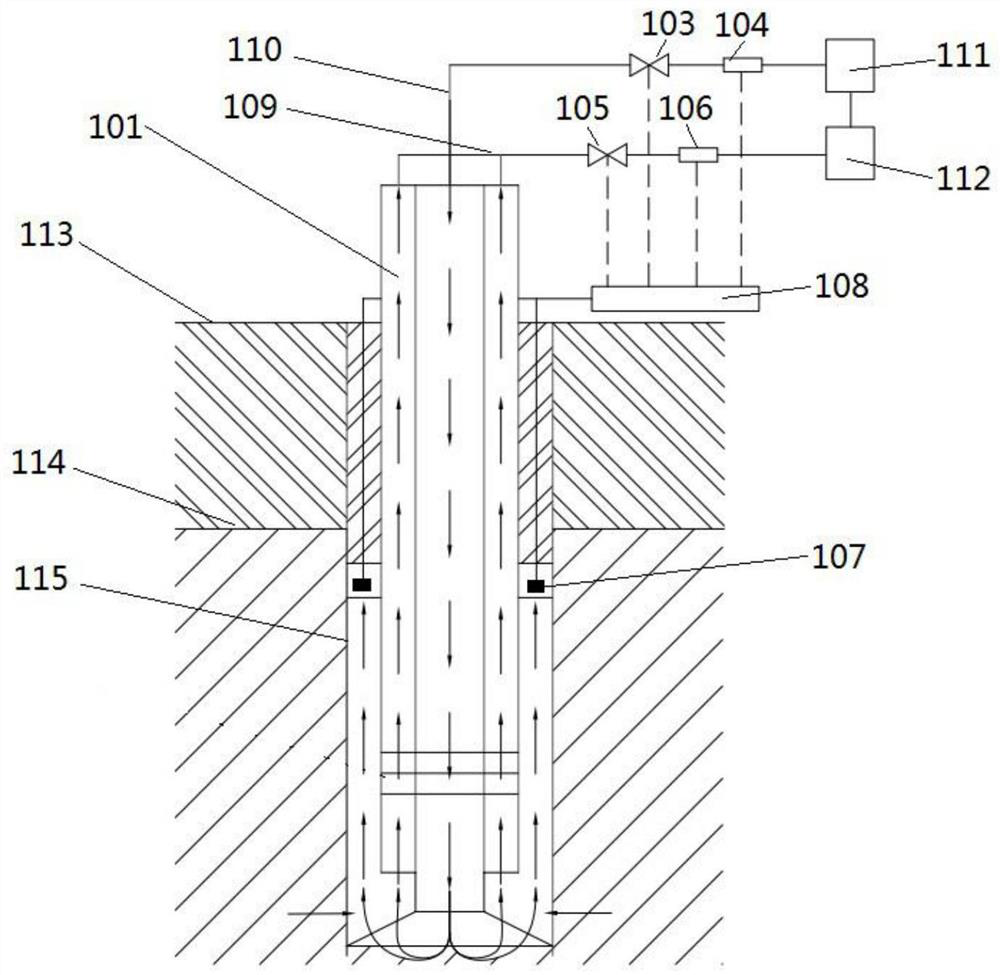

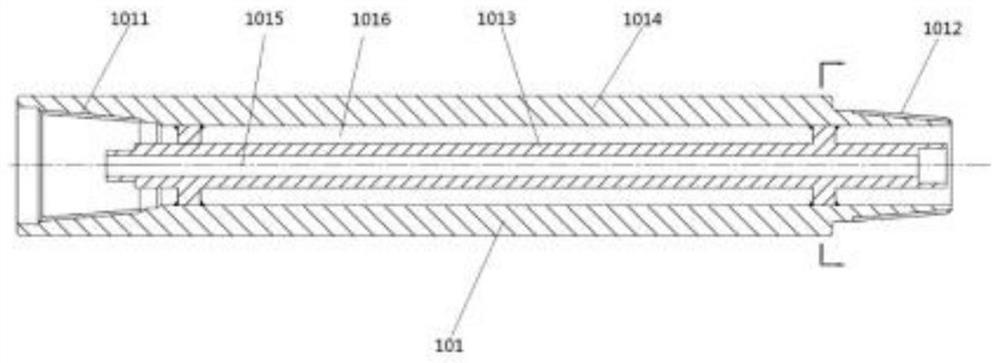

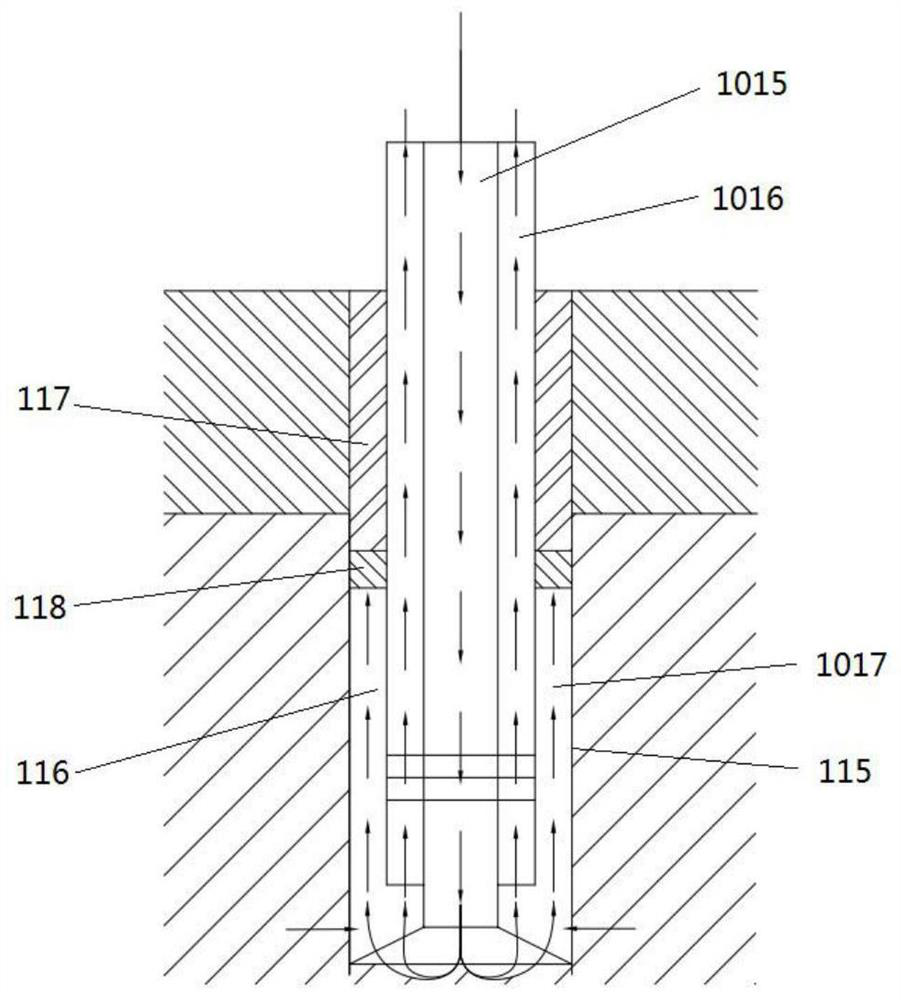

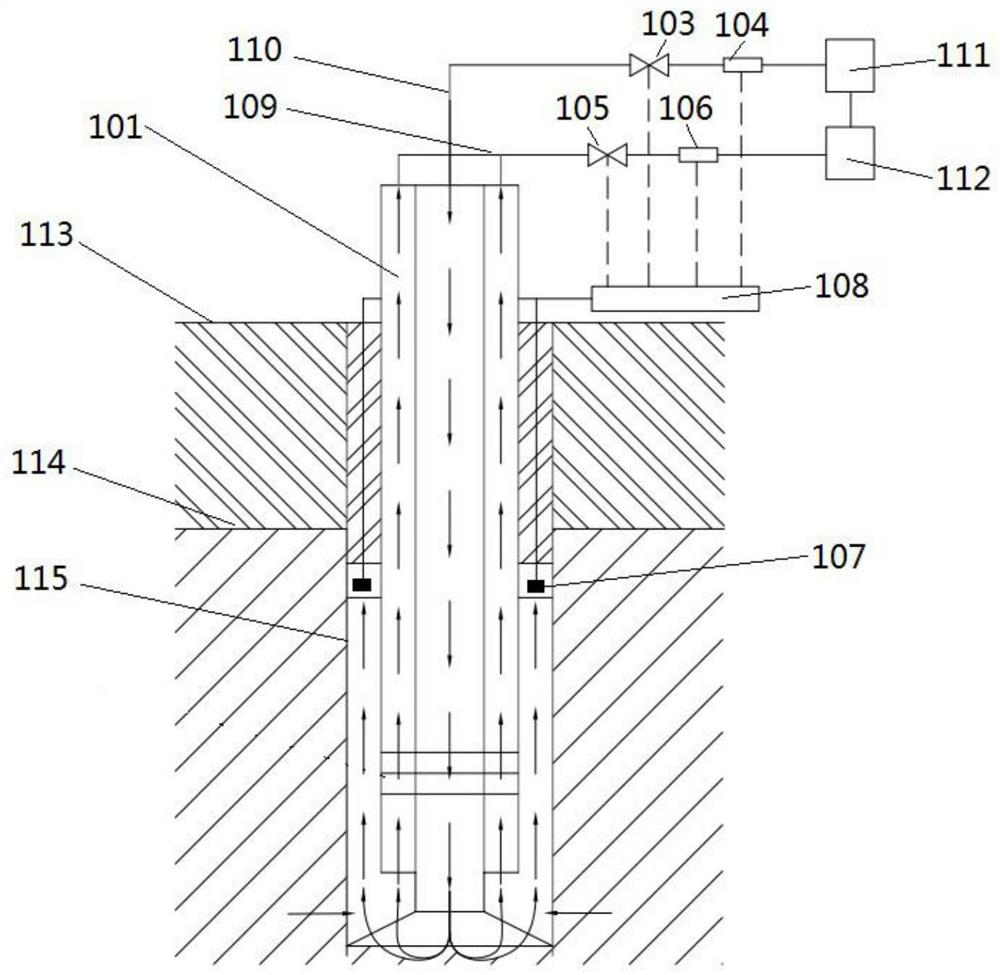

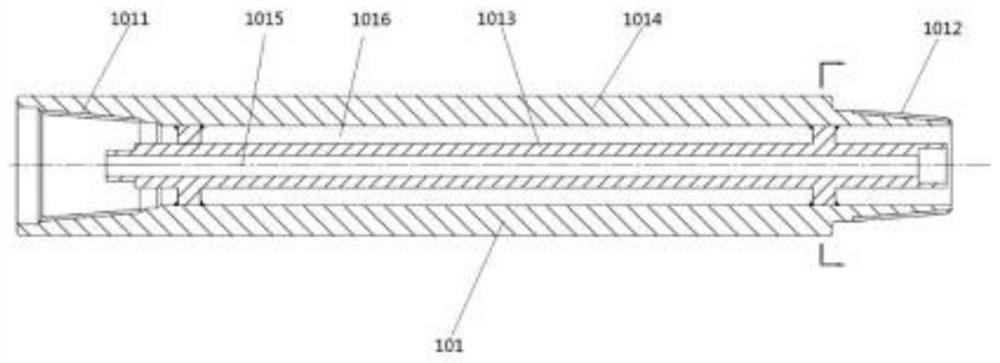

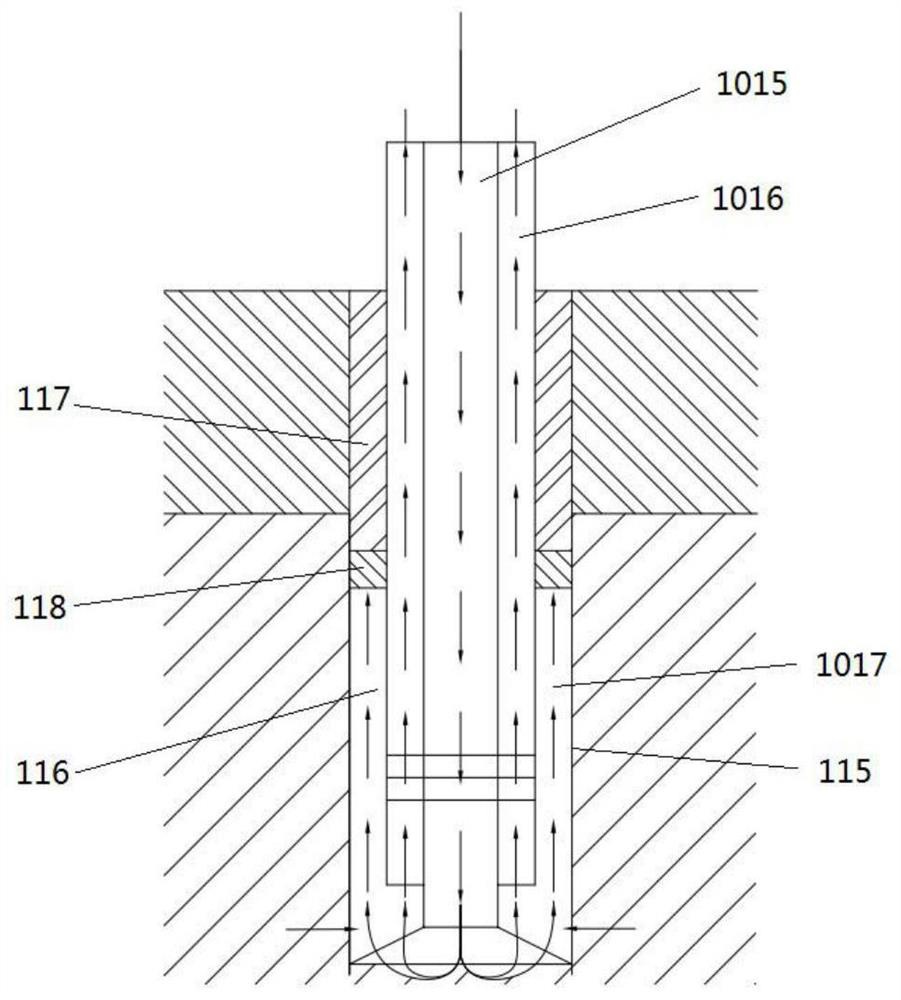

Control system and control method for deep sea double-layer pipe shaft bottom three-channel pressure

