A kind of emulsified drilling fluid with high density and low oil-water ratio for shale horizontal well

An emulsified drilling fluid and horizontal well technology, applied in the field of petroleum drilling, can solve the problems of high cost, collapse and instability of oil-based drilling fluid, etc., and achieve the effects of cost reduction, strong inhibition of dispersion and plugging ability, and product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

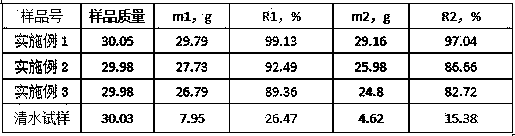

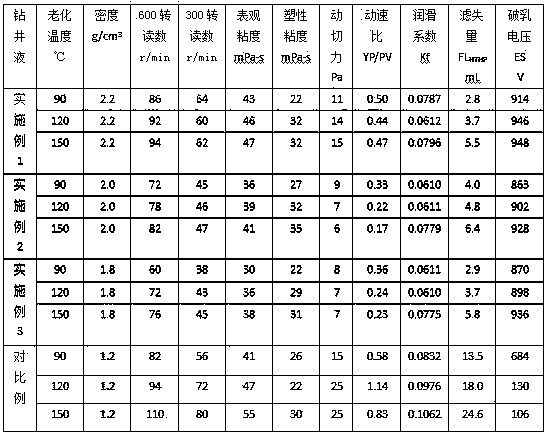

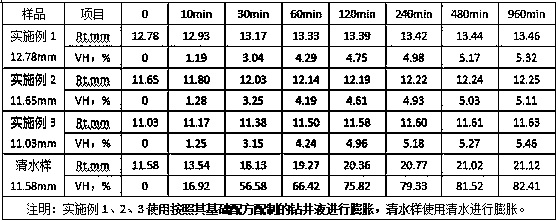

Examples

Embodiment 1

[0045] 1. A kind of emulsified drilling fluid with high density and low oil-water ratio for drilling into shale horizontal wells is made up of the following raw materials in parts by weight: 180 parts of 3# white oil, 120 parts of 30% calcium chloride solution, 3 parts of main emulsifier, 6 parts of auxiliary emulsifier, 15 parts of reversible emulsifier, 9 parts of calcium oxide, 3 parts of organic soil, 4.5 parts of plugging agent, 1 part of lifting agent, 9 parts of calcium carbonate, 750 parts of barite,

[0046] Wherein, the above-mentioned primary emulsifier is made by reacting tall oil fatty acid and maleic anhydride at a mass ratio of 100:15 at 200°C for 8 hours;

[0047] The above-mentioned co-emulsifier is prepared by mixing higher fatty acid sodium and sorbitan ester in a mass ratio of 1:3;

[0048] The above-mentioned reversible emulsifier is made by reacting methyl 9-octadecanoate and hydroxyethylethylenediamine at a mass ratio of 3:2 at a temperature of 135°C for...

Embodiment 2

[0055] A high-density, low-oil-water-ratio emulsified drilling fluid for drilling shale horizontal wells, consisting of the following raw materials in parts by weight: 180 parts of 3# white oil, 120 parts of 30% calcium chloride solution, 5 parts of main emulsifier, and auxiliary emulsifier 8 parts of emulsifier, 18 parts of reversible emulsifier, 5 parts of calcium oxide, 2 parts of organic soil, 3 parts of plugging agent, 0.5 part of cutting agent, 6 parts of calcium carbonate, 600 parts of barite, of which, the main emulsifier, auxiliary emulsifier The preparation of emulsifier, reversible emulsifier, plugging agent, and cutting agent is the same as in Example 1, and the organic soil and calcium carbonate are the same as in Example 1. The method for preparing emulsified drilling fluid with high density and low oil-water ratio for drilling shale horizontal wells With embodiment 1.

Embodiment 3

[0057] A high-density, low-oil-water-ratio emulsified drilling fluid for drilling shale horizontal wells, consisting of the following raw materials in parts by weight: 180 parts of 3# white oil, 120 parts of 30% calcium chloride solution, 2 parts of main emulsifier, and auxiliary emulsifier 4 parts of reversible emulsifier, 12 parts of reversible emulsifier, 10 parts of calcium oxide, 5 parts of organic soil, 8 parts of plugging agent, 3 parts of cutting agent, 12 parts of calcium carbonate, 450 parts of barite, of which, the main emulsifier, auxiliary emulsifier The preparation of emulsifier, reversible emulsifier, plugging agent, and cutting agent is the same as in Example 1, and the organic soil and calcium carbonate are the same as in Example 1. The method for preparing emulsified drilling fluid with high density and low oil-water ratio for drilling shale horizontal wells With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com