A kind of emulsifier based on oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and emulsifier technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of high cost of emulsifiers, achieve low cost, good application prospects, and reduce the number of additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The embodiment of the present invention provides an emulsifier based on oil-based drilling fluid, the emulsifier includes tall oil fatty acid, polyethylene polyamine, chloroacetic acid amide, higher fatty alcohol sulfates and polyhydric alcohols, wherein tall oil The mass ratio of fatty acid and polyethylene polyamine is 4:1; the mass ratio of fatty acid amide intermediate product and chloroacetic acid amide generated by the reaction of tall oil fatty acid and polyethylene polyamine is 1:1; fatty acid amide intermediate product and chloroacetic acid The mass ratio of the tall oil fatty acid amide generated by the amide reaction to higher fatty alcohol sulfates is 99:1; The mass ratio is 8:1.

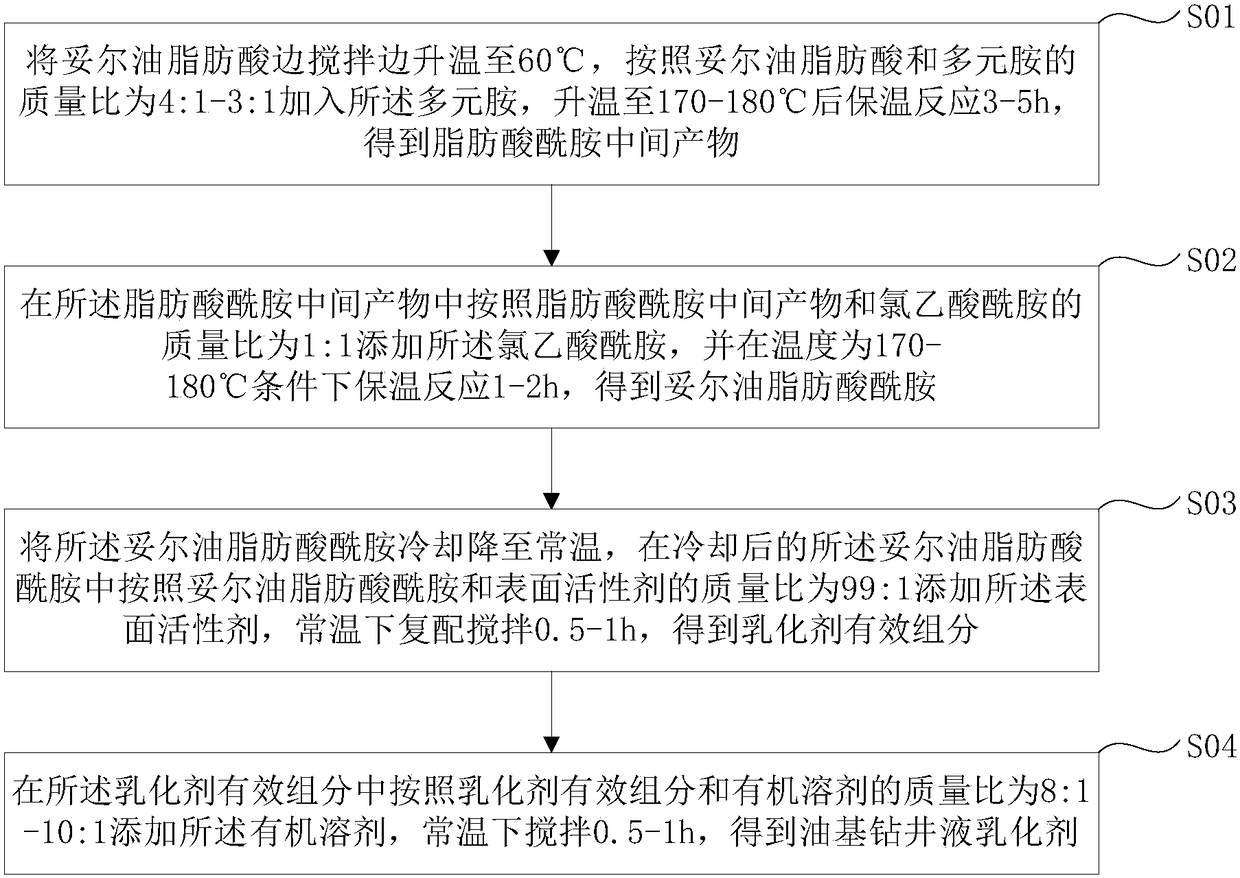

[0026] Embodiments of the present invention also provide a preparation method of an emulsifier based on oil-based drilling fluid, the preparation method comprising:

[0027] S101: Heat tall oil fatty acid to 60°C while stirring, add polyethylene polyamine according to the mass ra...

Embodiment 2

[0032]An embodiment of the present invention provides an emulsifier based on oil-based drilling fluid, the emulsifier includes tall oil fatty acid, diphenylmethanediamine, chloroacetic acid amide, alkyl aryl sulfonate and polyol ether, wherein , the mass ratio of tall oil fatty acid and diphenylmethanediamine is 3:1; the mass ratio of tall oil fatty acid and diphenylmethanediamine reaction generated fatty acid amide intermediate product and chloroacetic acid amide is 1:1 The mass ratio of tall oil fatty acid amide and alkyl aryl sulfonate produced by fatty acid amide intermediate product and chloroacetic acid amide reaction is 99:1; The emulsifier generated by tall oil fatty acid amide and surfactant reaction is effective The mass ratio of components to polyol ethers is 10:1.

[0033] Embodiments of the present invention also provide a preparation method of an emulsifier based on oil-based drilling fluid, the preparation method comprising:

[0034] S201: Heat tall oil fatty a...

Embodiment 3

[0039] An embodiment of the present invention provides an emulsifier based on oil-based drilling fluid, the emulsifier includes tall oil fatty acid, stearylamine, chloroacetic acid amide, alkyl naphthalene sulfonate and polyhydric alcohol, wherein tall oil fatty acid The mass ratio with octadecylamine is 4:1; the mass ratio of fatty acid amide intermediate product and chloroacetic acid amide generated by the reaction of tall oil fatty acid and octadecylamine is 1:1; the fatty acid amide intermediate product and chloroacetic acid amide reaction generate The mass ratio of tall oil fatty acid amide and alkylnaphthalene sulfonate of generation is 99:1; 9:1.

[0040] Embodiments of the present invention also provide a preparation method of an emulsifier based on oil-based drilling fluid, the preparation method comprising:

[0041] S301: Heat tall oil fatty acid to 60°C while stirring, add octadecylamine according to the mass ratio of tall oil fatty acid and octadecylamine at 4:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com