ActiveCN111622697AMaintain homeostasisHigh control precisionFlushingAdaptive controlEnvironmental geology

The invention discloses a control system and control method for deep sea double-layer pipe shaft bottom three-channel pressure. The control system comprises a double-layer pipe, a casing pipe, a bit,a transformation joint, an outer sleeve, an axial-flow pump, a turbine motor, a liquid level monitoring sensor, a valve group control unit, a double-layer pipe reflux manifold, a well drilling liquidpump inlet manifold, a well drilling pump and a well drilling liquid circulation jar, wherein the transformation joint is connected to the lower end of the double-layer pipe; the outer sleeve is arranged at the upper half part of the axial-flow pump in a sleeving manner; the axial-flow pump and the outer sleeve are connected to the lower end and the middle part of the transformation joint; the axial-flow pump, the turbine motor and the bit are sequentially connected; the double-layer pipe is arranged in the casing pipe; and the inner pipe, the outer pipe and the casing pipe are concentric tubecolumns. According to the control system disclosed by the invention, three well drilling liquid channels are formed by the two-layer pipe; and lifting performance of the axial-flow pump is changed, so that self-adapting control of bottom hole pressure is realized, and dynamic balance of liquid column pressure of bottom hole well drilling liquid is effectively maintained.

Owner:SOUTHWEST PETROLEUM UNIV

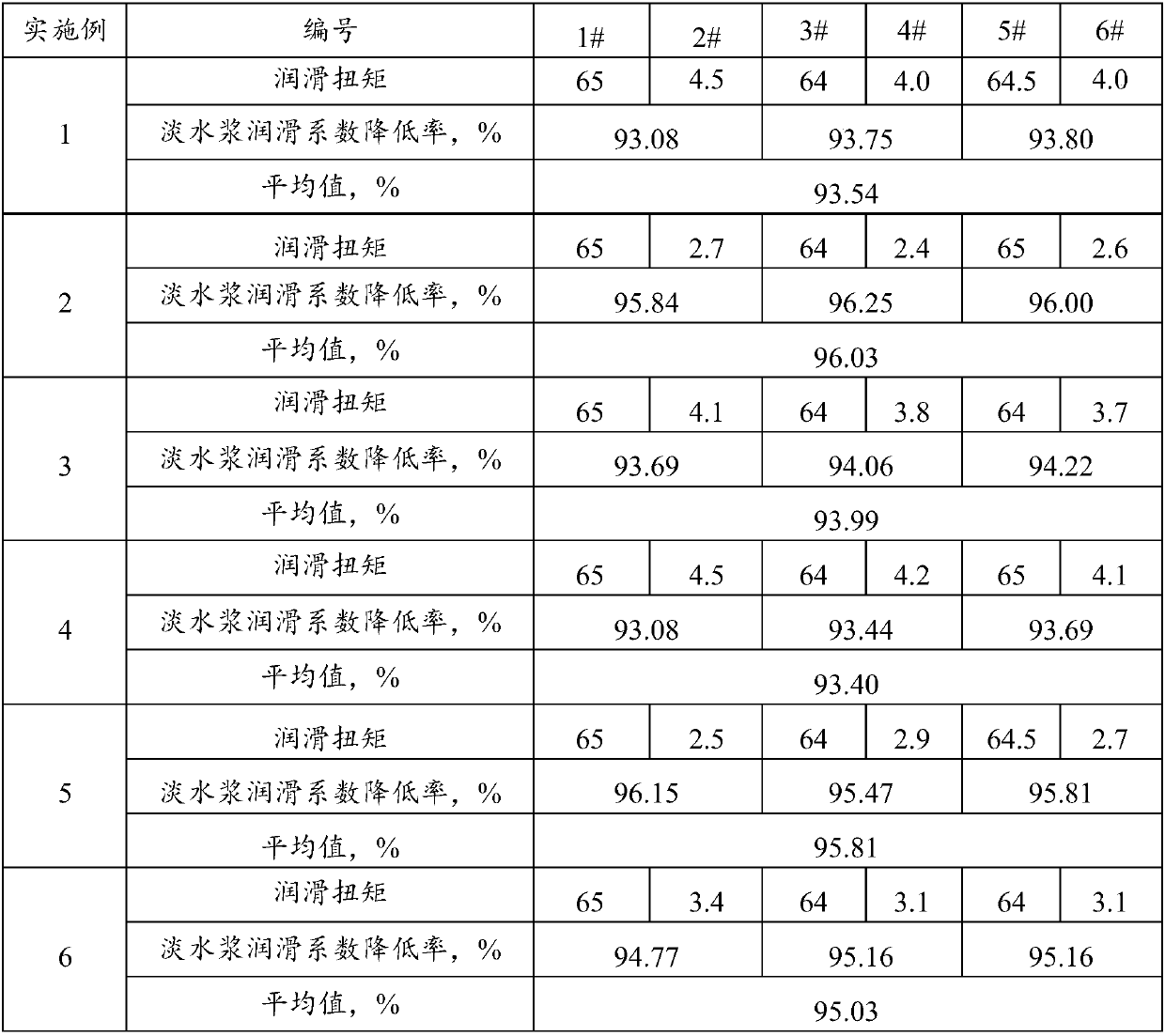

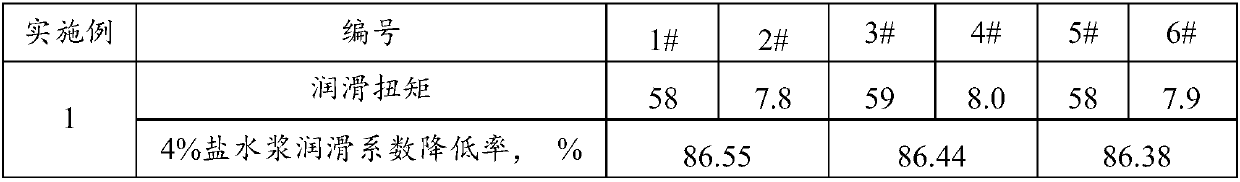

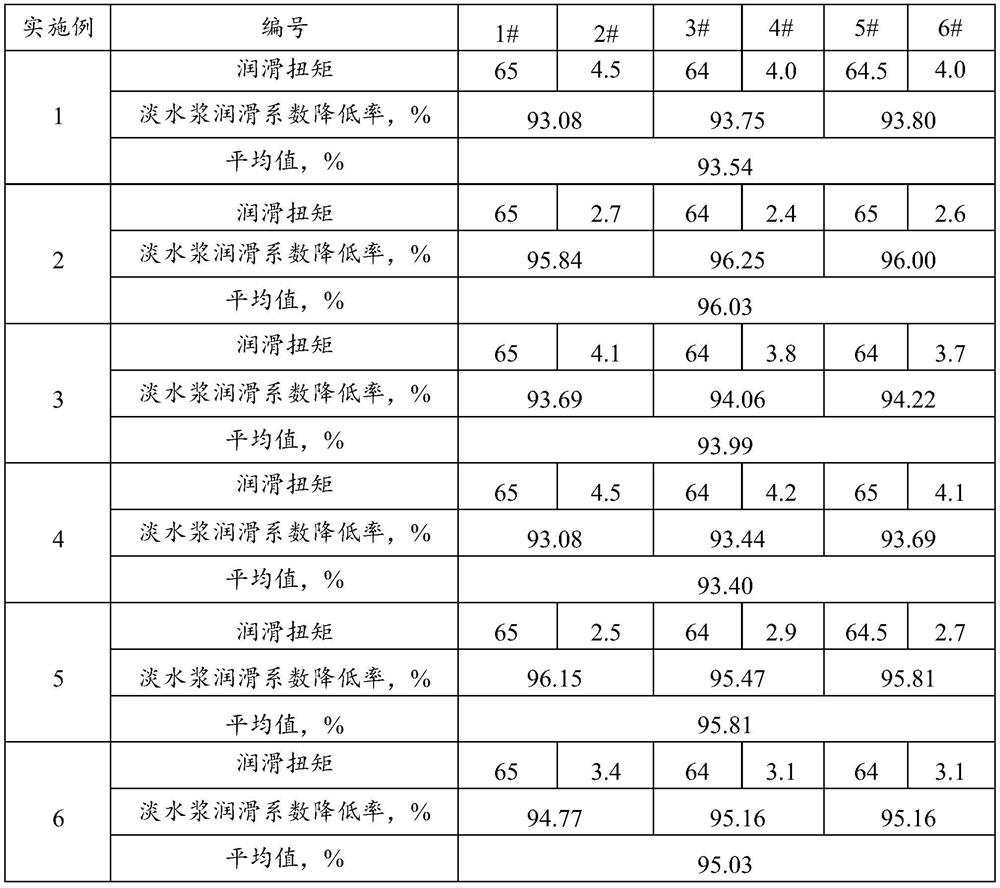

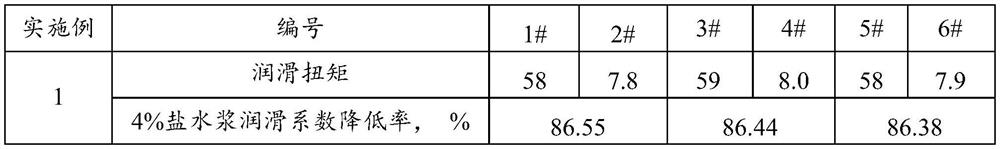

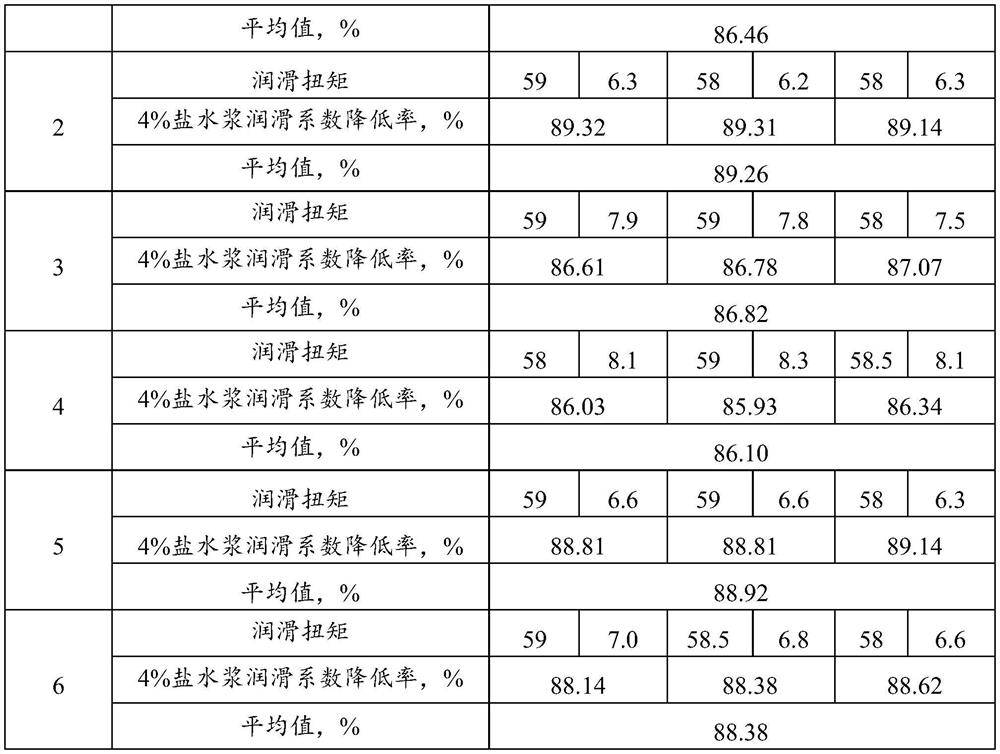

Biomass lubricant for drilling fluids, and preparation method thereof

ActiveCN109666462AThe preparation method is simpleSimple processDrilling compositionEnvironmental resistanceHorizontal wells

The invention provides a biomass lubricant for drilling fluids, wherein the biomass lubricant is prepared from the following raw materials by weight: 15-30 parts of biomass base oil, 3-5 parts of an ionic liquid anti-wear agent, 2-5 parts of an emulsifier, 0.5-1 part of an antifoaming agent, 0.05-0.1 part of a tackifier, and 58-80 parts of water, wherein the biomass base oil is prepared from the fore-distillate of natural fatty alcohol, an organic acid and a lipase catalyst, and the tackifier is high-viscosity sodium carboxymethyl cellulose. Compared with the biomass lubricant in the prior art, the biomass lubricant of the present invention contains the components with the specific contents so as to achieve good interaction, has advantages of strong lubrication, high-temperature resistance, environmental protection, no toxicity and good compatibility, and is suitable for special drilling operations of as large displacement wells, inclined wells, horizontal wells and the like, especially for oil and gas wells with deep reservoirs, high temperature and high pressure.

Owner:中石化石油工程技术服务有限公司 +1

Drilling bit of ice drill for drilling warm ice layer

InactiveCN107630664AReduce widthReduce cutting heatDrill bitsConstructionsMicro nanoPetroleum engineering

The invention discloses a drilling bit of an ice drill for drilling warm ice layer. The drilling bit comprises a drilling bit body, special-shaped cutting tools and pad shoes, wherein the bottom of the drilling bit body is provided with a plurality of water troughs, a channel is formed between the inner cavity and the outer wall of the drilling bit body due to the water troughs, the plurality of special-shaped cutting tools and the pad shoes are fixed on the bottom lip surface of the drilling bit body parallelly, and the bottom of the pad shoes is provided with a plurality of micro-nano bulgesor pits. The drilling bit has the beneficial effect of reducing friction heat of the bottom of the drilling bit. The drilling bit of the ice drill can lower cutting heat, is good for coolinga drilling liquid and carrying flake ice, can effectively prevent a large quantity of flake ice from bonding and gathering, and can drill warm ice layer of the glacier safely and rapidly.

Owner:JILIN UNIV

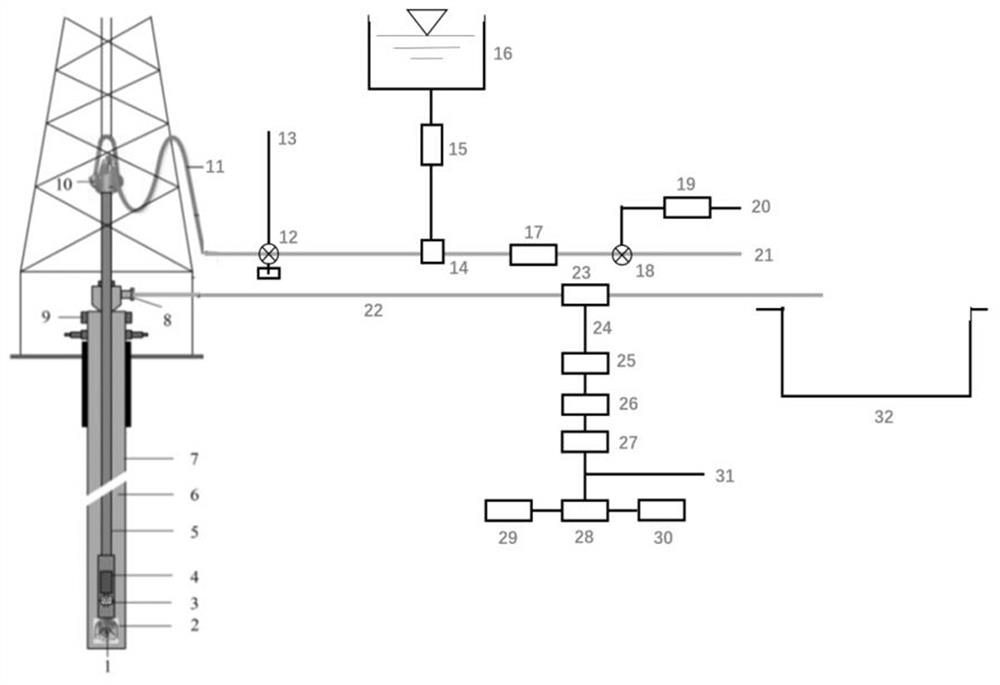

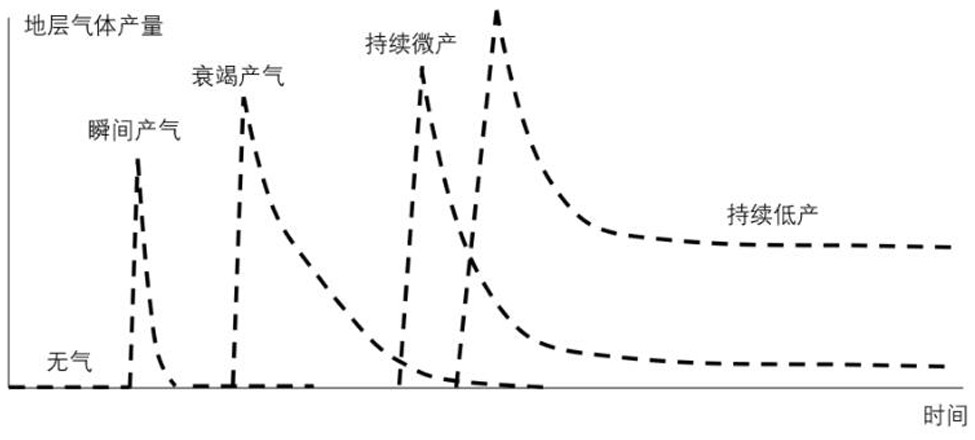

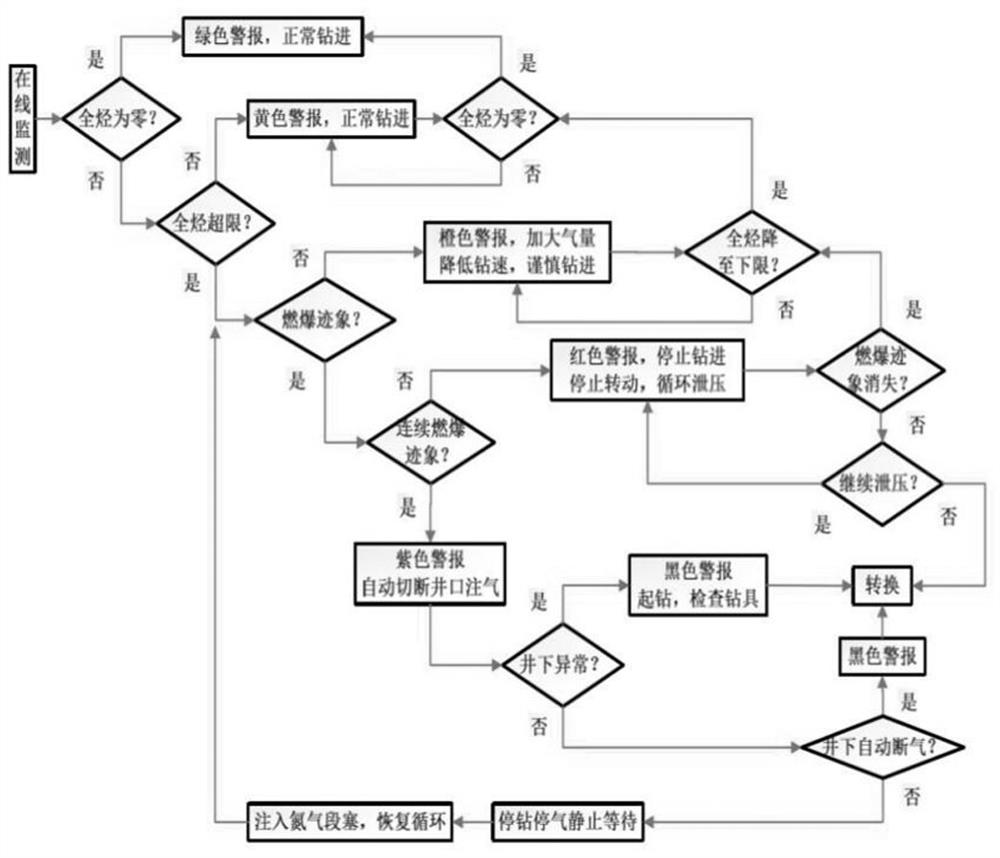

Method for preventing underground burning and explosion in non-reservoir air drilling

ActiveCN113073960AAvoid explosionThe principle of the method is reliableSurveyConstructionsPhysicsCarbon dioxide

The invention relates to a method for preventing underground burning and explosion in non-reservoir air drilling. The method comprises the following steps that pressure, temperature, flow, humidity and oxygen concentration sensors are mounted on a gas injection pipeline; pressure, temperature and humidity sensors are arranged inside and outside the 2 / 3 part of the whole length of a sand discharging pipeline; a gas sampling pipeline is connected to the position about 2 / 3 of the whole length of the sand discharging pipeline; gas enters a gas monitoring pipe section after being subjected to dust removal, dehydration and drying treatment, and the monitoring pipe section is provided with an oxygen concentration sensor, a carbon monoxide concentration sensor, a carbon dioxide concentration sensor, a nitrogen oxide concentration sensor, a hydrogen sulfide concentration sensor, a methane concentration sensor, a formaldehyde concentration sensor and an acetaldehyde concentration sensor; the monitoring pipe section is connected with an infrared total hydrocarbon component sensor and a gas chromatograph; and identification while drilling of the oil-gas-containing stratum, identification of the underground burning and explosion state or dynamic decision and implementation of underground burning and explosion control are carried out. By means of the method, underground burning and explosion possibly occurring when air drilling encounters a micro oil-gas-containing stratum can be effectively prevented, and safe, rapid and low-cost drilling of a non-reservoir stratum is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

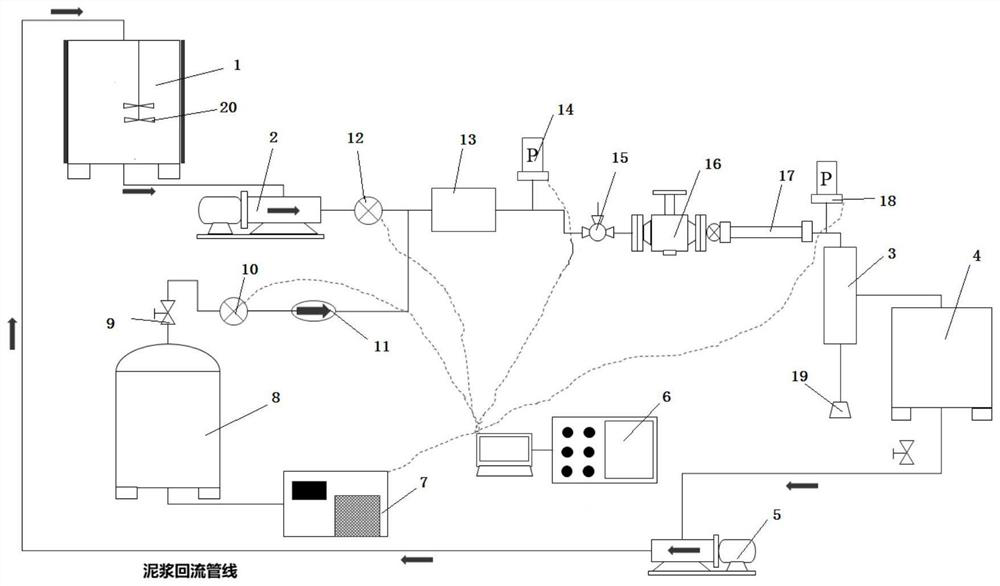

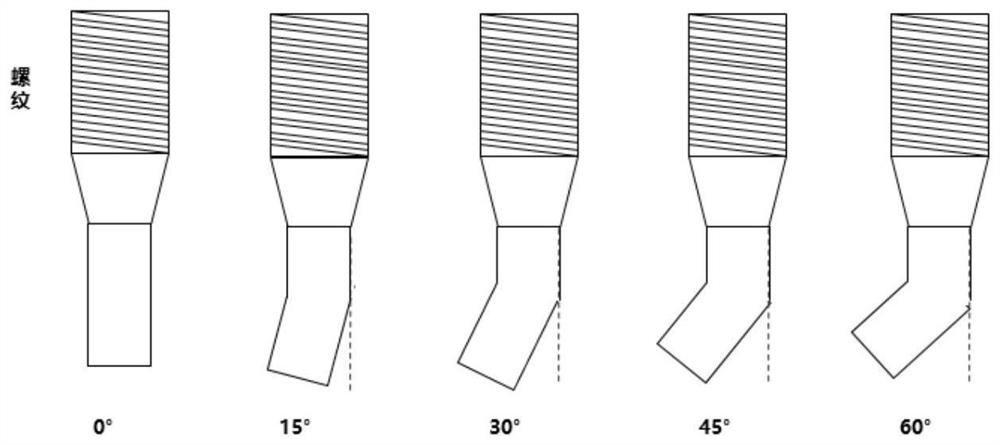

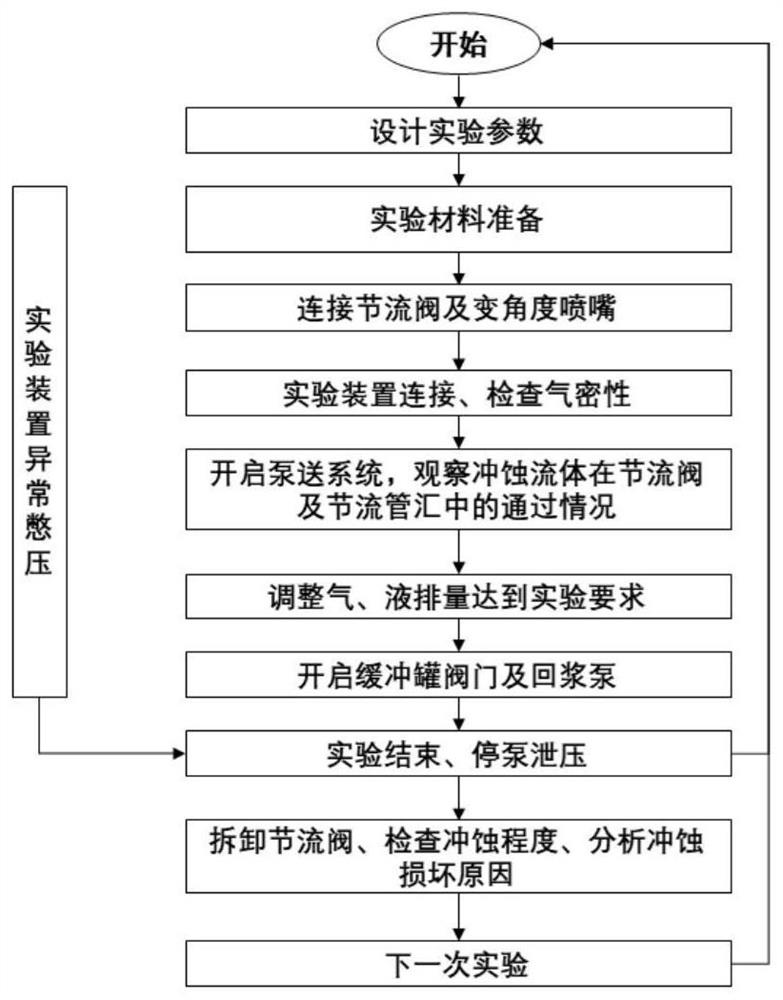

Method for testing erosion resistance of throttle valve of three-high oil-gas well

PendingCN112082891ARapid drillingEvaluation reliabilityInvestigating abrasion/wear resistanceEnvironmental geologyMechanics

The invention discloses a method for testing erosion resistance of a throttle valve of a three-high oil-gas well. The method comprises the following steps: designing experimental parameters; preparingexperimental materials; connecting the throttle valve and the variable-angle nozzle; connecting a test device to check air tightness; starting a pumping system, and observing the passing condition ofthe erosion fluid in the throttle valve and the throttle manifold; adjusting the gas and liquid discharge capacity to meet the experimental requirements; opening a valve of the buffer tank and a slurry return pump; after the experiment is finished, stopping the pump to release pressure; disassembling the throttle valve, checking the erosion degree, and analyzing the erosion damage reason; and carrying out next experiment. According to the invention, the erosion effect of throttling well killing on the throttle valve and the throttle manifold can be accurately and visually simulated under thecondition of mixed gas heavy mud, and the reliability and erosion resistance of the throttle valve and the conformity and adaptability of the throttle valve to well control technical process requirements are evaluated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Acid fracturing pipe column ball seat capable of fishing and being used repeatedly

ActiveCN103089229ASimple structureSimple installation and disassemblyFluid removalAcid fracturingCoupling

The invention discloses an acid fracturing pipe column ball seat capable of fishing and being used repeatedly. The acid fracturing pipe column ball seat is characterized in that an inward opening window fishing cylinder is connected to the bottom of a ball seat body of an acid fracturing pipe tail; a ball falling prevention ball seat is connected to the interior of the ball seat body of the acid fracturing pipe tail through a pin; the ball falling prevention ball seat and a ball seat outer cylinder fishing head are hooked by a shoulder and connected through the pin; the ball seat outer cylinder fishing head and a ball seat basket (a centralizing cylinder) are connected through an oil pipe coupling; by an elastic centralizer, the whole ball seat which is hit to fall off can be basically positioned in the center of a borehole for fishing; and by a bull nose ( a guiding shoe), the conditions that the elastic centralizer slips off through the outer wall of the ball seat basket (the centralizing cylinder), and after the pin of the ball falling prevention ball seat and the ball seat outer cylinder fishing head is cut off, the ball falling prevention ball seat and the ball seat outer cylinder fishing head fall into a downhole through the ball seat basket (the centralizing cylinder) and become falling substances can be avoided. When an acid fracturing pipe column is tripped, the ball seat and other accessories which are hit to fall to the downhole before acid fracturing can be fished directly at one time; and the acid fracturing pipe column ball seat can be used repeatedly and is safe and reliable.

Owner:新疆聚航石油工程技术有限公司

Automatic control system and method for underground annulus pressure of deep water surface layer drilling

ActiveCN102797451BRealize automatic adjustmentReduce biasAutomatic control for drillingAutomatic controlStream flow

The invention relates to an automatic control system and method for underground annulus pressure of deep water surface layer drilling. The system comprises three pipelines which are respectively arranged in a heavy slurry pond, a seawater pond and a treating agent pond, wherein each pipeline is connected with the input end of a mixer, the output end of the mixer is connected with an outflow pipeline, and the outflow pipeline is connected with a pup joint of a seabed underground PWD. Each pipeline is internally provided with a power pump, a regulating valve and an inlet flow meter, and the outflow pipeline is internally provided with an outlet flow meter. The underground PWD is connected with an MWD, a signal receiving device of the MWD is in communication connection with a remote computer control system, the remote computer control system is connected with a logging system and a PLC (Programmable Logic Controller) control system through a data bus, and the PLC control system is connected with the regulating valve, the inlet flow meter, the mixer and the outlet flow meter through data. According to the invention, a secondary microcomputer control system is created through the remote computer control system and the PLC control system, so that the mixing proportion of heavy slurry and seawater is automatically regulated, and drilling slurry with required density and flow is input to the underground to carry out underground pressure balance regulation to further realize safe drilling.

Owner:CHINA NAT OFFSHORE OIL CORP +1

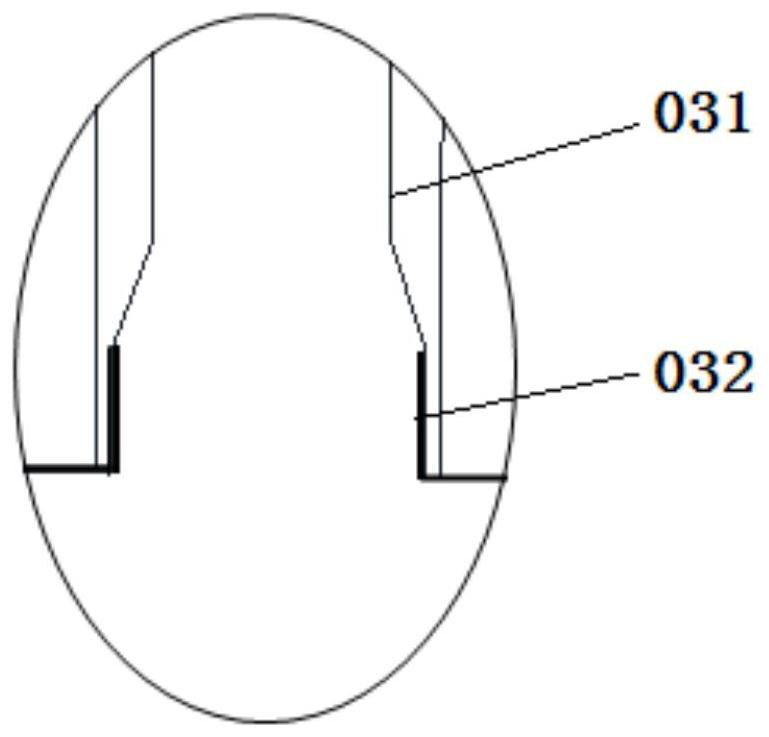

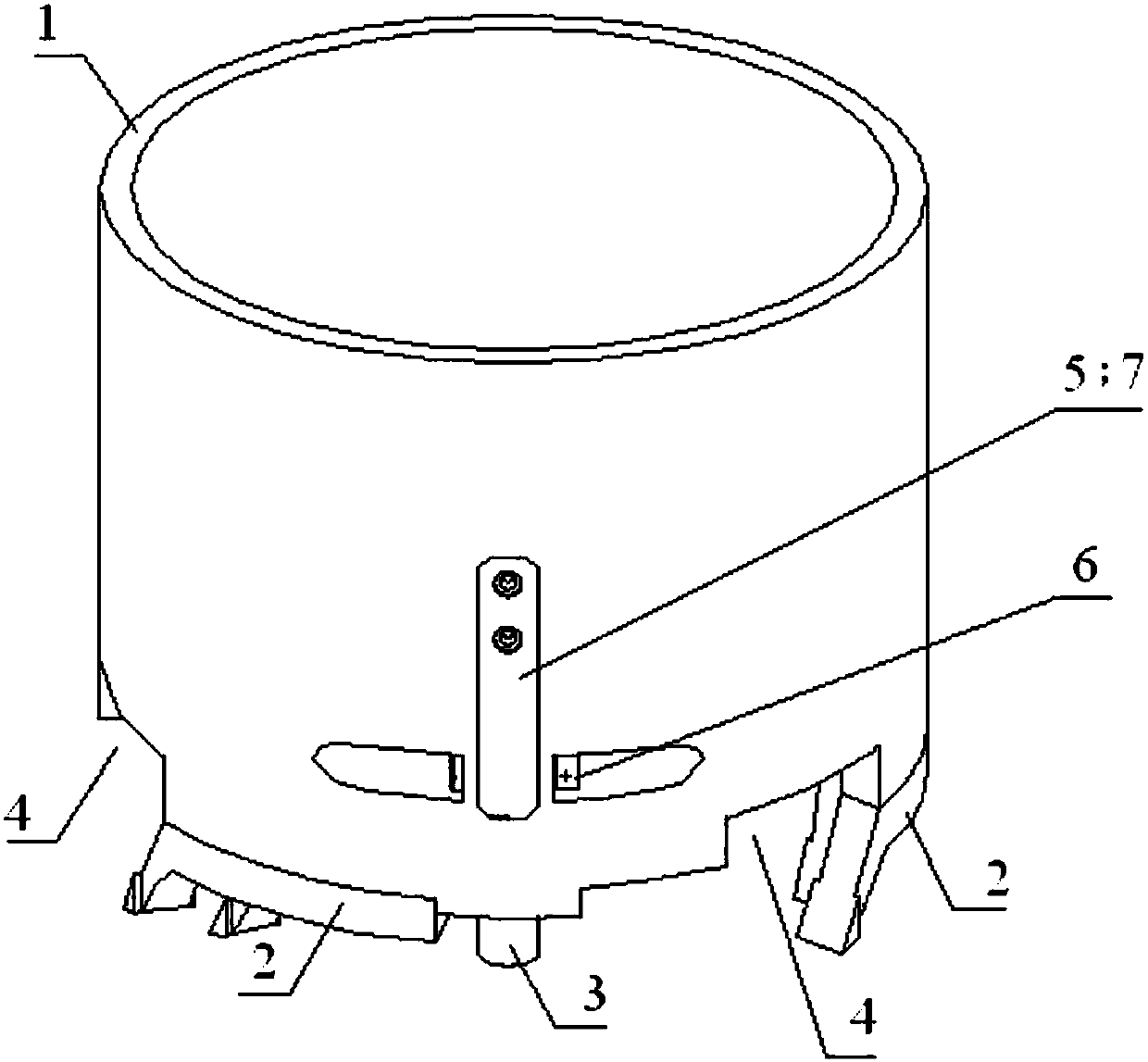

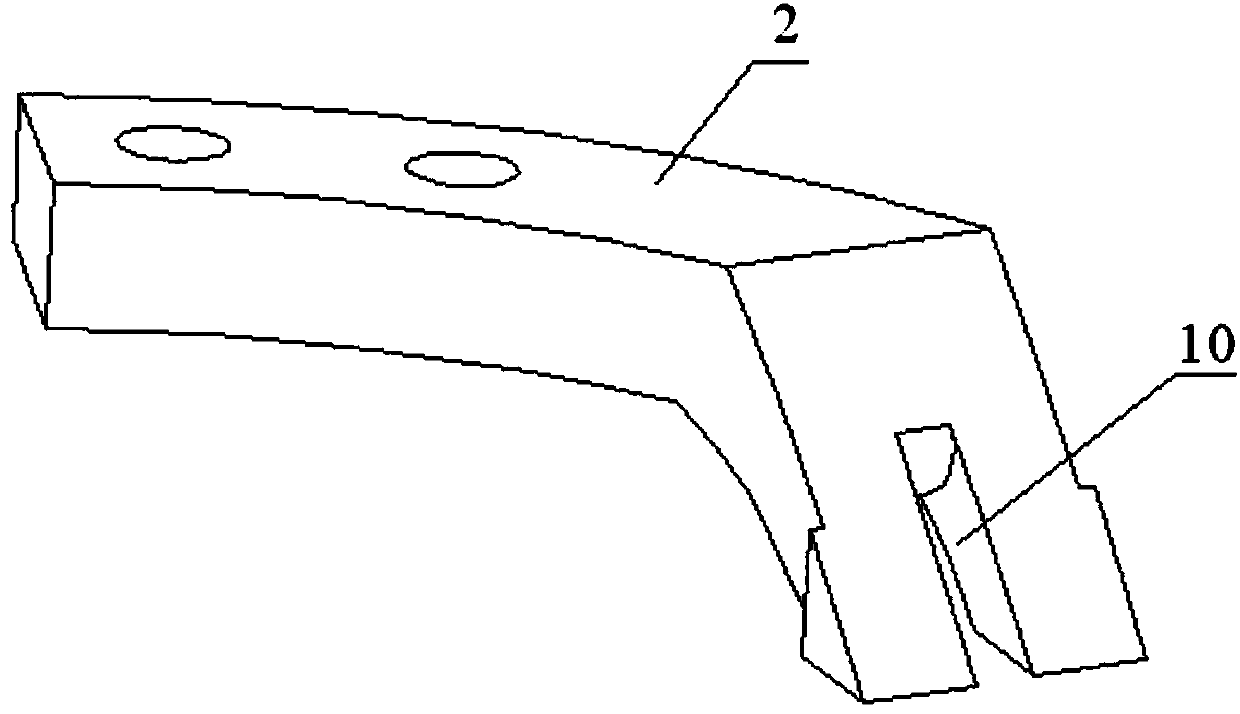

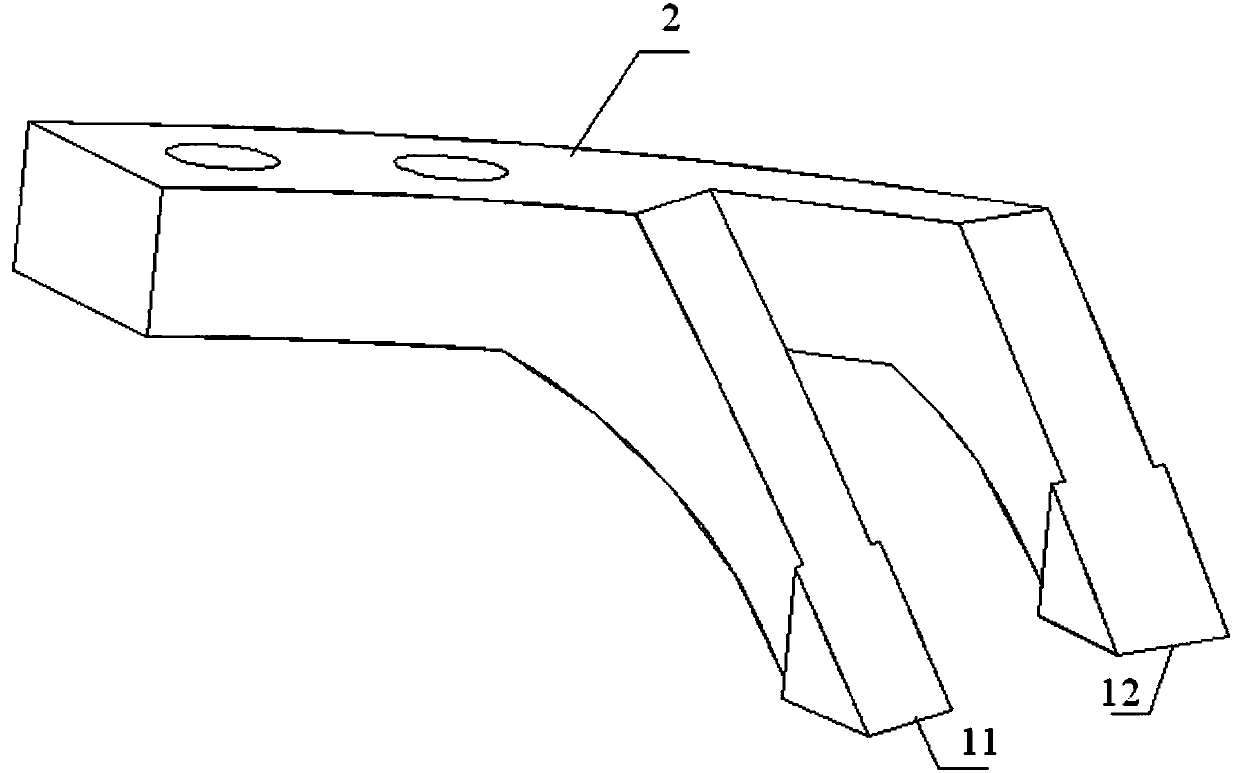

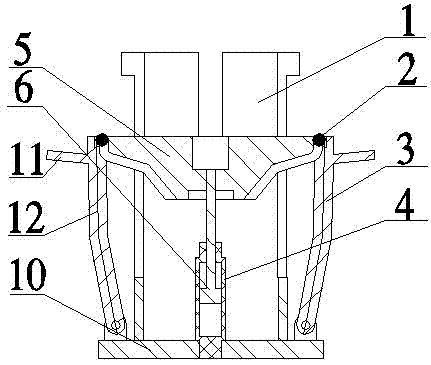

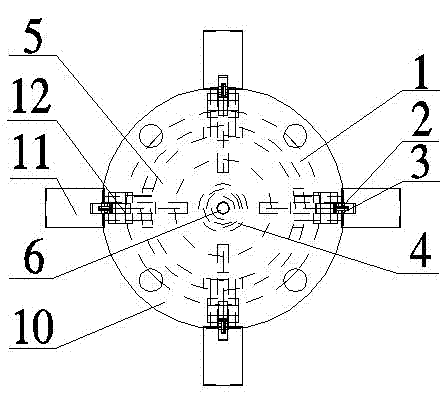

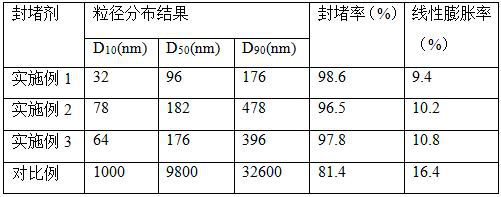

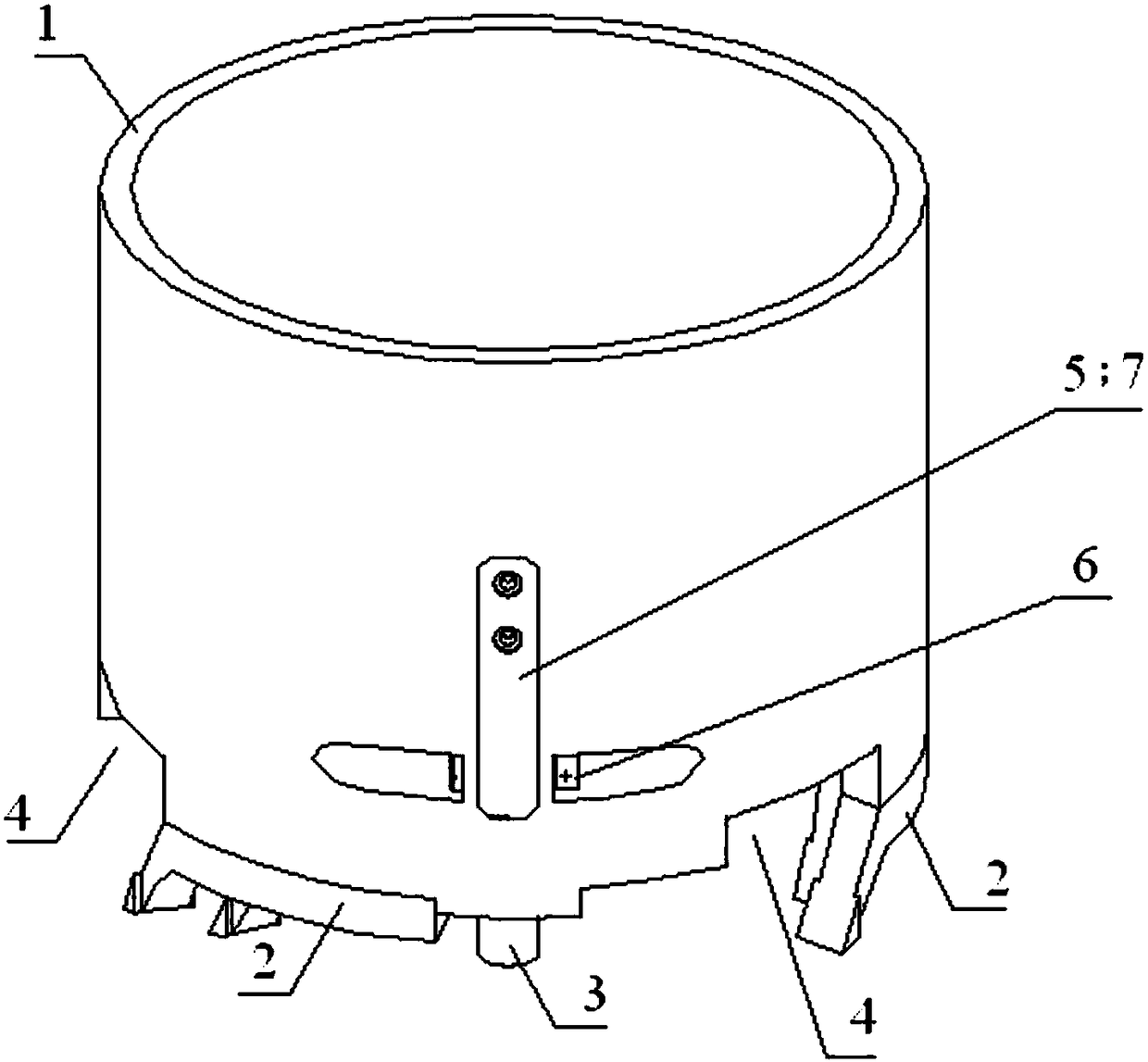

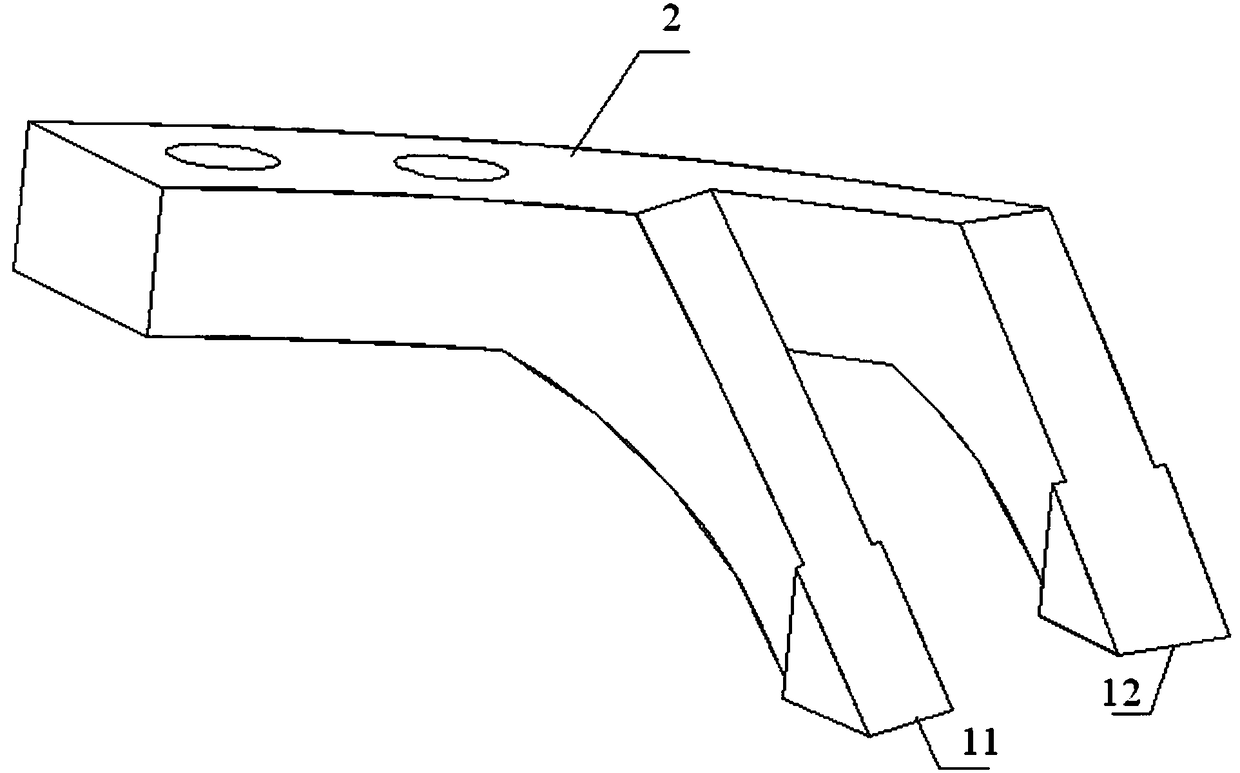

Supporting structure

InactiveCN103359270ASafe drillingEasy to drillVessel salvagingUnderwater equipmentHydraulic cylinderMotion generation

The invention provides a supporting structure which is applicable to a move-in-mud robot and has a supporting effect in soil. The invention aims to provide a supporting mechanism for providing enough friction force so as to reduce the influence on the movement of the move-in-mud robot by backward movement friction force generated by forward movement of the move-in-mud robot and guarantee the working efficiency of the move-in-mud robot. The supporting mechanism comprises a barrel wall (1), an roller wheel (2), a supporting rod (3), a sleeve (4), a slide block (4) and a piston rod (6), wherein the supporting rod is connected with the barrel wall and the roller wheel through pins respectively; the slide block is embedded in the sleeve; a hydraulic cylinder is fixedly connected with the slide block. The concertina movement of the hydraulic cylinder drives the slide block to move in an axial direction so as to enable the supporting rod to do expansion movement to achieve the supporting effect. The mechanism is simple in design and is economical and practical; the supporting structure is driven by hydraulic pressure and can provide enough power, so as to achieve the supporting effect.

Owner:解明强

A kind of curing plugging agent and its preparation method and plugging slurry

The invention relates to a solidified plugging agent in the field of oil drilling plugging, a preparation method thereof, and a plugging slurry; the cured plugging agent includes the following components in parts by weight: 100 parts of curing agent, 0.4 to 0.4 parts of activator 1.2 parts, 0.2-1 parts of viscosity reducer, 0.5-1.5 parts of dispersant, 4-10 parts of suspending agent, 1-5 parts of fiber crosslinking agent; the temperature resistance of the plugging slurry prepared by the solidified plugging agent is greater than 120°C , the pressure bearing capacity of the plugging slurry after curing is greater than 10 MPa, it can accommodate 20% of asphalt heavy oil, and the strength after curing is greater than 3.0 MPa. The cured plugging slurry of the present invention has good compatibility with asphalt, and can effectively block the asphalt loss layer. Reduce the occurrence of complicated situations; with the deepening of petroleum exploration and development, drilling encounters more and more complex geological environments. The solidified lost circulation slurry of the present invention can seal lost circulation layers in complex geological environments of asphalt layers to ensure drilling safety. Drill faster.

Owner:CHINA PETROLEUM & CHEM CORP +1

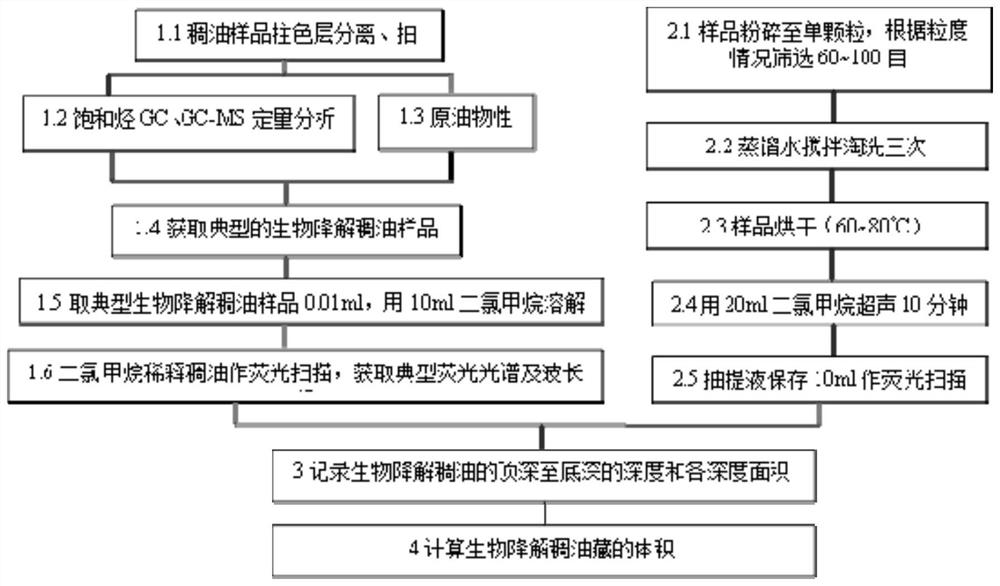

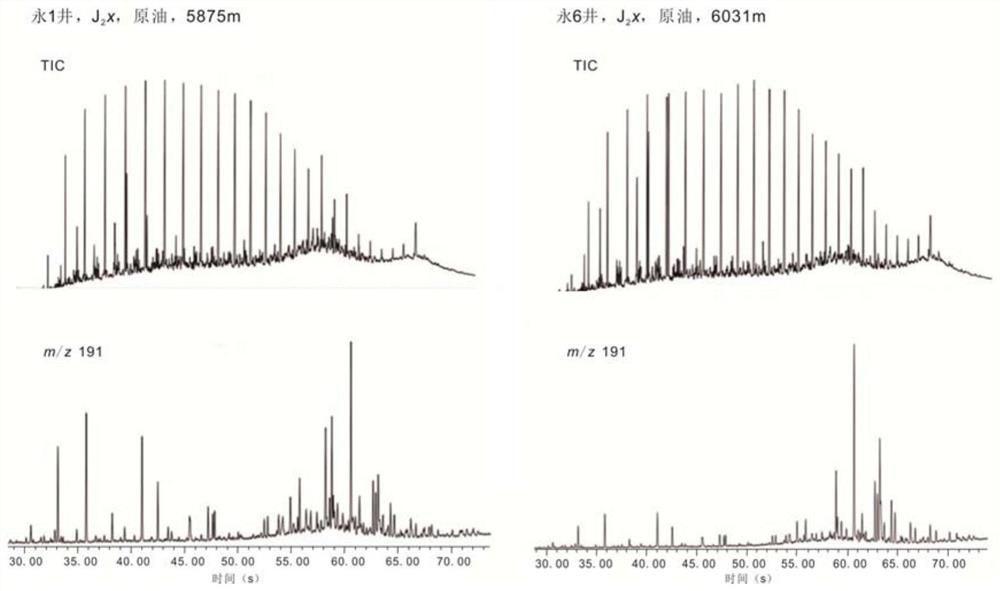

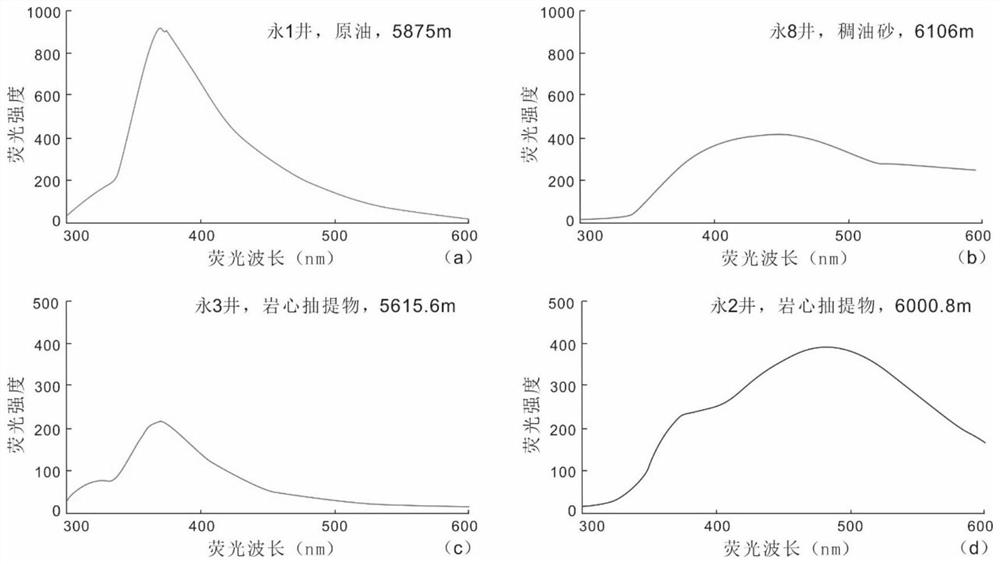

Method for depicting range of biodegradable heavy oil reservoir

PendingCN114441484AEffective predictionSafe and fast drillingFluorescence/phosphorescenceFluorescence spectraWell drilling

The invention belongs to the technical field of oil and gas geochemical exploration, and particularly relates to a method for depicting a biodegradable heavy oil reservoir range. Comprising the following steps: determining a typical biodegradable heavy oil standard sample by combining physical properties of crude oil; obtaining the typical fluorescence spectrum of the biodegradable thickened oil and the wavelength range W of the peak of the fluorescence spectrum; the to-be-detected thick oil sample component is dissolved in the extracting solution; identifying the components of the to-be-detected thickened oil sample with the fluorescence spectrum wave peak wavelength range within W; and calculating the volume of the heavy oil reservoir to obtain the range of the biodegradable heavy oil reservoir. According to the physical properties of the biodegradable thickened oil, saturated hydrocarbon biomarker compound parameters and fluorescence characteristics, a typical fluorescence spectrum and a wave crest wavelength range of the biodegradable thickened oil are obtained, hydrocarbons in a reservoir are screened, the ranges of the biodegradable thickened oil in the vertical direction and the plane are depicted, the volume of the deep biodegradable thickened oil is calculated, and the volume of the deep biodegradable thickened oil is calculated. And the range of the heavy oil reservoir can be predicted, so that safe and rapid drilling is effectively guided.

Owner:CHINA PETROLEUM & CHEM CORP +1

A deep-sea double-tube bottomhole three-channel pressure control system and control method

ActiveCN111622697BMaintain dynamic balanceAchieving Adaptive ControlFlushingAxial-flow pumpDynamic balance

Owner:SOUTHWEST PETROLEUM UNIV

Well killing polyacrylamide strong gel and preparation method thereof

The invention discloses a polyacrylamide strong gel for well control and a preparation method thereof. The polyacrylamide strong gel for well control consists of the following components in percentage by weight: a base solution comprising 1-6% of polyacrylamide, 2-8% of a structure reinforcing agent, 0.4-8% of an anti-dehydrating agent, 0.2-4% of an antioxidant and the balance of water according to the total solution mass of the prepared polyacrylamide strong gel for well control, and 0.2-10% of a crosslinking agent relative to the mass fraction of the base solution. The polyacrylamide strong gel prepared by the preparation method has the characteristics of high strength, good elasticity, good toughness, good adhesion, high compression strength, good gas tightness and the like, can be directly gelatinized and used in an N80 tube special for an oil field, can be adhered to a sleeve, and can effectively prevent gas from escaping out of a pit shaft to achieve good effects of well control and sealing.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

An easy-to-drill bridge plug for open-hole wells

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of emulsified drilling fluid with high density and low oil-water ratio for shale horizontal well

ActiveCN106566496BHigh breaking voltageHigh densityDrilling compositionEthylenediamineHorizontal wells

The invention discloses an emulsion drilling fluid with high density and low oil-water ratio for a shale horizontal well. The emulsion drilling fluid is prepared from raw materials in parts by weight as follows: 180 parts of 3# white oil, 120 parts of a 30% calcium chloride solution, 2-5 parts of a main emulsifier, 4-8 parts of an auxiliary emulsifier, 12-18 parts of a reversible emulsifier, 5-10 parts of calcium oxide, 2-5 parts of organic soil, 3-8 parts of a blocking agent, 0.5-3 parts of an extracting agent, 6-12 parts of calcium carbonate and 0-800 parts of barytes, wherein the main emulsifier is prepared from tall oil fatty acid and maleic anhydride, the auxiliary emulsifier is prepared from high-level fatty acid salt and high-level fatty acid polyol ester, the reversible emulsifier is prepared from methyl 9-octadecenoate and hydroxyethyl ethylenediamine, and the extracting agent is prepared from styrene, methyl methacrylate and hexadecyl acrylate. The oil-water ratio is 6:4, and the emulsion drilling fluid has higher inhibition dispersibility and blocking capacity, good lubricating property and good heat-resisting property and can be suitable for meeting the drilling requirement of a horizontal section of the shale deep well.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

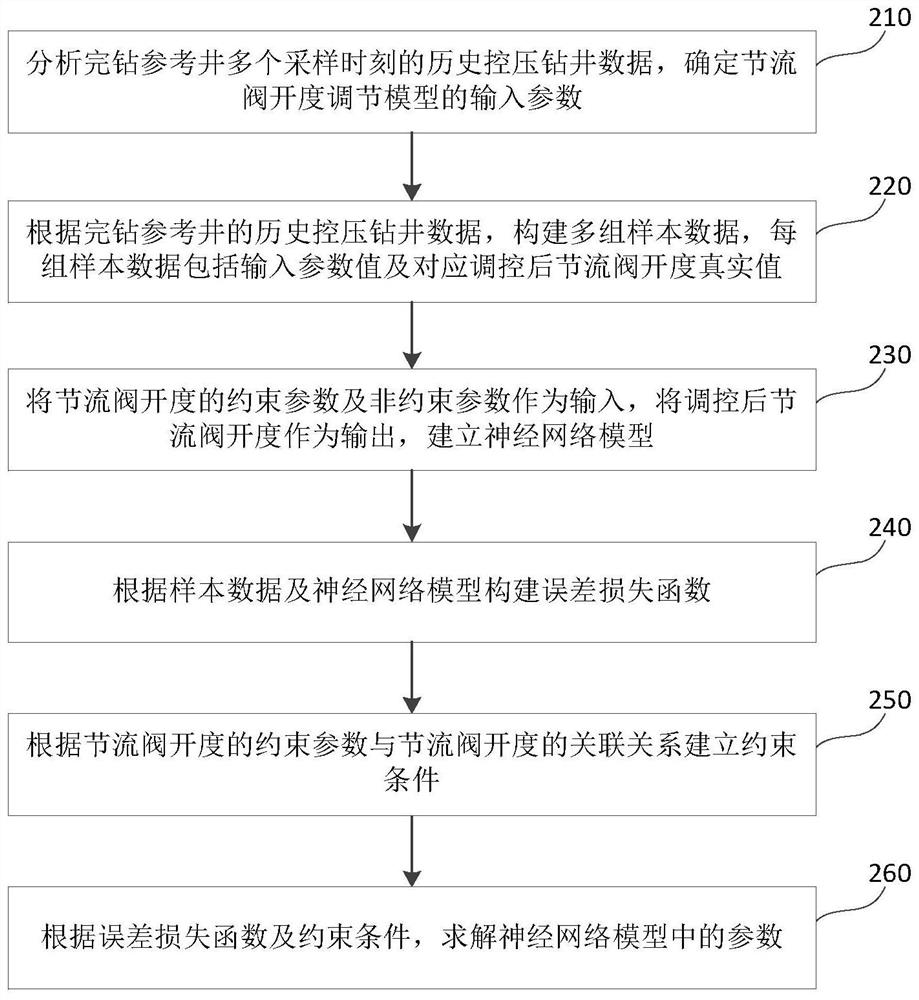

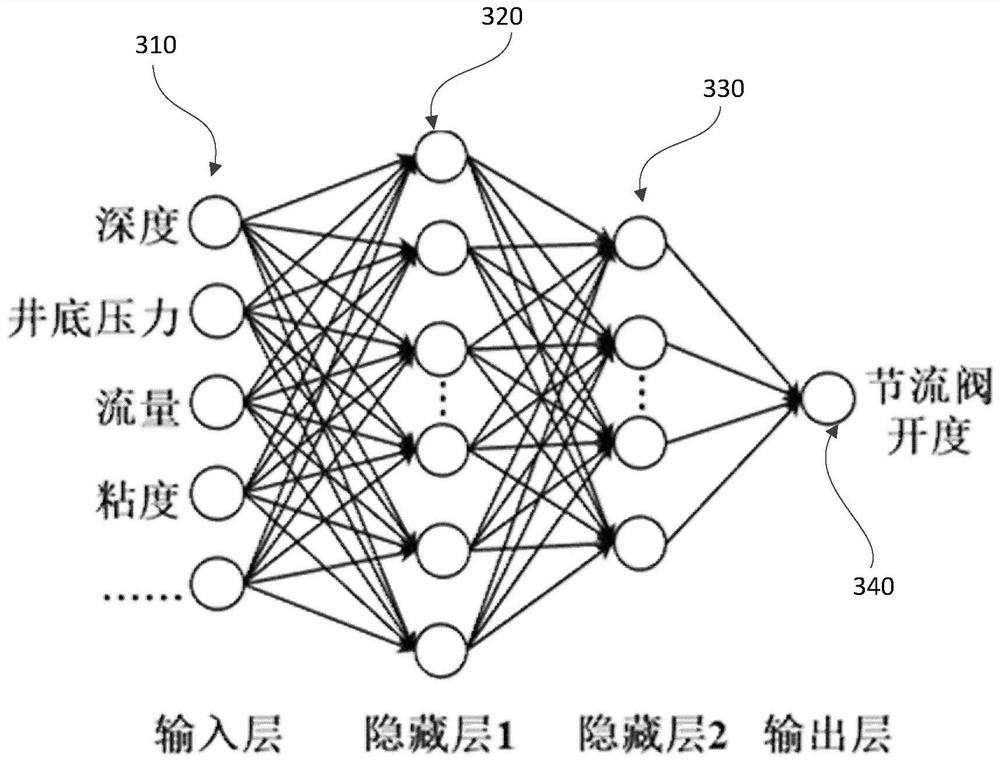

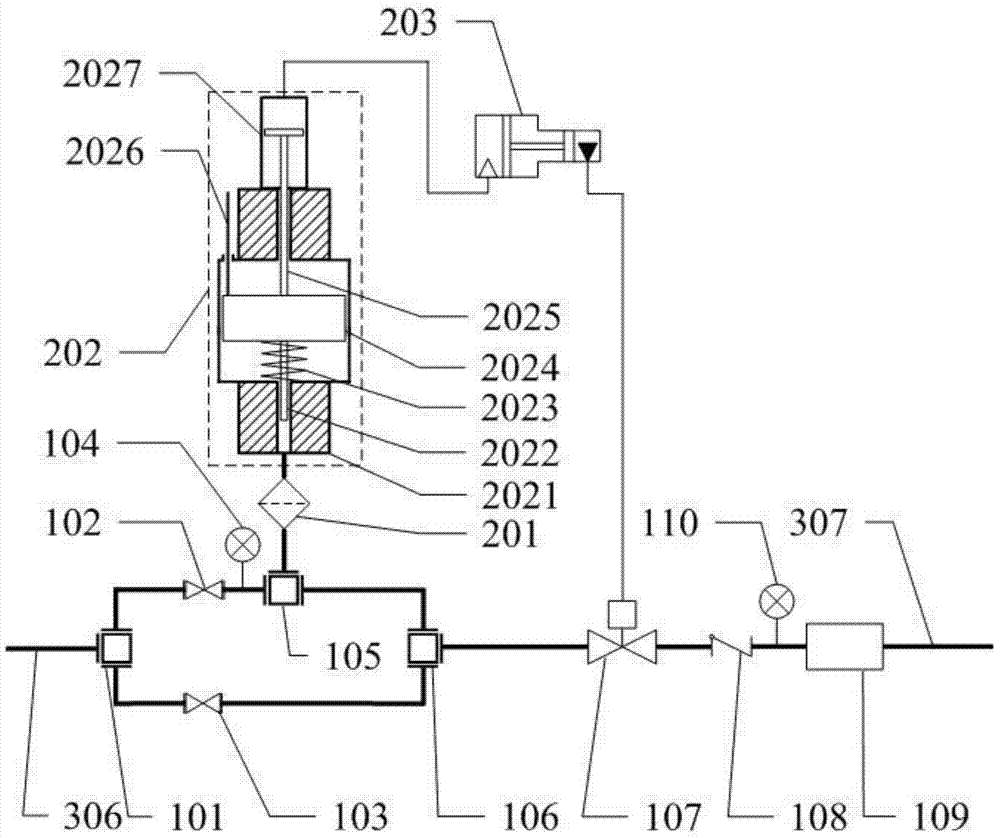

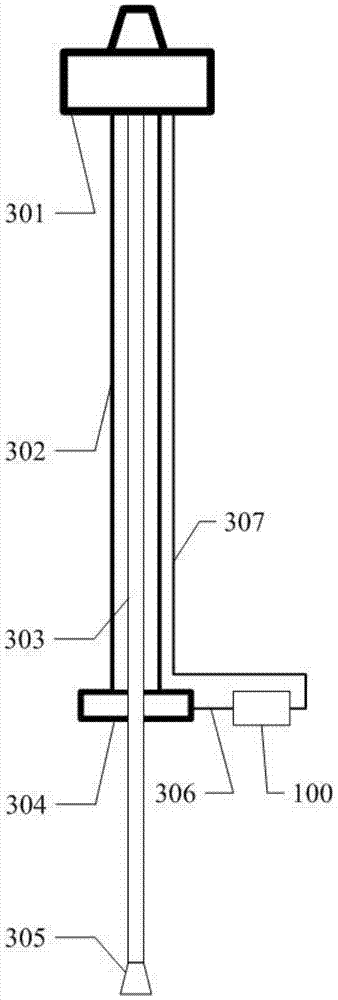

Intelligent shaft pressure control method and device based on physical constraint

PendingCN114737948AReduce dimensionalityReduce inputSurveyFluid removalBottom hole pressureValve opening

The invention provides a shaft pressure intelligent control method and device based on physical constraints. The method comprises the steps that pressure control drilling data of a drilled well is obtained; according to pressure control drilling data of a drilled well and input parameters of a throttle valve opening degree adjusting model, an input vector is constructed, the throttle valve opening degree adjusting model is trained through constraint conditions, a neural network and historical pressure control drilling data of a drilled reference well, and the constraint conditions are established according to the incidence relation between the constraint parameters and the throttle valve opening degree; inputting the input vector into a throttle valve opening adjustment model to obtain a predicted throttle valve opening; the predicted throttle valve opening degree is input into the bottom hole pressure calculation model, and the predicted and calculated bottom hole pressure is obtained; and judging whether the difference between the predicted and calculated bottom hole pressure and the target bottom hole pressure is within a preset range, if not, updating the input vector and returning to execute the prediction process, and if yes, adjusting the throttle valve according to the predicted throttle valve opening degree. According to the method, the stability and generalization ability of the throttle valve opening degree adjusting model can be effectively improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Submarine wellhead pressure indication and automatic adjustment device for deepwater dual-gradient drilling

ActiveCN104895548BSimple structureEasy to implementFluid removalAutomatic control for drillingOcean bottomAutomatic control

The invention belongs to the field of petroleum engineering deep-water drilling, and in particular relates to a submarine wellhead pressure indication and automatic adjustment device for deep-water double-gradient drilling. The subsea wellhead pressure indication and automatic adjustment device for deepwater dual-gradient drilling includes: subsea drilling fluid manifold system and subsea wellhead pressure indication and automatic adjustment system; Return to the drilling platform smoothly, and at the same time provide the foundation for the subsea wellhead pressure indication and automatic adjustment system; seawater hydrostatic pressure. The invention can automatically and in real time keep the seabed wellhead pressure equal to the seawater hydrostatic pressure at the seabed in the process of double-gradient drilling in deep water, thereby ensuring the smooth implementation of the double-gradient drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

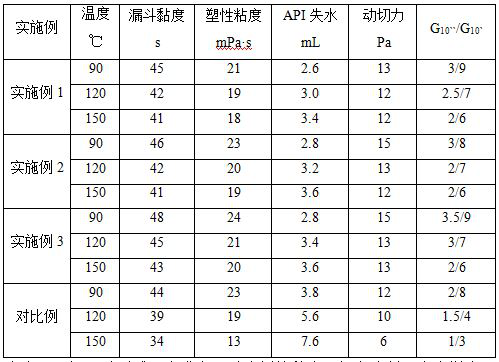

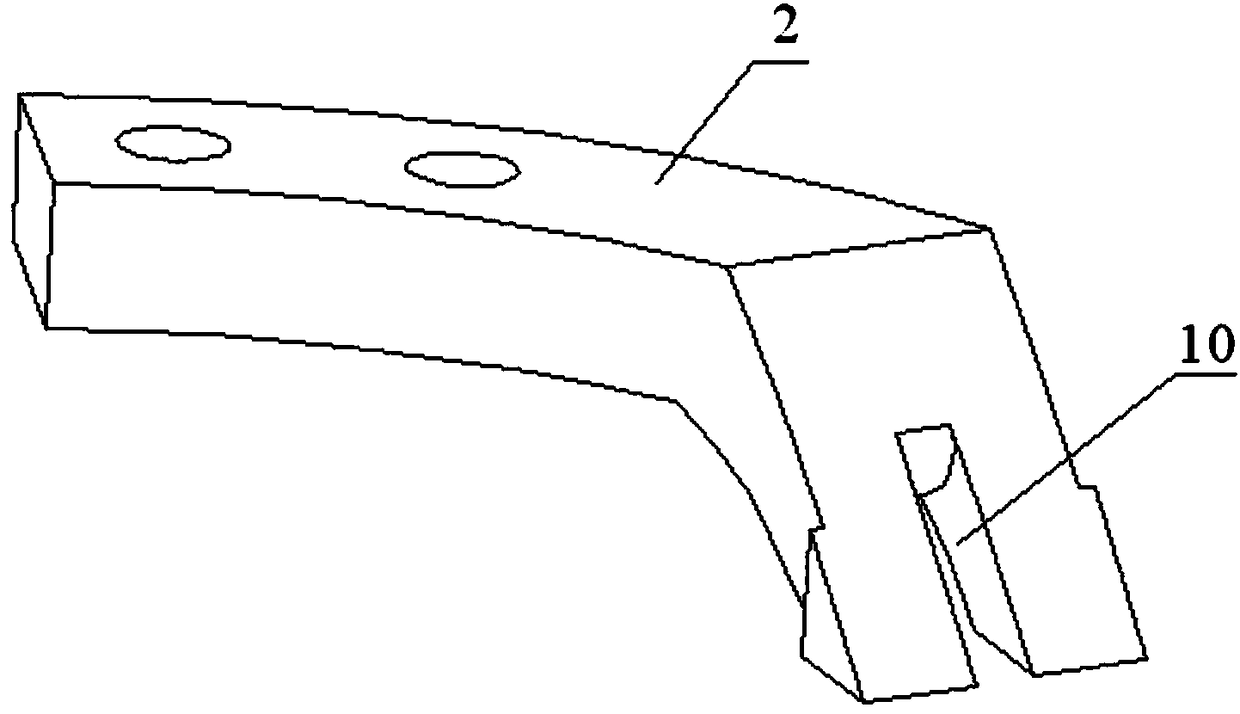

Nanocomposite plugging agent for drilling shale horizontal wells and preparation method thereof

ActiveCN108300433BImprove temperature resistanceEvenly dispersedDrilling compositionParaffin waxHorizontal wells

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Ice drill bit for warm ice layer drilling

The invention discloses a drilling bit of an ice drill for drilling warm ice layer. The drilling bit comprises a drilling bit body, special-shaped cutting tools and pad shoes, wherein the bottom of the drilling bit body is provided with a plurality of water troughs, a channel is formed between the inner cavity and the outer wall of the drilling bit body due to the water troughs, the plurality of special-shaped cutting tools and the pad shoes are fixed on the bottom lip surface of the drilling bit body parallelly, and the bottom of the pad shoes is provided with a plurality of micro-nano bulgesor pits. The drilling bit has the beneficial effect of reducing friction heat of the bottom of the drilling bit. The drilling bit of the ice drill can lower cutting heat, is good for coolinga drilling liquid and carrying flake ice, can effectively prevent a large quantity of flake ice from bonding and gathering, and can drill warm ice layer of the glacier safely and rapidly.

Owner:JILIN UNIV

Biomass lubricant for drilling fluid and preparation method thereof

ActiveCN109666462BEnhanced interactionEnvironmentally friendly and non-toxicDrilling compositionCellulosePtru catalyst

The invention provides a biomass lubricant for drilling fluid, which is prepared from raw materials comprising the following components: 15 to 30 parts by weight of biomass base oil; 3 to 5 parts by weight of ionic liquid antiwear agent; 2 to 5 parts by weight of an emulsifier; 0.5 to 1 part by weight of an antifoaming agent; 0.05 to 0.1 parts by weight of a tackifier; 58 to 80 parts by weight of water; the biomass base oil is made of natural fat It is prepared from the front fraction of alcohol, organic acid and lipase catalyst; the viscosity raising agent is high viscosity sodium carboxymethyl cellulose. Compared with the prior art, the biomass lubricant for drilling fluid provided by the present invention adopts specific content of components to achieve better interaction, and the product has strong lubrication, high temperature resistance, environmental protection and non-toxic characteristics, and good compatibility ; Suitable for special drilling operations such as extended reach wells, deviated wells and horizontal wells, especially for oil and gas wells with deep buried reservoirs and high temperature and high pressure.

Owner:中石化石油工程技术服务有限公司 +1

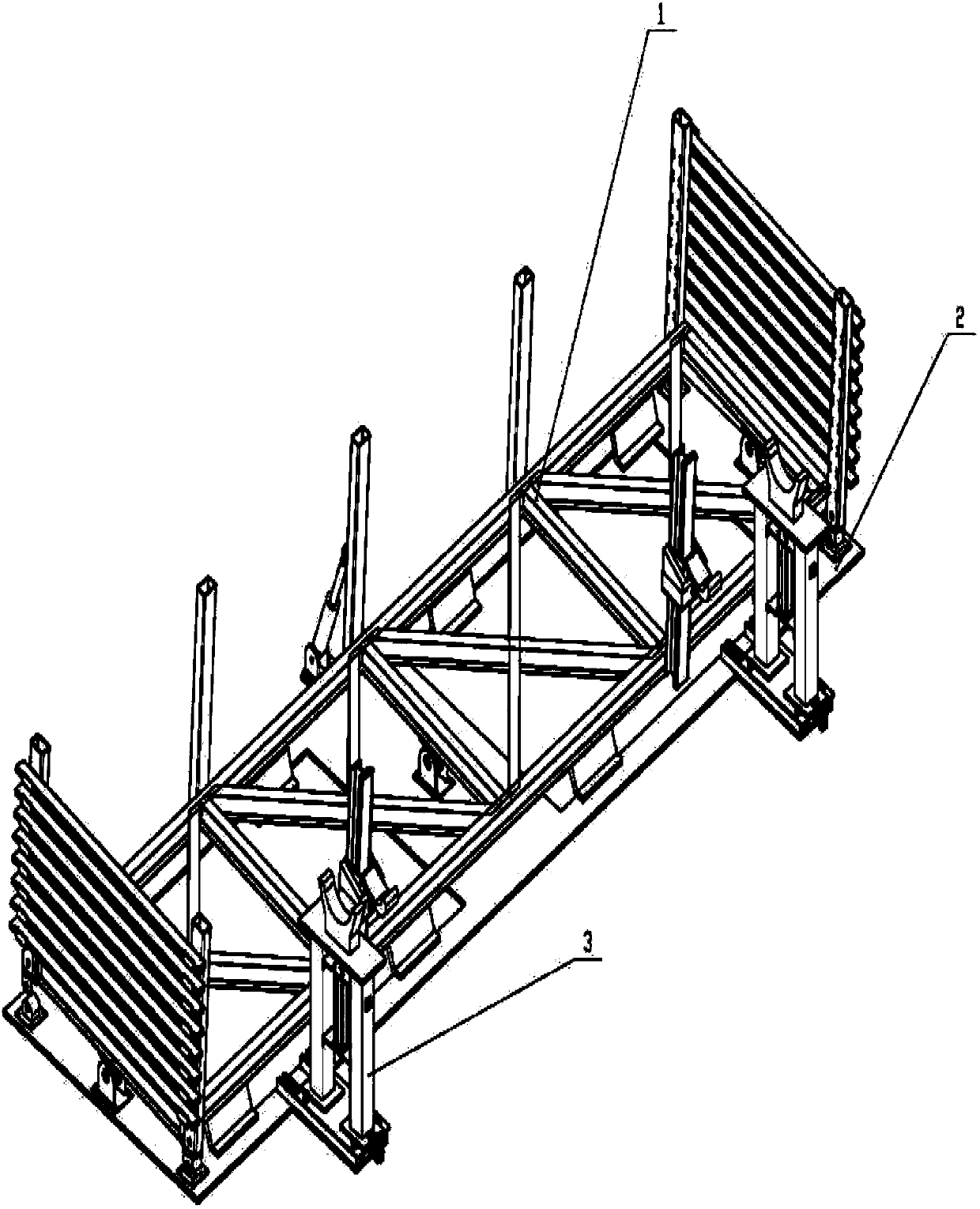

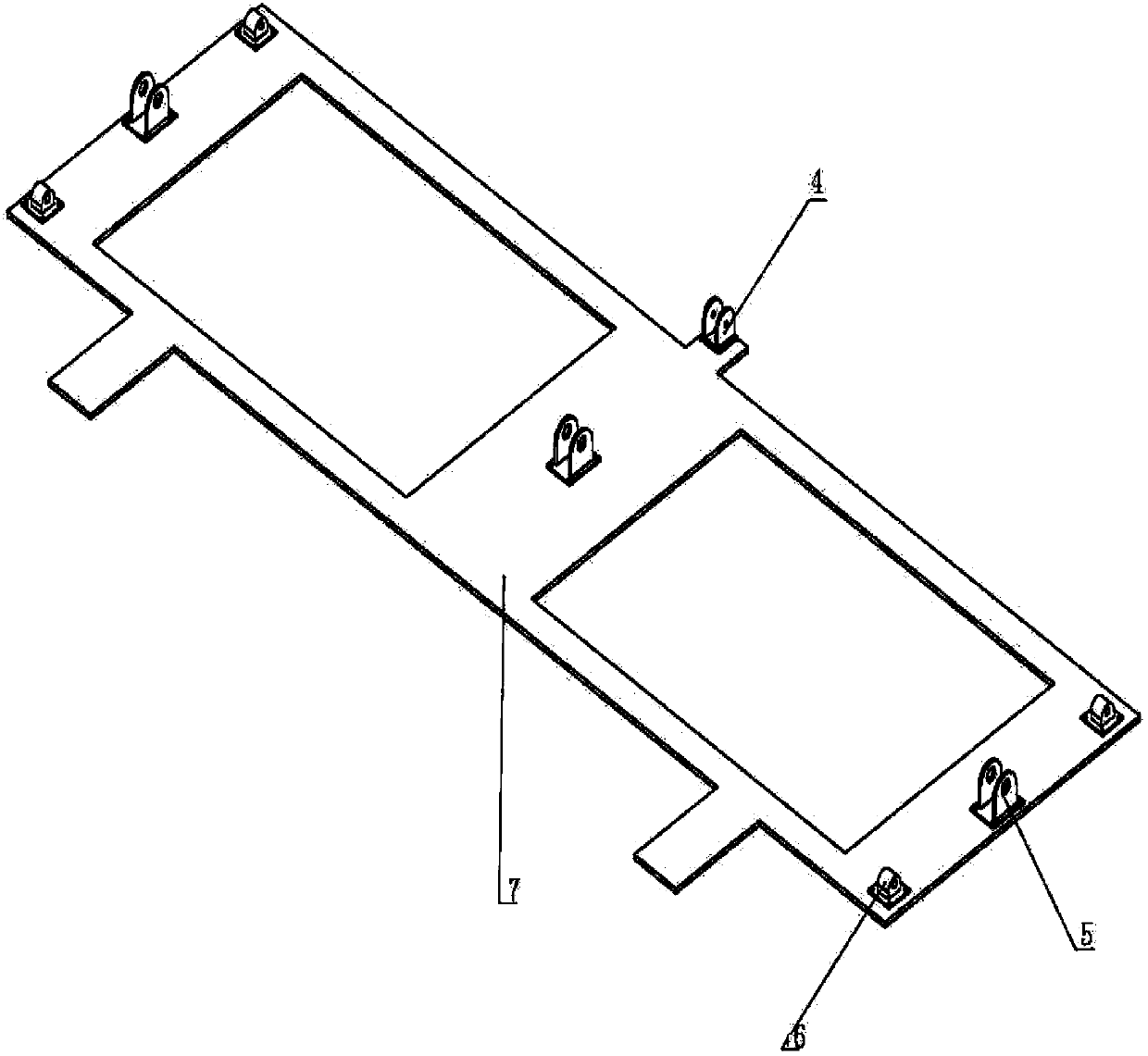

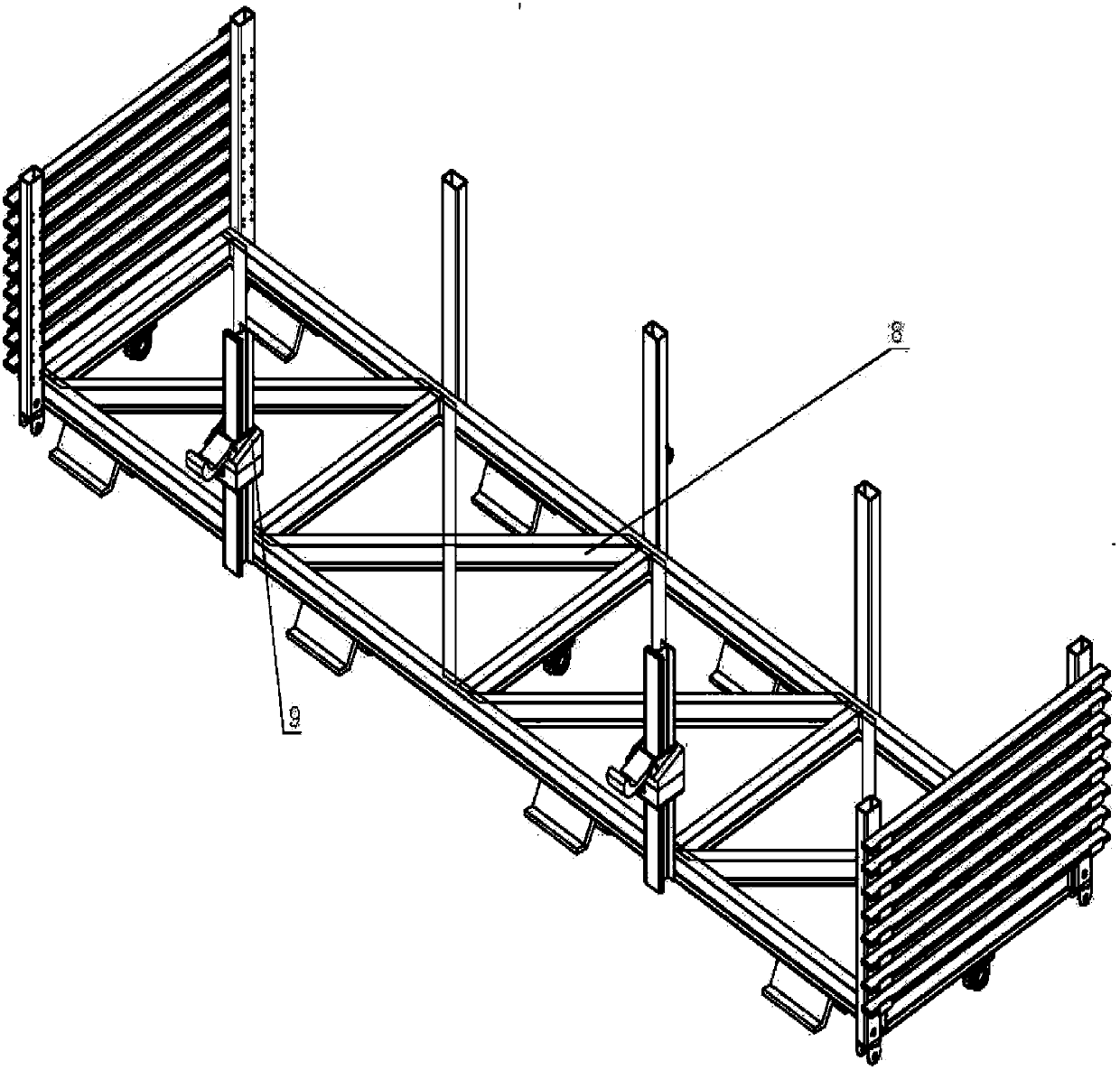

Automation device for storage of oil drilling string

InactiveCN102654040BReduce labor intensityReasonable manual operation designDrilling rodsDrilling casingsHydraulic cylinderHydraulic pump

The invention relates to an automation device for storage of an oil drilling string. The automation device is mainly used for solving the problems of great labor intensity and poor safety due to manual operation of the existing aboveground drilling string during racking construction. The automation device is characterized in that the device comprises a drilling string storage unit, a mounting base unit and a support unit, wherein the drilling string storage unit is formed by connecting two parts, namely a storage frame body and a pipe pulling mechanism; a No. 1 guide wheel and a No. 2 guide wheel in the pipe pulling mechanism are in sliding fit and connection with H-shaped steel of a guide track in the storage frame body; a bearing seat of the drilling string storage unit and a rotating support seat of the base mounting unit are connected through a rotating shaft so as to enable the drilling string storage unit to complete clockwise and counterclockwise rotation through a hydraulic cylinder under the action of a manual hydraulic pump; a frame body articulated support saddle and a base articulated support saddle are connected through a positioning pin, thereby realizing the stability of the device; and the drilling string storage unit is in hinge fit with the mounting base unit, and the drilling string storage unit is in threaded connection with the support unit. The device can realize the mechanical automation of the tripping and drilling string racking work of well repair operation.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com